Catalog

Material Insight: Faux Leather Meaning

Faux Leather Meaning: The Engineered Alternative for Modern Business Applications

Faux leather, also known as synthetic or artificial leather, refers to a high-performance material engineered to replicate the aesthetic, texture, and functional properties of genuine leather—without utilizing animal hides. Modern faux leather is predominantly crafted from advanced polymers like polyurethane (PU) or polyvinyl chloride (PVC), often layered onto durable textile backings (e.g., polyester or rayon). Crucially, today’s premium faux leathers transcend outdated “pleather” stereotypes, offering sophisticated finishes, superior consistency, and targeted performance characteristics tailored for demanding commercial use. Unlike genuine leather, it eliminates ethical concerns, batch variations, and lengthy tanning processes, positioning it as a responsible, reliable solution for forward-thinking businesses.

Why Faux Leather Is the Optimal Choice for Commercial Applications

- Sustainability Without Compromise: Eliminates land/water use and toxic runoff associated with leather tanning. WINIW’s eco-engineered options use water-based PU, recycled content, and OEKO-TEX® certified components, aligning with ESG goals.

- Unmatched Consistency & Efficiency: Delivers uniform color, texture, and thickness across all rolls—critical for large-scale production. Reduces waste and streamlines manufacturing versus variable natural hides.

- Performance Tailored to Demand: Engineered for specific needs—abrasion resistance for automotive seating, flame retardancy for public transit, or easy-clean surfaces for healthcare furniture.

- Cost Predictability: Avoids volatile leather market pricing and supply chain disruptions. Stable input costs support long-term budgeting.

- Ethical Assurance: Fully traceable, cruelty-free, and compliant with global regulations (REACH, RoHS), mitigating brand risk and appealing to conscious consumers.

WINIW: Your Trusted Partner in Advanced Synthetic Leather

With over 20 years of specialized expertise, WINIW has pioneered innovations that redefine synthetic leather performance and sustainability for B2B markets. We collaborate with leading brands in automotive, furniture, fashion, and technical textiles to deliver materials that meet rigorous commercial standards—not just environmental promises. Our vertically integrated R&D and production ecosystem ensures end-to-end control, from polymer formulation to final finishing. This mastery translates to:

– Customization Precision: Tailored thickness, weight, hand feel, and performance specs for your exact application.

– Eco-Leadership: Industry-first closed-loop water recycling, 30%+ recycled content options, and PVC-free portfolios.

– Global Reliability: ISO-certified manufacturing with consistent supply chain resilience across 50+ countries.

For businesses demanding materials that balance responsibility, performance, and profitability, WINIW’s synthetic leather isn’t just an alternative—it’s the strategic standard. Let’s engineer your next success story.

Technical Performance & Standards

WINIW Faux Leather: Technical Advantages and B2B Product Overview

WINIW’s faux leather is an engineered synthetic material designed to deliver high performance across industrial and commercial applications. Constructed using advanced polyurethane (PU) and polyester base technologies, WINIW’s solution offers a sustainable, high-quality alternative to genuine leather—without compromising on durability, aesthetics, or compliance standards.

Engineered for B2B partners in upholstery, automotive interiors, fashion accessories, and furniture manufacturing, WINIW’s faux leather combines cost efficiency with premium functionality. The material is developed under strict production protocols to ensure consistency, scalability, and environmental responsibility.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s faux leather reduces raw material and processing costs compared to genuine leather. With no dependency on animal hides, production cycles are faster, waste is minimized, and yield rates exceed 95%. This translates to lower unit costs and higher profitability for manufacturers. -

Superior Durability

The material exhibits excellent abrasion resistance (tested to >50,000 cycles in Martindale testing), high tensile strength (>30 MPa), and outstanding seam strength. It resists cracking, fading, and peeling, ensuring long-term performance in high-use environments. -

Customizable Color & Finish Options

WINIW supports full color customization with a palette of over 1,000 standard colors and the ability to match Pantone or customer-provided samples. Surface finishes include matte, glossy, embossed, and soft-touch textures—ideal for brand differentiation and design flexibility. -

REACH Compliance

WINIW’s faux leather is fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). It is free from SVHCs (Substances of Very High Concern), phthalates, heavy metals, and other restricted substances, ensuring safety in consumer and industrial applications. -

ISO 9001-Certified Manufacturing

All production facilities operate under ISO 9001 quality management systems. This ensures consistent product quality, process traceability, and continuous improvement in manufacturing efficiency and customer satisfaction.

Technical Specifications

| Specification | Value / Detail |

|---|---|

| Base Material | High-tenacity polyester + PU coating |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Weight | 200 – 400 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale, 500g load) |

| Color Fastness (light) | Grade 6–7 (ISO 105-B02) |

| Tensile Strength | >30 MPa (warp and weft) |

| Seam Strength | >80 N |

| Cold Crack Resistance | Passes -20°C bend test |

| REACH Status | Compliant (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, texture, roll length, backing |

| Eco-Friendly Attributes | Solvent-free process, recyclable packaging |

WINIW’s commitment to innovation, sustainability, and quality makes its faux leather the preferred choice for forward-thinking B2B partners. With scalable production, rapid lead times, and full technical support, WINIW enables businesses to meet evolving market demands efficiently and responsibly.

Why Choose Synthetic over Real Leather

B2B Product Guide: Understanding Faux Leather vs. Real Leather for Commercial Applications

As a leader in innovative synthetic materials, WINIW provides this objective comparison to support informed procurement and product development decisions. Understanding the distinction between faux leather (also termed synthetic leather, artificial leather, or vegan leather) and real leather is critical for balancing performance, sustainability, and cost in commercial goods.

Faux Leather Meaning:

Faux leather refers to human-engineered materials designed to replicate the aesthetic and functional properties of animal hide. Modern variants (e.g., polyurethane (PU) or polyvinyl chloride (PVC) leather, microfiber leather) are produced through controlled industrial processes. WINIW specializes in water-based PU leather and recycled-content synthetics, engineered for specific performance criteria while minimizing environmental impact.

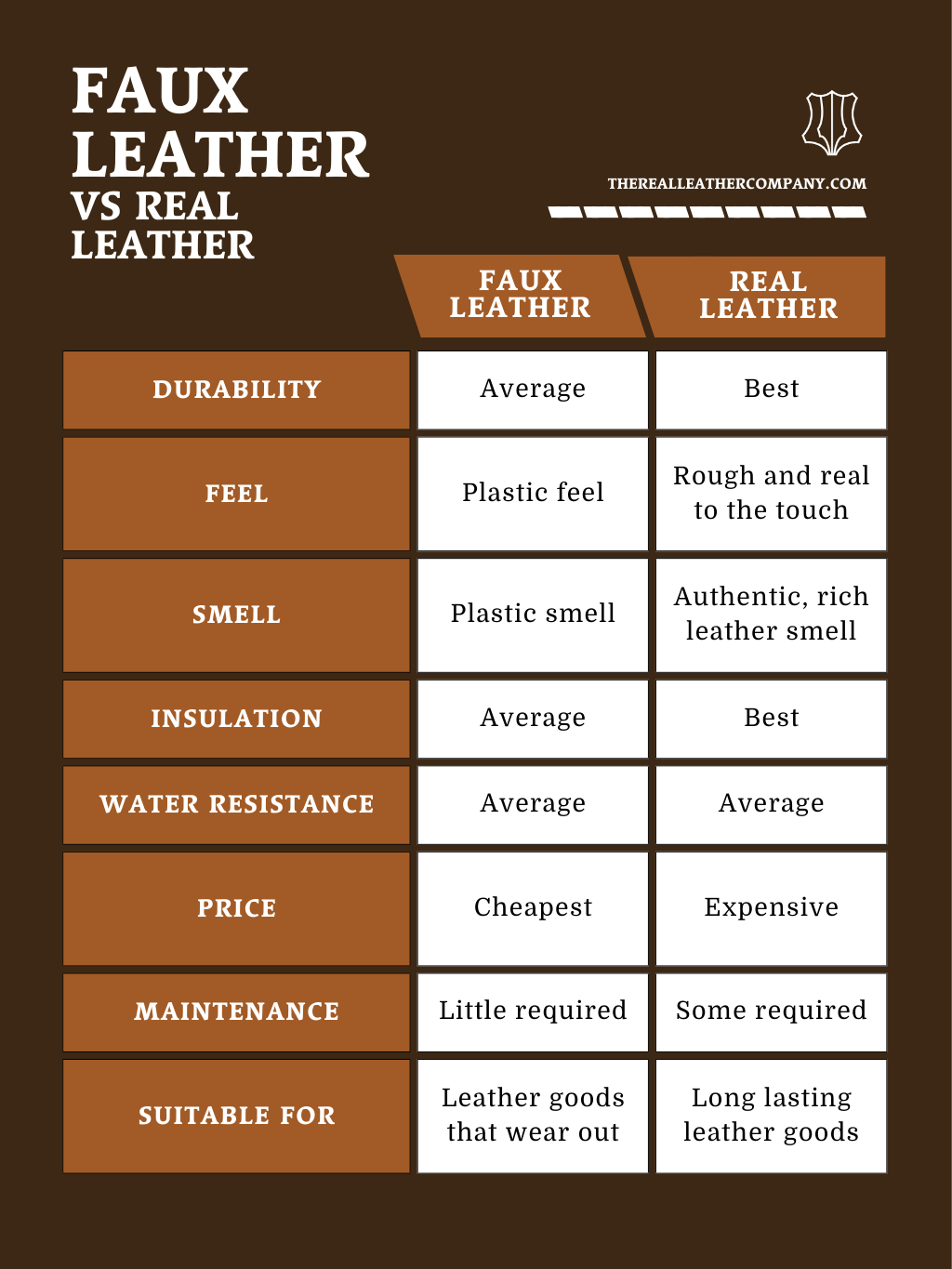

Key Differences: Faux Leather vs. Real Leather

The table below compares core attributes relevant to B2B buyers across fashion, automotive, furniture, and accessories sectors:

| Attribute | Faux Leather (Modern Synthetic, e.g., WINIW PU) | Real Leather (Full-Grain/Top-Grain) |

|---|---|---|

| Cost | – Lower upfront material cost (30-50% savings vs. premium leather) – Consistent pricing, unaffected by hide scarcity or grade fluctuations – Reduced waste during cutting due to uniform surface |

– Higher upfront cost (driven by hide quality, tanning complexity) – Price volatility due to livestock markets and hide availability – Significant waste (15-25%) from natural hide imperfections |

| Durability | – High resistance to scratches, fading, and moisture – Consistent thickness/texture ensures predictable performance – Lifespan: 5-7+ years in commercial use (e.g., automotive seats, upholstery) – Note: PVC variants may stiffen/crack over time; PU/microfiber excels |

– Develops patina but prone to scratches, water damage, and staining – Natural variations require grading; weak spots affect yield – Lifespan: 10-15+ years if meticulously maintained – Requires conditioning to prevent drying/cracking |

| Eco-Friendliness | – WINIW Advantage: Water-based PU uses 60% less energy vs. chrome tanning; 0% heavy metals – Recycled PET content options (up to 30%) – OEKO-TEX® certified, phthalate-free – Lower water consumption (vs. tanning) – Avoids livestock methane emissions & land use |

– Resource-intensive: 1 cowhide ≈ 16kg CO2e, 15,000L water per kg leather – Chrome tanning (80% of leather) generates toxic sludge – Biodegradable only if vegetable-tanned (rare commercially) – Certifications (e.g., LWG) mitigate but don’t eliminate impact |

Why This Matters for Your Business

- Sustainability Compliance: Faux leather (particularly WINIW’s eco-variants) aligns with ESG goals and circular economy mandates, avoiding deforestation/land degradation linked to leather supply chains.

- Supply Chain Resilience: Synthetic consistency ensures batch-to-batch reliability; no dependency on volatile hide markets.

- Design Flexibility: Custom colors, textures, and performance specs (e.g., flame resistance, UV stability) are achievable without post-production treatments.

- Ethical Sourcing: Eliminates animal welfare concerns and complex traceability requirements of leather.

WINIW’s synthetic leather solutions deliver commercial-grade performance with verifiable eco-credentials, making them the strategic choice for forward-thinking brands targeting conscious consumers and stringent regulatory environments. Request our technical datasheets for application-specific testing data and compliance documentation.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong commitment to sustainability and quality, WINIW serves industries ranging from automotive and furniture to fashion and sports, delivering reliable, customizable solutions tailored to diverse market demands.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry. This extensive production base enables high-volume output while maintaining operational efficiency and environmental control. The facility integrates advanced production lines with automated systems to ensure consistent product quality and reduce ecological impact.

WINIW’s competitive advantage is further strengthened by its dedicated R&D team composed of material scientists and technical engineers. This team continuously develops new formulations and textures, focusing on enhancing durability, softness, and environmental performance. Through ongoing innovation, WINIW has pioneered several eco-conscious material solutions, including water-based, solvent-free, and recycled content leathers that meet stringent international standards.

Quality control is a cornerstone of WINIW’s manufacturing process. The company enforces a strict QC system that monitors raw materials, in-line production, and final products through comprehensive testing protocols. Every batch undergoes rigorous evaluation for color fastness, abrasion resistance, tensile strength, and chemical compliance (including REACH, RoHS, and CPSIA). This ensures that all products meet or exceed global safety and performance requirements.

WINIW exports to key international markets, with established distribution and client partnerships across Europe and the USA. These regions demand high regulatory and ethical standards, which WINIW consistently meets through certified production practices and transparent supply chain management. The company’s ability to deliver reliable, scalable, and sustainable synthetic leather solutions has solidified its reputation as a trusted B2B supplier worldwide.

Key Strengths:

– 100,000 sqm advanced manufacturing facility enabling large-scale, efficient production

– In-house R&D team focused on innovation, performance, and eco-friendly material development

– Strict quality control system compliant with international standards (REACH, RoHS, CPSIA)

– Proven export capability to highly regulated markets including Europe and the USA

– Sustainable production practices supporting low-emission, recyclable, and non-toxic material solutions

WINIW continues to drive the evolution of synthetic leather by combining industrial strength with environmental responsibility, offering global partners a competitive edge through quality, innovation, and reliability.

Contact Us for Samples

WINIW Premium Synthetic Leather: B2B Product Guide

WINIW specializes in high-performance, eco-conscious synthetic leather solutions engineered for demanding commercial applications. Our materials deliver the aesthetic and functional properties of premium leather while meeting rigorous sustainability standards, reducing environmental impact without compromising durability or design flexibility. Ideal for furniture, automotive interiors, fashion accessories, and technical upholstery, WINIW microfiber leather supports your brand’s commitment to responsible innovation.

Understanding Faux Leather: Precision Terminology for Procurement

“Faux leather” is a broad industry term referring to any synthetic material designed to replicate genuine leather’s appearance and performance. At WINIW, we prioritize technical accuracy:

- Faux leather encompasses all non-animal leathers, including PVC-based, PU-coated, and advanced microfiber substrates.

- Vegan leather denotes materials free from animal derivatives (aligned with WINIW’s 100% animal-free production).

- Microfiber leather (WINIW’s specialty) uses ultra-fine polyester/polyamide fibers bonded with polyurethane, offering superior breathability, tear resistance, and longevity versus basic PU/PVC alternatives.

- Eco-leather specifically describes synthetics with verified reduced environmental impact—achieved through water-based coatings, recycled content, and OEKO-TEX® certified processes (core to WINIW’s manufacturing).

Confusion in terminology can lead to suboptimal material selection. WINIW provides full transparency on composition, certifications, and lifecycle impact to ensure your sourcing aligns with performance and ESG goals.

Material Comparison: Why WINIW Microfiber Excels

The table below highlights critical differentiators for commercial buyers prioritizing quality and sustainability:

| Feature | WINIW Microfiber Leather | Standard PU Leather | PVC Leather |

|---|---|---|---|

| Base Material | Recycled polyester microfiber + water-based PU | Woven fabric + solvent-based PU | Plasticized PVC film |

| Eco-Certifications | OEKO-TEX® STANDARD 100, GRS (Recycled Content), REACH compliant | Limited certifications; often contains DMF | Contains phthalates, heavy metals |

| Durability (Martindale) | 100,000+ cycles | 20,000–50,000 cycles | 15,000–30,000 cycles |

| Breathability | High (micro-porous structure) | Low to moderate | Very low (non-porous) |

| Eco-Impact | 60% lower CO2 vs. bovine leather; 30% recycled content | Moderate VOC emissions | High toxicity in production/disposal |

| Customization | Full color, texture, thickness, and performance tailoring | Limited options | Minimal flexibility |

Strategic Advantages for Your Business

- Supply Chain Resilience: Consistent quality unaffected by livestock volatility or tanning shortages.

- Design Freedom: Match exact colorways (Pantone®), textures (suede, pebble, exotic), and thicknesses (0.6mm–2.0mm) for brand differentiation.

- Compliance Assurance: Meets global flammability (CAL 117, MVSS302), abrasion, and chemical safety standards.

- Circularity Support: Recyclable at end-of-life; compatible with take-back programs for closed-loop processing.

Clarify Your Sourcing: Request Technical Details Today

Understanding “faux leather meaning” is critical for informed procurement. WINIW provides comprehensive documentation—including full material disclosures, test reports, and sustainability metrics—to eliminate ambiguity in your supply chain.

Request your free sample kit and technical dossier to evaluate WINIW’s performance against your specifications. Contact our B2B Solutions Team:

MKT88@MicrofiberLeather.com

Free samples available for qualified commercial projects. Validate durability, aesthetics, and eco-credentials with zero obligation.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.