Catalog

Material Insight: Custom Leather Clothing

B2B Product Guide: Custom Leather Clothing Solutions

For fashion brands and manufacturers seeking distinctive, high-performance custom apparel, the choice of material is foundational to both product success and brand integrity. Custom leather clothing demands exceptional versatility, durability, and ethical alignment—requirements increasingly unmet by traditional leather in today’s conscious marketplace. Faux leather (synthetic leather) has emerged as the strategic material of choice for this application, offering unparalleled advantages in design flexibility, sustainability, and operational efficiency.

Why Faux Leather is the Optimal Choice for Custom Leather Clothing:

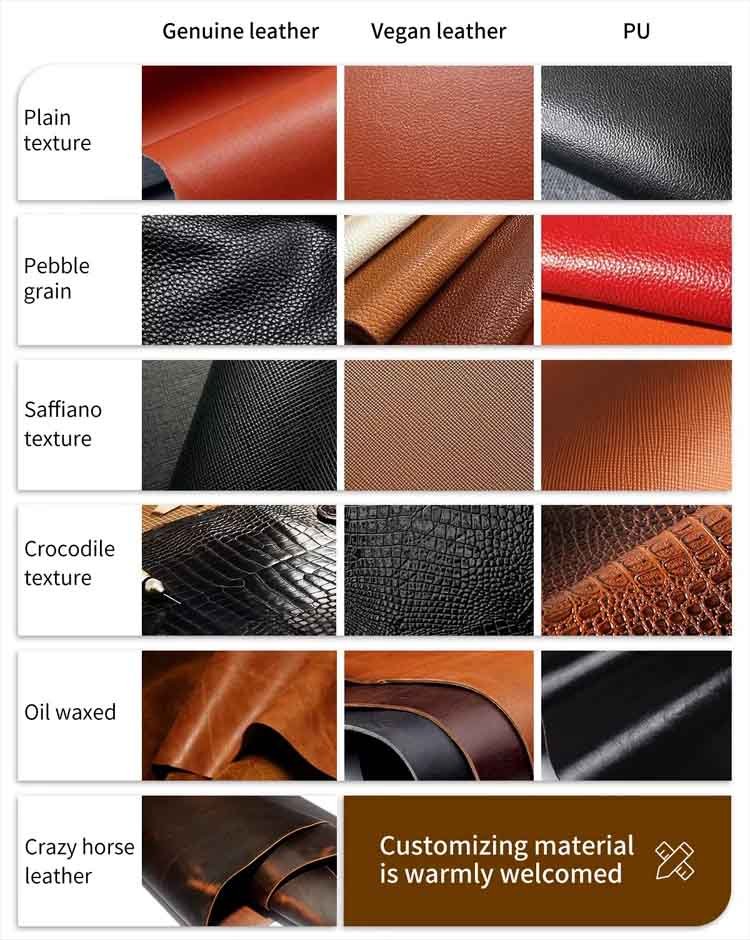

– Design Freedom & Consistency: Achieve precise color matching, unique textures, and complex patterns without the natural variations or limitations of animal hides, ensuring batch-to-batch uniformity critical for branded collections.

– Sustainability Compliance: Eliminate ethical concerns and environmental strain linked to tanning; modern faux leathers utilize recycled PET, plant-based polyols, and water-based coatings, aligning with global ESG mandates and consumer expectations.

– Performance Tailoring: Engineered for specific end-uses—whether abrasion-resistant for outerwear or ultra-soft for linings—with customizable thickness, drape, and breathability unattainable with real leather.

– Supply Chain Resilience: Avoid volatility in animal hide availability and pricing; synthetic alternatives offer stable lead times and scalable production for agile, responsive manufacturing.

Introducing WINIW: Your Precision Faux Leather Partner

With over 20 years of specialized expertise, WINIW is a globally trusted B2B innovator in high-performance synthetic leather solutions. We partner with forward-thinking fashion brands, sportswear leaders, and luxury manufacturers to transform design visions into market-ready realities. Our vertically integrated R&D and production—spanning raw material science to finishing technologies—ensure every meter of WINIW faux leather meets rigorous standards for aesthetics, durability, and eco-credentials. From traceable recycled materials to closed-loop manufacturing systems, we deliver not just material, but a competitive edge rooted in reliability, innovation, and shared commitment to a circular future. Partner with WINIW to elevate your custom leather clothing line with intelligence, integrity, and uncompromising quality.

Technical Performance & Standards

WINIW Custom Leather Clothing – B2B Product Guide

WINIW specializes in high-performance synthetic leather solutions designed for fashion and functional apparel brands seeking sustainable, cost-effective, and customizable materials. Our custom leather clothing line delivers exceptional value across manufacturing, compliance, and design flexibility—ideal for brands scaling production without compromising quality.

Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces raw material waste and lowers cutting and processing costs. The consistent surface texture and thickness minimize defects during cutting, improving yield rates. Additionally, no tanning or animal sourcing is required, leading to stable pricing and reduced environmental impact. -

Superior Durability

Engineered with high-density polyurethane (PU) and reinforced backings, WINIW leather resists abrasion, cracking, and peeling. It maintains integrity under repeated flexing and exposure to UV and moisture, making it ideal for outerwear, jackets, and performance garments. -

Customizable Colors & Finishes

We offer full color matching (Pantone, RAL, or custom swatches) and a wide range of surface textures—gloss, matte, embossed, or soft-touch. Brands can develop signature looks with batch consistency, supporting seasonal collections and private labeling. -

REACH Compliance

All WINIW synthetic leather products are fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted chemicals. Documentation is available for import compliance and sustainability reporting. -

ISO 9001-Certified Manufacturing

Our production processes are ISO 9001:2015 certified, guaranteeing strict quality control from raw material sourcing to finished roll. This ensures dimensional accuracy, consistent coating, and reliable batch-to-batch performance.

Product Specifications

| Specification | Detail |

|---|---|

| Material Base | High-tenacity polyester knit + nano-PU coating |

| Thickness Range | 0.6 mm – 1.2 mm (customizable) |

| Weight | 280 – 420 g/m² (depending on thickness and backing) |

| Width | 137 cm, 140 cm, or custom roll width |

| Color Options | Full Pantone matching; custom shades and effects (metallic, pearlescent) |

| Durability (Martindale) | ≥ 50,000 cycles (abrasion resistance) |

| Color Fastness (ISO 105) | Grade 4–5 (lightfastness), Grade 4 (rubbing) |

| Environmental Standards | REACH, RoHS, OEKO-TEX® STANDARD 100 (on request) |

| Certifications | ISO 9001:2015, LEATHER STANDARD™ (WINIW internal benchmark) |

| Lead Time | 15–25 days (standard order, 5,000–20,000 m) |

| Minimum Order Quantity | 1,000 meters (color and finish) |

WINIW’s custom leather clothing materials combine industrial efficiency with ecological responsibility. By integrating advanced polymer technology with scalable manufacturing, we empower B2B partners to deliver premium-quality, compliant, and visually distinctive apparel—on budget and on time.

Why Choose Synthetic over Real Leather

B2B Material Selection Guide: Custom Leather Clothing vs. Real Leather

Selecting the right material for apparel production requires balancing performance, sustainability, and operational efficiency. As a leader in advanced synthetic leather solutions, WINIW provides this objective comparison to support informed sourcing decisions for fashion brands and manufacturers. Understanding the distinctions between custom synthetic leather clothing (engineered materials like WINIW’s offerings) and traditional real leather is critical for aligning with modern market demands.

Key Comparative Analysis

| Criteria | Custom Synthetic Leather Clothing (e.g., WINIW) | Real Leather |

|---|---|---|

| Cost | – Predictable pricing (no volatile raw material fluctuations) – Lower waste during cutting (consistent roll goods) – Reduced labor costs (no grading/seaming required) |

– High volatility (subject to livestock market swings) – Significant waste (up to 30% due to hide defects) – Labor-intensive processing (grading, seaming, defect management) |

| Durability | – Uniform thickness & performance across entire roll – Resistant to water, UV fading, and cracking – Consistent tear strength (engineered for specific use cases) |

– Variable quality (natural hide imperfections) – Prone to water damage, staining, and hardening over time – Requires chemical treatments for basic weather resistance |

| Eco-Friendliness | – WINIW Standard: 30-100% recycled content (PET, PU) – Zero animal sourcing – Closed-loop water systems in production – Lower carbon footprint (verified by third-party LCAs) |

– Resource-intensive (16,000+ liters water per hide) – Heavy chemical use in tanning (chromium) – Significant methane emissions from livestock – Limited end-of-life recyclability |

Why This Matters for Your B2B Strategy

- Supply Chain Resilience: WINIW’s synthetic leathers eliminate dependence on livestock cycles and tannery backlogs, ensuring on-time delivery for collections.

- Design Flexibility: Achieve exact color, texture, and performance specs (e.g., stretch, breathability) without hide limitations—critical for technical apparel or consistent branding.

- Sustainability Compliance: Meet EU Ecodesign, California SB 261, and brand ESG targets with traceable, low-impact materials. Real leather’s environmental burden increasingly conflicts with regulatory trends.

- Waste Reduction: Uniform synthetic rolls optimize cutting room efficiency, directly improving yield rates by 15-25% versus graded hides.

WINIW’s custom synthetic leather solutions deliver the aesthetic and tactile qualities of premium leather while solving core B2B pain points: cost unpredictability, ethical concerns, and production inefficiencies. For brands scaling sustainably without compromising on quality or design ambition, engineered materials represent the strategic future of apparel manufacturing. Contact WINIW to discuss material specifications tailored to your production volume and performance requirements.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium quality materials engineered for durability, sustainability, and innovation. Our vertically integrated production capabilities and commitment to excellence have positioned us as a trusted supplier in the international market.

Our manufacturing facility spans over 100,000 square meters, making it one of the largest synthetic leather production bases in Asia. This expansive infrastructure supports high-volume output while maintaining flexibility for customized orders across diverse industries, including automotive, furniture, footwear, and fashion.

Key strengths of the WINIW factory include:

- Advanced production lines equipped with automated systems for consistent material quality and efficient throughput

- In-house R&D team of over 100 technical experts dedicated to material innovation, eco-friendly formulations, and application-specific development

- Stringent quality control protocols implemented at every stage of production, from raw material inspection to final product testing

- Compliance with international standards, including REACH, RoHS, and OEKO-TEX, ensuring safe and sustainable products for global markets

- Monthly production capacity exceeding 10 million meters, supporting large-scale OEM/ODM partnerships

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our logistics network ensures timely delivery and regulatory compliance across regions, backed by dedicated technical and customer support teams.

Through continuous innovation and sustainable manufacturing practices, WINIW delivers synthetic leather solutions that meet the evolving demands of global brands and manufacturers.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Solutions for Sustainable Fashion Brands

WINIW delivers high-performance, eco-conscious microfiber leather engineered specifically for forward-thinking fashion manufacturers. Our materials meet rigorous B2B requirements for durability, aesthetics, and environmental responsibility—without compromising on luxury feel. Partner with us to elevate your leather clothing collections with traceable, circular-economy-aligned materials.

Why WINIW Microfiber Leather for Apparel?

- Eco-Certified Performance: OEKO-TEX® STANDARD 100 Class I certified, 30% recycled content (GRS verified), and 40% lower carbon footprint vs. conventional PU leather.

- Unmatched Durability: Engineered for 50,000+ double-rub cycles (Martindale test) and 30% lighter than genuine leather—ideal for jackets, trousers, and tailored pieces.

- Designer Flexibility: 200+ stock colors/finishes; custom embossing, thickness (0.6–1.2mm), and roll widths (1.38m) available for seamless production integration.

- Ethical Compliance: Zero-Cr (chrome-free tanning equivalent), PFOA/PFOS-free, and compliant with EU REACH regulations.

Technical Specifications Comparison

| Property | WINIW EcoSoft™ Series | Conventional PU Leather | Genuine Leather (Avg.) |

|---|---|---|---|

| Tensile Strength | 280 N/mm² | 180 N/mm² | 220 N/mm² |

| Abrasion Resistance | 50,000+ cycles | 15,000 cycles | 35,000 cycles |

| Weight (g/m²) | 480 | 650 | 900 |

| Recycled Content | 30% | 0% | N/A |

| Water Absorption | <5% | 12% | 8% |

Streamlined Integration for Your Production

- Seamless Manufacturing: Consistent roll-to-roll thickness tolerance (±0.05mm) minimizes cutting waste.

- Eco-Conscious Finishing: Water-based coatings ensure low-VOC processing—compatible with standard sewing/embroidery workflows.

- Supply Chain Transparency: Full LCA reports and blockchain-tracked material origin provided upon request.

Request Custom Leather Clothing Samples Today

Accelerate your sustainable collection development with WINIW. We provide free physical samples tailored to your specific garment requirements—including color matching, texture, and performance testing. Our technical team collaborates directly with your design and production units to ensure flawless integration.

→ Contact WINIW’s B2B Solutions Team:

Email MKT88@MicrofiberLeather.com with “Custom Apparel Sample Request” in the subject line. Specify your target product (e.g., womenswear jackets, menswear trousers), volume needs, and timeline. Samples dispatched within 48 hours.

WINIW: Engineering Tomorrow’s Leather, Responsibly.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.