Catalog

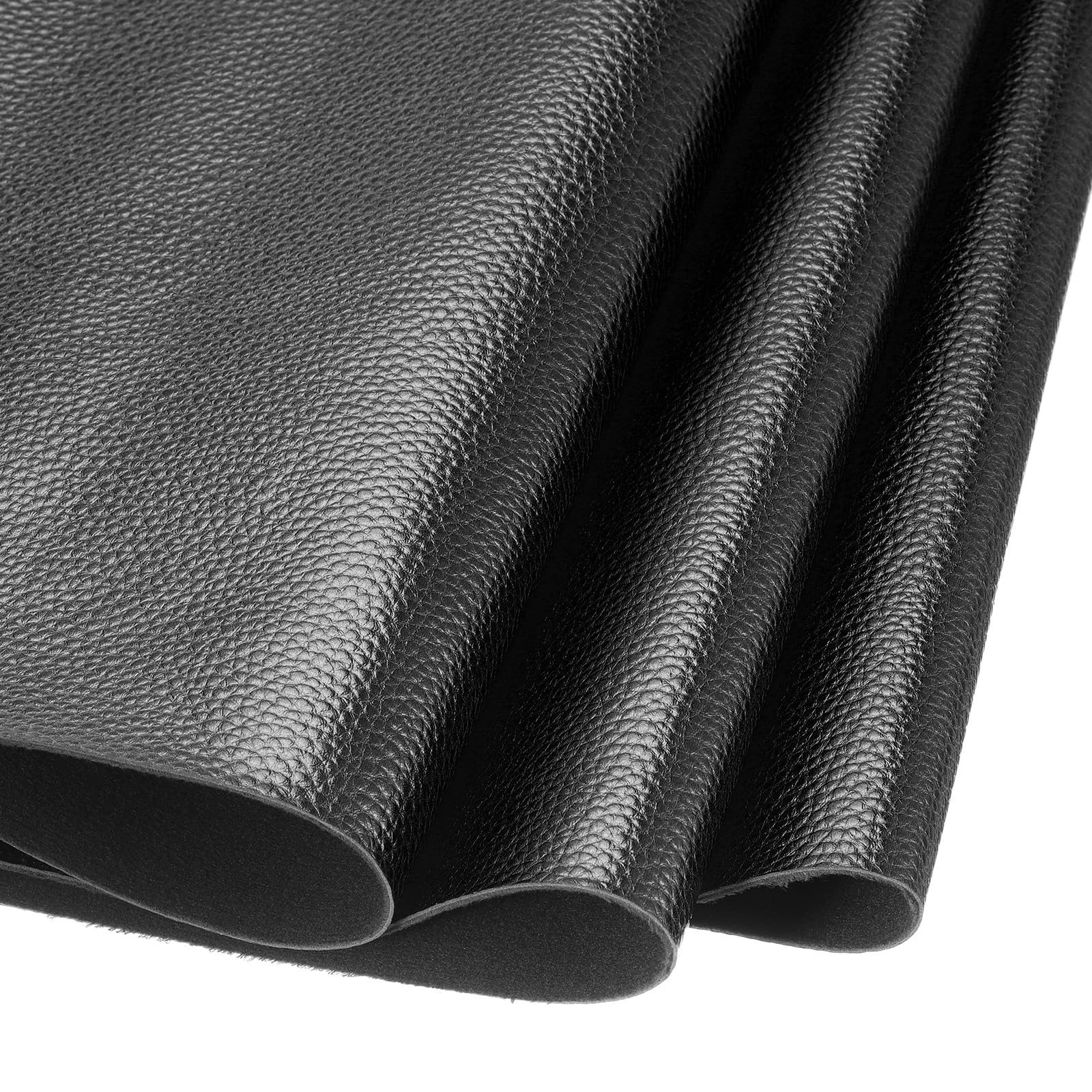

Material Insight: Auto Leather Material

B2B Product Guide: Automotive Leather Material

Introduction to Automotive Leather Material

Automotive leather material is a high-performance synthetic leather engineered specifically for interior applications in vehicles, including car seats, steering wheels, door panels, dashboards, and armrests. Combining the luxurious aesthetics of genuine leather with enhanced durability, environmental sustainability, and cost efficiency, synthetic automotive leather has become the preferred choice for OEMs and Tier-1 suppliers worldwide.

As vehicle interiors evolve to meet rising consumer demands for comfort, safety, and eco-conscious design, the role of advanced materials becomes increasingly critical. Automotive leather material delivers superior resistance to abrasion, UV exposure, temperature fluctuations, and microbial growth—making it ideal for long-term use in diverse driving conditions.

Why Automotive Leather Is the Best Choice for This Application

- Exceptional durability: Withstands heavy use and frequent cleaning without cracking or fading.

- Enhanced comfort: Offers excellent breathability, softness, and thermal stability for improved passenger experience.

- Design flexibility: Available in a wide range of colors, textures, and finishes to meet brand-specific aesthetic requirements.

- Lightweight properties: Contributes to vehicle weight reduction, supporting fuel efficiency and EV range optimization.

- Eco-friendly production: Many synthetic leather options, including those from WINIW, are free from harmful substances and align with global environmental standards.

- Cost-effective: Provides a consistent, scalable alternative to natural leather with lower maintenance and processing costs.

About WINIW

WINIW is a leading manufacturer of high-performance synthetic leather materials with over 20 years of specialized expertise in microfiber and PU-based solutions for the automotive industry. Headquartered in China and serving global markets, WINIW combines cutting-edge R&D, sustainable manufacturing practices, and rigorous quality control to deliver materials that meet the highest international standards—including REACH, RoHS, and OEKO-TEX®.

Our automotive leather materials are engineered in collaboration with automotive designers and engineers to ensure optimal performance, safety, and sustainability. With a strong commitment to innovation and environmental responsibility, WINIW supports forward-thinking brands in creating premium, eco-conscious vehicle interiors.

Technical Performance & Standards

WINIW Auto Leather Material: Technical Performance Specification Guide

WINIW’s premium auto leather material is engineered specifically for demanding automotive interior applications, delivering exceptional durability, environmental safety, and regulatory compliance without compromising aesthetic quality. Our advanced manufacturing process integrates eco-conscious materials and rigorous quality control to meet the highest industry standards for performance and sustainability.

Core Technical Advantages

- Superior Abrasion Resistance: Engineered to withstand rigorous daily use in vehicle cabins, WINIW auto leather consistently achieves >100,000 cycles in Martindale testing (ASTM D4966), significantly exceeding typical automotive requirements. This ensures long-term surface integrity and appearance retention for seats, steering wheels, and door panels.

- Exceptional UV Resistance: Formulated with high-performance stabilizers, our material maintains colorfastness and physical properties under prolonged sunlight exposure. Validated per SAE J2527 (accelerated xenon-arc exposure), it achieves AATCC Gray Scale Rating 4-5 for color change after 1000+ hours, preventing fading, cracking, or embrittlement.

- VOC Free & Low Emissions: WINIW auto leather is manufactured without volatile organic compounds (VOCs), solvents, or hazardous plasticizers. Certified to emit <10 µg/g total VOCs (validated per VDA 276), it ensures pristine cabin air quality and occupant health, critical for modern eco-conscious vehicles.

- Full REACH Compliance: All formulations strictly adhere to EU REACH regulations (EC 1907/2006), including SVHC (Substances of Very High Concern) restrictions. Comprehensive chemical screening guarantees no prohibited substances (e.g., phthalates, azo dyes, heavy metals above thresholds) are present, ensuring global market access.

- ISO 9001 Certified Quality Management: Our end-to-end production is governed by an ISO 9001-certified quality management system. This ensures consistent material properties, precise thickness control, and traceability from raw material sourcing through to finished roll, minimizing waste and ensuring batch-to-batch reliability for OEM assembly lines.

Key Performance Specifications

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Type | High-Performance Polyurethane (PU) Synthetic Leather | – |

| Thickness Range | 0.6 mm – 1.2 mm (customizable) | ASTM D374 |

| Basis Weight | 280 g/m² – 420 g/m² | ISO 9073-3 |

| Abrasion Resistance | >100,000 cycles (no wear-through) | ASTM D4966 (Martindale) |

| Lightfastness (Color) | Grade 4-5 (AATCC Gray Scale) | SAE J2527 |

| Total VOC Emissions | <10 µg/g | VDA 276 |

| REACH Compliance | Full SVHC compliance, No restricted substances | EC 1907/2006 |

| ISO Certification | ISO 9001:2015 | Quality Management |

| Eco-Profile | VOC-Free, Solvent-Free, Recyclable Support | Internal WINIW Protocol |

WINIW auto leather material provides automotive manufacturers with a sustainable, high-performance alternative to traditional leather, combining rigorous safety standards, environmental responsibility, and uncompromised durability for next-generation vehicle interiors. Our commitment to innovation ensures materials that support both your engineering specifications and corporate sustainability objectives.

Why Choose Synthetic over Real Leather

B2B Product Guide: Auto Leather Material vs. Real Leather

In the automotive and upholstery industries, selecting the right leather material is critical for balancing performance, cost, and sustainability. Two leading options—auto leather material (synthetic leather) and real leather—offer distinct advantages and trade-offs. This guide provides a clear comparison to support informed purchasing decisions for manufacturers, designers, and procurement specialists.

Auto Leather Material (Synthetic Leather)

Auto leather material, such as polyurethane (PU) or polyvinyl chloride (PVC)-based synthetic leather, is engineered to replicate the look and feel of real leather. Brands like WINIW specialize in high-performance synthetic leathers tailored for automotive interiors, offering consistent texture, color fastness, and design flexibility. These materials are increasingly formulated with eco-conscious processes, including water-based production and recycled content.

Key benefits:

– Uniform appearance with minimal batch variation

– Resistant to fading, cracking, and staining under controlled conditions

– Lower environmental footprint when produced sustainably

– Customizable in texture, thickness, and color for OEM specifications

– Animal-friendly and suitable for vegan product lines

Real Leather

Real leather is derived from animal hides, typically bovine, and undergoes tanning and finishing processes to enhance durability and aesthetics. It is valued for its natural grain, breathability, and premium tactile experience. However, real leather comes with significant variability in quality and sustainability concerns related to land use, water consumption, and chemical tanning.

Key considerations:

– Natural aging with a desirable patina over time

– Susceptible to moisture damage and UV degradation without treatment

– Higher carbon and water footprint due to livestock and tanning

– Limited by supply chain constraints and ethical sourcing challenges

– Preferred in luxury automotive segments for authenticity

Comparative Analysis

| Criteria | Auto Leather Material | Real Leather |

|---|---|---|

| Cost | Lower to moderate | High |

| Durability | High (resists abrasion, UV, and cracking) | Moderate to high (prone to drying and staining) |

| Eco-Friendliness | High (when using water-based PU and recycled substrates) | Low to moderate (high resource use and chemical processing) |

Conclusion

For B2B partners focused on cost-efficiency, design consistency, and environmental responsibility, auto leather material presents a compelling alternative to real leather. WINIW’s advanced synthetic leathers combine durability with eco-friendly manufacturing, aligning with global trends toward sustainable mobility and ethical sourcing. Real leather remains relevant in niche luxury applications but faces increasing scrutiny over environmental and ethical impacts.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a premier manufacturer of high-performance synthetic leather, built on a foundation of industrial scale, relentless innovation, and uncompromising quality. Our vertically integrated operations ensure consistent, sustainable supply for demanding global partners across fashion, automotive, and furniture sectors.

Core Manufacturing Strength

Our 100,000 sqm state-of-the-art facility in China represents one of Asia’s most advanced synthetic leather production ecosystems. This scale enables:

– End-to-end control from base polymer synthesis to finished roll goods, minimizing supply chain dependencies

– Dedicated production lines for specialized applications (e.g., automotive-grade, ultra-microfiber, recycled-content)

– Capacity to fulfill bulk orders exceeding 1 million meters monthly while maintaining agile responsiveness to urgent client needs

– Integrated eco-processing units for closed-loop water treatment and VOC recovery, aligning with EU environmental directives

Innovation-Driven R&D Capabilities

A 45+ member technical team with expertise in polymer chemistry and material science fuels our sustainable innovation pipeline:

– Proprietary water-based PU and ecological resin systems reducing carbon footprint by 30% vs. conventional processes

– Development of leathers containing >30% recycled PET content without compromising durability or aesthetics

– Customizable texture, thickness (0.3mm–2.5mm), and performance properties (abrasion resistance, lightfastness) tailored to client specifications

– Active collaboration with European and North American brands on next-generation bio-based polymers and circular material solutions

Rigorous Global Quality Assurance

WINIW implements a multi-stage QC framework exceeding international regulatory requirements:

– Raw material screening via ISO 17025-accredited in-house lab for heavy metals, phthalates, and restricted substances

– Real-time production monitoring with AI-powered defect detection systems (precision: 0.1mm)

– Batch-level certification to OEKO-TEX® STANDARD 100 Class I, REACH Annex XVII, and California Proposition 65

– Finished goods undergo 12+ performance tests including Martindale abrasion (50,000+ cycles), Taber wear, and colorfastness to light (ISO 105-B02)

Proven Global Market Compliance

WINIW products meet stringent regional standards for seamless market entry:

| Region | Key Certifications | Logistics Advantage |

|————–|—————————————-|———————————–|

| Europe | REACH, OEKO-TEX®, EN 14363 (transport) | Rotterdam/Antwerp hub shipments |

| North America| CPSIA, CA TB 117-2013, FTC Compliant | LA/Long Beach direct container ops|

| Global | ISO 9001, ISO 14001, SCMS verified | 30-day avg. transit to EU/US ports|

Our export infrastructure—backed by 15+ years of transatlantic trade experience—ensures duty-optimized delivery while navigating complex regulatory landscapes. WINIW delivers not just materials, but certified, scalable solutions that empower your sustainability commitments and operational resilience. Partner with us to transform your supply chain with traceable, high-performance synthetic leather engineered for global success.

Contact Us for Samples

B2B Product Guide: WINIW Auto Leather Material

WINIW specializes in high-performance synthetic leather solutions designed for the automotive industry. Our auto leather materials combine durability, sustainability, and premium aesthetics to meet the evolving demands of modern vehicle interiors. Engineered for OEMs, Tier-1 suppliers, and automotive design studios, WINIW delivers consistent quality and eco-conscious innovation.

Our microfiber-based auto leather is crafted to emulate the look and feel of premium genuine leather while offering superior performance characteristics. With a strong focus on sustainability, our manufacturing process reduces environmental impact through low-VOC emissions, recyclable components, and water-saving technologies.

Key Features of WINIW Auto Leather Material:

– High abrasion resistance for long-term durability

– Excellent color fastness and UV stability

– Soft hand feel with consistent texture

– Breathable and temperature-resistant (operational range: -30°C to +85°C)

– Low VOC and fogging emissions for improved cabin air quality

– Flame retardant options available (meeting FMVSS 302 standards)

– Customizable thickness (0.8mm to 1.8mm), weight, and finish

Typical Applications:

– Car seat upholstery

– Door panels and armrests

– Steering wheel covers

– Console trim and dashboard accents

– Headliners and pillar trims

Available Finishes & Textures:

– Grain leather (semi-aniline, full-aniline looks)

– Nubuck and suede finishes

– Embossed patterns (crocodile, basketweave, geometric)

– Smooth and matte finishes

– Custom embossing and digital printing

Environmental & Compliance Advantages:

– REACH, RoHS, and OEKO-TEX® certified

– Free from animal-derived materials (vegan-compliant)

– Recyclable substrate options

– Reduced carbon footprint compared to traditional leather

| Specification | Value/Range |

|---|---|

| Thickness | 0.8 mm – 1.8 mm |

| Width | 137 cm, 140 cm, 150 cm (custom) |

| Weight | 350 – 650 g/m² |

| Tensile Strength | ≥ 180 N/5cm (warp & weft) |

| Elongation at Break | ≤ 25% |

| Martindale Abrasion | ≥ 50,000 cycles |

| Light Fastness | ≥ 6 (on Blue Wool Scale) |

WINIW partners with global automotive manufacturers to co-develop tailored materials that align with brand identity and functional requirements. With advanced R&D capabilities and scalable production, we support both prototyping and high-volume supply.

Request Free Samples

Experience the quality and versatility of WINIW auto leather firsthand. Free samples are available for qualified B2B partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your vehicle interiors with sustainable, high-performance auto leather from WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.