Introduction: Navigating the Global Market for motorcycle seat cover material

In the ever-evolving landscape of motorcycle accessories, sourcing high-quality motorcycle seat cover material presents a unique challenge for international B2B buyers. With a diverse range of materials available—each offering distinct advantages and drawbacks—selecting the right option can significantly impact customer satisfaction and brand reputation. This guide delves into the intricacies of motorcycle seat cover materials, exploring various types such as vinyl, leather, and synthetic alternatives, alongside their applications across different motorcycle styles and riding conditions.

Beyond material selection, understanding the nuances of supplier vetting, cost considerations, and market trends is crucial for making informed purchasing decisions. This comprehensive resource equips buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil, with actionable insights to navigate their sourcing journey effectively. By addressing critical factors like durability, comfort, and aesthetic appeal, this guide empowers businesses to optimize their product offerings and meet the evolving demands of motorcycle enthusiasts globally.

Whether you are a manufacturer, retailer, or distributor, leveraging the insights in this guide will not only enhance your procurement strategy but also position your business for success in a competitive market.

Table Of Contents

- Top 5 Motorcycle Seat Cover Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motorcycle seat cover material

- Understanding motorcycle seat cover material Types and Variations

- Key Industrial Applications of motorcycle seat cover material

- 3 Common User Pain Points for ‘motorcycle seat cover material’ & Their Solutions

- Strategic Material Selection Guide for motorcycle seat cover material

- In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat cover material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat cover material’

- Comprehensive Cost and Pricing Analysis for motorcycle seat cover material Sourcing

- Alternatives Analysis: Comparing motorcycle seat cover material With Other Solutions

- Essential Technical Properties and Trade Terminology for motorcycle seat cover material

- Navigating Market Dynamics and Sourcing Trends in the motorcycle seat cover material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat cover material

- Strategic Sourcing Conclusion and Outlook for motorcycle seat cover material

- Important Disclaimer & Terms of Use

Understanding motorcycle seat cover material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl | Durable, water-resistant, easy to clean | Mass production, budget-conscious markets | Pros: Cost-effective, low maintenance. Cons: Can wear out over time. |

| Leather | Premium feel, develops a patina, natural material | High-end custom builds, luxury motorcycle brands | Pros: Luxurious, comfortable. Cons: Requires maintenance, susceptible to weather. |

| Synthetic Leather | Mimics leather appearance with enhanced durability | Mid-range products, custom upholstery shops | Pros: Aesthetic appeal, resistant to cracking. Cons: Quality varies widely. |

| Neoprene | Flexible, waterproof, shock-absorbing | Off-road and adventure motorcycles | Pros: Excellent grip, comfortable. Cons: Can be heavier than other materials. |

| Foam | Provides comfort, available in various densities | Replacement seat covers, custom modifications | Pros: Customizable comfort, various options. Cons: Not a standalone cover material. |

What Are the Key Characteristics of Vinyl as a Motorcycle Seat Cover Material?

Vinyl is a widely used material for motorcycle seat covers due to its durability and affordability. It is water-resistant, making it ideal for various weather conditions, and is easy to clean, which is a significant advantage for manufacturers catering to budget-conscious consumers. B2B buyers should consider the quality of vinyl, as lower-grade options may not withstand prolonged exposure to the elements and can wear out faster.

How Does Leather Compare to Other Motorcycle Seat Cover Materials?

Leather is regarded as a premium choice, offering a luxurious feel and the ability to develop a unique patina over time. It is favored in high-end custom builds and luxury motorcycle brands. However, it requires regular maintenance to prevent degradation from moisture and UV exposure. B2B buyers looking for leather options should focus on high-quality grades and consider treatments that enhance durability against environmental factors.

What Benefits Do Synthetic Leather Products Offer to B2B Buyers?

Synthetic leather offers the aesthetic appeal of genuine leather while being more resistant to wear and tear. It is commonly used in mid-range products and custom upholstery shops, balancing cost with quality. B2B buyers should evaluate the varying quality levels of synthetic leather, as inferior options can lead to premature cracking and reduced lifespan, impacting customer satisfaction.

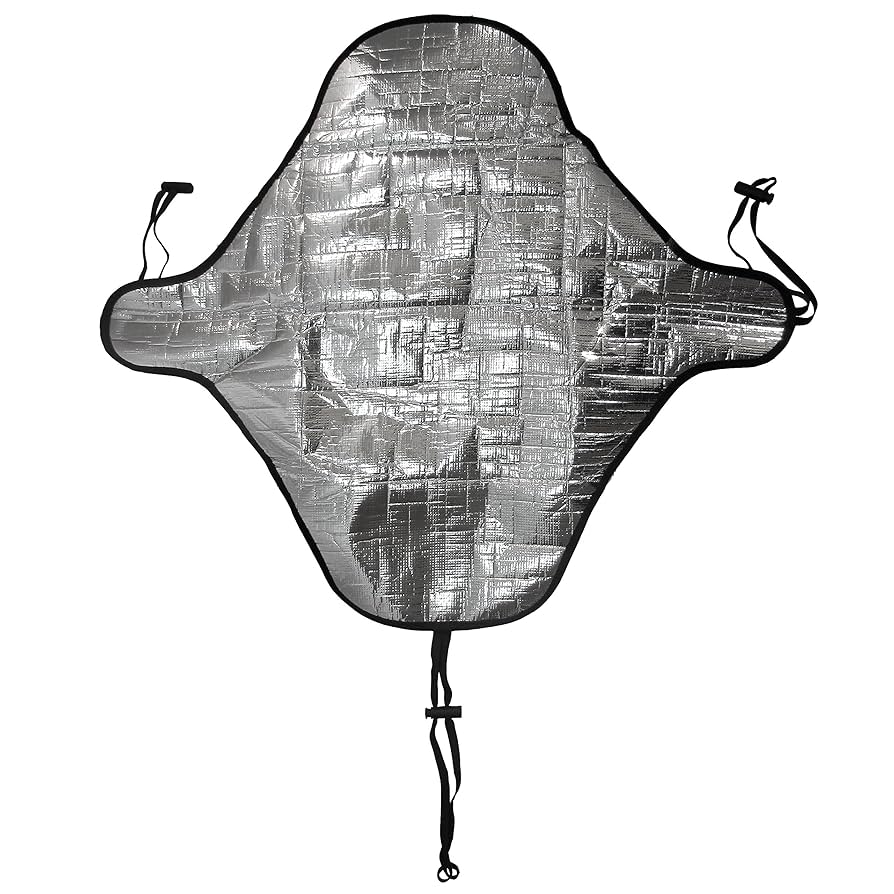

Illustrative image related to motorcycle seat cover material

Why is Neoprene a Suitable Choice for Off-Road Motorcycles?

Neoprene is a flexible and waterproof material that provides excellent shock absorption, making it ideal for off-road and adventure motorcycles. Its grip and comfort features are particularly beneficial for riders who encounter rugged terrains. B2B buyers should consider the weight of neoprene compared to other materials, as it may affect the overall bike weight and handling.

How Can Foam Be Effectively Used in Motorcycle Seat Covers?

Foam is primarily used as a comfort layer in motorcycle seats and is available in various densities to suit different riding styles. It can be customized for comfort and is often paired with other materials like vinyl or leather for enhanced performance. While foam alone is not a cover material, B2B buyers should consider the density and type of foam used in conjunction with seat covers to meet specific customer needs for comfort and support.

Key Industrial Applications of motorcycle seat cover material

| Industry/Sector | Specific Application of motorcycle seat cover material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | OEM seat covers for various motorcycle models | Ensures brand consistency and enhances product durability | Quality certifications, material specifications, and supply chain reliability |

| Custom Upholstery | Tailored seat covers for bespoke motorcycle builds | Provides unique aesthetic appeal and improved rider comfort | Custom design capabilities, material variety, and turnaround time |

| Rental & Touring Services | Durable seat covers for rental motorcycles | Reduces maintenance costs and enhances customer satisfaction | High durability, ease of cleaning, and weather resistance |

| Aftermarket Parts | Replacement seat covers for various motorcycle brands | Expands product offerings and meets diverse customer needs | Compatibility with different models, quality assurance, and warranty options |

| Sports & Racing | Specialized seat covers for racing motorcycles | Enhances performance through grip and comfort | Lightweight materials, high abrasion resistance, and compliance with racing regulations |

How is Motorcycle Seat Cover Material Used in Manufacturing?

In the motorcycle manufacturing sector, seat cover materials are essential for Original Equipment Manufacturer (OEM) applications. Manufacturers utilize durable materials such as high-grade vinyl and leather to ensure that the seat covers not only enhance the aesthetic appeal of the motorcycle but also withstand rigorous use. Key considerations for international B2B buyers include quality certifications to guarantee durability and adherence to local standards, as well as reliable supply chains to prevent production delays.

What Role Does Custom Upholstery Play in Motorcycle Seat Covers?

Custom upholstery businesses leverage motorcycle seat cover materials to create bespoke seating solutions tailored to individual customer preferences. This application is crucial for enhancing the visual appeal and comfort of motorcycles, especially in niche markets where personalization is valued. Buyers should focus on suppliers that offer a wide range of materials and design capabilities, as well as the ability to meet specific deadlines, which is vital for maintaining customer satisfaction.

How Do Rental and Touring Services Utilize Motorcycle Seat Covers?

For rental and touring services, motorcycle seat covers serve as a protective layer that minimizes wear and tear on their fleet. Durable and easy-to-clean materials are essential for maintaining the aesthetic and functional quality of rental motorcycles, ultimately leading to higher customer satisfaction and reduced maintenance costs. B2B buyers in this sector should prioritize sourcing materials that are weather-resistant and can withstand frequent use, ensuring longevity and performance.

What is the Importance of Aftermarket Parts in Motorcycle Seat Cover Material?

The aftermarket parts industry relies on motorcycle seat cover materials to provide replacement options for various motorcycle models. This application allows businesses to cater to a diverse customer base looking for cost-effective solutions to enhance comfort or aesthetics. Buyers should consider compatibility with different motorcycle models, along with quality assurance measures and warranty options to build trust with their customers.

How Do Sports and Racing Applications Benefit from Specialized Motorcycle Seat Covers?

In the sports and racing sector, specialized motorcycle seat covers are designed to enhance grip and rider comfort, significantly impacting performance. The materials used must be lightweight yet durable, with high abrasion resistance to withstand the rigors of racing. B2B buyers should ensure that the materials comply with racing regulations and offer the necessary performance attributes, thereby enhancing their competitive edge in the market.

3 Common User Pain Points for ‘motorcycle seat cover material’ & Their Solutions

Scenario 1: Struggling with Material Durability in Harsh Conditions

The Problem: B2B buyers often face challenges with sourcing motorcycle seat cover materials that can withstand extreme weather conditions, particularly in regions with high humidity, heavy rainfall, or intense sunlight. These environmental factors can lead to premature wear, fading, or cracking of the seat covers, resulting in increased replacement costs and dissatisfied customers. For manufacturers and distributors, this not only affects the product lifespan but also their reputation in a competitive market.

Illustrative image related to motorcycle seat cover material

The Solution: To ensure durability, it’s essential to prioritize materials that are specifically engineered for harsh climates. Buyers should look for marine-grade upholstery vinyl or high-quality synthetic materials that resist UV rays, moisture, and temperature fluctuations. When sourcing, request samples from suppliers to assess material thickness, flexibility, and resistance to wear. Additionally, consider integrating a protective coating or treatment that enhances water resistance and UV protection. Establishing a strong relationship with reputable suppliers who understand regional needs can also lead to better product recommendations tailored to local conditions.

Scenario 2: Navigating the Cost-Quality Dilemma

The Problem: Many B2B buyers encounter the challenge of balancing cost and quality when selecting motorcycle seat cover materials. Opting for lower-cost options can lead to subpar products that might not meet customer expectations, while higher-quality materials often come with a significant price increase. This dilemma can make it difficult for businesses to maintain competitive pricing while ensuring customer satisfaction.

The Solution: To navigate this cost-quality dilemma, buyers should adopt a strategic sourcing approach. Start by conducting a thorough market analysis to identify the average price range for various materials, ensuring you’re not overspending. Engage in discussions with manufacturers to understand the differences in material properties and their long-term benefits. Additionally, consider bulk purchasing agreements to lower costs without sacrificing quality. Establishing a tiered product line that includes both budget-friendly and premium options can cater to diverse customer segments, allowing for flexibility in pricing while maintaining product integrity.

Scenario 3: Addressing Customization Needs for Diverse Markets

The Problem: In the B2B motorcycle seat cover industry, customization is increasingly demanded by customers, especially in markets like Africa, South America, and Europe, where preferences can vary significantly. Buyers may struggle to find suppliers who offer a variety of colors, textures, and patterns that cater to specific regional tastes, which can limit their ability to meet market demands effectively.

The Solution: To address customization needs, buyers should proactively seek out suppliers who specialize in bespoke solutions. Communicate clearly about specific design requirements and regional preferences during the sourcing process. Additionally, consider leveraging digital tools that allow for virtual sampling and mock-ups of custom designs. Establish partnerships with manufacturers who have the capacity to produce small batches, as this can allow for greater flexibility and faster response times to market trends. Encouraging customer feedback on design preferences can also guide future orders, ensuring that offerings remain relevant and appealing to target demographics.

Strategic Material Selection Guide for motorcycle seat cover material

What Are the Key Properties of Common Motorcycle Seat Cover Materials?

Motorcycle seat covers are critical for both comfort and durability, as they endure exposure to various environmental conditions and the physical demands of riding. The choice of material can significantly impact performance, aesthetics, and user satisfaction. Below are analyses of four common materials used for motorcycle seat covers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Vinyl Perform as a Motorcycle Seat Cover Material?

Vinyl is a widely used synthetic material known for its affordability and durability. It typically has a temperature resistance ranging from -20°C to 60°C, making it suitable for various climates. Vinyl is also resistant to moisture and UV rays, which helps prevent fading and cracking over time.

Pros: Vinyl is cost-effective and easy to clean, making it a popular choice for manufacturers. It conforms well to the seat shape and provides a decent grip for riders.

Illustrative image related to motorcycle seat cover material

Cons: Lower-quality vinyl can crack and fade, especially under extreme conditions. Additionally, it may not provide the same level of comfort as more premium materials.

Impact on Application: Vinyl is compatible with a wide range of motorcycle types, from cruisers to sport bikes. However, it may not be the best choice for high-end models where aesthetics and luxury are prioritized.

Considerations for International Buyers: Buyers in regions like Europe and South America should ensure compliance with local standards such as ASTM for material safety. Preferences may vary, with some markets favoring eco-friendly options.

What Are the Advantages of Leather for Motorcycle Seat Covers?

Leather is often regarded as a premium choice for motorcycle seat covers due to its luxurious feel and aesthetic appeal. It offers natural breathability and can withstand temperature fluctuations, making it suitable for both hot and cold climates.

Pros: Leather develops a unique patina over time, enhancing its appearance. High-quality leather can also be treated to resist moisture and UV damage, extending its lifespan.

Illustrative image related to motorcycle seat cover material

Cons: Leather is generally more expensive than vinyl and requires regular maintenance to prevent cracking and degradation. It may also absorb moisture if not treated properly.

Impact on Application: Leather is ideal for high-end motorcycles and custom builds where aesthetics are a priority. However, it may not be suitable for off-road or adventure bikes that face harsher conditions.

Considerations for International Buyers: Buyers should look for leather that meets local environmental regulations, especially in Europe where sustainability is increasingly important.

Illustrative image related to motorcycle seat cover material

How Does Polyurethane Foam Enhance Comfort in Motorcycle Seats?

Polyurethane foam is commonly used as a cushioning layer in motorcycle seats. It comes in various densities, with open-cell foam providing comfort and closed-cell foam offering support for racing applications.

Pros: Polyurethane foam is versatile and cost-effective, making it a popular choice among manufacturers. It offers good shock absorption and can be customized for different riding styles.

Cons: Over time, polyurethane foam can compress and lose its supportive qualities. It may not be as comfortable as memory foam or gel options for long-distance riding.

Impact on Application: This material is suitable for a variety of motorcycles, particularly those designed for everyday use. It can be combined with other materials to enhance comfort.

Considerations for International Buyers: Compliance with foam density regulations is essential, especially in markets with strict safety standards. Buyers should also consider the availability of high-quality foam suppliers.

Illustrative image related to motorcycle seat cover material

What Role Do Gel Inserts Play in Motorcycle Seat Comfort?

Gel inserts are increasingly popular for enhancing comfort in motorcycle seats. They provide additional cushioning and pressure relief, making them ideal for long rides.

Pros: Gel inserts conform to the rider’s body, offering superior comfort compared to traditional foam alone. They can significantly reduce fatigue on longer journeys.

Cons: Gel inserts can add to the overall cost of the seat and may require specific fitting, which can complicate manufacturing.

Illustrative image related to motorcycle seat cover material

Impact on Application: Gel inserts are particularly beneficial for touring motorcycles and long-distance riders. They can be integrated into existing seats or used in new designs.

Considerations for International Buyers: Buyers should ensure that gel materials meet local safety and performance standards, particularly in Europe where consumer protection is robust.

Summary Table of Motorcycle Seat Cover Materials

| Material | Typical Use Case for motorcycle seat cover material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | General use across various motorcycle types | Affordable and durable | Can crack and fade over time | Low |

| Leather | High-end and custom motorcycles | Luxurious feel and aesthetic appeal | Requires maintenance and is costly | High |

| Polyurethane Foam | Everyday use in standard motorcycles | Versatile and cost-effective | Can compress over time | Med |

| Gel Inserts | Long-distance touring motorcycles | Superior comfort and pressure relief | Can complicate manufacturing | Med |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing motorcycle seat cover materials. Understanding the properties, advantages, and limitations of each material will help in selecting the most suitable options for their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat cover material

What Are the Main Stages in the Manufacturing Process of Motorcycle Seat Cover Material?

The manufacturing process of motorcycle seat cover materials consists of several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets quality standards and performs well under various conditions.

Illustrative image related to motorcycle seat cover material

How Is Material Prepared for Motorcycle Seat Covers?

The first step in the manufacturing process is material preparation, where different types of fabrics, such as vinyl, leather, or synthetic blends, are selected based on the specific requirements of the seat cover. This stage involves sourcing high-quality raw materials that are durable and resistant to wear, tearing, and environmental factors like UV exposure and moisture.

Once the materials are sourced, they undergo treatment processes, such as coating or laminating, to enhance their protective properties. For instance, marine-grade vinyl is often treated to resist water and mildew, making it suitable for outdoor use. Quality checks at this stage ensure that the materials meet specified standards, reducing the risk of defects later in the manufacturing process.

What Techniques Are Used in Forming Motorcycle Seat Covers?

The forming stage is where the prepared materials are shaped into the desired form for the motorcycle seat covers. This typically involves cutting the materials into specific patterns based on design templates. Advanced techniques such as CAD (Computer-Aided Design) software may be utilized to ensure precision and consistency across large production runs.

After cutting, the pieces are often sewn together using industrial sewing machines. The stitching must be robust, as it bears the load and stress during use. Techniques like double stitching or the use of reinforced seams can enhance durability. Manufacturers may also employ heat-sealing methods for seams to create a waterproof barrier, particularly important for motorcycle seat covers exposed to rain and other elements.

How Are Motorcycle Seat Covers Assembled and Finished?

The assembly stage involves attaching various components of the seat cover, including zippers, padding, and any decorative elements. This is where comfort features, such as gel inserts or additional foam layers, are integrated into the seat cover design. Quality checks during assembly ensure that all components fit correctly and function as intended.

Illustrative image related to motorcycle seat cover material

The finishing stage includes final inspections, cleaning, and packaging of the seat covers. This is a crucial step where any surface imperfections or defects are addressed before the products are shipped to customers. Attention to detail during this stage is vital for maintaining a high-quality standard, as it directly impacts customer satisfaction.

What Quality Control Measures Are Essential for Motorcycle Seat Cover Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process, ensuring that the final products are reliable and meet international standards. For motorcycle seat covers, adherence to standards such as ISO 9001 and industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) is crucial.

What Are the Key QC Checkpoints in Motorcycle Seat Cover Production?

Quality control in the manufacturing of motorcycle seat covers involves several checkpoints:

-

Incoming Quality Control (IQC): This initial phase assesses the quality of raw materials upon arrival. Suppliers must provide certification and documentation to prove that the materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to ensure that each stage is executed according to quality standards. This may include checking stitching, material integrity, and assembly accuracy.

-

Final Quality Control (FQC): Before the products are packaged and shipped, a final inspection is conducted. This includes checking for defects, ensuring that all features function as intended, and verifying that the products meet customer specifications.

What Testing Methods Are Commonly Used for Motorcycle Seat Covers?

Testing methods for motorcycle seat covers include tensile strength tests, UV resistance tests, water resistance tests, and abrasion resistance tests. These tests evaluate the durability and performance of the materials under various conditions. For instance, UV resistance tests assess how well the materials withstand sun exposure, while water resistance tests determine the effectiveness of coatings used to repel moisture.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers maintain stringent quality control measures. Here are actionable steps to verify supplier QC practices:

Illustrative image related to motorcycle seat cover material

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control practices. These audits should assess compliance with international standards and industry-specific regulations.

-

Quality Reports: Requesting detailed quality reports from suppliers can help verify their adherence to QC checkpoints. These reports should include data on testing results, defect rates, and corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be particularly beneficial for international buyers, ensuring that products meet both local and international standards.

What Are the Unique QC Considerations for International B2B Buyers?

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Factors such as differing regulations, material availability, and logistical challenges can impact quality assurance.

For instance, buyers in Europe may prioritize compliance with CE standards, while those in Africa might focus on cost-effective materials that perform well in local climates. Understanding these regional differences can help buyers make informed decisions when selecting suppliers and materials.

Conclusion: Ensuring Quality in Motorcycle Seat Cover Material Manufacturing

The manufacturing processes and quality assurance practices for motorcycle seat cover materials are critical to producing durable, high-performance products. By understanding the key stages of manufacturing, implementing robust quality control measures, and verifying supplier practices, B2B buyers can ensure that they are sourcing the best materials for their needs. This comprehensive approach not only enhances product quality but also builds trust and reliability in the supply chain, ultimately benefiting both manufacturers and buyers in the competitive motorcycle market.

Illustrative image related to motorcycle seat cover material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat cover material’

To successfully procure motorcycle seat cover material, it’s essential to follow a structured approach that ensures you select high-quality materials suitable for your target market. This guide outlines the critical steps to help you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify your requirements for motorcycle seat cover materials. Determine the type of material (e.g., vinyl, leather, synthetic) and specific features like durability, weather resistance, and comfort. Clear specifications help streamline the sourcing process and ensure you receive products that meet your needs.

Step 2: Research Market Trends and Consumer Preferences

Understanding market dynamics is crucial. Analyze current trends in motorcycle seat materials within your target regions, such as Africa, South America, the Middle East, and Europe. Consider factors like aesthetic preferences, climate conditions, and rider demographics, which can influence material selection. This insight will guide your negotiations and product offerings.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Request detailed company profiles, product catalogs, and references from existing clients. Pay attention to their manufacturing capabilities, quality assurance processes, and delivery timelines. A reliable supplier should have a proven track record in the motorcycle industry, particularly in your target regions.

Step 4: Request Samples for Quality Assessment

Before finalizing any orders, request samples of the materials you are considering. Evaluate these samples for durability, texture, and overall quality. This step is vital to ensure that the materials will withstand regular use and environmental factors, providing comfort and safety for riders.

Step 5: Verify Compliance with Industry Standards

Ensure that the materials comply with relevant industry regulations and standards. Check for certifications that indicate quality and safety, such as ISO or other regional standards. Compliance not only protects your brand but also builds trust with your customers.

Step 6: Negotiate Terms and Pricing

Once you have identified suitable suppliers, engage in negotiations to secure favorable terms. Discuss pricing, minimum order quantities, and payment terms. Be prepared to compare offers from different suppliers to ensure you are getting the best value without compromising on quality.

Step 7: Establish a Quality Control Process

After placing your order, implement a quality control process to monitor the incoming materials. This includes inspecting the shipment for defects and ensuring it meets your specifications. Establishing quality control measures helps mitigate risks and ensures that the products you receive are consistent with your expectations.

By following these steps, you can effectively navigate the procurement of motorcycle seat cover materials, ensuring that your sourcing decisions align with your business goals and customer demands.

Comprehensive Cost and Pricing Analysis for motorcycle seat cover material Sourcing

What Are the Key Cost Components for Motorcycle Seat Cover Material Sourcing?

When sourcing motorcycle seat cover materials, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Illustrative image related to motorcycle seat cover material

-

Materials: The choice of material significantly impacts the overall cost. Common materials such as vinyl and leather have different price points. For instance, high-quality vinyl can range from $30 to $60 per linear yard, while premium leather may exceed $100 per yard. Additionally, the inclusion of specialized foams, such as memory foam or gel inserts, adds to the material cost.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. Custom designs or intricate stitching patterns require more skilled labor, which can drive up costs. In regions like Europe, labor rates are generally higher compared to South American or African markets.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient production practices can help mitigate these expenses, but they remain a crucial part of the pricing structure.

-

Tooling: The initial investment in molds or cutting tools for specific designs can be significant. Custom tooling is often necessary for unique seat shapes, leading to higher upfront costs but potentially lower per-unit costs for larger orders.

-

Quality Control (QC): Ensuring the quality of materials and finished products adds to the cost. Implementing strict QC processes can prevent defects but may require additional resources.

-

Logistics: Shipping costs are vital, especially for international buyers. Factors such as distance, shipping method, and Incoterms (e.g., FOB, CIF) can influence logistics costs. Buyers should account for these when comparing suppliers.

-

Margin: Finally, supplier margins vary based on their business model and market positioning. Understanding the expected margins can help buyers negotiate better terms.

How Do Price Influencers Affect Motorcycle Seat Cover Material Sourcing?

Several factors influence the pricing of motorcycle seat cover materials:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower unit prices due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specifications can increase costs due to the need for specialized materials or processes. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials often come with certifications that ensure durability and safety. While these may have a higher upfront cost, they can lead to lower total costs over time due to reduced replacement and maintenance needs.

-

Supplier Factors: The supplier’s reputation, location, and reliability can also affect pricing. Established suppliers with a track record of quality may command higher prices but can offer peace of mind regarding product consistency.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing Motorcycle Seat Cover Materials?

International B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Leverage your purchasing power. Building long-term relationships with suppliers can lead to better pricing and terms over time. Be clear about your budget and expectations during negotiations.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacements. Investing in higher-quality materials may result in lower TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties when sourcing from different regions. Understanding these factors can help in accurately assessing total costs.

-

Local vs. International Sourcing: Weigh the benefits of sourcing locally against potential cost savings from international suppliers. Local sourcing may reduce shipping costs and lead times, while international suppliers may offer better material options.

Disclaimer on Indicative Prices

The prices mentioned in this analysis are indicative and subject to market fluctuations, supplier pricing strategies, and specific buyer agreements. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing and to reflect current market conditions accurately.

Alternatives Analysis: Comparing motorcycle seat cover material With Other Solutions

Introduction: Exploring Alternatives to Motorcycle Seat Cover Materials

When selecting motorcycle seat cover materials, it is essential to explore alternative solutions that may provide comparable or enhanced benefits. This analysis evaluates the performance, cost-effectiveness, implementation ease, maintenance requirements, and best use cases of motorcycle seat cover materials against two viable alternatives: gel inserts and memory foam padding. Each option has its strengths and weaknesses, which can significantly impact customer satisfaction and overall riding experience.

| Comparison Aspect | Motorcycle Seat Cover Material | Gel Inserts | Memory Foam Padding |

|---|---|---|---|

| Performance | Durable, weather-resistant, varying grip | Adds comfort, redistributes pressure | Conforms to body shape, enhances comfort |

| Cost | Mid-range, depending on material choice | Low to moderate | Moderate to high |

| Ease of Implementation | Requires professional installation for best results | Easy to install, often DIY | Requires professional installation for optimal fit |

| Maintenance | Low; easy to clean | Low; minimal upkeep needed | Moderate; may require specific cleaning products |

| Best Use Case | General riding, aesthetics | Long-distance touring, comfort | Custom builds, luxury motorcycles |

Detailed Breakdown of Alternatives

Gel Inserts: Enhancing Comfort on Long Rides

Gel inserts are an effective solution for enhancing motorcycle seat comfort. They work by redistributing pressure across the seat, significantly reducing discomfort during extended rides. While gel inserts are relatively affordable and easy to install, they may not provide the same level of durability as traditional seat cover materials. Additionally, they require minimal maintenance, making them a practical choice for riders seeking comfort without major modifications to their existing seat.

Memory Foam Padding: Tailored Comfort for Every Ride

Memory foam padding represents a premium option for motorcycle seating. This material molds to the rider’s body, providing tailored support and comfort. While it enhances the riding experience, memory foam can be pricier than other alternatives and typically requires professional installation to ensure proper fitment and performance. Maintenance can also be a consideration, as specific cleaning methods may be needed to maintain the material’s integrity over time. Memory foam is ideal for luxury motorcycle builds where comfort is paramount.

Illustrative image related to motorcycle seat cover material

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers in the motorcycle industry, selecting the right seat cover solution hinges on understanding both the specific requirements of their clientele and the unique characteristics of each option. Motorcycle seat cover materials offer a balance of durability and aesthetic appeal, making them suitable for a wide range of motorcycles. On the other hand, gel inserts and memory foam padding present unique advantages that cater to comfort and luxury. Ultimately, the choice will depend on factors such as budget constraints, installation preferences, and customer expectations regarding comfort and performance. By carefully assessing these alternatives, buyers can make informed decisions that align with their business goals and customer satisfaction.

Essential Technical Properties and Trade Terminology for motorcycle seat cover material

What Are the Key Technical Properties of Motorcycle Seat Cover Materials?

When sourcing motorcycle seat cover materials, understanding the technical properties is crucial for ensuring product durability, performance, and customer satisfaction. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the quality and composition of the fabric used for seat covers. Common grades include marine-grade vinyl and automotive-grade leather. High-grade materials are essential for longevity, especially in regions with extreme weather conditions. Choosing the right grade can reduce replacement costs and improve customer loyalty.

2. Abrasion Resistance

This property measures how well the material can withstand wear from friction. It is critical for motorcycle seats, as they experience constant contact and movement. Materials with high abrasion resistance reduce the likelihood of premature wear and tear, extending the life of the seat cover. For B2B buyers, this translates to fewer returns and warranty claims.

3. UV Resistance

UV resistance indicates how well a material can withstand sun exposure without degrading. This is particularly important for outdoor motorcycles, as prolonged sun exposure can cause fading and cracking. Opting for UV-resistant materials ensures that the seat covers maintain their aesthetic appeal and functional integrity over time, appealing to buyers in sunny climates.

4. Water Resistance

Water resistance is the ability of the material to repel water, preventing moisture from penetrating and causing damage. This property is vital for motorcycle seats that may be exposed to rain or wet conditions. For businesses, selecting water-resistant materials can enhance product offerings and improve customer satisfaction by reducing the risk of mold and mildew.

5. Comfort Layer Composition

The comfort layer, often made from various foam types, affects the overall riding experience. Common options include open-cell and closed-cell polyurethane foams, memory foam, and gel inserts. Understanding the differences can help buyers select the right material for their target market, whether they cater to long-distance riders or urban commuters.

6. Thickness and Density

The thickness and density of the seat cover material influence both comfort and support. Thicker, denser materials generally offer better cushioning but may weigh more. Buyers should balance these factors based on their specific market needs, ensuring that the final product aligns with consumer preferences for comfort and performance.

What Common Trade Terms Should B2B Buyers Know?

Navigating the procurement process requires familiarity with specific trade terminology. Here are key terms that B2B buyers in the motorcycle seat cover industry should understand:

Illustrative image related to motorcycle seat cover material

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand. In the motorcycle industry, OEM seat covers are typically made to the specifications of the motorcycle manufacturer. Understanding OEM standards can help buyers ensure compatibility and quality in their product offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory effectively and negotiate better terms with suppliers. It is crucial for new businesses to assess their purchasing power and align it with supplier expectations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process is vital for B2B buyers to compare options and select the most cost-effective solutions. A well-prepared RFQ can streamline procurement and foster better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms can prevent misunderstandings and ensure smooth logistics, especially for international transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for inventory management and customer satisfaction. Buyers should communicate their needs clearly to suppliers to ensure timely deliveries.

6. Customs Duties

Customs duties are taxes imposed on imported goods. Awareness of these costs is crucial for B2B buyers involved in international trade, as they can significantly impact overall pricing and profitability.

By comprehensively understanding both the technical properties and trade terminology associated with motorcycle seat cover materials, B2B buyers can make informed decisions that enhance their product offerings and strengthen their competitive position in the market.

Navigating Market Dynamics and Sourcing Trends in the motorcycle seat cover material Sector

What Are the Key Trends Shaping the Global Motorcycle Seat Cover Material Market?

The motorcycle seat cover material market is witnessing a dynamic transformation driven by several global factors. Firstly, the increasing popularity of motorcycles as a cost-effective mode of transport, especially in regions like Africa and South America, is propelling demand. As urbanization accelerates, the need for durable, weather-resistant materials that can withstand various climatic conditions has become paramount. Notably, vinyl and synthetic materials are gaining traction due to their affordability and resilience compared to traditional leather options.

Illustrative image related to motorcycle seat cover material

Emerging technologies are also reshaping sourcing trends. Digital platforms and B2B marketplaces are streamlining procurement processes, enabling international buyers to connect with manufacturers more efficiently. Additionally, the rise of custom and bespoke seat designs is influencing material choices, as buyers seek unique aesthetic and functional solutions. In Europe, particularly Germany, there is a growing demand for premium materials that combine comfort with high durability, reflecting an evolving consumer preference for quality.

Furthermore, market dynamics are shifting towards sustainability, with buyers increasingly prioritizing eco-friendly materials. This trend is particularly evident in the Middle East and Europe, where regulations and consumer expectations are driving manufacturers to adopt greener practices. As such, materials that boast sustainability certifications are becoming more desirable in the B2B landscape.

How Is Sustainability Impacting the Sourcing of Motorcycle Seat Cover Materials?

The environmental impact of manufacturing processes and materials is a significant concern for B2B buyers in the motorcycle seat cover material sector. As sustainability becomes a key focus, the demand for eco-friendly materials is on the rise. This includes options such as recycled vinyl and organic textiles that have a reduced carbon footprint compared to traditional materials. Buyers are encouraged to seek suppliers who utilize sustainable practices and can provide transparency in their supply chains.

Ethical sourcing is also gaining prominence. Buyers are increasingly aware of the importance of supporting suppliers who adhere to fair labor practices and environmentally responsible production methods. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for businesses looking to validate their commitment to sustainability and ethical sourcing.

Furthermore, incorporating sustainable materials not only meets regulatory requirements but also enhances brand reputation. Companies that prioritize environmental responsibility can attract a more extensive customer base, particularly in regions like Europe and North America, where consumers are more inclined to support brands with a strong sustainability ethos.

How Has the Motorcycle Seat Cover Material Market Evolved Over Time?

The evolution of motorcycle seat cover materials reflects broader changes in consumer preferences and technological advancements. Initially dominated by leather, the market has shifted towards synthetic options such as vinyl, which offer greater durability and lower maintenance costs. This shift became particularly evident in the late 20th century as manufacturers sought to provide more affordable options without compromising quality.

In recent years, the introduction of advanced materials, including memory foam and gel inserts, has revolutionized comfort and ergonomics in motorcycle seating. These innovations cater to a diverse range of riders, from casual commuters to long-distance tourers, highlighting the industry’s adaptability to consumer needs.

As the market continues to evolve, the focus on sustainability and ethical sourcing is likely to shape future trends. Buyers are encouraged to stay informed about new materials and technologies that can enhance their offerings and appeal to a growing segment of environmentally-conscious consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat cover material

-

How do I choose the right material for motorcycle seat covers?

Selecting the appropriate material for motorcycle seat covers involves considering durability, comfort, and environmental exposure. Vinyl is a popular choice due to its affordability and resistance to cracking, while leather offers a premium feel but requires more maintenance. For various climates, ensure the material can withstand moisture and UV rays. Additionally, think about the intended use: racing seats may require firmer materials, while touring seats benefit from cushioned options. Always request samples to assess the texture and quality before making a bulk order. -

What is the best foam type for motorcycle seat comfort?

The best foam for motorcycle seats typically includes open-cell polyurethane for comfort and breathability, while closed-cell polyurethane is ideal for racing due to its firmness and support. Memory foam is another premium option, conforming to the rider’s shape for enhanced comfort, but it can become dense over time. For long-distance rides, consider layering different foams with a gel insert to alleviate pressure points. Ultimately, the choice depends on the intended riding style and rider preferences. -

What customization options are available for motorcycle seat covers?

Many suppliers offer extensive customization options for motorcycle seat covers, including colors, textures, and stitching patterns. You can also select different materials based on performance requirements or aesthetic preferences. Custom logos or branding can often be added for businesses looking to enhance their market presence. When discussing customization, be clear about your specifications and the minimum order quantity (MOQ) to ensure the supplier can accommodate your needs effectively. -

What are the typical minimum order quantities (MOQ) for motorcycle seat cover materials?

Minimum order quantities for motorcycle seat cover materials vary by supplier and material type. Generally, MOQs can range from as low as 50 yards for standard fabrics to 500 yards or more for specialized materials. It’s essential to inquire about MOQs early in your discussions to align your purchasing strategy with supplier capabilities. If you have a smaller order, some suppliers may allow combining materials or colors to meet their MOQ requirements. -

How can I vet suppliers for motorcycle seat cover materials?

When vetting suppliers, consider their experience, reputation, and product quality. Request references from past clients and check online reviews to gauge their reliability. Additionally, assess their certifications and compliance with international standards, particularly for materials used in regions with strict regulations. Conducting a factory visit or asking for product samples can also help verify quality before committing to a larger order. -

What payment terms should I expect when sourcing motorcycle seat cover materials internationally?

Payment terms for international orders can vary significantly based on the supplier’s policies and your negotiation outcomes. Common terms include upfront deposits (typically 30-50%) with the balance due before shipment, or payment via letters of credit for larger transactions. Ensure you understand any additional fees associated with currency conversion or international banking. It’s advisable to establish clear terms in a written contract to prevent misunderstandings. -

What quality assurance measures should I implement when sourcing materials?

Implementing quality assurance (QA) measures involves setting clear specifications for materials and requesting samples for testing prior to large-scale production. Establishing a quality control checklist can help in assessing each batch upon delivery. Regular communication with suppliers about quality expectations and conducting inspections during production can also minimize discrepancies. If possible, work with third-party inspection services to ensure compliance with your standards before shipment. -

How do logistics and shipping impact my sourcing of motorcycle seat cover materials?

Logistics and shipping play a crucial role in the sourcing process, impacting costs and delivery timelines. Consider the shipping methods available (air vs. sea), as air freight is faster but more expensive. Factor in customs duties and import regulations that may affect your total cost. Collaborate with your supplier to determine the best shipping options and timelines to ensure your materials arrive on schedule. Proper logistics planning can help mitigate delays and additional costs.

Top 5 Motorcycle Seat Cover Material Manufacturers & Suppliers List

1. Luimoto – Motorcycle Seat Covers & Accessories

Domain: luimoto.com

Registered: 2004 (21 years)

Introduction: Motorcycle Seat Covers, Tank Grips & More – Luimoto

1. Rider Seat Covers: Premium aftermarket covers designed for comfort and style, made from marine-grade materials, tailored for various motorcycles, providing protection and aesthetic upgrade.

2. Passenger Seat Covers: High-quality aftermarket covers for two-up seating, made from marine-grade materials, offering better grip and styling, ensurin…

2. MotoDeal – Key Materials for Motorcycle Seats

Domain: motodeal.com.ph

Introduction: Key materials for motorcycle seats include: 1. **Backing Plate**: Typically made of plastic, fiberglass, or carbon fiber for rigidity and weight reduction. 2. **Foam Layer**: Commonly polyurethane (open-cell for comfort, closed-cell for support), with options for memory foam and gel inserts for added comfort. 3. **Seat Cover**: Options include vinyl (durable, affordable, mimics leather) and leathe…

3. Advrider – Sunbrella Outdoor Fabric & Vinyl

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: 1. **Sunbrella Outdoor Fabric**: Fade and stain resistant, waterproof, wear resistant, available in various colors, textures, and weights. Recommended for its traction and aesthetic appeal. 2. **Vinyl (Leather-look)**: High-grade vinyl from local sewing supply stores, durable but may not be breathable. 3. **4 Way Stretch Vinyl**: Easier to work with, helps avoid creases and folds, durable. 4. **Ho…

4. DIY Upholstery Supply – Motorcycle Vinyl

Domain: diyupholsterysupply.com

Registered: 2004 (21 years)

Introduction: Motorcycle Vinyl – All Sport upholstery vinyl is stretchable and pliable, ideal for gaming rails, marine applications, ATVs, snow machines, and motorcycles. Features include -60° cold crack resistance, 360° stretch, and flame retardant properties. Available colors: Black, High-Tac Black, Chalk, Nu Bright Yellow, Bright Red, Silver Met, Royal Blue, Electric Blue, Marine Green, Bright Violet. Price …

5. The Upholstery Forum – Motorcycle Seat Cover

Domain: theupholsteryforum.com

Registered: 2018 (7 years)

Introduction: Product: Motorcycle Seat Cover

Material: Stretch Tech grippy and Stretch Tech leather grained vinyl

Binding Tape: 1″ polyester binding tape

Project Reference: BMW R1150GS front seat

Techniques: Sewing a strip of material around the edge to eliminate gathering, making a pattern of the seat underside, adding seam allowance for a snug fit.

Strategic Sourcing Conclusion and Outlook for motorcycle seat cover material

In today’s competitive landscape, strategic sourcing of motorcycle seat cover materials is paramount for B2B buyers looking to enhance product offerings and meet diverse market demands. The insights gathered highlight the importance of selecting durable materials like vinyl and leather, which not only withstand the rigors of daily use but also cater to the aesthetic preferences of consumers. Additionally, understanding the intricacies of foam types, such as open-cell and memory foam, can significantly impact customer satisfaction and loyalty.

Investing in quality materials ensures that manufacturers can deliver products that are not only functional but also appealing to the growing segments of adventure and touring motorcycle riders. Buyers should prioritize suppliers who can provide consistent quality, innovative materials, and sustainable practices, aligning with global trends toward eco-friendly products.

As the motorcycle market continues to evolve, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are encouraged to explore partnerships with reliable suppliers who can support their growth ambitions. Embrace the opportunity to innovate and differentiate your product line, positioning your business for success in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.