Introduction: Navigating the Global Market for custom leather tool belt

In an increasingly competitive global marketplace, sourcing a high-quality custom leather tool belt presents unique challenges for B2B buyers. Whether you are looking to enhance your team’s productivity or ensure that your workforce is equipped with durable, reliable gear, selecting the right tool belt is crucial. This guide serves as your comprehensive resource, addressing various types of custom leather tool belts, their applications across different industries, and essential considerations for supplier vetting.

We delve into the specifics of material quality, construction methods, and design features that can impact the performance and longevity of tool belts in demanding work environments. Additionally, we provide insights into pricing structures, helping you navigate cost considerations while ensuring you receive value for your investment.

Designed specifically for international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Brazil—this guide empowers you to make informed purchasing decisions. By leveraging the information contained herein, you can confidently select a custom leather tool belt that meets your operational needs, enhances worker efficiency, and stands the test of time. Embrace the opportunity to streamline your sourcing process and elevate your business operations with the right tools at your disposal.

Table Of Contents

- Top 4 Custom Leather Tool Belt Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather tool belt

- Understanding custom leather tool belt Types and Variations

- Key Industrial Applications of custom leather tool belt

- 3 Common User Pain Points for ‘custom leather tool belt’ & Their Solutions

- Strategic Material Selection Guide for custom leather tool belt

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather tool belt

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather tool belt’

- Comprehensive Cost and Pricing Analysis for custom leather tool belt Sourcing

- Alternatives Analysis: Comparing custom leather tool belt With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather tool belt

- Navigating Market Dynamics and Sourcing Trends in the custom leather tool belt Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather tool belt

- Strategic Sourcing Conclusion and Outlook for custom leather tool belt

- Important Disclaimer & Terms of Use

Understanding custom leather tool belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pro Framer Tool Belt Setup | Multiple pockets, left/right options, durable leather construction | Carpentry, framing | Pros: Efficient organization, durable; Cons: Higher price point. |

| Pro Drywall Tool Belt Setup | Designed for drywall tools, hand-specific organization | Drywall installation | Pros: Tailored functionality, lightweight; Cons: Limited to drywall tasks. |

| Leather Pro Electrician Tool Belt | Specialized for electricians, includes hammer holder | Electrical work | Pros: Excellent tool accessibility, robust design; Cons: May lack versatility for other trades. |

| Pro Carpenter’s 5 Bag Tool Belt | 5 bags for comprehensive tool storage, buscadero-style belt | General carpentry | Pros: High capacity, distributes weight evenly; Cons: Can be bulky. |

| Stronghold Big Oxy Tool Belt Setup | Round-bottom design for maximum storage, heavy-duty construction | Heavy-duty construction | Pros: Superior storage capacity, rugged; Cons: Heavier and more expensive. |

What are the Key Features of the Pro Framer Tool Belt Setup?

The Pro Framer Tool Belt Setup is engineered for carpenters and framers, featuring multiple pockets and tool holders designed for easy access. Its construction from premium leather ensures durability against the elements, making it ideal for outdoor job sites. B2B buyers should consider its ergonomic design, which enhances efficiency during work. However, the higher price point may be a barrier for some businesses.

How Does the Pro Drywall Tool Belt Setup Cater to Specific Needs?

Tailored specifically for drywall professionals, the Pro Drywall Tool Belt Setup includes dedicated holders for essential tools like circle cutters and metal snips. This specialization allows for streamlined workflows, making it particularly suitable for companies focused on drywall installation. While it excels in functionality, its limited application may restrict versatility for buyers who work across multiple trades.

What Makes the Leather Pro Electrician Tool Belt Ideal for Electrical Work?

The Leather Pro Electrician Tool Belt is crafted for electricians, featuring hand-specific organization and a hammer holder for convenience. Its robust construction ensures that tools are secure and accessible, which is crucial for efficiency in electrical work. B2B buyers should note that while it provides excellent functionality for electricians, it may not be suitable for those requiring a multi-trade solution.

Why Choose the Pro Carpenter’s 5 Bag Tool Belt?

The Pro Carpenter’s 5 Bag Tool Belt combines durability with comfort, featuring a buscadero-style belt that distributes weight evenly. This design is particularly beneficial for general carpentry applications where multiple tools are needed. While its high capacity is a significant advantage, buyers should consider the potential bulkiness when selecting this option for their teams.

What Benefits Does the Stronghold Big Oxy Tool Belt Setup Offer?

The Stronghold Big Oxy Tool Belt Setup stands out with its innovative round-bottom design, providing maximum storage capacity for heavy-duty construction tasks. It is built to withstand rigorous use, making it suitable for professionals in demanding environments. However, its heavier weight and higher cost may be a consideration for businesses looking for lighter or more budget-friendly options.

Key Industrial Applications of custom leather tool belt

| Industry/Sector | Specific Application of custom leather tool belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Tool organization for carpenters and framers | Enhances efficiency and productivity on job sites | Durability, comfort, and specific pocket configurations |

| Electrical Services | Support for electricians’ specialized tools | Ensures quick access to tools, improving workflow | Customization for tool types, weight distribution, and fit |

| HVAC and Plumbing | Secure storage for HVAC and plumbing tools | Reduces downtime by keeping essential tools readily accessible | Weather resistance, size customization, and durability |

| Manufacturing | Tool management for assembly line workers | Streamlines operations and minimizes tool loss | Reinforced stitching, capacity for multiple tools, and comfort |

| Outdoor and Field Services | Versatile tool carrying for field technicians | Facilitates mobility and quick access to tools in varied environments | Lightweight design, resistance to elements, and ergonomic fit |

How Are Custom Leather Tool Belts Used in the Construction Industry?

In the construction sector, custom leather tool belts are indispensable for carpenters and framers. These belts are tailored to provide organized storage for essential tools, ensuring that workers can access what they need without delay. The belts typically feature multiple pockets and holders designed for specific tools, which helps minimize downtime and enhances productivity. For international buyers, especially in regions like Saudi Arabia or Brazil, sourcing belts that withstand extreme weather conditions and heavy use is crucial. Additionally, customization options for left- or right-handed users can significantly improve comfort and efficiency.

What Benefits Do Custom Leather Tool Belts Offer Electricians?

Electricians rely heavily on custom leather tool belts to manage their specialized tools effectively. These belts are designed with specific compartments for items like wire strippers, pliers, and screwdrivers, allowing electricians to work more efficiently. The durability of leather ensures that the belts can withstand rigorous daily use, which is vital in both commercial and residential settings. Buyers from South America and Europe should consider the availability of belts that accommodate various tool types and weight distributions, ensuring comfort during long working hours.

How Do HVAC and Plumbing Professionals Utilize Tool Belts?

In the HVAC and plumbing industries, custom leather tool belts provide secure storage for essential tools such as wrenches, pipe cutters, and gauges. These belts allow technicians to work hands-free while keeping tools easily accessible, which is essential for maintaining a smooth workflow. International buyers should focus on sourcing belts that offer weather resistance and durability, as these professionals often work in challenging environments. Customization for specific tool types can further enhance efficiency and reduce the risk of tool loss.

What Role Do Custom Tool Belts Play in Manufacturing?

In manufacturing environments, custom leather tool belts are vital for assembly line workers who need to manage various tools efficiently. These belts help streamline operations by keeping tools organized and within easy reach, thereby minimizing tool loss and improving productivity. Buyers from different regions should prioritize sourcing belts with reinforced stitching and ample capacity for multiple tools, ensuring that workers can perform their tasks without interruptions. Comfort is also a key consideration, as workers may be on their feet for extended periods.

How Do Outdoor and Field Services Benefit from Tool Belts?

Field technicians in outdoor services benefit significantly from custom leather tool belts designed for versatility. These belts facilitate mobility and provide quick access to tools necessary for various tasks, from repairs to installations. For international buyers, particularly in regions with diverse climates, sourcing lightweight yet durable belts that can withstand outdoor elements is essential. Ergonomic designs that distribute weight evenly can also enhance comfort, making it easier for technicians to perform their duties effectively in the field.

3 Common User Pain Points for ‘custom leather tool belt’ & Their Solutions

Scenario 1: Difficulty in Achieving the Right Fit for Various Users

The Problem: Sourcing a custom leather tool belt that fits multiple users in a workforce can be a significant challenge for B2B buyers. Different individuals have varying body shapes and sizes, which can lead to discomfort or inefficiency if the tool belt does not fit properly. This can result in decreased productivity and increased safety risks, as improperly fitted belts can hinder movement and accessibility to tools. Additionally, if a company purchases a one-size-fits-all solution, they may find themselves with belts that only suit a fraction of their workforce.

Illustrative image related to custom leather tool belt

The Solution: When sourcing custom leather tool belts, consider investing in a supplier that offers a range of sizes and customizable options. Prior to purchase, gather data on the body measurements of your workforce to ensure a proper fit for everyone. Look for suppliers that provide adjustable belts and multiple pouch configurations to accommodate various tools. This way, you can create a tailored solution that meets the diverse needs of your team while enhancing comfort and efficiency. Additionally, consider implementing a trial program where employees can test different configurations before making a bulk purchase to ensure satisfaction.

Scenario 2: Inadequate Tool Organization Leading to Inefficiency

The Problem: A common issue faced by B2B buyers is the lack of efficient tool organization within a custom leather tool belt. When tools are not easily accessible or properly organized, it can lead to wasted time searching for the right equipment, which in turn affects project timelines and overall productivity. This problem is exacerbated in high-pressure job sites where every second counts, and the inability to quickly access necessary tools can lead to frustration among workers.

The Solution: To overcome this challenge, prioritize the design of the tool belt by focusing on customized layouts that promote efficient organization. Work with manufacturers that offer various pouch configurations tailored to specific trades, ensuring that frequently used tools are easily accessible. Consider belts with a NoSpill system, which helps secure tools in place while preventing loss. Additionally, training employees on the optimal organization of their tool belts can enhance efficiency; regular workshops can be held to demonstrate the best practices for tool placement and retrieval.

Scenario 3: Concerns Over Durability in Harsh Environments

The Problem: For B2B buyers, sourcing custom leather tool belts that can withstand harsh working conditions is a critical concern. Many belts may look appealing but fail under the rigorous demands of construction sites or outdoor work. Factors such as extreme temperatures, moisture, and heavy tool loads can lead to premature wear and tear, resulting in increased replacement costs and operational downtime. Buyers need to ensure that the belts they procure can endure these conditions while maintaining functionality and comfort for the user.

The Solution: Seek out manufacturers who specialize in high-quality, top-grain leather specifically designed for durability in tough environments. These belts should be treated with protective oils and waxes to resist water and other elements. When placing an order, request detailed information regarding the material specifications and any warranties that guarantee long-term use. Additionally, consider incorporating a maintenance program for your tool belts, educating your workforce on proper cleaning and care techniques to extend the lifespan of their equipment. Investing in durable products and educating users will ultimately lead to cost savings and enhanced operational efficiency.

Strategic Material Selection Guide for custom leather tool belt

What Are the Key Materials for Custom Leather Tool Belts?

When selecting materials for custom leather tool belts, it is essential to consider various types of leather and their properties. The right choice can significantly impact the performance, durability, and overall user satisfaction of the tool belt. Here, we will analyze four common materials used in the production of leather tool belts: full-grain leather, top-grain leather, suede leather, and synthetic leather.

How Does Full-Grain Leather Perform in Custom Tool Belts?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, making it exceptionally durable and resistant to wear and tear. Its key properties include excellent breathability and moisture resistance, which are crucial for outdoor use.

Pros: Full-grain leather is known for its longevity and ability to develop a rich patina over time, enhancing its aesthetic appeal. It is also less prone to cracking and peeling, making it suitable for heavy-duty applications.

Cons: The primary drawback is its cost, as full-grain leather is often the most expensive option. Additionally, it may require more care and maintenance to preserve its appearance and performance.

Impact on Application: Full-grain leather is ideal for tool belts used in rugged environments, such as construction sites, where durability is paramount.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that their suppliers meet local environmental standards for leather production. Compliance with ASTM or DIN standards can also be a consideration for quality assurance.

What Are the Benefits of Top-Grain Leather for Tool Belts?

Top-grain leather is slightly less durable than full-grain but is more affordable and easier to work with. It is sanded and refinished to remove imperfections, giving it a smoother appearance.

Pros: This type of leather is more resistant to stains and is generally lighter than full-grain, making it comfortable for extended wear.

Illustrative image related to custom leather tool belt

Cons: While it is durable, top-grain leather does not develop the same patina as full-grain leather and may be more susceptible to wear over time.

Impact on Application: Top-grain leather is suitable for tool belts that require a balance between durability and comfort, particularly for tradespeople who work in less demanding conditions.

Considerations for International Buyers: Buyers should verify that the top-grain leather meets the necessary quality standards in their region, particularly in Europe where environmental regulations can be stringent.

How Does Suede Leather Compare in Tool Belt Applications?

Suede leather, made from the underside of the hide, offers a unique texture and aesthetic. It is less durable than full-grain and top-grain leather but provides a softer feel.

Illustrative image related to custom leather tool belt

Pros: Suede is lightweight and flexible, making it comfortable for wear. It also has a unique appearance that can appeal to certain markets.

Cons: Its main limitation is its susceptibility to stains and damage from moisture, which can compromise its integrity in outdoor applications.

Impact on Application: Suede leather is better suited for tool belts used in indoor environments or for lighter tasks, where durability is less of a concern.

Considerations for International Buyers: Buyers in humid regions should be cautious of suede’s limitations and may prefer more durable options. Compliance with local quality standards is also crucial.

Illustrative image related to custom leather tool belt

What Role Does Synthetic Leather Play in Tool Belt Design?

Synthetic leather, or faux leather, is made from plastic materials designed to mimic the look and feel of real leather.

Pros: It is often more affordable and easier to maintain than natural leather. Synthetic leather is also water-resistant and can be produced in various colors and textures.

Cons: However, synthetic leather typically lacks the durability and breathability of natural leather, making it less suitable for heavy-duty applications.

Impact on Application: Synthetic leather is ideal for budget-conscious buyers or those requiring a specific aesthetic without the need for high durability.

Considerations for International Buyers: Buyers should ensure that synthetic leather products comply with international safety standards, especially in markets like Europe where regulations on materials can be strict.

Summary of Material Selection for Custom Leather Tool Belts

| Material | Typical Use Case for Custom Leather Tool Belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Heavy-duty construction work | Exceptional durability and breathability | High cost and maintenance required | High |

| Top-Grain Leather | General tool use in various trades | More affordable and stain-resistant | Less durable than full-grain | Medium |

| Suede Leather | Indoor tasks and lighter applications | Soft and comfortable | Susceptible to stains and moisture | Medium |

| Synthetic Leather | Budget-friendly options | Affordable and easy to maintain | Lacks durability compared to natural leather | Low |

This strategic material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather tool belt

What Are the Key Stages in the Manufacturing Process of Custom Leather Tool Belts?

Manufacturing custom leather tool belts involves several critical stages, each aimed at ensuring the final product meets both functional requirements and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Goes Into the Leather Tool Belt?

The first step in manufacturing a custom leather tool belt is material preparation. Premium top-grain cowhide is commonly used due to its durability and resistance to wear and tear. The leather undergoes a tanning process using a proprietary blend of oils and waxes that enhances its weather resistance and longevity.

In this phase, suppliers must ensure that the leather meets specific quality criteria. This includes checking for uniformity in thickness, texture, and color. Non-compliant materials can lead to product failures, making stringent material selection crucial.

How Is the Forming Process Executed for Tool Belts?

Once the leather is prepared, the next stage is forming. This involves cutting the leather into specific shapes and sizes according to the design specifications. Advanced cutting techniques, such as die-cutting, ensure precision and reduce waste.

In addition to leather, other materials, such as rivets and buckles, are also prepared. Quality assurance during this stage includes verifying the strength and durability of these components, ensuring they can withstand heavy use in demanding environments.

What Happens During the Assembly Stage?

The assembly process is where the individual components come together to form the final product. Skilled craftsmen or automated machines stitch the leather pieces, incorporating features like pockets, tool holders, and reinforcements. Techniques such as double-stitching are often employed at stress points to enhance durability.

Quality control during assembly is critical. Manufacturers implement in-process quality checks (IPQC) to identify defects before the product moves to the finishing stage. This ensures that any issues, such as misalignment or stitching errors, can be rectified promptly.

How Is the Finishing Process Conducted for Quality Assurance?

Finishing is the final stage of the manufacturing process, where the tool belt is treated with protective coatings and additional features are added, such as branding or decorative elements. The finishing touches not only enhance the aesthetic appeal but also contribute to the product’s overall durability and functionality.

During this phase, final quality checks are conducted, which may include evaluating the overall appearance, checking for defects, and confirming that all components are securely attached.

What Quality Assurance Measures Are Commonly Implemented in Leather Tool Belt Manufacturing?

Quality assurance is an integral part of the manufacturing process, ensuring that each custom leather tool belt meets international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards is essential. ISO 9001 is a widely recognized quality management standard that focuses on process improvement and customer satisfaction. Compliance with this standard indicates that the manufacturer has effective quality management systems in place.

Illustrative image related to custom leather tool belt

Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for specific applications can further assure buyers of the product’s quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints during the manufacturing process include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC focuses on incoming materials, ensuring that leather and other components meet predefined specifications.

- IPQC monitors the production process, identifying defects or inconsistencies as they arise.

- FQC is the last line of defense, where the finished product is thoroughly inspected before shipment.

Common testing methods include tensile strength tests, abrasion resistance tests, and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers. Conducting audits is one effective method. These audits can be either announced or unannounced and should assess adherence to quality standards and operational efficiency.

Illustrative image related to custom leather tool belt

Buyers should also request quality assurance reports that detail the results of various tests and inspections conducted throughout the manufacturing process. Additionally, third-party inspections can provide an unbiased evaluation of the supplier’s capabilities and adherence to quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and certifications is crucial. Each region may have specific requirements that impact quality assurance practices.

For instance, buyers from the European market may prioritize CE certification, while those in the Middle East might look for compliance with local standards. Understanding these nuances can help buyers make informed decisions and select suppliers that align with their quality expectations.

Illustrative image related to custom leather tool belt

Conclusion: Why Quality Assurance Is Essential for Custom Leather Tool Belts

In conclusion, the manufacturing processes and quality assurance measures for custom leather tool belts play a vital role in delivering a product that meets the demands of professionals. By understanding the stages of manufacturing and the importance of quality control, B2B buyers can make informed decisions that ensure they receive durable, reliable, and high-quality leather tool belts tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather tool belt’

To assist B2B buyers in procuring custom leather tool belts, this guide offers a comprehensive checklist to ensure you make informed decisions. Whether you are sourcing for construction, carpentry, or electrical work, following these steps will help you find a reliable supplier and quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the tool belts you require. Consider factors such as the type of leather, design features, and the number of pockets needed. This clarity will help suppliers provide accurate quotes and ensure that the products meet your operational requirements.

- Leather Quality: Look for top-grain or full-grain leather that offers durability and resistance to wear.

- Functionality: Determine if you need tool-specific holders for various tools, and whether customizations like colors or additional pockets are necessary.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather tool belts. Use online resources, industry directories, and trade shows to compile a list of potential partners.

- Supplier Reputation: Check reviews and testimonials to gauge the reliability and quality of their products.

- Industry Experience: Prefer suppliers with a proven track record in your industry, as they will better understand your needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

Illustrative image related to custom leather tool belt

- Certifications and Compliance: Ensure that suppliers adhere to relevant industry standards and regulations.

- Production Capabilities: Verify their ability to meet your volume requirements and timelines.

Step 4: Request Samples and Specifications

Once you have shortlisted suppliers, request samples of their custom leather tool belts. This step is vital to evaluate the quality and craftsmanship of their products firsthand.

- Quality Assessment: Inspect the leather quality, stitching, and overall durability of the sample.

- Customization Options: Assess how well they can accommodate your specific design requests.

Step 5: Negotiate Pricing and Terms

Engage in discussions regarding pricing, payment terms, and delivery schedules. This step is essential to ensure you receive a fair deal and that both parties have aligned expectations.

- Bulk Discounts: Inquire about discounts for bulk orders, as this can significantly reduce your costs.

- Warranty and Return Policies: Ensure that the supplier offers satisfactory warranty coverage and a clear return policy for defective products.

Step 6: Finalize the Contract

Once you are satisfied with the samples and pricing, finalize the contract with the supplier. Ensure that all terms, including delivery timelines and quality standards, are clearly articulated.

- Legal Considerations: Consult with legal experts to review the contract, ensuring that your interests are protected.

- Communication Plan: Establish a communication plan for updates and any potential issues during the production process.

Step 7: Establish a Quality Control Process

After placing your order, implement a quality control process to ensure that the delivered tool belts meet your specifications and standards.

- Inspection Criteria: Define clear criteria for inspecting the quality upon receipt.

- Feedback Loop: Create a feedback mechanism with the supplier to address any concerns that may arise post-delivery.

By following this checklist, you can streamline your sourcing process for custom leather tool belts, ensuring that you partner with a reliable supplier who meets your business needs.

Comprehensive Cost and Pricing Analysis for custom leather tool belt Sourcing

What Are the Key Cost Components in Sourcing Custom Leather Tool Belts?

When sourcing custom leather tool belts, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The quality of leather significantly influences cost. Premium top-grain leather, which is durable and ideal for heavy-duty use, tends to be more expensive than lower-grade options. Additional materials like stitching, rivets, and any synthetic reinforcements also contribute to overall costs.

-

Labor: Skilled craftsmanship is essential in producing high-quality leather tool belts. Labor costs will vary by region and the complexity of the design. Customization requires additional labor hours, which should be factored into the pricing.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, equipment maintenance, and general administrative expenses. Efficient manufacturing processes can help reduce overhead, impacting the final price.

-

Tooling: Custom designs often necessitate specialized tools or molds. These initial setup costs can be significant and are typically spread across the production run, influencing the unit price.

-

Quality Control (QC): Ensuring that each tool belt meets quality standards requires investment in QC processes. This may involve inspections, testing materials, and ensuring compliance with industry certifications, all of which can add to the cost.

-

Logistics: Shipping and handling costs, particularly for international orders, can be substantial. Factors such as distance, mode of transport, and customs duties must be considered in the overall pricing strategy.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. The margin can vary based on market competition, the supplier’s business model, and the perceived value of the product.

How Do Price Influencers Affect Custom Leather Tool Belt Costs?

Several factors can influence the pricing of custom leather tool belts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer price breaks based on order size, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs tailored to specific requirements can increase costs. Unique features, such as additional pockets, reinforced stitching, or specialized fasteners, can add to the base price.

-

Material Quality and Certifications: Higher-quality materials or those with certifications (like eco-friendly or sustainably sourced leather) may come at a premium. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: Relationships with suppliers can impact pricing. Established suppliers may offer better terms based on ongoing partnerships, while new suppliers might have introductory pricing strategies.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in shipping arrangements. Understanding these terms can help buyers manage logistics costs more effectively.

What Tips Can Help Buyers Negotiate Better Prices for Custom Leather Tool Belts?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiate Terms: Always negotiate price, payment terms, and delivery schedules. Suppliers may have flexibility, especially for large orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the durability and lifespan of the tool belts. Investing in higher-quality products may lead to lower replacement costs over time.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations and varying import tariffs can affect final costs. Buyers should factor in potential additional costs when sourcing internationally.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This helps in making informed decisions and reduces the risk of dissatisfaction with the final product.

Disclaimer on Indicative Prices

Prices for custom leather tool belts can vary widely based on the factors discussed. The figures provided in reference materials may not reflect current market conditions, and buyers should conduct thorough market research to obtain accurate, up-to-date pricing information.

Illustrative image related to custom leather tool belt

Alternatives Analysis: Comparing custom leather tool belt With Other Solutions

Exploring Alternative Solutions to Custom Leather Tool Belts

In the realm of professional tool management, the custom leather tool belt stands out for its durability, design, and efficiency. However, various alternatives exist that cater to different needs and preferences. This section evaluates the custom leather tool belt against other viable solutions, helping B2B buyers make informed decisions based on performance, cost, and usability.

| Comparison Aspect | Custom Leather Tool Belt | Synthetic Tool Belt | Tool Chest / Organizer |

|---|---|---|---|

| Performance | High durability and comfort; tailored for specific tools | Moderate durability; lightweight and flexible | Excellent storage; not portable |

| Cost | Premium pricing; long-term investment | Generally lower cost; budget-friendly | Varies widely; can be expensive |

| Ease of Implementation | Requires sizing and fitting; may need custom orders | Easy to purchase off-the-shelf; available in various sizes | Requires space and installation |

| Maintenance | Needs occasional conditioning; long lifespan | Low maintenance; easy to clean | Minimal maintenance; depends on usage |

| Best Use Case | Ideal for skilled trades and heavy-duty use | Suitable for casual users and light tasks | Best for workshops and static environments |

What Are the Pros and Cons of Synthetic Tool Belts?

Synthetic tool belts offer a lightweight and cost-effective alternative to custom leather options. Typically made from nylon or other synthetic materials, they are easier to clean and maintain. They excel in situations where budget constraints are significant or where users require a less bulky option for casual or light-duty work. However, they may not provide the same level of durability or comfort as leather, particularly in demanding environments.

How Does a Tool Chest or Organizer Compare?

A tool chest or organizer serves as a robust solution for storing and managing tools, especially in workshop settings. With various compartments and a substantial storage capacity, they keep tools organized and easily accessible. The downside is their lack of portability; they are not ideal for on-site work or situations where mobility is essential. Additionally, the cost can vary significantly based on the size and features, making it important for buyers to assess their specific needs.

Conclusion: Which Tool Management Solution Is Right for Your Business?

Choosing the right tool management solution depends on the specific requirements of your workforce and the nature of the tasks at hand. For businesses involved in heavy-duty trades, investing in custom leather tool belts may yield long-term benefits in terms of durability and comfort. On the other hand, companies with budget constraints or those requiring less intensive tool management may find synthetic tool belts or tool chests more suitable. Evaluating the performance, cost, and maintenance needs of each option will enable B2B buyers to select the most appropriate solution for their unique operational demands.

Essential Technical Properties and Trade Terminology for custom leather tool belt

What Are the Key Technical Properties of a Custom Leather Tool Belt?

When considering a custom leather tool belt, understanding its technical properties is essential for ensuring durability, functionality, and suitability for specific applications. Here are some critical specifications that B2B buyers should keep in mind:

Illustrative image related to custom leather tool belt

-

Material Grade

The most common material for high-quality tool belts is premium top-grain leather. This grade is favored for its durability, flexibility, and resistance to wear, making it ideal for heavy-duty use in various job site conditions. Using top-grain leather ensures that the tool belt can withstand the rigors of daily operations, which is crucial for professionals in construction or electrical work. -

Tanning Process

Leather tanning refers to the chemical treatment that preserves the hide and enhances its durability. Tool belts made from leather tanned with a proprietary blend of oils and waxes are particularly effective in resisting moisture and stains. This property is vital for B2B buyers in regions with humid or variable climates, as it ensures the longevity of the product. -

Reinforcement Features

Reinforced stress points, often achieved through copper riveting, are a hallmark of high-quality leather tool belts. These reinforcements prevent wear and tear at critical junctures, ensuring that the tool belt can carry heavy loads without compromising its structure. For buyers, this translates into reduced replacement costs and enhanced reliability. -

Weight Distribution Design

A well-designed tool belt should feature a balanced weight distribution system, often facilitated by ergonomic designs and wide belts. This is particularly important for reducing fatigue during long work hours, enhancing worker productivity. Buyers should prioritize tool belts that offer this feature to improve user experience and comfort. -

Pocket Configuration

The arrangement and number of pockets should be tailored to specific trades, such as carpentry or electrical work. A tool belt with a well-thought-out pocket layout allows for quick access to tools, thereby increasing efficiency on the job. For B2B buyers, understanding the unique needs of their workforce can guide them in selecting the right configuration.

What Are Common Trade Terms Associated with Custom Leather Tool Belts?

Navigating the procurement of custom leather tool belts involves familiarizing oneself with industry jargon. Here are some common terms that every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather tool belts, knowing if a supplier is an OEM can help buyers assess product quality and compatibility with other equipment. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for buyers who need to manage inventory levels effectively while negotiating bulk pricing. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This is particularly useful for B2B buyers looking to compare costs and specifications for custom leather tool belts across different vendors. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is crucial for B2B buyers involved in international trade, as it clarifies issues such as shipping costs, insurance, and risk transfer. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. For buyers, understanding lead time is essential for planning inventory and ensuring that projects are not delayed due to supply chain issues. -

Customization Options

This term refers to the ability to modify the standard features of a product to meet specific requirements. Buyers should inquire about customization options to ensure that the tool belt aligns with their unique operational needs.

Understanding these technical properties and trade terms will empower B2B buyers to make informed purchasing decisions regarding custom leather tool belts, ensuring they select the best products for their workforce and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the custom leather tool belt Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Tool Belt Sector?

The global market for custom leather tool belts is experiencing significant growth, driven by several key factors. Firstly, the rising demand for durable, high-quality workwear in construction and trades is propelling the need for reliable tool-carrying solutions. In regions such as Africa, South America, the Middle East, and Europe, particularly in countries like Saudi Arabia and Brazil, there is an increasing focus on professional-grade equipment that enhances productivity and ensures safety on job sites. Moreover, advancements in manufacturing technologies are allowing for more customizable options, enabling buyers to source products tailored to specific needs.

Emerging B2B tech trends are also shaping the sourcing landscape. E-commerce platforms are becoming vital for international buyers, facilitating easier access to a broader range of suppliers and products. Digitalization in supply chain management is enhancing transparency and efficiency, allowing businesses to track orders and manage inventories more effectively. Additionally, the integration of AI and data analytics into procurement processes is enabling companies to make more informed decisions, ensuring they source products that align with their operational needs and budget constraints.

How Is Sustainability and Ethical Sourcing Shaping the Custom Leather Tool Belt Market?

Sustainability is becoming a central theme in the custom leather tool belt sector, with increasing awareness of environmental impacts influencing purchasing decisions. Buyers are increasingly seeking out suppliers that adhere to ethical sourcing practices, which includes the use of environmentally friendly materials and processes. The leather industry has historically faced scrutiny regarding waste and resource usage, prompting manufacturers to adopt more sustainable methods.

Illustrative image related to custom leather tool belt

Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction among B2B buyers. These certifications assure that the leather used in tool belts is sourced responsibly, minimizing environmental impact while supporting ethical labor practices. Furthermore, the trend towards using vegetable-tanned leather and other sustainable alternatives is appealing to environmentally conscious businesses, as these materials are often less harmful to the ecosystem compared to traditional tanning processes.

What Is the Brief Evolution of the Custom Leather Tool Belt Industry?

The custom leather tool belt industry has evolved significantly over the decades, transitioning from basic utility designs to sophisticated, ergonomically engineered systems that cater to the specific needs of various trades. Initially, tool belts were simple leather pouches designed for carrying a limited number of tools. However, as the construction and trades sectors have advanced, so too have the requirements for tool organization and accessibility.

With the rise of professional trades, particularly in the late 20th century, manufacturers began to innovate, introducing features such as reinforced stitching, specialized pockets, and ergonomic designs. This evolution reflects the increasing complexity of modern construction tasks, where efficiency and safety are paramount. Today, custom leather tool belts are not only valued for their functionality but also for their durability and style, making them a staple in the professional toolkit.

Illustrative image related to custom leather tool belt

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather tool belt

-

How do I ensure the quality of custom leather tool belts before purchasing?

To ensure the quality of custom leather tool belts, request samples from potential suppliers. Inspect the leather type, stitching quality, and hardware used in the belts. Additionally, verify if the leather is treated for durability against various environmental conditions. It’s also prudent to check for certifications or standards that the supplier adheres to, as this can provide reassurance about the product’s quality. Conducting factory visits or third-party inspections can further help in assessing the manufacturing process and quality control measures. -

What is the best type of leather for durable tool belts?

The best type of leather for durable tool belts is typically top-grain or full-grain leather. Top-grain leather offers a balance of durability and flexibility, making it suitable for heavy-duty use while maintaining comfort. Full-grain leather, while more expensive, is the most durable option and develops a unique patina over time. When sourcing, ensure that the leather has been treated to withstand the elements, especially if it will be used in harsh working conditions. -

What customization options are available for leather tool belts?

Customization options for leather tool belts can include size adjustments, pocket configurations, and personalized branding such as logos or initials. Buyers can also select specific hardware colors, leather finishes, and stitching styles to match their branding or aesthetic preferences. Discussing these options with your supplier is crucial, as they may offer different levels of customization based on their manufacturing capabilities and minimum order quantities. -

What are the minimum order quantities (MOQs) for custom leather tool belts?

Minimum order quantities (MOQs) for custom leather tool belts can vary widely among suppliers, typically ranging from 50 to several hundred units. Factors influencing MOQs include the supplier’s production capacity, the complexity of customization, and the material used. It’s advisable to communicate your needs clearly with potential suppliers to find a partner who can accommodate your order size while ensuring competitive pricing. -

How can I vet suppliers for custom leather tool belts?

Vetting suppliers for custom leather tool belts involves several steps: researching their reputation online, checking reviews and testimonials, and asking for references from previous clients. It’s also beneficial to assess their production capabilities, lead times, and quality control processes. Visiting their facility or requesting a factory audit can provide deeper insights into their operations. Look for suppliers who comply with international standards and certifications relevant to your market. -

What payment terms should I expect when sourcing leather tool belts internationally?

Payment terms when sourcing leather tool belts internationally typically range from upfront deposits (often 30-50%) to full payment upon delivery. Some suppliers may offer net payment terms, allowing you to pay within a set period after receiving the goods. It’s essential to clarify these terms in advance and consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially in new supplier relationships. -

How do I handle logistics and shipping for international orders of tool belts?

Handling logistics for international orders involves selecting a reliable freight forwarder familiar with customs regulations in your target market. Consider shipping methods such as air freight for faster delivery or sea freight for cost-effective bulk shipments. Ensure that your supplier can provide the necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Lastly, factor in lead times, potential delays, and additional fees when planning your inventory levels. -

What quality assurance measures should be in place for custom leather tool belts?

Quality assurance measures for custom leather tool belts should include regular inspections throughout the production process, from material selection to final assembly. Suppliers should implement testing for durability, such as stress tests and environmental exposure assessments, to ensure the belts can withstand intended use. Requesting detailed reports on quality checks and any certifications related to leather quality and safety standards can also provide peace of mind regarding your purchase.

Top 4 Custom Leather Tool Belt Manufacturers & Suppliers List

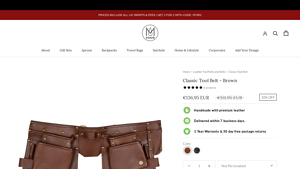

1. Mahileather – Classic Tool Belt

Domain: mahileather.com

Registered: 2014 (11 years)

Introduction: {“name”: “Classic Tool Belt – Brown”, “price”: “$156.21”, “original_price”: “$173.57”, “discount”: “10% OFF”, “materials”: “100% full grain leather exterior and a waterproof lining interior”, “dimensions”: “H21cm X W54cm X D5cm (main pockets)”, “features”: “11 pockets in varying sizes, tool holding pouch, 3 tool holding loops, fabric belt (L 99-119cm)”, “personalization_options”: [“Not Personalize…

2. Style N Craft – Tool Pouches & Belts

Domain: stylencraft.com

Registered: 2007 (18 years)

Introduction: Work Belts, Tool Pouches & Holsters to Make Your Own Combo. Free Shipping in USA on orders over $50. Products include: 10 Pocket Carpenter’s Nail and Tool Pouch in Oiled Full Grain Leather ($71.00), 10 Pocket Carpenter’s Nail and Tool Pouch in Full Grain Leather ($71.00), 10 Pocket Carpenter’s Nail & Tool Pouch with Tape Clip in Full Grain Leather ($72.00), 9 Pocket Framer’s Nail and Tool Pouch in…

3. Pikore – Personalized Leather Tool Belts

Domain: pikore.shop

Registered: 2021 (4 years)

Introduction: Personalized Leather Tool Belts with Suspenders

– Handmade from premium leather

– Reinforced for durability

– Designed for comfort

– Available in 5 colors: Cognac, Green, Black, Light Cognac, Brown

– Adjustable sizing for a perfect fit

– Heavy-duty rivets and hardware

– Comfortable suspenders with strong attachment points

– Multiple tool compartments for organization

– Custom engraving options ava…

4. Bolt Belts – Custom Leather Tool Belts

Domain: boltbelts.com

Registered: 2024 (1 years)

Introduction: Leather Tool Belts & Pouches – Custom Fit | Bolt Belts

**Discounts:**

– 10% Off Your Purchase – Use Code: BOLTSAVE10

– Free Shipping on Orders of $250+

– Additional Discounts: 15% OFF $200 | 10% OFF $150

**Product Categories:**

– Leather Tool Belt Sets

– Tool Bags & Pouches

– Accessories (Belts, Hammer & Tape Holders, Suspenders, Utility Snaps, Mobile Holsters, Clip-On Products)

**Featured Prod…

Strategic Sourcing Conclusion and Outlook for custom leather tool belt

In the competitive landscape of tool accessories, the strategic sourcing of custom leather tool belts offers significant advantages for international B2B buyers. By prioritizing high-quality materials, such as premium top-grain leather, companies can ensure durability and functionality that meets the demanding conditions of various job sites. Leveraging established relationships with trusted manufacturers can lead to optimized supply chains, cost efficiencies, and tailored solutions that enhance operational productivity.

Furthermore, understanding regional preferences and requirements is crucial, especially for buyers from Africa, South America, the Middle East, and Europe. Sourcing partners should be equipped to accommodate specific market needs, including customization options for left-handed users or unique tool configurations for specialized trades.

As the industry evolves, embracing innovative designs and sustainable practices in leather sourcing will not only improve product longevity but also align with global trends towards environmental responsibility.

International buyers are encouraged to explore these opportunities, fostering partnerships that emphasize quality and efficiency. By investing in custom leather tool belts, companies can equip their workforce with the tools necessary for success, ensuring they remain competitive in an ever-changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.