Introduction: Navigating the Global Market for how to make leather darker

In the competitive landscape of leather goods, understanding how to make leather darker is crucial for businesses aiming to enhance their product offerings. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to source high-quality leather products, the ability to effectively darken leather can significantly impact both aesthetics and durability. This guide will delve into various methods for darkening leather, including the use of natural oils and dyes, while also exploring the implications of each technique on quality and longevity.

Throughout this comprehensive resource, we will cover essential aspects such as different types of leather treatments, applications for various products, and supplier vetting strategies. Additionally, we will provide insights into cost considerations to help you make informed purchasing decisions that align with your business objectives. By equipping yourself with knowledge about the darkening process and its benefits, you will be better positioned to negotiate with suppliers and select the best options for your leather inventory.

Whether you are looking to revitalize existing stock or enhance new products, this guide serves as a valuable tool for navigating the complexities of the leather market. Embrace the opportunity to elevate your brand’s offerings by mastering the art of leather darkening, ensuring your products meet the discerning tastes of customers worldwide.

Table Of Contents

- Top 3 How To Make Leather Darker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather darker

- Understanding how to make leather darker Types and Variations

- Key Industrial Applications of how to make leather darker

- 3 Common User Pain Points for ‘how to make leather darker’ & Their Solutions

- Strategic Material Selection Guide for how to make leather darker

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather darker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather darker’

- Comprehensive Cost and Pricing Analysis for how to make leather darker Sourcing

- Alternatives Analysis: Comparing how to make leather darker With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather darker

- Navigating Market Dynamics and Sourcing Trends in the how to make leather darker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather darker

- Strategic Sourcing Conclusion and Outlook for how to make leather darker

- Important Disclaimer & Terms of Use

Understanding how to make leather darker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Oils | Derived from plants or animal fats, rehydrates leather | Footwear, furniture, automotive interiors | Pros: Eco-friendly, enhances flexibility. Cons: May require regular reapplication. |

| Leather Dyes | Alcohol-based solutions that penetrate leather fibers | Fashion accessories, upholstery, crafts | Pros: Offers vibrant color options. Cons: Can dry out leather if overused. |

| Beeswax | Natural wax that provides a protective barrier | Outdoor gear, high-end leather goods | Pros: Water-resistant, adds sheen. Cons: May alter texture if applied excessively. |

| Mink Oil | Animal-derived oil that softens and darkens leather | Boots, outdoor apparel | Pros: Durable, enhances longevity. Cons: Can darken too much if not applied carefully. |

| Neatsfoot Oil | Derived from animal fats, ideal for quick fixes | Leather goods maintenance, repairs | Pros: Restores moisture, easy application. Cons: Risk of deterioration with overuse. |

What Are the Key Characteristics of Natural Oils for Darkening Leather?

Natural oils, such as coconut oil and mink oil, are popular choices for darkening leather due to their ability to penetrate the material and enhance its natural beauty. These oils not only darken the leather but also provide hydration and protection against wear. For B2B buyers, sourcing high-quality natural oils can lead to increased product longevity and customer satisfaction, particularly in industries like footwear and furniture manufacturing. However, businesses should consider the need for regular reapplication to maintain the desired darkening effect.

How Do Leather Dyes Differ from Oils in Darkening Leather?

Leather dyes are primarily alcohol-based and designed to change the color of leather more dramatically than oils. They penetrate deeper into the material, making them suitable for unfinished leather surfaces. B2B applications range from fashion accessories to upholstery. While dyes can provide vibrant color options, they can also dry out the leather over time, necessitating careful application and ongoing maintenance. Buyers should weigh the aesthetic benefits against the potential for increased wear and tear.

What Advantages Does Beeswax Offer in Leather Darkening?

Beeswax is a unique option for darkening leather, providing a protective barrier that enhances both appearance and durability. It is especially useful in applications for outdoor gear and high-end leather goods, where water resistance is critical. The application of beeswax can yield a beautiful sheen, but businesses must be cautious about over-application, which can alter the texture of the leather. Buyers should consider the balance between protective qualities and potential changes to the leather’s feel.

Why Is Mink Oil a Popular Choice for Darkening Leather?

Mink oil is favored for its dual action of softening and darkening leather, making it a staple in industries producing boots and outdoor apparel. Its ability to enhance the leather’s durability and flexibility is particularly beneficial for products subjected to harsh conditions. However, B2B buyers should exercise caution, as excessive application can lead to overly darkened leather. Understanding the right application techniques is crucial for maintaining the desired look and feel of the product.

How Can Neatsfoot Oil Be Utilized Effectively for Leather Care?

Neatsfoot oil is a practical solution for quick fixes and maintenance of leather goods. It is particularly effective for restoring moisture and repairing minor damages, making it popular among manufacturers and retailers of leather products. However, its acidic properties can lead to deterioration if used too frequently, which is a critical consideration for B2B buyers. Proper usage guidelines can help mitigate risks while ensuring that leather products remain in excellent condition.

Key Industrial Applications of how to make leather darker

| Industry/Sector | Specific Application of how to make leather darker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Darkening leather garments and accessories | Enhances aesthetic appeal and product longevity | Quality of dyes/oils, compatibility with materials |

| Furniture and Upholstery | Darkening leather furniture | Improves visual appeal and durability | Sourcing natural dyes/oils, environmental compliance |

| Automotive | Darkening leather car interiors | Creates a luxurious look and feel, increases resale value | Supplier reliability, product safety certifications |

| Footwear | Darkening leather shoes | Increases marketability and product lifespan | Versatility of oils/dyes, ease of application |

| Leather Goods Manufacturing | Darkening raw leather for various products | Meets diverse client demands for color and finish | Consistency of color, sourcing sustainable materials |

How is Darkening Leather Applied in the Fashion and Apparel Industry?

In the fashion industry, darkening leather is crucial for enhancing the aesthetic appeal of garments and accessories. By utilizing oils or dyes, manufacturers can achieve rich, earthy tones that appeal to consumers. Additionally, darkening leather can restore the material’s natural oils, prolonging its lifespan. Buyers in this sector must consider the compatibility of dyes with various leather types and the quality of the products sourced, ensuring they meet international standards.

What Role Does Leather Darkening Play in Furniture and Upholstery?

For furniture manufacturers, darkening leather is an effective method to improve the visual appeal of sofas, chairs, and other upholstered items. Darker leather not only looks more luxurious but also hides wear and tear better than lighter shades. Businesses need to source high-quality, natural dyes or oils that comply with environmental regulations, as sustainability is a growing concern among consumers in Europe and beyond.

How is Leather Darkening Used in Automotive Interiors?

In the automotive sector, darkening leather is a popular choice for enhancing the luxurious look of car interiors. Dark leather is often associated with high-end vehicles, thereby increasing perceived value and resale potential. Automotive suppliers must prioritize sourcing reliable suppliers that provide safe, durable products that meet stringent safety certifications, especially in international markets like the Middle East and Africa.

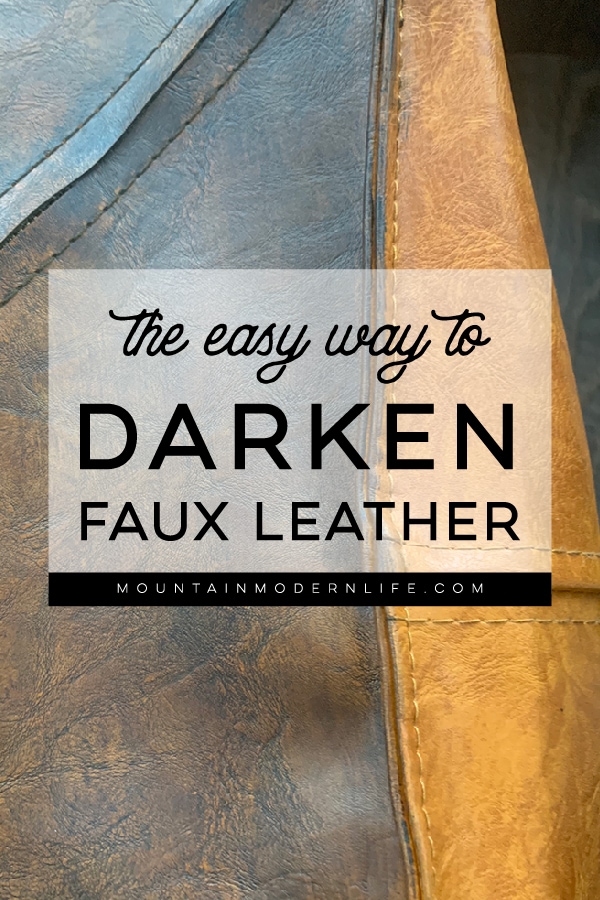

Illustrative image related to how to make leather darker

Why is Darkening Leather Important for Footwear Manufacturers?

For footwear manufacturers, darkening leather shoes can significantly enhance marketability and longevity. Darker tones are often more appealing to consumers, as they offer a classic look that pairs well with various outfits. Companies should focus on sourcing versatile oils and dyes that are easy to apply and can be integrated into existing production processes without compromising quality.

What are the Key Considerations for Leather Goods Manufacturers in Darkening Leather?

Leather goods manufacturers benefit from darkening raw leather to meet diverse client demands for color and finish. This process allows for customization and differentiation in a competitive market. Sourcing consistent colors and sustainable materials is crucial, especially as global consumers increasingly prioritize ethical production practices. Businesses must ensure they are aligned with international standards to cater to buyers from regions such as South America and Europe.

3 Common User Pain Points for ‘how to make leather darker’ & Their Solutions

Scenario 1: Inconsistent Color Application on Large Leather Goods

The Problem: B2B buyers, particularly those in the fashion or furniture industry, often face the challenge of achieving a consistent color across large leather items, such as couches or jackets. When trying to darken leather, uneven application of oils or dyes can result in patchy coloring, leading to customer dissatisfaction and returns. Additionally, the drying time varies, causing delays in production schedules and affecting inventory management.

The Solution: To ensure a uniform darkening effect, buyers should invest in high-quality leather dyes specifically designed for large applications. It’s crucial to conduct a test on a small, inconspicuous area before full application. When applying dyes, utilize spray methods or airbrush tools to achieve an even coat. This technique allows for better control over the application, minimizing the risk of over-saturation in some areas. Following the application, allow adequate drying time in a controlled environment to avoid any inconsistencies caused by temperature fluctuations. This process not only enhances the final product’s aesthetics but also streamlines production efficiency.

Illustrative image related to how to make leather darker

Scenario 2: Damage to Leather During Darkening Processes

The Problem: Many B2B buyers are concerned about the potential damage to leather during the darkening process. Common issues include drying, cracking, or losing the leather’s natural texture when using certain oils or dyes. This can be particularly problematic for high-end leather goods where quality is paramount. Buyers may feel hesitant to proceed with darkening techniques that could compromise their product’s integrity.

The Solution: To mitigate damage, buyers should select leather care products that contain conditioning agents alongside coloring properties. For instance, using mink oil or a specialized leather cream can darken the leather while simultaneously nourishing it. Before applying any product, it’s essential to clean the leather thoroughly and perform a patch test to observe how the material reacts. Additionally, incorporating a gentle buffing technique post-application can help maintain the leather’s natural luster and flexibility. By emphasizing the use of dual-purpose products, businesses can enhance both the aesthetic appeal and longevity of their leather goods.

Scenario 3: Environmental Concerns with Leather Treatment Products

The Problem: In regions like Africa and South America, environmental regulations are becoming increasingly stringent, and B2B buyers must navigate the complexities of sourcing eco-friendly leather darkening products. Many traditional dyes and oils contain harmful chemicals that can negatively impact the environment and pose health risks to workers, raising concerns about compliance and ethical sourcing.

The Solution: Buyers should prioritize sourcing plant-based, eco-friendly leather darkening solutions. Options such as vegetable-based dyes and organic oils like coconut or jojoba oil can effectively darken leather without harming the environment. When sourcing these products, it’s essential to ask suppliers for certifications that confirm their eco-friendliness and sustainability practices. Conducting a thorough vetting process for suppliers not only helps in compliance with local regulations but also aligns with the growing consumer demand for environmentally responsible products. By adopting sustainable practices, businesses can enhance their brand reputation while contributing positively to the planet.

Strategic Material Selection Guide for how to make leather darker

What Are the Key Materials for Darkening Leather?

When considering how to darken leather, several materials stand out for their effectiveness and suitability for various applications. This guide analyzes four common materials—oils, dyes, creams, and waxes—highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to how to make leather darker

Which Oils Are Effective for Darkening Leather?

Key Properties: Natural oils such as mink oil and neatsfoot oil are commonly used to darken leather. They provide hydration, enhance flexibility, and offer some level of waterproofing. These oils have a low temperature sensitivity, making them suitable for various climates.

Pros & Cons: Oils are generally easy to apply and can rejuvenate old leather. However, they may require frequent reapplication and can sometimes leave a greasy residue. The cost of oils is typically low to medium, depending on the source and quality.

Impact on Application: Oils are compatible with most leather types but may not penetrate well into dyed or treated leathers. They work best with unfinished leather, allowing for deeper absorption.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local environmental regulations regarding oil products. Additionally, understanding the local market preferences for natural versus synthetic options can guide purchasing decisions.

How Do Dyes Change the Color of Leather?

Key Properties: Leather dyes are alcohol-based and designed to penetrate the leather fibers. They offer a wide range of color options and can create vibrant, long-lasting effects. However, they can dry out leather if not used properly.

Illustrative image related to how to make leather darker

Pros & Cons: Dyes provide a more dramatic change in color compared to oils, making them suitable for applications requiring specific color matching. On the downside, they can be more challenging to apply evenly and may require multiple coats, increasing manufacturing complexity. Dyes are generally of medium cost.

Impact on Application: Dyes are best suited for unfinished or lightly finished leathers. They may not adhere well to heavily treated surfaces, limiting their application scope.

Considerations for International Buyers: Buyers should be aware of local regulations regarding chemical products, especially in Europe, where stringent compliance standards exist. Familiarity with ASTM or DIN standards for dyes can help ensure product quality.

What Role Do Creams Play in Leather Darkening?

Key Properties: Leather creams typically contain a blend of oils, waxes, and colorants. They offer conditioning benefits while also providing a mild darkening effect. Creams can enhance the leather’s natural sheen and are less likely to dry out the material.

Illustrative image related to how to make leather darker

Pros & Cons: Creams are easy to apply and can rejuvenate the leather’s appearance while offering protection against wear. However, they may not provide as significant a color change as dyes or oils. The cost is usually medium, depending on the brand and formulation.

Impact on Application: Creams work well on finished leather surfaces, making them suitable for a variety of products, including furniture and accessories.

Considerations for International Buyers: When sourcing creams, buyers should consider the formulation and ensure compliance with local health and safety regulations. Preferences for organic or vegan formulations are increasingly relevant in markets like Europe and North America.

How Do Waxes Contribute to Leather Darkening?

Key Properties: Waxes, such as beeswax, provide a protective barrier while darkening leather. They are often used in combination with oils or dyes to enhance durability and water resistance.

Illustrative image related to how to make leather darker

Pros & Cons: Waxes offer excellent protection against moisture and wear, making them suitable for outdoor leather goods. However, they can be difficult to apply evenly and may require additional effort to buff out. The cost of waxes is generally low.

Impact on Application: Waxes are compatible with most leather types but are best used as a finishing product after applying oils or dyes.

Considerations for International Buyers: Buyers should ensure that wax products meet local environmental standards, particularly in regions with strict regulations on chemical use. Understanding regional preferences for natural versus synthetic waxes can also guide purchasing decisions.

Summary Table

| Material | Typical Use Case for how to make leather darker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Oils | Conditioning and darkening leather goods | Hydrates and protects leather | May leave a greasy residue | Low |

| Dyes | Dramatic color changes for leather | Wide range of colors available | Can dry out leather if misapplied | Med |

| Creams | Conditioning and mild darkening | Easy to apply and rejuvenate leather | Less significant color change | Med |

| Waxes | Protective finishing for darkened leather | Excellent moisture resistance | Difficult to apply evenly | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to enhance their leather products by darkening them effectively while considering regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather darker

What Are the Key Stages in the Manufacturing Process of Darkening Leather?

The process of darkening leather involves several critical stages, each designed to ensure the leather not only achieves the desired color but also maintains its quality and durability. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Darkening Leather?

Material preparation is the foundational step in the leather darkening process. This begins with the selection of high-quality leather, typically full-grain or top-grain, which has the best ability to absorb oils and dyes. Once the leather is selected, it undergoes cleaning to remove any surface contaminants. This is essential because any residue can affect how evenly the oil or dye penetrates the leather.

In some cases, a pre-conditioning step is performed where the leather is lightly moistened to improve its flexibility and absorption capabilities. This is often followed by testing the leather for its pH balance, ensuring that the material is in optimal condition for the subsequent darkening processes.

What Techniques Are Used in the Forming Stage?

Once the leather is prepared, it moves to the forming stage. This may involve cutting the leather into specific shapes, depending on the end product, such as jackets, shoes, or furniture. During this stage, manufacturers often apply a base coat of oil or dye to the leather using techniques such as spraying, brushing, or dipping. Each technique has its benefits:

Illustrative image related to how to make leather darker

- Spraying allows for a uniform application and is ideal for larger surfaces.

- Brushing provides more control over the amount applied, which can be critical for intricate designs.

- Dipping can ensure deep penetration of the dye or oil, resulting in a richer color.

How is Leather Assembled and Finished?

The assembly stage involves stitching or bonding the leather pieces together to create the final product. Quality stitching techniques not only enhance the aesthetic appeal but also contribute to the durability of the leather goods. After assembly, the leather undergoes a finishing process where additional treatments are applied. This can include buffing, polishing, or the application of protective coatings that enhance water resistance and overall appearance.

The finishing stage is crucial for achieving the desired darkening effect. Depending on the intended final look, manufacturers may choose to apply multiple layers of oils or dyes, allowing each layer to dry completely before applying the next. This ensures a deep, rich color while also maintaining the leather’s natural texture and flexibility.

What Quality Assurance Measures Are Essential in Darkening Leather?

Quality assurance (QA) is critical in the leather manufacturing process to ensure that the final products meet both industry standards and customer expectations. Various international and industry-specific standards guide this process.

Which International Standards Should B2B Buyers Consider?

One of the most recognized quality management standards is ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing processes to ensure consistent quality.

In addition to ISO standards, industry-specific certifications may also apply, such as CE marking for products sold in the European Economic Area and API standards for products used in specific applications, such as oil and gas.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection occurs before the raw materials enter the production process. The quality of the leather and any oils or dyes used is assessed at this stage to ensure they meet predefined standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor various parameters, including color consistency, application techniques, and overall workmanship.

-

Final Quality Control (FQC): Once the products are completed, a final inspection is performed to verify that the leather has been darkened to the required specifications and that the products meet all quality standards. This may involve physical testing, such as checking for colorfastness and the effectiveness of protective coatings.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Are the Best Practices for Auditing Suppliers?

Conducting audits is one of the most effective ways to evaluate a supplier’s QC processes. Buyers should request reports from previous audits and certifications to assess compliance with international standards. Third-party inspections can also provide an unbiased evaluation of the manufacturing processes and the final products.

Buyers should look for suppliers who provide detailed documentation regarding their QC measures, including inspection reports, testing results, and compliance certificates. This transparency is crucial for building trust and ensuring that the products meet the buyer’s quality expectations.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of the nuances in QC and certification requirements across different regions. For example, certain markets may have specific regulations regarding the use of chemicals in leather treatment, which can impact the choice of oils and dyes used for darkening.

Understanding these regional regulations can help buyers select suppliers who are compliant and can provide products that meet local standards. Engaging in open communication with suppliers about these requirements can facilitate smoother transactions and ensure that the final products are suitable for the intended markets.

Conclusion

The process of darkening leather involves meticulous manufacturing stages and robust quality assurance measures. For international B2B buyers, understanding these processes is vital for making informed purchasing decisions. By prioritizing suppliers who adhere to recognized quality standards and demonstrating transparency in their QC practices, buyers can ensure they receive leather products that not only meet but exceed their expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather darker’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure solutions for darkening leather. Whether you’re in the fashion, furniture, or automotive industry, understanding the methods and products available for leather darkening is essential. This checklist will help you navigate the process effectively, ensuring you select the best materials and suppliers to meet your needs.

Illustrative image related to how to make leather darker

Step 1: Assess Your Leather Type

Identifying the type of leather you intend to darken is crucial, as different leathers react differently to oils and dyes. Full-grain leather, for instance, may absorb products more readily than corrected grain leather. Ensure that you understand the properties of your leather to choose the most appropriate darkening method.

Step 2: Define Your Desired Outcome

Before sourcing darkening solutions, clarify the level of darkness you want to achieve. Are you looking for a subtle enhancement or a dramatic transformation? Understanding your desired outcome will guide you in selecting the right products, whether oils, dyes, or conditioners, ensuring they align with your aesthetic and functional requirements.

Step 3: Research Available Products

Explore a range of oils, dyes, and conditioners suitable for darkening leather. Focus on natural options like mink oil or neatsfoot oil, as these not only darken but also nourish the leather. Compare product reviews, ingredient lists, and application methods to identify the most effective solutions for your specific leather type.

- Consider Eco-Friendly Options: If sustainability is a priority, look for plant-based or vegan alternatives that provide similar darkening effects without compromising the environment.

Step 4: Verify Supplier Certifications

When sourcing products, ensure that potential suppliers have the necessary certifications and quality assurance processes in place. Certifications such as ISO or environmental standards can indicate a commitment to quality and sustainability. This step helps mitigate risks associated with product performance and compliance with local regulations.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the darkening products to test on your leather. This allows you to evaluate the effectiveness and compatibility of the product with your leather type. Testing will help you confirm the desired results and prevent costly mistakes later in the procurement process.

Step 6: Evaluate Supplier Experience and Reputation

Investigate the background and reputation of potential suppliers. Look for those with experience in the leather industry and positive feedback from other B2B buyers. A supplier’s history can provide insights into their reliability, product quality, and customer service, which are critical for long-term partnerships.

Step 7: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, discuss the terms of purchase, including pricing, delivery timelines, and return policies. Clear communication during this stage can prevent misunderstandings and ensure that both parties are aligned on expectations. It’s also wise to inquire about bulk discounts or loyalty programs that may benefit your business.

By following this checklist, you can confidently procure leather darkening solutions that meet your specific needs, enhancing the quality and appeal of your leather products.

Comprehensive Cost and Pricing Analysis for how to make leather darker Sourcing

What Are the Key Cost Components for Darkening Leather?

When sourcing materials for darkening leather, several cost components should be considered. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to how to make leather darker

-

Materials: The choice of oils, dyes, and conditioning agents directly impacts costs. For instance, natural oils like mink or neatsfoot are typically more expensive than synthetic options. Leather dyes can also vary significantly in price based on the brand and quality.

-

Labor: The labor costs associated with applying these treatments can vary based on the complexity of the process and the skill level required. For instance, applying dyes requires more expertise than simple oil treatments, which may increase labor costs.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and other indirect costs associated with production. Companies that specialize in leather treatment may have higher overhead due to specialized equipment.

-

Tooling: Initial investments in tools for application—such as brushes, applicators, and protective gear—are necessary. These costs can be amortized over time but should be factored into the overall pricing structure.

-

Quality Control: Ensuring the durability and aesthetic quality of the leather after treatment requires quality assurance processes. This could include testing for colorfastness and flexibility, adding to the overall costs.

-

Logistics: Shipping costs for raw materials and finished products can vary based on location and Incoterms. For international buyers, understanding these costs is crucial for budgeting.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions and supplier relationships.

How Do Price Influencers Affect the Sourcing of Leather Darkening Products?

Several factors influence pricing in the leather darkening market, particularly for international B2B buyers.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger orders often qualify for bulk discounts, making it cost-effective for businesses to invest in larger quantities.

-

Specifications and Customization: Tailored solutions, such as specific dye colors or unique oil blends, can raise costs. Customization often requires additional R&D and testing, impacting the final price.

-

Materials: The quality of materials—be it organic oils or premium dyes—directly correlates with price. Buyers should evaluate whether the higher costs associated with premium materials align with their quality standards and customer expectations.

-

Quality Certifications: Suppliers with industry certifications may charge higher prices due to the added assurance of quality and sustainability. However, this can also reduce the risk of product failures and returns.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may have higher prices but offer better service and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery can impact total costs. Buyers should negotiate Incoterms that minimize their risk and ensure timely delivery.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Darkening Sourcing?

International B2B buyers should consider several strategies to maximize cost-efficiency when sourcing leather darkening products.

-

Negotiation: Always be prepared to negotiate prices, especially for larger orders. Suppliers may offer discounts for long-term contracts or repeat business.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, shipping, storage, and potential return costs. A lower initial price might not be the most cost-effective choice in the long run.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs that could affect the final price. Establishing contracts in stable currencies can mitigate risks.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, favorable payment terms, and priority service during high-demand periods.

-

Market Research: Regularly conduct market analysis to stay updated on pricing trends and new suppliers. This knowledge can provide leverage during negotiations.

Disclaimer

Prices for leather darkening products can fluctuate based on market conditions, availability, and other factors. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how to make leather darker With Other Solutions

Exploring Alternatives for Darkening Leather

When it comes to enhancing the appearance of leather goods, various methods can be employed to achieve darker tones. B2B buyers must consider not only the effectiveness of these solutions but also their costs, ease of implementation, and maintenance requirements. Below, we compare the traditional method of darkening leather with two viable alternatives: using leather dyes and applying synthetic leather treatments.

| Comparison Aspect | How To Make Leather Darker | Leather Dyes | Synthetic Leather Treatments |

|---|---|---|---|

| Performance | Provides a natural, rich darkening effect, rehydrates leather | Can achieve vibrant colors, but may dry out leather | Generally offers a consistent finish, but may not penetrate as deeply |

| Cost | Moderate (cost of oils and application tools) | Varies (generally low-cost) | Higher initial investment for high-quality treatments |

| Ease of Implementation | Requires careful application and drying time | Easy to apply but may need multiple coats | Typically straightforward, often with pre-packaged solutions |

| Maintenance | Requires regular reapplication to maintain color and hydration | Long-lasting if applied correctly, but may fade over time | Minimal maintenance once applied, although durability may vary |

| Best Use Case | Ideal for high-quality, full-grain leather goods | Best for unfinished or porous leather | Suitable for synthetic or treated leathers needing color enhancement |

What Are the Pros and Cons of Using Leather Dyes?

Leather dyes are a popular choice for those looking to achieve a specific color or a vibrant finish. Their alcohol-based formulation allows for deep penetration, resulting in a strong color change. However, the downside is that dyes can dry out leather over time if not used with a conditioner. Additionally, achieving an even coat may require multiple applications, which can be time-consuming. This method works best on unfinished leather, making it less ideal for pre-treated goods.

Illustrative image related to how to make leather darker

How Do Synthetic Leather Treatments Compare?

Synthetic leather treatments are formulated to provide a consistent color finish and often come in user-friendly applications. They are typically designed for synthetic or coated leather materials, making them less effective on natural hides. While these treatments offer ease of use and quick application, they may not penetrate the leather as deeply as oils or dyes, potentially leading to a less durable finish. However, they do require minimal maintenance once applied, making them a convenient choice for mass production scenarios.

Conclusion: Choosing the Right Darkening Solution for Leather

For B2B buyers, selecting the appropriate method to darken leather depends on specific needs, such as the type of leather, desired aesthetic, and maintenance capabilities. If the goal is to enhance high-quality leather goods with a natural finish, traditional oil-based darkening methods may be the best option. For those focusing on vibrant colors or working with unfinished leather, dyes present a viable alternative. Conversely, synthetic treatments may cater to manufacturers looking for quick, consistent results on synthetic leathers. Understanding these alternatives ensures that businesses can make informed decisions that align with their product offerings and customer expectations.

Essential Technical Properties and Trade Terminology for how to make leather darker

What Are the Essential Technical Properties for Darkening Leather?

When it comes to darkening leather, understanding the technical properties and specifications is crucial for B2B buyers involved in sourcing or manufacturing leather goods. Here are some key properties that should be considered:

Illustrative image related to how to make leather darker

1. Material Grade

Material grade refers to the quality of the leather being used. Full-grain leather, for instance, retains the natural texture and is more durable, making it ideal for darkening processes. Higher-grade leather typically absorbs oils and dyes more effectively, resulting in a richer, more uniform color. For buyers, investing in high-grade leather means better product longevity and customer satisfaction.

2. Absorbency

Absorbency indicates how well leather can take in oils or dyes. This property is critical for achieving the desired color depth when darkening leather. A more absorbent leather will soak in treatments quickly, allowing for faster production times. Buyers should evaluate absorbency levels to ensure compatibility with the darkening agents they plan to use.

3. Flexibility

Flexibility refers to the leather’s ability to bend and conform without cracking or breaking. Darkening treatments should enhance rather than compromise this property. Flexible leather is particularly important in applications like footwear and upholstery, where movement is frequent. A balance between flexibility and durability ensures that products remain functional and appealing.

Illustrative image related to how to make leather darker

4. Resistance to Environmental Factors

This property includes resistance to water, UV light, and temperature changes. Products treated to darken leather should also provide protection against these factors to maintain the leather’s appearance and integrity over time. For B2B buyers, selecting treatments that enhance environmental resistance is vital for reducing returns and improving customer loyalty.

5. Color Fastness

Color fastness is the ability of leather to retain its color over time and under various conditions. This property is particularly important when using dyes, as some may fade or bleed. Buyers should inquire about the color fastness ratings of dyes and oils to ensure that the final product meets customer expectations and standards.

Which Common Trade Terms Are Relevant for Darkening Leather?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms relevant to darkening leather:

Illustrative image related to how to make leather darker

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of leather goods, an OEM might provide darkened leather components to brands that assemble finished products. This term is critical for buyers looking to source leather treatments from manufacturers who specialize in darkening processes.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it can affect inventory levels and cash flow. When sourcing leather treatments for darkening, buyers should assess whether they can meet the MOQ without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For businesses looking to procure leather treatment solutions, submitting an RFQ can provide insights into market pricing and supplier capabilities. A well-structured RFQ can lead to more favorable purchasing agreements.

Illustrative image related to how to make leather darker

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial when sourcing leather treatments from international suppliers, as they dictate shipping costs, risk, and ownership transfer. Familiarity with Incoterms can help buyers negotiate better terms and avoid potential disputes.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the leather industry, lead times can be affected by the complexity of the darkening process and the availability of materials. B2B buyers should consider lead times in their planning to ensure timely delivery and meet customer demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring the quality and consistency of their leather products while fostering strong supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the how to make leather darker Sector

What Are the Current Market Dynamics in the Leather Darkening Sector?

The leather darkening sector is experiencing a notable transformation, driven by the increasing demand for premium leather products across global markets, especially in regions like Africa, South America, the Middle East, and Europe. This demand is bolstered by a growing consumer preference for high-quality, durable goods that exhibit a rich aesthetic appeal. Key trends include the rise of DIY leather care solutions and the adoption of innovative technologies in the manufacturing process. This shift is being driven by advancements in eco-friendly dyes and oils, which not only enhance the appearance of leather but also improve its longevity and wear resistance.

Furthermore, the international B2B landscape is influenced by fluctuating raw material costs, particularly in regions rich in livestock and leather production. Buyers are increasingly seeking reliable suppliers who can provide consistent quality while adhering to ethical sourcing practices. The emergence of online marketplaces and digital sourcing platforms has also streamlined procurement processes, enabling businesses to connect with manufacturers globally. As the competition intensifies, companies that can effectively leverage technology and innovate in their product offerings will gain a competitive edge.

How Important Is Sustainability and Ethical Sourcing in the Leather Darkening Industry?

Sustainability and ethical sourcing have become paramount in the leather darkening sector, reflecting a growing awareness of environmental impacts among B2B buyers. The leather industry, traditionally criticized for its ecological footprint, is now shifting towards greener practices. This includes the use of eco-friendly dyes, natural oils, and sustainable tanning processes that minimize water usage and chemical waste. Buyers from regions such as Europe and North America are particularly keen on sourcing materials that are certified as environmentally friendly, which can significantly influence purchasing decisions.

Ethical supply chains are also gaining traction as consumers demand transparency regarding the origins of their products. This shift is prompting suppliers to adopt certifications like the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG), which validate environmentally responsible practices. For B2B buyers, partnering with suppliers who prioritize sustainability not only enhances brand reputation but also meets the increasing regulatory requirements for environmentally conscious production.

Illustrative image related to how to make leather darker

What Is the Historical Context of Leather Darkening Techniques?

Historically, the techniques for darkening leather have evolved significantly. Ancient civilizations employed natural substances such as vegetable dyes and animal fats to enhance the color and durability of leather goods. As trade routes expanded, so did the knowledge of various dyeing processes, leading to the development of more sophisticated methods. The introduction of synthetic dyes in the 19th century revolutionized the industry, allowing for a wider range of colors and quicker application methods.

In recent decades, there has been a resurgence in the use of traditional techniques, as consumers seek authenticity and craftsmanship in their leather products. This evolution reflects not just a desire for aesthetic enhancement but also an appreciation for the history and cultural significance of leather craftsmanship. Understanding this historical context can provide B2B buyers with deeper insights into consumer preferences and the evolving landscape of leather care products.

Conclusion

As the leather darkening sector continues to evolve, B2B buyers must navigate a complex landscape characterized by changing consumer preferences, sustainability imperatives, and technological advancements. By staying informed about market dynamics, sourcing trends, and the historical context of leather care, businesses can position themselves strategically to meet the demands of an increasingly discerning clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather darker

-

1. How do I solve the problem of uneven leather darkening?

To address uneven darkening of leather, first ensure proper preparation by cleaning the leather thoroughly to remove any dirt or oils. If the darkening is uneven after applying oils or dyes, consider lightly sanding the area with fine-grit sandpaper to create a smoother surface. Reapply the product in thin, even coats, allowing each layer to dry fully before adding another. Conduct a patch test on a less visible area to gauge how the leather reacts to the product, ensuring a consistent finish across the entire surface. -

2. What is the best oil for darkening leather while maintaining flexibility?

Mink oil is widely regarded as the best option for darkening leather while keeping it supple and flexible. It penetrates deeply to nourish the leather and provides a protective barrier against moisture. Additionally, it enhances the leather’s natural sheen. When applying mink oil, use a small amount on a soft cloth and work it into the leather evenly, buffing afterward to remove excess. This method ensures a rich, darker hue without compromising the leather’s integrity. -

3. How can I ensure the quality of leather products from international suppliers?

To ensure quality when sourcing leather products internationally, start by vetting suppliers through references and reviews from previous clients. Request samples to assess the leather’s texture, durability, and darkening capabilities. Establish clear communication regarding quality standards and certifications, such as ISO or specific leather grades. Additionally, consider visiting manufacturing facilities if possible to evaluate production processes firsthand, ensuring they align with your quality expectations. -

4. What are the minimum order quantities (MOQs) for leather darkening products?

MOQs for leather darkening products can vary significantly depending on the supplier and product type. Generally, MOQs range from 100 to 1,000 units, but some suppliers may offer lower quantities for initial orders or samples. When negotiating, inquire about flexibility in MOQs, especially if you’re testing a new product line. Building a strong relationship with your supplier can often lead to more favorable terms and potential discounts on larger orders in the future. -

5. What payment terms are typically offered by suppliers for leather goods?

Payment terms for leather goods can vary based on the supplier’s policies and your negotiation skills. Common terms include 30% upfront payment with the balance due upon shipment or a net 30-60 days payment after delivery. Some suppliers may offer letter of credit (LC) options for larger orders, providing security for both parties. Always clarify payment methods accepted, such as wire transfers or credit terms, and ensure they align with your company’s financial practices. -

6. How can I customize leather products for my business needs?

Customizing leather products typically involves discussing your specifications with the supplier, including design, color, and finish. Most suppliers can accommodate requests for specific dyes or oils used in the darkening process to match your branding. Provide detailed sketches or samples to ensure accurate production. Additionally, inquire about lead times for customization, as bespoke products may require longer manufacturing periods compared to standard offerings. -

7. What logistics considerations should I keep in mind when importing leather products?

When importing leather products, consider logistics factors such as shipping methods, tariffs, and customs regulations. Choose a reliable freight forwarder experienced in handling leather goods to navigate potential delays and ensure compliance with local laws. Understand the import duties applicable in your country, especially for leather products, to avoid unexpected costs. Also, factor in lead times, as international shipping can impact your inventory management and customer delivery timelines. -

8. How can I assess the effectiveness of leather darkening products?

To assess the effectiveness of leather darkening products, conduct thorough testing on sample swatches of the leather you intend to use. Apply the product according to the supplier’s instructions and evaluate the color change after drying. Look for consistency in color, texture, and flexibility. Additionally, consider factors like water resistance and durability by exposing treated samples to various conditions. Gathering feedback from your team on the visual appeal and feel of the leather can also guide your final product selection.

Top 3 How To Make Leather Darker Manufacturers & Suppliers List

1. Reddit – Leather Care Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Leather dye, mink oil, beeswax, deglazer, Obenauf’s, sunshine

2. Leatherworker – Natural Veg Tan Leather

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Natural Veg Tan Leather, Neatsfoot Oil, Extra Virgin Olive Oil, Coffee, Walnut Hulls

3. The Fedora Lounge – Leather Care Essentials

Domain: thefedoralounge.com

Registered: 2003 (22 years)

Introduction: 1. Obenauf’s Leather Oil – Customer feedback indicates it effectively darkens leather, transforming light colors to a dark, rich appearance. 2. Apache Crème Oil Restorer – Mentioned as a potential product for darkening leather.

Strategic Sourcing Conclusion and Outlook for how to make leather darker

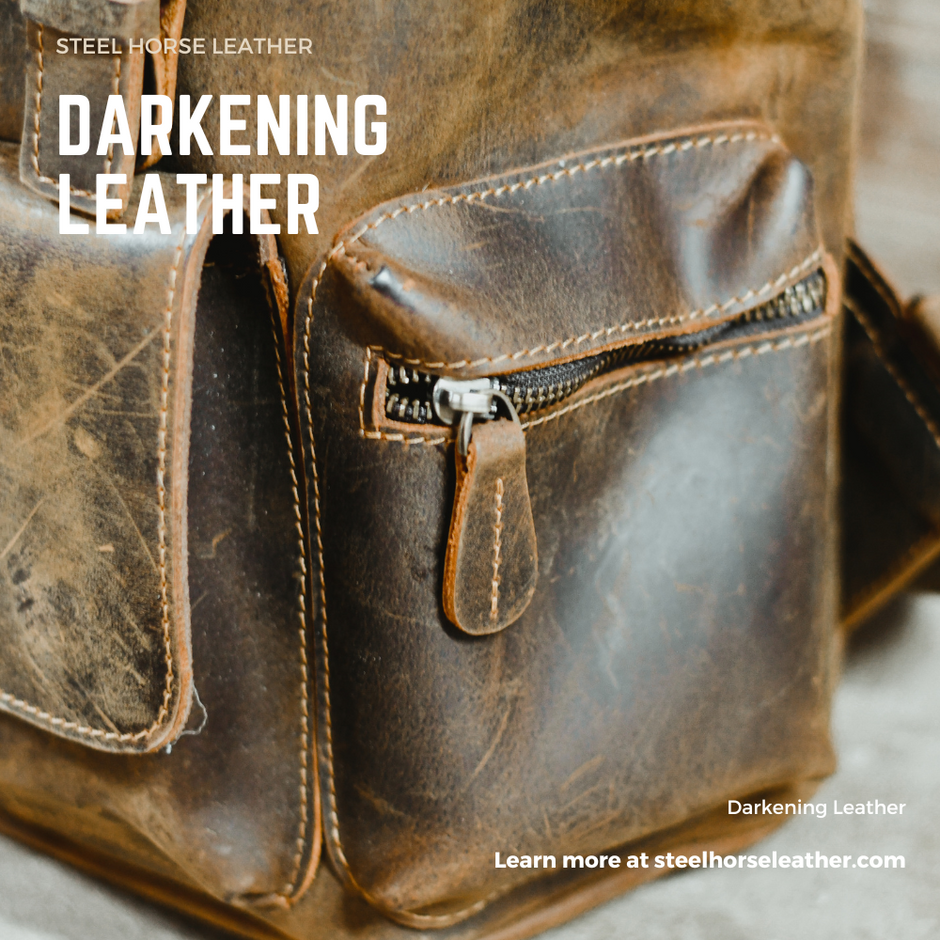

In conclusion, darkening leather is not just an aesthetic choice but a strategic opportunity for businesses looking to enhance product longevity and appeal. By utilizing various oils and dyes, international buyers can significantly elevate the quality of their leather goods, ensuring they meet the demands of diverse markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to how to make leather darker

Strategic sourcing of high-quality leather care products, such as mink oil or plant-based alternatives, can create a competitive edge, fostering customer loyalty through superior product offerings. Additionally, understanding the preparation and application processes ensures that businesses maintain the integrity and durability of their leather items, translating to higher customer satisfaction and reduced return rates.

As the global market continues to evolve, staying informed about innovative leather treatment methods will be crucial. We encourage B2B buyers to explore partnerships with reputable suppliers who prioritize quality and sustainability. Investing in effective leather darkening techniques not only enhances the aesthetic appeal but also positions your brand as a leader in the leather goods industry. Embrace this opportunity to differentiate your offerings and meet the growing consumer demand for high-quality, well-maintained leather products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.