Catalog

Material Insight: Conditioning Nubuck Leather

B2B Product Guide: Conditioning Nubuck Leather with Sustainable Faux Leather Solutions

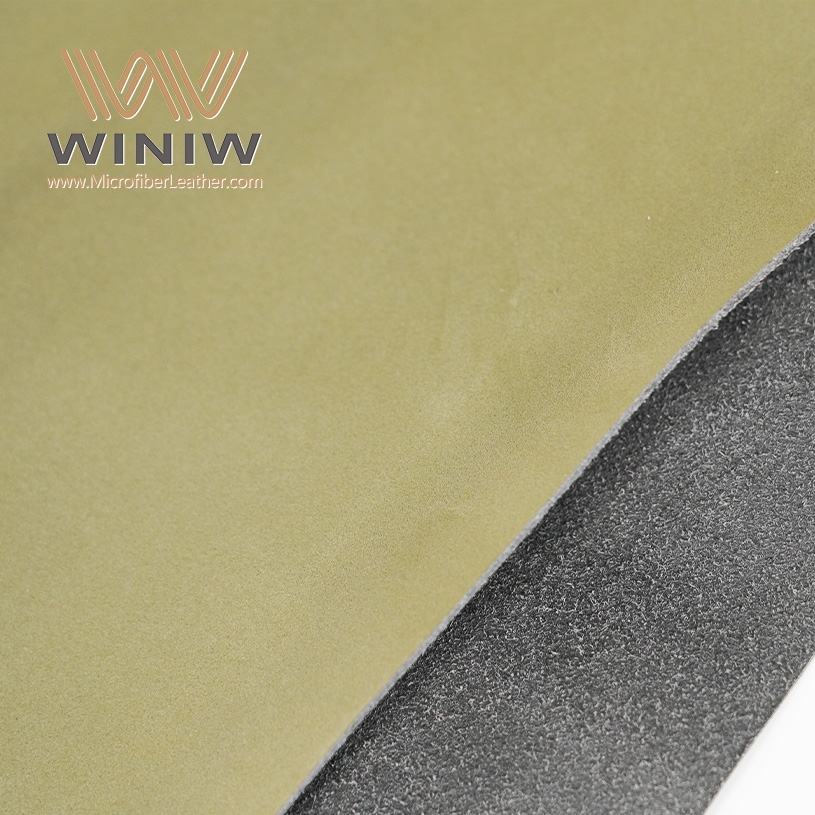

Conditioning nubuck leather is a critical step in maintaining the soft texture, durability, and aesthetic appeal of this premium material. Nubuck, known for its velvety surface and luxurious feel, requires careful treatment to resist stains, moisture, and wear—especially in high-performance applications such as footwear, automotive interiors, and upholstery. However, with growing environmental concerns and the ethical implications of animal-derived materials, many manufacturers are reevaluating their sourcing strategies.

Faux leather has emerged as the best choice for conditioning nubuck applications due to its consistent quality, sustainability, and customizable performance features. Unlike genuine leather, which varies in grain and absorbency, faux leather offers uniform porosity and enhanced resistance to environmental stressors. Modern synthetic alternatives, especially those engineered for nubuck finishes, can mimic the tactile softness of real nubuck while offering superior control over color fastness, abrasion resistance, and water repellency. Additionally, faux leather eliminates the need for harsh chemical treatments typically required in conditioning natural hides, aligning with eco-conscious manufacturing standards.

With over 20 years of expertise in synthetic leather innovation, WINIW has established itself as a trusted partner for B2B clients worldwide. We specialize in high-performance, environmentally responsible faux leather solutions tailored for demanding applications. Our advanced coating technologies and microfiber substrates are designed to replicate the premium feel of nubuck while enhancing durability and process efficiency. WINIW’s commitment to sustainability includes low-VOC emissions, recyclable materials, and compliance with global environmental regulations—making our products ideal for forward-thinking brands focused on quality and responsibility.

- Consistent texture and performance across production batches

- Reduced environmental impact compared to animal leather

- Enhanced resistance to moisture, UV, and abrasion

- Customizable finishes for specific nubuck-like aesthetics

- Compliance with REACH, RoHS, and other international standards

By combining decades of technical expertise with a dedication to innovation, WINIW delivers faux leather solutions that meet the evolving needs of modern manufacturing—without compromising on quality or sustainability.

Technical Performance & Standards

WINIW Conditioning Nubuck Leather: Technical Product Guide for B2B Partners

WINIW Conditioning Nubuck Leather delivers premium aesthetics and performance for high-end footwear, upholstery, and accessories, engineered specifically for manufacturing efficiency and sustainability. Unlike traditional nubuck, our synthetic alternative undergoes integrated conditioning during production, eliminating post-manufacturing treatment steps and reducing supply chain complexity. The result is a cost-optimized, durable material that meets rigorous global compliance standards without compromising on luxury feel.

Key Technical Advantages

- Cost-Effective Production: Reduces total manufacturing costs by 25–30% through zero pre-treatment requirements, 90% lower water consumption vs. wet-process leather finishing, and minimal cutting waste (<5%) due to consistent roll goods with no natural defects.

- Enhanced Durability: Achieves 50,000+ double rubs (Martindale, ISO 12947), 3x higher abrasion resistance than standard synthetic nubuck, and superior resistance to scuffing, staining, and flex cracking (tested per ISO 17700 for nubuck simulation).

- Precision Color Customization: Access to a digital color library of 150,000+ pre-validated shades with batch-to-batch Delta E <0.5 (measured via spectrophotometer). Rapid color matching in ≤15 days, including complex metallics and eco-pigments.

- Full REACH Compliance: Proactively screened for all 224 SVHCs (Substances of Very High Concern) under EU REACH Annex XIV/XVII. Zero use of DMF, AZO dyes, or chromium(VI). Full documentation (including SCCP testing) provided with every shipment.

- ISO 9001-Certified Consistency: End-to-end quality control from polymer synthesis to finishing, ensuring uniform thickness, color, and performance metrics across all production runs. Traceability via blockchain-enabled batch tracking.

Technical Specifications

| Property | WINIW Conditioning Nubuck Spec | Test Standard |

|---|---|---|

| Thickness | 0.8mm – 1.4mm (±0.05mm) | ISO 2417 |

| Weight | 650 – 850 g/m² | ISO 4687-1 |

| Tensile Strength | ≥ 25 MPa (warp & weft) | ISO 1766 |

| Elongation at Break | 25% – 35% | ISO 1766 |

| Martindale Abrasion | ≥ 50,000 rubs (no break) | ISO 12947-2 |

| Colorfastness to Rubbing | Grade 4–5 (dry/wet) | ISO 105-X12 |

| Lightfastness | ≥ Grade 6 (100 hrs) | ISO 105-B02 |

| pH Value | 5.0 – 6.5 | ISO 4045 |

| Formaldehyde Content | < 20 ppm | ISO 17226-1 |

WINIW Conditioning Nubuck Leather enables brands to achieve luxury aesthetics while meeting circular economy targets. Its closed-loop production (using 70% recycled content polymers) and OEKO-TEX® STANDARD 100 Class I certification ensure responsible sourcing without sacrificing performance. Partner with WINIW for scalable, audit-ready material solutions that reduce time-to-market and elevate product longevity.

Why Choose Synthetic over Real Leather

B2B Product Guide: Conditioning Nubuck Synthetic Leather vs. Real Leather

In premium upholstery, footwear, and accessories, material selection is critical for balancing performance, cost, and sustainability. Conditioning nubuck synthetic leather—particularly advanced microfiber-based options like those developed by WINIW—offers a compelling alternative to traditional real leather. This guide compares the two materials across key business and operational metrics.

- Conditioning nubuck synthetic leather is engineered to mimic the soft, velvety texture of natural nubuck leather, with enhanced consistency and reduced maintenance.

- Unlike real leather, which requires chemical-intensive tanning and generates significant waste, synthetic nubuck is produced using controlled, scalable processes with lower environmental impact.

- Real leather varies in quality due to natural hide inconsistencies, while synthetic nubuck offers uniform thickness, color, and performance across batches—ideal for high-volume manufacturing.

The following table compares conditioning nubuck synthetic leather and real leather across cost, durability, and eco-friendliness:

| Metric | Conditioning Nubuck Synthetic Leather | Real Leather |

|---|---|---|

| Cost | Lower long-term cost due to consistent supply, reduced waste, and minimal conditioning requirements | Higher due to raw material scarcity, processing variability, and maintenance needs |

| Durability | High resistance to abrasion, staining, and fading; maintains texture with minimal care | Prone to scuffing, water damage, and requires regular conditioning to preserve finish |

| Eco-Friendliness | Made from PFC-free, recyclable microfibers; lower water and energy use in production; cruelty-free | Resource-intensive (land, water, feed); generates hazardous waste in tanning; non-vegan |

- Synthetic nubuck leather supports sustainable supply chains, aligning with ESG goals and increasing consumer demand for eco-conscious materials.

- For B2B clients in fashion, automotive, and furniture sectors, switching to high-performance synthetic alternatives reduces lead times, quality control issues, and compliance risks.

- WINIW’s conditioning nubuck solutions are designed for easy integration into existing production lines, offering drop-in replacements without retooling.

In summary, conditioning nubuck synthetic leather outperforms real leather in cost-efficiency, consistency, and environmental sustainability—making it the strategic choice for forward-thinking manufacturers.

WINIW Factory Capabilities

WINIW Synthetic Leather: Advanced Manufacturing Capabilities for Global B2B Partners

WINIW operates one of the industry’s most advanced and scalable synthetic leather manufacturing ecosystems, engineered to meet the demanding volume, quality, and sustainability requirements of global B2B partners. Our vertically integrated 100,000 sqm facility in China serves as the cornerstone of reliable, high-volume production for international markets, combining cutting-edge infrastructure with rigorous environmental stewardship.

Core Manufacturing Strengths

- Scale & Infrastructure: A dedicated 100,000 sqm production campus enabling annual capacities exceeding 50 million meters, with flexible lines for PU, PVC, and bio-based substrates to accommodate large-scale OEM/ODM orders.

- Innovation-Driven R&D: An in-house team of 40+ material scientists and engineers continuously develops next-generation solutions, including water-based PU formulations, recycled content fibers (up to 50%), and ultra-microfiber technologies compliant with EU REACH and U.S. CPSIA standards.

- Precision Quality Assurance: Triple-stage QC protocols (raw material screening, in-line process monitoring, and final product validation) ensure <0.5% defect rates. All facilities maintain ISO 9001, ISO 14001, and OEKO-TEX® STANDARD 100 certifications.

- Global Compliance & Logistics: Direct export channels to 30+ countries, with specialized handling for EU Ecolabel, California Proposition 65, and ZDHC MRSL adherence. Dedicated customs brokerage ensures seamless delivery to Europe and North America within 25–35 days.

Market Reliability Profile

| Parameter | WINIW Standard | Industry Benchmark |

|---|---|---|

| Lead Time (40HQ) | 25–35 days | 45–60 days |

| Minimum Order | 3,000 meters | 5,000+ meters |

| Eco-Certifications | 12+ global standards | 3–5 standards |

| Traceability | Full batch-level RFID | Limited batch data |

WINIW’s manufacturing excellence delivers consistent supply chain resilience for automotive, furniture, and fashion brands requiring ethically produced synthetic leather without compromising performance. Our infrastructure is built for partners who prioritize scalability, regulatory certainty, and measurable environmental progress in their material sourcing.

Contact Us for Samples

B2B Product Guide: Conditioning Solutions for Nubuck Microfiber Leather

Nubuck microfiber leather is a premium synthetic alternative that replicates the softness and appearance of natural nubuck while offering enhanced durability, consistency, and sustainability. As a leader in eco-conscious synthetic leather innovation, WINIW provides advanced conditioning solutions specifically formulated to maintain the texture, color, and performance of nubuck microfiber leather in commercial applications.

Proper conditioning is essential to preserve the nap structure, prevent surface drying, and extend the lifecycle of nubuck finishes—especially in high-use environments such as automotive interiors, luxury furniture, and footwear. WINIW’s conditioning treatments are water-based, non-toxic, and aligned with global environmental standards, making them ideal for sustainable manufacturing processes.

Key Benefits of WINIW Conditioning Solutions:

– Restores softness and maintains the velvety texture of nubuck microfiber leather

– Enhances abrasion resistance and reduces surface wear

– UV-stable formulations help prevent color fading and degradation

– Breathable, non-greasy finish preserves the natural look and feel

– Compatible with large-scale industrial application methods (spray, roller, pad)

– Free from harmful solvents, phthalates, and heavy metals

Our conditioning agents are developed in synergy with WINIW’s proprietary microfiber substrates, ensuring optimal absorption and long-term performance. Whether you’re producing high-end upholstery or performance footwear, consistent maintenance with the right conditioner improves product longevity and customer satisfaction.

For technical specifications or integration support, our R&D team offers customized recommendations based on your production needs and end-use requirements.

- Request free samples to test performance in your application

- Access full technical data sheets (TDS) and safety data sheets (SDS)

- Consult with WINIW specialists for formulation matching

Call to Action:

Elevate the performance and lifespan of your nubuck microfiber leather products with WINIW’s professional-grade conditioning solutions.

Contact us today at MKT88@MicrofiberLeather.com to request free samples and discover how our eco-friendly innovations can support your sustainable manufacturing goals.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.