Introduction: Navigating the Global Market for 10 ounce leather

In the ever-evolving global market, sourcing high-quality 10 ounce leather can be a daunting challenge for international B2B buyers. This robust material, known for its exceptional strength and durability, is essential for a myriad of applications ranging from heavy-duty equipment to exquisite leather goods. However, navigating the complexities of supplier reliability, material specifications, and cost-effectiveness is critical to making informed purchasing decisions.

This comprehensive guide delves into the multifaceted world of 10 ounce leather, addressing key aspects such as types of leather, diverse applications, supplier vetting processes, and pricing strategies. Each section is designed to equip buyers from regions such as Africa, South America, the Middle East, and Europe—including major markets like Germany and Saudi Arabia—with actionable insights that enhance their procurement strategies.

By understanding the nuances of 10 ounce leather, including its workability and suitability for various industries, you can optimize your sourcing efforts and minimize risks associated with subpar materials. This guide empowers you to confidently identify reliable suppliers and make informed choices that align with your business needs, ensuring that you harness the full potential of this exceptional leather in your products.

Table Of Contents

- Top 5 10 Ounce Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 10 ounce leather

- Understanding 10 ounce leather Types and Variations

- Key Industrial Applications of 10 ounce leather

- 3 Common User Pain Points for ’10 ounce leather’ & Their Solutions

- Strategic Material Selection Guide for 10 ounce leather

- In-depth Look: Manufacturing Processes and Quality Assurance for 10 ounce leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ’10 ounce leather’

- Comprehensive Cost and Pricing Analysis for 10 ounce leather Sourcing

- Alternatives Analysis: Comparing 10 ounce leather With Other Solutions

- Essential Technical Properties and Trade Terminology for 10 ounce leather

- Navigating Market Dynamics and Sourcing Trends in the 10 ounce leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 10 ounce leather

- Strategic Sourcing Conclusion and Outlook for 10 ounce leather

- Important Disclaimer & Terms of Use

Understanding 10 ounce leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned Leather | Naturally tanned, eco-friendly, excellent dye absorption | Belts, holsters, craft items, dog collars | Pros: Eco-friendly, versatile; Cons: Limited flexibility for molding. |

| Chrome-Tanned Leather | Quick tanning process, soft texture, water-resistant | Upholstery, fashion accessories, bags | Pros: Soft and flexible; Cons: Less eco-friendly than vegetable tanning. |

| Full Grain Leather | Retains natural grain, high durability, and breathability | High-end furniture, luxury goods | Pros: Premium quality; Cons: Higher cost, can be heavy. |

| Suede Leather | Soft, napped finish, less durable than full grain | Fashion items, gloves, linings | Pros: Unique texture; Cons: Less durable, prone to staining. |

| Split Leather | Cost-effective, thinner layer from hides, versatile | Industrial applications, tool belts, workwear | Pros: Affordable; Cons: Generally lower quality than full grain. |

What Are the Key Characteristics of Vegetable-Tanned Leather?

Vegetable-tanned leather is distinguished by its natural tanning process, which utilizes tree bark and other organic materials. This type is known for its eco-friendliness and ability to absorb dyes and oils effectively, making it ideal for various crafts. B2B buyers often choose this leather for products like belts, holsters, and dog collars due to its workability and durability. However, its thickness limits flexibility, making it less suitable for projects requiring extensive molding or shaping.

How Does Chrome-Tanned Leather Differ from Other Types?

Chrome-tanned leather is characterized by its rapid tanning process, resulting in a softer, more pliable material. It is often preferred for fashion accessories and upholstery due to its water-resistant properties. While it offers excellent flexibility and comfort for wearables, it is less environmentally friendly compared to vegetable-tanned options. B2B buyers should weigh the soft texture against their sustainability goals when selecting this type of leather.

Why Choose Full Grain Leather for Premium Applications?

Full grain leather is recognized for its natural grain, which enhances its aesthetic appeal while ensuring high durability and breathability. This type is commonly used in high-end furniture and luxury goods, appealing to businesses targeting premium markets. While its quality justifies the higher price point, buyers must consider the weight and potential bulkiness in their designs.

Illustrative image related to 10 ounce leather

What Are the Advantages and Disadvantages of Suede Leather?

Suede leather features a soft, napped finish that provides a unique tactile experience, making it popular for fashion items and linings. While it offers an appealing aesthetic, suede is less durable than full grain leather and is prone to staining. B2B buyers must consider the end-use of their products, as the luxurious feel of suede may come at the cost of longevity.

How Can Split Leather Be Utilized in Industrial Applications?

Split leather, derived from the thinner layers of hides, is a cost-effective option widely used in industrial applications such as tool belts and workwear. It offers versatility while being more affordable than higher-quality leathers. However, buyers should be aware that split leather typically lacks the durability and aesthetic appeal of full grain options. This makes it suitable for utility-focused applications rather than high-end products.

Key Industrial Applications of 10 ounce leather

| Industry/Sector | Specific Application of 10 ounce leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of protective gear and luggage | High durability ensures safety and longevity of products | Ensure compliance with aviation standards and regulations |

| Automotive | Upholstery for high-end vehicles | Enhances luxury appeal and extends the life of interiors | Look for suppliers with experience in automotive-grade leather |

| Outdoor Equipment | Production of tactical gear and saddles | Provides resilience against harsh weather conditions | Sourcing from reputable tanneries that specialize in outdoor applications |

| Fashion | Creation of premium handbags and accessories | Elevates brand perception through quality craftsmanship | Consider sourcing from Italian or other high-quality leather producers |

| Construction | Heavy-duty workwear and tool belts | Ensures worker safety and durability in demanding environments | Verify the leather’s strength and compliance with safety standards |

How is 10 Ounce Leather Used in Aerospace Applications?

In the aerospace industry, 10 ounce leather is utilized for crafting protective gear and luggage tailored for aviation professionals. Its exceptional durability is crucial for ensuring that products withstand the rigors of air travel while maintaining safety standards. International B2B buyers must consider compliance with aviation regulations when sourcing this leather, ensuring that it meets stringent quality and safety requirements.

What Role Does 10 Ounce Leather Play in Automotive Upholstery?

The automotive sector frequently employs 10 ounce leather for upholstery in high-end vehicles. This leather not only enhances the aesthetic appeal but also significantly extends the lifespan of vehicle interiors. Buyers from Europe and the Middle East should prioritize suppliers who specialize in automotive-grade leather to ensure compatibility with industry standards and customer expectations for luxury finishes.

Illustrative image related to 10 ounce leather

Why is 10 Ounce Leather Essential for Outdoor Equipment?

In outdoor equipment manufacturing, 10 ounce leather is favored for its resilience, making it ideal for tactical gear and saddles designed for extreme conditions. This leather’s ability to withstand harsh weather ensures that products remain functional and reliable over time. For buyers in Africa and South America, sourcing from tanneries with a focus on outdoor applications is essential for obtaining materials that fulfill specific durability and functionality requirements.

How Does 10 Ounce Leather Enhance Fashion Accessories?

In the fashion industry, 10 ounce leather is a preferred choice for premium handbags and accessories due to its luxurious appearance and durability. This leather allows designers to create high-quality, long-lasting products that elevate brand perception. International buyers should consider sourcing from renowned Italian leather producers to ensure top-notch craftsmanship and material quality.

What Are the Benefits of Using 10 Ounce Leather in Construction?

The construction industry utilizes 10 ounce leather in the production of heavy-duty workwear and tool belts, providing essential durability and safety for workers. This leather can withstand significant wear and tear, making it suitable for demanding environments. Buyers must verify that the leather meets safety standards and offers the necessary strength for construction applications, ensuring that their workforce is equipped with reliable gear.

3 Common User Pain Points for ’10 ounce leather’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality 10 Ounce Leather

The Problem: B2B buyers often struggle to find suppliers that consistently provide high-quality 10 ounce leather that meets their specific needs. This can be particularly challenging when sourcing leather internationally, where variations in quality and standards can lead to issues with durability and performance in final products. Buyers may face challenges such as receiving leather that does not match specifications, inconsistent thickness, or inferior tanning processes that compromise the leather’s integrity.

The Solution: To overcome sourcing difficulties, buyers should establish relationships with reputable suppliers who specialize in high-quality leather, such as those with a strong track record in the industry. Conduct thorough research by requesting samples before placing larger orders to ensure the leather meets your specifications. Additionally, consider suppliers that offer detailed product descriptions, including information on the tanning process, thickness tolerances, and the origin of the leather. Engaging in direct communication with suppliers can clarify these aspects and help build trust. Utilizing international trade platforms that focus on leather products can also provide access to vetted suppliers who maintain consistent quality standards.

Scenario 2: Challenges in Working with Thick Leather for Crafting

The Problem: Artisans and manufacturers often find that working with 10 ounce leather presents specific challenges due to its thickness and limited flexibility. Crafting intricate designs or achieving precise cuts can be difficult without the right tools, leading to delays in production and potential errors that could impact product quality. This scenario is particularly relevant for businesses engaged in high-end leather goods where craftsmanship is paramount.

The Solution: To effectively work with 10 ounce leather, it is essential to invest in specialized tools designed for thicker materials, such as heavy-duty cutting knives, rotary cutters, and powerful stitching machines. Additionally, training employees on the best practices for handling thick leather can enhance efficiency and reduce mistakes. Consider implementing a prototyping phase where small batches are created to refine techniques before full-scale production. Collaborating with skilled artisans or consultants who have experience with heavy leather can also provide valuable insights into effective crafting methods, ultimately leading to superior finished products.

Scenario 3: Inconsistent Dyeing and Finishing Results

The Problem: B2B buyers often encounter issues with dyeing and finishing 10 ounce leather, where results can vary significantly from batch to batch. This inconsistency can lead to mismatched products, which is especially problematic for businesses that rely on uniformity in color and texture for branding purposes. Buyers may experience frustration when trying to achieve specific aesthetic goals or when a product’s appearance fails to meet customer expectations.

The Solution: To achieve consistent dyeing and finishing results, buyers should source leather from suppliers who provide detailed information on the dyeing process used. Opt for vegetable-tanned leather, as it generally accepts dyes and finishes more uniformly. Additionally, establishing a standardized dyeing process in-house can help maintain consistency across different production runs. Testing dyes on smaller samples before applying them to larger pieces can mitigate risks and ensure that the desired outcome is achieved. Lastly, consider consulting with dyeing experts who can offer guidance on techniques and products that enhance the appearance of 10 ounce leather while maintaining its durability.

Strategic Material Selection Guide for 10 ounce leather

What Are the Key Properties of Common Materials Used in 10 Ounce Leather?

When selecting materials for 10 ounce leather, various types offer distinct properties that can significantly affect product performance. Understanding these materials helps B2B buyers make informed decisions based on their specific needs and applications.

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is made using natural tannins from tree bark and other plant materials, resulting in a durable and environmentally friendly product. It has excellent dye absorption and tooling capabilities, making it suitable for intricate designs.

Pros & Cons: The primary advantage of vegetable-tanned leather is its workability and aesthetic appeal, as it develops a rich patina over time. However, it may not be as water-resistant as chrome-tanned leather, which can be a drawback for certain applications. The manufacturing process is also time-consuming, which can increase costs.

Impact on Application: This type of leather is ideal for products like belts, bags, and other accessories where aesthetics and craftsmanship are paramount. Its compatibility with dyes allows for customization, but its susceptibility to moisture may limit its use in outdoor gear.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East often prefer vegetable-tanned leather due to its sustainability. Compliance with environmental regulations (e.g., REACH in Europe) is crucial, and buyers should ensure that their suppliers adhere to these standards.

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is processed using chromium salts, resulting in a softer, more pliable material that is resistant to water and heat. This leather can withstand significant wear and tear, making it suitable for heavy-duty applications.

Pros & Cons: The main advantage of chrome-tanned leather is its durability and resistance to environmental factors, making it ideal for outdoor and industrial applications. However, it may not accept dyes as well as vegetable-tanned leather, limiting customization options.

Impact on Application: This leather is often used in manufacturing workwear, tool belts, and outdoor gear due to its robustness. Its water resistance makes it suitable for environments where moisture exposure is a concern.

Considerations for International Buyers: Buyers in regions like South America and Africa may find chrome-tanned leather more accessible due to its widespread availability. However, they should be aware of regulations regarding chromium usage, particularly in Europe, where stringent standards exist.

3. Suede Leather

Key Properties: Suede leather, made from the underside of animal hides, offers a unique texture and aesthetic appeal. It is softer than traditional leather and provides a luxurious feel.

Illustrative image related to 10 ounce leather

Pros & Cons: Suede is highly desirable for fashion items due to its softness and appearance. However, it is less durable than full-grain leather and can be more susceptible to staining and damage from moisture.

Impact on Application: Suede is often used in high-end fashion accessories, upholstery, and footwear. Its luxurious texture adds value but may limit its use in rugged applications.

Considerations for International Buyers: Buyers from Europe, particularly in the fashion sector, may prioritize suede for its aesthetic qualities. However, they should consider the maintenance requirements and potential for wear over time, especially in high-traffic applications.

4. Nubuck Leather

Key Properties: Nubuck leather is similar to suede but made from the outer side of the hide, giving it a more durable finish. It is sanded or buffed to create a soft, velvety texture.

Pros & Cons: Nubuck offers a balance between durability and softness, making it suitable for a variety of applications. However, like suede, it can be prone to staining and requires special care.

Illustrative image related to 10 ounce leather

Impact on Application: Nubuck is commonly used in premium footwear, bags, and upholstery. Its unique texture can enhance product appeal, but buyers must consider its maintenance needs.

Considerations for International Buyers: In markets like the Middle East, where luxury items are in demand, nubuck can be a preferred choice. Buyers should ensure that suppliers provide adequate care instructions to maintain the material’s integrity.

Summary Table of Material Selection for 10 Ounce Leather

| Material | Typical Use Case for 10 ounce leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, bags, accessories | Excellent workability and aesthetics | Less water-resistant | Medium |

| Chrome-Tanned Leather | Workwear, tool belts, outdoor gear | High durability and water resistance | Limited dye acceptance | Medium |

| Suede Leather | Fashion accessories, upholstery | Luxurious texture | Less durable, prone to staining | High |

| Nubuck Leather | Premium footwear, bags, upholstery | Balance of durability and softness | Requires special care | High |

This guide provides a comprehensive overview of the various materials suitable for 10 ounce leather, equipping international B2B buyers with the knowledge necessary to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for 10 ounce leather

What Are the Main Stages in the Manufacturing Process of 10 Ounce Leather?

The manufacturing process of 10 ounce leather involves several critical stages, each contributing to the final product’s quality and durability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is 10 Ounce Leather Initially Processed?

Material preparation begins with selecting high-quality hides, often sourced from reputable suppliers. The hides undergo a rigorous tanning process, typically vegetable tanning, which can take one to three months. This method uses natural tannins from tree bark, ensuring that the leather retains its strength and flexibility. During this stage, the hides are also cleaned and conditioned to remove any impurities, ensuring a smooth surface for further processing.

How Is 10 Ounce Leather Formed and Assembled?

Once prepared, the leather is cut into specific shapes and sizes based on the intended application. Advanced cutting techniques, such as die cutting or laser cutting, are employed to achieve precision. Forming involves shaping the leather into the desired product, whether it’s bags, belts, or industrial equipment. For thicker leather like 10 ounce, specialized tools may be necessary to ensure clean edges and avoid damaging the material.

After forming, assembly takes place, where various components are stitched or glued together. High-strength threads are used to ensure durability, particularly for items that will experience significant wear and tear. For instance, tool belts or heavy-duty bags require robust stitching techniques to withstand the stress of daily use.

What Finishing Techniques Enhance the Quality of 10 Ounce Leather?

Finishing is the final stage of the manufacturing process and involves applying various treatments to enhance the leather’s appearance and performance. This may include dyeing, oiling, or applying protective coatings. Finishing techniques not only improve aesthetic appeal but also provide additional water resistance and UV protection.

The finishing process for 10 ounce leather often involves buffing and polishing to create a smooth surface. This step also allows for the application of natural oils or waxes, which enhance the leather’s durability and give it a rich, lustrous finish. The final product should meet specific quality standards to ensure it is suitable for heavy-duty applications.

How Do International Standards Impact Quality Assurance for 10 Ounce Leather?

Quality assurance (QA) is crucial in the leather industry, especially for B2B buyers looking for reliable suppliers. International standards, such as ISO 9001, provide a framework for consistent quality management systems. Compliance with these standards indicates that a manufacturer has implemented effective processes for quality control throughout the production cycle.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are essential for certain applications. These certifications ensure that the leather meets specific safety and performance requirements, particularly for products used in industrial settings or consumer goods in Europe.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in the manufacturing of 10 ounce leather typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage checks the quality of raw materials upon arrival at the facility. Factors such as thickness, texture, and defects are assessed to ensure that only high-quality hides are used.

-

In-Process Quality Control (IPQC): During production, various checks are performed to monitor adherence to specifications. This includes inspecting cutting accuracy, stitching quality, and adherence to design specifications.

-

Final Quality Control (FQC): After finishing, the final product undergoes a thorough inspection. This includes checking for any defects, verifying color consistency, and ensuring that the leather meets the required performance standards.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

B2B buyers must take proactive steps to ensure that their suppliers adhere to stringent quality control measures. Here are some actionable steps:

-

Conduct Audits: Request on-site audits to assess the supplier’s manufacturing processes and quality control measures. This provides firsthand insight into their operations and commitment to quality.

-

Request Quality Reports: Ask for detailed quality control reports that outline the results of IQC, IPQC, and FQC. This documentation should include any corrective actions taken in response to identified issues.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection services to evaluate the quality of the leather before shipment. These inspectors can provide an unbiased assessment and verify that the products meet international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Understanding local regulations and standards is essential. For example, European buyers must ensure compliance with REACH regulations regarding chemical safety in materials.

Illustrative image related to 10 ounce leather

Additionally, cultural differences may affect communication and expectations regarding quality. Buyers should establish clear specifications and quality standards upfront to avoid misunderstandings. Building strong relationships with suppliers can also facilitate better communication and adherence to quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for 10 ounce leather is vital for B2B buyers. By focusing on these aspects, buyers can ensure they source high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10 ounce leather’

Introduction

Navigating the procurement of 10 ounce leather can be a complex process, especially for B2B buyers across diverse international markets. This guide provides a step-by-step checklist designed to streamline your sourcing efforts, ensuring you acquire high-quality leather that meets your specific requirements. By following these actionable steps, you can enhance your purchasing decisions and foster long-term supplier relationships.

Step 1: Define Your Technical Specifications

Before starting your search, it’s essential to outline the technical specifications of the 10 ounce leather you need. Consider factors such as thickness, type (e.g., vegetable-tanned), and any additional treatments or finishes that may be required.

– Application Suitability: Identify the intended use, whether for heavy-duty equipment, commercial upholstery, or crafting.

– Durability Requirements: Assess how the leather will perform under stress, including its resistance to wear and tear.

Illustrative image related to 10 ounce leather

Step 2: Research and Identify Reliable Suppliers

Take the time to conduct thorough research to identify potential suppliers who specialize in 10 ounce leather. Look for companies with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe.

– Supplier Reputation: Check online reviews, ratings, and testimonials from other B2B buyers.

– Experience in Your Industry: Prioritize suppliers with experience in your specific application area to ensure they understand your needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

– Sample Requests: Ask for samples of the leather to evaluate its quality and suitability for your projects.

– Certifications: Verify that suppliers adhere to industry standards, such as environmental certifications for tanning processes.

Step 4: Negotiate Terms and Conditions

Once you’ve shortlisted potential suppliers, engage in negotiations to discuss pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms.

– Volume Discounts: Inquire about pricing breaks for bulk orders, which can significantly impact your overall budget.

– Lead Times: Clarify lead times and ensure they align with your production schedule to avoid delays.

Step 5: Assess Shipping and Logistics

Understand the shipping options and logistics involved in transporting 10 ounce leather from your chosen supplier. This step is vital, especially for international orders.

– Shipping Costs: Request detailed shipping quotes that include customs duties and taxes, which can vary significantly by region.

– Delivery Times: Ensure that the expected delivery times fit within your project timelines to maintain workflow continuity.

Step 6: Implement Quality Control Measures

Establish quality control protocols to ensure that the leather received meets your specifications. This step is crucial for maintaining the integrity of your final products.

– Inspection Procedures: Develop a checklist for inspecting the leather upon arrival, assessing factors like thickness, color consistency, and surface quality.

– Return Policies: Familiarize yourself with the supplier’s return policy in case the leather does not meet your standards.

Step 7: Build Long-Term Supplier Relationships

After successfully sourcing your 10 ounce leather, focus on developing a strong, ongoing relationship with your supplier. This can lead to better service and pricing in the future.

– Regular Communication: Keep lines of communication open for feedback and updates on future orders.

– Collaborative Development: Explore opportunities for collaborative product development, which can enhance both parties’ offerings in the marketplace.

By following this structured checklist, B2B buyers can confidently navigate the complexities of sourcing 10 ounce leather, ensuring they make informed decisions that align with their business objectives.

Illustrative image related to 10 ounce leather

Comprehensive Cost and Pricing Analysis for 10 ounce leather Sourcing

When sourcing 10 ounce leather, it is crucial to understand the comprehensive cost structure and pricing dynamics that impact your procurement strategy. This analysis will provide insights into the various cost components, price influencers, and practical tips for B2B buyers.

What Are the Key Cost Components in 10 Ounce Leather Sourcing?

The total cost of 10 ounce leather consists of several components:

-

Materials: The primary cost driver in leather sourcing is the raw material itself. The price of 10 ounce leather can vary significantly based on the type (e.g., vegetable-tanned vs. chrome-tanned), origin (European vs. South American), and quality grade. For instance, premium Italian leather may command higher prices due to its superior tanning processes and quality.

-

Labor: Labor costs encompass the expenses associated with tanning, cutting, and finishing the leather. Skilled artisans are often required for quality assurance in the production process, which can add to the overall cost.

-

Manufacturing Overhead: This includes fixed costs such as factory rent, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads and, subsequently, the price of the leather.

-

Tooling: Depending on the complexity of the orders, tooling costs can vary. Custom dies or molds for specific shapes or designs will increase initial costs but can lead to lower per-unit costs for larger orders.

-

Quality Control (QC): Ensuring that leather meets specific standards requires investment in QC processes. This can include testing for durability, colorfastness, and overall quality, impacting the final price.

-

Logistics: Shipping costs, especially for international buyers, can significantly affect total expenditure. Factors such as distance, mode of transport, and import duties should be carefully considered.

-

Margin: Suppliers will typically add a margin to cover their business risks and profit expectations. Understanding this can help in negotiations.

How Do Price Influencers Affect 10 Ounce Leather Costs?

Several factors can influence the pricing of 10 ounce leather:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Suppliers may offer tiered pricing based on volume, encouraging bulk purchases.

-

Specifications and Customization: Custom orders can lead to higher costs due to additional processing. Standard specifications are generally more cost-effective.

-

Material Quality and Certifications: Certifications like ISO or environmental standards can increase costs but also add value, especially in markets that prioritize sustainable sourcing.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more than lesser-known entities.

-

Incoterms: Understanding the shipping terms (like FOB or CIF) is crucial as they define who bears the shipping costs and risks, influencing overall pricing.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate for Volume Discounts: Leverage larger orders to negotiate better pricing. Establishing a long-term relationship with suppliers can also lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider factors such as durability, maintenance, and potential waste, which can affect the long-term value of your leather investment.

-

Be Aware of Pricing Nuances: Understand the local market conditions and economic factors affecting leather prices in both your region and the supplier’s region. This knowledge can strengthen your negotiation position.

-

Request Samples: Before finalizing orders, request samples to assess quality. This helps avoid costly mistakes due to poor material selection.

Conclusion

In summary, sourcing 10 ounce leather requires a thorough understanding of cost components, pricing influencers, and effective negotiation strategies. By considering these factors, international B2B buyers can make informed purchasing decisions that align with their business goals while optimizing costs. Always remember that prices can fluctuate, and it’s advisable to consult multiple suppliers to ensure competitive pricing and quality.

Alternatives Analysis: Comparing 10 ounce leather With Other Solutions

Introduction: Understanding Alternatives to 10 Ounce Leather

In the realm of leather materials, 10 ounce leather stands out for its remarkable durability and versatility. However, various alternatives exist that may suit specific applications or preferences. This section explores viable alternatives, comparing their characteristics and performance against 10 ounce leather. By evaluating these options, B2B buyers can make informed decisions based on their unique requirements.

Comparison Table

| Comparison Aspect | 10 Ounce Leather | Alternative 1: Veg Tanned Leather (9/10 oz) | Alternative 2: Synthetic Leather (PU) |

|---|---|---|---|

| Performance | High durability; ideal for heavy use | Excellent workability; accepts dyes easily | Moderate durability; less wear-resistant |

| Cost | Higher price point; quality investment | Mid-range pricing; good value for quality | Lower cost; economical for bulk purchases |

| Ease of Implementation | Requires specialized tools for shaping | Easy to tool and carve; suitable for various crafts | Simple to cut and sew; no special tools needed |

| Maintenance | Low; develops a patina over time | Low; easy to clean and maintain | Low; resistant to stains and moisture |

| Best Use Case | Heavy-duty gear and industrial use | Crafting belts, holsters, and decorative items | Fashion items, upholstery, and accessories |

Detailed Breakdown of Alternatives

Veg Tanned Leather (9/10 oz)

Veg tanned leather, particularly at 9/10 ounces, is a robust alternative that excels in versatility. It can absorb dyes and oils, allowing for creative customization while maintaining a high level of durability. This type of leather is particularly favored for crafting items like belts and holsters. However, its pasted back may limit certain applications, such as molding or dip-dyeing. While it is slightly less thick than 10 ounce leather, it offers a similar quality for many artisanal projects, making it a solid choice for those seeking an artisanal touch.

Synthetic Leather (PU)

Synthetic leather, commonly known as polyurethane (PU), provides a budget-friendly alternative to natural leathers. While it does not match the durability of 10 ounce leather, it offers decent resistance to wear and tear, making it suitable for fashion items and upholstery. Additionally, synthetic leather is easier to work with, requiring no specialized tools, which can lower production costs. However, it may lack the aesthetic appeal and longevity of genuine leather, making it less ideal for high-end applications. This option is often chosen for its affordability and ease of maintenance, but it may not satisfy buyers seeking premium quality.

Conclusion: Choosing the Right Leather Solution for Your Needs

When selecting a leather solution, B2B buyers should carefully consider the specific requirements of their applications. While 10 ounce leather is unrivaled in strength and durability for heavy-duty uses, alternatives like veg tanned leather and synthetic leather offer distinct advantages in terms of customization and cost. Buyers should assess factors such as performance, cost, and ease of implementation against their project needs to make a well-informed decision. Ultimately, the right choice will align with both the functional demands and the aesthetic goals of the intended application.

Essential Technical Properties and Trade Terminology for 10 ounce leather

What Are the Key Technical Properties of 10 Ounce Leather?

Understanding the essential technical properties of 10 ounce leather is crucial for B2B buyers, especially when sourcing materials for high-demand applications. Here are several critical specifications to consider:

-

Material Grade

The material grade indicates the quality of the leather, which can significantly affect durability and aesthetics. 10 ounce leather typically falls under high-grade categories, often sourced from premium cowhide. A higher grade means better resistance to wear and tear, making it ideal for products like heavy-duty bags and protective gear. -

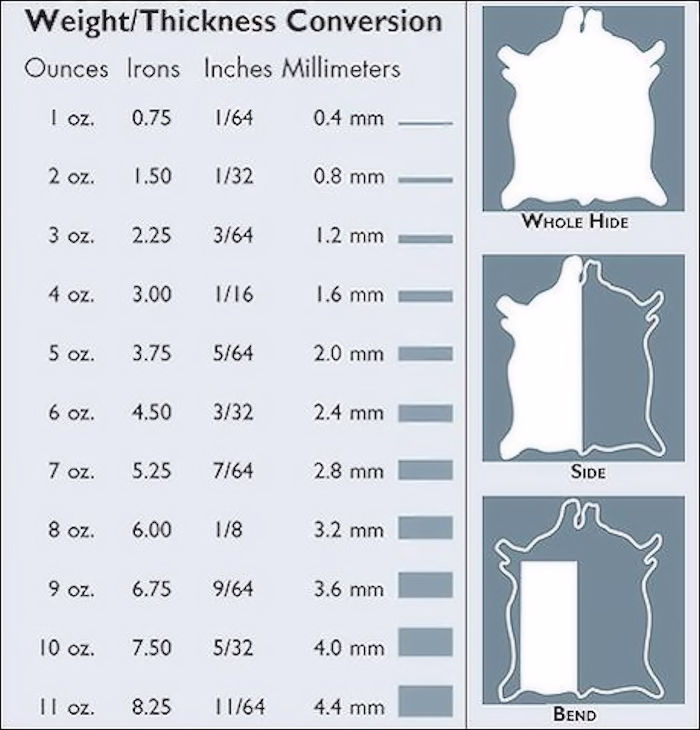

Thickness Measurement

Measured in ounces (1 ounce = 1/64 of an inch), 10 ounce leather has a thickness of approximately 4mm. This substantial thickness contributes to its robustness and shape retention, which are essential for applications requiring structural integrity, such as tool belts and luggage. Understanding thickness helps buyers assess whether the leather meets their project specifications. -

Tolerances

Tolerance levels refer to the acceptable variations in thickness and size of the leather hides. For 10 ounce leather, manufacturers may provide a tolerance range (e.g., ±0.5mm). Knowing tolerances is vital for B2B buyers to ensure consistency in production and to avoid complications during manufacturing. -

Flexibility and Workability

While 10 ounce leather is known for its strength, it also has limited flexibility due to its thickness. This characteristic may require specialized tools and techniques for crafting, influencing production timelines and costs. Buyers should be aware of this to better prepare their teams for the crafting process. -

Finish Type

The finish of the leather can affect both its appearance and performance. Options such as vegetable-tanned or chrome-tanned finishes can influence how the leather interacts with dyes and oils. Buyers must consider the finish type when determining the best use for the leather, as it impacts the final product’s aesthetic and durability. -

Country of Origin

Many buyers prefer leather sourced from specific regions known for quality, such as Italy or the USA. The country of origin can affect not only the leather’s quality but also compliance with local regulations and trade agreements. Understanding this helps buyers make informed decisions aligned with their branding and sourcing policies.

What Are the Common Trade Terms Relevant to 10 Ounce Leather?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather supply chain. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, this term is important for buyers looking to source custom leather goods that meet specific design requirements. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of goods a supplier is willing to sell. Understanding the MOQ for 10 ounce leather is crucial for B2B buyers, as it affects inventory management and initial investment costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should utilize RFQs when seeking quotes for 10 ounce leather, ensuring they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, risk, and insurance. Familiarity with these terms is essential for B2B transactions, especially for international buyers from regions like Africa and South America. -

Tannery Certification

This term refers to certifications that indicate compliance with environmental and quality standards in leather production. Buyers should look for tanneries with certifications to ensure they are sourcing leather that meets ethical and quality benchmarks. -

Vegetable Tanning

A traditional tanning method using natural tannins from plant sources. This term is significant for buyers interested in sustainable and eco-friendly leather options. Understanding the tanning process helps buyers align their sourcing decisions with sustainability goals.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 10 ounce leather, ensuring they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the 10 ounce leather Sector

What Are the Current Market Trends Influencing the 10 Ounce Leather Sector?

The 10 ounce leather market is experiencing a dynamic shift driven by several global factors. Notably, the rising demand for high-durability materials in various industries, including automotive, fashion, and outdoor equipment, is propelling the market forward. Buyers from Africa, South America, the Middle East, and Europe are increasingly seeking robust leather solutions that can withstand extreme conditions, making 10 ounce leather an ideal choice due to its strength and durability.

Emerging technologies are also reshaping sourcing trends. Digital platforms are enabling international buyers to connect with suppliers more efficiently, streamlining the procurement process. The use of advanced supply chain management software is becoming commonplace, allowing for better tracking of inventory and quality assurance. Additionally, the integration of e-commerce solutions is facilitating easier access to a diverse range of 10 ounce leather products, ensuring that buyers can find the specific types they need with minimal effort.

Illustrative image related to 10 ounce leather

Moreover, buyers are becoming increasingly discerning about the origins of their materials. This is leading to a growing emphasis on transparency and ethical sourcing practices, as consumers demand products that align with their values. In regions like Germany and Saudi Arabia, where sustainability is a significant concern, the ability to provide verified sourcing information can be a competitive advantage.

How Is Sustainability and Ethical Sourcing Shaping the 10 Ounce Leather Market?

Sustainability is a critical consideration for B2B buyers in the 10 ounce leather sector. The environmental impact of leather production, particularly in terms of water usage and chemical runoff, has come under scrutiny. As such, many suppliers are adopting sustainable practices to minimize their ecological footprint. This includes using vegetable tanning processes, which utilize natural materials and significantly reduce the reliance on harmful chemicals.

Ethical sourcing is also gaining traction. Buyers are increasingly looking for suppliers who can demonstrate responsible practices throughout their supply chains. This includes fair labor conditions and the use of ethically sourced raw materials. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers aiming to appeal to conscientious buyers. By prioritizing these certifications, businesses can enhance their credibility and attract a broader customer base.

Additionally, the trend toward upcycled and recycled leather is gaining momentum. This not only supports sustainability efforts but also offers unique product characteristics that can appeal to niche markets. Buyers looking to differentiate their offerings can leverage these materials to create distinctive products that resonate with environmentally conscious consumers.

How Has the 10 Ounce Leather Sector Evolved Over Time?

Historically, leather has been a staple material, prized for its durability and aesthetic appeal. The 10 ounce leather, in particular, has evolved from traditional tanning methods to embrace modern technological advancements. The shift towards vegetable tanning processes has not only improved the environmental sustainability of leather production but also enhanced the material’s quality and workability.

In recent decades, the global market for leather has expanded significantly, influenced by the rise of fashion and outdoor lifestyle brands that demand high-performance materials. The advent of globalization has facilitated the sourcing of leather from various regions, allowing for diverse applications and styles. As a result, international B2B buyers now have access to a broader array of 10 ounce leather products, tailored to meet the specific needs of their markets.

Illustrative image related to 10 ounce leather

In summary, the 10 ounce leather sector is marked by a blend of tradition and innovation, with sustainability and ethical sourcing becoming pivotal in shaping the future landscape. As international buyers navigate this evolving market, understanding these dynamics will be crucial for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of 10 ounce leather

-

How do I choose the right 10 ounce leather supplier for my business needs?

When selecting a supplier for 10 ounce leather, consider their reputation, experience, and product quality. Request samples to evaluate the leather’s texture, durability, and finish. Additionally, assess their production capabilities, lead times, and compliance with international standards. It’s beneficial to check customer reviews and testimonials to gauge reliability. Ensure the supplier can meet your specific requirements, including customization options and minimum order quantities (MOQs). -

What are the common applications of 10 ounce leather in various industries?

10 ounce leather is renowned for its durability and strength, making it ideal for heavy-duty applications. Common uses include crafting outdoor gear, tool belts, saddles, luggage, and commercial upholstery. This thickness provides excellent shape retention, essential for products requiring rigidity. Industries such as fashion, automotive, and outdoor sports frequently utilize 10 ounce leather for its robust characteristics, ensuring longevity in high-wear environments. -

What should I consider regarding the minimum order quantity (MOQ) for 10 ounce leather?

MOQs can vary significantly among suppliers and may be influenced by factors like production capabilities and material sourcing. When negotiating, consider your business’s demand and storage capacity. If your needs fluctuate, discuss flexible options with suppliers. Some may offer reduced MOQs for specific products or allow for combining orders to meet minimum requirements. Always clarify MOQ terms before finalizing your order to avoid unexpected costs. -

How can I ensure the quality of 10 ounce leather during international shipping?

To ensure quality during shipping, work with suppliers who package leather properly to prevent damage from moisture or physical stress. Request detailed shipping documentation, including quality assurance reports. Opt for suppliers who offer a guarantee or return policy, allowing you to address any issues upon receipt. Additionally, consider logistics partners experienced in handling leather goods to mitigate potential risks associated with international transport. -

What are the payment terms typically offered by suppliers of 10 ounce leather?

Payment terms can vary widely, but common practices include upfront payments, net 30/60 days, or letters of credit for larger orders. It’s crucial to discuss and negotiate terms upfront to align with your cash flow needs. Some suppliers may offer discounts for early payments or bulk orders, which can enhance profitability. Ensure you understand all fees associated with the transaction, including currency conversion and international banking charges. -

How does the tanning process impact the quality of 10 ounce leather?

The tanning process significantly affects leather’s characteristics, including durability, flexibility, and aesthetic appeal. Vegetable tanning, for example, uses natural tannins, resulting in a firmer and more environmentally friendly product. This type of tanning enhances the leather’s ability to accept dyes and finishes, making it ideal for custom applications. Understanding the tanning methods used by suppliers can help you choose the right leather for your specific needs. -

What customization options are available for 10 ounce leather products?

Many suppliers offer various customization options, including dye colors, finishes, and embossing or tooling designs. When discussing customization, provide clear specifications regarding your design needs and any branding elements you wish to incorporate. Be aware that custom orders may have longer lead times and higher MOQs. Always request samples of customizations to ensure they meet your quality standards before placing a full order. -

What logistics considerations should I be aware of when sourcing 10 ounce leather internationally?

When sourcing internationally, consider customs regulations and import duties that may apply to leather products. Research the specific requirements for your target market, as regulations can differ by region. Ensure that your supplier can provide necessary documentation, such as certificates of origin and compliance with international standards. Collaborate with a logistics provider experienced in international shipping to streamline the process and minimize delays.

Top 5 10 Ounce Leather Manufacturers & Suppliers List

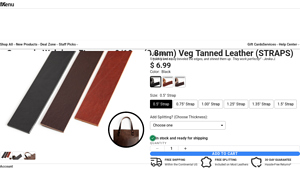

1. Conceria Walpier – Etrusco Veg Tanned Leather Straps

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: {“name”: “Conceria Walpier – Etrusco Veg Tanned Leather Straps”, “weight”: “9/10oz (3.8mm)”, “tannage”: “Vegetable”, “origin”: “Italy”, “price”: “$6.99”, “shipping”: “Free Shipping Within the Continental US”, “return_policy”: “30-Day Hassle-Free Returns”, “splitting_service”: “Available down to preferred thickness”, “note”: “Color may vary due to device screens and dye lot differences. Request sam…

2. Leather – Medieval Armor Supplies

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 10oz+ leather, suitable for making medieval armor for LARP, available from suppliers like Springfield Leather, Tandy, and Buckleguy.com. Recommended thickness for belts is 7-9oz. Options include saddle leather, bridle leather, and scrap leather. Notable suppliers mentioned include Wickett and Craig, American Leather Direct, and Montana Leather.

3. Tandy Leather – Veg-Tan Leather

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Veg-Tan Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

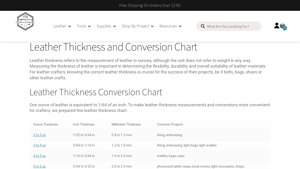

4. Montana Leather – Thickness & Ounces Chart

Domain: montanaleather.com

Registered: 2000 (25 years)

Introduction: Leather Thickness & Ounces Chart – Montana Leather Company. Leather thickness is measured in ounces, with 1 ounce equivalent to 1/64 of an inch. The chart provides thickness measurements in ounces, inches, and millimeters, along with common applications for each thickness. Common thickness ranges include: 2-3 oz (1/32 to 3/64 in, 0.8 to 1.2 mm) for lining and embossing; 3-4 oz (3/64 to 1/16 in, 1….

5. Buckleguy – Vegetable Tanned Leather

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Buckleguy offers a wide range of vegetable tanned leather sourced from leading tanneries in the USA and globally, including Wickett & Craig, Hermann Oak, Horween, Korba Buffalo Calf, Sedgwick English Bridle, and Valdibrana Italian Vachetta. The leather is available in various forms such as hides, sides, straps, panels, shoulders, bellies, and scrap. Vegetable tanning is an eco-friendly process usi…

Strategic Sourcing Conclusion and Outlook for 10 ounce leather

In the rapidly evolving landscape of leather sourcing, 10 ounce leather stands out for its unparalleled strength and versatility, making it a prime choice for a variety of demanding applications. International B2B buyers should recognize the importance of strategic sourcing in securing high-quality materials that meet their specific needs. By leveraging relationships with reputable suppliers, businesses can ensure access to premium 10 ounce leather that enhances product durability and aesthetic appeal.

Moreover, understanding the unique characteristics of 10 ounce leather—such as its limited flexibility and exceptional durability—can guide buyers in selecting the right leather for their projects, whether it be heavy-duty industrial applications or exquisite artisanal goods. As demand for high-quality leather increases globally, particularly in regions like Africa, South America, the Middle East, and Europe, proactive sourcing strategies will be crucial in staying competitive.

Looking ahead, B2B buyers are encouraged to explore innovative partnerships and invest in sustainable sourcing practices. By doing so, they can not only enhance their product offerings but also align with evolving consumer preferences for eco-friendly materials. Embrace the opportunity to elevate your business with 10 ounce leather—your gateway to durability and craftsmanship excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.