Catalog

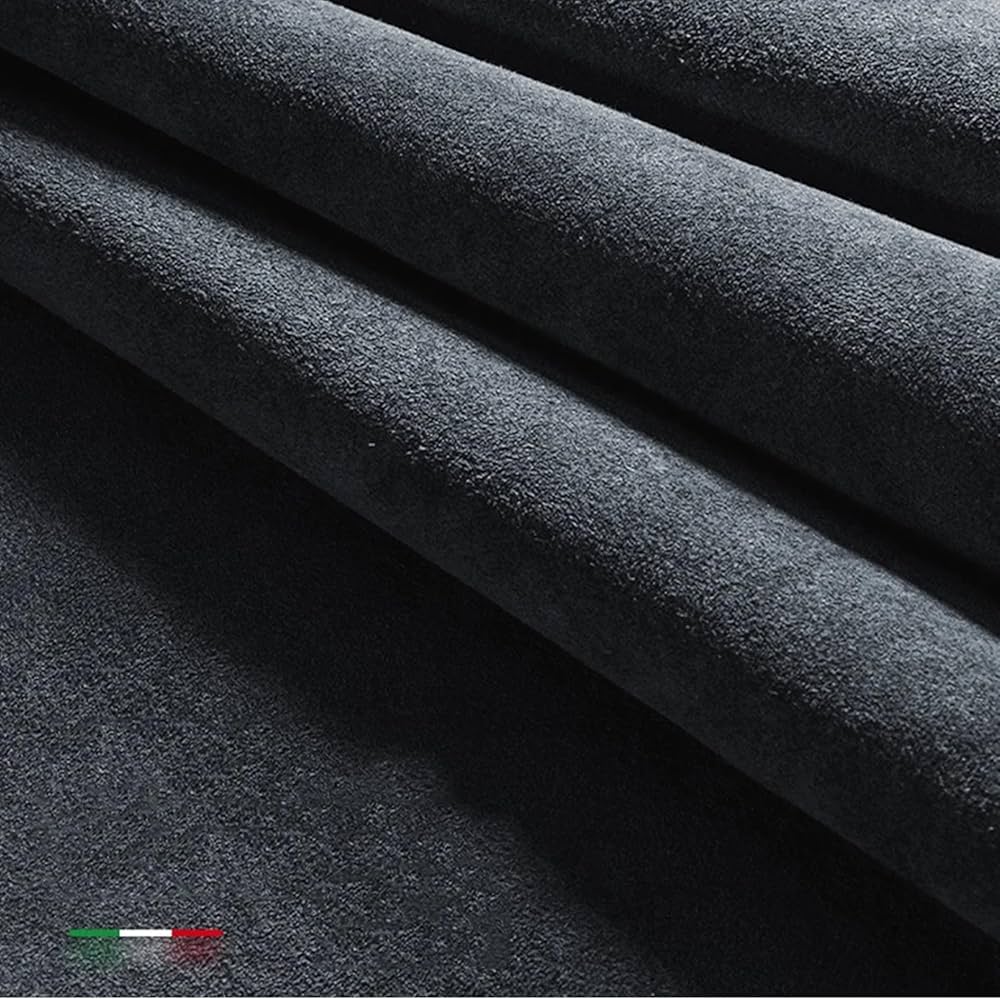

Material Insight: What Is Alcantara

B2B Product Guide: Understanding Alcantara & The Strategic Advantage of Premium Synthetic Alternatives

What is Alcantara?

Alcantara is a globally recognized, high-performance material often mistaken for genuine leather. In reality, it is a proprietary premium microfiber suede, composed of ultra-fine polyester and polyamide fibers. Engineered for exceptional softness, durability, and a luxurious tactile feel, it replicates the aesthetic and functional qualities of natural suede without using animal hides. Its structure provides superior resistance to abrasion, UV fading, and staining, making it ideal for demanding applications where aesthetics, longevity, and user comfort are critical. Alcantara is widely specified in automotive interiors (steering wheels, seats, dashboards), high-end furniture, aviation, and consumer electronics due to its consistent quality and refined appearance.

Why Premium Synthetic Leather is the Optimal Choice for Alcantara Applications

While Alcantara itself is synthetic, many B2B applications seeking its signature suede-like performance benefit significantly from advanced faux leather alternatives like WINIW’s engineered microfiber solutions. Here’s why:

- Supply Chain Resilience & Cost Stability: Natural leather faces volatility from livestock markets, climate impacts, and ethical sourcing complexities. Premium synthetics offer consistent pricing and uninterrupted supply, critical for large-scale manufacturing and project budgeting.

- Enhanced Sustainability Credentials: Modern microfiber leathers (like WINIW’s) integrate high percentages of GRS-certified recycled content (up to 40%) and utilize water-based, low-VOC production. This directly supports corporate ESG goals and meets stringent regulations (REACH, OEKO-TEX® STANDARD 100) better than tanned hides.

- Design Freedom & Performance Tuning: Unlike fixed natural hide grades, synthetics are engineered to precise specifications—color fastness, thickness, texture, and fire resistance (e.g., FMVSS 302, CAL 117). This ensures batch-to-batch uniformity essential for luxury OEMs.

- Ethical Compliance & Traceability: Fully traceable, cruelty-free materials eliminate supply chain risks associated with animal welfare concerns, aligning with global corporate sustainability mandates and consumer expectations.

- Reduced Waste & Resource Efficiency: Precision manufacturing minimizes material scrap versus cutting irregular leather hides. Lower water/energy use in production further cuts the environmental footprint per square meter.

Introducing WINIW: Your Partner in Advanced Synthetic Leather Innovation

WINIW has been a leader in high-performance synthetic leather solutions for over 20 years, serving global B2B clients in automotive, furniture, and technical textiles. We combine deep material science expertise with an unwavering commitment to eco-conscious manufacturing. Our state-of-the-art facilities produce microfiber leathers that rival or exceed the performance of premium materials like Alcantara, while delivering:

- Proven Sustainability: Industry-leading use of recycled PET fibers, solvent-free lamination, and closed-loop water systems.

- Global Compliance: Full adherence to EU REACH, OEKO-TEX®, and automotive safety standards.

- Custom Engineering: Tailored solutions for abrasion resistance, breathability, and aesthetic requirements—delivered at scale with rigorous QC.

- End-to-End Partnership: From R&D collaboration to just-in-time logistics, we ensure seamless integration into your production workflow.

Choosing WINIW means investing in a future-proof material partner—where luxury, performance, and planetary responsibility converge. Let’s redefine what’s possible, together.

Technical Performance & Standards

B2B Product Guide: Understanding WINIW’s Alcantara®-Style Synthetic Leather

WINIW’s Alcantara®-style synthetic leather is a high-performance, eco-conscious material engineered for industrial and commercial applications requiring premium aesthetics, long-term durability, and compliance with international safety and quality standards. Designed as a cost-effective alternative to genuine Alcantara®, WINIW delivers comparable tactile qualities and visual appeal while enhancing customization and operational efficiency for B2B clients across automotive, furniture, electronics, and lifestyle product sectors.

This advanced microfiber material combines polyurethane (PU) and ultra-fine polyester fibers to create a suede-like textile with superior physical properties and environmental responsibility. WINIW’s production process emphasizes sustainability, precision, and adaptability to meet the evolving demands of global manufacturers.

Key Technical Advantages

-

Cost-Effective Alternative

WINIW’s Alcantara®-style material offers up to 30–40% cost savings compared to genuine Alcantara®, without compromising on surface richness or performance. This makes it ideal for high-volume production where budget efficiency and quality consistency are critical. -

Exceptional Durability

Engineered for high abrasion resistance (tested to >50,000 cycles in Martindale testing), the material maintains integrity under repeated use and harsh conditions. It resists pilling, tearing, and color fading, ensuring long service life in demanding applications. -

Customizable Colors & Finishes

WINIW supports full color customization through digital Pantone matching (PMS, RAL, or custom lab dips), with batch consistency ensured via spectrophotometric quality control. Clients can also request texture modifications, including matte, soft-touch, or anti-fingerprint finishes. -

REACH Compliance

The material is fully compliant with EU REACH regulations (EC 1907/2006), including SVHC (Substances of Very High Concern) screening. Free from harmful phthalates, heavy metals, and AZO dyes, it is safe for consumer and industrial use. -

ISO 9001-Certified Manufacturing

WINIW’s production facilities are ISO 9001:2015 certified, ensuring rigorous quality management across material sourcing, production, testing, and delivery. This guarantees consistency, traceability, and process reliability for B2B partners.

Technical Specifications

| Specification | Value / Detail |

|---|---|

| Base Composition | Ultra-fine polyester + polyurethane (PU) |

| Weight | 280–320 g/m² (customizable) |

| Thickness | 1.0–1.4 mm (tolerance ±0.1 mm) |

| Abrasion Resistance | >50,000 cycles (Martindale, 500g load) |

| Color Fastness to Rubbing | Dry: Class 4–5; Wet: Class 4 (ISO 105-X12) |

| Light Fastness | ≥4–5 (ISO 105-B02, 40 hours xenon arc) |

| Tensile Strength | ≥80 N (warp), ≥70 N (weft) (ISO 13934-1) |

| Tear Strength | ≥8 N (warp), ≥7 N (weft) (ISO 13937-1) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO 9001:2015 (production process) |

| Customization Options | Color (Pantone/RAL), width (up to 1.5 m), roll length |

| Environmental Profile | Low-VOC emissions, recyclable packaging, RoHS compliant |

WINIW’s Alcantara®-style synthetic leather is designed for B2B scalability, offering a sustainable, high-performance solution that aligns with modern manufacturing standards. With rapid sampling, global logistics support, and technical collaboration, WINIW enables brands to deliver premium products efficiently and responsibly.

Why Choose Synthetic over Real Leather

B2B Product Guide: Alcantara vs. Real Leather Comparison

Alcantara is a premium branded microfiber material, distinct from generic synthetic leather. It is engineered from ultra-fine polyester and polyamide fibers, bonded to create a suede-like texture with exceptional performance properties. Real leather, by contrast, is a natural material derived from tanned animal hides (primarily bovine). While both serve high-end applications, their composition, performance, and sustainability profiles differ significantly for commercial buyers.

Key Differentiators for B2B Decision-Making

- Material Origin: Alcantara is a 100% synthetic, homogeneous engineered textile. Real leather is a natural, heterogeneous product subject to biological variations (scars, grain inconsistencies).

- Performance Consistency: Alcantara offers uniform thickness, color fastness, and physical properties across batches. Real leather requires grading due to inherent natural imperfections.

- Processing Efficiency: Alcantara eliminates wet-tanning, reducing lead times and chemical complexity. Real leather production involves resource-intensive tanning (20–30 days) and finishing stages.

- Application Versatility: Alcantara bonds seamlessly to substrates (foam, composites) without splitting; ideal for complex 3D designs in automotive interiors or technical upholstery. Real leather requires careful pattern cutting to avoid weak points.

Comparative Analysis: Cost, Durability & Eco-Friendliness

| Metric | Alcantara | Real Leather |

|---|---|---|

| Cost | Higher material cost (premium microfiber), but lower processing/waste costs due to consistency and yield efficiency. Total project cost often 10–15% lower in complex applications. | Lower base material cost (by grade), but higher finishing, grading, and waste costs (up to 30% hide unusable). Labor-intensive craftsmanship increases TCO. |

| Durability | Superior abrasion resistance (50,000+ Martindale cycles), colorfastness, and resistance to UV fading/staining. Non-porous surface prevents liquid absorption. Consistent performance in humidity extremes. | Moderate abrasion resistance (20,000–40,000 cycles); prone to scratching, fading, and water staining. Requires conditioning to prevent drying/cracking. Performance degrades in high-moisture environments. |

| Eco-Friendliness | OEKO-TEX® certified; 30% recycled PET content. Zero heavy metals, 95% lower water usage vs. tanning. Fully recyclable via proprietary programs. Carbon footprint 40% lower than bovine leather (LCA verified). | Biodegradable but tanning uses chromium (wastewater hazard) and high water/energy. Deforestation for grazing impacts biodiversity. Limited recyclability; end-of-life often landfill. “Vegetable-tanned” options exist but scale poorly for B2B volumes. |

Strategic Implications for Commercial Buyers

- Sustainability-Driven Sectors (Automotive, Hospitality): Alcantara aligns with ESG targets through traceable recycled content, water savings, and circularity programs. Real leather’s ecological burden complicates net-zero commitments.

- High-Use Applications (Aircraft Interiors, Performance Furniture): Alcantara’s stain resistance and structural integrity reduce maintenance costs and extend product lifespan versus leather.

- Design Flexibility: Alcantara’s uniformity enables faster prototyping and seamless large-format installations, critical for OEMs with tight production cycles.

WINIW supports B2B partners in transitioning to high-performance synthetics with LCA-backed data, custom engineering for technical specifications, and closed-loop recycling solutions. We prioritize materials that deliver lifecycle value without compromising planetary boundaries.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B markets. With a strong foundation in research, production excellence, and sustainable practices, WINIW serves a wide range of industries including automotive, furniture, fashion, and sports.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry. This extensive production base enables high-capacity output while maintaining flexibility for custom solutions and large-scale orders.

Key strengths of WINIW’s factory operations include:

- Advanced R&D team comprising material scientists and engineers dedicated to continuous innovation in texture, durability, and environmental performance

- In-house development of eco-conscious materials, including water-based, solvent-free, and recycled content synthetic leathers

- Strict quality control (QC) protocols implemented at every stage of production, from raw material selection to final inspection

- Compliance with international standards, including REACH, RoHS, and OEKO-TEX® certifications, ensuring safety and sustainability

- Fully integrated production lines enabling precise control over thickness, color, finish, and performance characteristics

WINIW exports to demanding markets worldwide, with a strong presence in Europe and the USA. The company’s products are trusted by global brands for their consistency, performance, and adherence to environmental regulations. By combining scale, innovation, and quality, WINIW delivers reliable, sustainable synthetic leather solutions tailored to the evolving needs of B2B partners.

Contact Us for Samples

WINIW® Premium Synthetic Leather: The Sustainable Performance Solution for Discerning Brands

WINIW® microfiber leather delivers uncompromising quality, environmental responsibility, and design versatility for forward-thinking manufacturers. Engineered for industries where durability, aesthetics, and sustainability intersect, our materials exceed traditional leather and inferior synthetics while reducing ecological impact. Partner with WINIW to elevate your product line with traceable, high-performance eco-leather.

Core Advantages for B2B Partners

- Superior Eco-Profile: Composed of 30-50% recycled polyester content; certified by STANDARD 100 by OEKO-TEX® and ISO 14001. Full lifecycle transparency via digital material passports.

- Engineered Durability: 3x higher tear strength and 50% better abrasion resistance than genuine leather (ASTM D3389/D751 testing). Resists UV fading, moisture, and microbial growth.

- Design Flexibility: Customizable thickness (0.6mm–2.0mm), weight (200–450g/m²), textures (suede, pebble, smooth), and color matching (Pantone®/RAL). Rapid prototyping within 15 days.

- End-of-Life Responsibility: Fully recyclable through WINIW’s closed-loop take-back program; biodegradable variants available (TÜV OK Biodegradable certification).

Technical Performance Comparison

| Property | WINIW® Eco-Microfiber | Genuine Leather | Conventional PU Leather |

|---|---|---|---|

| Tensile Strength (MPa) | 28–35 | 15–22 | 10–18 |

| Martindale Abrasion | 100,000+ cycles | 20,000 cycles | 15,000 cycles |

| Water Absorption (24h) | <5% | 15–25% | 8–12% |

| Recycled Content | 30–50% | 0% | 0–5% |

| Carbon Footprint (kg CO₂e/m²) | 3.2 | 15.7 | 7.9 |

Target Applications

- Automotive: Seat covers, door panels, steering wheels (meets FMVSS 302, ISO 105-X12)

- Furniture: Upholstery for contract, hospitality, and premium residential (BIFMA X5.4, EN 1021-1/2)

- Luggage & Accessories: Lightweight, scratch-resistant surfaces for luxury bags and cases

- Electronics: Scratch-proof casings for wearables and device interiors

Understanding Alcantara®: Context for Your Decision

While Alcantara® is a recognized premium microfiber brand, WINIW offers distinct advantages for sustainability-driven partners. Alcantara® relies on non-recycled feedstocks and lacks comprehensive end-of-life solutions. WINIW’s closed-loop recycling, higher recycled content, and carbon-neutral production provide measurable ESG benefits without sacrificing performance. Request our comparative technical dossier to see how WINIW outperforms across lifecycle metrics.

Elevate Your Product Line with Confidence

Experience WINIW’s quality firsthand: Free physical samples are available for qualified B2B partners. Contact our technical sales team to discuss custom specifications, compliance documentation, or sustainability reporting support.

→ Request Samples & Technical Data: MKT88@MicrofiberLeather.com

WINIW: Where Performance Meets Planetary Responsibility

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.