Catalog

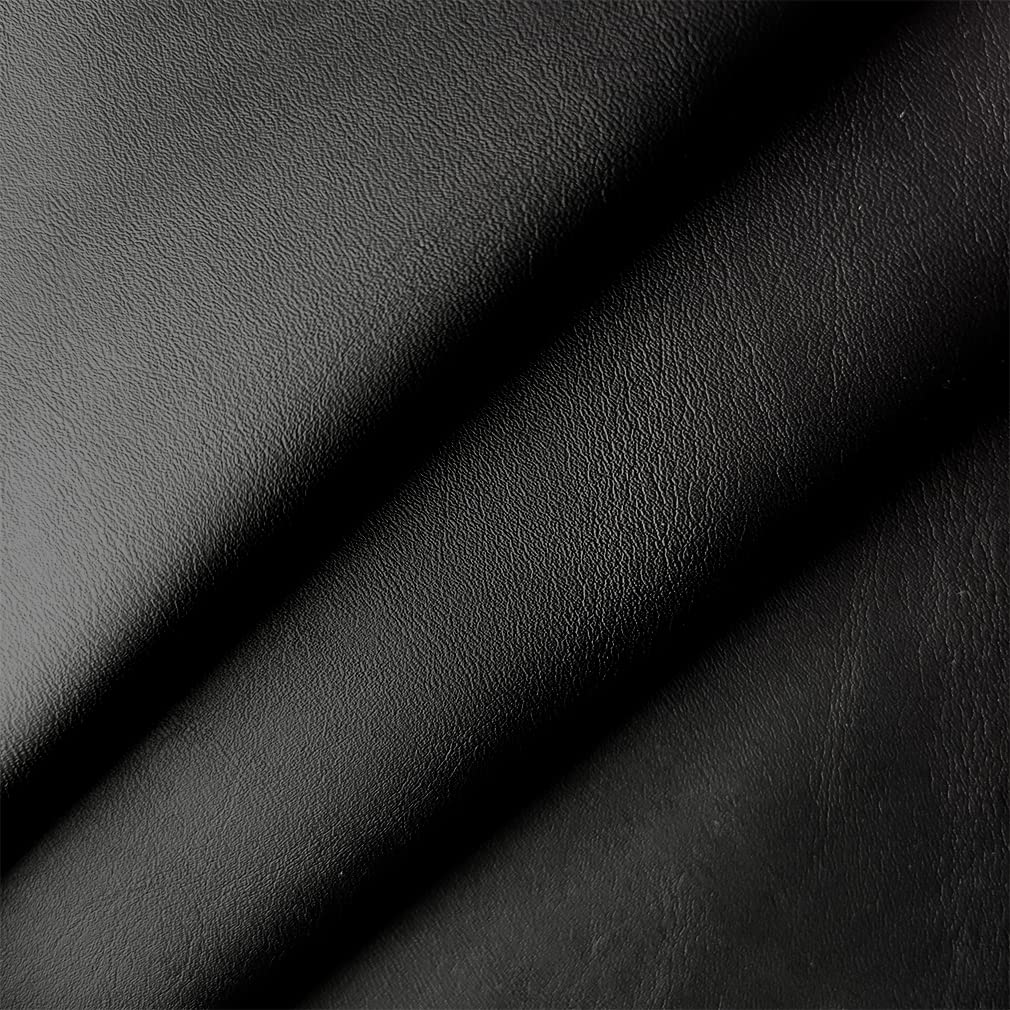

Material Insight: Black Faux Leather Fabric

B2B Product Guide: Premium Black Faux Leather Fabric

For demanding commercial applications requiring sophisticated aesthetics, durability, and ethical sourcing, premium black faux leather fabric stands as the optimal material solution. Unlike genuine leather, high-performance faux leather delivers unparalleled consistency in color depth and texture across every yard—critical for large-scale production where batch variations compromise quality control. Its inherent resistance to fading, staining, and wear ensures longevity in high-traffic environments like hospitality furniture, automotive interiors, and retail fixtures. Crucially, faux leather eliminates the ethical and supply chain complexities of animal hides while offering significant cost stability and design flexibility.

Why Black Faux Leather Excels for Commercial Use:

– Absolute Color Uniformity: Achieves deep, consistent black tones without the natural variations or dyeing inconsistencies common in genuine leather.

– Enhanced Durability: Resists abrasion, UV degradation, and common stains (oils, inks, cleaning agents), maintaining appearance through rigorous use.

– Streamlined Production: Simplifies cutting and sewing with consistent thickness and no grain directionality, reducing waste and labor costs.

– Ethical & Traceable: Provides a verified animal-free alternative with transparent manufacturing, aligning with corporate sustainability mandates.

– Design Versatility: Accepts embossing, laminating, and coating modifications to achieve specific textures (suede, pebble, glossy) without compromising integrity.

WINIW leverages over 20 years of specialized expertise in advanced synthetic leather innovation to deliver these performance advantages at scale. As a vertically integrated B2B manufacturer, we control every stage—from eco-conscious polymer formulation to precision finishing—ensuring our black faux leather fabrics meet the stringent physical, aesthetic, and environmental standards demanded by global furniture, automotive, and fashion brands. Our commitment to sustainable manufacturing, including water-based PU systems and recycled substrate options, provides partners with high-performance materials that advance both product excellence and ESG goals. Choose WINIW for black faux leather that performs without compromise.

Technical Performance & Standards

WINIW Black Faux Leather Fabric – B2B Product Guide

WINIW’s black faux leather fabric is engineered for performance-driven industries seeking a sustainable, high-quality alternative to genuine leather. Designed for applications in automotive interiors, furniture, footwear, and accessories, this synthetic leather delivers consistent quality, environmental compliance, and operational efficiency. Our advanced manufacturing process ensures a balance of durability, cost-effectiveness, and customization, meeting the evolving demands of global B2B clients.

Technical Advantages

-

Cost-effective: WINIW’s black faux leather offers significant cost savings compared to genuine leather without sacrificing performance. The material reduces dependency on fluctuating raw hide markets and lowers production waste through precise roll goods formatting.

-

Durable: Constructed with a high-tenacity polyurethane (PU) coating and reinforced polyester backing, this fabric resists abrasion, tearing, and cracking. It maintains structural integrity under repeated stress and varying environmental conditions, making it ideal for high-use applications.

-

Customizable Colors: While standard black is available off-the-shelf, WINIW offers full color customization across the Pantone spectrum. Our pigmentation process ensures excellent color fastness and batch-to-batch consistency, supporting brand-specific design requirements.

-

REACH Compliant: This product is fully compliant with EU REACH regulations (EC 1907/2006), with no detectable levels of SVHCs (Substances of Very High Concern). It is safe for consumer use and meets stringent chemical safety standards for international markets.

-

ISO 9001 Certified Production: Manufactured in ISO 9001-certified facilities, WINIW’s black faux leather undergoes rigorous quality control at every stage—from raw material sourcing to final inspection—ensuring reliability, traceability, and process consistency.

Application Suitability

- Automotive seating and interior trim

- Upholstered furniture and contract furnishings

- Luggage, handbags, and fashion accessories

- Footwear uppers and linings

- Industrial and protective covers

Product Specifications

| Property | Specification |

|---|---|

| Base Material | Polyester fabric + PU coating |

| Thickness | 0.8 mm – 1.2 mm (customizable) |

| Width | 137 cm (54 inches) standard |

| Weight | 280 – 320 g/m² |

| Abrasion Resistance | >30,000 cycles (Martindale) |

| Color Fastness to Rubbing | Grade 4–5 (dry), Grade 4 (wet) |

| Light Fastness | >4–5 (Blue Wool Scale) |

| Tensile Strength | ≥80 N/5cm (warp and weft) |

| Tear Strength | ≥3.5 kgf (Elmendorf) |

| Cold Crack Resistance | Passes at -20°C |

| REACH Status | Compliant (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Environmental Profile | Phthalate-free, low-VOC emissions |

WINIW’s black faux leather fabric supports sustainable supply chains with consistent performance and reduced environmental impact. Our B2B partners benefit from scalable production, rapid lead times, and technical support for integration into existing manufacturing workflows.

Why Choose Synthetic over Real Leather

B2B Product Guide: Black Faux Leather Fabric vs. Real Leather for Commercial Applications

Selecting the right material is critical for product performance, sustainability goals, and cost efficiency in commercial manufacturing. WINIW specializes in premium synthetic leather solutions designed to meet rigorous B2B demands while prioritizing environmental responsibility. Below is an objective comparison of black faux leather fabric (specifically high-performance PU/PVC-free options like WINIW’s offerings) versus traditional real leather across key operational metrics.

Key Considerations for B2B Buyers

- Consistency & Scalability: Faux leather provides uniform color, texture, and thickness across large production runs, eliminating natural variations inherent in animal hides. This reduces waste and streamlines manufacturing.

- Customization: Synthetic options offer precise control over weight, flexibility, breathability, and surface finish to match specific product requirements (e.g., automotive seating, furniture upholstery, accessories).

- Ethical & Regulatory Compliance: Faux leather eliminates exposure to tannery chemicals (e.g., chromium VI) and aligns with growing global restrictions on hazardous substances in consumer goods.

- Supply Chain Resilience: Not subject to livestock market volatility or hide scarcity, ensuring stable pricing and lead times.

Performance & Sustainability Comparison

| Metric | Black Faux Leather Fabric (WINIW Premium Grade) | Real Leather (Top-Grain) |

|---|---|---|

| Cost | – Lower upfront material cost (30-50% savings vs. premium hides) – Reduced processing costs (no dyeing/finishing required for consistent black) – Minimal waste due to uniform roll goods |

– High raw material cost (driven by hide quality/scarcity) – Additional costs for dyeing, finishing, and defect correction – Significant waste (15-30% due to natural imperfections) |

| Durability | – Superior abrasion resistance (tested to 50,000+ double rubs) – Consistent performance in UV exposure and humidity – No risk of cracking or fading with proper formulation – Resists staining and microbial growth |

– Variable durability (depends on hide grade) – Prone to fading, cracking, and water damage without meticulous care – Susceptible to insect damage and microbial degradation over time |

| Eco-Friendliness | – PVC-free formulations (WINIW uses water-based PU) – OEKO-TEX® STANDARD 100 certified (non-toxic) – 60-70% lower carbon footprint vs. bovine leather – Recyclable via closed-loop systems (GRS-certified) – Zero animal sourcing |

– High water/land use in livestock farming – Toxic tanning chemicals (e.g., chromium) contaminate waterways – Significant methane emissions from livestock – Limited recyclability; biodegradation releases methane |

Why WINIW Stands Out for Sustainable B2B Solutions

WINIW’s black faux leather fabric is engineered for commercial excellence without compromising planetary health:

– Certified Eco-Materials: Our PVC-free PU leather holds ISO 14001, OEKO-TEX® STANDARD 100, and Global Recycled Standard (GRS) certifications.

– Performance Parity: Matches or exceeds real leather in tear strength, seam slippage, and colorfastness for automotive (AISI standards), furniture (ISO 12947), and fashion applications.

– Circular Economy Integration: Offers take-back programs for end-of-life products, converting waste into new material feedstock.

– Traceable Supply Chain: Full transparency from raw material to finished roll, ensuring compliance with EU REACH and U.S. CPSIA regulations.

For brands committed to scalable, ethical production without sacrificing quality, WINIW’s synthetic leather delivers measurable advantages in cost control, reliability, and environmental stewardship. Contact our technical team to request samples or lifecycle analysis reports tailored to your application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong commitment to sustainability and quality, WINIW serves diverse industries including automotive, furniture, apparel, and accessories.

Our manufacturing capabilities are anchored in a state-of-the-art facility spanning 100,000 square meters. This expansive production base integrates advanced automation and environmentally responsible processes to ensure high efficiency and consistent output. The facility is designed to support large-scale production while maintaining flexibility for customized solutions to meet specific client requirements.

Key strengths of WINIW’s factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and sustainable development. The team continuously develops new formulations to improve performance, reduce environmental impact, and meet evolving international standards.

- Comprehensive quality control systems implemented at every stage of production. From raw material selection to finished product inspection, WINIW enforces strict QC protocols compliant with ISO and other global benchmarks, ensuring every batch meets exacting performance and safety criteria.

- In-house testing laboratories equipped to conduct abrasion resistance, color fastness, tensile strength, and eco-compliance testing (including REACH, RoHS, and OEKO-TEX® standards).

WINIW exports to key markets worldwide, with a strong presence in Europe and the United States. Our products are trusted by leading brands for their consistency, sustainability, and premium aesthetics. All materials are developed with a focus on low-VOC emissions, recyclability, and reduced carbon footprint, aligning with the growing demand for responsible sourcing in global supply chains.

By combining advanced manufacturing, rigorous quality assurance, and a forward-thinking R&D approach, WINIW delivers synthetic leather solutions that meet the highest standards of performance and sustainability for international partners.

Contact Us for Samples

WINIW Black Microfiber Leather: Premium Eco-Conscious Performance Fabric for B2B Applications

WINIW delivers industry-leading black faux leather fabric engineered for demanding commercial applications without compromising environmental responsibility. Our microfiber leather technology provides superior durability, aesthetics, and processing efficiency compared to conventional PU or PVC leather alternatives. As a vertically integrated manufacturer adhering to strict REACH and OEKO-TEX® standards, we ensure traceable, non-toxic materials suitable for global supply chains in automotive, furniture, and luxury goods sectors.

Key Advantages for Your Production Line

- Exceptional Durability: 50,000+ double rubs (Martindale test), resistant to cracking, peeling, and UV degradation for extended product lifecycles.

- Eco-Intelligent Composition: Water-based, solvent-free production; 30% lower carbon footprint vs. standard PU leather; fully recyclable backing options.

- Processing Efficiency: Consistent thickness (±0.1mm), excellent cuttability, and thermal stability for reduced waste in high-volume manufacturing.

- Luxury Performance: Authentic leather grain texture, superior color depth (ΔE <0.5 for batch consistency), and breathability unmatched by vinyl alternatives.

Technical Specifications Comparison

| Property | WINIW Black Microfiber Leather | Standard PU Leather |

|---|---|---|

| Abrasion Resistance | 50,000+ double rubs | 15,000–25,000 rubs |

| Color Fastness (Light) | Grade 7–8 (ISO 105-B02) | Grade 4–5 |

| Tensile Strength | 280 N/5cm (warp) | 180 N/5cm |

| Elongation at Break | 85% | 55% |

| VOC Emissions | <10 μg/g (EN 16516) | 50–200 μg/g |

| Recyclable Content | Up to 40% (backing options) | 0% |

Ideal Applications

- Automotive Interiors: Seat covers, door panels, and steering wheels requiring FMVSS 302 compliance and premium tactile feel.

- Contract Furniture: High-traffic seating for hospitality, healthcare, and corporate environments demanding antimicrobial finishes.

- Luxury Accessories: Handbags, footwear, and tech accessories where color uniformity and scratch resistance are critical.

Elevate your product line with WINIW’s black microfiber leather—combining uncompromising quality with verifiable sustainability. Request free samples today to experience the performance difference in your prototyping process. Contact our technical sales team at MKT88@MicrofiberLeather.com for material datasheets, compliance documentation, or volume pricing tailored to your production needs.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.