Introduction: Navigating the Global Market for fabric faux suede

In an increasingly competitive global marketplace, sourcing high-quality fabric faux suede can present significant challenges for B2B buyers. As businesses from Africa, South America, the Middle East, and Europe (including key markets like Germany and Saudi Arabia) seek to diversify their product offerings, understanding the nuances of faux suede becomes critical. This guide delves into the various types of faux suede available, their diverse applications—from upholstery and fashion to event decor—and the intricacies of supplier vetting, ensuring that buyers can make informed choices.

Navigating the complexities of faux suede sourcing requires more than just a surface-level understanding. This comprehensive guide equips international buyers with essential insights into cost structures, quality assessments, and supplier reliability. By highlighting the importance of sample swatches and color consistency, it addresses common pitfalls that can lead to costly mistakes.

With a focus on empowering businesses to enhance their product lines while ensuring quality and affordability, this guide serves as a vital resource for B2B buyers aiming to make strategic sourcing decisions in the fabric faux suede market. Whether you are a seasoned buyer or new to the industry, the actionable insights presented here will facilitate successful procurement processes, helping you stay ahead in a dynamic market.

Table Of Contents

- Top 6 Fabric Faux Suede Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric faux suede

- Understanding fabric faux suede Types and Variations

- Key Industrial Applications of fabric faux suede

- 3 Common User Pain Points for ‘fabric faux suede’ & Their Solutions

- Strategic Material Selection Guide for fabric faux suede

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric faux suede

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric faux suede’

- Comprehensive Cost and Pricing Analysis for fabric faux suede Sourcing

- Alternatives Analysis: Comparing fabric faux suede With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric faux suede

- Navigating Market Dynamics and Sourcing Trends in the fabric faux suede Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric faux suede

- Strategic Sourcing Conclusion and Outlook for fabric faux suede

- Important Disclaimer & Terms of Use

Understanding fabric faux suede Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microsuede | Soft, brushed finish; lightweight; available in many colors | Upholstery, fashion, accessories | Pros: Versatile, easy to clean; Cons: Not stretchable, may require special care. |

| Ultra Suede | Durable, water-resistant; thicker than regular faux suede | Automotive interiors, high-end upholstery | Pros: Long-lasting, easy maintenance; Cons: Higher cost, limited color options. |

| Faux Nubuck | Velvety texture; mimics real nubuck leather | Footwear, handbags, apparel | Pros: Luxurious feel, good for high-end products; Cons: Can be sensitive to stains. |

| Faux Leather Suede | Combination of leather-like finish with suede texture | Fashion, upholstery, accessories | Pros: Stylish, available in various finishes; Cons: May not be as breathable as other fabrics. |

| Eco-Friendly Suede | Made from recycled materials; sustainable production methods | Eco-conscious brands, fashion, upholstery | Pros: Appeals to environmentally-focused buyers; Cons: Availability can be limited. |

What Are the Characteristics and Suitability of Microsuede for B2B Buyers?

Microsuede is a lightweight, soft fabric characterized by its brushed finish, resembling traditional suede but made from 100% polyester. Its versatility makes it suitable for various applications, including upholstery, fashion accessories, and event decorations. B2B buyers should consider its ease of cleaning, as it often requires dry cleaning. However, it lacks stretchability, which may limit its use in certain apparel designs. Additionally, given the wide range of colors available, microsuede can cater to diverse branding needs.

How Does Ultra Suede Stand Out in the Market?

Ultra suede is a more robust alternative, known for its durability and water resistance. This thicker variant is ideal for high-traffic areas and is commonly used in automotive interiors and premium upholstery projects. B2B buyers appreciate its longevity and ease of maintenance, making it a cost-effective choice in the long run. However, its higher price point and more limited color selection may deter some buyers seeking budget-friendly options. This fabric is particularly appealing to those in industries that demand both style and functionality.

Illustrative image related to fabric faux suede

What Makes Faux Nubuck a Preferred Choice for Luxury Products?

Faux nubuck offers a luxurious texture that closely mimics real nubuck leather, making it a popular choice for high-end footwear, handbags, and apparel. Its velvety finish enhances the aesthetic appeal of products, attracting buyers looking for upscale materials. However, it can be sensitive to stains, which necessitates careful handling and maintenance. B2B purchasers should weigh its premium feel against the need for proper care, particularly in industries where product longevity is crucial.

Why Choose Faux Leather Suede for Fashion and Upholstery?

Faux leather suede combines the stylish appearance of leather with the soft touch of suede, making it a versatile option for fashion, upholstery, and accessories. This fabric is available in various finishes, allowing for creative flexibility in design. While it offers a fashionable alternative to genuine leather, B2B buyers should be aware that it may not provide the same breathability, which can be a consideration for clothing applications. Its stylish nature and variety make it appealing for brands looking to enhance their product lines.

What Are the Benefits of Eco-Friendly Suede for Sustainable Brands?

Eco-friendly suede is crafted from recycled materials and produced through sustainable practices, appealing to environmentally conscious brands. This type of fabric is gaining traction in the market, particularly among businesses that prioritize sustainability in their offerings. While it can attract a niche customer base, buyers may find that availability is often limited compared to traditional options. For B2B buyers, investing in eco-friendly suede can enhance brand reputation and appeal to a growing segment of eco-conscious consumers.

Key Industrial Applications of fabric faux suede

| Industry/Sector | Specific Application of fabric faux suede | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture & Upholstery | Upholstery for sofas and chairs | Durable, easy to clean, and offers a premium look | Ensure colorfastness, weight specifications, and texture consistency. |

| Fashion & Apparel | Clothing items such as jackets and dresses | Cost-effective alternative to leather with a soft feel | Verify material composition, stretchability, and dye lot consistency. |

| Automotive | Interior car upholstery | Enhances aesthetic appeal and provides comfort | Check for stain resistance, durability under wear, and compliance with safety standards. |

| Home Decor | Decorative items like cushions and throws | Versatile and stylish addition to home interiors | Look for fabric weight, color variety, and ease of maintenance. |

| Event Management | Tablecloths and event decor | Creates an elegant atmosphere and is reusable | Consider bulk purchasing options, custom colors, and shipping timelines. |

How is Fabric Faux Suede Used in the Furniture & Upholstery Sector?

In the furniture and upholstery industry, fabric faux suede is frequently utilized for covering sofas, chairs, and other furniture pieces. Its durability and ease of cleaning make it an attractive choice for businesses aiming to provide high-quality products at competitive prices. Faux suede offers a luxurious appearance similar to leather, appealing to consumers looking for stylish yet affordable options. International buyers should ensure they source materials with consistent colorfastness and weight specifications to maintain product quality.

Illustrative image related to fabric faux suede

What Role Does Fabric Faux Suede Play in Fashion & Apparel?

In the fashion industry, fabric faux suede is commonly used in the production of jackets, dresses, and accessories. Its soft texture and aesthetic appeal make it a popular choice among designers aiming to deliver trendy, cruelty-free products. B2B buyers should pay attention to the material composition and stretchability to ensure the fabric meets specific design requirements. Additionally, verifying dye lot consistency is crucial to avoid discrepancies in large orders.

Why is Fabric Faux Suede Important in the Automotive Sector?

The automotive sector leverages fabric faux suede primarily for car interiors, enhancing the aesthetic appeal and comfort of vehicles. This material is favored for its ability to withstand wear while providing a plush feel, making it suitable for upscale vehicle models. When sourcing faux suede for automotive applications, businesses must prioritize stain resistance and durability, as well as ensure compliance with safety standards to meet regulatory requirements.

How is Fabric Faux Suede Used in Home Decor?

In home decor, fabric faux suede is increasingly used for decorative items such as cushions, throws, and wall hangings. Its versatility allows for a range of creative applications, enhancing the visual appeal of living spaces. B2B buyers should consider the fabric weight and color variety when sourcing faux suede for home decor products, as these factors significantly influence the final product’s quality and marketability.

What is the Application of Fabric Faux Suede in Event Management?

Event management companies often utilize fabric faux suede for tablecloths and event decor due to its ability to create an elegant atmosphere. The material is not only visually appealing but also reusable, making it a sustainable choice for businesses in this sector. When sourcing faux suede for events, companies should look for bulk purchasing options and custom color availability to meet specific event themes and requirements, while also considering shipping timelines to ensure timely delivery.

3 Common User Pain Points for ‘fabric faux suede’ & Their Solutions

Scenario 1: Sourcing Reliable Suppliers for Faux Suede Fabrics

The Problem: B2B buyers often face difficulties in sourcing high-quality faux suede fabrics from reliable suppliers. With a vast array of manufacturers and distributors, distinguishing between those who deliver subpar products and those who maintain high standards can be daunting. This issue is exacerbated by inconsistent quality control, varying dye lots, and the risk of receiving defective materials, which can lead to project delays and increased costs. Buyers may also struggle with understanding the specific characteristics of faux suede, such as weight and texture, which are crucial for their intended applications.

Illustrative image related to fabric faux suede

The Solution: To mitigate these challenges, buyers should prioritize establishing long-term relationships with reputable suppliers who have a proven track record in the faux suede market. Conducting due diligence is essential; this includes requesting samples to assess quality, color accuracy, and texture. Furthermore, buyers should inquire about the supplier’s quality assurance processes and certifications. When placing orders, specifying detailed requirements regarding the fabric’s weight, color consistency, and finish can help ensure that the received product meets expectations. Utilizing platforms that facilitate supplier ratings and reviews can also guide buyers toward trustworthy sources.

Scenario 2: Managing Color Consistency Across Orders

The Problem: Color inconsistency is a common pain point for B2B buyers of faux suede fabrics. Variations between dye lots can lead to mismatched materials, which is particularly problematic for businesses that require uniformity in their products, such as upholstery manufacturers or fashion designers. This issue not only affects the aesthetic appeal but can also damage a brand’s reputation if customers receive products that do not match their expectations.

The Solution: To address this issue, buyers should implement a robust color management strategy when ordering faux suede. This includes requesting swatch samples of each dye lot before placing a larger order. Additionally, buyers should communicate clearly with suppliers about the importance of color consistency and inquire about their dyeing processes. Establishing a minimum order quantity for specific colors can help ensure that future orders come from the same dye lot. Investing in color-matching technology, such as spectrophotometers, can also aid in maintaining color accuracy across different batches, reducing the risk of discrepancies.

Scenario 3: Understanding Care Instructions for Faux Suede Fabrics

The Problem: Another significant challenge for B2B buyers is understanding the proper care instructions for faux suede fabrics. Mismanagement in cleaning and maintenance can lead to damage or degradation of the fabric, affecting the longevity and performance of the end products. This issue is particularly relevant for sectors such as hospitality and automotive, where faux suede is commonly used in upholstery and interior design.

Illustrative image related to fabric faux suede

The Solution: Buyers should proactively educate themselves and their teams about the specific care requirements for faux suede fabrics. This includes adhering to dry-clean-only recommendations and avoiding machine washing or exposure to harsh chemicals. Suppliers should provide comprehensive care guidelines with their products, and buyers should ensure these instructions are clearly communicated to end-users. For businesses with high turnover rates of fabric products, offering training sessions on proper maintenance can significantly extend the life of faux suede items. Additionally, developing partnerships with cleaning service providers who specialize in fabric care can further enhance the durability and appearance of faux suede applications.

Strategic Material Selection Guide for fabric faux suede

What Are the Key Materials Used in Fabric Faux Suede?

Fabric faux suede is typically made from synthetic materials, primarily polyester and polyurethane. These materials mimic the soft, luxurious feel of genuine suede while offering various advantages and disadvantages that are crucial for B2B buyers to consider. Below is an analysis of the most common materials used in faux suede, focusing on their properties, pros and cons, and implications for international buyers.

How Does Polyester Perform in Faux Suede Applications?

Key Properties: Polyester is known for its durability, resistance to wrinkles, and ability to retain color. It has a moderate temperature tolerance and is generally resistant to mildew and abrasion.

Pros & Cons: The main advantages of polyester include its affordability and ease of maintenance, as it can be machine washed. However, it may not be as breathable as natural materials, which can be a limitation in warmer climates. Additionally, while polyester faux suede is durable, it may not withstand high temperatures as effectively as some other materials.

Impact on Application: Polyester faux suede is suitable for a wide range of applications, including upholstery, fashion, and accessories. Its compatibility with various dyes and finishes allows for a diverse color palette, making it appealing for design flexibility.

Illustrative image related to fabric faux suede

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should consider the climate when selecting polyester, as its breathability may be a concern. Compliance with local textile standards, such as ASTM or DIN, is also essential to ensure product quality and safety.

What Role Does Polyurethane Play in Faux Suede Production?

Key Properties: Polyurethane (PU) is a versatile polymer that offers excellent flexibility and durability. It is resistant to wear and tear, making it ideal for high-traffic applications.

Pros & Cons: PU faux suede has a luxurious feel and closely resembles real suede. It is easy to clean and maintain, making it suitable for various applications. However, PU can be more expensive than polyester and may have a shorter lifespan in extreme conditions.

Impact on Application: PU is often used in high-end fashion items and upholstery. Its softness and durability make it a preferred choice for products that require a premium look and feel.

Illustrative image related to fabric faux suede

Considerations for International Buyers: Buyers in Europe, particularly in Germany, may favor PU for its eco-friendliness and compliance with stringent environmental regulations. Understanding local preferences for material quality and sustainability is crucial for successful procurement.

How Does Microfiber Enhance Faux Suede Products?

Key Properties: Microfiber is a synthetic fiber that is finer than silk, providing a soft and plush texture. It is highly absorbent and has excellent stain resistance.

Pros & Cons: The main advantage of microfiber faux suede is its softness and luxurious appearance. It is also lightweight and easy to clean. However, microfiber can be more costly than traditional polyester and may require special care to maintain its appearance.

Impact on Application: Microfiber is commonly used in luxury upholstery and fashion accessories. Its compatibility with various dyeing processes allows for vibrant color options, appealing to designers looking for aesthetic versatility.

Considerations for International Buyers: Buyers from South America should be aware of the growing demand for high-quality materials like microfiber. Compliance with local textile standards and consumer preferences for sustainable materials can influence purchasing decisions.

Illustrative image related to fabric faux suede

Summary Table of Material Properties for Faux Suede

| Material | Typical Use Case for fabric faux suede | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Upholstery, fashion, accessories | Affordable and easy to maintain | Less breathable, moderate durability | Low |

| Polyurethane | High-end fashion, luxury upholstery | Luxurious feel, durable | Higher cost, shorter lifespan in extremes | High |

| Microfiber | Luxury upholstery, fashion accessories | Soft, plush texture, stain-resistant | Higher cost, requires special care | Med |

This guide provides a comprehensive overview of the materials commonly used in fabric faux suede, helping international B2B buyers make informed decisions based on performance, cost, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric faux suede

What Are the Key Stages in the Manufacturing Process of Fabric Faux Suede?

The manufacturing process of fabric faux suede involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Goes Into Faux Suede?

The initial step in producing faux suede is the preparation of raw materials, typically polyester fibers. These fibers are chosen for their durability and ability to mimic the soft texture of natural suede. The polyester is processed into a non-woven fabric or woven into a twill weave, creating a base that will undergo further treatment.

During this stage, manufacturers may also incorporate dyes and additives to enhance the fabric’s color and texture. It is essential for B2B buyers to inquire about the sourcing of these raw materials, as sustainable and high-quality inputs can significantly impact the final product’s performance.

Illustrative image related to fabric faux suede

Forming: How Is Faux Suede Fabric Created?

Once the materials are prepared, the next step is forming. This involves several techniques, including:

-

Weaving or Non-Woven Techniques: Depending on the desired texture, manufacturers may use weaving methods or create a non-woven fabric. The latter often involves bonding fibers through heat and pressure to achieve a soft, suede-like finish.

-

Brushing: After forming, the fabric undergoes a brushing process that lifts the fibers, giving faux suede its characteristic soft, napped surface. This is a crucial step that influences both the aesthetic appeal and tactile quality of the fabric.

Assembly: What Processes Ensure Fabric Integrity?

The assembly stage typically involves cutting the fabric into desired dimensions and preparing it for finishing. This may include sewing or bonding layers together, depending on the end application. For instance, faux suede used in upholstery might require different assembly methods compared to that used in fashion.

Quality control checkpoints during this phase are vital. Manufacturers often implement in-process quality control (IPQC) measures to identify defects early, ensuring that only high-quality fabric proceeds to the finishing stage.

Finishing: How Is Faux Suede Enhanced?

Finishing treatments are applied to enhance the fabric’s properties. Common treatments may include:

-

Coating: A protective coating is often applied to increase water resistance and durability. This is particularly important for applications in harsh environments or for products like bags and upholstery.

-

Dyeing: Final dyeing processes may occur to ensure color uniformity and vibrancy. B2B buyers should be aware that dye lots can vary, so requesting samples is advisable.

What Quality Assurance Standards Should B2B Buyers Consider for Faux Suede?

Quality assurance is critical in the faux suede manufacturing process. B2B buyers should understand the standards and certifications that suppliers should meet to ensure product reliability and safety.

Which International Standards Are Relevant for Faux Suede Manufacturing?

International standards such as ISO 9001 play a significant role in ensuring quality management systems are in place. This standard emphasizes a process-based approach, focusing on continuous improvement and customer satisfaction.

Illustrative image related to fabric faux suede

Additionally, industry-specific certifications such as CE marking (for products sold in the European Economic Area) ensure that the fabric meets health, safety, and environmental protection standards. Buyers from regions such as Europe and the Middle East, where regulatory compliance is stringent, should prioritize suppliers with these certifications.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified criteria. For B2B buyers, verifying the IQC processes of suppliers can help mitigate risks associated with subpar materials.

-

In-Process Quality Control (IPQC): This ongoing monitoring during production helps catch defects early. Techniques such as statistical process control (SPC) may be used to monitor production metrics.

-

Final Quality Control (FQC): The last checkpoint involves a comprehensive inspection of the finished product, assessing it for defects, color consistency, and adherence to specifications. Buyers should request FQC reports to verify the quality of the products before shipment.

What Testing Methods Are Commonly Used for Faux Suede?

Faux suede undergoes several testing methods to ensure it meets performance standards:

-

Physical Testing: This includes tensile strength, abrasion resistance, and pilling tests to ensure durability. B2B buyers should inquire about these tests, as they directly correlate with the fabric’s suitability for specific applications.

-

Chemical Testing: Testing for harmful substances, such as those regulated under REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe, is essential for compliance and safety.

-

Colorfastness Testing: Ensuring that the fabric retains its color through various conditions (e.g., washing, exposure to light) is vital for customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for establishing a reliable partnership. Here are some actionable steps B2B buyers can take:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the quality management systems and processes in place. Buyers should consider scheduling these audits to assess compliance with international standards.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. Reviewing these documents can help buyers gauge the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality assurance measures employed by the supplier. This can be particularly beneficial for international buyers unfamiliar with local suppliers.

What Nuances Should International Buyers Be Aware Of in Quality Control?

International B2B buyers, particularly from regions like Africa and South America, should be aware of specific nuances in quality control:

-

Diverse Regulatory Standards: Different regions may have varying standards for quality and safety. Understanding these can help in negotiating contracts and ensuring compliance.

-

Cultural Differences in Business Practices: Business practices and expectations around quality assurance may differ across cultures. Building strong relationships and clear communication can help bridge these gaps.

-

Logistics and Supply Chain Considerations: Shipping distances and customs regulations can impact quality. Buyers should work with suppliers who have robust logistics strategies to ensure products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance protocols for faux suede, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric faux suede’

When sourcing fabric faux suede, it’s essential to follow a systematic approach to ensure you find the right materials that meet your business needs. This guide will provide you with a step-by-step checklist to streamline your procurement process effectively.

Illustrative image related to fabric faux suede

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify your requirements for the faux suede fabric. Consider factors such as weight, width, and composition.

– Weight: Determine the appropriate fabric weight (e.g., upholstery weight) for your intended use, whether for clothing, upholstery, or accessories.

– Composition: Most faux suede is made from polyester; however, understanding the exact blend can impact texture and durability.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers specializing in fabric faux suede. Utilize online platforms, trade shows, and industry networks to compile a list.

– Supplier Reputation: Look for suppliers with a proven track record in your target markets (Africa, South America, the Middle East, and Europe).

– Product Range: Ensure suppliers offer a variety of colors and textures to meet diverse customer preferences.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications to ensure quality and compliance with international standards.

– Quality Standards: Check for ISO certifications or other relevant quality management systems that indicate a commitment to quality.

– Sustainability Practices: Inquire about eco-friendly practices, especially if your target market prioritizes sustainable sourcing.

Step 4: Request Samples

Always request fabric samples before making bulk purchases. This step allows you to assess the quality, texture, and color accuracy.

– Color Accuracy: Be aware that dye lots may vary, so confirm that samples represent the final product.

– Physical Properties: Test the sample for durability, softness, and care instructions to ensure it meets your performance criteria.

Step 5: Negotiate Terms and Conditions

Once you’ve selected potential suppliers, engage in negotiations regarding pricing, minimum order quantities, and payment terms.

– Pricing Structure: Understand the pricing model, including any discounts for bulk orders and shipping costs.

– Lead Times: Clarify production and delivery timelines to avoid delays in your supply chain.

Illustrative image related to fabric faux suede

Step 6: Establish a Clear Communication Channel

Maintain open lines of communication with your suppliers throughout the procurement process.

– Regular Updates: Schedule regular check-ins to monitor order status and address any potential issues.

– Feedback Loop: Encourage suppliers to provide feedback on your requirements to foster a collaborative relationship.

Step 7: Review and Finalize Contracts

Before finalizing your order, ensure all agreements are documented in a contract that outlines the terms discussed.

– Legal Considerations: Include clauses for quality assurance, delivery schedules, and penalties for non-compliance to protect your interests.

– Dispute Resolution: Specify the process for resolving disputes to mitigate potential conflicts in the future.

By following this checklist, you can navigate the complexities of sourcing fabric faux suede effectively, ensuring that your procurement aligns with your business objectives and quality standards.

Comprehensive Cost and Pricing Analysis for fabric faux suede Sourcing

When sourcing fabric faux suede, understanding the cost structure and pricing dynamics is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the core components that influence costs and provides actionable insights for maximizing value.

What Are the Key Cost Components in Faux Suede Manufacturing?

The cost structure of fabric faux suede comprises several critical components:

-

Materials: The primary ingredient is polyester, which is chosen for its durability and soft texture. The cost of raw polyester can fluctuate based on market conditions, impacting the final price of the fabric.

-

Labor: Manufacturing faux suede involves skilled labor for processes such as weaving and finishing. Labor costs can vary significantly depending on the location of production. For instance, countries with higher labor costs, like Germany, may yield a pricier product compared to those in regions with lower labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and administrative costs. Efficient production processes can help mitigate these overheads.

-

Tooling and Equipment: Initial setup costs for weaving and finishing machines are significant. These costs are often amortized over large production runs, which means larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that the fabric meets quality standards is vital, especially for B2B transactions. QC processes may add to the cost but are essential to avoid expensive returns or rework.

-

Logistics: Shipping costs can vary based on the distance from the manufacturer to the buyer, the shipping method, and current fuel prices. International buyers should account for these costs when assessing the total price.

-

Margin: Suppliers typically mark up prices to cover their costs and achieve profitability. Understanding the typical margins in the faux suede market can help buyers negotiate better deals.

What Influences the Pricing of Faux Suede Fabrics?

Several factors significantly influence the pricing of faux suede:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing, reducing the per-unit cost. Buyers should assess their capacity to purchase in bulk to leverage cost savings.

-

Specifications and Customization: Custom colors or finishes may incur additional costs. Buyers should weigh the benefits of customization against the added expense.

-

Quality and Certifications: Fabrics that meet specific quality standards or have certifications (such as eco-friendly materials) may command higher prices. Buyers should determine the importance of these factors in their sourcing decisions.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their perceived reliability and quality assurance.

-

Incoterms: The terms of shipping and delivery can affect total costs. Buyers should understand the implications of different Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), to manage logistics costs effectively.

How Can Buyers Negotiate Better Prices for Faux Suede?

To secure favorable pricing, buyers should consider the following strategies:

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and more favorable terms.

-

Assess Total Cost of Ownership (TCO): Beyond the unit price, consider all associated costs, including shipping, storage, and potential wastage. A lower unit price may not always equate to lower overall costs.

-

Market Research: Understanding the competitive landscape and current market prices can empower buyers during negotiations. This knowledge can help in identifying fair pricing and spotting potential red flags.

-

Timing and Flexibility: Being flexible with order timing can help buyers take advantage of seasonal pricing changes or supplier promotions.

Conclusion

Sourcing fabric faux suede requires a nuanced understanding of cost structures and pricing influences. By focusing on the key cost components, recognizing price influencers, and employing effective negotiation strategies, international B2B buyers can make informed decisions that enhance their procurement processes. While indicative prices can provide a baseline, thorough research and strategic planning are essential for achieving optimal sourcing outcomes.

Illustrative image related to fabric faux suede

Alternatives Analysis: Comparing fabric faux suede With Other Solutions

When sourcing materials for upholstery and fashion applications, B2B buyers often explore various options that can meet performance, cost, and aesthetic requirements. Among these, fabric faux suede stands out, but it is essential to compare it against other viable alternatives to make informed decisions.

| Comparison Aspect | Fabric Faux Suede | Microfiber Leather | Velvet Fabric |

|---|---|---|---|

| Performance | Soft, durable, and water-resistant | Durable, easy to clean, and versatile | Luxurious feel but less durable |

| Cost | Moderate ($8.99/yard) | Moderate to high ($10-$20/yard) | Variable ($5-$15/yard) |

| Ease of Implementation | Easy to sew and manipulate | Requires specialized sewing techniques | Simple to sew but requires careful handling |

| Maintenance | Dry clean only | Easy to wipe clean | Requires delicate care |

| Best Use Case | Upholstery, bags, costumes | Upholstery, car interiors, handbags | Dresses, curtains, luxury items |

What Are the Advantages and Disadvantages of Microfiber Leather Compared to Fabric Faux Suede?

Microfiber leather is a synthetic alternative that mimics the appearance and texture of genuine leather. It is highly durable, making it suitable for high-traffic areas like car interiors and furniture. One of its main advantages is its easy maintenance; stains can be wiped away with a damp cloth. However, the cost can be higher than fabric faux suede, and it may require specialized sewing techniques, which could increase labor costs.

How Does Velvet Fabric Stack Up Against Fabric Faux Suede?

Velvet fabric offers a luxurious aesthetic, making it a popular choice for high-end applications such as evening wear and upscale upholstery. Its soft texture provides a comfortable feel, but it is less durable than fabric faux suede, which may limit its use in high-traffic areas. Maintenance can also be challenging, as velvet requires careful handling and often professional cleaning. While the cost can vary widely, it generally falls within the same range as fabric faux suede, making it a viable alternative for luxury applications.

How Can B2B Buyers Choose the Right Solution for Their Specific Needs?

Selecting the right fabric requires an understanding of the specific application and the target market. B2B buyers should assess factors such as durability, maintenance requirements, and aesthetic appeal relative to their product offerings. Fabric faux suede is an excellent choice for applications requiring softness and durability, while alternatives like microfiber leather may be better suited for environments that demand high resilience. Conversely, velvet may be ideal for luxury items where appearance is paramount. By weighing these factors, buyers can make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for fabric faux suede

What Are the Key Technical Properties of Fabric Faux Suede?

When sourcing fabric faux suede for various applications, understanding its technical properties is essential for making informed purchasing decisions. Here are several critical specifications:

-

Material Composition: Faux suede is typically made from 100% polyester. This synthetic fiber not only replicates the luxurious feel of real suede but also offers enhanced durability and resistance to wear and tear. For B2B buyers, the choice of material affects product quality and longevity, making it crucial to select the right composition for specific applications.

-

Fabric Weight: Commonly, faux suede has a weight of approximately 225 grams per square meter (GSM). The weight impacts the fabric’s drape, durability, and suitability for various uses, such as upholstery, garments, or accessories. Heavier fabrics may be preferred for upholstery due to their durability, while lighter options could be ideal for clothing.

-

Width and Cut: Faux suede is generally available in widths of 58 to 60 inches. Buyers should consider the width when estimating material requirements for large projects. Additionally, understanding how fabric is sold—by the yard or by the bolt—can influence pricing and availability, which are key factors in procurement strategies.

-

Cleaning and Maintenance Requirements: Most faux suede fabrics are designated as “dry clean only.” This specification is essential for buyers in industries like fashion or home textiles, where maintenance impacts customer satisfaction. Understanding cleaning requirements helps ensure that products remain in excellent condition over time.

-

Color Fastness and Dye Lots: Faux suede fabrics can experience dye lot variations, which may affect color consistency across batches. B2B buyers should be aware of this when placing large orders to avoid discrepancies that could impact branding or product appearance.

What Are Common Trade Terminologies in the Faux Suede Industry?

Navigating the fabric faux suede market requires familiarity with industry-specific jargon. Here are some common terms:

Illustrative image related to fabric faux suede

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that can be branded by another company. Understanding OEM relationships is vital for buyers seeking partnerships for custom fabric solutions.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, as it can impact overall costs and supply chain efficiency.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of fabric. Utilizing RFQs allows buyers to compare offers and negotiate better deals, ensuring they get the best value for their procurement.

-

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and duties. Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border transactions, as they directly influence cost and risk management.

-

Lead Time: This term refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is essential for planning production schedules and managing inventory effectively, particularly in industries where timing is critical.

-

Sample Swatch: A sample swatch is a small piece of fabric that allows buyers to assess color, texture, and quality before making a larger commitment. Requesting sample swatches is a practical approach for ensuring product satisfaction, especially when dealing with multiple suppliers.

By grasping these technical properties and trade terminologies, B2B buyers can make more strategic decisions when sourcing fabric faux suede, ultimately leading to better product outcomes and enhanced business relationships.

Navigating Market Dynamics and Sourcing Trends in the fabric faux suede Sector

What Are the Key Trends Shaping the Fabric Faux Suede Market?

The fabric faux suede sector is experiencing dynamic shifts driven by several global factors. The increasing demand for sustainable and animal-friendly alternatives to genuine leather is a significant driver. As consumers become more environmentally conscious, businesses in Africa, South America, the Middle East, and Europe are aligning their offerings with this demand. The versatility of faux suede, which can be used in upholstery, fashion, and accessories, makes it appealing to a broad range of industries, including automotive, home décor, and fashion retail.

Emerging technologies are also influencing sourcing trends. Digital platforms and e-commerce solutions are facilitating direct connections between suppliers and international buyers, reducing lead times and enhancing transparency. Moreover, advancements in textile production technologies have led to the development of high-quality faux suede that mimics the look and feel of genuine leather, further driving its adoption across various sectors.

Illustrative image related to fabric faux suede

In terms of market dynamics, buyers are increasingly prioritizing quality and customization in their sourcing strategies. International buyers are seeking suppliers who can provide a variety of colors and textures, as seen in offerings of faux suede in multiple shades. This trend towards customization allows businesses to differentiate their products and cater to the specific tastes of their target markets.

How Is Sustainability and Ethical Sourcing Impacting the Faux Suede Sector?

Sustainability is becoming a cornerstone of business strategy in the faux suede industry. The environmental impact of textile production is under scrutiny, prompting companies to adopt more responsible sourcing practices. Faux suede, typically made from synthetic fibers like polyester, offers a more eco-friendly alternative to traditional leather. However, the production processes still have significant environmental footprints, including resource consumption and waste generation.

To address these concerns, B2B buyers should prioritize suppliers who adhere to ethical sourcing standards and offer environmentally friendly certifications. Materials that are recycled or derived from sustainable sources are gaining traction in the faux suede market. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® ensure that the materials used are not only safe for consumers but also produced with minimal environmental impact.

Furthermore, ethical supply chains are becoming essential for brand reputation. Companies that can demonstrate their commitment to sustainable practices are likely to appeal more to conscious consumers and business partners. This shift towards transparency and accountability in sourcing is not just a trend; it is becoming a necessity for businesses aiming to thrive in a competitive landscape.

What Is the Historical Context of Faux Suede in B2B Markets?

The evolution of faux suede can be traced back to the mid-20th century when synthetic materials began to gain popularity as alternatives to natural fibers. Initially, faux suede was viewed as a lower-quality substitute for leather. However, advancements in textile engineering and dyeing techniques have transformed it into a high-quality, durable option that offers a similar aesthetic to genuine suede.

Over the years, the faux suede industry has expanded significantly. It has transitioned from being a niche product to a mainstream choice for various applications, including fashion, automotive interiors, and home furnishings. Today, international B2B buyers recognize faux suede not only for its aesthetic appeal but also for its versatility and potential for customization, making it a staple in diverse product offerings across multiple industries.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric faux suede

-

1. How do I choose the right faux suede fabric for my project?

Selecting the right faux suede fabric involves considering the intended use, texture, and durability. For upholstery, a heavier weight fabric is preferable, while lighter options may suit clothing or accessories. Additionally, consider the color palette and whether you need a specific finish, such as water-resistant or stain-resistant. Always request sample swatches to evaluate the fabric’s texture and color in person before placing a bulk order, as dye lot variations can occur. -

2. What are the common applications of faux suede fabric in B2B industries?

Faux suede is widely used in various industries, including fashion, upholstery, automotive, and event décor. Its soft, luxurious feel makes it ideal for garments, bags, and accessories, while its durability and ease of maintenance make it suitable for furniture and vehicle interiors. Additionally, faux suede is popular in the event industry for tablecloths and decorative elements, providing an elegant appearance at a lower cost compared to genuine leather. -

3. What are the minimum order quantities (MOQs) for faux suede fabrics?

MOQs for faux suede fabrics can vary significantly among suppliers, typically ranging from 10 to 100 yards, depending on the manufacturer and product type. Some suppliers may offer flexibility for smaller orders, especially for custom or specialty fabrics. When sourcing, inquire about MOQs early in your discussions to ensure they align with your project requirements and budget. -

4. How can I ensure the quality of faux suede fabric from international suppliers?

To ensure quality, conduct thorough vetting of potential suppliers. This includes checking their certifications, customer reviews, and previous work samples. Request detailed product specifications and quality assurance processes. Additionally, consider arranging for third-party inspections or audits before shipment to verify the fabric meets your standards. Establishing a solid communication channel with your supplier can also help address any concerns promptly. -

5. What payment terms should I expect when sourcing faux suede fabric internationally?

Payment terms can vary by supplier and region but often include options such as advance payment, net 30, or letter of credit. It’s crucial to clarify these terms before finalizing any agreements. Using secure payment methods like PayPal or escrow services can provide additional protection. Always ensure that the payment terms align with your cash flow needs and risk tolerance. -

6. How do I handle shipping and logistics for faux suede fabric orders?

Shipping logistics involve selecting a reliable freight forwarder familiar with textile transportation. Ensure you understand the shipping costs, delivery times, and customs regulations in your country. For bulk orders, consider sea freight for cost-efficiency, while air freight may be necessary for urgent orders. Discuss the packaging and handling procedures with your supplier to prevent damage during transit. -

7. What customization options are available for faux suede fabrics?

Many suppliers offer customization options, including color, texture, and weight variations. You may also request specific treatments, such as water resistance or flame retardancy, depending on your application. When discussing custom orders, clearly communicate your requirements and ask for samples to ensure the final product meets your expectations. -

8. How can I address potential issues with faux suede fabric after purchase?

If issues arise after purchase, such as quality discrepancies or incorrect colors, promptly contact your supplier to discuss the problem. Document any issues with photos and detailed descriptions for clarity. Many suppliers have policies for returns or exchanges; however, understanding their terms before purchasing can mitigate complications. Establishing a good relationship with your supplier can also facilitate smoother resolutions to any concerns.

Top 6 Fabric Faux Suede Manufacturers & Suppliers List

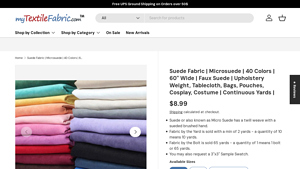

1. My Textile Fabric – Suede Fabric | Microsuede

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Suede Fabric | Microsuede”, “Colors Available”: 40, “Width”: “60 inches”, “Type”: “Faux Suede”, “Price”: “$8.99 per yard”, “Minimum Order”: “2 yards”, “Bolt Size”: “65 yards”, “Sample Swatch Size”: “3×3 inches”, “Fabric Weight”: “Approximately 225 grams per square meter”, “Fabric Content”: “100% Polyester”, “Cleaning Instructions”: “Dry Clean Only”, “Uses”: [“Upholstery”, “Tablec…

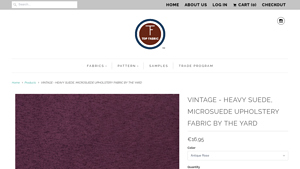

2. Top Fabric – Vintage Heavy Suede Microsuede Upholstery Fabric

Domain: topfabric.com

Registered: 2003 (22 years)

Introduction: {“name”: “Vintage – Heavy Suede, Microsuede Upholstery Fabric by the Yard”, “price”: “$18.99”, “original_price”: “$29.99”, “description”: “Medium-weight microsuede fabric with a very soft hand. Vegan faux suede, perfect for home decor, upholstery, duvet covers, pillows, cushions, tablecloths, and furniture. Heavy-duty fabric ideal for high-use or spill-prone furniture. 100% Vegan, looks and feels …

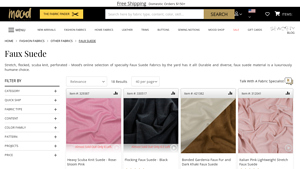

3. Mood Fabrics – Faux Suede Fabrics

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: This company, Mood Fabrics – Faux Suede Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

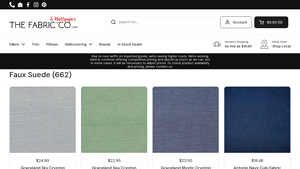

4. The Fabric Co – Faux Suede

Domain: thefabricco.com

Registered: 2000 (25 years)

Introduction: Faux Suede (662) – $24.99

Graceland Sky Crypton Fabric – $22.95

Graceland Sea Crypton Fabric – $23.50

Graceland Mystic Crypton Fabric – $18.48

Antonio Navy Culp Fabric – $23.02

Abbington Seven Sea Culp Fabric – $24.99

Graceland Chambray Crypton Fabric – $22.95

Graceland Buff Crypton Fabric – $24.99

Graceland Sorrell Crypton Fabric – $24.99

Graceland Snow Crypton Fabric – $18.48

Antonio Goldenrod C…

5. Online Fabric Store – Faux Suede

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, Online Fabric Store – Faux Suede, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Decorative Fabrics Direct – Faux Suede Upholstery Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Faux Suede Upholstery Fabric – Microsuede Fabric

– Material: 100% Polyester (synthetic fabric resembling genuine suede)

– Type: Faux Suede, Microsuede (lightweight, made from micro denier fibers)

– Characteristics: Durable, cost-effective, easy to care for, soft and supple texture

– Available Colors: Various colors including Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, P…

Strategic Sourcing Conclusion and Outlook for fabric faux suede

In today’s competitive market, strategic sourcing of fabric faux suede presents a significant opportunity for international B2B buyers. This versatile material, available in a plethora of colors and weights, caters to diverse applications ranging from upholstery to fashion. By leveraging strategic sourcing practices, businesses can ensure consistent quality, optimize costs, and enhance supply chain efficiency.

Key takeaways for buyers include the importance of selecting reliable suppliers who offer sample swatches to mitigate color discrepancies and ensure alignment with project specifications. Additionally, understanding the fabric’s care instructions—dry clean only—and the potential for dye lot variations will aid in making informed purchasing decisions.

Illustrative image related to fabric faux suede

Looking ahead, the demand for faux suede is poised to grow, driven by its eco-friendly appeal and versatility across various industries. International buyers, especially in Africa, South America, the Middle East, and Europe, should proactively engage with suppliers to explore customized solutions that meet their unique market needs. Embracing strategic sourcing now will position your business for success in a rapidly evolving landscape. Take the next step—connect with trusted suppliers to secure your fabric faux suede needs and stay ahead of market trends.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to fabric faux suede

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.