Introduction: Navigating the Global Market for custom leather interior for trucks

In the ever-evolving global market, sourcing custom leather interiors for trucks presents a unique set of challenges for international B2B buyers. With a growing demand for luxury and comfort in commercial vehicles, companies must navigate a complex landscape of suppliers, quality standards, and pricing strategies. This guide aims to equip you with the insights needed to make informed decisions about custom leather interiors, ensuring that your fleet not only meets but exceeds customer expectations.

We delve into various types of leather upholstery options, exploring applications across different truck models and configurations. Whether you’re looking for premium, performance-grade materials or budget-friendly alternatives, we cover the spectrum of choices available. Additionally, we provide a framework for vetting suppliers, assessing their capabilities, and understanding the intricacies of pricing—critical factors that can significantly impact your bottom line.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—this comprehensive guide is an essential resource. By highlighting best practices and actionable strategies, we empower you to navigate the complexities of sourcing custom leather interiors, enabling you to enhance your fleet’s appeal while ensuring durability and comfort. Prepare to elevate your vehicle interiors and strengthen your competitive edge in the market.

Table Of Contents

- Top 7 Custom Leather Interior For Trucks Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather interior for trucks

- Understanding custom leather interior for trucks Types and Variations

- Key Industrial Applications of custom leather interior for trucks

- 3 Common User Pain Points for ‘custom leather interior for trucks’ & Their Solutions

- Strategic Material Selection Guide for custom leather interior for trucks

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather interior for trucks

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather interior for trucks’

- Comprehensive Cost and Pricing Analysis for custom leather interior for trucks Sourcing

- Alternatives Analysis: Comparing custom leather interior for trucks With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather interior for trucks

- Navigating Market Dynamics and Sourcing Trends in the custom leather interior for trucks Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather interior for trucks

- Strategic Sourcing Conclusion and Outlook for custom leather interior for trucks

- Important Disclaimer & Terms of Use

Understanding custom leather interior for trucks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Leather Interior Kits | Complete replacement of factory upholstery, tailored fit | Automotive dealerships, fleet services | Pros: Premium feel, long-lasting durability. Cons: Higher initial investment. |

| Leather Trimmed Seat Covers | Leather covering over existing seats, easier installation | Aftermarket retailers, custom shops | Pros: Cost-effective, quick installation. Cons: Less durable than full kits. |

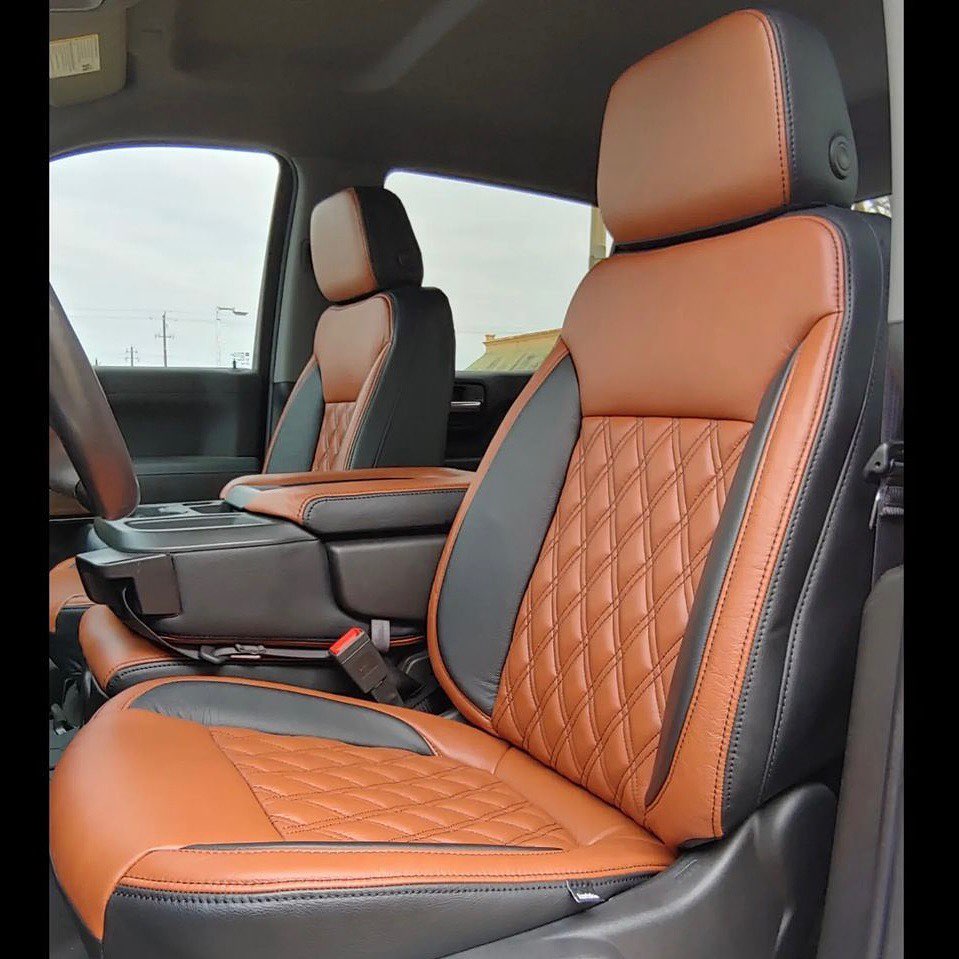

| Two-Tone Leather Interiors | Combination of different leather colors/textures | Luxury vehicle customizers | Pros: Aesthetic appeal, customization options. Cons: Potential for higher costs. |

| Heated and Ventilated Leather Seats | Integrated temperature control features | High-end vehicle manufacturers, fleet | Pros: Enhanced comfort, premium feature. Cons: Requires additional installation expertise. |

| Exotic Leather Options | Use of rare and premium leather types | Luxury automotive brands, custom shops | Pros: Unique appearance, high value. Cons: Limited availability, high price point. |

What Are Full Leather Interior Kits and Their Suitability for B2B Buyers?

Full leather interior kits provide a comprehensive solution for upgrading a truck’s interior by completely replacing the factory upholstery. This option is ideal for automotive dealerships and fleet services looking to enhance the vehicle’s value and appeal. Buyers should consider the durability and luxurious feel of full leather, which can significantly increase resale value. However, the initial investment is higher than other options, making it essential to evaluate the long-term benefits.

Illustrative image related to custom leather interior for trucks

How Do Leather Trimmed Seat Covers Compare in Terms of Cost and Installation?

Leather trimmed seat covers are designed to fit over existing seats, offering a more cost-effective and less labor-intensive solution for businesses. This option is popular among aftermarket retailers and custom shops that want to provide customers with a quick upgrade. While these covers are easier to install and less expensive, they may not offer the same level of durability as full kits. B2B buyers should weigh the immediate cost savings against potential long-term wear and tear.

Why Choose Two-Tone Leather Interiors for Customization?

Two-tone leather interiors allow for unique customization by combining different colors and textures. This option appeals to luxury vehicle customizers who want to create a distinctive look for their clients. The aesthetic appeal of two-tone designs can attract buyers looking for personalized vehicles. However, it’s important to consider that these options can sometimes come at a premium cost, which may affect budget-conscious projects.

What Are the Benefits of Heated and Ventilated Leather Seats in Trucks?

Heated and ventilated leather seats add a level of comfort that can significantly enhance the driving experience. This feature is particularly attractive to high-end vehicle manufacturers and fleet operators looking to provide added value. While the installation requires specialized knowledge, the investment can result in higher customer satisfaction and potentially better resale value. B2B buyers should ensure that their installation teams are trained in these advanced features.

How Do Exotic Leather Options Enhance the Value of Custom Interiors?

Exotic leather options offer unique and luxurious materials that can elevate a truck’s interior beyond standard offerings. This choice is often pursued by luxury automotive brands and custom shops aiming to provide exclusive products. While the appeal of exotic leathers can justify a higher price point, buyers must also consider availability and sourcing challenges. Such options can significantly enhance the perceived value of a vehicle, making them a worthwhile investment for the right clientele.

Illustrative image related to custom leather interior for trucks

Key Industrial Applications of custom leather interior for trucks

| Industry/Sector | Specific Application of custom leather interior for trucks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Fleet vehicle upgrades for comfort and branding | Enhances driver comfort, reduces fatigue, and promotes company branding through custom interiors | Consider durability, maintenance requirements, and customization options to meet brand identity |

| Construction & Heavy Machinery | Custom interiors for utility trucks used on job sites | Improves comfort for workers, increasing productivity and job satisfaction | Look for weather-resistant materials and ease of cleaning options |

| Luxury & Executive Transport | High-end interiors for chauffeur-driven vehicles | Provides a premium experience for clients, enhancing company image and client retention | Focus on luxury finishes, advanced features (like heating/cooling), and bespoke design options |

| Agriculture & Farming | Custom interiors for agricultural trucks and equipment | Increases operator comfort during long hours, leading to better focus and efficiency | Ensure materials withstand harsh conditions and offer ergonomic support |

| Emergency Services | Custom interiors for emergency response vehicles | Improves response time and comfort for personnel during operations | Prioritize safety features, ease of cleaning, and durability under stress |

How is Custom Leather Interior for Trucks Used in the Transportation & Logistics Sector?

In the transportation and logistics sector, custom leather interiors are utilized to upgrade fleet vehicles, providing drivers with enhanced comfort during long hours on the road. This upgrade not only reduces fatigue but also serves as a branding opportunity, allowing companies to showcase their identity through custom designs. International buyers should consider the durability and maintenance of materials, ensuring that they can withstand various climates and heavy use.

What Benefits Does Custom Leather Interior Offer in Construction & Heavy Machinery?

In the construction industry, utility trucks equipped with custom leather interiors significantly improve worker comfort, which can lead to increased productivity and job satisfaction. These interiors are designed to be durable and easy to clean, addressing the unique challenges faced on job sites. Buyers in this sector should prioritize weather-resistant materials that can endure rugged conditions while still providing a comfortable workspace.

How Does Custom Leather Interior Enhance Luxury & Executive Transport?

For luxury and executive transport services, custom leather interiors create a premium experience for clients. These interiors are meticulously crafted to reflect sophistication and comfort, thereby enhancing the company’s image and promoting client retention. B2B buyers should focus on high-quality finishes, advanced features like heating and cooling, and bespoke design options that cater to the specific preferences of their clientele.

Illustrative image related to custom leather interior for trucks

Why is Custom Leather Interior Important in Agriculture & Farming?

In the agriculture sector, custom interiors in trucks and equipment are essential for increasing operator comfort during extended periods of use. This comfort translates to better focus and efficiency in operations. Buyers should ensure that the selected materials can withstand harsh agricultural conditions while providing ergonomic support to reduce strain during long hours.

What Role Does Custom Leather Interior Play in Emergency Services?

Custom leather interiors in emergency response vehicles are crucial for improving both response time and comfort for personnel. These interiors must be designed with safety features in mind, ensuring that they can endure the high-stress environment typical of emergency situations. Key considerations for international buyers include the ease of cleaning and maintenance, as well as the durability of materials under pressure.

3 Common User Pain Points for ‘custom leather interior for trucks’ & Their Solutions

Scenario 1: Sourcing High-Quality Materials for Custom Leather Interiors

The Problem: B2B buyers often encounter challenges when sourcing high-quality leather for truck interiors. Many suppliers may not meet the desired standards for durability, comfort, or aesthetic appeal, leading to dissatisfaction among end-users. In regions like Africa and South America, where local supply chains may be less developed, buyers may find it difficult to verify the quality of materials before purchase. This can result in increased costs due to returns, rework, or even potential damage to the vehicle’s reputation if the interiors do not perform as expected.

The Solution: To mitigate these risks, buyers should prioritize establishing relationships with reputable suppliers who provide detailed specifications and samples of their leather products. Look for suppliers that offer certifications regarding the quality of their materials, such as durability tests or environmental sustainability credentials. Additionally, consider investing in a quality assurance process that includes on-site inspections or third-party evaluations. Utilizing a detailed material sourcing checklist can streamline this process, ensuring that all necessary quality parameters are met before finalizing orders.

Scenario 2: Customization Complexity in Design and Fit

The Problem: Customization can often become a double-edged sword for B2B buyers. While offering a range of design options is appealing, the complexity involved in ensuring the correct fit and design for various truck models can lead to significant headaches. Inconsistent dimensions, incompatible styles, or a lack of clear communication about customer requirements can cause delays and frustrations, impacting the buyer’s ability to meet client deadlines.

Illustrative image related to custom leather interior for trucks

The Solution: To navigate this complexity, it is crucial to implement a robust design specification process. Buyers should collaborate closely with manufacturers to create detailed design briefs that include exact measurements, preferred styles, and material choices. Utilizing advanced design software can help visualize the final product and identify potential fit issues before production begins. Additionally, a clear communication protocol should be established to handle any changes or adjustments during the design phase, ensuring that all parties are aligned and minimizing the risk of errors.

Scenario 3: Installation Challenges and Aftercare

The Problem: Once the custom leather interiors are sourced and delivered, the installation phase can present its own set of challenges. Many B2B buyers may not have access to skilled technicians who can ensure a professional installation, leading to subpar results. Moreover, inadequate aftercare instructions can result in premature wear and tear, diminishing the product’s lifespan and customer satisfaction.

The Solution: To address installation challenges, buyers should partner with manufacturers that provide comprehensive installation training and support. This could include access to instructional videos, detailed manuals, or even on-site training sessions for local technicians. Furthermore, suppliers should offer clear aftercare guidelines tailored to the specific leather type used, including cleaning protocols and maintenance tips. By ensuring that installation and aftercare processes are well-defined and supported, buyers can enhance the longevity and performance of their custom leather interiors, ultimately leading to higher customer satisfaction and repeat business.

Strategic Material Selection Guide for custom leather interior for trucks

When selecting materials for custom leather interiors in trucks, it is essential to consider various factors such as durability, aesthetic appeal, and compliance with international standards. Here, we analyze four common materials used in custom leather interiors, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What are the Key Properties of Genuine Leather for Truck Interiors?

Genuine leather is renowned for its luxurious feel and durability. It offers excellent temperature regulation, making it comfortable in both hot and cold climates. Additionally, genuine leather has a high resistance to wear and tear, which is crucial for truck interiors that undergo heavy use.

Pros: The primary advantages of genuine leather include its longevity, aesthetic appeal, and ability to improve with age. It can also be treated to enhance its resistance to stains and moisture.

Cons: However, genuine leather comes at a higher cost compared to synthetic alternatives. It requires regular maintenance to preserve its appearance and prevent cracking.

Impact on Application: Genuine leather is suitable for high-end truck models where luxury is a selling point. Buyers in regions with extreme weather conditions should ensure that the leather is treated for UV and moisture resistance.

Considerations for International Buyers: Compliance with international standards like ASTM for leather quality is crucial. Buyers from Europe may prefer leather sourced from EU-compliant tanneries, while those in Africa and South America might prioritize local sourcing to reduce costs.

Illustrative image related to custom leather interior for trucks

How Does Synthetic Leather Compare for Custom Truck Interiors?

Synthetic leather, often referred to as faux leather or vegan leather, is a popular alternative to genuine leather. It is made from polyurethane (PU) or polyvinyl chloride (PVC), offering a more cost-effective solution.

Pros: Synthetic leather is generally more affordable, easier to clean, and resistant to stains and moisture. It is also available in a wide range of colors and textures, allowing for greater customization.

Cons: The primary drawback is its lower durability compared to genuine leather. Over time, synthetic leather can crack or peel, especially in high-temperature environments.

Impact on Application: Synthetic leather is ideal for budget-conscious buyers or those seeking a variety of design options. However, it may not be suitable for high-end truck models where premium materials are expected.

Considerations for International Buyers: Buyers should verify that synthetic leather meets standards for chemical emissions, particularly in regions like Europe, where regulations are stringent.

What Role Does Alcantara Play in Custom Truck Interiors?

Alcantara is a synthetic material that mimics suede and is often used in luxury vehicles. It is made from polyester and polyurethane, providing a soft touch and a unique aesthetic.

Pros: Alcantara is lightweight, durable, and offers excellent breathability. It is also resistant to fading and staining, making it suitable for truck interiors that require a stylish yet practical solution.

Illustrative image related to custom leather interior for trucks

Cons: The main disadvantage of Alcantara is its cost, which can be comparable to genuine leather. Additionally, it may require special cleaning products to maintain its appearance.

Impact on Application: Alcantara is particularly appealing for luxury truck models, providing a high-end look without the drawbacks of genuine leather.

Considerations for International Buyers: Buyers should ensure that Alcantara meets the necessary fire safety standards, especially in markets with strict regulations like Germany.

How Does Vinyl Compare as a Material for Truck Interiors?

Vinyl is a synthetic material that is often used as a budget-friendly alternative for truck interiors. It is made from PVC and is known for its versatility.

Illustrative image related to custom leather interior for trucks

Pros: Vinyl is highly durable, easy to clean, and resistant to moisture and stains. It is also available in various colors and textures, making it a flexible choice for customization.

Cons: The downside of vinyl is its lack of breathability, which can lead to discomfort in extreme temperatures. Additionally, it may not provide the same luxurious feel as leather or Alcantara.

Impact on Application: Vinyl is suitable for fleet vehicles or trucks that undergo heavy use, where durability is prioritized over luxury.

Considerations for International Buyers: Buyers should check for compliance with international standards regarding chemical safety and emissions, particularly in regions with stringent environmental regulations.

Illustrative image related to custom leather interior for trucks

Summary of Material Selection for Custom Truck Interiors

| Material | Typical Use Case for custom leather interior for trucks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end trucks requiring luxury and durability | Luxurious feel and long-lasting | High cost and maintenance required | High |

| Synthetic Leather | Budget-friendly options for various truck models | Affordable and easy to maintain | Lower durability over time | Low |

| Alcantara | Luxury trucks needing a stylish, soft-touch material | Breathable and resistant to fading | Comparable cost to genuine leather | High |

| Vinyl | Fleet vehicles or heavy-use trucks | Durable and easy to clean | Lacks breathability and luxury feel | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions when selecting materials for custom leather interiors in trucks. By understanding the properties, advantages, and limitations of each material, buyers can choose the best options that meet their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather interior for trucks

What Are the Key Stages in the Manufacturing Process of Custom Leather Interiors for Trucks?

The manufacturing process for custom leather interiors in trucks typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the desired quality and aesthetic standards.

Material Preparation

The first step in the manufacturing process is selecting high-quality leather and other materials. Suppliers often source leather from reputable tanneries, ensuring it meets specific standards for durability, texture, and appearance. Once the materials are selected, they undergo preparation, which includes cutting to size and treating to enhance longevity and resistance to wear and tear. This stage may also involve applying dyes or finishes to achieve the desired color and texture.

Illustrative image related to custom leather interior for trucks

Forming

After material preparation, the next phase is forming. This involves creating patterns and templates that match the specific dimensions of the truck’s interior. Advanced technologies such as CAD (Computer-Aided Design) are often employed to ensure precision. The leather is then shaped using techniques such as die-cutting or laser cutting, which allow for intricate designs and perfect fits.

Assembly

The assembly stage is where the various components come together. Skilled artisans or automated systems stitch the leather pieces, ensuring that seams are strong and aesthetically pleasing. This stage may include adding features like padding, heating elements, or ventilation systems, depending on the customization options chosen by the buyer. Quality control checkpoints are critical during assembly to catch any defects early.

Finishing

The final stage is finishing, which involves inspecting the assembled product for any imperfections. This may include applying protective coatings or treatments to enhance the leather’s durability. The finished product is then prepared for shipping, often including a thorough cleaning and packaging process to ensure it arrives in pristine condition.

Illustrative image related to custom leather interior for trucks

How Is Quality Assurance Implemented in the Custom Leather Interior Manufacturing Process?

Quality assurance is paramount in the manufacturing of custom leather interiors, ensuring that the products meet both international standards and customer expectations. The quality assurance process typically involves several key components.

International Standards and Certifications

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines a framework for consistent quality management systems. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for certain automotive applications can enhance credibility. These certifications help ensure that the materials used and the manufacturing processes are of high quality.

Quality Control Checkpoints

Quality control (QC) is integral to the manufacturing process, with several checkpoints established throughout. Incoming Quality Control (IQC) checks the materials upon arrival, ensuring they meet specified criteria. In-Process Quality Control (IPQC) monitors the manufacturing process to catch defects early, while Final Quality Control (FQC) involves a comprehensive review of the completed product before shipping. These checkpoints help maintain high standards and reduce the risk of defects reaching the customer.

Common Testing Methods

Various testing methods are employed to ensure the quality and durability of the leather interiors. These may include tensile strength tests, colorfastness tests, and abrasion resistance tests. Manufacturers often conduct these tests in-house or through third-party labs to provide an unbiased assessment of product performance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps to ensure that suppliers meet high-quality standards.

Illustrative image related to custom leather interior for trucks

Supplier Audits

Conducting audits of potential suppliers can provide valuable insight into their manufacturing processes and quality control measures. Buyers can assess the supplier’s compliance with international standards, the effectiveness of their quality management systems, and their overall production capabilities.

Requesting Quality Reports

Buyers should not hesitate to request quality reports or certificates from suppliers. These documents can detail the quality assurance processes in place, including any third-party testing results. Comprehensive reports can help buyers make informed decisions and ensure they are partnering with reliable manufacturers.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can further enhance the verification process. These independent firms can conduct on-site inspections of the manufacturing facility, assess product quality at various stages, and provide unbiased reports to the buyer. This added layer of scrutiny can reassure buyers, particularly when dealing with international suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control that can differ significantly from local standards. Here are some key considerations:

Illustrative image related to custom leather interior for trucks

Understanding Regional Regulations

Different regions have varying regulations regarding automotive materials and safety standards. Buyers should familiarize themselves with these regulations to ensure compliance. For instance, European buyers may need to consider REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) compliance for materials used.

Cultural Considerations in Quality Expectations

Cultural differences can influence expectations regarding quality and craftsmanship. Buyers from regions with a strong focus on artisanal craftsmanship may prioritize different aspects of quality compared to those from regions that emphasize technological precision. Understanding these cultural nuances can aid in establishing better communication and expectations with suppliers.

Building Long-Term Relationships

Establishing long-term relationships with suppliers can enhance quality assurance. Regular communication and feedback loops can help ensure that suppliers remain aligned with the buyer’s quality expectations over time. Engaging in collaborative quality improvement initiatives can also foster a culture of quality and continuous improvement.

Illustrative image related to custom leather interior for trucks

In conclusion, the manufacturing processes and quality assurance measures for custom leather interiors in trucks are intricate and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with reliable manufacturers who can deliver high-quality products tailored to their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather interior for trucks’

To assist B2B buyers in sourcing custom leather interiors for trucks, this guide outlines essential steps for a successful procurement process. Whether you’re looking to enhance vehicle aesthetics, improve comfort, or increase resale value, following these steps will ensure that you make informed decisions that align with your business goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the custom leather interiors meet your requirements. Specify details such as the type of leather (e.g., genuine, synthetic, or exotic), color options, and any additional features like heating or ventilation. This clarity will help potential suppliers provide tailored solutions that meet your exact needs.

Illustrative image related to custom leather interior for trucks

Step 2: Conduct Market Research

Thorough market research is essential for understanding the landscape of custom leather suppliers. Identify key players in the industry and analyze their offerings, pricing structures, and customer reviews. This knowledge will empower you to make comparisons and select suppliers that align with your quality and budget expectations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct a thorough evaluation. Request detailed company profiles, including years in business, production capabilities, and client testimonials. Look for suppliers who have experience with your specific truck models and can demonstrate a history of successful projects within your region.

- Consider Certifications: Ensure that suppliers adhere to industry standards, which may include ISO certifications or compliance with environmental regulations. This ensures quality and sustainability in production.

Step 4: Request Samples

Requesting samples of leather materials is a critical step in the decision-making process. Physical samples allow you to assess the texture, color accuracy, and overall quality of the leather. Pay attention to the stitching and finish, as these details contribute significantly to the final product’s aesthetics and durability.

Step 5: Discuss Customization Options

Engage in discussions with suppliers about customization options available for your truck interiors. Inquire about design flexibility, such as color combinations, stitching patterns, and additional features. A supplier that offers extensive customization will enable you to create a unique interior that reflects your brand identity and meets customer preferences.

Illustrative image related to custom leather interior for trucks

Step 6: Review Installation Services

Confirm whether the supplier provides installation services or if you need to source a third-party installer. If installation is included, ensure that the technicians are trained and experienced in handling custom leather interiors. A well-installed interior will enhance the overall quality and longevity of the product.

- Warranty Information: Review warranty options offered by the supplier. A robust warranty can provide peace of mind, assuring you of the product’s durability and the supplier’s confidence in their workmanship.

Step 7: Finalize Terms and Negotiate Pricing

Once you have selected a supplier, finalize the procurement terms, including pricing, payment schedules, and delivery timelines. Be prepared to negotiate based on volume orders or long-term partnerships, which may lead to better pricing structures. Clear contract terms will help avoid misunderstandings and ensure a smooth transaction.

By following this structured approach, B2B buyers can effectively source high-quality custom leather interiors for trucks that meet their specific needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for custom leather interior for trucks Sourcing

What Are the Key Cost Components in Custom Leather Interior Sourcing for Trucks?

When sourcing custom leather interiors for trucks, it’s essential to understand the various cost components that contribute to the overall price. These typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of leather used significantly impacts costs. Options range from synthetic leather to premium exotic leathers. High-quality materials not only enhance durability but also elevate the aesthetic appeal, which can justify higher prices. Buyers should consider the trade-offs between cost and quality to align with their target market.

-

Labor: Skilled labor is required for the meticulous process of installing custom leather interiors. Labor costs can vary based on the complexity of the design and the expertise of the workforce. Regions with a high demand for skilled labor may see increased costs, while areas with a surplus may offer competitive pricing.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead and ultimately lower the price for buyers.

-

Tooling: Custom designs often necessitate specialized tools and equipment. The initial investment in tooling can be significant, but it is amortized over the production run. Buyers should inquire about tooling costs, especially for custom specifications, to understand their impact on pricing.

-

Quality Control (QC): Ensuring that the final product meets quality standards incurs additional costs. This includes inspections and testing, which are vital for maintaining a good reputation and minimizing returns.

-

Logistics: Shipping and handling costs can vary widely based on location and volume. International buyers should consider customs duties and tariffs, which can add to the total cost. Efficient logistics management can help mitigate these expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the margins within the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Custom Leather Interior Costs?

Several factors influence the pricing of custom leather interiors for trucks, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

Illustrative image related to custom leather interior for trucks

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit prices due to economies of scale. Buyers should explore minimum order quantities (MOQs) and consider consolidating orders to achieve cost savings.

-

Specifications/Customization: Highly customized designs will generally incur higher costs due to the additional labor and materials required. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Materials: The choice of leather type—whether standard, premium, or exotic—will significantly affect pricing. Buyers should assess their market’s preferences to select appropriate materials that balance quality and cost.

-

Quality/Certifications: Certifications related to material quality, environmental standards, and labor practices can influence pricing. Suppliers with certifications may charge a premium, but they also provide assurance of quality and compliance.

-

Supplier Factors: Supplier reputation, experience, and reliability play a crucial role in pricing. Established suppliers may charge more but often provide better quality and service, which can reduce long-term costs.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, which can significantly affect the total cost of ownership.

What Are Some Tips for Negotiating and Ensuring Cost-Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost-efficiency and effective negotiation.

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and quality standards. Benchmark against competitors to identify reasonable pricing.

-

Negotiate Terms: Don’t hesitate to negotiate terms, including price, payment schedules, and delivery timelines. Establishing a good relationship with suppliers can lead to better deals.

-

Total Cost of Ownership (TCO): Consider not just the upfront costs but also the TCO, which includes maintenance, durability, and potential resale value. A higher initial investment in quality materials can lead to lower long-term costs.

-

Understand Local Regulations: Be aware of local regulations regarding imports and tariffs. This knowledge can help in negotiating with suppliers and understanding the total cost implications.

-

Flexibility in Specifications: If possible, be flexible with design specifications to allow for cost-effective alternatives without compromising quality.

By thoroughly analyzing these cost components, price influencers, and implementing strategic negotiation tips, B2B buyers can make informed decisions when sourcing custom leather interiors for trucks.

Alternatives Analysis: Comparing custom leather interior for trucks With Other Solutions

Exploring Alternatives to Custom Leather Interiors for Trucks

When considering enhancements for truck interiors, custom leather upholstery stands out for its luxury and durability. However, several alternative solutions exist that can provide similar benefits, each with its unique advantages and drawbacks. This analysis compares custom leather interiors against two viable alternatives: synthetic leather upholstery and traditional fabric seat covers.

| Comparison Aspect | Custom Leather Interior For Trucks | Synthetic Leather Upholstery | Traditional Fabric Seat Covers |

|---|---|---|---|

| Performance | High durability and luxury feel | Good durability, less expensive | Moderate durability, more prone to wear |

| Cost | Higher initial investment | Mid-range cost, budget-friendly | Lowest cost, affordable option |

| Ease of Implementation | Requires professional installation | Easier DIY installation possible | Simple installation; often slip-on |

| Maintenance | Requires regular conditioning | Low maintenance, easy to clean | Requires regular cleaning and care |

| Best Use Case | Luxury vehicles and long-term investment | Budget-conscious upgrades or rentals | Temporary solutions or older vehicles |

What Are the Benefits and Drawbacks of Synthetic Leather Upholstery?

Synthetic leather, often referred to as vegan leather, is a cost-effective alternative to custom leather interiors. Its affordability makes it attractive to budget-conscious businesses, particularly in regions where cost is a significant factor. Additionally, synthetic leather is generally easier to maintain, requiring minimal care compared to genuine leather. However, it may lack the luxury feel and durability of real leather, often showing wear and tear more quickly. For businesses seeking a balance between aesthetics and cost, synthetic leather can be an effective solution.

Illustrative image related to custom leather interior for trucks

How Do Traditional Fabric Seat Covers Compare?

Traditional fabric seat covers are the most economical option among the alternatives. They are easy to install, often designed as slip-on covers that can be fitted without professional help, making them ideal for businesses looking to upgrade older vehicles quickly. However, they typically offer lower durability and can wear out faster than both leather and synthetic options. They also require more frequent cleaning to maintain their appearance and may not provide the same level of comfort or aesthetic appeal as leather alternatives. This option is best suited for those who need a temporary or budget-friendly solution.

Making the Right Choice for Your Truck Interior Needs

When selecting the right interior solution for your trucks, consider the specific needs of your business and your target market. Custom leather interiors are ideal for companies wanting to project a premium image or provide high-end services, especially in industries like luxury transport or hospitality. On the other hand, synthetic leather and traditional fabric seat covers offer practical alternatives for businesses focused on cost efficiency or temporary solutions. By evaluating the performance, cost, implementation ease, maintenance requirements, and best use cases of each option, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for custom leather interior for trucks

What Are the Essential Technical Properties of Custom Leather Interiors for Trucks?

When sourcing custom leather interiors for trucks, B2B buyers should consider several key technical properties that affect both the quality and performance of the products. Understanding these specifications can ensure that the final product meets industry standards and customer expectations.

-

Material Grade

The grade of leather used in upholstery is a critical factor. Higher-grade leathers, such as full-grain or top-grain, offer superior durability, breathability, and aesthetics compared to lower grades like corrected grain. For B2B buyers, investing in higher-grade materials can lead to fewer returns and increased customer satisfaction, as these leathers are more resistant to wear and aging. -

Tolerance Levels

Tolerance refers to the allowable variation in the dimensions of leather cut pieces. In the context of custom interiors, precise tolerances ensure that the upholstery fits perfectly within the vehicle’s framework. For manufacturers, maintaining tight tolerances is essential to avoid costly rework and to uphold the reputation for quality. -

Fire Resistance Rating

Compliance with fire safety standards is a non-negotiable aspect of custom interiors, especially in commercial trucks. The fire resistance rating indicates how well the material can withstand ignition and how quickly it burns. For B2B buyers, understanding these ratings is crucial to meet safety regulations and protect their end customers. -

UV Stability

UV stability measures how well the leather can resist fading and degradation from sunlight exposure. Given that trucks are often exposed to harsh outdoor conditions, selecting materials with high UV resistance can extend the life of the interior and maintain its visual appeal. This property is especially important for buyers in regions with intense sunlight. -

Permeability

Permeability indicates how breathable the leather is, affecting comfort and moisture management. High permeability allows for better air circulation, which is essential in preventing heat buildup and moisture retention. Buyers should prioritize materials that strike a balance between durability and comfort, particularly for long-haul truck applications.

What Are the Common Trade Terms Used in Custom Leather Interiors for Trucks?

Understanding industry jargon can facilitate smoother communication between B2B buyers and suppliers, ensuring clarity in negotiations and transactions.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in another company’s end product. In the context of custom leather interiors, understanding OEM specifications helps buyers ensure that the new upholstery will fit seamlessly with existing vehicle designs. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ is crucial for budget planning and inventory management, especially when considering bulk purchases for fleet upgrades. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Including detailed specifications in an RFQ can lead to more accurate and competitive pricing, making it an essential tool for B2B buyers in sourcing custom leather interiors. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is important for buyers to understand shipping costs and risk allocation. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is vital for planning and ensuring that customer demands are met without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their business goals and customer needs, ultimately enhancing the value of their offerings in the competitive market of custom leather interiors for trucks.

Navigating Market Dynamics and Sourcing Trends in the custom leather interior for trucks Sector

What Are the Current Trends in the Custom Leather Interior for Trucks Market?

The custom leather interior for trucks market is witnessing significant growth, driven by increasing consumer demand for vehicle personalization and enhanced comfort. Global buyers are particularly focused on premium materials that not only elevate the aesthetic appeal of vehicles but also provide durability and easy maintenance. Key trends include the rise of online configurators that allow customers to design their interiors with precision, offering a variety of colors, textures, and stitching options. This shift towards customization is supported by advancements in B2B technology, such as augmented reality (AR) and virtual reality (VR), enabling potential buyers to visualize their selected designs in real-time.

In regions like Africa, South America, the Middle East, and Europe, emerging markets are seeing a surge in demand for custom interiors, especially among affluent consumers seeking luxury and comfort in their vehicles. The European market, particularly in countries like Germany, is leading the charge with an emphasis on high-quality materials and craftsmanship. Meanwhile, Brazil and South Africa are experiencing a growing trend of local manufacturers entering the market, which enhances competition and drives innovation in design and materials.

How Is Sustainability Shaping the Custom Leather Interior Sourcing Process?

Sustainability is becoming a critical factor in the sourcing of materials for custom leather interiors. International B2B buyers are increasingly concerned about the environmental impact of leather production, which has prompted a shift towards more sustainable practices. Ethical sourcing and transparency in supply chains are now paramount, as consumers demand assurance that the leather used is obtained from responsible sources.

Brands are responding by adopting eco-friendly practices, such as using vegetable-tanned leather and sourcing hides from suppliers with rigorous animal welfare standards. Certifications like the Leather Working Group (LWG) audit and other ‘green’ certifications are gaining traction, providing buyers with credible assurances about the sustainability of their materials. This movement not only helps mitigate environmental impact but also enhances brand reputation in the global marketplace, especially among environmentally conscious consumers in Europe and the Middle East.

How Has the Custom Leather Interior Market Evolved Over Time?

The evolution of the custom leather interior market can be traced back to the early days of automotive design, where leather was primarily associated with luxury vehicles. Over the decades, advancements in manufacturing techniques and materials have made custom leather interiors accessible to a broader range of consumers. The introduction of synthetic leathers and eco-friendly alternatives has diversified options for buyers, catering to various preferences and budgets.

In recent years, the digital transformation of the automotive aftermarket has revolutionized the way customers interact with manufacturers. Online configurators and e-commerce platforms now enable buyers to customize their interiors from the comfort of their homes, streamlining the purchasing process. This shift has not only enhanced customer experience but has also increased market competition, prompting brands to innovate continuously in design and quality. As a result, the custom leather interior market is poised for sustained growth, driven by consumer demand for both luxury and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather interior for trucks

-

How do I ensure the quality of custom leather interiors for trucks?

To ensure high-quality custom leather interiors, it’s crucial to vet suppliers thoroughly. Request samples of their leather materials and inquire about their manufacturing processes. Look for certifications that demonstrate compliance with international quality standards. Additionally, check customer reviews and testimonials to gauge satisfaction levels. A warranty on the product can also provide peace of mind, indicating the supplier’s confidence in their work. -

What customization options are available for truck leather interiors?

Customization options for truck leather interiors typically include a variety of leather types, colors, and stitching patterns. Buyers can select from options like two-tone designs, perforation styles, and additional features such as heating and cooling. It’s beneficial to work closely with suppliers who offer a configurator tool, allowing you to visualize the final product before production. Ensure that the supplier understands your specific needs and preferences to achieve a truly personalized interior. -

What are the minimum order quantities (MOQ) for custom leather interiors?

Minimum order quantities can vary widely among suppliers, often depending on the complexity of the customization and the materials used. For bulk orders, MOQs might range from 10 to 50 units. It’s advisable to discuss your requirements directly with suppliers to negotiate favorable terms, especially if you anticipate ongoing orders. Understanding the MOQ is essential for budgeting and planning your inventory effectively. -

What payment terms should I expect when sourcing custom leather interiors?

Payment terms can differ among suppliers, but typical arrangements include a deposit followed by the balance upon delivery or installation. Many suppliers may offer flexible payment options, including credit terms for established businesses. It’s essential to clarify payment methods accepted, whether through bank transfers, credit cards, or letters of credit, especially for international transactions. Always ensure that payment terms are documented in the contract to avoid disputes. -

How can I verify the legitimacy of a supplier for custom leather interiors?

To verify a supplier’s legitimacy, start by checking their business credentials and registration status in their country. Look for industry certifications and memberships in professional organizations. Engage with previous clients or request case studies to assess their reputation. Additionally, consider conducting a factory visit or requesting third-party audits to evaluate manufacturing practices and capabilities, ensuring they meet your quality standards. -

What logistics considerations should I keep in mind for importing leather interiors?

When importing custom leather interiors, consider shipping methods, costs, and delivery timelines. Understand the customs regulations in your country and ensure that all necessary documentation, such as invoices and certificates of origin, is in order. Collaborate with logistics providers experienced in handling automotive components, as they can assist with customs clearance and transportation. Planning for potential delays and ensuring proper insurance for shipments can also mitigate risks. -

How can I address potential issues with product quality upon delivery?

To address quality issues with delivered products, establish a clear return and warranty policy with your supplier beforehand. Upon receipt, conduct a thorough inspection of the leather interiors against your order specifications. Document any discrepancies with photos and detailed descriptions. Communicate promptly with the supplier to resolve issues, whether through replacements, repairs, or refunds. Maintaining open lines of communication is essential for effective resolution. -

What trends should I be aware of in the custom leather interior market?

Stay informed about trends such as eco-friendly materials and sustainable manufacturing practices, which are gaining traction globally. Additionally, advancements in technology, like integrated heating and cooling systems, are becoming popular features in custom interiors. Pay attention to design trends, including minimalist aesthetics and personalized touches, as these can enhance the appeal of your offerings. Understanding these trends can help you better cater to your customers’ evolving preferences.

Top 7 Custom Leather Interior For Trucks Manufacturers & Suppliers List

1. Leather Seats – Custom Upholstery Kits

Domain: leatherseats.com

Registered: 2000 (25 years)

Introduction: Leather Interior Kits, Custom Upholstery Car Seat Covers, Build Your Own Interior, Pre-Configured Interior Packages, Matching Materials, Ecstasy Leather Hides, Standard Leather Hides, Vinyl by the Yard, DIY Installation Tools, Basic Install Kit, Complete Install Kit, Headrest Shrinker, Hog-Ring Pliers, Upholstery Adhesive, Leather Maintenance, Interior Accessories, Console Lid Covers, Door Armrest…

2. Katzkin – Custom Leather Seat Covers

Domain: katzkin.com

Registered: 1998 (27 years)

Introduction: Katzkin offers custom leather seat covers and interiors for vehicles, transforming cloth seats into luxurious leather interiors. They provide over 3,000 interior options in 120 colors and materials. Katzkin’s products include high-quality leather upholstery that replaces cloth on seats, door panels, and center consoles. They offer installation services through a network of professional installers …

3. Tint World – Custom Leather Interiors

Domain: tintworld.com

Registered: 2001 (24 years)

Introduction: Custom Leather Interiors for Cars and Trucks, OEM Quality, 1000+ Patterns, Heating/Cooling Systems, Alea leather interiors, Grade ‘A’ Italian Leather, Custom Tailor-Made for Each Vehicle, Original Manufacturer Specifications Fitment, Seat Heating and Cooling System Options, OEM Factory Approved Worldwide, Complete Cloth Interior Replacement, Door Panels and Custom Consoles, Authorized Leather Spec…

4. Covercraft – Genuine Leather Custom-Fit Seat Covers

Domain: covercraft.com

Registered: 1995 (30 years)

Introduction: Covercraft Genuine Leather Custom-Fit Seat Covers are designed for a snug fit, providing protection and style for your vehicle’s interior. They are made from genuine leather, ensuring durability and a luxurious feel. The seat covers are custom-fit, tailored to specific vehicle models for easy installation and a perfect fit. They are suitable for various vehicles, including cars, trucks, and SUVs. …

5. All Out Offroad – Katzkin Leather Interiors

Domain: alloutoffroad.com

Registered: 2000 (25 years)

Introduction: Leather Interior services offered by All Out Offroad include high-end quality customizable options for upgrading vehicle interiors with Katzkin leather. Key features include:

– Extensive selection of imported automotive leathers in a full spectrum of colors.

– Options for pre-designed packages, factory match designs, or custom designs created by leather experts.

– Katzkin designer and factory mat…

6. Barbarossa Leather – Custom Leather Colors

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: Custom Leather Colors available in a full spectrum including traditional earth tones and vibrant colors like turquoise, yellow, and lavender. Variegated patterns and textures are also offered. Key colors include: White, Beige, Sepia, Orange, Red, Purple, Blue, Green, Grey, Brown, Black, and Metallic options. Specific color names include Abyss, Amazon, Anaconda, Arabesque, Aspen, Aviator, Aztec, Ba…

7. Covers and Camo – Exotic Seat Covers

Domain: coversandcamo.com

Registered: 2007 (18 years)

Introduction: {“Product Name”: “Exotic Seat Covers”, “Price”: “Starting at $577.95”, “Features”: [“Waterproof”, “Airbag compatible”, “Thick foam backing”], “Production Time”: “3-4 Weeks”, “Shipping”: “FREE Shipping to mainland USA”, “Custom Options”: [“Pistol Holster™”, “MOLLE Pocket™”, “Headrest Logos”, “More pockets to store guns & gear”], “Warranty”: “2 Years”, “Made In”: “USA”, “Customer Reviews”: “5.0 Star…

Strategic Sourcing Conclusion and Outlook for custom leather interior for trucks

In the competitive landscape of custom leather interiors for trucks, strategic sourcing emerges as a critical factor for success. By leveraging partnerships with reputable manufacturers and suppliers, businesses can ensure high-quality materials, diverse customization options, and timely delivery. This approach not only enhances the product offering but also fosters customer loyalty and satisfaction, particularly in regions such as Africa, South America, the Middle East, and Europe, where demand for luxury automotive interiors is on the rise.

Illustrative image related to custom leather interior for trucks

B2B buyers should prioritize suppliers that provide comprehensive support, from design selection to installation services. Understanding local market preferences and regulations can also facilitate smoother transactions and better alignment with customer expectations. As the market evolves, staying ahead of trends—such as sustainable materials and advanced technologies—will be crucial.

Looking ahead, the potential for growth in the custom leather interior market is vast. International buyers are encouraged to explore innovative solutions and robust supplier networks to capitalize on emerging opportunities. By embracing strategic sourcing, businesses can not only enhance their product offerings but also position themselves as leaders in the evolving automotive interior landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather interior for trucks