Introduction: Navigating the Global Market for who makes the best quality leather furniture

In the quest for sourcing the best quality leather furniture, international B2B buyers often face a daunting challenge: how to navigate a crowded marketplace filled with competing claims of excellence. With a myriad of options available, ranging from luxurious sofas to durable office chairs, understanding who truly makes the best quality leather furniture can be overwhelming. This guide serves as a comprehensive resource, covering various types of leather furniture, their applications, and the critical factors to consider when vetting suppliers.

Our aim is to empower decision-makers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—by providing actionable insights and expert evaluations. We delve into essential aspects such as material quality, construction methods, cost considerations, and warranty responsiveness, ensuring that buyers can make informed choices that align with their specific needs and budgets.

By synthesizing decades of industry experience, this guide not only simplifies the purchasing process but also enhances the confidence of B2B buyers in selecting furniture that meets their quality standards and aesthetic preferences. With our structured approach, you’ll be equipped to identify reliable manufacturers and secure investments that will stand the test of time.

Table Of Contents

- Top 9 Who Makes The Best Quality Leather Furniture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for who makes the best quality leather furniture

- Understanding who makes the best quality leather furniture Types and Variations

- Key Industrial Applications of who makes the best quality leather furniture

- 3 Common User Pain Points for ‘who makes the best quality leather furniture’ & Their Solutions

- Strategic Material Selection Guide for who makes the best quality leather furniture

- In-depth Look: Manufacturing Processes and Quality Assurance for who makes the best quality leather furniture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes the best quality leather furniture’

- Comprehensive Cost and Pricing Analysis for who makes the best quality leather furniture Sourcing

- Alternatives Analysis: Comparing who makes the best quality leather furniture With Other Solutions

- Essential Technical Properties and Trade Terminology for who makes the best quality leather furniture

- Navigating Market Dynamics and Sourcing Trends in the who makes the best quality leather furniture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of who makes the best quality leather furniture

- Strategic Sourcing Conclusion and Outlook for who makes the best quality leather furniture

- Important Disclaimer & Terms of Use

Understanding who makes the best quality leather furniture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather Furniture | Made from the top layer of the hide, showcasing natural grain. | High-end residential and commercial | Pros: Durable, ages beautifully. Cons: Higher cost. |

| Top Grain Leather Furniture | Sanded and treated for a refined finish, less natural than full grain. | Office furniture, luxury hotels | Pros: More affordable than full grain. Cons: Less durability. |

| Bonded Leather Furniture | Made from leather scraps bonded together, often with a polyurethane coating. | Budget-conscious buyers, retail stores | Pros: Cost-effective, versatile. Cons: Less durable, may peel. |

| Aniline Leather Furniture | Dyed with transparent dyes, retaining the hide’s natural look. | Luxury residential, art galleries | Pros: Natural appearance, breathable. Cons: Sensitive to stains. |

| Pigmented Leather Furniture | Coated with a polymer to enhance durability and color consistency. | High-traffic areas, commercial settings | Pros: Resistant to wear and stains. Cons: Less natural feel. |

What Are the Characteristics of Full Grain Leather Furniture?

Full grain leather furniture is crafted from the top layer of the hide, preserving the natural grain and imperfections. This type of leather is renowned for its durability and unique character, making it ideal for high-end residential and commercial applications. B2B buyers should consider the longevity and aesthetic appeal of full grain leather, as it ages beautifully, developing a rich patina over time. However, its premium pricing may be a consideration for budget-conscious businesses.

How Does Top Grain Leather Furniture Compare?

Top grain leather is created by sanding and treating the hide, resulting in a more uniform appearance than full grain leather. It is widely used in office furniture and luxury hotel settings due to its balance of quality and affordability. B2B buyers appreciate its durability and ease of maintenance, although it may not offer the same level of longevity as full grain leather. Understanding the trade-off between cost and durability is crucial for making informed purchasing decisions.

What Is Bonded Leather Furniture?

Bonded leather furniture is made from leather scraps that are bonded together, often with a polyurethane coating. This type is particularly appealing to budget-conscious buyers and is commonly found in retail stores. While it offers versatility and affordability, bonded leather may lack the durability of higher-quality options and can peel over time. B2B purchasers should weigh the cost benefits against the potential need for more frequent replacements.

What Makes Aniline Leather Furniture Unique?

Aniline leather furniture is dyed with transparent dyes, allowing the natural texture of the hide to shine through. This type is favored for luxury residential spaces and art galleries, where aesthetics are paramount. While aniline leather boasts a natural appearance and breathability, it is sensitive to stains and requires more care. B2B buyers should consider the maintenance implications when selecting aniline leather for their projects.

Why Choose Pigmented Leather Furniture?

Pigmented leather furniture is treated with a polymer coating that enhances its durability and color consistency. This type is often found in high-traffic areas and commercial settings due to its resistance to wear and stains. B2B buyers benefit from its practicality, but they may find that it lacks the natural feel of less processed leathers. Evaluating the specific application and expected use will help businesses determine if pigmented leather aligns with their needs.

Key Industrial Applications of who makes the best quality leather furniture

| Industry/Sector | Specific Application of who makes the best quality leather furniture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Luxury hotel lobbies and lounges | Enhances guest experience and promotes brand prestige | Durability, style, and maintenance requirements |

| Corporate Offices | Executive offices and meeting rooms | Creates a professional atmosphere and fosters client confidence | Ergonomics, design compatibility, and warranty services |

| Retail and Showrooms | Display areas and customer seating | Attracts customers and encourages longer visits | Aesthetic appeal, comfort, and customization options |

| Residential Interior Design | High-end residential spaces | Adds value to properties and meets luxury market demands | Material quality, sustainability, and design options |

| Healthcare Facilities | Waiting areas and patient rooms | Provides comfort and enhances the healing environment | Hygiene standards, durability, and ease of maintenance |

How is Quality Leather Furniture Utilized in the Hospitality Sector?

In the hospitality industry, quality leather furniture is essential for creating inviting and luxurious environments in hotel lobbies and lounges. High-end leather sofas and chairs not only enhance the aesthetic appeal but also improve guest comfort, leading to positive reviews and repeat business. International buyers, especially from regions like Africa and the Middle East, should prioritize sourcing options that offer durability and easy maintenance, given the high foot traffic in these spaces.

What Role Does Quality Leather Furniture Play in Corporate Offices?

For corporate offices, quality leather furniture is integral in executive offices and meeting rooms. It conveys professionalism and sophistication, enhancing the company’s image during client interactions. Buyers should consider ergonomic designs that promote comfort during long meetings and look for brands that provide robust warranties, ensuring long-term investment protection.

Illustrative image related to who makes the best quality leather furniture

How Can Retail Environments Benefit from Quality Leather Furniture?

Retail and showroom spaces benefit significantly from quality leather furniture, which serves as both functional seating and attractive displays. Well-designed leather furniture can create a welcoming atmosphere that encourages customers to linger longer, ultimately increasing sales. When sourcing, businesses should evaluate the aesthetic compatibility of the furniture with their brand image while also considering comfort and durability to withstand frequent use.

Why is Quality Leather Furniture Important in Residential Interior Design?

In residential interior design, high-quality leather furniture adds substantial value to properties, appealing to luxury market demands. Buyers from South America and Europe often seek customizable options that reflect personal styles while ensuring long-lasting quality. It is crucial to assess the leather’s quality and sustainability credentials, as environmentally conscious consumers increasingly prioritize sustainable sourcing.

How Does Quality Leather Furniture Enhance Healthcare Facilities?

Quality leather furniture is particularly beneficial in healthcare facilities, where it is used in waiting areas and patient rooms. The comfort provided by high-quality leather can significantly enhance the patient experience, promoting a sense of calm and well-being. Buyers should focus on sourcing options that meet stringent hygiene standards while ensuring durability and ease of maintenance to handle the demands of a healthcare environment.

3 Common User Pain Points for ‘who makes the best quality leather furniture’ & Their Solutions

Scenario 1: Navigating Brand Reputation and Quality Claims

The Problem:

B2B buyers often face confusion when evaluating the quality of leather furniture due to the myriad of brands claiming superiority. For instance, a buyer from Nigeria may struggle to determine whether a specific manufacturer, such as Natuzzi or Barcalounger, truly delivers high-quality products or if their claims are simply marketing fluff. This challenge is compounded by the lack of transparent information on the materials used, manufacturing processes, and real customer reviews, making it difficult to trust brand reputations.

The Solution:

To effectively navigate this landscape, buyers should conduct thorough market research that includes checking independent reviews and ratings of various brands. Engaging with industry experts, visiting trade shows, and leveraging platforms that specialize in furniture evaluations can provide deeper insights into the actual quality of products. Additionally, buyers should ask manufacturers for detailed specifications regarding materials, such as the type of leather used (e.g., full grain vs. top grain) and the construction methods employed (like 8-way hand-tied springs). Establishing a clear set of criteria that includes warranty details and customer service responsiveness can further help in assessing brand reliability.

Scenario 2: Balancing Budget Constraints with Quality Expectations

The Problem:

International buyers, especially from regions like South America, often face tight budget constraints while attempting to procure high-quality leather furniture for their businesses. They may find themselves torn between choosing economical options that compromise quality and higher-end products that stretch their budgets. This dilemma can lead to frustration, as opting for lower-quality furniture may result in higher long-term costs due to repairs or replacements.

The Solution:

To strike the right balance, buyers should adopt a strategic sourcing approach that involves evaluating the total cost of ownership rather than just the initial purchase price. This means considering factors like durability, maintenance costs, and the expected lifespan of the furniture. Buyers can also explore bulk purchasing options or negotiate long-term contracts with manufacturers, which can yield significant discounts. Furthermore, conducting a thorough analysis of the cost-to-value relationship of different brands can help identify options that provide the best quality within the budget constraints. Utilizing resources like industry reports and manufacturer rankings can also assist in making informed decisions.

Scenario 3: Ensuring Compatibility with Local Preferences and Climate

The Problem:

When sourcing leather furniture, B2B buyers from regions such as the Middle East often encounter issues related to local climate conditions and cultural preferences. For instance, the high humidity in coastal areas can affect the longevity of leather products, while cultural aesthetics may demand specific styles or colors that are not readily available from all manufacturers. This misalignment can result in poor product performance and customer dissatisfaction.

The Solution:

To address these compatibility challenges, buyers should conduct a needs assessment that incorporates local climate factors and cultural preferences. It is advisable to collaborate closely with manufacturers to ensure that the chosen leather types are suitable for the intended environment. Buyers should inquire about treatments or coatings that enhance durability in humid climates and seek out customization options that align with local tastes. Establishing relationships with local distributors who understand the market can also provide valuable insights into which brands are most likely to meet regional demands effectively. By taking these proactive steps, buyers can ensure their selections not only meet quality standards but also resonate with their target audience.

Strategic Material Selection Guide for who makes the best quality leather furniture

What Are the Key Materials Used in High-Quality Leather Furniture?

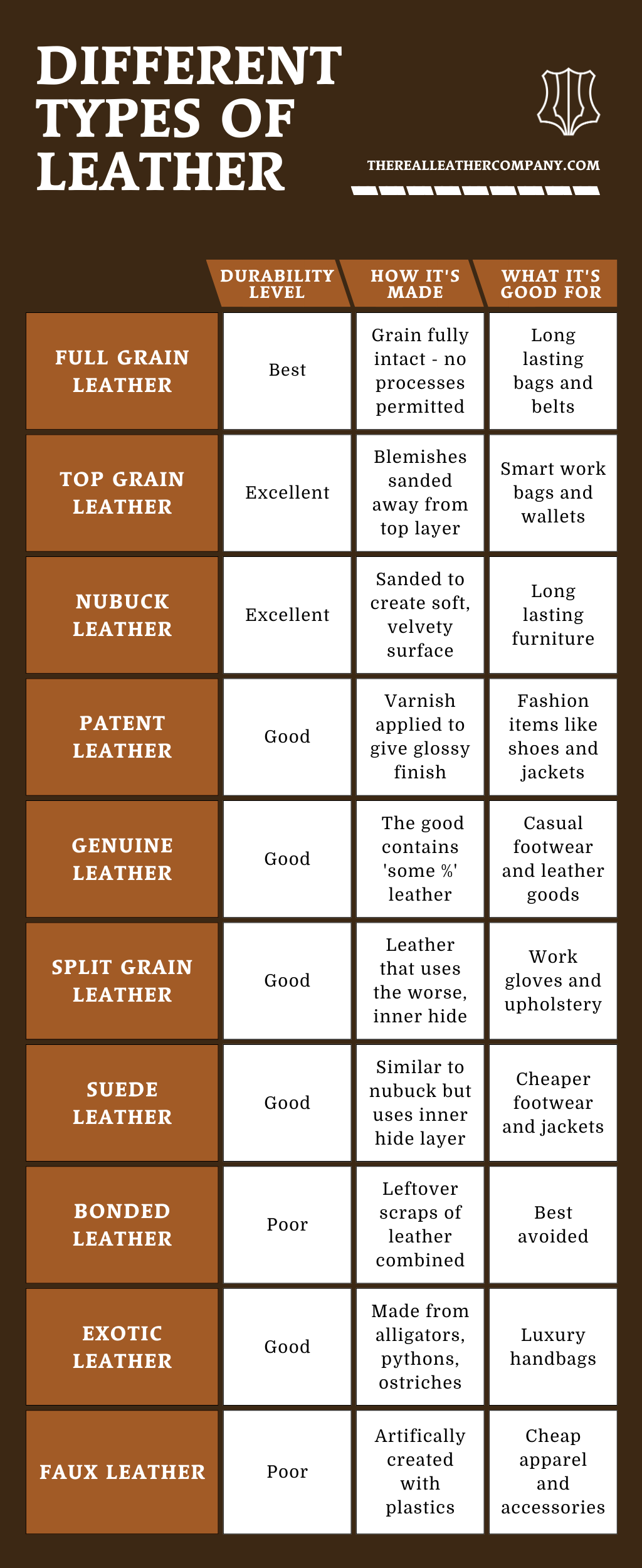

When evaluating who makes the best quality leather furniture, the choice of materials is paramount. Different materials can significantly affect the durability, aesthetics, and overall performance of leather furniture. Below, we analyze four common materials used in leather furniture manufacturing: full-grain leather, top-grain leather, plywood, and solid hardwood. Each material has unique properties, advantages, and disadvantages that international B2B buyers should consider.

What Are the Key Properties of Full-Grain Leather?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain and imperfections, which contribute to its unique character.

- Key Properties: Full-grain leather is highly breathable and develops a rich patina over time, enhancing its aesthetic appeal. It also offers excellent resistance to wear and tear, making it suitable for high-traffic environments.

- Pros & Cons: While full-grain leather is incredibly durable and luxurious, it comes at a higher cost compared to other leather types. Its natural imperfections may not appeal to all consumers, and it requires regular maintenance to keep it looking its best.

- Impact on Application: Full-grain leather is ideal for upscale residential and commercial applications, where longevity and appearance are critical.

- Considerations for International Buyers: Compliance with international leather standards, such as ISO 17075, is essential. Buyers from regions like Africa and South America may prefer full-grain leather for its premium quality, while also considering local climate impacts on leather maintenance.

How Does Top-Grain Leather Compare?

Top-grain leather is the second-highest quality leather, created by sanding down the surface of full-grain leather to remove imperfections.

- Key Properties: It is more uniform in appearance than full-grain leather and is still quite durable. It also provides a softer feel, which can be appealing for furniture.

- Pros & Cons: While top-grain leather is less expensive than full-grain, it is also less durable and may not develop the same rich patina. It is easier to clean and maintain, making it suitable for households with children and pets.

- Impact on Application: This material is often used in both residential and commercial settings, striking a balance between luxury and practicality.

- Considerations for International Buyers: Buyers should ensure that the leather meets local quality standards and consider the environmental impact of tanning processes, especially in regions with strict regulations.

What Role Do Plywood and Solid Hardwood Play?

Plywood and solid hardwood are critical components for the frames of leather furniture, affecting its structural integrity.

Illustrative image related to who makes the best quality leather furniture

- Key Properties: Plywood is lightweight and resistant to warping, while solid hardwood offers exceptional strength and durability. Both materials can withstand significant weight and pressure.

- Pros & Cons: Plywood is generally less expensive and easier to work with, but it may not provide the same level of durability as solid hardwood. Solid hardwood is more expensive and can be susceptible to moisture damage if not properly treated.

- Impact on Application: Plywood is suitable for budget-friendly furniture, while solid hardwood is preferred for high-end products that require longevity.

- Considerations for International Buyers: Compliance with local standards for wood sourcing and sustainability is crucial. Buyers should also consider the availability of these materials in their regions, particularly in Africa and the Middle East, where sourcing may vary.

Summary Table of Material Selection for Leather Furniture

| Material | Typical Use Case for who makes the best quality leather furniture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end residential and commercial furniture | Exceptional durability and aesthetics | Higher cost; requires maintenance | High |

| Top-Grain Leather | Residential and commercial furniture | Softer feel; easier to maintain | Less durable than full-grain | Medium |

| Plywood | Budget-friendly furniture frames | Lightweight; resistant to warping | Less durable than solid hardwood | Low |

| Solid Hardwood | High-end furniture frames | Exceptional strength and durability | Higher cost; moisture susceptibility | High |

This strategic material selection guide provides B2B buyers with actionable insights into the materials that define quality leather furniture. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their market needs and consumer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for who makes the best quality leather furniture

What Are the Main Stages in the Manufacturing Process of High-Quality Leather Furniture?

Manufacturing high-quality leather furniture involves several critical stages that ensure durability, comfort, and aesthetic appeal. Understanding these stages can help B2B buyers make informed decisions when sourcing products from manufacturers.

Material Preparation: Sourcing and Selection

The first step in the manufacturing process is material preparation, which includes sourcing high-grade leather and other materials. Premium leather is typically sourced from reputable suppliers who ensure that hides are processed without defects. The quality of leather significantly influences the final product’s durability and appearance.

Manufacturers often use full-grain or top-grain leather, as these types retain the natural characteristics of the hide and offer superior strength. In addition to leather, other materials such as solid hardwood for frames and high-density foam for cushioning are selected to enhance the furniture’s longevity and comfort.

Forming: Cutting and Shaping Components

Once the materials are selected, the next stage involves cutting and shaping. Skilled craftsmen use precision tools and machinery to cut leather and other components to the required dimensions. The accuracy of this stage is crucial; improper cuts can lead to wasted materials and compromised quality.

Illustrative image related to who makes the best quality leather furniture

Manufacturers may employ techniques such as die-cutting for intricate shapes or laser cutting for precision. This stage also includes the preparation of wooden frames, where solid hardwood is typically used for its strength and stability. The wood is often kiln-dried to prevent warping and cracking.

Assembly: Joining Components for Structural Integrity

The assembly phase is where all prepared components come together. This stage involves various techniques, including:

- Frame Construction: Strong joints are created using methods like doweling, mortise and tenon, or corner blocks to ensure stability.

- Upholstery: Leather is carefully stitched to cushions and frames. High-quality upholstery techniques, such as double-stitching, are employed to enhance durability and aesthetics.

- Suspension Systems: Manufacturers integrate advanced suspension systems, such as eight-way hand-tied springs or sinuous springs, which provide superior support and comfort.

Quality control is critical during assembly to ensure that all parts fit together seamlessly, which impacts the overall comfort and longevity of the furniture.

Finishing: Adding the Final Touches

The finishing stage involves several processes that enhance the product’s appearance and protect it from wear. This can include:

- Staining and Sealing: Wood surfaces may be stained and sealed to provide a rich finish and protect against moisture and scratches.

- Leather Treatment: Leather is treated with conditioners and protective finishes that help resist stains and enhance its natural beauty.

- Quality Checks: Before the product is packaged, final inspections are conducted to ensure all aspects meet quality standards.

How Is Quality Assurance Implemented in Leather Furniture Manufacturing?

Quality assurance is vital in the leather furniture industry to maintain product standards and meet buyer expectations. Here are key aspects of quality assurance relevant to B2B buyers.

Illustrative image related to who makes the best quality leather furniture

What International Standards Should B2B Buyers Consider?

Manufacturers often adhere to international quality management standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards demonstrates a manufacturer’s commitment to quality and continuous improvement.

Additionally, industry-specific certifications, such as CE marking for safety standards in the European market and API (American Petroleum Institute) standards for certain materials, may also be relevant. These certifications ensure that products meet regulatory requirements and consumer safety expectations.

What Are the Key Quality Control Checkpoints?

Quality control typically involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Materials that do not meet specified standards are rejected.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections ensure that processes are followed correctly. This includes checking stitching, assembly integrity, and material handling.

- Final Quality Control (FQC): Before products leave the factory, a final inspection ensures that all specifications are met. This includes visual checks for defects and functional tests for comfort and durability.

What Common Testing Methods Are Used?

Manufacturers employ various testing methods to verify quality, including:

- Durability Testing: Simulating wear and tear to assess how the furniture holds up under stress.

- Colorfastness Testing: Ensuring that dyes used in leather do not fade or bleed over time.

- Fire Resistance Testing: Evaluating materials to meet fire safety standards, particularly important in commercial applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to quality standards, B2B buyers can take several proactive steps:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the quality control processes and compliance with international standards.

- Request Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including test results and compliance certificates.

- Engage Third-Party Inspectors: Utilizing independent third-party inspection services can offer an unbiased assessment of product quality before shipment.

What Nuances Should International B2B Buyers Be Aware Of?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Import regulations may differ significantly, and ensuring compliance with both local and international standards can prevent costly delays and fines.

Additionally, cultural differences in business practices may affect negotiations and expectations regarding quality assurance. Establishing clear communication channels and setting mutual expectations can lead to successful partnerships.

Conclusion

Understanding the manufacturing processes and quality assurance practices in the leather furniture industry is essential for B2B buyers seeking high-quality products. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions that lead to successful procurement and long-lasting partnerships with manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes the best quality leather furniture’

Introduction

When sourcing high-quality leather furniture, it’s essential for B2B buyers to navigate the selection process methodically. This checklist provides a structured approach to identify the best manufacturers, ensuring that your investment meets your business’s quality standards and budgetary constraints.

Step 1: Define Your Quality Standards

Establish clear quality parameters based on your target market and intended use for the leather furniture. Consider factors such as durability, aesthetics, and comfort. High-quality leather should be robust and maintain its appearance over time, which is critical for both residential and commercial applications.

Step 2: Research Manufacturer Credentials

Investigate potential manufacturers to assess their industry reputation and reliability. Look for certifications, such as ISO or other quality assurance standards, that indicate adherence to best practices. Additionally, check for years of experience and customer reviews to gauge their reliability.

Step 3: Evaluate Material Quality

Focus on the types of leather used in production, as not all leathers are created equal. Prioritize suppliers that utilize full-grain or top-grain leather, which offer superior durability and aesthetic appeal. Request samples to inspect the texture, thickness, and finish, ensuring they align with your quality expectations.

Step 4: Assess Manufacturing Processes

Inquire about the manufacturing processes employed by potential suppliers. Understanding their techniques, such as whether they use solid hardwood frames and 8-way hand-tied springs, can provide insight into the furniture’s longevity and comfort. A transparent manufacturing process often indicates a commitment to quality.

Illustrative image related to who makes the best quality leather furniture

Step 5: Review Warranty and Service Policies

A robust warranty can be a strong indicator of a manufacturer’s confidence in their product. Review the warranty terms to ensure they cover key components such as leather quality and structural integrity. Additionally, assess their customer service responsiveness, as this will be crucial if issues arise post-purchase.

Step 6: Compare Price vs. Value

Conduct a comparative analysis of pricing among various suppliers while considering the quality they offer. Be wary of significantly lower prices, as they may indicate compromised quality. Aim to balance cost with the value of the materials, craftsmanship, and service provided to ensure a wise investment.

Step 7: Seek Feedback from Other Buyers

Leverage your network to gather insights from other businesses that have purchased leather furniture. Their experiences can provide valuable information about supplier reliability, product performance, and overall satisfaction. Engaging in discussions with peers can reveal potential pitfalls and best practices in sourcing.

By following this checklist, B2B buyers can make informed decisions when sourcing high-quality leather furniture, ultimately ensuring satisfaction and long-term value for their investments.

Comprehensive Cost and Pricing Analysis for who makes the best quality leather furniture Sourcing

When sourcing quality leather furniture, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will provide insights into the various cost components involved, pricing influencers, and strategic buyer tips for maximizing value, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Leather Furniture Manufacturing?

The primary cost components in leather furniture manufacturing include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of leather used (e.g., full grain vs. top grain) significantly impacts the cost. Higher-quality hides are more expensive but offer better durability and aesthetics. Solid hardwood frames and high-quality upholstery materials also contribute to overall costs.

-

Labor: Skilled craftsmanship is essential in leather furniture production. Labor costs can vary significantly based on the region, with countries like Vietnam offering lower wages compared to European manufacturers, impacting the overall pricing structure.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with running a factory. Efficient manufacturing processes can help mitigate overhead costs, allowing for competitive pricing.

-

Tooling: The initial investment in machinery and tools for production is a one-time cost that can affect pricing. Advanced machinery increases production efficiency but requires a higher upfront investment.

-

Quality Control (QC): Rigorous quality checks add to the manufacturing costs but are essential for maintaining high standards, especially for premium products.

-

Logistics: Transportation costs, including shipping and handling, can fluctuate based on distance, mode of transport, and Incoterms used in the transaction.

-

Margin: Manufacturers typically add a profit margin to cover risks and ensure business sustainability. Margins can vary widely based on the brand’s positioning in the market.

How Do Volume and Customization Affect Leather Furniture Pricing?

Volume and minimum order quantities (MOQ) play a significant role in pricing negotiations. Larger orders typically lead to volume discounts, which can significantly reduce the per-unit cost. Customization options, such as specific leather types, colors, or designs, can also influence prices. While bespoke products often come at a premium, they allow buyers to differentiate themselves in their markets.

What Quality Certifications Should Buyers Look For?

Quality certifications can serve as a price influencer, as they often justify higher costs. Look for manufacturers that have certifications related to leather quality, environmental standards, and labor practices. These certifications not only assure product quality but also enhance brand reputation in competitive markets.

What Buyer Tips Can Help in Negotiating Better Prices?

-

Negotiate Terms: Leverage your purchase volume to negotiate better pricing, payment terms, and delivery schedules. Establishing a long-term relationship with suppliers can also yield better terms over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, which includes maintenance, durability, and potential resale value. Investing in higher-quality products may yield long-term savings.

-

Understand Pricing Nuances in International Trade: Be aware of how local economic conditions, tariffs, and exchange rates can affect pricing. Understanding Incoterms will also help clarify responsibilities in shipping and logistics, which can significantly impact overall costs.

-

Request Samples: Before committing to large orders, request samples to assess quality firsthand. This can prevent costly mistakes and ensure the product meets your expectations.

Conclusion

Sourcing quality leather furniture requires a thorough understanding of cost structures and pricing dynamics. By considering the various cost components, leveraging volume, and understanding quality certifications, B2B buyers can make informed decisions that maximize value. Additionally, strategic negotiation and awareness of total costs will help in securing the best deals in this competitive market.

Alternatives Analysis: Comparing who makes the best quality leather furniture With Other Solutions

The search for high-quality leather furniture often leads B2B buyers to assess various options, including alternative materials and production methods. Understanding these alternatives is crucial for making informed purchasing decisions that align with specific business needs and budgets.

| Comparison Aspect | Who Makes The Best Quality Leather Furniture | Alternative 1: Fabric Upholstery | Alternative 2: Synthetic Leather |

|---|---|---|---|

| Performance | Exceptional durability and comfort; often lasts a lifetime with proper care | Good comfort but may wear out faster; less durable | Varies widely; can mimic leather but may not be as durable |

| Cost | Generally higher upfront investment, reflecting quality | More budget-friendly, with a wider range of pricing | Typically lower than genuine leather but varies by brand |

| Ease of Implementation | Requires careful selection and sourcing, often with longer lead times | Easier to source and more widely available | Generally easy to procure, with many options readily available |

| Maintenance | Requires regular conditioning and care to maintain appearance | Easier to clean and maintain; may require less frequent upkeep | Minimal maintenance; often wipe-clean surfaces |

| Best Use Case | Ideal for high-end commercial spaces, luxury residential projects | Suitable for everyday use in residential settings | Good for budget-conscious projects or temporary setups |

What Are the Pros and Cons of Fabric Upholstery as an Alternative to Leather Furniture?

Fabric upholstery is often seen as a viable alternative to leather furniture, especially in budget-conscious environments. One of its primary advantages is cost; fabric options are generally more affordable than high-quality leather. Additionally, fabric is available in a vast array of colors and patterns, allowing for greater customization in design. However, fabric tends to wear out more quickly, especially in high-traffic areas, and may not withstand spills or stains as well as leather. For B2B buyers, fabric upholstery is best suited for casual settings or environments where style versatility is essential, but it may not provide the longevity or prestige associated with leather.

How Does Synthetic Leather Compare to High-Quality Leather Furniture?

Synthetic leather, often marketed as “vegan leather,” presents another alternative to traditional leather furniture. One of its main advantages is the affordability and ease of maintenance; synthetic materials are usually less expensive and can be cleaned easily with a damp cloth. They also offer a wide range of aesthetic options that can mimic genuine leather. However, synthetic leather often lacks the durability and luxurious feel of high-quality leather, which can be a significant downside for businesses aiming for a premium image. This option is best for businesses looking for cost-effective solutions without the commitment to long-term durability.

How Can B2B Buyers Choose the Right Solution for Their Needs?

In conclusion, the choice between high-quality leather furniture and its alternatives depends on various factors, including budget, intended use, and desired aesthetic. B2B buyers should consider the specific requirements of their projects—whether they prioritize durability and prestige or cost-effectiveness and ease of maintenance. By assessing the performance, cost, and maintenance needs of each option, buyers can select the best solution that aligns with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for who makes the best quality leather furniture

What Are the Key Technical Properties to Consider When Evaluating Quality Leather Furniture?

When assessing leather furniture, several technical specifications are critical to determining the overall quality and durability. Understanding these properties enables B2B buyers to make informed decisions that align with their business needs and customer expectations.

1. Material Grade: What Does It Mean for Leather Quality?

The material grade refers to the quality of the leather hides used in furniture production. Common classifications include full-grain, top-grain, and corrected grain leather. Full-grain leather, the highest quality, retains the natural grain and is known for its durability and breathability. Top-grain leather is slightly sanded and treated, making it more uniform in appearance but less durable than full-grain. Understanding material grades helps buyers select products that will withstand wear and tear, especially in commercial settings.

2. Frame Construction: Why Is It Important?

The frame construction of leather furniture significantly affects its durability and comfort. Solid hardwood frames are preferred over particleboard or softwood because they provide better stability and longevity. Additionally, the type of joints used (e.g., dowels, mortise and tenon) can impact the structural integrity of the furniture. B2B buyers should prioritize manufacturers that use robust framing materials to ensure the longevity of their investment.

3. Suspension System: How Does It Affect Comfort?

The suspension system is crucial for the comfort and support of leather seating. Common systems include sinuous springs and eight-way hand-tied springs. The latter is often seen as a hallmark of quality, providing even weight distribution and enhanced durability. Buyers should evaluate the suspension system when considering the comfort level of the furniture, particularly for products intended for high-use environments.

4. Upholstery Detail: What Does It Include?

Upholstery detail encompasses stitching, seam finishes, and overall craftsmanship. High-quality leather furniture often features double-stitched seams, which enhance durability and aesthetic appeal. Attention to upholstery detail can reflect the overall quality of the product and is essential for maintaining the furniture’s appearance over time. B2B buyers should look for brands known for meticulous craftsmanship to ensure they are investing in superior products.

5. Warranty Terms: How Do They Reflect Quality?

A warranty is a key indicator of a manufacturer’s confidence in their product. Warranties often cover defects in materials and workmanship and can range from one year to a lifetime. B2B buyers should carefully review warranty terms to understand what is covered and for how long. A robust warranty can provide peace of mind and reduce long-term costs associated with repairs and replacements.

What Are the Common Trade Terms Related to Leather Furniture Manufacturing?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather furniture market. Here are some common trade terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the leather furniture industry, this term often refers to manufacturers who create furniture based on another company’s designs. Understanding OEM relationships can help buyers navigate sourcing options and brand partnerships.

Illustrative image related to who makes the best quality leather furniture

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it influences purchasing decisions, especially for smaller businesses looking to stock inventory. Knowing the MOQ can help buyers plan their orders more effectively and manage cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing for specific products or services. This process is essential for comparing costs and ensuring that the buyer receives competitive pricing. A well-structured RFQ can facilitate better negotiations and help buyers secure the best deals.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers for the delivery of goods. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the overall cost of procurement. Familiarity with Incoterms is crucial for B2B buyers engaging in international trade, as it helps avoid misunderstandings and ensures smooth transactions.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing high-quality leather furniture, ensuring they meet the demands of their markets while maximizing value.

Navigating Market Dynamics and Sourcing Trends in the who makes the best quality leather furniture Sector

What Are the Current Market Dynamics Impacting Quality Leather Furniture Sourcing?

The global leather furniture market is currently experiencing several dynamic shifts influenced by changing consumer preferences, economic conditions, and technological advancements. Key drivers include an increasing demand for high-quality, durable furniture that combines aesthetics with functionality. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for reliable manufacturers that can provide both custom and standardized solutions.

Emerging technologies such as 3D printing and advanced manufacturing processes are revolutionizing the production of leather furniture, allowing for greater customization and efficiency. Additionally, the rise of e-commerce platforms is transforming how buyers source leather furniture, enabling them to compare products, read reviews, and make informed decisions from the comfort of their offices.

Another significant trend is the shift towards local sourcing, driven by the desire to reduce shipping costs and lead times. For B2B buyers, this means evaluating local manufacturers who can deliver quality products while ensuring compliance with international standards. Understanding these market dynamics is crucial for making strategic sourcing decisions that align with evolving consumer preferences and operational efficiencies.

How Important Is Sustainability and Ethical Sourcing in Leather Furniture Production?

Sustainability and ethical sourcing have become critical considerations in the leather furniture industry, particularly for B2B buyers focused on environmental impact and corporate social responsibility. The production of leather has historically been associated with various environmental concerns, including deforestation, water pollution, and carbon emissions. Therefore, buyers are increasingly prioritizing manufacturers who adopt sustainable practices and use eco-friendly materials.

Certification programs such as the Leather Working Group (LWG) and the Forest Stewardship Council (FSC) provide frameworks for assessing the environmental and ethical standards of leather production. These certifications ensure that the leather sourced is produced in a manner that minimizes environmental impact and supports ethical labor practices.

B2B buyers are encouraged to seek partnerships with manufacturers who are transparent about their sourcing and production processes. This not only aligns with global sustainability goals but also enhances brand reputation among increasingly eco-conscious consumers. By investing in sustainable products, buyers can differentiate themselves in the marketplace and contribute positively to the environment.

Illustrative image related to who makes the best quality leather furniture

What Is the Historical Context of Leather Furniture Manufacturing?

The history of leather furniture manufacturing dates back centuries, with roots in ancient civilizations where leather was used for both functional and decorative purposes. Over time, the craft evolved, particularly during the Industrial Revolution, which introduced mechanized production methods. This period marked a significant shift as furniture manufacturers began to standardize processes and materials, making leather furniture more accessible to the general public.

In the modern era, the leather furniture market has continued to evolve, influenced by technological innovations and changing consumer tastes. Today, the industry is characterized by a blend of traditional craftsmanship and modern design aesthetics, with a focus on quality and durability. The rise of globalization has further expanded market opportunities, allowing manufacturers from different regions to compete on a global scale.

Understanding this historical context can provide B2B buyers with insights into the craftsmanship and quality standards associated with various manufacturers, enabling them to make informed sourcing decisions that reflect both heritage and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of who makes the best quality leather furniture

-

How do I identify the best quality leather furniture manufacturers?

To identify top-quality leather furniture manufacturers, start by evaluating their reputation in the industry. Look for brands that provide transparent information about their materials, craftsmanship, and warranty policies. Examine customer reviews and ratings to gauge satisfaction. Additionally, consider manufacturers with a history of exporting to your region, as they are likely familiar with local preferences and regulations. Industry rankings can also help, providing insights into factors like durability, aesthetics, and value for money. -

What is the best type of leather for furniture quality?

Full-grain leather is widely regarded as the best quality for furniture due to its durability and natural look. It retains the hide’s original texture, making it more resistant to wear and tear. Top-grain leather is another good option, offering a balance between quality and cost, as it is slightly less durable but more affordable. When sourcing, ensure that the manufacturer discloses the type of leather used, as this significantly impacts the furniture’s longevity and maintenance requirements. -

What are the key factors to consider when sourcing leather furniture suppliers?

When sourcing leather furniture suppliers, consider their production capacity, lead times, and minimum order quantities (MOQs). Assess their quality control processes to ensure consistent standards. It’s also essential to evaluate their ability to customize products according to your specifications. Additionally, investigate their experience in international trade, including familiarity with export regulations and logistics. Effective communication and responsiveness to inquiries are crucial for a successful partnership. -

How do I negotiate payment terms with leather furniture suppliers?

Negotiating payment terms involves discussing the balance between upfront deposits and final payments. Common terms include a 30% deposit with the remainder due upon shipment. Consider leveraging your purchasing volume to negotiate more favorable terms, such as extended payment periods or discounts for bulk orders. Establish clear terms for payment methods, including letters of credit or bank transfers, ensuring they align with your cash flow requirements. -

What is the standard lead time for leather furniture orders?

Lead times for leather furniture can vary widely based on factors such as the manufacturer’s location, order complexity, and current production schedules. Generally, expect a lead time of 6 to 12 weeks for standard orders. Custom orders may take longer, depending on the level of customization required. Always clarify lead times with suppliers during the negotiation phase to align expectations and avoid delays in your supply chain. -

How can I ensure quality assurance for leather furniture products?

To ensure quality assurance for leather furniture, request samples before placing large orders. Establish clear quality standards in your contract, including specifications for materials, craftsmanship, and finish. Regularly inspect production processes or consider third-party quality audits to maintain standards. Building a strong relationship with your supplier can facilitate open communication about quality issues, ensuring that any concerns are addressed promptly. -

What are the logistics considerations when importing leather furniture?

Logistics considerations for importing leather furniture include shipping methods, customs regulations, and warehousing. Choose a reliable freight forwarder experienced in handling furniture to navigate international shipping challenges. Understand the import duties and taxes applicable in your country to avoid unexpected costs. Plan for warehousing options upon arrival, ensuring adequate space and conditions for leather products to prevent damage during storage. -

How can I customize leather furniture to meet my market’s preferences?

To customize leather furniture for your market, engage in thorough market research to understand local tastes, preferences, and cultural influences. Collaborate with your supplier to explore options for materials, colors, styles, and sizes that resonate with your target audience. Discuss potential design modifications, such as stitching patterns or hardware choices, to enhance appeal. Providing detailed specifications and feedback throughout the design process will ensure the final product aligns with market demands.

Top 9 Who Makes The Best Quality Leather Furniture Manufacturers & Suppliers List

1. Leather Shoppes – Quality Rankings for Leather Furniture

Domain: leathershoppes.com

Registered: 1996 (29 years)

Introduction: Manufacturer Rankings of Leather Furniture Brands, Quality Rankings for Best Made Sofas, Leather Sofas and Sets, Reclining Sofas, Leather Sectionals, Recliners/Chairs, Bar Stools/Counter Stools, Ottomans, Swivel Chairs. Brands include American Heritage, Bradington-Young, Natuzzi, R.H.-Restoration Hardware, Flexsteel, Roche-Bobois, Palliser, Franklin, Abbyson Living, American Leather, Stickley Upho…

2. BHG – Pottery Barn Turner Sofa

Domain: bhg.com

Registered: 1999 (26 years)

Introduction: Best Overall: Pottery Barn Turner Sofa – Dimensions: From 64.5 x 38.5 x 35 in. | Weight Capacity: Not listed | Care Instructions: Vacuum and spot-clean. Features: Aniline-dyed top-grain leather, no-sag springs, kiln-dried engineered wood, adjustable levelers, Greenguard Gold certification. Best Design: Crate & Barrel Gather Leather 2-Piece Sectional Sofa – 45 different leather finishes available. …

3. Article – Sven Couch vs. Flexsteel – Endurance Couch

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is looking for a leather couch, specifically a 3-seater/88″ in a modern style. They mentioned three options: 1) Article Sven – visually appealing but has bad reviews about cushions flattening and poor customer service. 2) Flexsteel Endurance – recommended for quality but visually less appealing, with concerns about quality decline after 2010 and foam density issues. 3) Ikea Stockholm – more e…

4. Facebook – Best Leather Couches Recommendations

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: I need recommendations for the best (real) leather couches

5. Ethan Allen – Leather Furniture

Domain: ethanallen.com

Registered: 1995 (30 years)

Introduction: Leather Furniture includes a variety of options such as Leather Sofas, Leather Sectionals, Leather Chairs, Leather Recliners, Leather Ottomans & Benches. The collection features customizable options, allowing customers to build their own sectional and choose from various fabrics and leathers. The product range is designed for living room settings and includes accent chairs, coffee tables, end tabl…

6. Bradington-Young – Luxury Leather Furniture

Domain: fineleatherfurniture.com

Registered: 1997 (28 years)

Introduction: 1. Bradington-Young: Luxury and timeless elegance, using only the finest leather hides, offering classic and contemporary designs.

2. Omnia Leather: Handcrafted excellence with top-grain leather, combining comfort and durability.

3. Hancock and Moore: Bespoke luxury with made-to-order options, allowing customization of leather and finishes.

4. Carolina Custom: Innovation and comfort with ergonomic…

7. Smith Brothers – Custom Handcrafted Leather Sofas

Domain: sunsgoods.com

Registered: 2017 (8 years)

Introduction: Top 9 Leather Sofa Manufacturers in USA: Quality & Comfort. 1. Smith Brothers – Established 1926, Old Mission, Michigan. Custom handcrafted sofas, solid wood frames, wide range of leather options. 2. Craftmaster – Established 1972, Hickory, North Carolina. Customizable designs, soft aging leather, made in the USA. 3. BenchMade Modern – Established 2012, Atlanta, Georgia. Bespoke modern leather sof…

8. Bassett – Ellery Leather Roll Arm L-Shaped Sectional

Domain: bassettfurniture.com

Registered: 1996 (29 years)

Introduction: Custom Leather Furniture includes a variety of products such as Sofas, Sectionals, Chairs, and Recliners. Key products include: 1. Ellery Leather Roll Arm L-Shaped Sectional – Price: $7,929 (reduced from $11,339) 2. Garner Leather Barrel Swivel Chair – Price: $1,749 (reduced from $2,339) 3. Carolina Leather Roll Arm Sofa – Price: $3,729 (reduced from $5,339) 4. Everett Leather Reclining Sofa – Pri…

9. Pottery Barn – Leather Sofa

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Best Overall: Pottery Barn Leather Sofa – Comes in a variety of styles and sizes, waterproof cushion covers, durable frame and leather. Dimensions: 5 sizes available, Weight: 120-200 pounds, Seat Capacity: 2-3, Seat Fill: Springs, foam, down blend, Frame Material: Hardwood, Assembly Required: No, Type of Leather: Top-grain aniline dyed. Best Value: Simpli Home Morrison Sectional in Genuine Leather…

Strategic Sourcing Conclusion and Outlook for who makes the best quality leather furniture

In conclusion, understanding who makes the best quality leather furniture is crucial for international B2B buyers seeking to invest in durable and aesthetically pleasing products. Key takeaways from our guide highlight the importance of assessing brands based on factors such as the quality of leather hides, framing materials, and overall craftsmanship. Notably, manufacturers like Bradington-Young and Hancock & Moore stand out for their exceptional quality, while brands like Abbyson Living and Ashley/Millenium may cater to budget-conscious markets without compromising style.

Strategic sourcing in this sector requires a keen eye for value, ensuring that the selected furniture not only meets aesthetic desires but also withstands the rigors of use, particularly in diverse climates and settings. Buyers should prioritize partnerships with reputable manufacturers that offer robust warranties and responsive customer service, as these elements are indicative of long-term value.

Looking ahead, we encourage B2B buyers from Africa, South America, the Middle East, and Europe to leverage this knowledge in their sourcing decisions. By aligning with quality-focused brands, businesses can enhance their offerings and foster lasting customer satisfaction. Explore opportunities today to elevate your product line with superior leather furniture that speaks to quality and craftsmanship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.