Catalog

Material Insight: Fake Leather Upholstery Fabric

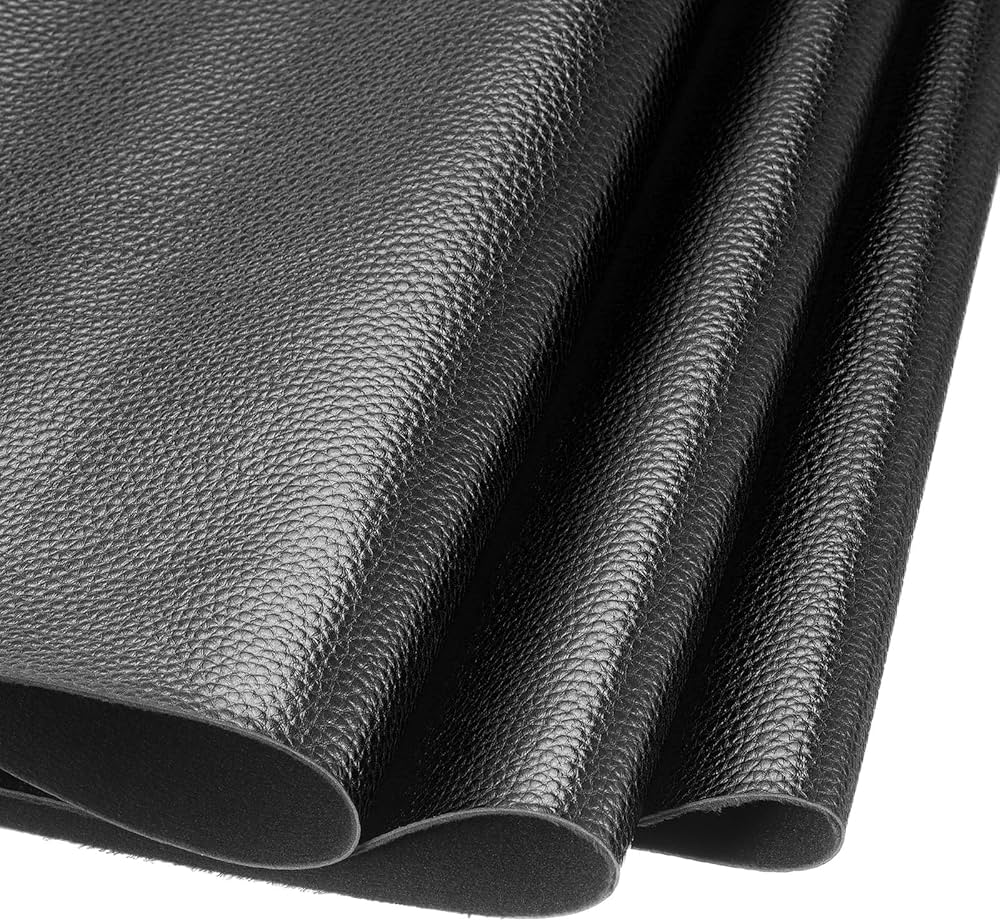

Synthetic Leather Upholstery Fabric: The Professional Choice for Modern Interiors

Synthetic leather upholstery fabric—engineered to replicate the aesthetic and performance of genuine leather without its limitations—has become the strategic material of choice for commercial and residential furniture applications. Unlike traditional leather or inferior alternatives, high-performance synthetic upholstery leather delivers consistent quality, enhanced durability, and tailored functionality critical for demanding environments. It eliminates concerns like natural hide variations, ethical sourcing complexities, and vulnerability to moisture or UV degradation, while offering designers unparalleled creative freedom in color, texture, and finish.

Why Synthetic Leather Upholstery Outperforms Alternatives

- Superior Durability & Longevity: Engineered for high-traffic settings (hospitality, office, healthcare), it resists abrasion, tearing, and staining far better than genuine leather, reducing replacement costs and extending product lifecycle.

- Eco-Responsible Manufacturing: Modern production minimizes water usage, avoids toxic tanning chemicals, and utilizes recycled or plant-based components—aligning with stringent environmental regulations and ESG goals.

- Design Precision & Consistency: Uniform grain, color fastness, and seamless large-scale patterning ensure flawless execution for bulk orders, eliminating waste from natural leather’s inherent imperfections.

- Total Cost Efficiency: Lower maintenance, easier cleaning, and extended service life deliver a superior return on investment versus genuine leather or low-grade vinyl alternatives.

Introducing WINIW: Your Trusted Partner in Sustainable Performance Materials

For over 20 years, WINIW has pioneered advanced synthetic leather solutions for global B2B clients in furniture, automotive, and design industries. We combine deep material science expertise with a commitment to circular innovation—our upholstery fabrics are certified by OEKO-TEX® STANDARD 100, ISO 14001, and GREENGUARD Gold, ensuring safety, traceability, and minimal ecological impact. By leveraging proprietary microfiber and PU/TPU technologies, WINIW transforms sustainability into tangible commercial value: reducing carbon footprints while meeting the rigorous fire, wear, and aesthetic standards demanded by architects, OEMs, and specifiers worldwide. Partner with us to future-proof your upholstery supply chain with materials engineered for performance, planet, and profit.

Technical Performance & Standards

WINIW Synthetic Leather Upholstery Fabric – B2B Product Technical Guide

WINIW specializes in high-performance synthetic leather solutions designed for commercial and industrial upholstery applications. Our faux leather upholstery fabric combines advanced material engineering with sustainable manufacturing practices to deliver a product that meets rigorous international standards while supporting eco-conscious business objectives. Engineered for durability and aesthetic excellence, WINIW’s synthetic leather is ideal for furniture, transportation, healthcare, and hospitality sectors.

Key technical advantages include compliance with fire safety regulations in both the UK and US markets, superior cleanability, a premium soft-touch finish, full REACH compliance, and certification under ISO9001 for consistent quality management.

Core Technical Advantages

-

Fire Retardant Performance (UK/US Standards)

WINIW’s synthetic leather is formulated to meet or exceed fire safety requirements for public and commercial spaces. The material passes BS 5852:2006 (UK) for ignition sources including smoldering cigarettes and match flames, as well as CAL 117 (USA) for open flame resistance. This ensures suitability for use in contract furniture, mass transit, and healthcare environments where fire safety is critical. -

Easy to Clean and Maintain

The tightly bonded polyurethane (PU) surface resists stains, spills, and microbial growth. Routine cleaning requires only mild soap and water, reducing lifecycle maintenance costs. The non-porous structure prevents liquid absorption, making it ideal for high-traffic or hygiene-sensitive applications. -

Premium Soft-Touch Feel

WINIW utilizes a proprietary finishing process to replicate the tactile comfort of genuine leather. The micro-embossed surface delivers a natural grain appearance and supple hand feel, enhancing user comfort without sacrificing durability. -

REACH Compliant Chemistry

All formulations are fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern). WINIW’s commitment to chemical safety supports our clients’ sustainability goals and regulatory compliance in global markets. -

ISO9001-Certified Quality Management

WINIW operates under ISO9001-certified production systems, ensuring consistent product quality, traceability, and process efficiency. Each batch undergoes rigorous in-line and final inspection to maintain dimensional stability, color fastness, and performance uniformity.

Product Specifications

| Property | Specification |

|---|---|

| Base Material | High-density polyurethane (PU) on polyester knitted backing |

| Thickness | 0.8 mm – 1.2 mm (customizable) |

| Weight | 380 – 450 g/m² |

| Fire Resistance | BS 5852:2006 (Source 0 & 1), CAL 117 (USA) |

| Color Fastness (ISO 105-B02) | ≥ Grade 4 (40+ hours Xenon arc exposure) |

| Martindale Abrasion | ≥ 50,000 cycles (dry) |

| Cold Crack Resistance | Passes at -20°C (ISO 14363) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO9001:2015 (Quality Management) |

| Cleaning Method | Wipe with damp cloth and neutral detergent; no harsh solvents required |

| Environmental Profile | Phthalate-free, heavy metal-free, low VOC emissions |

WINIW’s synthetic leather upholstery fabric offers a technically advanced, sustainable, and compliant alternative to traditional leather and lower-grade synthetics. By integrating performance, safety, and environmental responsibility, WINIW supports B2B partners in delivering premium, future-ready products to demanding markets.

Why Choose Synthetic over Real Leather

B2B Product Guide: Upholstery Material Selection – Real Leather vs. Synthetic Leather (WINIW PU Leather)

Selecting the optimal upholstery material for commercial and residential furniture requires balancing performance, cost, sustainability, and aesthetics. As a leader in innovative, eco-conscious synthetic leather solutions, WINIW provides this objective comparison to support informed procurement decisions. Understanding the distinct characteristics of real leather and modern synthetic leather (specifically high-performance PU leather like WINIW’s) is crucial for meeting project specifications and long-term value.

Key Considerations for Commercial Upholstery:

- Total Cost of Ownership: Beyond initial material cost, consider yield efficiency, waste reduction, maintenance, and replacement frequency.

- Performance Consistency: Uniformity in color, texture, and thickness is critical for large-scale production and seamless installations.

- Sustainability Compliance: Increasingly vital for brand reputation, meeting green building standards (LEED, BREEAM), and regulatory requirements.

- Application Demands: Traffic volume, light exposure, required cleanability, and desired aesthetic longevity dictate material suitability.

Direct Comparison: Real Leather vs. WINIW Synthetic Leather (PU)

The following table outlines critical differentiators relevant to B2B furniture manufacturing and interior design:

| Attribute | Real Leather | WINIW Synthetic Leather (PU) |

|---|---|---|

| Cost | High initial cost (2-4x synthetic). Significant price volatility based on hide grade/origin. Lower yield due to natural defects (scars, stretch marks) requiring cutting around flaws, increasing waste (15-25%). High maintenance costs over lifespan. | 30-50% lower initial material cost vs. comparable grade leather. Stable pricing unaffected by livestock markets. Near 100% usable yield with consistent width/thickness, minimizing waste (<5%). Low maintenance costs (easy wipe-clean). |

| Durability | Excellent long-term durability if properly maintained. Prone to drying, cracking, and fading with UV exposure and improper cleaning. Susceptible to staining and water damage. Performance varies significantly by hide origin and tannage. Abrasion resistance good but not uniform. | Superior resistance to UV fading, staining, and moisture. Highly consistent abrasion resistance (typically exceeding 50,000+ double rubs for commercial grades). Resists cracking and peeling with modern formulations. Performance is highly uniform and predictable across every meter. Excellent cleanability with standard solutions. |

| Eco-Friendliness | Resource-intensive: Requires significant land, water, and feed for livestock. Tanning (especially chrome) generates hazardous wastewater and sludge. High carbon footprint from animal agriculture and processing. Biodegradability is slow and dependent on tanning chemicals. | Dramatically lower resource footprint: No animal husbandry. WINIW utilizes water-based, solvent-free production processes, eliminating VOC emissions and hazardous wastewater. High potential for recycled content (e.g., PET bottles in base fabric). Significantly lower water consumption (>90% reduction vs. tanning). Carbon footprint typically 60-75% lower than bovine leather. Compliant with strict eco-standards (Oeko-Tex, Greenguard). |

Strategic Value of WINIW Synthetic Leather for B2B Partners:

- Predictable Supply Chain: Eliminate hide scarcity and price fluctuations, ensuring on-time production for large contracts.

- Design Flexibility: Achieve consistent color matching and an extensive range of textures/finishes impossible with natural hides, accelerating time-to-market.

- Enhanced Sustainability Credentials: Meet corporate ESG goals and qualify for green building certifications with verifiable, low-impact materials.

- Reduced Waste & Higher Efficiency: Maximize material utilization and streamline cutting processes, directly improving production margins.

- Lower Lifetime Costs: Combine competitive upfront pricing with minimal maintenance and extended aesthetic life in demanding environments.

WINIW’s commitment to R&D ensures our synthetic leathers deliver the premium look, feel, and performance demanded by the market, while providing a demonstrable environmental and economic advantage over traditional materials. We partner with manufacturers to specify the optimal WINIW solution for durability, aesthetics, and sustainability targets in any commercial application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly solutions for global B2B clients. With a strong foundation in research, production excellence, and international compliance, WINIW delivers premium materials trusted by industries across fashion, automotive, furniture, and technical applications.

Our manufacturing capabilities are anchored in a state-of-the-art facility spanning 100,000 square meters. This large-scale production base integrates advanced automation and environmentally responsible processes, enabling high-volume output without compromising quality or sustainability.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and eco-compliant formulations.

- Continuous investment in new technologies, including water-based and solvent-free production methods, to meet evolving environmental standards.

- Strict quality control (QC) protocols implemented at every stage—from raw material inspection to final product testing—ensuring consistency, performance, and compliance with international standards.

- In-house testing laboratories equipped to conduct abrasion resistance, color fastness, bonding strength, and ecological safety assessments (REACH, RoHS, OEKO-TEX®).

WINIW maintains a robust global supply chain, with products exported to more than 50 countries. Our primary markets include Europe and the USA, where we serve established brands and manufacturers requiring premium synthetic leather that meets rigorous regulatory and ethical requirements.

Our commitment to quality, innovation, and sustainability has positioned WINIW as a trusted partner for forward-thinking businesses seeking reliable, eco-conscious materials on a global scale.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Upholstery Solutions for Sustainable Design

WINIW delivers next-generation microfiber leather engineered specifically for high-performance upholstery applications. As a certified eco-conscious manufacturer (ISO 14001, OEKO-TEX® STANDARD 100), we provide designers and manufacturers with durable, luxurious alternatives to genuine leather that align with circular economy principles. Our solvent-free production process reduces water usage by 60% and CO2 emissions by 45% compared to conventional leather processing, without compromising on quality or aesthetics.

Core Advantages for B2B Partners

- Superior Durability: 100,000+ double-rub test results (Martindale) ensure longevity in high-traffic commercial seating, automotive interiors, and hospitality furniture.

- Eco-Integrity: Made from 40% recycled polyester content; fully recyclable at end-of-life through WINIW’s take-back program.

- Design Flexibility: 200+ color/texture options (including custom matching) with consistent roll-to-roll performance.

- Operational Efficiency: Laser-cut compatible with 0.2mm precision; reduces material waste by up to 15% versus traditional leather.

- Compliance Ready: Meets FMVSS 302 (automotive), CA TB 117-2013 (furniture), and REACH Annex XVII standards globally.

Technical Specifications at a Glance

| Property | WINIW Premium Upholstery Grade | Industry Standard | WINIW Advantage |

|---|---|---|---|

| Thickness | 0.6–1.2 mm | 0.8–1.5 mm | Consistent caliper for precision cutting |

| Weight | 380–450 g/m² | 400–500 g/m² | 12% lighter for fuel-efficient transport |

| Colorfastness (ISO 105) | Grade 4–5 | Grade 3–4 | UV-stable for 5+ years in direct sunlight |

| Tensile Strength | 180–220 N | 150–180 N | Resists tearing during heavy use |

| Eco-Certifications | GRS, OEKO-TEX®, ISO 14001 | Varies | Full traceability from fiber to finish |

Ideal Applications

- Contract furniture (office seating, healthcare, aviation)

- Automotive & RV interior trim

- Luxury residential furniture manufacturing

- Retail fixture and display systems

Request Samples Today

Experience WINIW’s tactile quality and sustainable performance firsthand. Our technical team provides free material samples (A4 size) with full spec sheets for qualified B2B partners. Validate durability, color accuracy, and processing compatibility risk-free.

→ Contact WINIW Marketing: MKT88@MicrofiberLeather.com

Specify your application, volume requirements, and target certifications for a tailored solution proposal.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.