Introduction: Navigating the Global Market for bulk leather gloves

In an increasingly competitive global marketplace, sourcing bulk leather gloves presents a unique challenge for international B2B buyers. From ensuring the right quality and durability to understanding the complexities of supply chains, businesses must navigate a landscape filled with options and potential pitfalls. This guide is designed to empower you with comprehensive insights into the bulk leather gloves market, covering various types, applications, and the nuances of supplier vetting. Whether you are looking for gloves for industrial work, agricultural tasks, or outdoor applications, understanding these factors is crucial for making informed purchasing decisions.

This guide will delve into the essential aspects of bulk leather gloves, including material specifications, design features, and pricing structures. We will provide actionable insights into the best practices for evaluating suppliers, ensuring compliance with regional standards, and negotiating favorable terms. Special attention will be given to the specific needs of buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Germany and Saudi Arabia, where market demands and preferences may vary significantly.

By equipping yourself with this knowledge, you can enhance your procurement strategy, optimize your supply chain, and ultimately secure the best products for your business. With a clear understanding of the bulk leather gloves market, you will be better positioned to meet your operational needs while maximizing your return on investment.

Table Of Contents

- Top 5 Bulk Leather Gloves Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bulk leather gloves

- Understanding bulk leather gloves Types and Variations

- Key Industrial Applications of bulk leather gloves

- 3 Common User Pain Points for ‘bulk leather gloves’ & Their Solutions

- Strategic Material Selection Guide for bulk leather gloves

- In-depth Look: Manufacturing Processes and Quality Assurance for bulk leather gloves

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bulk leather gloves’

- Comprehensive Cost and Pricing Analysis for bulk leather gloves Sourcing

- Alternatives Analysis: Comparing bulk leather gloves With Other Solutions

- Essential Technical Properties and Trade Terminology for bulk leather gloves

- Navigating Market Dynamics and Sourcing Trends in the bulk leather gloves Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bulk leather gloves

- Strategic Sourcing Conclusion and Outlook for bulk leather gloves

- Important Disclaimer & Terms of Use

Understanding bulk leather gloves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cowhide Leather Gloves | Durable, abrasion-resistant, reinforced palm | Construction, warehousing, outdoor tasks | Pros: Long-lasting, versatile. Cons: May be heavier. |

| Pigskin Leather Gloves | Soft, flexible, good dexterity, water-resistant | Automotive, assembly, general labor | Pros: Comfortable fit, excellent grip. Cons: Less durable than cowhide. |

| Deerskin Leather Gloves | Soft, lightweight, high dexterity, natural insulation | Precision tasks, electronics assembly | Pros: Superior comfort, flexible. Cons: Higher cost. |

| Goatskin Leather Gloves | Soft, durable, good abrasion resistance | Heavy machinery, metal handling | Pros: Excellent dexterity, durable. Cons: Slightly more expensive. |

| Welding Leather Gloves | Heat-resistant, reinforced for welding tasks | Welding, metal fabrication | Pros: High protection against heat, durable. Cons: Limited flexibility. |

What Are the Key Characteristics of Cowhide Leather Gloves?

Cowhide leather gloves are renowned for their durability and resistance to abrasion, making them ideal for demanding environments such as construction and warehousing. They typically feature reinforced palms, enhancing their lifespan during rough handling tasks. B2B buyers should consider their weight and potential bulkiness, which may affect comfort during prolonged use, but their versatility and long-lasting nature often outweigh these concerns.

Why Choose Pigskin Leather Gloves for Your Workforce?

Pigskin leather gloves are favored for their softness and flexibility, providing excellent dexterity for tasks that require precision, such as automotive assembly. They also offer a degree of water resistance, making them suitable for various working conditions. Buyers should note that while they provide superior comfort and grip, they may not last as long as cowhide gloves in extremely abrasive environments.

When to Use Deerskin Leather Gloves?

Deerskin leather gloves are lightweight and offer a high degree of dexterity, making them perfect for precision tasks such as electronics assembly or fine craftsmanship. Their natural insulation keeps hands warm in cooler conditions. However, their higher price point may be a consideration for bulk purchases, especially for industries where gloves are frequently replaced.

Illustrative image related to bulk leather gloves

What Advantages Do Goatskin Leather Gloves Offer?

Goatskin leather gloves are appreciated for their balance of softness and durability, making them ideal for heavy machinery operation and metal handling. They provide excellent dexterity, allowing workers to handle tools and materials with precision. While they tend to be slightly more expensive than cowhide options, their longevity and performance in varied conditions justify the investment for many B2B buyers.

How Do Welding Leather Gloves Stand Out?

Welding leather gloves are specifically designed for high-heat environments, featuring reinforced areas to protect against sparks and molten metal. They are crucial for industries involved in welding and metal fabrication. While they offer exceptional protection, buyers should be aware of their limited flexibility, which may hinder fine motor tasks. For companies prioritizing safety in welding operations, these gloves are a necessary investment.

Key Industrial Applications of bulk leather gloves

| Industry/Sector | Specific Application of bulk leather gloves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Handling heavy materials and tools | Enhanced safety and durability reduce workplace injuries | Ensure compliance with local safety regulations and standards. |

| Agriculture | Crop handling and livestock management | Improved grip and protection during outdoor tasks | Look for gloves with abrasion resistance and comfort for long wear. |

| Manufacturing | Assembly line work and machinery operation | Increased productivity and worker comfort | Source gloves that are durable and provide tactile sensitivity. |

| Logistics/Warehousing | Package handling and transportation | Enhanced grip and protection against cuts and abrasions | Consider bulk purchasing options for cost efficiency. |

| Automotive Repair | Vehicle maintenance and repair tasks | Protection against oils, chemicals, and sharp objects | Ensure gloves meet specific automotive industry standards. |

How Are Bulk Leather Gloves Used in the Construction Industry?

In the construction sector, bulk leather gloves are essential for handling heavy materials and tools. Their durable nature and reinforced palms provide excellent protection against cuts and abrasions, ensuring worker safety on-site. Buyers should prioritize sourcing gloves that comply with local safety regulations, especially in regions like Europe and the Middle East, where standards can be stringent. Additionally, gloves should feature a comfortable fit for extended wear, as workers often spend long hours on tasks that require dexterity.

What Role Do Bulk Leather Gloves Play in Agriculture?

In agriculture, bulk leather gloves are used for various tasks, including crop handling and livestock management. The gloves offer a robust barrier against thorns and rough surfaces while providing a firm grip for handling tools and equipment. For international buyers in Africa and South America, selecting gloves that are both abrasion-resistant and comfortable is crucial, as these factors directly impact productivity and safety. Sourcing from reputable manufacturers ensures that gloves meet the unique demands of agricultural work.

How Are Bulk Leather Gloves Applied in Manufacturing?

In manufacturing environments, bulk leather gloves are utilized for assembly line work and machinery operation. Their ability to withstand wear and tear while providing tactile sensitivity enhances productivity and worker comfort. B2B buyers should consider gloves that offer a balance of durability and flexibility, particularly when working with small parts or intricate machinery. Ensuring that the sourced gloves meet industry-specific standards can help mitigate risks associated with workplace injuries.

Illustrative image related to bulk leather gloves

Why Are Bulk Leather Gloves Important for Logistics and Warehousing?

Within logistics and warehousing, bulk leather gloves are vital for package handling and transportation. These gloves provide an enhanced grip and protection against cuts, which is essential for workers handling sharp objects or heavy parcels. Buyers in this sector should seek bulk purchasing options to optimize costs while ensuring that the gloves meet safety and quality standards. Additionally, gloves with features like breathable materials can improve comfort during long shifts.

How Do Bulk Leather Gloves Benefit the Automotive Repair Industry?

In the automotive repair industry, bulk leather gloves are crucial for vehicle maintenance and repair tasks. They protect against oils, chemicals, and sharp tools, ensuring that mechanics can work safely and efficiently. B2B buyers should focus on sourcing gloves that are specifically designed for automotive applications, as these often have enhanced grip and durability. Compliance with industry standards is also essential to ensure that the gloves provide adequate protection in various repair scenarios.

3 Common User Pain Points for ‘bulk leather gloves’ & Their Solutions

Scenario 1: Inconsistent Quality Across Bulk Orders

The Problem: B2B buyers often face challenges with quality consistency when ordering bulk leather gloves. One batch may arrive with superior craftsmanship, while another might have flaws such as weak seams or inferior materials. This inconsistency can lead to increased returns, unsatisfied customers, and ultimately, a tarnished reputation for businesses that rely on these gloves for safety and performance.

The Solution: To mitigate this issue, buyers should prioritize sourcing gloves from reputable manufacturers who offer transparent quality assurance processes. Before placing a large order, request samples from potential suppliers to evaluate the quality firsthand. Establish a clear quality specification document that outlines the expected standards, including material type, stitching methods, and durability tests. Additionally, consider suppliers who provide certifications or quality guarantees, ensuring that their products meet industry standards. Regular communication with the supplier throughout the production process can also help to address any discrepancies before shipment.

Scenario 2: Difficulty in Sizing and Fit for Diverse Workforces

The Problem: Another common issue arises from the challenge of sizing and fit when purchasing bulk leather gloves. Different workers may require various sizes to perform their tasks effectively, and a one-size-fits-all approach can lead to discomfort, decreased productivity, and increased risk of accidents due to improper fit. This is particularly pertinent for businesses operating in regions with diverse populations, where average hand sizes may vary significantly.

Illustrative image related to bulk leather gloves

The Solution: To address sizing challenges, conduct a thorough assessment of your workforce’s glove size requirements. Distribute a simple sizing chart or conduct a fitting session to gather data on hand sizes. When placing an order, consider purchasing a range of sizes or customizable options to ensure all employees have access to appropriately fitting gloves. Some suppliers offer bulk discounts on mixed-size orders, which can be a cost-effective way to accommodate a diverse workforce. Additionally, providing a clear return policy can encourage employees to exchange gloves that do not fit properly without incurring additional costs.

Scenario 3: Ensuring Compliance with Safety Standards

The Problem: Compliance with safety regulations is critical for B2B buyers in industries such as construction, manufacturing, and logistics. However, many buyers struggle to ensure that the bulk leather gloves they purchase meet the necessary safety standards for their specific applications. Failure to comply can lead to legal repercussions, financial losses, and increased workplace injuries.

The Solution: Buyers should familiarize themselves with the relevant safety standards applicable to their industry, such as ANSI/ISEA or EN standards, which outline the required protective features for work gloves. When sourcing gloves, specifically ask suppliers for documentation that verifies compliance with these standards. It is beneficial to work with suppliers who specialize in personal protective equipment (PPE) and have a deep understanding of safety regulations. Additionally, consider investing in training programs for employees to ensure they understand how to select and use gloves effectively based on the specific hazards they face in their roles. Regularly reviewing and updating safety practices can help maintain compliance and improve overall workplace safety.

Strategic Material Selection Guide for bulk leather gloves

What Are the Key Properties of Common Materials Used in Bulk Leather Gloves?

When selecting bulk leather gloves, understanding the materials involved is crucial for ensuring that the gloves meet specific performance requirements. Here, we analyze four common materials used in the production of bulk leather gloves: cowhide, pigskin, goatskin, and deerskin. Each material has unique properties that influence its suitability for various applications.

Illustrative image related to bulk leather gloves

How Does Cowhide Leather Perform in Bulk Leather Gloves?

Cowhide leather is one of the most popular materials for work gloves due to its durability and versatility. It offers excellent abrasion resistance and a good grip, making it suitable for heavy-duty applications such as construction and warehousing. Cowhide can withstand high temperatures, which is beneficial for tasks involving heat exposure.

Pros: Cowhide gloves are generally more affordable than other leather types and provide a long lifespan, making them a cost-effective choice for bulk purchases. They are also widely available, ensuring that international buyers can source them easily.

Cons: While cowhide is durable, it can be less flexible than other leathers, which may affect dexterity in tasks requiring fine motor skills. Additionally, it may not perform as well in wet conditions unless treated.

Impact on Application: Cowhide gloves are ideal for tasks that involve rough handling and exposure to various media, including oils and chemicals. However, buyers should ensure compliance with local safety standards, such as ASTM or EN 388.

Illustrative image related to bulk leather gloves

What Are the Advantages of Pigskin Leather in Bulk Leather Gloves?

Pigskin leather is known for its softness and breathability, making it a comfortable choice for extended wear. It provides good abrasion resistance and is less prone to stiffening when wet, which is a significant advantage for outdoor applications.

Pros: Pigskin gloves are often more affordable than cowhide and offer excellent flexibility, making them suitable for tasks that require dexterity. They also dry relatively quickly, which is advantageous in humid environments.

Cons: While pigskin is durable, it may not be as resistant to cuts and punctures as cowhide. Additionally, its availability may vary by region, which could impact bulk sourcing.

Impact on Application: Pigskin gloves are suitable for agricultural work, landscaping, and other outdoor tasks. Buyers from regions with high humidity, such as parts of South America and Africa, may find pigskin gloves particularly advantageous.

How Does Goatskin Leather Compare for Bulk Leather Gloves?

Goatskin leather is recognized for its exceptional softness and flexibility, providing a high level of dexterity. It is also highly resistant to abrasion and offers a good grip, making it suitable for precision tasks.

Pros: The comfort and dexterity of goatskin make it ideal for intricate work, such as automotive assembly or delicate handling. It also has good insulation properties, which can be beneficial in cooler climates.

Cons: Goatskin gloves tend to be more expensive than cowhide and pigskin, which could be a consideration for bulk purchases. They may also require more careful maintenance to preserve their quality.

Impact on Application: Goatskin gloves are well-suited for industries requiring precision and dexterity, such as electronics or fine assembly work. International buyers should consider compliance with industry-specific standards, especially in Europe.

What Makes Deerskin Leather a Unique Choice for Bulk Leather Gloves?

Deerskin leather is prized for its softness and luxurious feel, providing excellent comfort for the wearer. It is highly flexible and offers good insulation, making it suitable for colder environments.

Pros: Deerskin gloves are exceptionally comfortable and conform well to the hand, providing a natural fit. They also have a unique aesthetic appeal, which can be a selling point in certain markets.

Cons: The primary drawback of deerskin is its cost, as it is one of the more expensive leather types. Additionally, it may not be as durable as cowhide or pigskin in high-abrasion environments.

Impact on Application: Deerskin gloves are ideal for tasks that require comfort and dexterity, such as driving or light industrial work. Buyers should ensure that they are aware of any specific import regulations regarding leather goods in their respective regions.

Summary Table of Material Properties for Bulk Leather Gloves

| Material | Typical Use Case for bulk leather gloves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Construction, warehousing | Durable and cost-effective | Less flexible than other leathers | Medium |

| Pigskin | Agricultural work, landscaping | Soft, breathable, good flexibility | Less cut-resistant | Low |

| Goatskin | Precision tasks, automotive assembly | High dexterity and comfort | Higher cost | High |

| Deerskin | Driving, light industrial work | Exceptional comfort and fit | Expensive, less durable | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various leather materials used in bulk gloves, enabling informed purchasing decisions tailored to their specific needs and regional compliance requirements.

Illustrative image related to bulk leather gloves

In-depth Look: Manufacturing Processes and Quality Assurance for bulk leather gloves

What Are the Main Stages of Manufacturing Bulk Leather Gloves?

The manufacturing of bulk leather gloves involves several critical stages that ensure the final product meets the required quality standards for various applications. Each stage has specific techniques that contribute to the overall durability, comfort, and functionality of the gloves.

Material Preparation: What Is Involved?

The first stage in the manufacturing process is material preparation. High-quality leather, often sourced from cowhide or pigskin, is carefully selected based on its thickness, grain, and durability. The leather undergoes a tanning process to enhance its resistance to moisture, wear, and microbial growth. Once tanned, the leather is cut into various shapes and sizes according to the glove design. This cutting process is often executed using precision machinery to ensure uniformity across batches, reducing waste and improving efficiency.

How Are Leather Gloves Formed?

Following material preparation, the forming stage begins. This involves shaping the leather pieces into glove forms, which may include techniques such as sewing or molding. The forming process often uses a combination of manual and automated methods. For instance, a keystone thumb design, which allows for greater dexterity and comfort, may require more intricate sewing techniques. At this stage, additional features like reinforced palms or double stitching are incorporated to enhance durability, particularly for gloves intended for heavy-duty tasks.

Illustrative image related to bulk leather gloves

What Happens During Assembly?

The assembly stage is where all the components come together. This includes attaching the leather parts, adding linings for comfort, and incorporating any additional protective features such as safety cuffs or insulation for cold weather use. Quality is paramount during assembly, and many manufacturers employ skilled artisans to oversee the stitching and attachment processes. This stage may also involve the use of automated sewing machines for consistency and speed, particularly for bulk orders.

What Finishing Touches Are Applied?

Finally, the finishing stage focuses on the aesthetic and functional enhancements of the gloves. This includes processes such as edge trimming, polishing, and the application of coatings that improve water resistance. The gloves are then inspected for any defects, and packaging is prepared for bulk shipment. This stage is critical for ensuring that the gloves not only meet industry standards but also appeal to buyers’ preferences in terms of design and usability.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is integral to ensuring that the gloves produced meet international standards. B2B buyers should be aware of several quality certifications and industry-specific standards that enhance the credibility of suppliers.

Which International Standards Apply?

One of the most recognized international quality management standards is ISO 9001. This standard outlines criteria for a quality management system and is applicable to any organization looking to improve customer satisfaction and operational efficiency. Manufacturers of leather gloves that comply with ISO 9001 demonstrate a commitment to quality and consistent production processes.

What Industry-Specific Certifications Are Relevant?

In addition to ISO certifications, there are specific industry standards such as CE marking for personal protective equipment (PPE) in Europe, which indicates that the gloves meet safety, health, and environmental protection standards. For specialized applications, such as welding gloves, compliance with American Petroleum Institute (API) standards may also be necessary. Buyers should verify that their suppliers hold the relevant certifications for their specific markets.

How Can B2B Buyers Verify Quality Control Processes?

Quality control (QC) is a multi-faceted approach that involves various checkpoints throughout the manufacturing process. B2B buyers should familiarize themselves with the common QC checkpoints to ensure the gloves meet their expectations.

What Are the Key QC Checkpoints?

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. Suppliers should have procedures in place to evaluate the leather and other components for defects or inconsistencies.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors the production process to catch defects early. This may involve random sampling of gloves at various stages to ensure they meet specified dimensions and quality standards.

-

Final Quality Control (FQC): The final inspection occurs once the gloves are fully assembled. This stage ensures that the gloves meet all quality standards, including stitching integrity, material defects, and overall appearance.

How Can Buyers Conduct Audits and Inspections?

B2B buyers can strengthen their assurance of quality by conducting supplier audits and requesting detailed QC reports. Audits can be performed by the buyers themselves or through third-party inspection agencies. These inspections can provide insights into the manufacturing processes, adherence to quality standards, and the effectiveness of the supplier’s QC protocols.

What Testing Methods Are Commonly Used?

Various testing methods are employed to validate the performance and safety of leather gloves. Some common tests include:

- Abrasion Resistance Tests: Assess how well the gloves withstand wear over time.

- Puncture Resistance Tests: Determine the gloves’ ability to resist punctures from sharp objects.

- Water Resistance Tests: Evaluate the effectiveness of any water-resistant coatings applied during finishing.

What Are the QC Nuances for International Buyers?

For international B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Regulations and quality expectations may vary significantly between regions. Buyers should ensure that suppliers are familiar with the specific requirements of their target markets, including any regional certifications that may be necessary.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for bulk leather gloves can empower B2B buyers to make informed purchasing decisions. By prioritizing suppliers who adhere to recognized standards and maintain robust QC procedures, buyers can ensure they receive high-quality products that meet their operational needs.

Illustrative image related to bulk leather gloves

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bulk leather gloves’

To effectively source bulk leather gloves for your business, it’s essential to follow a structured approach. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process, ensuring you make informed decisions and secure high-quality products.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing leather gloves that meet your operational needs. Consider factors such as material type (e.g., cowhide, pigskin), glove design (e.g., reinforced palms, keystone thumb), and intended use (e.g., industrial, outdoor).

- Material Quality: Look for gloves made from genuine leather to ensure durability and comfort.

- Design Features: Identify any specific design features that enhance functionality, such as double stitching for added strength or moisture-wicking properties.

Step 2: Research Potential Suppliers

A thorough market research process will help you identify reliable suppliers. Utilize online directories, trade shows, and industry networks to compile a list of manufacturers and distributors specializing in leather gloves.

- Supplier Reputation: Investigate supplier reviews and ratings to gauge their reliability.

- Local vs. International: Consider the pros and cons of sourcing locally versus internationally, including shipping costs and lead times.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with international standards. This step is vital for ensuring the gloves meet safety regulations and quality benchmarks.

- Quality Assurance Certifications: Look for ISO certifications or similar quality management standards.

- Safety Compliance: Ensure the gloves comply with relevant safety standards for your industry, such as EN 388 for protective gloves in Europe.

Step 4: Request Samples for Quality Assessment

Always request samples from potential suppliers before placing a bulk order. This allows you to assess the quality, fit, and comfort of the gloves.

Illustrative image related to bulk leather gloves

- Test Durability: Evaluate the gloves in real-world conditions relevant to your business operations.

- Feedback from Users: Gather input from employees who will use the gloves to ensure they meet practical needs.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a preferred supplier, it’s time to negotiate pricing and terms of sale. Bulk purchasing often allows for discounts, so be sure to leverage this.

- Bulk Discounts: Inquire about tiered pricing structures based on order quantities.

- Payment Terms: Discuss payment options, including deposits and payment upon delivery, to manage cash flow effectively.

Step 6: Establish a Clear Order Process

After finalizing your supplier, establish a clear order process to ensure timely delivery and quality control. This includes defining order quantities, delivery schedules, and quality assurance measures.

- Order Tracking: Implement a system for tracking orders and delivery dates to avoid disruptions.

- Return Policy: Clarify the supplier’s return policy in case the gloves do not meet the agreed-upon specifications.

Step 7: Build a Long-term Relationship with Suppliers

Finally, focus on establishing a long-term relationship with your chosen supplier. Strong partnerships can lead to better pricing, priority service, and improved product offerings over time.

- Regular Communication: Maintain open lines of communication to discuss any issues or changes in your requirements.

- Feedback Loop: Provide feedback on product performance to help suppliers improve their offerings.

Following these steps will help you successfully navigate the sourcing process for bulk leather gloves, ensuring that you secure a high-quality product that meets your business needs.

Comprehensive Cost and Pricing Analysis for bulk leather gloves Sourcing

What Are the Key Cost Components in Bulk Leather Gloves Sourcing?

When sourcing bulk leather gloves, understanding the cost structure is crucial for B2B buyers to make informed decisions. The primary components influencing the cost include:

Illustrative image related to bulk leather gloves

-

Materials: The type of leather (cowhide, pigskin, deerskin) and its grade significantly impact pricing. Premium materials often lead to higher costs but may provide better durability and protection.

-

Labor: Labor costs vary based on geographic location and the complexity of the glove design. Regions with lower labor costs may offer more competitive pricing, but it’s essential to ensure that quality isn’t compromised.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can lower overhead costs, which may be reflected in the final price.

-

Tooling: Custom tooling for specific glove designs can add to initial costs. Buyers should consider whether the investment in tooling is justified by the expected volume of orders.

-

Quality Control (QC): Implementing strict QC measures ensures that gloves meet safety and quality standards. While this adds to production costs, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs, including freight, customs duties, and warehousing, play a significant role in the total cost. International buyers must factor in these logistics expenses, which can vary greatly depending on the shipping method and destination.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the market rates can help buyers gauge if the pricing is fair.

How Do Price Influencers Impact Bulk Leather Gloves Pricing?

Several factors influence the pricing of bulk leather gloves, making it essential for buyers to consider:

-

Volume/MOQ: Suppliers often offer tiered pricing structures based on minimum order quantities (MOQs). Higher volumes can lead to substantial discounts, making bulk purchases more cost-effective.

-

Specifications and Customization: Custom features, such as reinforced stitching or unique designs, can increase production costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Gloves that meet specific safety standards or are made from premium materials typically command higher prices. Certifications can also influence buyer decisions, especially in regulated industries.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) dictate who is responsible for costs at various stages of transit. Understanding these terms can help buyers manage their total landed costs effectively.

What Buyer Tips Can Enhance Cost-Efficiency in Bulk Leather Gloves Procurement?

To maximize value when sourcing bulk leather gloves, consider the following tips:

-

Negotiate Effectively: Engage in discussions with suppliers about pricing, especially if you plan to place large orders. Leverage competing quotes to strengthen your negotiating position.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate costs related to maintenance, longevity, and potential liability. A cheaper glove may incur higher costs over time if it wears out quickly.

-

Understand Pricing Nuances for International Buyers: Factors such as currency fluctuations, tariffs, and local taxes can significantly affect the final cost. Buyers from Africa, South America, the Middle East, and Europe must stay informed about these variables to avoid unexpected expenses.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with a supplier can lead to better pricing and improved service. Many suppliers are willing to negotiate favorable terms for repeat business.

Disclaimer on Pricing

Pricing for bulk leather gloves can vary widely based on the aforementioned factors. The prices mentioned in various sources serve as indicative figures, and actual costs may differ based on market conditions and specific buyer requirements. Always request detailed quotes and confirm prices directly with suppliers.

Alternatives Analysis: Comparing bulk leather gloves With Other Solutions

In the quest for effective hand protection solutions, bulk leather gloves stand out as a robust option, particularly for industrial and outdoor applications. However, businesses often face the challenge of selecting the most suitable protective gear from various alternatives. This section provides a comparative analysis of bulk leather gloves against other viable solutions, helping B2B buyers make informed decisions tailored to their unique requirements.

| Comparison Aspect | Bulk Leather Gloves | Synthetic Work Gloves | Cotton-PVC Dotted Gloves |

|---|---|---|---|

| Performance | High durability and abrasion resistance; ideal for rough tasks | Good grip and flexibility; suitable for light to moderate tasks | Moderate durability; excellent for light-duty tasks |

| Cost | Generally higher upfront investment; bulk discounts available | Lower initial cost; less durable over time | Very affordable; low-cost option for disposable use |

| Ease of Implementation | Requires proper sizing and fit; easy to stock in bulk | Simple to source and fit; available in various sizes | Very easy to implement; often sold in large quantities |

| Maintenance | Requires occasional cleaning; long lifespan with care | Generally disposable; minimal maintenance | Disposable; no maintenance required |

| Best Use Case | Heavy-duty industrial work, outdoor tasks, and equipment handling | Construction, landscaping, and warehousing | General light-duty tasks, assembly lines, and food handling |

What Are the Advantages and Disadvantages of Synthetic Work Gloves?

Synthetic work gloves are designed to offer flexibility and comfort, making them ideal for light to moderate tasks. These gloves typically feature a blend of materials that enhance grip and dexterity. They are often less expensive than leather gloves, which can be a significant factor for businesses operating on tight budgets. However, their durability is generally lower, leading to more frequent replacements. This can increase long-term costs and waste, making them less ideal for heavy-duty applications where longevity is paramount.

Illustrative image related to bulk leather gloves

How Do Cotton-PVC Dotted Gloves Compare?

Cotton-PVC dotted gloves are an economical alternative widely used in various light-duty applications. Their unique dotted pattern provides decent grip on smooth surfaces, making them suitable for assembly lines or light handling tasks. The low cost of these gloves makes them a favorite for businesses looking to minimize expenditures on personal protective equipment. However, they lack the durability and protection offered by leather gloves, making them unsuitable for tasks involving heavy lifting or exposure to harsh conditions.

Making the Right Choice: How Should B2B Buyers Decide?

When determining the appropriate hand protection solution, B2B buyers should assess their specific operational needs, budget constraints, and the nature of the tasks at hand. Bulk leather gloves offer unparalleled durability and protection for heavy-duty applications, making them ideal for industries such as construction and manufacturing. Conversely, if the work environment involves lighter tasks with minimal risk, synthetic or cotton-PVC dotted gloves may provide sufficient protection at a lower cost. Ultimately, understanding the trade-offs between performance, cost, and application will empower buyers to make informed decisions that best suit their operational requirements.

Essential Technical Properties and Trade Terminology for bulk leather gloves

What Are the Key Technical Properties of Bulk Leather Gloves?

When sourcing bulk leather gloves, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

1. Material Grade

Leather gloves are typically made from various grades of leather, such as cowhide, pigskin, or goatskin. Cowhide is the most common due to its balance of durability and comfort. Higher-grade leather often features better abrasion resistance and longer wear life, making it essential for heavy-duty applications. For B2B buyers, selecting the appropriate material grade can impact product longevity and worker safety.

2. Stitching Quality

The stitching on leather gloves can significantly affect their durability. High-quality gloves often feature heavy-duty stitching with reinforced seams that resist tearing. The type of stitch, such as double or triple stitching, also contributes to the glove’s strength. For bulk purchases, ensuring the gloves have robust stitching can reduce replacement costs and enhance user satisfaction.

Illustrative image related to bulk leather gloves

3. Safety Features

Many bulk leather gloves come equipped with safety features such as reinforced palms, safety cuffs, and thumb protection. These elements help protect workers from injuries associated with heavy lifting or hazardous materials. For B2B buyers, these features are vital in ensuring compliance with workplace safety regulations and minimizing liability.

4. Grip and Dexterity

A glove’s design should allow for a firm grip while maintaining dexterity for handling tools and equipment. Features such as textured palms and finger design, like keystone thumbs, enhance grip without sacrificing flexibility. Buyers must consider these aspects to ensure their workers can perform tasks efficiently and safely.

5. Comfort and Fit

Comfort is a significant factor in glove selection. Many gloves incorporate elasticized backs or adjustable cuffs to provide a secure fit without restricting movement. A well-fitting glove reduces fatigue and enhances productivity. In bulk purchasing, it is advisable to select gloves that offer various sizes to accommodate different hand shapes and sizes within the workforce.

Illustrative image related to bulk leather gloves

6. Washability and Maintenance

The ability to wash and maintain gloves extends their lifespan and hygiene. Some leather gloves are treated to be machine washable, while others may require special care. For B2B buyers, understanding the maintenance requirements is essential for budget management and ensuring that gloves remain in good condition over time.

What Are Common Trade Terms Used in Bulk Leather Gloves Procurement?

Familiarizing yourself with industry jargon can streamline the purchasing process. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that can be rebranded by other companies. For bulk leather gloves, this means sourcing from manufacturers who can produce gloves to specific design and quality standards for your brand. Understanding OEM partnerships can enhance product quality and brand reputation.

Illustrative image related to bulk leather gloves

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. For bulk leather gloves, MOQs can vary widely, impacting your purchasing strategy. Knowing the MOQ is essential for managing inventory and cash flow, especially for businesses with fluctuating demand.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for a specific quantity of goods. When purchasing bulk leather gloves, sending an RFQ helps ensure competitive pricing and can facilitate negotiations. This is a vital step in the procurement process for securing the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit. This knowledge can prevent misunderstandings and protect your investment.

5. Lead Time

Lead time is the period from placing an order to receiving the product. In bulk leather glove procurement, understanding lead times can help in planning and inventory management. Buyers should factor in lead times when placing orders to ensure they have adequate stock for operational needs.

6. Certification Standards

Certain certifications, such as EN388 for protective gloves, indicate compliance with safety and quality standards. B2B buyers should seek gloves that meet relevant certification standards to ensure worker safety and regulatory compliance, which can significantly impact purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can navigate the procurement process more effectively and select the right bulk leather gloves for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the bulk leather gloves Sector

What Are the Key Trends Shaping the Global Bulk Leather Gloves Market?

The bulk leather gloves market is experiencing significant growth driven by several global factors. Increasing safety regulations across industries such as construction, manufacturing, and agriculture are propelling demand for personal protective equipment (PPE), including leather gloves. Furthermore, the rise in outdoor recreational activities and the growing automotive sector, particularly in regions like Africa and South America, are enhancing the need for durable gloves that offer both protection and comfort.

Emerging technologies are also influencing sourcing trends. Digital platforms and B2B marketplaces facilitate streamlined procurement processes, enabling buyers to compare prices, quality, and supplier certifications efficiently. This shift towards e-commerce in procurement is particularly beneficial for international buyers from regions like the Middle East and Europe, who can access a broader range of suppliers and negotiate better terms. Additionally, the use of data analytics in inventory management allows businesses to optimize their stock levels and reduce costs, enhancing operational efficiency.

Illustrative image related to bulk leather gloves

Market dynamics are also evolving with the introduction of bulk pricing strategies. Suppliers are increasingly offering tiered pricing models to incentivize larger purchases, thus appealing to businesses looking to maximize their budget. As competition intensifies, suppliers who can demonstrate quality, reliability, and transparency in their supply chain are more likely to secure long-term partnerships with B2B buyers.

How Is Sustainability Influencing Ethical Sourcing in the Bulk Leather Gloves Industry?

Sustainability is becoming a pivotal consideration for B2B buyers in the bulk leather gloves sector. The environmental impact of leather production, including deforestation and water usage, has led to increased scrutiny of sourcing practices. Buyers are now prioritizing suppliers who adhere to sustainable practices and can provide transparency regarding their supply chains.

Ethical sourcing is not just about environmental considerations; it also encompasses social responsibility. Buyers are seeking suppliers who ensure fair labor practices and humane treatment of workers throughout the production process. Certifications such as the Leather Working Group (LWG) certification and Global Organic Textile Standard (GOTS) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

The trend towards green materials is also gaining momentum. Innovations in alternative leather, such as plant-based leathers or recycled materials, are appealing to environmentally conscious buyers. By choosing gloves made from sustainable materials, businesses can not only reduce their carbon footprint but also enhance their brand reputation in a market that increasingly values corporate social responsibility.

What Is the Historical Context of Bulk Leather Gloves in the B2B Market?

The history of bulk leather gloves dates back centuries, with their use in various industries evolving alongside advancements in manufacturing techniques. Initially, leather gloves were handcrafted, offering limited availability and high costs. However, the industrial revolution brought about mechanization, allowing for mass production and making leather gloves more accessible to a broader market.

In the late 20th century, the introduction of synthetic materials began to challenge traditional leather gloves, prompting manufacturers to innovate and improve the quality and durability of leather products. This evolution has led to the development of specialized gloves for various applications, from welding to gardening, catering to specific industry needs.

Today, the bulk leather gloves market is marked by a blend of traditional craftsmanship and modern technology, with a focus on meeting the demands of an increasingly globalized marketplace. As businesses continue to seek reliable and high-quality protective gear, the evolution of bulk leather gloves remains a significant aspect of the broader PPE landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of bulk leather gloves

-

How do I ensure the quality of bulk leather gloves before purchasing?

To ensure quality, request samples from potential suppliers to evaluate the material and craftsmanship firsthand. Look for certifications that meet international safety standards. Additionally, inquire about the supplier’s quality assurance processes, including inspections during production and before shipment. Customer reviews and feedback can provide insight into the gloves’ durability and performance in real-world applications. Establishing a clear communication channel with the supplier can also help address any quality concerns before finalizing your order. -

What are the best types of leather gloves for industrial use?

The best types of leather gloves for industrial use depend on the specific tasks and hazards involved. Cowhide gloves are known for their durability and abrasion resistance, making them ideal for heavy-duty tasks. Goatskin gloves offer flexibility and comfort, suitable for tasks requiring dexterity. For welding, elkskin gloves provide superior heat resistance. Assess the working environment and specific requirements to choose the right type that offers optimal protection and functionality. -

What is the typical minimum order quantity (MOQ) for bulk leather gloves?

The minimum order quantity for bulk leather gloves can vary significantly based on the supplier and the type of gloves. Generally, MOQs range from 100 to 1,000 pairs. Some suppliers may offer lower MOQs for specific styles, while others might have higher thresholds for custom orders. It’s essential to clarify the MOQ with potential suppliers before proceeding, as this can affect your budget and inventory management. -

How can I customize bulk leather gloves for my brand?

Customization options typically include adding your company logo, selecting specific colors, or altering design features such as cuff style or palm reinforcement. Most suppliers offer customization services, but it’s crucial to discuss your requirements upfront. Be prepared to provide design specifications or artwork files for logos. Additionally, confirm any minimum order quantities or price increases associated with customization to ensure your project remains within budget. -

What payment terms are commonly offered by suppliers of bulk leather gloves?

Payment terms can vary by supplier, but common options include upfront payment, net 30 or 60 days, and letter of credit for larger transactions. Some suppliers may offer a deposit followed by the balance upon shipment. It’s essential to negotiate terms that align with your cash flow needs while ensuring the supplier’s confidence in fulfilling the order. Always confirm the accepted payment methods to avoid any delays in processing your order. -

What logistics considerations should I keep in mind when importing bulk leather gloves?

When importing bulk leather gloves, consider shipping costs, customs duties, and potential delays in transit. Work with a logistics partner experienced in international shipping to ensure compliance with local regulations and customs requirements. It’s also vital to confirm the supplier’s shipping capabilities and timelines. Additionally, evaluate options for insurance during transit to protect your investment against loss or damage. -

How can I vet suppliers of bulk leather gloves effectively?

To vet suppliers, start by researching their reputation through online reviews and industry forums. Request references from previous clients and check their compliance with international quality standards. Visiting the supplier’s manufacturing facility, if possible, provides insights into their production processes. Additionally, verify their certifications and memberships in trade associations to ensure they adhere to industry best practices. -

What are the benefits of sourcing leather gloves from different regions?

Sourcing leather gloves from different regions can offer several advantages, including cost savings, access to unique materials, and diverse manufacturing techniques. For instance, some countries may specialize in specific types of leather, providing a quality that meets particular needs. Additionally, regional suppliers may offer competitive pricing due to lower labor costs. However, consider factors like shipping times and tariffs when evaluating suppliers from various regions to ensure your supply chain remains efficient and cost-effective.

Top 5 Bulk Leather Gloves Manufacturers & Suppliers List

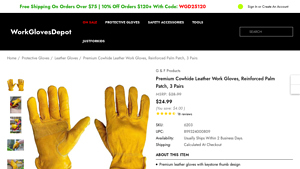

1. G & F Products – Premium Cowhide Leather Work Gloves

Domain: workglovesdepot.com

Registered: 2005 (20 years)

Introduction: Product Name: Premium Cowhide Leather Work Gloves, Reinforced Palm Patch, 3 Pairs

Brand: G & F Products

MSRP: $28.99

Sale Price: $24.99 (You save: $4.00)

SKU: 6203

UPC: 899324000809

Availability: Usually ships within 2 business days

Shipping: Calculated at Checkout

Key Features:

– Premium leather gloves with keystone thumb design

– Washable and durable with elastic shirred back for secure fit

– Ve…

2. MCR Safety – Bulk Leather Gloves

Domain: shop.mcrsafety.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Bulk Leather Gloves”, “price”: {“individual_pair”: “$12.00”, “dozen”: “$144.00”}, “sizes_available”: [“XL”], “ansi_ratings”: {“abrasion”: 4, “contact_heat”: 5, “puncture”: 5}, “leather_type”: “Elk”, “products”: [{“model”: “P49751”, “description”: “Premium Gold Elkskin Welder”, “sold_by”: “Pair”}, {“model”: “P49750”, “description”: “Premium Pearl Gray Elkskin Welder”, “sold_by”: “…

3. The Glove Warehouse – Leather Palm Work Gloves

Domain: theglovewarehouse.com

Registered: 2010 (15 years)

Introduction: Leather Palm Work Gloves made from Cowhide, Goathide, and Pigskin leather. Designed for safety and comfort while handling heavy or sharp objects. Available in various styles and sizes. Recommended minimum quality rating of select grade for side split leather. Options include uninsulated and insulated gloves. Brands include LIBERTY SAFETY, RADIANS, CAIMAN, PYRAMEX, MAJESTIC, HYPERFIT, SHOWA ELITE, …

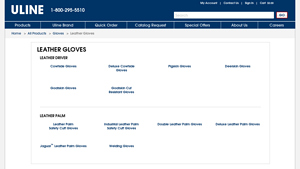

4. Uline – Leather Work Gloves

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Leather Gloves, Leather Palm Work Gloves, Leather Driver Cowhide Gloves, Deluxe Cowhide Gloves, Pigskin Gloves, Deerskin Gloves, Goatskin Gloves, Goatskin Cut Resistant Gloves, Leather Palm Safety Cuff Gloves, Industrial Leather Palm Safety Cuff Gloves, Double Leather Palm Gloves, Deluxe Leather Palm Gloves, Jaguar ™ Leather Palm Gloves, Welding Gloves.

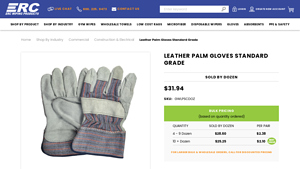

5. ERC Wipe – Leather Palm Gloves Standard Grade

Domain: ercwipe.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Leather Palm Gloves Standard Grade”, “UPC”: “Not specified”, “Sold By”: “Dozen”, “Price”: “$31.94”, “Bulk Pricing”: {“4 – 9 Dozen”: “$28.60”, “10+ Dozen”: “$25.25”}, “Description”: “Standard Grade Leather Palm Gloves are a popular work glove choice for abrasion and durability. They offer high puncture resistance and are easy to maintain. Durable and comfortable with good insulati…

Strategic Sourcing Conclusion and Outlook for bulk leather gloves

As the global demand for bulk leather gloves continues to rise, strategic sourcing remains paramount for international buyers looking to enhance their procurement processes. Key takeaways include the importance of evaluating suppliers based on quality, durability, and pricing structures. Consideration of bulk pricing incentives can lead to significant cost savings, enabling buyers to optimize their budgets while ensuring the safety and comfort of their workforce.

Illustrative image related to bulk leather gloves

Moreover, leveraging reliable suppliers from diverse regions—including Africa, South America, the Middle East, and Europe—can provide access to various leather types and glove designs tailored to specific industry needs. Understanding regional market dynamics and supplier capabilities will empower buyers to make informed decisions that align with their operational requirements.

Looking forward, as industries evolve and safety standards tighten, investing in high-quality leather gloves will not only enhance employee protection but also contribute to overall productivity. We encourage international B2B buyers to actively explore partnerships with reputable manufacturers and distributors, positioning themselves to meet future demands while fostering sustainable sourcing practices. The time to act is now; secure your supply chain and ensure your business remains competitive in an ever-changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to bulk leather gloves

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.