Introduction: Navigating the Global Market for how to make a leather dog collar

In the competitive landscape of pet accessories, sourcing high-quality leather dog collars can present a significant challenge for international B2B buyers. As consumer demand for durable and stylish pet products rises, understanding the intricacies of how to make a leather dog collar becomes essential. This comprehensive guide delves into the various types of leather, appropriate sourcing strategies, and essential tools and materials necessary for production. By addressing critical aspects such as supplier vetting, cost analysis, and market trends, this resource empowers businesses in Africa, South America, the Middle East, and Europe—particularly in countries like Brazil and Nigeria—to make informed purchasing decisions.

Navigating the global market for leather dog collars requires a keen understanding of local preferences and quality standards. This guide not only outlines the step-by-step process for crafting leather collars but also highlights best practices for selecting reliable suppliers and negotiating favorable terms. With actionable insights and detailed recommendations, buyers will be equipped to meet the rising expectations of pet owners while enhancing their product offerings. Whether you are a retailer looking to expand your inventory or a manufacturer aiming to optimize your production processes, this guide serves as your go-to resource for successfully entering and thriving in the leather dog collar market.

Table Of Contents

- Top 4 How To Make A Leather Dog Collar Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather dog collar

- Understanding how to make a leather dog collar Types and Variations

- Key Industrial Applications of how to make a leather dog collar

- 3 Common User Pain Points for ‘how to make a leather dog collar’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather dog collar

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather dog collar

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather dog collar’

- Comprehensive Cost and Pricing Analysis for how to make a leather dog collar Sourcing

- Alternatives Analysis: Comparing how to make a leather dog collar With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather dog collar

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather dog collar Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather dog collar

- Strategic Sourcing Conclusion and Outlook for how to make a leather dog collar

- Important Disclaimer & Terms of Use

Understanding how to make a leather dog collar Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Collar | Simple design, adjustable fit, available in various colors | Retail pet stores, online pet supply shops | Pros: Timeless appeal, easy to produce. Cons: May lack unique branding opportunities. |

| Decorative Stamped Collar | Customizable with unique patterns and designs | Boutique pet shops, artisan markets | Pros: High perceived value, differentiation. Cons: More time-consuming to produce. |

| Reflective Safety Collar | Incorporates reflective materials for visibility | Dog training facilities, outdoor retailers | Pros: Enhances safety for pets at night. Cons: May require special materials. |

| Personalized Name Collar | Custom engraving options for pet names and contact info | Online personalization platforms, gift shops | Pros: Adds a personal touch, attracts gift buyers. Cons: Higher production costs. |

| Martingale Collar | Designed for control without choking, adjustable | Dog trainers, behavioral specialists | Pros: Effective for training, adjustable fit. Cons: Requires knowledge of proper use. |

What Are the Key Characteristics of Classic Leather Collars?

Classic leather collars are characterized by their straightforward design and functionality. Typically made from high-quality full-grain leather, they offer durability and comfort for dogs. These collars are adjustable, accommodating various neck sizes, which makes them suitable for a wide range of dog breeds. For B2B buyers, classic collars are a staple product that can be easily sourced and marketed in retail environments, although they may not stand out in terms of unique branding.

How Do Decorative Stamped Collars Enhance Brand Identity?

Decorative stamped collars allow for customization through unique patterns, logos, or designs, making them ideal for boutique pet shops and artisan markets. These collars not only serve functional purposes but also act as a canvas for creative expression, which can enhance brand identity. B2B buyers should consider the additional time and resources required for production and customization, but the higher perceived value can justify the investment.

What Are the Benefits of Reflective Safety Collars?

Reflective safety collars are designed with visibility in mind, incorporating reflective materials that ensure pets are seen in low-light conditions. This feature makes them particularly appealing to dog training facilities and outdoor retailers that prioritize safety. While they provide significant advantages for pet owners concerned about nighttime visibility, B2B buyers must be aware of the need for specialized materials, which may increase production costs.

Why Are Personalized Name Collars Popular Among Consumers?

Personalized name collars offer customization options, such as engraving pet names and contact information, which resonate well with consumers looking for unique gifts. These collars are particularly popular in online personalization platforms and gift shops. For B2B buyers, the ability to offer personalized products can create a competitive edge, although it typically involves higher production costs and requires efficient logistics for customization.

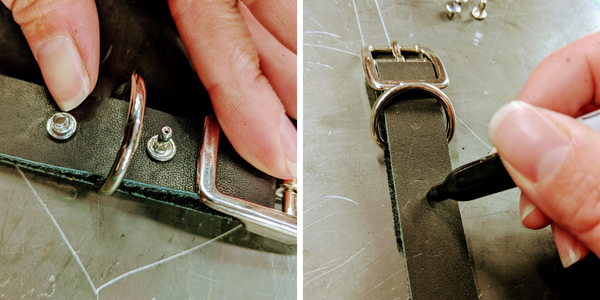

Illustrative image related to how to make a leather dog collar

How Do Martingale Collars Work in Training Scenarios?

Martingale collars are specifically designed to provide control without choking, making them suitable for training and behavioral correction. They are adjustable and can fit snugly around the dog’s neck, preventing escape. B2B buyers in the dog training and behavioral specialist sectors should consider the demand for such collars, as they combine functionality with a focus on dog safety. However, proper usage knowledge is essential to ensure they are marketed and used effectively.

Key Industrial Applications of how to make a leather dog collar

| Industry/Sector | Specific Application of how to make a leather dog collar | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Accessories Retail | Custom leather dog collars for boutique stores | Differentiates offerings in a competitive market | Sourcing high-quality leather and unique designs |

| Veterinary Clinics | Personalized collars for pet identification | Enhances pet safety and owner peace of mind | Need for durable, hypoallergenic materials |

| Leather Craftsmanship Schools | Educational workshops on leather collar making | Provides hands-on skills and promotes local craftsmanship | Access to quality tools and materials for training |

| E-commerce Platforms | DIY leather dog collar kits for online sales | Appeals to DIY enthusiasts and increases product variety | Reliable suppliers for kits, including leather, tools, and dyes |

| Animal Shelters | Collars for rescued dogs to enhance adoptability | Improves the perceived value of pets and encourages adoption | Cost-effective sourcing of materials to support budget constraints |

How Can Pet Accessories Retailers Benefit from Making Leather Dog Collars?

Pet accessories retailers can leverage the process of making leather dog collars by offering customized products that stand out in a crowded market. By sourcing high-quality leather and unique designs, businesses can attract discerning customers looking for premium pet products. Customization options, such as personalized engravings, can also enhance customer loyalty, as pet owners are often willing to pay a premium for unique items that reflect their pets’ personalities.

What Value Do Veterinary Clinics Gain from Personalized Leather Dog Collars?

Veterinary clinics can utilize personalized leather dog collars to improve pet identification and safety. These collars can feature the pet’s name and owner’s contact information, providing peace of mind to pet owners. For clinics, offering this service can enhance client relationships, showcasing a commitment to pet welfare and safety. Sourcing durable and hypoallergenic materials is essential to ensure the collars withstand wear and are safe for all pets.

Illustrative image related to how to make a leather dog collar

How Do Leather Craftsmanship Schools Use Leather Dog Collar Making in Education?

Leather craftsmanship schools can incorporate the making of leather dog collars into their curriculum, providing students with practical, hands-on skills in leatherworking. This application not only teaches essential crafting techniques but also promotes the value of local craftsmanship. To be successful, these schools need access to quality tools and materials, ensuring students can create professional-grade products that can be sold or showcased.

What Opportunities Do E-commerce Platforms Have with DIY Leather Dog Collar Kits?

E-commerce platforms can capitalize on the growing DIY trend by offering kits for making leather dog collars. These kits can attract a diverse customer base, including hobbyists and pet owners looking to create personalized items. To maximize success, platforms should ensure reliable sourcing of all necessary components, including leather, tools, and dyes, allowing customers to enjoy a seamless crafting experience while boosting product variety.

How Can Animal Shelters Enhance Adoptability with Leather Dog Collars?

Animal shelters can improve the adoptability of rescued dogs by providing them with high-quality leather collars. These collars not only enhance the dogs’ appearance but also convey a sense of care and professionalism that can attract potential adopters. Cost-effective sourcing of materials is crucial for shelters operating on tight budgets, ensuring they can provide these valuable items without compromising their financial sustainability.

3 Common User Pain Points for ‘how to make a leather dog collar’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Dog Collars

The Problem: One of the primary challenges B2B buyers face when creating leather dog collars is sourcing high-quality leather that meets both aesthetic and durability standards. Many suppliers offer various grades of leather, but distinguishing between genuine leather and premium options like full-grain or vegetable-tanned leather can be confusing. Buyers in regions such as Africa or South America may struggle with limited access to reputable suppliers, leading to inconsistent product quality and potential customer dissatisfaction.

The Solution: To effectively source quality leather, B2B buyers should establish relationships with reputable leather suppliers who specialize in full-grain and vegetable-tanned leather. This can often be achieved by attending industry trade shows or local craft fairs where suppliers showcase their products. Buyers should request samples to evaluate the leather’s texture, durability, and color consistency before making bulk purchases. Additionally, leveraging online platforms or local leather craft communities can help connect buyers with reliable sources. Collaborating with suppliers who prioritize sustainable practices can also enhance the product’s appeal in the market, catering to environmentally conscious consumers.

Scenario 2: Ensuring Proper Tooling and Finishing Techniques

The Problem: Another significant pain point for B2B buyers is mastering the tooling and finishing techniques necessary for creating professional-grade leather dog collars. Many buyers may lack experience in leatherworking, resulting in poorly finished products that fail to meet customer expectations. This can be especially problematic in competitive markets where product quality is paramount for brand reputation.

The Solution: To overcome this challenge, buyers should invest in comprehensive training and resources focused on leatherworking techniques. This could involve enrolling in workshops or online courses that cover essential skills such as cutting, dyeing, stamping, and sealing leather. It’s also beneficial to create a detailed process guide that outlines each step, from material preparation to final assembly. Engaging with experienced leatherworkers through forums or mentorship programs can provide invaluable tips and tricks for achieving high-quality finishes. Furthermore, sourcing the right tools from reputable suppliers ensures that buyers have access to reliable equipment that enhances the overall quality of their products.

Scenario 3: Addressing Design Customization and Market Trends

The Problem: In the ever-evolving pet accessory market, staying ahead of design trends and customer preferences is crucial for B2B buyers. However, many face the challenge of balancing customization options with production efficiency. Buyers may find themselves overwhelmed with requests for unique designs while struggling to maintain a streamlined manufacturing process, leading to delayed deliveries and unsatisfied customers.

The Solution: To effectively address this issue, buyers should implement a modular design approach that allows for customization without compromising production efficiency. This could involve offering a core line of dog collars with customizable elements, such as colors, patterns, and hardware options. Conducting market research to identify trending designs and materials can guide the customization process and ensure that offerings align with consumer demand. Additionally, investing in design software can facilitate rapid prototyping and visualization, making it easier to present options to clients. Collaborating with a network of local artisans can also enhance the creative process while supporting community businesses, thus enriching the brand’s story and appeal in diverse markets.

Strategic Material Selection Guide for how to make a leather dog collar

What Are the Key Materials for Making Leather Dog Collars?

When selecting materials for manufacturing leather dog collars, it is crucial to consider the properties, advantages, and limitations of each option. The choice of material can significantly influence the product’s durability, comfort, and overall appeal to consumers. Here, we analyze four common materials used in leather dog collar production.

How Does Full Grain Leather Perform in Dog Collar Manufacturing?

Key Properties: Full grain leather is derived from the top layer of the hide, retaining the natural grain. It is known for its breathability, flexibility, and resistance to wear and tear. This material can withstand various environmental conditions, making it suitable for outdoor use.

Illustrative image related to how to make a leather dog collar

Pros & Cons: The durability of full grain leather is unmatched, providing a long-lasting product that can withstand daily wear. However, it is relatively expensive compared to other leather grades. The manufacturing process is straightforward but may require skilled artisans for high-quality finishing.

Impact on Application: Full grain leather’s natural oils allow it to age beautifully, adding character over time. It is compatible with various dyes and finishes, enhancing customization options for brands.

Considerations for International Buyers: Compliance with international leather standards, such as the ISO 14001 for environmental management, is essential. Buyers from regions like Africa and South America should also consider local sourcing options to reduce costs and support local economies.

What Are the Benefits of Using Top Grain Leather?

Key Properties: Top grain leather is the second-highest quality leather, sanded and refinished to remove imperfections. It offers a smooth surface and is lighter than full grain leather, making it easier to work with.

Pros & Cons: While top grain leather is more affordable than full grain, it sacrifices some durability. It is less resistant to scratches and wear, making it suitable for less active dogs or decorative collars. The manufacturing complexity is moderate, requiring less skill than full grain leather.

Impact on Application: This material is ideal for collars designed for fashion rather than function. It can be dyed in various colors and finishes, appealing to a broader market.

Considerations for International Buyers: Buyers should ensure that top grain leather meets local regulations regarding animal welfare and environmental impact. In Europe, for example, compliance with REACH regulations is critical.

How Does Synthetic Leather Compare to Natural Options?

Key Properties: Synthetic leather, or faux leather, is made from polyurethane or polyvinyl chloride (PVC). It is designed to mimic the look and feel of real leather while being resistant to moisture and stains.

Pros & Cons: The primary advantage of synthetic leather is its cost-effectiveness and ease of maintenance. However, it lacks the durability and breathability of natural leather, which can lead to discomfort for the dog over time. Manufacturing synthetic leather is generally less complex, allowing for mass production.

Impact on Application: Synthetic leather collars are ideal for fashion-forward consumers looking for affordable options. They can be produced in various colors and patterns, appealing to diverse markets.

Considerations for International Buyers: Buyers should be aware of regulations concerning the use of chemicals in synthetic materials. In regions like the Middle East, where environmental concerns are rising, eco-friendly synthetic options may be preferred.

What Role Does Vegetable-Tanned Leather Play in Dog Collar Production?

Key Properties: Vegetable-tanned leather is treated using natural tannins from plant sources, making it biodegradable and environmentally friendly. It is known for its firmness and ability to develop a rich patina over time.

Pros & Cons: The eco-friendly nature of vegetable-tanned leather is a significant advantage, appealing to environmentally conscious consumers. However, it can be less water-resistant than other types of leather, which may limit its use in wet conditions. The manufacturing process is labor-intensive, requiring skilled craftsmanship.

Impact on Application: This type of leather is well-suited for premium dog collars that emphasize sustainability. Its natural look and feel can enhance the product’s appeal to high-end markets.

Considerations for International Buyers: Buyers should ensure that the vegetable-tanned leather complies with international standards, such as the Global Organic Textile Standard (GOTS). This is particularly relevant for markets in Europe, where sustainability is increasingly prioritized.

Summary Table of Material Selection for Leather Dog Collars

| Material | Typical Use Case for how to make a leather dog collar | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-quality, durable collars for active dogs | Exceptional durability and breathability | Higher cost, requires skilled artisans | High |

| Top Grain Leather | Fashion collars with a smooth finish | More affordable than full grain | Less durable, prone to scratches | Medium |

| Synthetic Leather | Affordable, trendy collars for fashion-conscious buyers | Cost-effective and easy to maintain | Less durable and breathable | Low |

| Vegetable-Tanned Leather | Eco-friendly premium collars | Biodegradable and sustainable | Less water-resistant, labor-intensive | Medium |

This strategic material selection guide provides essential insights for B2B buyers in the leather dog collar market, enabling informed decisions that align with consumer preferences and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather dog collar

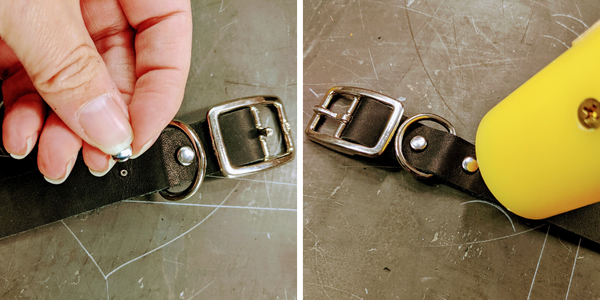

What Are the Main Stages in the Manufacturing Process of Leather Dog Collars?

The manufacturing of leather dog collars consists of several stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the final product meets quality standards and customer expectations.

Material Preparation: How to Choose and Prepare Leather

The first stage involves selecting the right type of leather, which significantly impacts the collar’s durability and aesthetics. Full-grain leather is preferred due to its robustness, while vegetable-tanned leather is favored for its eco-friendliness and ability to absorb dyes well.

Illustrative image related to how to make a leather dog collar

After selecting the leather, it must be cut to the desired dimensions. This is typically done using a leather strap cutter or a sharp utility knife, ensuring clean edges for better finishing. Additionally, tools like edge bevelers are employed to round off sharp edges, enhancing comfort for the dog.

Forming: What Techniques Are Used to Shape Leather?

In the forming stage, the cut leather is subjected to various techniques to achieve the desired shape and design. This may include tooling and stamping, where decorative patterns are pressed into the leather. Damping the leather before stamping makes it more pliable, allowing for deeper impressions.

Holes are then punched for the buckle and D-rings, which are necessary for attachment points. This stage requires precision, as incorrect hole placements can lead to functional issues.

Assembly: How Is the Leather Dog Collar Constructed?

Once the leather pieces are shaped, they are assembled. This involves attaching the buckle, D-rings, and Chicago screws. The assembly must be secure to withstand the wear and tear from daily use. The initial stiffness of the leather will soften over time with wear, so manufacturers often test the collar for fit and comfort during this stage.

Illustrative image related to how to make a leather dog collar

What Quality Assurance Measures Should Be Implemented?

Quality assurance (QA) is crucial in the leather dog collar manufacturing process to ensure that the final product meets international standards and customer expectations. Implementing robust QA measures can significantly enhance product reliability and brand reputation.

What Are the Relevant International Standards for Leather Products?

For B2B buyers, understanding the quality standards applicable to leather products is essential. The ISO 9001 standard is widely recognized and provides a framework for quality management systems. It emphasizes customer satisfaction and continuous improvement, making it suitable for leather goods manufacturers.

Additionally, certain industry-specific standards may apply. For example, CE marking is mandatory for products sold within the European Economic Area and indicates compliance with health, safety, and environmental protection standards. Buyers from regions such as Africa and South America should also be aware of local regulations that may affect product compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints should be integrated throughout the manufacturing process. Commonly used checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival. Leather should be examined for defects such as tears, discoloration, or inconsistencies in thickness.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, manufacturers should conduct inspections to ensure that the collars are being produced according to specifications. This might involve checking dimensions, hole placements, and decorative stamping.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes a thorough inspection. This includes checking for overall quality, functionality, and aesthetic appeal, ensuring that each collar meets the established standards.

What Common Testing Methods Are Used in Leather Collar Manufacturing?

Testing methods are essential to validate the quality of leather collars. Common methods include:

- Durability Testing: Assessing how the collar withstands wear and tear, including stress tests on buckles and D-rings.

- Water Resistance Testing: Evaluating how well the collar repels water, especially if a water-resistant sealer has been applied.

- Colorfastness Testing: Ensuring that dyes do not bleed or fade over time, which is crucial for maintaining the collar’s appearance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is vital. Here are some strategies:

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, material sourcing, and adherence to quality standards. Buyers should request to see documentation related to their quality management systems.

-

Quality Reports: Suppliers should be able to provide quality reports that detail the results of their QC checks and any testing performed on products. These documents can serve as proof of compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices. This is especially useful for buyers from regions with stringent import regulations.

What Are the QC and Certification Nuances for International Buyers?

When sourcing leather dog collars from international suppliers, buyers must consider certification nuances based on their region. For instance, buyers in Europe may require CE marking, while those in Africa may need to comply with local import regulations. Understanding these requirements can help mitigate compliance risks.

Furthermore, buyers should ensure that suppliers understand the specific quality expectations for their target markets. This includes not only compliance with international standards but also cultural preferences in design and functionality.

Conclusion: Ensuring Quality in Leather Dog Collar Manufacturing

The manufacturing process of leather dog collars involves meticulous attention to detail at every stage, from material preparation to finishing. By implementing stringent quality assurance measures and adhering to relevant international standards, manufacturers can produce high-quality products that meet the needs of B2B buyers worldwide. For buyers, understanding the manufacturing process and quality control practices can lead to better purchasing decisions and stronger supplier relationships, ultimately enhancing their market competitiveness.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather dog collar’

To assist B2B buyers in the production of leather dog collars, this guide provides a clear, actionable checklist to streamline the sourcing process. Understanding the key components and steps involved will ensure you procure quality materials and tools, ultimately leading to a successful product line.

Illustrative image related to how to make a leather dog collar

Step 1: Identify Quality Leather Types

Choosing the right leather is crucial for durability and comfort. Full-grain leather, such as natural cowhide or vegetable-tanned leather, is recommended for its strength and aesthetic appeal. Verify the source of the leather, ensuring it meets industry standards for quality and sustainability, especially if you’re targeting eco-conscious markets.

Step 2: Source Essential Tools

A well-equipped workshop is vital for producing high-quality collars. Key tools include leather strap cutters, hole punches, and edge bevelers. Look for suppliers that offer comprehensive toolkits or individual high-quality tools, and consider second-hand options to reduce costs while maintaining quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product samples, and references from other businesses in your region. This step is essential to gauge reliability and quality, ensuring you partner with suppliers who understand your specific market needs.

Step 4: Assess Supplier Certifications and Compliance

Ensure that your suppliers adhere to relevant industry certifications and standards. This includes verifying compliance with environmental regulations and labor practices. Certifications can enhance your product’s marketability, particularly in regions where consumers prioritize ethical sourcing.

Step 5: Determine Your Design Specifications

Establish clear design specifications for the collars, including sizes, colors, and any custom features. This step is important for both production efficiency and market differentiation. Collaborate with designers or use customer feedback to refine these specifications to meet consumer demands effectively.

Step 6: Plan for Quality Control Processes

Implement a quality control process to monitor the production of leather collars. This can include regular inspections of materials and finished products to ensure they meet your established standards. Quality assurance not only enhances product reliability but also builds trust with your customers.

Step 7: Consider Packaging and Shipping Options

Finally, think about how you will package and ship the collars. Packaging should reflect your brand’s identity and protect the product during transit. Explore eco-friendly packaging options to appeal to environmentally conscious buyers and ensure reliable shipping methods to minimize delays.

By following this checklist, B2B buyers can effectively navigate the sourcing process for leather dog collars, ensuring quality and satisfaction in their final products.

Comprehensive Cost and Pricing Analysis for how to make a leather dog collar Sourcing

What Are the Key Cost Components in Sourcing Leather Dog Collars?

When considering the manufacturing of leather dog collars, understanding the cost structure is vital for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials: The choice of leather significantly affects costs. Full-grain leather, while more expensive, offers superior durability and aesthetics compared to genuine leather. Other materials such as buckles, D-rings, and dyes also contribute to the total material cost. Prices can range widely based on the leather source and type, with natural cowhide being more premium than synthetic alternatives.

Illustrative image related to how to make a leather dog collar

Labor: Skilled labor is essential in leather crafting, particularly for custom designs or intricate tooling. Labor costs vary by region, with countries in Europe typically having higher labor rates compared to some regions in Africa or South America. It’s crucial to assess labor availability and skill levels when sourcing.

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Overhead can be minimized by optimizing production processes or outsourcing to countries with lower operational costs.

Tooling Costs: Initial investments in tools can be substantial, especially for businesses just starting. However, these costs can be amortized over time through increased production volume. Consider sourcing second-hand tools or collaborating with local artisans to reduce these expenses.

Quality Control (QC): Implementing robust QC processes ensures that products meet quality standards, reducing returns and enhancing customer satisfaction. While QC adds to costs, it is essential for maintaining a brand’s reputation.

Logistics: Shipping costs can vary significantly depending on the destination, mode of transport, and Incoterms. International logistics can become complex, requiring careful planning to avoid delays and additional expenses.

Margin: Establishing a competitive yet profitable pricing strategy is critical. Margins will depend on the market segment you are targeting, production costs, and perceived value.

Illustrative image related to how to make a leather dog collar

How Do Price Influencers Affect the Sourcing of Leather Dog Collars?

Price influencers play a significant role in determining the final cost of leather dog collars. Factors such as volume or Minimum Order Quantity (MOQ), specifications, materials used, quality certifications, supplier relationships, and Incoterms can all impact pricing.

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their inventory management strategies to maximize cost efficiency.

Specifications and Customization: Custom designs and specific material requirements can increase costs. Buyers should clearly define specifications to avoid unexpected charges during production.

Materials and Quality/Certifications: Premium materials and certifications (such as eco-friendly or cruelty-free) can elevate costs but may also enhance marketability and customer appeal. It’s essential to balance quality with budget constraints.

Supplier Factors: Building strong relationships with suppliers can lead to better pricing and terms. Consider sourcing from suppliers who understand the local market dynamics and can offer insights into cost-saving opportunities.

Illustrative image related to how to make a leather dog collar

Incoterms: Understanding Incoterms is crucial for managing shipping costs and responsibilities. Choosing the right Incoterm can help mitigate risks associated with international shipping, ensuring a smoother transaction.

What Buyer Tips Should Be Considered for Cost-Efficiency in International Markets?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency.

Negotiation: Always engage in negotiations to secure better pricing and terms. Understanding the supplier’s cost structure can provide leverage in discussions.

Illustrative image related to how to make a leather dog collar

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also factors like shipping, import duties, and potential return costs. A comprehensive view of TCO can uncover hidden costs and inform better purchasing decisions.

Pricing Nuances: Be aware of local market trends and pricing strategies. For instance, in emerging markets, affordability may take precedence over premium pricing, which could influence your pricing strategy.

Leverage Local Partnerships: Collaborating with local distributors or manufacturers can reduce logistics costs and improve market penetration. Local partners may also provide valuable insights into consumer preferences and regulatory requirements.

Disclaimer for Indicative Prices: It is important to note that prices can fluctuate based on market conditions, supplier negotiations, and changes in material costs. Buyers should conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how to make a leather dog collar With Other Solutions

Introduction to Alternatives for Making Leather Dog Collars

When considering the production of leather dog collars, businesses have various methods at their disposal. Each method has distinct advantages and disadvantages that can impact overall performance, cost efficiency, ease of implementation, maintenance requirements, and suitability for specific use cases. Understanding these alternatives is essential for B2B buyers looking to optimize their manufacturing processes and product offerings.

Comparison Table

| Comparison Aspect | How To Make A Leather Dog Collar | Alternative 1: Pre-Made Leather Collars | Alternative 2: Synthetic Dog Collars |

|---|---|---|---|

| Performance | High durability and customization | Consistent quality, limited customization | Good durability, but may lack premium feel |

| Cost | Moderate initial investment, potential savings in bulk | Higher upfront cost per unit | Generally lower cost, but quality varies |

| Ease of Implementation | Requires skills and tools | Simple procurement, no skills needed | Easy to source, often mass-produced |

| Maintenance | Regular care needed for longevity | Minimal maintenance required | Varies by material, often easy to clean |

| Best Use Case | Custom, high-end market | Retail settings with standard offerings | Budget-conscious consumers or mass markets |

Detailed Breakdown of Alternatives

Alternative 1: Pre-Made Leather Collars

Pre-made leather collars offer a straightforward solution for businesses that prefer not to engage in the labor-intensive process of crafting collars from scratch. These products typically provide consistent quality and are ready for immediate sale, making them ideal for retailers looking to quickly fill inventory without the need for skilled craftsmanship. However, the downside is the limited ability to customize designs or materials, which may not appeal to consumers seeking unique or personalized products. Additionally, the cost per unit can be higher, especially for premium leather options.

Alternative 2: Synthetic Dog Collars

Synthetic dog collars represent an affordable alternative that appeals to a wide range of consumers. These collars are often less expensive than leather options and can be produced in bulk, making them suitable for mass-market retail. They typically require less maintenance and are easier to clean, which is a significant selling point for busy pet owners. However, synthetic materials may not provide the same level of durability or premium feel as leather, potentially affecting customer satisfaction among those seeking high-quality products. This option is best suited for budget-conscious buyers or those targeting large-scale markets.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the best method for producing dog collars, B2B buyers must carefully consider their target market and business objectives. If customization and quality are priorities, crafting leather collars may be the best route, despite the initial investment in skills and tools. For businesses focused on speed and consistency, pre-made collars provide a practical solution, while synthetic options cater to cost-sensitive consumers. Ultimately, aligning the chosen method with market demand and operational capabilities will ensure a successful product offering.

Essential Technical Properties and Trade Terminology for how to make a leather dog collar

What Are the Key Technical Properties to Consider When Making a Leather Dog Collar?

When manufacturing leather dog collars, several technical properties are crucial for ensuring quality, durability, and customer satisfaction. Here are the primary specifications to consider:

1. Material Grade

Definition: The grade of leather determines its quality and suitability for specific applications. Full grain leather, for example, is the highest quality, retaining the natural grain and durability, while genuine leather is often a lower grade.

B2B Importance: Buyers must understand the differences in leather grades to make informed purchasing decisions. High-quality materials contribute to the collar’s longevity and appeal, directly impacting customer satisfaction and brand reputation.

2. Leather Thickness

Definition: The thickness of leather is typically measured in ounces (1 ounce = 1/64 inch). Common thicknesses for dog collars range from 8 oz to 10 oz.

B2B Importance: Thickness affects the collar’s strength, flexibility, and comfort. A thicker collar may provide greater durability, while a thinner one may offer better comfort for smaller dogs. Understanding these specifications helps buyers select the right product for their target market.

Illustrative image related to how to make a leather dog collar

3. Tolerance Levels

Definition: Tolerance refers to the allowable variation in measurements during the manufacturing process. For instance, a collar width of 1 inch might have a tolerance of ±0.1 inches.

B2B Importance: Maintaining strict tolerances is vital for product consistency. Buyers should ensure that manufacturers adhere to these tolerances to avoid issues related to fit and functionality, which can lead to product returns and decreased customer trust.

4. Water Resistance

Definition: Water resistance indicates a material’s ability to repel water. This property is often enhanced with sealants or special treatments.

B2B Importance: For outdoor use, collars that are water-resistant are highly desirable. Buyers need to assess the effectiveness of water resistance treatments to meet consumer expectations, especially in regions with diverse climates.

Illustrative image related to how to make a leather dog collar

5. Colorfastness

Definition: Colorfastness refers to the ability of the leather dye to resist fading or bleeding when exposed to moisture, sunlight, or friction.

B2B Importance: Colorfastness is essential for maintaining the aesthetic appeal of the collar over time. Buyers should prioritize suppliers that use high-quality dyes and treatments to ensure that products retain their vibrant colors, enhancing customer satisfaction and reducing returns.

What Are Common Trade Terms in the Leather Dog Collar Industry?

Understanding industry jargon can significantly enhance communication and negotiation with suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

Definition: An OEM is a company that produces goods that are branded and sold by another company.

Importance: Buyers often collaborate with OEMs to create custom leather dog collars that reflect their brand identity, allowing for differentiation in the market.

2. MOQ (Minimum Order Quantity)

Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

Importance: Knowing the MOQ helps buyers plan their inventory and budget. It is crucial for ensuring that production runs are cost-effective while meeting demand.

Illustrative image related to how to make a leather dog collar

3. RFQ (Request for Quotation)

Definition: An RFQ is a document issued by buyers to solicit price quotations from suppliers for specific products.

Importance: Issuing an RFQ enables buyers to compare prices, terms, and conditions from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Definition: Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

Illustrative image related to how to make a leather dog collar

Importance: Understanding Incoterms is essential for buyers engaged in international trade to manage logistics, costs, and risks associated with shipping leather dog collars.

5. Lead Time

Definition: Lead time refers to the amount of time it takes from placing an order to receiving the product.

Importance: Buyers need to consider lead times when planning inventory and marketing strategies. Long lead times can affect sales and customer satisfaction, making it important to choose suppliers that can meet deadlines.

By understanding these essential technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they procure high-quality leather dog collars that meet market demands.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather dog collar Sector

What Are the Key Market Dynamics and Trends in the Leather Dog Collar Sector?

The leather dog collar market is experiencing significant growth, driven by rising pet ownership and an increasing focus on pet wellness. Globally, the demand for high-quality, durable, and aesthetically pleasing pet accessories is on the rise, with consumers willing to invest in premium products. This trend is particularly evident in emerging markets across Africa, South America, and the Middle East, where disposable incomes are increasing and pet ownership is becoming more mainstream. B2B buyers in these regions are looking for reliable suppliers that can offer both traditional craftsmanship and innovative designs.

Moreover, technological advancements are reshaping sourcing strategies. Digital platforms that facilitate direct communication between manufacturers and retailers are becoming essential. For instance, online marketplaces allow B2B buyers to compare prices, quality, and supplier reputations, streamlining the procurement process. Additionally, the rise of customization technology enables businesses to offer personalized leather dog collars, catering to the unique preferences of consumers. This trend is particularly strong in Europe, where customers often seek bespoke products that reflect their pets’ personalities.

How Is Sustainability and Ethical Sourcing Impacting the Leather Dog Collar Industry?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the leather dog collar sector. The environmental impact of leather production is under scrutiny, prompting businesses to seek out suppliers who prioritize sustainable practices. This includes sourcing leather from tanneries that adhere to stringent environmental regulations and use eco-friendly tanning processes. Buyers are increasingly interested in suppliers that can demonstrate compliance with international sustainability standards and certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG).

Moreover, the demand for alternative materials, such as vegetable-tanned leather or synthetic options, is growing. These alternatives often come with a lower environmental footprint and appeal to consumers who prioritize animal welfare. B2B buyers are also exploring opportunities in upcycling and recycling leather products, which not only helps reduce waste but also aligns with the growing consumer preference for sustainable goods. By embracing these practices, businesses can enhance their brand reputation and attract environmentally conscious consumers.

What Is the Historical Context of Leather Dog Collars Relevant to B2B Buyers?

Historically, leather dog collars have evolved from simple functional items to fashionable accessories. Initially, collars were primarily used for controlling and identifying dogs, often made from materials that were readily available. As the pet industry grew, so did the variety and quality of dog collars, with leather becoming a preferred material due to its durability and aesthetic appeal.

In recent years, the leather dog collar market has seen a shift towards premium and custom-made products. This evolution is driven by a combination of consumer trends favoring personalization and the desire for high-quality, long-lasting pet accessories. For B2B buyers, understanding this historical context is essential for recognizing the increasing value placed on craftsmanship and brand storytelling in the leather dog collar sector. As the market continues to evolve, businesses must adapt their sourcing strategies to meet the demands of modern consumers while maintaining a commitment to quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather dog collar

-

How do I choose the right leather for making dog collars?

Selecting the appropriate leather is critical for durability and comfort. Full grain leather is recommended as it is more robust than genuine leather, ensuring longevity. Veg-tan leather is also a good option, especially for custom dyeing and tooling. When sourcing leather, consider local suppliers in your region to minimize shipping costs and support local economies. Ensure that the leather is free from harmful chemicals, especially if you are targeting markets that prioritize pet safety. -

What tools and equipment do I need to produce leather dog collars?

Essential tools include a leather strap cutter, hole punches, a mallet, and edge tools for finishing. For customization, decorative stamping tools may be beneficial. It’s advisable to connect with local leatherworking communities to access second-hand tools or borrow equipment, reducing initial investment costs. Additionally, consider sourcing tools from established suppliers who can provide quality assurance and support in case of defects. -

What are the minimum order quantities (MOQs) for leather dog collars?

MOQs can vary significantly by supplier, but many manufacturers may require orders of 50 to 100 units to justify production costs. For smaller businesses, it’s advisable to negotiate MOQs or consider partnering with other local businesses to meet minimum requirements. Always inquire about bulk discounts, as purchasing larger quantities often leads to better pricing, enabling you to offer competitive rates in your market. -

How can I customize leather dog collars for my brand?

Customization options include varying sizes, colors, and decorative elements such as engravings or stamping. Many suppliers offer the ability to create bespoke designs or colors to match your branding. When negotiating with manufacturers, present your design concepts clearly and ask about their capabilities in terms of tooling and dyeing. It’s also useful to request samples before committing to larger orders to ensure the final product meets your specifications. -

What payment terms should I expect when sourcing leather collars internationally?

Payment terms can vary widely, but typical arrangements include 30% upfront and 70% upon delivery. For first-time orders, be prepared to pay in full upfront, especially with new suppliers. It’s advisable to negotiate favorable terms that align with your cash flow. Always use secure payment methods and ensure that payment terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

How do I ensure quality assurance (QA) when sourcing from suppliers?

Establishing a QA process is vital when sourcing leather dog collars. Request samples from potential suppliers to evaluate the quality of materials and craftsmanship. Discuss their production processes and any certifications they may hold, such as ISO standards. Additionally, consider using third-party inspection services to verify the quality of goods before shipment, especially for large orders, to prevent costly returns and maintain your brand’s reputation. -

What are the best logistics practices for importing leather products?

When importing, choose a reliable freight forwarder familiar with the intricacies of international shipping. Understand the customs regulations in your destination country, including any tariffs or import duties. Use proper packaging to protect the collars during transit, and consider insurance for high-value shipments. Timely communication with your supplier about shipping schedules can help mitigate delays and ensure that you meet your market demands. -

How can I market my leather dog collars effectively in international markets?

To successfully market leather dog collars internationally, leverage social media platforms and pet-related online communities to build brand awareness. Create engaging content showcasing the quality and customization of your collars. Collaborate with local influencers or pet stores to gain credibility. Additionally, tailor your marketing strategies to resonate with cultural preferences in specific regions, ensuring that you highlight features that appeal to local consumers, such as sustainability or artisanal craftsmanship.

Top 4 How To Make A Leather Dog Collar Manufacturers & Suppliers List

1. Instructables – Leather Dog Collar

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather Dog Collar made from full grain leather, available in natural cowhide or veg-tan leather. Requires materials such as a belt buckle, Chicago screws, D-rings, Gum Tragacanth, leather deglazer, leather dye (preferably antique), and a water resistant sealer. Suggested tools include a hole punch, leather mallet, oblong leather punch, granite slab, swivel knife, edge beveler, edge slicker, leath…

2. Pet Hardware – Black Nickel Tested D Ring & Roller Buckle

Domain: pethardware.com

Registered: 2006 (19 years)

Introduction: Black Nickel Tested D ring – Inner width: 10–50 mm, Sizes: 9, Material: steel, Breaking load: up to 300 kg, 10 pcs/pack, Price per pcs from $0.052 excl. VAT; Black Nickel Tested Roller buckle – Bestselling saddlery roller buckle with welded joint rated up to 200 kg, Price from $0.124 excl. VAT; Cowhide leather – double butts, natural, Type: Double Butts – Full-grain leather, Thickness: 2.4–5.2 mm,…

3. Leatherworker – Rolled Leather Dog Leads

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Rolled leather dog leads; traditional method involves multiple steps; alternative method includes sewing a thin piece of leather around a cord; Al Stohlman’s book “The Art of Handsewing Leather” provides instructions; discussions on techniques and tools for making rounds.

4. Tandy Leather – Personalized Dog Collars

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Personalized Dog Collars, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how to make a leather dog collar

In the dynamic landscape of the leather goods market, the art of making leather dog collars presents a unique opportunity for international B2B buyers. By strategically sourcing high-quality materials such as full-grain leather and essential tools, companies can create durable and aesthetically pleasing products that resonate with pet owners’ desires for both style and functionality. Leveraging local leather communities for resources and knowledge not only enhances craftsmanship but also fosters valuable partnerships that can lead to innovation in product offerings.

The emphasis on quality and customization positions businesses to meet the growing demand for personalized pet accessories, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As consumer preferences evolve, companies should remain agile and responsive, exploring diverse design possibilities and sustainable practices that appeal to environmentally conscious buyers.

Looking ahead, the potential for growth in the leather dog collar segment is significant. Companies are encouraged to invest in training, tool acquisition, and sustainable sourcing strategies to stay competitive. Embrace this opportunity to differentiate your product line, build lasting relationships, and ultimately capture the loyalty of pet owners worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.