Introduction: Navigating the Global Market for belt types

In today’s diverse global marketplace, sourcing the right belt types can pose significant challenges for international B2B buyers. From selecting appropriate materials to understanding the nuances of design and functionality, the options available are vast and often overwhelming. This comprehensive guide is designed to streamline your purchasing decisions by providing an in-depth exploration of various belt types, their applications, and the critical factors to consider when vetting suppliers.

We will cover everything from classic leather belts that convey professionalism to casual fabric options that cater to diverse lifestyle needs. Additionally, our guide will delve into cost considerations, quality assessments, and supplier reliability, ensuring that you have all the tools necessary to make informed choices.

Whether you’re operating in emerging markets like Nigeria and South Africa or established regions in Europe and the Middle East, understanding the intricacies of belt types can significantly impact your purchasing strategy. By equipping you with actionable insights and expert guidance, this resource empowers you to navigate the complexities of the global belt market effectively, ultimately enhancing your supply chain and driving business success.

Table Of Contents

- Top 6 Belt Types Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for belt types

- Understanding belt types Types and Variations

- Key Industrial Applications of belt types

- 3 Common User Pain Points for ‘belt types’ & Their Solutions

- Strategic Material Selection Guide for belt types

- In-depth Look: Manufacturing Processes and Quality Assurance for belt types

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt types’

- Comprehensive Cost and Pricing Analysis for belt types Sourcing

- Alternatives Analysis: Comparing belt types With Other Solutions

- Essential Technical Properties and Trade Terminology for belt types

- Navigating Market Dynamics and Sourcing Trends in the belt types Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of belt types

- Strategic Sourcing Conclusion and Outlook for belt types

- Important Disclaimer & Terms of Use

Understanding belt types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather | Timeless design, often smooth or textured leather | Formal business attire, corporate gifts | Pros: Durable, versatile; Cons: Can be costly |

| Fabric | Lightweight, often colorful or patterned | Casual wear, promotional items | Pros: Comfortable, affordable; Cons: Less formal |

| Dress Belt | High-quality leather, minimalist design | Business meetings, formal events | Pros: Elegant, professional; Cons: Limited versatility |

| Ratchet | Micro-adjustable mechanism, modern buckle design | Everyday wear, casual and formal settings | Pros: Perfect fit, stylish; Cons: May be unfamiliar to some |

| Western | Intricate designs, often embellished | Themed events, casual wear | Pros: Unique style, eye-catching; Cons: Niche appeal |

What Are the Characteristics of Classic Leather Belts?

Classic leather belts are characterized by their timeless appeal and durability. Typically made from high-quality cowhide or exotic leathers, they are suitable for formal business attire and professional environments. Buyers should consider the belt’s craftsmanship and material quality, as these factors directly impact longevity and appearance. While they can be more expensive, their versatility makes them a valuable addition to any wardrobe.

How Do Fabric Belts Stand Out in Casual Applications?

Fabric belts are known for their lightweight nature and vibrant designs, making them ideal for casual wear and promotional items. They are often made from materials such as cotton or nylon and are available in various colors and patterns. B2B buyers seeking to provide comfortable, stylish options for employees or customers will find fabric belts to be a cost-effective solution. However, their informal nature may limit their use in more formal settings.

What Makes Dress Belts Essential for Formal Occasions?

Dress belts are specifically designed for formal occasions, typically crafted from high-quality leather with understated buckles. They are essential for business meetings and formal events, complementing suits and dress trousers. When purchasing dress belts, B2B buyers should focus on the quality of the leather and the belt’s overall design to ensure a polished appearance. While they offer elegance, their limited versatility may restrict their use to formal contexts.

Why Choose Ratchet Belts for Everyday Wear?

Ratchet belts feature a unique micro-adjustable mechanism that allows for a precise fit, making them suitable for both casual and formal settings. Their modern buckle design provides a sleek appearance, appealing to a contemporary audience. B2B buyers looking for stylish and functional options will appreciate the comfort and adaptability of ratchet belts. However, some consumers may be unfamiliar with this innovative design, potentially requiring education on its benefits.

In What Situations Are Western Belts Most Appropriate?

Western belts are distinguished by their bold designs and intricate embellishments, often reflecting a cowboy aesthetic. They are ideal for themed events or casual wear, providing a unique style statement. B2B buyers in the fashion industry or event planning should consider Western belts for their distinctive appeal. However, their niche market may limit broader applicability, making them less suitable for conventional business environments.

Key Industrial Applications of belt types

| Industry/Sector | Specific Application of belt types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

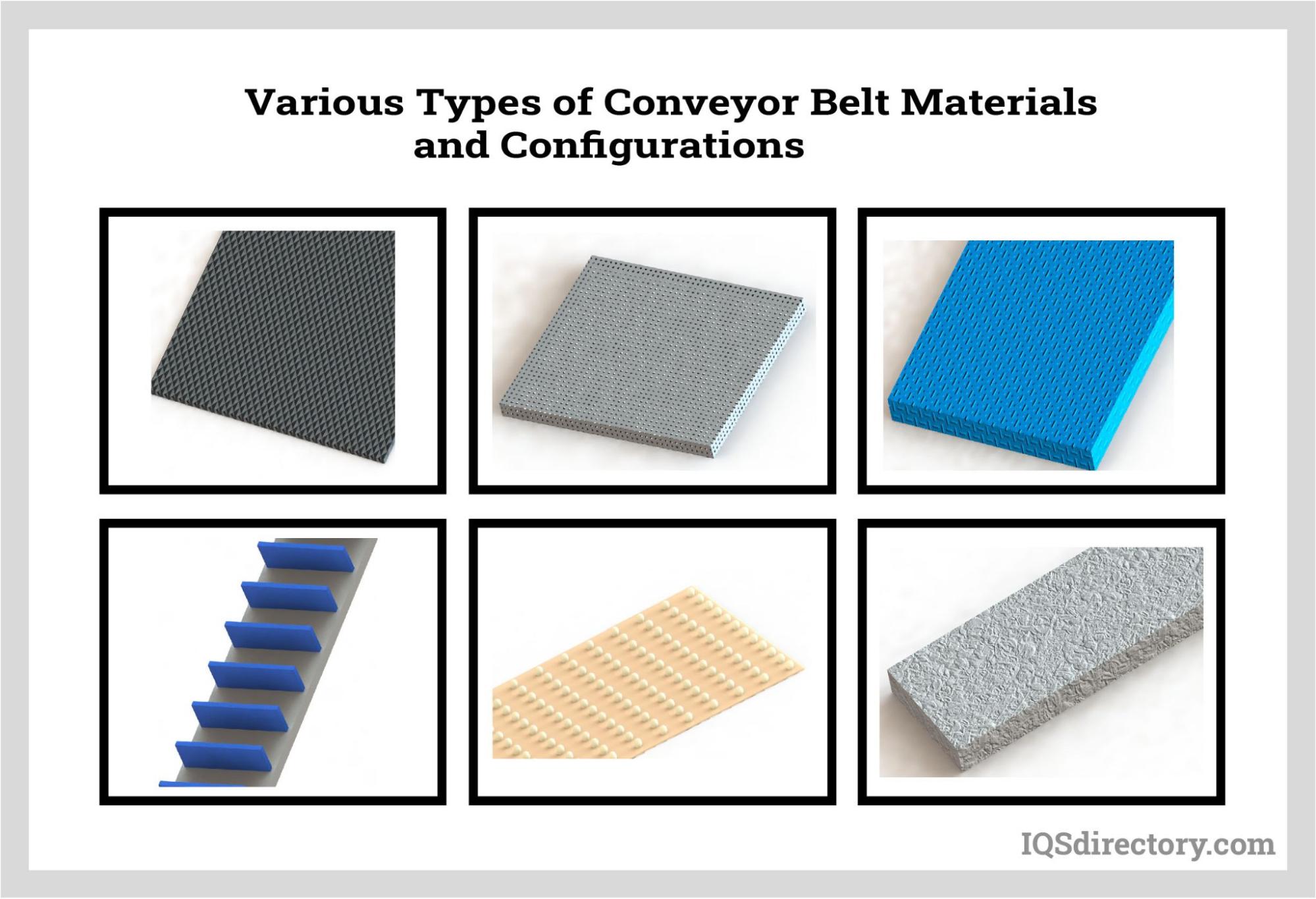

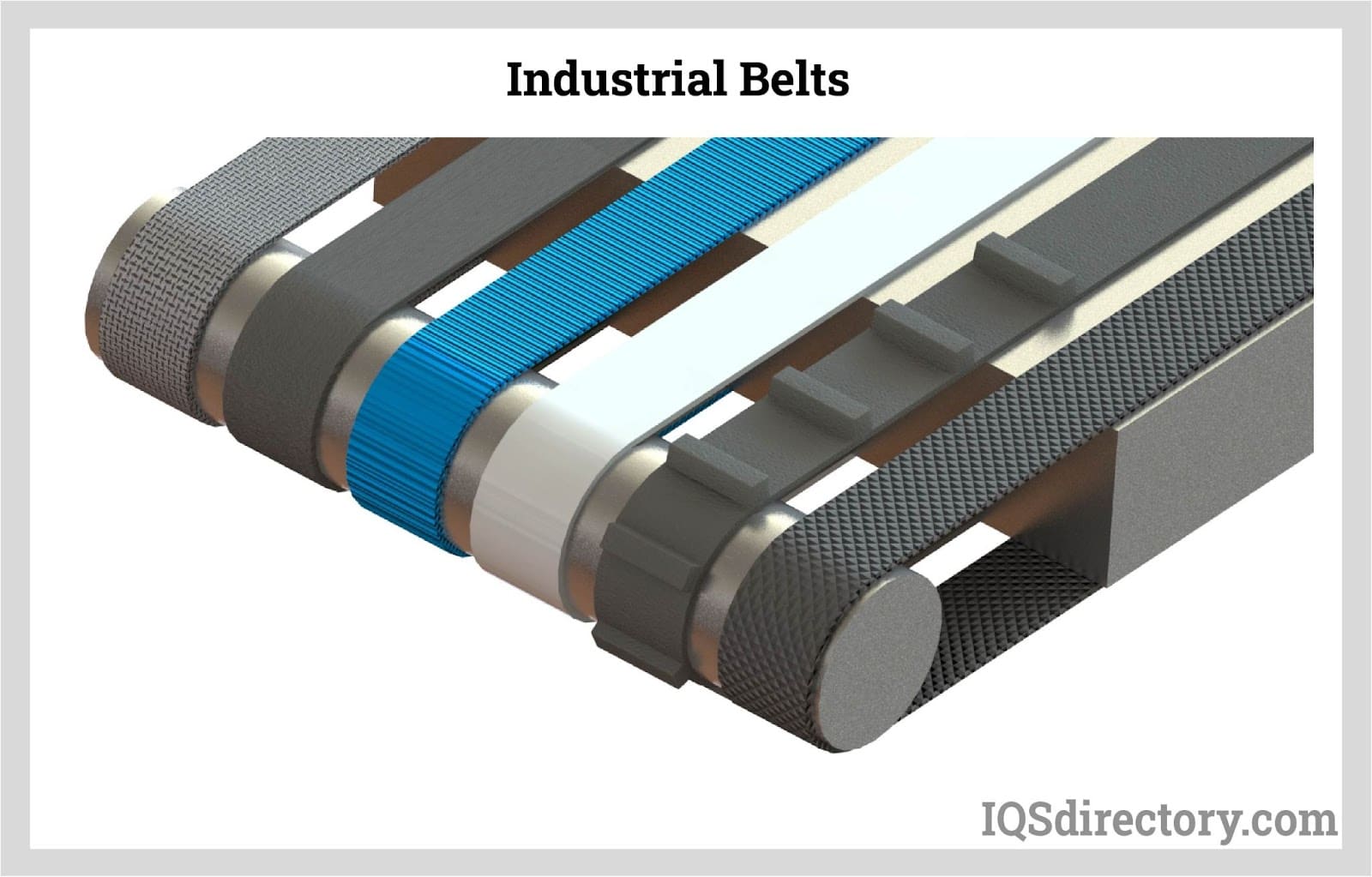

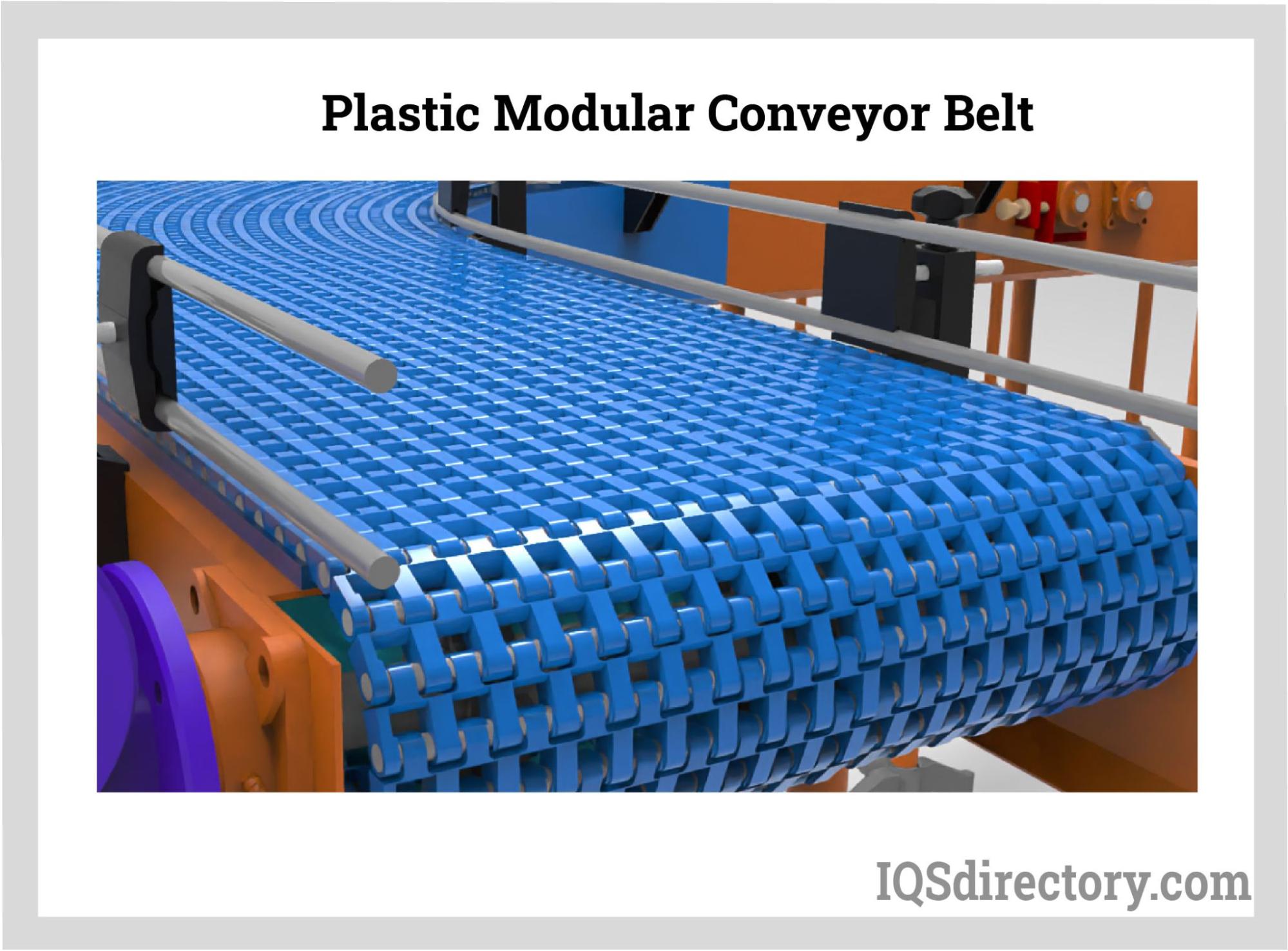

| Manufacturing | Conveyor Belts for Assembly Lines | Enhances operational efficiency by ensuring smooth material handling and reducing downtime. | Durability, resistance to wear, and compatibility with machinery are crucial. |

| Agriculture | Agricultural Belts for Equipment | Increases productivity by ensuring optimal performance of machinery like harvesters and tractors. | Sourcing belts that withstand harsh conditions and provide flexibility is essential. |

| Mining and Construction | Heavy-Duty Belts for Material Transport | Improves the reliability of transporting materials, minimizing delays and operational costs. | Considerations include load capacity, resistance to abrasion, and environmental factors. |

| Automotive | Timing and Drive Belts in Vehicles | Ensures reliable engine performance, enhancing vehicle longevity and reducing maintenance costs. | Buyers should focus on specifications that meet OEM standards and provide temperature resilience. |

| Textile and Apparel | Textile Conveyor Belts for Production | Streamlines production processes, increasing throughput and reducing labor costs. | Quality of materials, ease of cleaning, and compatibility with various textile types are important. |

How Are Conveyor Belts Used in Manufacturing?

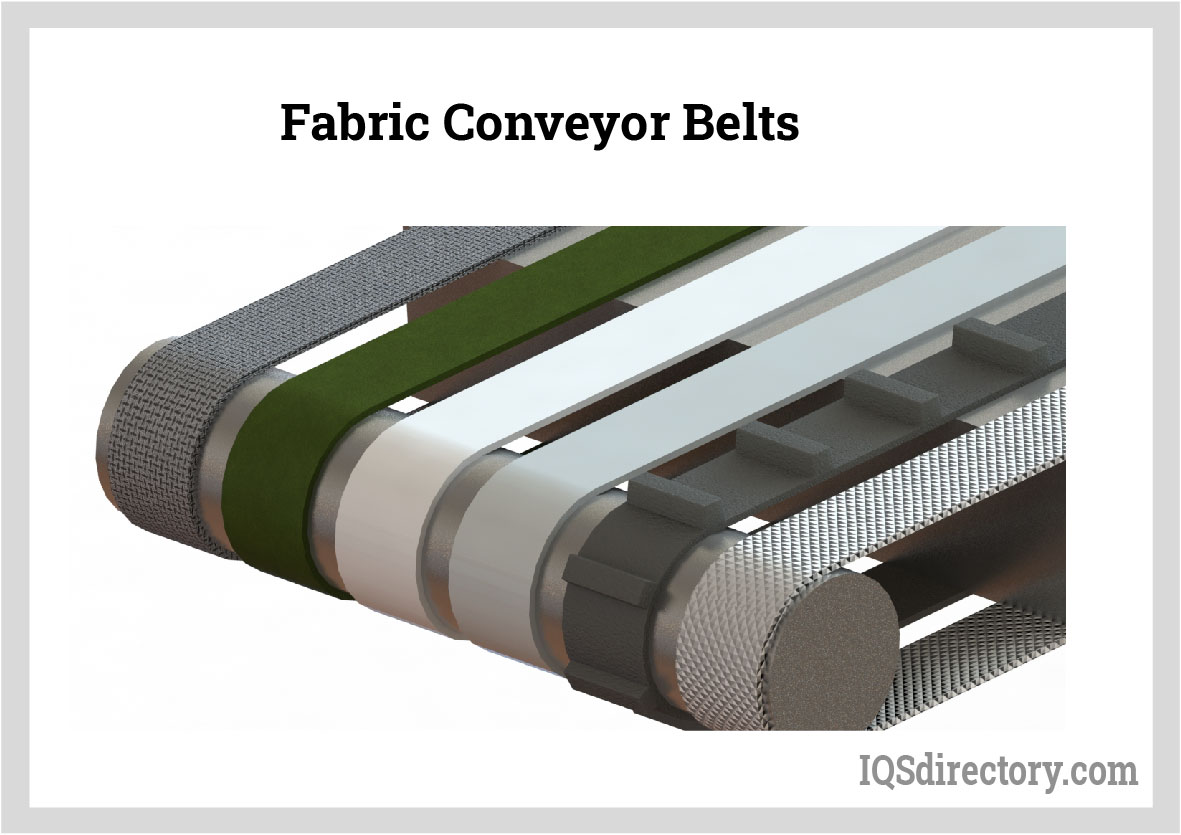

In the manufacturing sector, conveyor belts are essential for assembly lines, facilitating the efficient movement of goods. These belts help streamline workflows by reducing manual handling, thus minimizing the risk of injury and improving production rates. For international buyers, especially from regions like Africa and South America, sourcing durable conveyor belts that can withstand heavy loads and resist wear is critical. Additionally, compatibility with existing machinery is a key consideration to ensure seamless integration into production processes.

Illustrative image related to belt types

What Role Do Agricultural Belts Play in Equipment?

In agriculture, belts are crucial for the optimal functioning of machinery such as tractors and harvesters. Agricultural belts ensure that equipment operates efficiently, leading to increased productivity during planting and harvesting seasons. Buyers from the Middle East and Africa should prioritize sourcing belts that can endure extreme temperatures and rough terrains. Flexibility and resistance to environmental factors are vital to maintaining agricultural equipment’s performance, ultimately impacting yield and profitability.

How Are Heavy-Duty Belts Utilized in Mining and Construction?

Heavy-duty belts are indispensable in the mining and construction industries for transporting materials like gravel, coal, and ores. These belts enhance operational reliability and efficiency by minimizing transportation delays, which can significantly impact project timelines and costs. For international buyers, especially in regions with challenging terrains, it’s essential to source belts with high load capacities and exceptional abrasion resistance. Understanding environmental conditions and operational demands is crucial for selecting the right belt type.

Why Are Timing and Drive Belts Important in Automotive Applications?

In the automotive industry, timing and drive belts are critical components that ensure the smooth operation of engines. They synchronize engine functions, enhancing vehicle performance and longevity while reducing maintenance costs. Buyers must focus on sourcing belts that meet OEM specifications and can withstand high temperatures and stress. This is particularly important for buyers in Europe and the Middle East, where vehicle reliability and performance standards are stringent.

How Do Textile Conveyor Belts Improve Production Efficiency?

Textile conveyor belts are vital in the textile and apparel industries, facilitating the movement of materials through various production stages. By streamlining processes, these belts can significantly increase throughput and reduce labor costs. International buyers should prioritize sourcing high-quality belts that are easy to clean and maintain, as well as compatible with various types of textiles. Understanding the specific requirements of the production line is essential to ensure optimal performance and longevity of the belts.

3 Common User Pain Points for ‘belt types’ & Their Solutions

Scenario 1: Sourcing High-Quality Belts for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality belts that cater to the varied preferences and cultural nuances of their target markets. For instance, a buyer in Nigeria may need durable leather belts suited for both formal occasions and everyday wear, while a buyer in Saudi Arabia may seek belts with ornate designs that resonate with local fashion sensibilities. This can lead to a mismatch between product offerings and customer expectations, resulting in poor sales and inventory turnover.

The Solution: To effectively source belts that meet diverse market needs, buyers should conduct thorough market research to understand local fashion trends and customer preferences. Engaging with local distributors or attending regional trade shows can provide insights into popular styles and materials. Additionally, collaborating with manufacturers who offer customization options allows buyers to order belts tailored to specific cultural aesthetics, such as color choices or decorative elements. Establishing a flexible supply chain that accommodates variations in demand can further enhance customer satisfaction and market responsiveness.

Scenario 2: Ensuring Proper Fit and Size Across Different Belt Types

The Problem: One of the most common pain points for B2B buyers is managing the sizing and fit of various belt types. Discrepancies in sizing standards across manufacturers can lead to customers receiving belts that do not fit properly, resulting in returns and dissatisfied buyers. This issue is particularly pronounced when dealing with international suppliers, where measurement conventions may differ significantly.

The Solution: To mitigate sizing issues, B2B buyers should implement a standardized sizing guide that aligns with both local and international standards. This guide should include detailed instructions on how to measure waist size accurately and determine belt length. Buyers can also request samples from manufacturers to evaluate fit before making bulk orders. Additionally, providing clear product descriptions, including sizing charts and fitting tips on e-commerce platforms, can help customers make informed decisions, reducing return rates and enhancing overall satisfaction.

Scenario 3: Balancing Functionality and Style in Belt Selection

The Problem: Many B2B buyers face the challenge of selecting belts that strike a balance between functionality and style, especially when catering to corporate clients who expect both durability and aesthetic appeal. For example, a company looking to outfit its employees may require belts that are comfortable for daily wear while also projecting a professional image. This dual requirement can complicate the selection process, leading to potential compromises on quality or design.

Illustrative image related to belt types

The Solution: To address this challenge, buyers should prioritize versatility in their selection of belt types. Investing in belts made from high-quality materials, such as durable leather or synthetic blends, ensures longevity while maintaining a polished appearance. Buyers can also consider offering a range of styles, such as reversible or adjustable belts, which allow wearers to adapt their look without sacrificing comfort. Furthermore, engaging with suppliers who specialize in functional fashion can provide access to innovative designs that meet both aesthetic and practical needs, ultimately enhancing the overall value proposition for corporate clients.

Strategic Material Selection Guide for belt types

When selecting the appropriate materials for various belt types in a B2B context, it is essential to analyze their properties, advantages, disadvantages, and specific applications. This analysis will help international buyers make informed decisions based on their unique needs and regional considerations.

What Are the Key Properties of Leather as a Belt Material?

Leather is one of the most traditional and widely used materials for belts, particularly in formal and business settings. Its key properties include excellent durability, flexibility, and a natural aesthetic appeal. Leather belts can withstand significant wear and tear, making them suitable for everyday use. However, they may have limitations regarding temperature resistance, as extreme heat or moisture can degrade the material over time.

Illustrative image related to belt types

Pros & Cons: Leather belts offer a classic look and can last for years if properly maintained. However, they can be more expensive than synthetic alternatives and may require regular conditioning to prevent cracking. Additionally, leather production can involve complex manufacturing processes that may not be environmentally friendly.

Impact on Application: Leather is compatible with a wide range of clothing styles, making it a versatile choice for both formal and casual wear. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider the potential for mold and mildew.

How Does Canvas Compare as a Belt Material?

Canvas is a popular choice for casual belts, known for its lightweight and breathable properties. It is made from woven cotton or synthetic fibers, providing a comfortable fit. Canvas belts are often available in various colors and patterns, appealing to a younger demographic or those seeking a more relaxed style.

Pros & Cons: The primary advantage of canvas is its affordability and ease of maintenance. However, it may not offer the same level of durability as leather, particularly under heavy use or in harsh conditions. Additionally, canvas belts can lose their shape over time, especially if they are not reinforced.

Impact on Application: Canvas is suitable for casual wear and outdoor activities, making it a popular choice in regions with warmer climates. Buyers should consider the availability of color and design options to cater to local fashion trends.

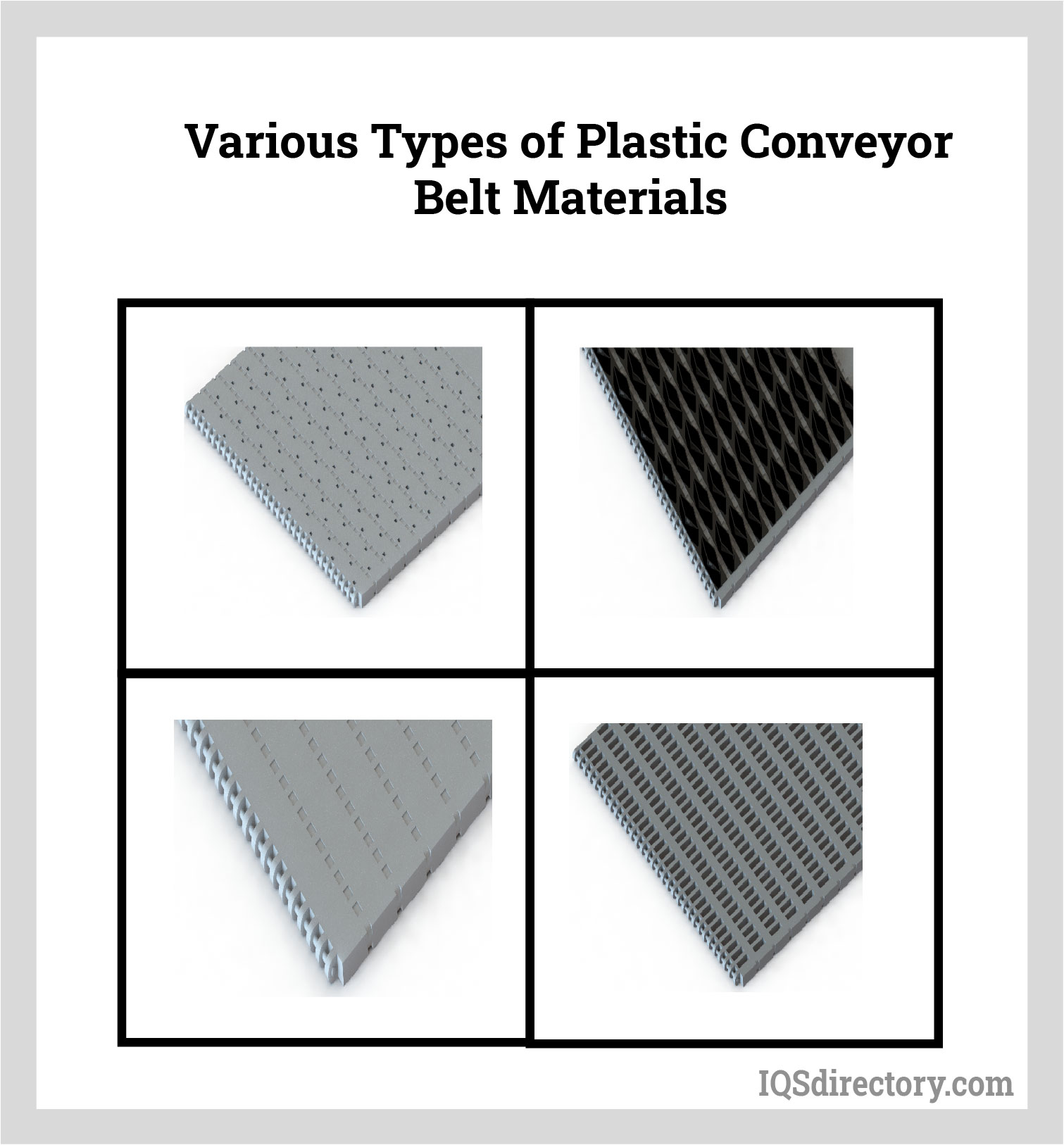

What Are the Benefits of Synthetic Materials for Belt Types?

Synthetic materials, such as polyester and nylon, are increasingly used in belt manufacturing due to their durability and resistance to environmental factors. These materials are often lightweight and can be designed to mimic the appearance of leather while offering superior moisture resistance.

Pros & Cons: Synthetic belts are generally more affordable and easier to clean than leather. However, they may lack the luxurious feel and aesthetic appeal of natural materials. Additionally, the manufacturing process can raise concerns about environmental sustainability.

Impact on Application: Synthetic belts are particularly suitable for active wear and outdoor applications, making them ideal for buyers in regions with diverse climates, such as the Middle East and Europe. Compliance with local regulations regarding synthetic materials is essential for international buyers.

Why Are Metal Components Important in Belt Design?

Metal components, such as buckles and fittings, play a crucial role in the overall performance and aesthetic of belts. Common materials include stainless steel and brass, known for their corrosion resistance and durability. Metal components can enhance the functionality of belts, especially in industrial applications.

Pros & Cons: Metal buckles offer robustness and a polished appearance, but they can add weight to the belt. Additionally, high-quality metal components may increase the overall cost of the belt, which could be a consideration for budget-conscious buyers.

Impact on Application: The choice of metal components can affect the belt’s suitability for specific environments, such as those with high humidity or exposure to chemicals. Buyers should ensure that the metal used complies with international standards, such as ASTM or DIN.

Summary of Material Selection for Belt Types

| Material | Typical Use Case for belt types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Formal and business attire | Excellent durability and aesthetic | Higher cost and maintenance required | High |

| Canvas | Casual and outdoor wear | Lightweight and affordable | Less durable under heavy use | Low |

| Synthetic | Active and outdoor applications | Moisture-resistant and versatile | May lack luxury feel | Medium |

| Metal Components | Industrial and decorative belts | Robust and corrosion-resistant | Can add weight and increase cost | Medium |

This comprehensive analysis provides international B2B buyers with valuable insights into material selection for belts, taking into account regional preferences and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for belt types

What Are the Key Manufacturing Processes for Different Types of Belts?

The manufacturing process for belts involves several critical stages, each contributing to the final product’s quality, durability, and functionality. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Illustrative image related to belt types

How Are Belt Materials Prepared for Production?

The first stage of belt manufacturing is material preparation. Depending on the type of belt, materials can range from natural leather and synthetic fabrics to metals for buckles.

-

Material Selection: Suppliers must choose high-quality materials that match the intended use of the belt. For instance, leather belts may use cowhide or exotic leathers, while fabric belts often utilize cotton or polyester.

-

Cutting: Once selected, the materials are cut into specific shapes and sizes. For leather belts, this involves precise cutting to ensure uniformity. Fabric belts may require different cutting techniques to accommodate various patterns and designs.

-

Pre-Treatment: Leather may undergo tanning and conditioning to enhance its durability and appearance. Fabrics often require treatments to resist moisture and stains.

What Are the Forming Techniques Used in Belt Manufacturing?

The forming stage shapes the cut materials into their final form. This process varies significantly between different belt types.

-

Sewing and Stitching: For fabric and some leather belts, sewing is a primary method of assembly. This includes attaching the buckle and reinforcing seams for added strength. High-quality stitching techniques, such as double-stitching, are often employed to enhance durability.

-

Molding and Casting: For belts with plastic or metal components, such as ratchet belts, molding techniques are used. Injection molding allows for the creation of complex buckle designs while ensuring consistency and precision.

-

Braiding: Braided belts require a unique technique where strips of material are interwoven. This process demands skilled craftsmanship to maintain uniformity and strength in the final product.

How Do Belt Manufacturers Assemble the Components?

Assembly is a crucial stage where all components come together.

-

Buckle Attachment: The buckle is often the last component attached to the belt. Depending on the design, this can involve sewing, snapping, or using screws.

-

Quality Checks: During assembly, manufacturers conduct preliminary quality checks to ensure that components fit correctly and that there are no defects.

-

Customization: Many manufacturers offer custom options, including personalized engraving on buckles or unique fabric patterns, which can be added during assembly.

What Finishing Touches Are Applied to Belts?

Finishing processes enhance the aesthetic appeal and functionality of belts.

-

Polishing and Coating: Leather belts may undergo polishing to achieve a lustrous finish. Fabric belts can be treated with coatings that enhance durability and stain resistance.

-

Quality Control: After finishing, belts are inspected for color consistency, texture, and overall appearance. This step is crucial for maintaining brand standards.

-

Packaging: Finally, belts are packaged in a manner that protects them during shipping while also appealing to consumers. Proper labeling with care instructions can also enhance customer satisfaction.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is vital in ensuring that the belts meet international standards and customer expectations.

Which International Standards Should Be Considered in Belt Manufacturing?

Buyers should look for suppliers that comply with relevant international standards.

-

ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent quality and continuous improvement in manufacturing processes.

-

CE Marking: For belts used in specific applications, particularly in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For belts used in industrial applications, adherence to API standards can indicate quality and reliability.

What Are the Quality Control Checkpoints in Belt Manufacturing?

Quality control is typically structured around several checkpoints during the manufacturing process:

Illustrative image related to belt types

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor production processes and identify defects early.

-

Final Quality Control (FQC): This final inspection assesses the completed belts for defects, functionality, and adherence to specifications before they are shipped.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facility’s quality management practices and adherence to standards.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the products and processes used by suppliers.

What Are the Nuances of Quality Control for International B2B Buyers?

Navigating quality control in international trade can present unique challenges.

-

Cultural Differences: Understanding local manufacturing practices and quality expectations is critical. Buyers should communicate clearly about their quality requirements.

-

Compliance with Local Regulations: Different regions may have specific regulations affecting quality standards. Buyers must ensure suppliers are compliant with these local laws.

-

Traceability: Establishing a traceability system for materials used in belts can enhance accountability, allowing buyers to track the origins of materials and their compliance with quality standards.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing belts, ensuring they receive high-quality products that meet their specifications and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt types’

To effectively procure various types of belts, whether for fashion retail, corporate uniformity, or promotional purposes, a systematic approach is essential. This guide provides a step-by-step checklist tailored for B2B buyers, ensuring that you make informed decisions throughout the sourcing process.

Step 1: Define Your Technical Specifications

Establish clear specifications for the types of belts you need. Consider factors such as material (leather, canvas, synthetic), style (formal, casual, reversible), and sizing options. This clarity helps in communicating your requirements to potential suppliers and ensures that the products align with your brand’s image.

Step 2: Research Market Trends and Demands

Understanding current market trends is vital for successful procurement. Analyze regional preferences in belt styles and materials, particularly focusing on the target markets in Africa, South America, the Middle East, and Europe. This knowledge will guide you in selecting products that meet consumer demands and enhance your competitive edge.

Step 3: Identify Potential Suppliers

Create a list of potential suppliers who specialize in the types of belts you require. Use industry directories, trade shows, and online platforms to locate manufacturers and wholesalers. Ensure that these suppliers have a good reputation for quality and reliability, as this will impact your overall sourcing experience.

Step 4: Verify Supplier Certifications

Before entering into any agreements, it’s crucial to confirm that your suppliers hold necessary certifications and adhere to industry standards. Look for certifications related to quality management (ISO), environmental compliance, and labor practices. These credentials not only ensure product quality but also demonstrate ethical sourcing practices.

Step 5: Request Samples for Evaluation

Once you have shortlisted suppliers, request samples of their belt offerings. Evaluating physical samples allows you to assess the quality, craftsmanship, and material suitability. Pay attention to details such as stitching, buckle durability, and overall aesthetic appeal to ensure they meet your specifications.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, minimum order quantities, and payment terms. Transparent negotiations can lead to mutually beneficial agreements. Consider factors such as bulk discounts, shipping costs, and lead times to ensure that you maintain a healthy profit margin.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the production and delivery of belts. Define clear quality benchmarks and arrange for inspections at various stages—pre-production, during manufacturing, and upon arrival. This step is crucial to avoid discrepancies and ensure that the final products meet your standards.

By following these steps, B2B buyers can navigate the complexities of sourcing different belt types effectively. A well-structured approach not only enhances procurement efficiency but also fosters long-term partnerships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for belt types Sourcing

Understanding the cost structure and pricing nuances involved in sourcing different types of belts is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis will break down the key components influencing costs, factors affecting pricing, and essential tips for buyers.

What are the Key Cost Components in Belt Manufacturing?

-

Materials: The type of material significantly affects the cost of belts. Leather belts, for example, typically cost more than fabric or canvas belts due to the premium nature of leather. Exotic materials such as alligator or ostrich can further increase costs. Fabric belts, while generally more affordable, vary in price based on the type and quality of textile used.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality. Skilled labor is often required for more intricate designs or high-quality finishes, impacting overall costs.

-

Manufacturing Overhead: Overhead costs encompass utilities, rent, and indirect labor associated with production. These expenses can fluctuate based on the scale of production and efficiency of the manufacturing process. High-volume orders often benefit from lower overhead per unit.

-

Tooling: Custom tooling for specific belt designs or unique buckles adds to the initial cost. This is particularly relevant for companies seeking bespoke solutions or unique branding features. Tooling costs can be amortized over larger production runs, making it more economical for high-volume orders.

-

Quality Control (QC): Investing in QC is essential to ensure product consistency and compliance with international standards. This can add to the cost but is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation costs, including shipping and customs duties, can significantly impact the final price. Variability in shipping methods (air vs. sea) and distances can lead to different logistics costs. Understanding Incoterms is vital in determining who bears these costs.

-

Margin: Supplier margins will vary based on market conditions and competition. Buyers should be aware that higher margins can indicate either premium offerings or a lack of competitive pricing.

What Influences Pricing for Different Belt Types?

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better prices, especially if they anticipate future orders.

-

Specifications and Customization: Custom features such as unique buckle designs, specific colors, or branding can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can justify higher prices. International buyers should consider the Total Cost of Ownership, factoring in long-term durability and brand value.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge a premium for their proven quality and service levels.

-

Incoterms: Understanding Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Are Essential Tips for Negotiating Belt Prices?

-

Research Market Prices: Before negotiations, conduct market research to understand standard pricing for the specific belt types you are interested in. This will provide leverage during discussions.

-

Leverage Volume Orders: If possible, consolidate orders to meet or exceed MOQs. This can lead to bulk pricing discounts and more favorable terms.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also long-term costs associated with quality, durability, and potential returns. A slightly higher upfront cost may yield savings over time.

-

Build Relationships with Suppliers: Establishing a strong relationship can lead to better pricing and terms. Suppliers are more likely to offer discounts or favorable terms to reliable partners.

-

Be Aware of Pricing Nuances: Understand how factors such as seasonality, market demand, and economic conditions can affect pricing. This knowledge can help you time your purchases effectively.

Disclaimer on Indicative Prices

Prices for belt types can vary widely based on numerous factors, including market conditions and specific buyer requirements. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing and value for your investment.

Illustrative image related to belt types

Alternatives Analysis: Comparing belt types With Other Solutions

Introduction to Alternatives in Belt Solutions

When considering belt types, it is essential to evaluate viable alternatives that may offer similar functionality or benefits. Understanding these alternatives can help international B2B buyers make informed decisions based on performance, cost-effectiveness, and suitability for specific applications. This analysis will compare traditional belt types with two alternative solutions: suspenders and adjustable waistbands, which have distinct advantages and drawbacks.

Comparison Table

| Comparison Aspect | Belt Types | Suspenders | Adjustable Waistbands |

|---|---|---|---|

| Performance | Reliable for holding up clothing; versatile across settings | Effective for maintaining pant position; stylish option | Provides a flexible fit; easily adjustable for comfort |

| Cost | Varies widely by material (e.g., leather, fabric); generally affordable | Mid-range cost; higher for designer options | Typically low-cost; simple design keeps prices down |

| Ease of Implementation | Easy to wear and remove; requires no additional setup | Requires attachment to pants; may take time to adjust | Straightforward; no additional items needed |

| Maintenance | Requires occasional cleaning and care based on material | Minimal maintenance; occasional washing needed | Very low maintenance; machine washable |

| Best Use Case | Formal and casual attire; essential for business environments | Casual and semi-formal settings; adds flair to outfits | Ideal for active wear and casual settings; great for varying body sizes |

Detailed Breakdown of Alternatives

Suspenders:

Suspenders offer a practical solution for holding up pants without the need for a traditional belt. They come in various styles, from classic to modern, allowing users to express personal style while ensuring a secure fit. However, suspenders may require more time to adjust properly and can be less versatile in formal settings compared to traditional belts. Their mid-range cost can also be a consideration for bulk purchases, particularly for B2B buyers looking for uniform solutions.

Adjustable Waistbands:

Adjustable waistbands are an increasingly popular alternative, particularly in casual and active wear. These waistbands provide comfort and flexibility, allowing wearers to modify their fit easily throughout the day. They are typically low-cost and require minimal maintenance, making them an attractive option for bulk purchases. However, they may lack the aesthetic appeal of traditional belts and suspenders, making them less suitable for formal or business environments.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right solution between belt types, suspenders, and adjustable waistbands ultimately depends on the specific needs and preferences of the buyer. For formal business environments where appearance matters, traditional belts remain the best choice. Conversely, suspenders can add a unique style element while still being functional. For casual and active scenarios, adjustable waistbands provide comfort and ease of use. By assessing the performance, cost, and suitability of each option, B2B buyers can make informed decisions that align with their operational requirements and branding strategies.

Essential Technical Properties and Trade Terminology for belt types

What Are the Key Technical Properties of Belt Types in B2B Transactions?

Understanding the technical specifications of various belt types is crucial for B2B buyers, especially when sourcing for industrial applications or fashion retail. Here are some essential properties to consider:

Illustrative image related to belt types

1. Material Grade

The material grade determines the durability and functionality of the belt. Common materials include leather, synthetic fibers, and textiles, each offering different levels of strength and flexibility. For instance, belts made from high-grade leather are ideal for formal settings, while nylon belts may be preferred for outdoor activities. Selecting the appropriate material grade ensures that the belt meets the specific needs of the application, whether it’s for fashion or industrial use.

2. Tolerance

Tolerance refers to the permissible limit of variation in belt dimensions and performance. In manufacturing, maintaining strict tolerances is vital to ensure that belts fit properly and perform as expected. This is especially important in automated settings where belts are part of machinery. A belt that does not meet the specified tolerance can lead to operational inefficiencies or equipment damage, impacting overall productivity.

3. Width and Thickness

The width and thickness of a belt affect its strength and load-bearing capacity. For industrial applications, belts must be wide enough to handle the required load without slipping or breaking. In contrast, fashion belts may prioritize aesthetics over load capacity. Understanding these dimensions helps B2B buyers choose the right belt for their specific application, ensuring both functionality and style.

4. Buckle Design and Material

The buckle is an integral part of a belt, influencing both its functionality and aesthetics. Buckles can be made from various materials, including metal, plastic, or composite materials. The design can also vary from simple to ornate, affecting the belt’s overall appeal. For B2B buyers, selecting the right buckle material and design is essential for ensuring durability and matching the intended market or application.

5. Finish and Coating

The finish and coating of a belt can enhance its durability and resistance to wear and tear. For instance, belts may undergo processes such as waterproofing or UV resistance treatments, making them suitable for specific environments. Buyers should consider these properties based on the intended use, ensuring longevity and reduced maintenance costs.

What Are Common Trade Terms Used in the Belt Industry?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B space. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the belt industry, this could mean a manufacturer creating belts specifically for a fashion brand or an industrial company. Understanding OEM relationships helps buyers evaluate product quality and the reliability of supply chains.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers who need to ensure that their orders meet the supplier’s minimum requirements, which can affect pricing and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price proposals from suppliers for specific products or services. In the context of belts, an RFQ can help buyers compare prices and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in the shipping process. They dictate who is responsible for shipping costs, insurance, and risk during transportation. Understanding these terms is crucial for B2B buyers to mitigate risks and ensure clarity in international transactions.

Illustrative image related to belt types

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the belt industry, lead times can vary significantly based on material availability and manufacturing processes. Buyers should factor lead time into their planning to avoid disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance efficiency, reduce costs, and align with their strategic goals in sourcing belt types.

Navigating Market Dynamics and Sourcing Trends in the belt types Sector

What Are the Key Market Dynamics and Trends Influencing the Belt Types Sector?

The global belt market is witnessing dynamic shifts driven by evolving consumer preferences, technological advancements, and regional economic conditions. As B2B buyers from regions like Africa, South America, the Middle East, and Europe explore sourcing options, understanding these market dynamics becomes paramount. The rise of e-commerce platforms has streamlined the procurement process, allowing international buyers to access a diverse range of belt types from manufacturers worldwide. Additionally, the demand for customization and personalization is increasing, with buyers seeking unique designs that reflect local tastes and cultural influences.

Emerging technologies such as 3D printing and digital fabrication are reshaping the production landscape, enabling manufacturers to create bespoke belts efficiently. Moreover, the trend towards athleisure and casual wear is pushing the demand for versatile belt types, such as fabric and canvas belts, that cater to a more relaxed lifestyle. In regions like Nigeria and Saudi Arabia, the influence of fashion trends combined with local craftsmanship is leading to a surge in demand for traditional and culturally significant belt designs. B2B buyers must remain agile and informed to capitalize on these trends, ensuring that they align their sourcing strategies with market demands.

How Is Sustainability Shaping Sourcing Practices in the Belt Types Sector?

Sustainability is increasingly becoming a focal point in the belt types sector, influencing sourcing practices and consumer choices alike. International B2B buyers are placing greater emphasis on the environmental impact of their purchases, driving demand for ethically sourced and sustainable materials. The use of eco-friendly materials such as organic cotton, recycled plastics, and vegetable-tanned leather is gaining traction, as companies strive to reduce their carbon footprint and appeal to environmentally conscious consumers.

Illustrative image related to belt types

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers who demonstrate transparency in their sourcing processes and adhere to fair labor practices. Certifications such as Global Organic Textile Standard (GOTS) and Fair Trade are becoming critical in the decision-making process for B2B buyers, as they seek assurance of the sustainability and ethicality of their suppliers. By prioritizing these factors, buyers can not only enhance their brand image but also contribute to a more sustainable future for the industry.

What Is the Historical Context of Belt Types and Their Significance in the B2B Market?

The evolution of belts from mere functional items to essential fashion accessories has significant implications for B2B buyers today. Historically, belts have served practical purposes since ancient times, evolving through various cultural contexts. In contemporary markets, belts are not only about functionality but also about style and brand identity. This shift has led to a diversification of belt types, catering to various occasions and consumer preferences.

Understanding this historical context allows B2B buyers to appreciate the craftsmanship and design intricacies involved in belt manufacturing. As buyers look to source belts, recognizing the cultural significance and craftsmanship behind different belt types can enhance their product offerings and appeal to specific consumer markets. By integrating this knowledge into their sourcing strategies, B2B buyers can better meet the demands of their target audiences while fostering partnerships with manufacturers that value heritage and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of belt types

-

1. How do I solve issues with sizing and fit when sourcing belts for my business?

To ensure proper sizing and fit for the belts you source, establish clear communication with suppliers regarding your specific requirements. Request detailed sizing charts that include measurements for different styles. It’s also beneficial to order samples before committing to a bulk order, allowing you to verify the fit and quality. Consider the end users’ preferences and regional sizing standards, especially if you’re targeting markets in diverse regions like Africa and Europe. -

2. What is the best material for belts intended for formal business attire?

Leather is typically the best material for belts intended for formal business attire due to its durability, sophistication, and classic appearance. High-quality leather belts, particularly those made from cowhide or exotic skins, convey professionalism and can enhance the overall look of business attire. When sourcing, ensure that the leather is sourced ethically and complies with international trade regulations to appeal to environmentally conscious markets. -

3. How can I ensure the quality of belts when sourcing from international suppliers?

To ensure quality when sourcing belts, conduct thorough supplier vetting by checking their certifications and industry reputation. Request samples to assess craftsmanship and materials firsthand. Establish quality assurance protocols such as third-party inspections or factory audits to verify compliance with your quality standards. Maintaining open lines of communication with your suppliers can also facilitate quality control throughout the production process. -

4. What customization options should I consider when sourcing belts for my brand?

Customization options for belts can include materials, colors, buckle styles, and branding elements such as logos or monograms. Discuss your specific needs with suppliers to explore their capabilities for custom designs. Consider the target market’s preferences and trends, which may influence customization choices. Ensure that your suppliers can accommodate minimum order quantities (MOQs) for customized products, as this can affect your overall costs and inventory management. -

5. What are the typical minimum order quantities (MOQs) for belt types from international suppliers?

Minimum order quantities for belts can vary significantly based on the supplier and the complexity of the design. Standard MOQs might range from 50 to 500 units for generic styles, while custom designs may require higher quantities. It’s essential to clarify MOQs during negotiations to avoid unexpected costs or delays. Assess your sales forecasts and budget to determine the feasibility of meeting these requirements before placing orders. -

6. What payment terms should I expect when sourcing belts internationally?

Payment terms for international belt sourcing can vary widely, but common practices include a deposit upfront (typically 30% to 50%) and the balance due before shipment. Some suppliers may offer letters of credit or payment through escrow services for added security. Always negotiate terms that align with your cash flow and risk management strategies. Additionally, consider currency fluctuations and payment fees associated with international transactions. -

7. How do logistics and shipping impact the cost of sourcing belts internationally?

Logistics and shipping can significantly affect the total cost of sourcing belts. Factors such as shipping methods (air vs. sea), distance, and carrier rates should be considered. To minimize costs, consolidate shipments and explore different logistics providers for competitive pricing. Additionally, be aware of customs duties and import taxes that may apply upon arrival in your country, as these can increase overall expenses. -

8. What are the best practices for managing returns and exchanges of belts sourced internationally?

Establishing a clear returns and exchanges policy is crucial when sourcing belts internationally. Communicate this policy to your suppliers and ensure it aligns with local regulations. Implement a systematic process for handling returns, including documentation and shipping instructions for customers. Consider the costs associated with returns and include them in your pricing strategy. By proactively managing returns, you can enhance customer satisfaction and maintain a positive brand reputation.

Top 6 Belt Types Manufacturers & Suppliers List

1. GRIP6 – Modern Adjustable Belts

Domain: grip6.com

Registered: 2012 (13 years)

Introduction: GRIP6 offers modern, high-quality belts that excel in both functionality and style. Key features include: 1. Slide Belt Innovation: Infinite adjustability with a sleek, minimalist appearance. 2. Durable Materials: Aerospace-grade aluminum buckles and military-grade webbing ensure long-lasting performance. 3. TSA Compliance: Options like the Forged Carbon Fiber Belt are ideal for frequent travelers…

2. Toyota – Types of Belts in a Car

Domain: toyota.com

Registered: 1994 (31 years)

Introduction: Types of Belts in a Car: 1. Timing Belt: Synchronizes crankshaft and camshaft for optimal combustion timing; made from rubber with reinforced fibers; may be a timing chain in some designs. 2. Serpentine Belt: Drives multiple accessory components (water pump, alternator, air conditioning compressor) using a single belt; replaces multiple V-belts in modern vehicles; requires regular inspection and m…

3. Obscure Belts – Stone Fractal 2.0 Buckle on Leather Belt

Domain: obscurebelts.com

Registered: 2005 (20 years)

Introduction: High quality leather belts are made using full grain leather from a double butt cut hide in 8.5 – 9.5 ounce thickness. The products mentioned include: 1. Stone Fractal 2.0 Buckle on Leather Belt – Regular price: $105.00 2. Black Ops Fractal 2.0 Buckle on Leather Belt – Regular price: $105.00 3. Outlaw Gun Buckle on Western Leather Belt – Regular price: $125.00 4. Series 7 Space Dial on Leather Bel…

4. Texas Belting – V-Belt Types

Domain: texasbelting.com

Registered: 2009 (16 years)

Introduction: V-Belt Types: Light Duty, Classical Heavy Duty, Molded Cogged, Wedge, Wedge Cogged, Banded. V-belts are wedge-shaped belts made from rubber compounds with tensile cords for power transmission. They are used in engines, air compressors, fans, and pumps. Identification involves checking branding, measuring cross-section, construction type (wrapped or raw edge), and length. Key measurements include T…

5. The Fashionisto – Types of Belts for Men

Domain: thefashionisto.com

Registered: 2007 (18 years)

Introduction: Types of Belts for Men: 1. Leather Belts – Timeless appeal, versatile for suits, dress trousers, and jeans. 2. Dress Belts – Sleek, crafted from full-grain leather, pairs with formal garments. 3. Suede Belts – Luxurious texture, ideal for casual or business-casual outfits. 4. Reversible Belts – Dual-sided design for versatility, suitable for various outfits. 5. Double Prong Belts – Features twin m…

6. Treasurie – 26 Types of Belts

Domain: blog.treasurie.com

Registered: 2017 (8 years)

Introduction: 26 Types of Belts: 1. Single Buckle Belts – Classic with one buckle, adjustable fit. 2. Double Buckle Belts – Trendy with two buckles, suitable for various occasions. 3. T-Lock Belts – Features a T-shaped automatic lock, no holes in the strap. 4. Horseshoe Buckle Belts – Buckle shaped like a horseshoe. 5. Horse-Bit Buckle Belts – Cowboy style with horse-bit buckle, suitable for casual wear. 6. Emb…

Strategic Sourcing Conclusion and Outlook for belt types

As we conclude our exploration of various belt types, it’s essential to recognize the pivotal role that strategic sourcing plays in enhancing your supply chain efficiency. By understanding the diverse offerings—from classic leather belts to innovative ratchet belts—international buyers can make informed purchasing decisions that align with their market needs and consumer preferences.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, sourcing quality belts that resonate with local styles and functional demands can significantly impact customer satisfaction and brand loyalty. Prioritizing suppliers who demonstrate reliability, quality craftsmanship, and innovative designs will position your business for success in an increasingly competitive landscape.

Looking ahead, we encourage you to leverage the insights gained from this guide to optimize your sourcing strategies. Engage with suppliers who not only understand the trends but also offer sustainable and cost-effective solutions. As consumer preferences evolve, staying ahead of the curve will ensure that your offerings remain relevant and appealing. Take action today—review your sourcing strategies, connect with reputable suppliers, and elevate your product offerings in the belt market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.