Introduction: Navigating the Global Market for custom leather cowboy belts

In the competitive landscape of B2B commerce, sourcing custom leather cowboy belts presents a unique challenge for international buyers. With diverse markets spanning Africa, South America, the Middle East, and Europe, understanding the nuances of this product category is essential for making informed purchasing decisions. Custom leather cowboy belts are not merely fashion accessories; they represent cultural significance, craftsmanship, and personal branding opportunities. This guide will delve into various types of custom belts, their applications across different sectors, and key considerations for supplier vetting and cost analysis.

By exploring the essential aspects of sourcing custom leather cowboy belts, this comprehensive resource equips B2B buyers with the knowledge to navigate the global marketplace effectively. Whether you are a retailer seeking unique inventory for your store in Nigeria, a corporate buyer looking for branded promotional items in Saudi Arabia, or an entrepreneur in South America aiming to tap into the growing leather accessories market, this guide empowers you to make strategic choices. We will cover critical topics, including customization options, material quality, market trends, and best practices for supplier relationships, ensuring you are well-prepared to select products that resonate with your target audience while maintaining quality and profitability.

Table Of Contents

- Top 4 Custom Leather Cowboy Belts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather cowboy belts

- Understanding custom leather cowboy belts Types and Variations

- Key Industrial Applications of custom leather cowboy belts

- 3 Common User Pain Points for ‘custom leather cowboy belts’ & Their Solutions

- Strategic Material Selection Guide for custom leather cowboy belts

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather cowboy belts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather cowboy belts’

- Comprehensive Cost and Pricing Analysis for custom leather cowboy belts Sourcing

- Alternatives Analysis: Comparing custom leather cowboy belts With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather cowboy belts

- Navigating Market Dynamics and Sourcing Trends in the custom leather cowboy belts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather cowboy belts

- Strategic Sourcing Conclusion and Outlook for custom leather cowboy belts

- Important Disclaimer & Terms of Use

Understanding custom leather cowboy belts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Cowboy Belt | Traditional design, often features leather tooling | Retail, promotional giveaways, branding | Pros: Timeless appeal; Cons: Limited modern styles |

| Embossed Leather Belt | Custom patterns embossed into leather | Corporate gifts, personal branding | Pros: Unique designs; Cons: Potentially higher cost |

| Personalized Name Belt | Customizable with names or logos | Personal gifts, employee recognition | Pros: Highly personal; Cons: May take longer to produce |

| Decorative Buckle Belt | Features interchangeable or custom buckles | Fashion retail, promotional events | Pros: Versatile styling; Cons: Buckle may wear out |

| Themed Motif Belt | Incorporates specific themes (e.g., wildlife, culture) | Specialty shops, niche markets | Pros: Appeals to specific audiences; Cons: Limited audience reach |

What Are the Characteristics of Classic Cowboy Belts?

Classic cowboy belts are characterized by their traditional leather craftsmanship and often include intricate tooling designs. Typically made from high-quality cowhide, these belts are designed to withstand daily wear while maintaining a rugged aesthetic. For B2B buyers, classic cowboy belts are ideal for retail environments, promotional giveaways, or branding opportunities, as they appeal to a wide audience. Buyers should consider the craftsmanship quality and customization options available to ensure they meet market demands.

How Do Embossed Leather Belts Stand Out?

Embossed leather belts are distinguished by custom patterns that are pressed into the leather, adding depth and texture. This type of belt is particularly suitable for corporate gifts or personal branding, as the unique designs can reflect a company’s identity. For B2B buyers, the key consideration is the balance between design complexity and production cost, as more intricate patterns may increase the final price. Buyers should also assess the durability of the embossing to ensure longevity.

What Makes Personalized Name Belts Popular Among Buyers?

Personalized name belts offer a high degree of customization, allowing buyers to add individual names or logos. This feature makes them popular as personal gifts or for employee recognition programs. B2B buyers should focus on the production timeline, as personalized items may require longer lead times. Additionally, understanding the target demographic’s preferences for font styles and colors can significantly enhance the appeal of these products.

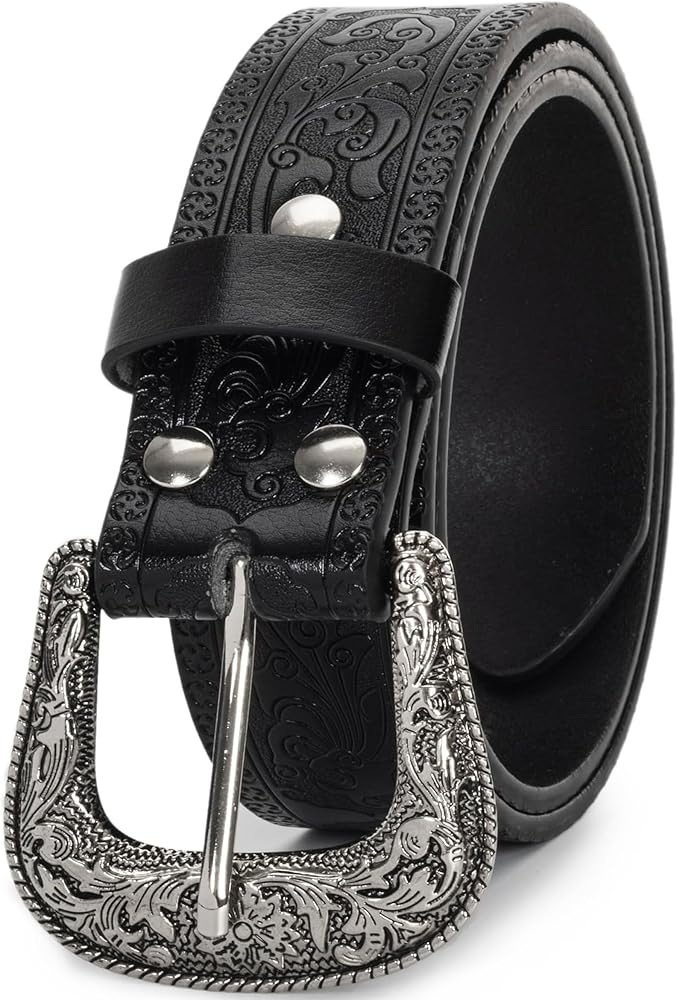

Illustrative image related to custom leather cowboy belts

Why Choose Decorative Buckle Belts for Versatility?

Decorative buckle belts are unique due to their interchangeable buckles, allowing users to switch styles easily. This versatility makes them attractive for fashion retail and promotional events, where changing trends demand adaptability. B2B buyers should consider the quality of both the belt and the buckles, as durability is essential for frequent use. Furthermore, ensuring a range of buckle designs can cater to various customer preferences and increase sales potential.

What Are The Benefits of Themed Motif Belts?

Themed motif belts incorporate specific designs that resonate with particular interests, such as wildlife or cultural symbols. These belts are often found in specialty shops and appeal to niche markets. For B2B buyers, the primary consideration is the target audience’s interests, as this will drive sales. While themed belts can attract dedicated customers, their limited audience reach may pose challenges in broader retail settings. Buyers should ensure that the themes chosen align with current market trends to maximize appeal.

Key Industrial Applications of custom leather cowboy belts

| Industry/Sector | Specific Application of custom leather cowboy belts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Customized belts for branding and promotional events | Enhances brand identity and customer loyalty through unique offerings | Quality of leather, customization options, delivery times |

| Equestrian Sports | Belts designed for equestrian activities and competitions | Provides functionality and style, catering to a niche market | Durability, comfort, and design specific to equestrian needs |

| Hospitality and Tourism | Souvenir belts for tourists in Western-themed locations | Boosts revenue through unique, locally-made products | Local craftsmanship, cultural relevance, and price point |

| Corporate Gifting | Personalized belts as corporate gifts for clients or employees | Strengthens relationships and showcases company values | Custom branding options, lead times, and bulk pricing |

| Agricultural Sector | Functional belts for ranchers and farmers | Offers durability and practicality for outdoor work | Material quality, sizing options, and ruggedness |

How Are Custom Leather Cowboy Belts Used in the Fashion Retail Sector?

In the fashion retail industry, custom leather cowboy belts serve as a unique branding tool. Retailers can offer personalized belts that feature logos or designs, enhancing brand identity and customer loyalty. These bespoke items appeal to consumers looking for distinctive fashion statements. International buyers should focus on the quality of leather used, the variety of customization options available, and reliable delivery times to ensure timely inventory replenishment.

Illustrative image related to custom leather cowboy belts

What Role Do Custom Leather Cowboy Belts Play in Equestrian Sports?

In the equestrian sports sector, custom leather cowboy belts are not just fashion accessories; they are practical gear designed for riders and competitors. These belts often feature durable materials that withstand the rigors of outdoor activities while providing style. Buyers in this sector require belts that are comfortable, functional, and specifically designed to meet equestrian needs. Sourcing should prioritize durability and the ability to customize designs that resonate with equestrian culture.

Why Are Custom Leather Cowboy Belts Important for Hospitality and Tourism?

For the hospitality and tourism industry, custom leather cowboy belts act as unique souvenirs for tourists visiting Western-themed locations. These belts can be marketed as high-quality, locally-made products that capture the essence of the region. This not only boosts revenue but also enhances the tourist experience. When sourcing, businesses must consider local craftsmanship, cultural significance, and competitive pricing to attract both tourists and local buyers.

How Can Corporate Gifting Benefit from Custom Leather Cowboy Belts?

Custom leather cowboy belts are increasingly popular as corporate gifts, allowing businesses to strengthen relationships with clients and employees. Personalized belts showcase company values and foster a sense of belonging among recipients. Buyers in this sector should focus on custom branding options, lead times for production, and bulk pricing to effectively manage gifting strategies while maximizing impact.

What Advantages Do Custom Leather Cowboy Belts Offer in the Agricultural Sector?

In the agricultural sector, custom leather cowboy belts provide essential functionality for ranchers and farmers. These belts are designed to be durable and practical, ensuring they can withstand daily outdoor work. Buyers should prioritize high-quality materials, sizing options, and rugged designs that meet the demands of agricultural life. This attention to detail not only enhances user experience but also supports the longevity of the product, making it a wise investment for agricultural professionals.

3 Common User Pain Points for ‘custom leather cowboy belts’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality Across Orders

The Problem: One major challenge faced by B2B buyers when sourcing custom leather cowboy belts is ensuring consistent quality across bulk orders. Buyers may experience variability in leather quality, craftsmanship, and design fidelity, leading to customer dissatisfaction and potential loss of business. This inconsistency can stem from suppliers using different materials or processes for each batch, making it crucial for buyers to establish a reliable source that can maintain quality standards.

Illustrative image related to custom leather cowboy belts

The Solution: To mitigate this problem, B2B buyers should prioritize establishing long-term partnerships with reputable manufacturers known for their quality craftsmanship. Before placing a large order, request samples of the leather and finished products to evaluate the quality firsthand. It’s also advisable to conduct factory visits or audits to understand the production processes and quality control measures in place. Specifying detailed quality standards and having clear communication regarding expectations can further ensure that each order meets the required criteria, thereby safeguarding your brand’s reputation.

Scenario 2: Navigating Customization Options and Design Complexity

The Problem: Many buyers find themselves overwhelmed by the myriad customization options available for custom leather cowboy belts. From selecting the type of leather and color to intricate design details such as tooling, buckles, and patterns, the decision-making process can become daunting. This complexity can lead to confusion and dissatisfaction if the final product does not align with the buyer’s original vision.

The Solution: To streamline the customization process, buyers should create a detailed specification sheet outlining their design preferences, including dimensions, material choices, and desired features. Utilizing 3D design tools or belt configurators offered by some manufacturers can also aid in visualizing the final product. Collaborating closely with the supplier during the design phase, including sharing inspiration images and examples of preferred styles, can enhance the likelihood of achieving the desired outcome. Additionally, consider establishing a feedback loop where prototypes can be reviewed and modified before final production, ensuring alignment with expectations.

Illustrative image related to custom leather cowboy belts

Scenario 3: Understanding Sizing and Fit for Diverse Markets

The Problem: Sizing issues can pose a significant pain point for B2B buyers, particularly those catering to diverse markets with varying body types and preferences. Incorrect sizing can lead to high return rates and dissatisfied customers, impacting profitability and brand loyalty. Buyers may struggle to understand how to effectively communicate sizing needs to manufacturers who may not be familiar with specific regional sizing standards.

The Solution: To address sizing challenges, buyers should invest time in gathering accurate sizing data from their target market. This could involve conducting surveys or focus groups to determine the most common sizes and preferences. Clear communication with suppliers is essential; provide them with detailed sizing charts that include conversions for different regions. Consider offering a range of sizes that accommodates various body types and promote adjustable options where possible. Implementing a robust return policy can also ease customer concerns, allowing for exchanges if the sizing is not perfect. Ultimately, educating both your team and customers about the sizing process can lead to a more satisfying purchasing experience.

Strategic Material Selection Guide for custom leather cowboy belts

What Are the Key Materials Used in Custom Leather Cowboy Belts?

When selecting materials for custom leather cowboy belts, various leather types and finishes play a crucial role in determining the product’s performance, durability, and aesthetic appeal. Understanding the properties, advantages, and limitations of these materials is essential for B2B buyers looking to make informed purchasing decisions.

What Are the Key Properties of Full-Grain Leather for Cowboy Belts?

Full-grain leather is considered the highest quality leather available. It retains the natural grain and texture of the hide, which enhances its durability and aesthetic. Full-grain leather can withstand significant wear and tear, making it an excellent choice for cowboy belts that need to endure rugged conditions. It also ages beautifully, developing a unique patina over time.

Pros: Full-grain leather is highly durable and resistant to moisture and abrasion. It has a luxurious appearance and can be easily customized with tooling or embossing.

Illustrative image related to custom leather cowboy belts

Cons: The cost of full-grain leather is relatively high, which may impact the overall price point of the belts. Additionally, it requires proper care to maintain its appearance.

Impact on Application: Full-grain leather is suitable for outdoor use and can withstand varying temperatures and humidity levels, making it ideal for regions with extreme weather conditions.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local regulations regarding leather sourcing and treatment. Additionally, full-grain leather may be preferred in markets that value traditional craftsmanship.

How Does Top-Grain Leather Compare for Custom Cowboy Belts?

Top-grain leather is the second-highest quality leather, made by sanding down the surface of full-grain leather to remove imperfections. This process makes it more pliable and easier to work with, which can be beneficial for intricate designs.

Illustrative image related to custom leather cowboy belts

Pros: Top-grain leather is more affordable than full-grain leather while still offering good durability and a refined look. It is also less susceptible to stains and easier to clean.

Cons: While it is durable, top-grain leather does not develop the same rich patina as full-grain leather and may not last as long under heavy use.

Impact on Application: This material is suitable for a range of applications, including casual and formal cowboy belts, making it versatile for different market segments.

Illustrative image related to custom leather cowboy belts

Considerations for International Buyers: Buyers should check for compliance with international leather quality standards, such as ASTM and ISO, to ensure they are sourcing high-quality materials.

What Are the Benefits of Suede in Cowboy Belt Manufacturing?

Suede, made from the underside of the hide, offers a soft texture and unique aesthetic. It is often used for more casual or fashion-forward cowboy belts.

Pros: Suede is lightweight and comfortable, making it suitable for everyday wear. It can also be dyed in various colors, providing a wide range of customization options.

Cons: Suede is less durable than full-grain or top-grain leather and can be more susceptible to staining and damage from moisture.

Illustrative image related to custom leather cowboy belts

Impact on Application: Suede belts are best suited for fashion applications rather than rugged use, making them popular in urban markets.

Considerations for International Buyers: Buyers should be aware of the care requirements for suede, especially in humid climates, and ensure that the material meets local environmental regulations regarding leather treatment.

How Does Synthetic Leather Fit into the Cowboy Belt Market?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an alternative to traditional leather. It can mimic the look of real leather while being more affordable.

Pros: Synthetic leather is generally more cost-effective and resistant to water and stains. It is also easier to clean and maintain.

Cons: While it can be durable, synthetic leather may not offer the same longevity or aesthetic appeal as genuine leather. It can also be less breathable.

Impact on Application: This material is suitable for budget-conscious consumers or those looking for vegan options, expanding the market reach for custom cowboy belts.

Considerations for International Buyers: Buyers should ensure that synthetic materials comply with local regulations regarding chemical use and environmental impact, particularly in regions with strict sustainability standards.

Summary Table of Material Options for Custom Leather Cowboy Belts

| Material | Typical Use Case for custom leather cowboy belts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end, rugged cowboy belts | Exceptional durability and patina | Higher cost and requires maintenance | High |

| Top-Grain Leather | Versatile, casual to formal belts | Good balance of cost and quality | Less durable than full-grain | Medium |

| Suede | Fashion-forward, casual belts | Soft texture and wide color options | Less durable and susceptible to stains | Medium |

| Synthetic Leather | Budget-friendly, vegan options | Cost-effective and easy to maintain | May lack longevity and aesthetic appeal | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them navigate the complexities of sourcing materials for custom leather cowboy belts while considering regional preferences and compliance requirements.

Illustrative image related to custom leather cowboy belts

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather cowboy belts

What Are the Main Stages of Manufacturing Custom Leather Cowboy Belts?

The production of custom leather cowboy belts involves several critical stages, each designed to ensure the final product meets high standards of quality and craftsmanship. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: How Is Quality Leather Selected?

The first step in the manufacturing process is selecting high-quality leather, which is fundamental to the durability and aesthetic appeal of cowboy belts. Top-grain cowhide is often preferred due to its strength and suppleness. Suppliers typically perform rigorous quality checks at this stage, assessing the leather for consistency in texture, color, and thickness.

Once the leather is chosen, it undergoes conditioning to enhance its pliability and prevent future cracking. This preparation phase may also involve cutting the leather into required shapes and sizes based on the design specifications provided by the customer.

Illustrative image related to custom leather cowboy belts

Forming: What Techniques Are Used in Shaping the Belts?

Forming involves shaping the leather into the desired belt configuration. This stage may employ techniques such as hand-tooling, embossing, or laser engraving, depending on the customization options selected by the buyer. Hand-tooling, in particular, is a hallmark of high-quality cowboy belts, allowing for intricate designs and personal inscriptions that enhance the product’s uniqueness.

At this point, the belts are also prepared for adding buckles and any additional hardware. This can involve cutting holes for buckle attachment and ensuring that the edges are smoothed to prevent fraying.

Assembly: How Are the Different Components Joined?

During the assembly phase, the various components of the belt are brought together. This includes attaching the buckle, which is often designed to be interchangeable, allowing for personalization. The assembly process may involve stitching or riveting, and suppliers often utilize heavy-duty threads to ensure longevity.

Illustrative image related to custom leather cowboy belts

B2B buyers should be aware of the assembly techniques used, as they directly influence the durability and functionality of the belts. Hand-stitched belts typically offer superior strength compared to machine-stitched alternatives.

Finishing: What Processes Ensure a High-Quality End Product?

The finishing stage is crucial for enhancing both the appearance and durability of the belts. This may include dyeing, polishing, and applying protective coatings. Manufacturers often use natural dyes to ensure that the color is deep and rich, while also being environmentally friendly.

Quality assurance during finishing involves checking for consistency in color and texture, as well as ensuring that all edges are sealed to prevent moisture penetration. This is particularly important for belts intended for outdoor use, where exposure to elements can lead to rapid deterioration.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a vital aspect of the manufacturing process, ensuring that custom leather cowboy belts meet international and industry-specific standards. Understanding these can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to custom leather cowboy belts

Which International Standards Are Relevant for Leather Goods?

ISO 9001 is one of the most recognized international standards for quality management systems. It emphasizes a customer-focused approach and continuous improvement, making it essential for manufacturers aiming to deliver high-quality products consistently.

In addition, specific certifications like CE (Conformité Européenne) may be relevant for products exported to Europe, ensuring that the items meet safety and environmental requirements. For buyers in regions like Africa and South America, it’s essential to verify that suppliers adhere to both local and international standards to ensure product reliability.

What Are the Key Quality Control Checkpoints in Leather Belt Manufacturing?

Quality control checkpoints are integral to the manufacturing process, ensuring that any defects are identified and addressed promptly. Common checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials, such as leather, before production begins. Any subpar materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are performed to ensure that each stage meets quality standards. This could include checking for stitching quality and verifying that tooling is applied correctly.

-

Final Quality Control (FQC): Before shipping, finished belts undergo a thorough inspection to ensure they meet all specifications. This includes checking dimensions, finishes, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring that the products meet their expectations. Here are several methods to consider:

What Role Do Audits and Reports Play in Supplier Verification?

Requesting quality control reports and audit records from potential suppliers can provide insights into their adherence to quality standards. Regular audits, whether internal or conducted by third parties, should be documented, demonstrating a commitment to maintaining high production standards.

Buyers should consider scheduling on-site audits to assess the manufacturing environment firsthand. This allows for a deeper understanding of the processes and quality measures in place.

How Can Third-Party Inspections Enhance Confidence in Supplier Quality?

Utilizing third-party inspection services can further bolster confidence in supplier quality. These independent entities can conduct thorough inspections and provide unbiased reports on the quality of the belts before they are shipped. This is especially important for international transactions, where logistics and communication challenges can complicate quality assurance.

What Are the Specific Quality Control Nuances for International Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, may encounter unique challenges in verifying quality control. Understanding these nuances can facilitate smoother transactions.

How Do Regional Standards Affect Quality Expectations?

Each region may have different quality expectations and standards. For instance, European buyers might prioritize compliance with CE standards, while Middle Eastern buyers may focus on durability and resistance to extreme weather conditions. Buyers should familiarize themselves with these regional standards to ensure compatibility with their target markets.

Illustrative image related to custom leather cowboy belts

What Are the Challenges in Communicating Quality Requirements?

Language barriers and cultural differences can complicate communication regarding quality expectations. Buyers should strive for clear, concise specifications and consider using visual aids or samples to convey their requirements effectively.

In conclusion, understanding the manufacturing processes and quality assurance standards for custom leather cowboy belts is essential for B2B buyers. By focusing on material selection, production techniques, and robust quality control measures, buyers can confidently select suppliers that align with their quality expectations and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather cowboy belts’

To assist B2B buyers in sourcing custom leather cowboy belts effectively, this guide provides a structured checklist to ensure a smooth procurement process. Each step is designed to help you evaluate suppliers, clarify specifications, and secure quality products that meet your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the specifications for your custom leather cowboy belts. This includes the materials (e.g., top-grain cowhide), dimensions, styles (like tapered or rancher), and any specific features such as tooling or stitching patterns. Defining these parameters upfront will streamline communication with potential suppliers and help ensure that the final product aligns with your brand’s requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in custom leather goods. Look for companies with a proven track record and positive customer feedback. Utilize online platforms, trade shows, and industry networks to gather information and reviews, focusing on suppliers who have experience serving businesses in your target regions, such as Africa, South America, the Middle East, and Europe.

Illustrative image related to custom leather cowboy belts

Step 3: Evaluate Supplier Capabilities

Once you’ve shortlisted potential suppliers, assess their production capabilities. Inquire about their manufacturing processes, quality control measures, and lead times. Understanding their capacity to fulfill your order volume and customization requests will help you avoid delays and ensure that they can meet your business demands.

Step 4: Request Samples for Quality Assessment

Before finalizing your order, request samples of the custom leather cowboy belts. This is crucial for evaluating the craftsmanship, material quality, and overall aesthetic of the products. Pay attention to details such as stitching, finish, and the feel of the leather to ensure they meet your standards and reflect your brand’s image.

Step 5: Verify Compliance and Certifications

Ensure that your chosen suppliers adhere to industry standards and regulations. Request documentation for compliance with relevant quality and safety certifications. This step is vital, especially for international transactions, as it guarantees that the products meet the necessary legal requirements in your market.

Illustrative image related to custom leather cowboy belts

Step 6: Negotiate Terms and Conditions

Engage in discussions about pricing, payment terms, and delivery schedules. Negotiating favorable terms can lead to better profitability for your business. Be clear about your expectations regarding minimum order quantities, lead times, and any warranties or return policies to avoid misunderstandings later.

Step 7: Establish Communication Channels

Effective communication is key to successful sourcing. Establish clear channels for ongoing dialogue with your supplier. Regular updates on production status, any potential issues, and feedback can help build a strong partnership and ensure that both parties are aligned throughout the procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom leather cowboy belts, ensuring quality products that resonate with their brand identity and meet customer expectations.

Comprehensive Cost and Pricing Analysis for custom leather cowboy belts Sourcing

What Are the Key Cost Components for Sourcing Custom Leather Cowboy Belts?

When sourcing custom leather cowboy belts, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of leather significantly impacts costs. Full-grain and top-grain leathers are more expensive due to their durability and quality. Buyers should also consider additional materials like buckles, conchos, and stitching options that enhance the product’s appeal.

-

Labor: Skilled craftsmanship is essential in creating high-quality leather products. Labor costs vary based on the complexity of the design and the artisans’ expertise. Customization often requires more intricate labor, which can increase costs.

-

Manufacturing Overhead: This encompasses the costs of running the factory, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can help reduce these costs.

-

Tooling: Custom designs may require specific tools or molds, contributing to upfront costs. It’s important to factor in these expenses when negotiating prices.

-

Quality Control: Ensuring each belt meets quality standards is vital. QC processes may involve additional labor and materials, impacting overall pricing.

-

Logistics: Shipping costs can vary widely based on the destination and Incoterms. International buyers must account for tariffs, customs duties, and freight costs when calculating total expenses.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding market rates can help buyers gauge whether pricing is competitive.

How Do Price Influencers Affect Custom Leather Cowboy Belt Costs?

Several factors can influence the pricing of custom leather cowboy belts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts. Buyers should negotiate MOQs to maximize cost-efficiency.

-

Specifications and Customization: More elaborate designs and personalization options, such as custom tooling and unique finishes, can raise costs. Balancing customization with budget constraints is essential.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or ethical sourcing) typically lead to higher prices. Buyers should assess the value of certifications against their brand image and market positioning.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their quality assurance and service.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) can affect pricing significantly. Buyers must evaluate the total landed cost, including shipping, insurance, and import duties.

What Are Effective Buyer Tips for Negotiating Custom Leather Cowboy Belt Prices?

For B2B buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and value:

-

Research and Benchmarking: Conduct market research to understand average pricing for similar products. This information empowers buyers during negotiations.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs associated with durability, maintenance, and replacement. High-quality belts may have a higher upfront cost but save money over time.

-

Be Transparent About Needs: Clearly communicate requirements and expectations to suppliers. This transparency can foster stronger relationships and more favorable pricing.

-

Flexibility on Design: Be open to suggestions from suppliers regarding materials or designs that can reduce costs without compromising quality.

-

Establish Long-Term Relationships: Building a strong partnership with suppliers can result in better terms, discounts, and priority service over time.

Conclusion

Sourcing custom leather cowboy belts involves navigating a complex landscape of costs and pricing factors. By understanding the underlying cost components, recognizing price influencers, and employing effective negotiation tactics, B2B buyers can secure the best value for their investments. It’s essential to approach sourcing with a strategic mindset to maximize both quality and cost-efficiency, particularly in international markets where various economic factors come into play. Always request indicative prices and be prepared for fluctuations based on market conditions.

Alternatives Analysis: Comparing custom leather cowboy belts With Other Solutions

When considering custom leather cowboy belts, it’s essential to evaluate alternative solutions that can serve similar purposes or meet comparable needs. This analysis aims to compare custom leather cowboy belts with two viable alternatives: synthetic leather belts and traditional fabric belts. Each of these options has its unique benefits and drawbacks, which are crucial for international B2B buyers from diverse markets.

| Comparison Aspect | Custom Leather Cowboy Belts | Synthetic Leather Belts | Traditional Fabric Belts |

|---|---|---|---|

| Performance | High durability, superior style, and unique customization options. | Good durability, water-resistant, and often lighter. | Moderate durability, versatile designs, but less formal appeal. |

| Cost | Higher upfront investment due to premium materials and craftsmanship. | Generally lower cost, making it a budget-friendly option. | Cost-effective, but may require more frequent replacement. |

| Ease of Implementation | Custom orders can take time; requires size and design specifications. | Readily available in various styles and sizes. | Widely available, easy to find in different markets. |

| Maintenance | Requires occasional conditioning and care to maintain quality. | Low maintenance; easy to clean and resistant to wear. | Easy to wash, but can wear out quickly; may not be durable. |

| Best Use Case | Ideal for branding, personalized gifts, and high-end fashion. | Suitable for casual wear, outdoor activities, and budget-conscious consumers. | Great for everyday use, casual settings, and bulk purchases. |

What Are the Advantages and Disadvantages of Synthetic Leather Belts?

Synthetic leather belts offer a practical alternative to custom leather cowboy belts. They are typically more affordable and provide a range of styles, making them accessible for a broader audience. Their water-resistant properties and lighter weight make them suitable for outdoor activities. However, they may lack the same level of prestige and durability as genuine leather, which can be a crucial factor for businesses aiming for a luxury image.

How Do Traditional Fabric Belts Compare to Custom Leather Cowboy Belts?

Traditional fabric belts are another viable option, especially for bulk purchases and casual settings. They are cost-effective and widely available, making them easy to source for retailers. However, their durability is usually less than that of leather belts, and they may not convey the same level of sophistication. For companies looking to provide practical, everyday accessories without a heavy investment, fabric belts can be a sensible choice.

How Should B2B Buyers Choose Between These Options?

In conclusion, the choice between custom leather cowboy belts and alternative solutions like synthetic leather or traditional fabric belts depends on the specific needs and goals of the buyer. For those looking to create a unique brand identity or offer high-quality, personalized products, custom leather belts are an excellent investment. Conversely, if cost and ease of availability are primary concerns, synthetic leather or fabric belts may be more suitable. B2B buyers should carefully consider their target market, budget constraints, and desired brand positioning when making their selection. This strategic approach will ensure that they choose the most appropriate solution for their business needs.

Essential Technical Properties and Trade Terminology for custom leather cowboy belts

What Are the Key Technical Properties of Custom Leather Cowboy Belts?

When sourcing custom leather cowboy belts, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade refers to the quality of the leather used in belt production. Common grades include top-grain and full-grain leather, with full-grain being the highest quality, showcasing natural imperfections. The choice of material affects durability, comfort, and aesthetics, making it vital for buyers to specify their desired grade to ensure longevity and a premium look.

2. Belt Width

Belt width is a crucial specification, typically ranging from 1 to 1.5 inches for cowboy belts. The width impacts both style and functionality; wider belts often provide more support for heavy buckles, while narrower belts can offer a more refined appearance. Understanding the appropriate width helps in aligning the product with market expectations and regional fashion preferences.

Illustrative image related to custom leather cowboy belts

3. Stitching Techniques

Stitching is an important detail that affects both the durability and visual appeal of the belt. Common techniques include edge border stitching, buckstitching, and lined stitching. Each method varies in strength and aesthetic, and selecting the right technique ensures that the final product meets quality standards while appealing to target customers.

4. Customization Options

Customization options encompass everything from color selection to personalized engraving. Buyers should consider the range of available finishes and motifs, as these features can significantly enhance the product’s marketability. Offering extensive customization options can attract a broader customer base looking for unique, personalized items.

5. Tolerance Levels

Tolerance levels refer to the acceptable variation in measurements during production. For belts, this could involve dimensions like length and width. Maintaining strict tolerance levels is crucial to ensure that the belts fit as intended and meet customer specifications. This can reduce returns and enhance customer satisfaction, making it a key concern for B2B buyers.

What Are the Common Trade Terms Associated with Custom Leather Cowboy Belts?

Familiarity with industry jargon can streamline communication and negotiations. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are marketed by another company. In the context of custom leather belts, partnering with an OEM can allow buyers to offer unique products under their brand, leveraging the manufacturer’s expertise while focusing on marketing and sales.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for buyers to manage inventory effectively and avoid excess stock. It is particularly important for B2B transactions, where bulk purchases are common.

3. RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests pricing information from suppliers. For custom leather cowboy belts, submitting an RFQ allows buyers to compare offers from multiple manufacturers, facilitating better decision-making based on cost and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is crucial for B2B buyers engaged in international trade, as they clarify who is responsible for shipping costs, insurance, and risk during transit.

Illustrative image related to custom leather cowboy belts

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the custom leather belt industry, lead times can vary based on the complexity of the order and the manufacturer’s capacity. Buyers should factor in lead times when planning inventory to ensure that they meet customer demand without delays.

By grasping these technical properties and trade terms, B2B buyers can navigate the custom leather cowboy belt market more effectively, ensuring they select the right products that align with their business goals and customer needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather cowboy belts Sector

What Are the Key Trends Driving the Custom Leather Cowboy Belts Market?

The custom leather cowboy belts market is experiencing a robust growth trajectory, driven by a resurgence in Western fashion, the rise of personalized accessories, and a growing appreciation for artisanal craftsmanship. Global buyers are increasingly seeking unique, bespoke products that reflect individual identity and cultural heritage. This demand is particularly pronounced in regions like Africa and South America, where traditional craftsmanship is valued, and in the Middle East and Europe, where Western styles are gaining popularity.

Technological advancements are also reshaping the sourcing landscape. The integration of e-commerce platforms and digital customization tools allows manufacturers to offer personalized designs, catering to specific customer preferences. For instance, buyers can now visualize their customizations in real-time, selecting styles, colors, and patterns that resonate with their brand identity. This trend is complemented by a growing emphasis on quality assurance, with buyers increasingly demanding transparency in production processes and material sourcing.

Additionally, the shift towards sustainable practices is influencing market dynamics. International buyers are prioritizing suppliers who adopt eco-friendly materials and ethical labor practices. This trend is particularly relevant in regions where consumers are becoming more socially conscious, and brands are expected to align with these values. Overall, the custom leather cowboy belts market is evolving into a space where personalization, technology, and sustainability converge, presenting lucrative opportunities for B2B buyers.

How Is Sustainability Impacting the Sourcing of Custom Leather Cowboy Belts?

Sustainability is becoming a pivotal factor in the sourcing of custom leather cowboy belts, reflecting a broader shift towards environmentally responsible practices within the fashion industry. Leather production has historically raised concerns regarding environmental impact, particularly in terms of resource consumption and waste generation. As a result, buyers are increasingly seeking suppliers that demonstrate a commitment to sustainable practices, including the use of vegetable-tanned leather, which is less harmful to the environment compared to traditional tanning methods.

Ethical sourcing is equally important. Buyers are inclined to partner with manufacturers that ensure fair labor practices and provide safe working conditions. Certifications such as the Leather Working Group (LWG) and Fair Trade can serve as indicators of a supplier’s commitment to ethical practices. Furthermore, there is a growing trend towards utilizing recycled or upcycled materials, which not only reduces waste but also appeals to eco-conscious consumers.

Incorporating sustainability into sourcing strategies is not merely a compliance issue; it is an opportunity to enhance brand reputation and appeal to a broader customer base. B2B buyers who prioritize sustainable and ethical practices can differentiate their offerings in a competitive market, aligning with the values of a growing segment of conscious consumers.

What Is the Historical Context of Custom Leather Cowboy Belts?

The history of custom leather cowboy belts is deeply rooted in the American West, where they emerged as functional accessories for cowboys and ranchers in the 19th century. Initially, these belts served practical purposes, providing support for tools and firearms. Over time, they evolved into symbols of Western culture and identity, characterized by intricate designs and craftsmanship.

Illustrative image related to custom leather cowboy belts

The rise of the Western movie genre in the mid-20th century further popularized cowboy aesthetics, leading to a renewed interest in custom leather goods. Artisans began to offer personalized belts, allowing wearers to express individuality through unique designs, patterns, and embellishments. This tradition of craftsmanship continues today, with modern manufacturers blending traditional techniques with contemporary design elements to cater to a global market.

As the demand for custom leather cowboy belts grows, buyers are not only seeking quality and style but also a connection to the rich history and cultural significance behind these timeless accessories. Understanding this context enhances the value proposition for B2B buyers, enabling them to market products that resonate with both heritage and modern consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather cowboy belts

-

How do I ensure quality when sourcing custom leather cowboy belts?

To guarantee quality, start by vetting potential suppliers through their online presence and customer reviews. Request samples to assess the craftsmanship, leather quality, and finishing details. Additionally, inquire about their production processes, including whether they utilize hand-tooling techniques, which typically indicate higher quality. Establish clear communication with the supplier about your quality expectations and consider setting up quality assurance checkpoints throughout the production process. -

What is the best way to customize leather cowboy belts for my brand?

The best customization options include selecting specific leather types, colors, buckle styles, and hand-tooled designs that reflect your brand identity. Many suppliers offer a configurator tool to visualize your choices. Ensure that you communicate your brand story and target audience to the supplier, allowing them to suggest personalized design elements that resonate with your market. Also, consider adding your logo or brand name as part of the belt design for better brand visibility. -

What are the typical minimum order quantities (MOQ) for custom leather cowboy belts?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for custom leather belts range from 50 to 100 units, depending on the complexity of the customization and the supplier’s production capabilities. When negotiating, discuss your specific needs and explore flexibility in MOQs, especially if you are a new buyer or testing the market. Some suppliers may offer lower MOQs for first-time orders or promotional trials. -

What payment terms should I expect when ordering custom leather cowboy belts?

Payment terms can differ by supplier, but common practices include a 30% deposit upfront with the balance due upon completion or before shipping. For larger orders, you might negotiate extended payment terms, such as net 30 or net 60 days. Always clarify payment methods accepted (e.g., bank transfer, PayPal, letter of credit) and ensure that your chosen method provides adequate protection against fraud or non-delivery. -

How can I manage logistics for shipping custom leather cowboy belts internationally?

To manage logistics effectively, partner with a supplier experienced in international shipping. Discuss shipping options, costs, and estimated delivery times upfront. Consider using Incoterms (like FOB or CIF) to clarify responsibilities for shipping, customs clearance, and insurance. Make sure to stay informed about import duties and regulations in your country to avoid unexpected costs or delays upon arrival. -

What should I look for in a supplier’s quality assurance (QA) processes?

When evaluating a supplier’s QA processes, inquire about their inspection protocols at various production stages. A reputable supplier should have a clear QA plan that includes material checks, in-process inspections, and final product evaluations. Request documentation or certifications that demonstrate adherence to quality standards, such as ISO certifications. Regular audits and customer feedback mechanisms can also indicate a supplier’s commitment to maintaining high-quality products. -

How can I assess a supplier’s reliability and reputation in the market?

Research a supplier’s reliability by checking their history, customer testimonials, and industry reputation. Utilize platforms like Alibaba, Global Sources, or industry-specific forums to read reviews and feedback from other B2B buyers. Additionally, consider requesting references from previous clients to gauge their experiences. A reliable supplier should have a solid track record of on-time deliveries and consistent product quality. -

What are the common customization options available for leather cowboy belts?

Customization options for leather cowboy belts typically include choices in leather type (e.g., full-grain, top-grain), color, width, and buckle style. Many suppliers also offer hand-tooling services for personalized designs, such as logos, names, or unique patterns. Additional features may include contrasting stitching, conchos, and specific belt sizes. Discuss your vision with the supplier to explore all available options that can enhance the uniqueness of your product.

Top 4 Custom Leather Cowboy Belts Manufacturers & Suppliers List

1. Gavere Leather – Unique Leather Accessories

Domain: gavereleather.net

Registered: 2003 (22 years)

Introduction: Gavere Leather offers unique leather accessories and custom leather belts, including personalized name belts for adults and kids, everyday styles, and various designs such as embossed, hand-painted, and western looks. Key product features include:

– Made from top-grain cowhide

– 16-step finishing process for durability

– Includes a sturdy buckle, leather keeper, and snaps for easy buckle change…

2. Wyoming Belts – Custom Hand Tooled Leather Belts

Domain: wyomingbelts.com

Registered: 2011 (14 years)

Introduction: Custom hand tooled leather belts, personalized designs, floral and tooling patterns, high-quality leather, one of a kind belts, currently booked out on custom floral belts, waiting list available.

3. Custom Cowboy Shop – Hand-Tooled Leather Belt

Domain: customcowboyshop.com

Registered: 2000 (25 years)

Introduction: {‘name’: ‘Hand-Tooled Leather Belt’, ‘sku’: ‘GRB-32’, ‘price’: ‘$335.00’, ‘customization_options’: ‘Custom made in-house, customizable with brands, initials, color options, varying buckle sizes, lined and stitched, buckstitch, laced edge, Ranger Style.’, ‘pricing_structure’: {‘plain_single_ply’: ‘$80’, ‘basket_tooled_single_ply’: ‘$115’, ‘basket_lined_and_stitched’: ‘$155’, ‘full_flower_single_ply…

4. Trail’s End Saddle Shop – Custom Belts

Domain: trailsendsaddleshop.com

Registered: 2022 (3 years)

Introduction: {“name”: “Custom Belts”, “brand”: “Trail’s End Saddle Shop”, “price_range”: “$250.00 – $335.00”, “craftsmanship”: “Handmade by saddlemaker Ben Geisler using top-quality Hermann Oak leather with masterful hand-tooling.”, “width”: “1-1/2 inch”, “materials”: “Top-grade Hermann Oak vegetable tanned saddle skirting lined with burgundy latigo.”, “customization_options”: {“leather_color”: [“Oiled Russet”…

Strategic Sourcing Conclusion and Outlook for custom leather cowboy belts

The custom leather cowboy belt market presents a unique opportunity for international B2B buyers seeking high-quality, personalized products that resonate with cultural heritage and craftsmanship. Key takeaways include the importance of selecting suppliers who prioritize hand-tooling techniques and offer extensive customization options, such as styles, colors, and buckles. This level of personalization not only enhances brand identity but also fosters customer loyalty in diverse markets across Africa, South America, the Middle East, and Europe.

Strategic sourcing is essential to navigating the complexities of global supply chains, ensuring that buyers can identify reliable partners who deliver on quality and craftsmanship. Building relationships with established artisans can lead to exclusive designs and competitive pricing, ultimately enhancing your product offerings.

As we look to the future, the demand for custom leather cowboy belts is expected to grow, driven by trends in personalized fashion and sustainable materials. Now is the time for B2B buyers to invest in these unique products that tell a story and reflect their values. Engage with skilled manufacturers and explore how tailored leather goods can elevate your business in the competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.