Introduction: Navigating the Global Market for custom leather craft

Navigating the global market for custom leather craft presents a unique set of challenges for international B2B buyers. Sourcing high-quality leather products that meet specific requirements—such as durability, design, and comfort—can be daunting, especially in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the custom leather craft landscape, providing insights into various types of products, their applications, and essential considerations for supplier vetting.

From tool pouches and work gear to bespoke fashion items, the scope of custom leather craft is vast and varied. Buyers will benefit from a thorough understanding of cost factors, quality indicators, and sourcing strategies tailored to their regional contexts. By equipping B2B decision-makers with actionable insights, this guide empowers them to make informed purchasing decisions that align with their operational needs and market expectations.

Whether you’re looking for reliable suppliers in Germany or innovative designs in Vietnam, this guide serves as a vital resource. It not only highlights the best practices for evaluating potential partners but also emphasizes the importance of aligning product specifications with your business objectives. With a clear focus on enhancing efficiency and satisfaction, this guide will support you in navigating the complexities of the custom leather craft market.

Table Of Contents

- Top 5 Custom Leather Craft Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather craft

- Understanding custom leather craft Types and Variations

- Key Industrial Applications of custom leather craft

- 3 Common User Pain Points for ‘custom leather craft’ & Their Solutions

- Strategic Material Selection Guide for custom leather craft

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather craft

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather craft’

- Comprehensive Cost and Pricing Analysis for custom leather craft Sourcing

- Alternatives Analysis: Comparing custom leather craft With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather craft

- Navigating Market Dynamics and Sourcing Trends in the custom leather craft Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather craft

- Strategic Sourcing Conclusion and Outlook for custom leather craft

- Important Disclaimer & Terms of Use

Understanding custom leather craft Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tool Pouches | Multiple pockets, durable suede leather | Construction, electrical trades | Pros: Enhanced organization, quick access to tools. Cons: May require cleaning to maintain appearance. |

| Soft-Sided Toolboxes | Lightweight, open-top design, numerous pockets | Contractors, DIY projects | Pros: Easy access, portable. Cons: Less protection from elements compared to hard cases. |

| Work Gloves | Flexible fit, reinforced grip, protective design | General construction, DIY tasks | Pros: Comfort during extended use, improved grip. Cons: Sizing may vary, requiring careful selection. |

| Leather Tool Belts | Adjustable, heavy-duty leather, multiple attachment points | Various trades | Pros: Durable and reliable, customizable fit. Cons: Can be bulky if overloaded. |

| Specialty Tool Holders | Designed for specific tools, secure attachment | Carpentry, electrical work | Pros: Tailored for specific tools, enhances efficiency. Cons: Limited versatility for other tools. |

What are the Key Characteristics of Tool Pouches in Custom Leather Craft?

Tool pouches are essential for professionals in construction and electrical trades. Typically made from durable suede leather, these pouches feature multiple pockets that allow for organized storage of various tools. Their design ensures quick access, which is crucial in fast-paced environments. Buyers should consider the weight, number of pockets, and ease of cleaning when selecting a tool pouch, as these factors can significantly impact efficiency on the job site.

How Do Soft-Sided Toolboxes Benefit B2B Buyers?

Soft-sided toolboxes are favored for their lightweight and portable nature, making them ideal for contractors and DIY enthusiasts. With an open-top design and numerous pockets, they facilitate easy access to tools and materials. When purchasing, businesses should evaluate the durability of the materials and the overall design, as these elements can affect usability in diverse working conditions. While they offer convenience, buyers must also consider their vulnerability to environmental factors compared to hard-sided alternatives.

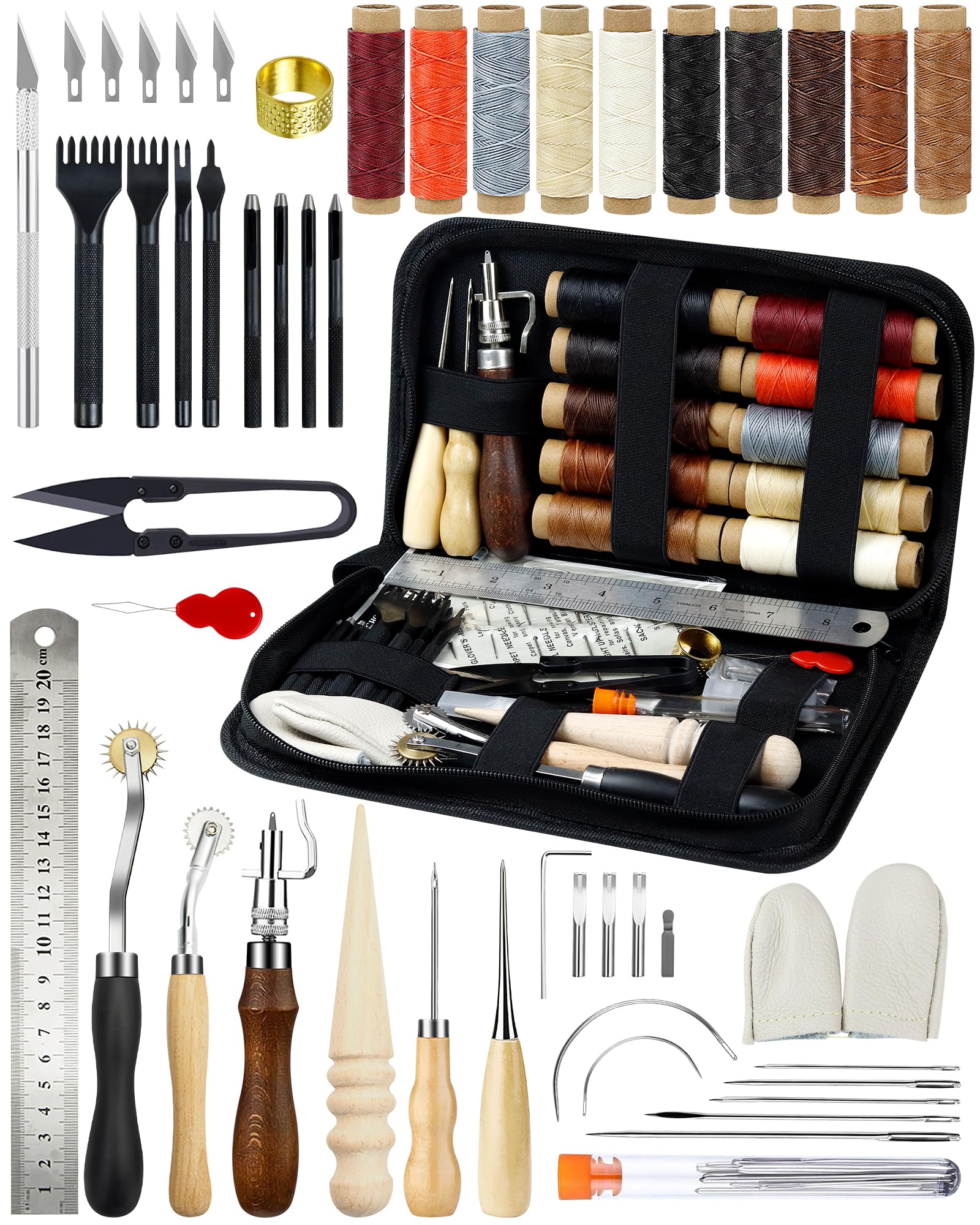

Illustrative image related to custom leather craft

Why Are Work Gloves Crucial for Tradespeople?

Work gloves are an integral part of personal protective equipment for professionals across various trades. Designed with a flexible fit and reinforced grip, they provide comfort and protection during prolonged use. Buyers should pay attention to sizing and material quality, as these can influence grip and durability. While work gloves enhance safety and efficiency, it’s essential to select models that balance protection with dexterity to avoid compromising performance.

What Should B2B Buyers Know About Leather Tool Belts?

Leather tool belts are a staple for many trades, offering a durable and adjustable solution for carrying tools. They feature multiple attachment points for hanging tools, making them versatile for various applications. When considering a purchase, businesses should assess the belt’s weight capacity and comfort, especially for extended use. However, buyers should be cautious of overloading belts, which can lead to discomfort and hinder movement on the job.

How Do Specialty Tool Holders Enhance Efficiency?

Specialty tool holders are designed to securely hold specific tools, making them invaluable in carpentry and electrical work. Their tailored designs allow for quick access and optimal organization, significantly improving workflow. When selecting specialty holders, businesses should consider the compatibility with existing tools and the security of the attachment mechanisms. While these holders enhance efficiency, their limited versatility may require additional purchases for different tools.

Illustrative image related to custom leather craft

Key Industrial Applications of custom leather craft

| Industry/Sector | Specific Application of custom leather craft | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Tool pouches and belts for contractors | Enhanced organization and efficiency on job sites | Durability of materials, customization options, bulk pricing |

| Electrical Services | Tool bags for electricians | Secure storage and easy access to tools | Size and pocket configuration, material quality, safety features |

| Agriculture | Protective gear and tool holders for farm workers | Improved safety and comfort during long working hours | Weather resistance, ergonomic design, availability of sizes |

| Manufacturing | Custom leather aprons and gloves for factory workers | Protection from hazards and increased productivity | Compliance with safety standards, flexibility of design, cost-effectiveness |

| Retail and Craft | Personalized leather goods for artisanal shops | Unique branding and customer engagement | Customization capabilities, lead times, quality assurance |

How Is Custom Leather Craft Used in Construction?

In the construction sector, custom leather craft is utilized to create tool pouches and belts specifically designed for contractors. These products enhance organization and efficiency by providing secure storage for tools and easy access while working on job sites. Buyers should consider the durability of materials, customization options for branding, and bulk pricing when sourcing these items, particularly in regions like Africa and South America where outdoor conditions may be harsher.

What Role Does Custom Leather Craft Play in Electrical Services?

Electricians often rely on custom leather tool bags to keep their essential tools organized and readily accessible. These bags are designed with multiple pockets to accommodate various tools, ensuring safety and efficiency during electrical installations or repairs. International buyers, especially from Europe and the Middle East, should prioritize size and pocket configuration, material quality, and safety features to meet specific job requirements.

How Does Custom Leather Craft Enhance Safety in Agriculture?

In agriculture, custom leather craft provides protective gear and tool holders that significantly improve safety for farm workers. These products are designed to withstand rigorous outdoor conditions while offering comfort during extended use. When sourcing, businesses should focus on weather resistance, ergonomic design, and the availability of various sizes to cater to different worker needs, particularly in diverse climates across Africa and South America.

Why Is Custom Leather Craft Important in Manufacturing?

Manufacturing workers benefit from custom leather aprons and gloves that provide protection against hazards while enhancing productivity. These items are essential for ensuring worker safety in environments where exposure to sharp tools and machinery is common. Buyers in this sector should ensure compliance with safety standards, flexibility of design for different tasks, and cost-effectiveness when sourcing from suppliers.

How Can Retail and Craft Businesses Leverage Custom Leather Craft?

Artisanal shops and retail businesses can utilize personalized leather goods to enhance their branding and customer engagement. Custom leather products, such as wallets and bags, not only serve practical purposes but also resonate with consumers looking for unique and high-quality items. Key considerations for sourcing include the customization capabilities of suppliers, lead times for production, and quality assurance to maintain brand integrity.

3 Common User Pain Points for ‘custom leather craft’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Custom Leather Products

The Problem: Many B2B buyers, especially those in developing regions such as Africa and South America, face challenges in sourcing high-quality custom leather products. The issues can include limited access to reliable suppliers, variations in leather quality, and inconsistent product offerings. This can lead to frustration, as businesses require dependable materials to maintain their reputation and meet customer expectations. Additionally, buyers often struggle with understanding the specifications of leather types and their suitability for specific applications, which can result in costly mistakes.

The Solution: To effectively source quality custom leather products, B2B buyers should establish relationships with reputable manufacturers who specialize in leather craftsmanship. Conducting thorough research to identify suppliers with a strong track record in quality assurance and customer service is crucial. Buyers should request samples to evaluate the leather quality firsthand and inquire about the sourcing practices of the supplier. Furthermore, leveraging trade shows and industry networks can help connect buyers with trusted suppliers. When specifying requirements, be clear about the intended use of the leather products, such as whether they need to be water-resistant, durable, or flexible. This clarity will help suppliers provide the most suitable materials for your needs.

Scenario 2: Balancing Customization with Production Efficiency

The Problem: Customization is a significant selling point for leather products, yet it often leads to longer production times and increased costs. B2B buyers may find it challenging to balance the desire for unique, tailored products with the need for timely delivery and cost-effectiveness. This dilemma can be particularly pronounced in industries with tight deadlines, where delays in product availability can result in lost sales and dissatisfied customers.

The Solution: To address this pain point, buyers should engage with manufacturers that offer a streamlined customization process. Discussing design parameters early in the negotiation phase can help clarify capabilities and limitations. It is beneficial to understand the manufacturer’s production timelines and find a balance between customization and efficiency. Consider using modular designs that allow for personalization without extensive modifications to the production line. Additionally, implementing a clear communication strategy with the manufacturer can help track progress and address any potential delays proactively. Establishing minimum order quantities for customized products may also facilitate better pricing and faster production.

Scenario 3: Ensuring Compliance with International Standards

The Problem: International B2B buyers often encounter difficulties ensuring that the custom leather products they procure meet local regulatory and quality standards. This challenge is particularly relevant for industries such as fashion, automotive, and furniture, where compliance with material safety regulations is essential. Failing to meet these standards can lead to costly recalls, legal issues, and damage to brand reputation.

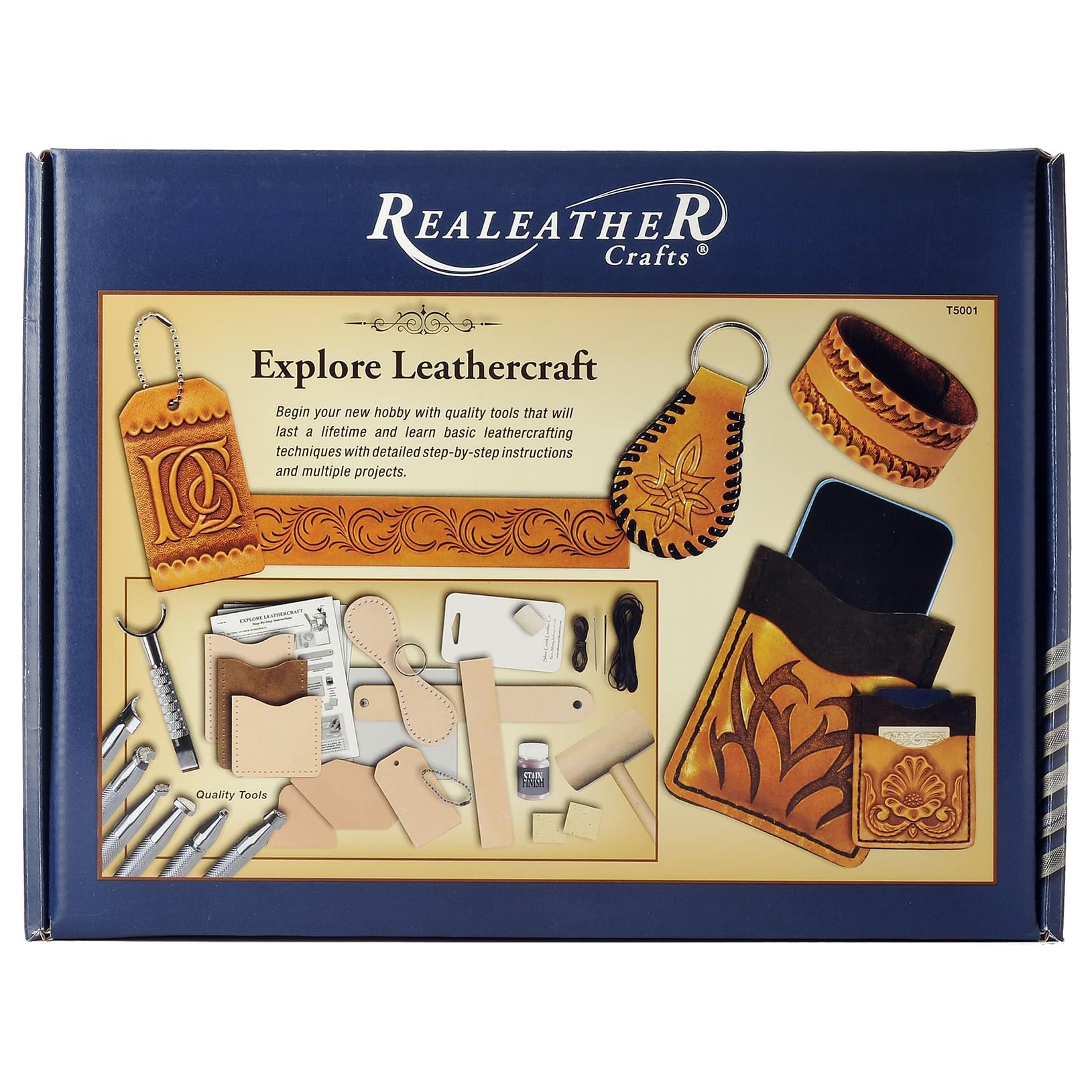

Illustrative image related to custom leather craft

The Solution: To navigate compliance challenges effectively, B2B buyers should familiarize themselves with the specific regulations applicable in their markets. Collaborating with suppliers who understand these requirements is crucial. Requesting documentation that verifies compliance with international standards, such as ISO certifications or REACH compliance, can provide peace of mind. Additionally, consider conducting audits or site visits to the manufacturing facilities to assess their adherence to quality control processes. Establishing a robust quality assurance protocol that includes third-party inspections can further ensure that products meet necessary standards before they are shipped. By prioritizing compliance from the outset, businesses can mitigate risks and enhance their marketability in international arenas.

Strategic Material Selection Guide for custom leather craft

What Are the Key Properties of Common Materials Used in Custom Leather Craft?

When selecting materials for custom leather craft, several options stand out due to their unique properties and suitability for various applications. Understanding these materials is crucial for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Full-Grain Leather

Key Properties: Full-grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. It offers excellent breathability and is resistant to wear and tear, making it suitable for high-stress applications. It typically withstands temperatures up to 90°C (194°F) and has a strong resistance to moisture.

Illustrative image related to custom leather craft

Pros & Cons: The primary advantage of full-grain leather is its durability and aesthetic appeal, as it develops a unique patina over time. However, it is also the most expensive type of leather, which may impact overall manufacturing costs. Additionally, it requires specialized techniques for processing, which can complicate manufacturing.

Impact on Application: Full-grain leather is ideal for high-end products such as luxury handbags and durable work gear. Its moisture resistance makes it suitable for environments where exposure to humidity is a concern.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ISO 4045 for leather testing. Preferences for full-grain leather may vary by region, particularly in Europe, where quality and sustainability are prioritized.

2. Suede Leather

Key Properties: Suede leather is made from the underside of the hide, providing a soft texture and a unique aesthetic. It is less durable than full-grain leather but offers good flexibility and comfort. Suede typically performs well in moderate temperatures and has limited moisture resistance.

Pros & Cons: The softness of suede makes it comfortable for wearables and accessories, enhancing user experience. However, its susceptibility to stains and moisture can limit its applications, particularly in outdoor environments. Suede is generally less expensive than full-grain leather, making it a cost-effective option for certain products.

Impact on Application: Suede is commonly used in fashion items, such as jackets and shoes, where comfort and style are paramount. Its limited durability may not suit heavy-duty applications.

Illustrative image related to custom leather craft

Considerations for International Buyers: Buyers should be aware of regional preferences for suede, particularly in fashion-forward markets in Europe and South America. Compliance with environmental regulations regarding tanning processes is also essential.

3. Top-Grain Leather

Key Properties: Top-grain leather is slightly less durable than full-grain leather but is more affordable. It is sanded and refinished to remove imperfections, resulting in a smooth surface. Top-grain leather can withstand moderate temperatures and has good resistance to wear.

Pros & Cons: The main advantage of top-grain leather is its balance of quality and cost, making it suitable for a wide range of products. However, it lacks the unique character of full-grain leather and can be less durable over time.

Impact on Application: This material is widely used in mid-range products such as wallets, belts, and furniture upholstery. Its versatility makes it a popular choice for B2B buyers looking for a balance between quality and cost.

Considerations for International Buyers: Buyers must consider the varying standards for leather quality in different regions, such as ASTM D2202 in the U.S. and DIN EN 15987 in Europe. Understanding local consumer preferences for leather quality can guide purchasing decisions.

Illustrative image related to custom leather craft

4. Bonded Leather

Key Properties: Bonded leather is made from leather scraps that are bonded together with polyurethane or latex. It offers a leather-like appearance at a fraction of the cost. However, it is less durable and can degrade over time, especially under high stress.

Pros & Cons: The affordability of bonded leather makes it an attractive option for budget-conscious buyers. However, its limited durability and lower quality can lead to dissatisfaction among end-users, particularly in high-use applications.

Impact on Application: Bonded leather is often used for promotional items, low-cost accessories, and furniture. Its lower durability makes it unsuitable for high-end applications.

Considerations for International Buyers: Buyers should be cautious about the quality of bonded leather and ensure it meets relevant standards, such as JIS K 6852 in Japan. Transparency regarding the material composition is crucial for building trust with customers.

Summary Table

| Material | Typical Use Case for custom leather craft | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags, durable work gear | Exceptional durability and aesthetics | High cost, complex manufacturing | High |

| Suede Leather | Fashion items, jackets, shoes | Soft texture and comfort | Limited durability and moisture resistance | Med |

| Top-Grain Leather | Wallets, belts, furniture upholstery | Good quality at a reasonable price | Lacks character compared to full-grain | Med |

| Bonded Leather | Promotional items, low-cost accessories | Affordable alternative to leather | Limited durability and quality | Low |

This guide aims to assist international B2B buyers in making informed decisions regarding material selection for custom leather craft, ensuring that they choose the right materials for their specific applications and market demands.

Illustrative image related to custom leather craft

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather craft

What Are the Key Stages in the Manufacturing Process of Custom Leather Craft?

The manufacturing process of custom leather craft involves several critical stages that ensure the final product meets the desired standards of quality and durability. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: How Is Leather Processed for Custom Products?

The first stage in leather crafting is material preparation. High-quality leather is sourced, often from reputable tanneries that adhere to ethical sourcing practices. The leather undergoes a thorough inspection for imperfections, ensuring that only the best hides are selected. Following this, the hides are cut to size, with careful consideration given to the specific requirements of each product design. This step may also involve tanning, dyeing, and conditioning the leather to enhance its durability and aesthetic appeal.

Forming: What Techniques Are Used to Shape Leather Products?

Once the leather is prepared, it moves to the forming stage, where it is shaped into the desired product. Techniques such as die-cutting, molding, and stitching are commonly employed. Die-cutting allows for precise shapes to be formed, while molding can create complex structures that enhance the product’s functionality. Skilled artisans often hand-stitch leather items, ensuring each seam is strong and aesthetically pleasing. This stage may also incorporate additional materials, such as metal components or fabric linings, to enhance the product’s overall performance.

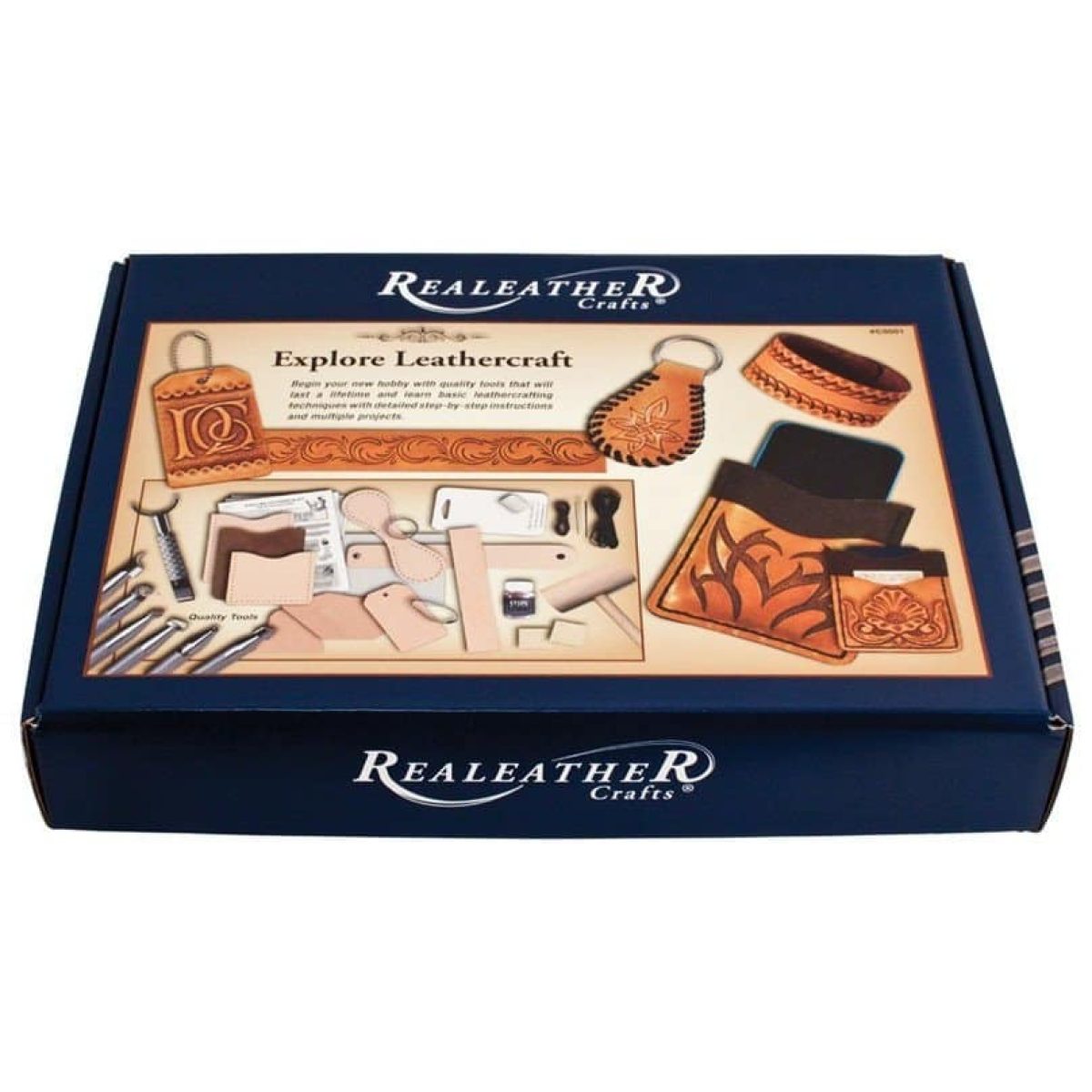

Illustrative image related to custom leather craft

Assembly: How Are Custom Leather Products Put Together?

The assembly stage involves bringing all components together to form the final product. This process requires meticulous attention to detail, as each piece must fit together seamlessly. Workers may use industrial sewing machines or hand tools, depending on the product’s complexity. Quality control measures are implemented throughout this stage, including visual inspections and functional tests, to ensure that the assembly meets the required standards.

Finishing: What Are the Final Touches Applied to Leather Products?

Finishing is the last step in the manufacturing process, where products are polished and treated to enhance their appearance and longevity. This may include applying protective coatings, burnishing edges, or adding decorative elements such as embossing or stitching. The finishing process not only improves the aesthetic quality of the leather craft but also helps protect it from wear and tear, ensuring a longer lifespan for the product.

What Quality Assurance Measures Are Essential in Custom Leather Craft Production?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for B2B buyers who require consistent product quality. Implementing rigorous QA measures ensures that products meet international standards and customer expectations.

What International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that comply with internationally recognized standards, such as ISO 9001. This standard outlines a framework for quality management systems, ensuring that suppliers maintain high levels of quality control throughout the manufacturing process. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) for leather goods used in industrial applications can provide further assurance of quality and safety.

Illustrative image related to custom leather craft

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process to ensure consistency and compliance with quality standards. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify their quality and suitability for production.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to identify and address any issues that may arise during production.

- Final Quality Control (FQC): Conducting thorough inspections of finished products to ensure they meet all specifications and standards before shipment.

These checkpoints help minimize defects and ensure that only high-quality products reach the market.

What Common Testing Methods Are Used to Ensure Product Quality?

Various testing methods are employed to assess the quality of leather products. These may include:

- Durability Testing: Assessing the wear resistance and longevity of leather through abrasion tests.

- Flexural Testing: Evaluating the leather’s ability to withstand bending and flexing without cracking.

- Colorfastness Testing: Ensuring that dyes used in the leather do not fade or bleed when exposed to moisture or friction.

- Chemical Resistance Testing: Checking the leather’s ability to resist damage from oils, solvents, and other chemicals.

By employing these testing methods, manufacturers can ensure their products meet the required quality standards.

Illustrative image related to custom leather craft

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. This due diligence helps mitigate risks associated with product quality and supplier reliability.

What Steps Can Buyers Take to Audit Supplier Quality Control?

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers can request:

- Quality Assurance Reports: Suppliers should provide documentation detailing their quality control procedures, including results from recent audits and tests.

- Certification Verification: Confirming that the supplier holds relevant certifications can provide confidence in their commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures, ensuring compliance with international standards.

What Are the Unique QC Considerations for Different International Markets?

When sourcing from suppliers in different regions, B2B buyers should be aware of the unique quality control considerations specific to those markets. For instance:

- Africa: Buyers should ensure that suppliers adhere to local regulations regarding labor practices and environmental sustainability, as these factors can impact product quality.

- South America: Understanding regional tanning practices and their impact on leather quality is essential for ensuring that products meet buyer expectations.

- Middle East: Buyers should be cautious of cultural differences that may affect product specifications, particularly in luxury leather goods.

- Europe (e.g., Germany): Compliance with stringent EU regulations on product safety and environmental impact is crucial for successful market entry.

By considering these regional nuances, B2B buyers can make informed decisions when selecting suppliers for custom leather crafts.

Conclusion: Why Is It Crucial to Understand Manufacturing and Quality Assurance in Custom Leather Craft?

Understanding the manufacturing processes and quality assurance measures in custom leather craft is essential for B2B buyers seeking reliable suppliers. By familiarizing themselves with the production stages, quality control standards, and verification methods, buyers can ensure they partner with manufacturers who deliver high-quality products that meet their specific needs. This knowledge not only enhances procurement strategies but also fosters long-term relationships with trustworthy suppliers in the global leather market.

Illustrative image related to custom leather craft

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather craft’

Introduction

Navigating the procurement of custom leather craft products requires careful planning and strategic decision-making. This guide outlines a practical checklist to help B2B buyers effectively source high-quality leather goods that meet their business needs. By following these steps, you can streamline your sourcing process, ensuring you find the right suppliers and products for your operations.

Step 1: Identify Your Requirements

Begin by defining the specific leather products you need, including types, sizes, and functionalities. Understanding your requirements helps narrow down potential suppliers who specialize in those products. Consider factors such as durability, design, and intended use in your industry, whether it’s for tools, apparel, or accessories.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather craft. Utilize online platforms, trade directories, and industry forums to gather a list of potential partners. Pay attention to their market reputation, years of experience, and geographical presence, especially if you are targeting regions like Africa, South America, or Europe.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their production capabilities and quality assurance processes. Look for certifications that demonstrate compliance with international standards, as well as their ability to handle custom orders. Inquire about their production timelines and capacity to ensure they can meet your demand.

Illustrative image related to custom leather craft

- Considerations:

- Are they equipped to handle large orders?

- What quality control measures are in place?

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of their leather products. This allows you to evaluate the quality, craftsmanship, and suitability for your needs firsthand. Examine the materials used, stitching quality, and overall finish to ensure they meet your standards.

Step 5: Verify References and Reviews

Reach out to previous clients or check online reviews to gauge the reliability and performance of the suppliers. Understanding other buyers’ experiences can provide valuable insights into the supplier’s customer service, product quality, and responsiveness. This step is crucial in mitigating risks associated with new partnerships.

Step 6: Discuss Customization Options

Engage in discussions about customization capabilities with your selected suppliers. Ensure they can accommodate your specific design requirements and provide flexibility in terms of materials, colors, and branding options. A supplier that offers extensive customization can better meet your unique business needs.

Step 7: Negotiate Terms and Conditions

Finally, negotiate the terms of your partnership, including pricing, payment terms, delivery schedules, and warranties. Ensure that all agreements are documented to avoid misunderstandings. Clarifying these details upfront can prevent potential disputes and ensure a smoother procurement process.

Illustrative image related to custom leather craft

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing custom leather craft products, ensuring they select the right suppliers and products to support their business objectives.

Comprehensive Cost and Pricing Analysis for custom leather craft Sourcing

What Are the Key Cost Components in Custom Leather Craft Sourcing?

When sourcing custom leather craft products, understanding the cost structure is essential for effective budgeting and pricing strategies. Key cost components include:

-

Materials: The choice of leather significantly impacts the overall cost. High-quality, full-grain or top-grain leather typically incurs higher costs compared to lower grades. Additionally, sourcing sustainable or specialized materials can further elevate expenses.

-

Labor: Skilled artisans are crucial for crafting quality leather goods. Labor costs vary based on the region, skill level, and the complexity of the craftsmanship required for custom designs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate overhead costs.

-

Tooling: Customization often requires specific tools or molds, which can add to initial investment costs. It’s important to factor in these one-time expenses when assessing overall pricing.

-

Quality Control (QC): Ensuring that products meet quality standards involves additional costs. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and volume. In international trade, understanding import duties and taxes is crucial for accurate cost forecasting.

-

Margin: Finally, suppliers will add a profit margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Custom Leather Craft Costs?

Several factors can influence the pricing of custom leather craft products:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often leads to discounted rates. Negotiating favorable terms based on volume can significantly reduce per-unit costs.

-

Specifications and Customization: Highly customized orders generally incur higher costs due to the need for specialized labor and materials. Clear communication of design specifications can help manage expectations and costs.

-

Material Quality and Certifications: Products made from premium materials or with specific certifications (e.g., eco-friendly, ethically sourced) may command higher prices. Buyers should weigh the value of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The agreed-upon Incoterms can affect pricing by determining who bears the risk and costs associated with shipping. Understanding these terms can help buyers avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Pricing and Terms: Don’t hesitate to negotiate prices, especially for large orders. Building a good relationship with suppliers can lead to better terms and discounts over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes shipping, customs, potential returns, and maintenance costs. This holistic view can reveal the true cost of sourcing decisions.

-

Understand Pricing Nuances for International Trade: Be aware of currency fluctuations and their impact on pricing. Additionally, familiarize yourself with local regulations that may affect import duties and taxes.

-

Evaluate Supplier Performance: Regularly assess supplier performance regarding quality, delivery times, and responsiveness. Consistent issues can indicate the need to explore alternative sourcing options.

-

Stay Informed About Market Trends: Keeping abreast of trends in leather sourcing, such as shifts towards sustainable materials, can provide leverage in negotiations and help you make informed purchasing decisions.

Disclaimer

The prices mentioned throughout this analysis are indicative and may vary based on specific requirements, supplier negotiations, and market conditions. Always conduct thorough research and consult with suppliers for the most accurate and relevant pricing information.

Alternatives Analysis: Comparing custom leather craft With Other Solutions

Introduction: Exploring Alternatives to Custom Leather Craft

When considering custom leather craft for professional use, it’s essential to evaluate alternative solutions that might meet similar needs. These alternatives can vary in material, functionality, and cost-effectiveness. Understanding the strengths and weaknesses of each option will empower B2B buyers to make informed purchasing decisions that align with their specific operational requirements.

Illustrative image related to custom leather craft

Comparison Table

| Comparison Aspect | Custom Leather Craft | Durable Synthetic Materials | Traditional Fabric Solutions |

|---|---|---|---|

| Performance | High durability; withstands wear | Good durability; resistant to weather | Moderate durability; wear over time |

| Cost | Higher initial investment | Generally lower cost | Low cost but may require frequent replacement |

| Ease of Implementation | Requires some custom specifications | Readily available, off-the-shelf | Easy to source and use |

| Maintenance | Low maintenance; easy to clean | Requires regular cleaning | Moderate maintenance; prone to stains |

| Best Use Case | Ideal for high-end, professional environments | Suitable for outdoor applications | Good for casual or light-duty tasks |

Detailed Breakdown of Alternatives

Durable Synthetic Materials

Durable synthetic materials, such as high-denier nylon or polyester, are becoming popular alternatives to custom leather craft, especially for tool bags and pouches. These materials offer good durability and are resistant to weather conditions, making them suitable for outdoor use. They are typically less expensive than leather, which can be appealing for budget-conscious buyers. However, while they provide decent performance, they may not match the longevity and aesthetic appeal of leather. Moreover, synthetic materials may require more frequent cleaning to maintain their appearance.

Traditional Fabric Solutions

Traditional fabric solutions, such as canvas or cotton-based materials, are often the most cost-effective options available. They are lightweight and easy to handle, making them suitable for casual or light-duty tasks. However, their durability is significantly lower than that of leather or synthetic alternatives. Over time, they can wear out, leading to additional replacement costs. While they are easy to source and implement, buyers should consider the long-term implications of using fabric solutions, especially in professional settings where reliability is crucial.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right solution for your business requires careful consideration of your specific needs and operational environment. Custom leather craft stands out for its durability and professional appearance, making it ideal for high-demand settings. However, if budget constraints or specific environmental conditions are a concern, durable synthetic materials or traditional fabric solutions may be more appropriate. Assess your requirements regarding performance, cost, maintenance, and the intended use case to make an informed choice that best serves your business objectives.

Essential Technical Properties and Trade Terminology for custom leather craft

What Are the Key Technical Properties of Custom Leather Craft?

In the custom leather craft industry, understanding the technical properties of materials and products is essential for making informed purchasing decisions. Here are some critical specifications that every B2B buyer should consider:

1. Material Grade

Material grade refers to the quality of leather used in crafting products. Common grades include top-grain, full-grain, and suede. Top-grain leather is known for its durability and resistance to wear, making it ideal for professional tools and gear. Full-grain leather retains the natural grain and is often more expensive due to its superior quality. Understanding material grades helps buyers select products that meet their durability and budgetary requirements.

2. Thickness

Leather thickness is typically measured in ounces or millimeters. Thicker leather offers greater durability and resistance to damage, making it suitable for heavy-duty applications. Conversely, thinner leather provides flexibility and is often used in lighter-duty products. Buyers should consider the intended use of the leather product to determine the appropriate thickness for their needs.

3. Stitching Strength

The strength of stitching is crucial for ensuring the longevity of leather products. This property is usually measured in stitches per inch (SPI). A higher SPI indicates a tighter and stronger seam, which enhances durability. For B2B buyers, understanding stitching strength is vital, especially when sourcing products for demanding environments where wear and tear are common.

Illustrative image related to custom leather craft

4. Finish Type

Leather finishes can significantly affect the appearance and functionality of the final product. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather showcases the natural look of the hide but is less resistant to stains, while pigmented leather offers enhanced durability and stain resistance. Buyers should evaluate the finish type based on aesthetic preferences and practical usage.

5. Weight Capacity

For items like tool belts and pouches, understanding weight capacity is essential. Each product is designed to hold a specific load without compromising its structural integrity. Buyers must assess their needs for carrying tools and equipment to ensure the selected product can handle the intended weight.

What Are Common Trade Terms in Custom Leather Craft?

Familiarity with trade terminology is crucial for effective communication and negotiation in the custom leather craft industry. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s final product. In the leather industry, OEM suppliers may manufacture custom leather goods for brands. Understanding OEM is important for buyers seeking tailored solutions without the overhead of producing items in-house.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires a buyer to purchase. This term is significant for B2B buyers, as it impacts inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases according to demand and budget constraints.

Illustrative image related to custom leather craft

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other relevant information for a specific order. This process allows buyers to compare options and negotiate terms before making a commitment. Understanding how to effectively create and use RFQs can streamline purchasing processes.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and liabilities in international transactions, ensuring smoother trade across borders.

5. Customization Options

This term refers to the ability to tailor products according to specific buyer requirements, such as size, color, or branding. Customization is a key selling point in the leather craft industry, allowing businesses to differentiate their offerings and meet unique client needs.

Illustrative image related to custom leather craft

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, negotiate effectively, and enhance their procurement strategies in the custom leather craft market.

Navigating Market Dynamics and Sourcing Trends in the custom leather craft Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Craft?

The custom leather craft sector is experiencing notable growth driven by several global factors. Firstly, there is an increasing demand for personalized and high-quality leather goods across various industries, including fashion, automotive, and home décor. This trend is particularly pronounced in emerging markets in Africa and South America, where consumers are seeking unique products that reflect their cultural identity and personal style.

Moreover, advancements in B2B technology are reshaping sourcing strategies. The rise of e-commerce platforms and digital marketplaces allows international buyers to easily access a broader range of suppliers and products, facilitating competitive pricing and efficient procurement processes. Additionally, data analytics and artificial intelligence are being utilized to optimize inventory management and forecast demand, providing businesses with a strategic advantage in a fluctuating market.

Another significant trend is the shift towards sustainability and ethical sourcing. As consumers become more environmentally conscious, B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices. This includes the use of eco-friendly materials and responsible manufacturing processes. For buyers from Europe, particularly Germany, this trend is crucial, as stringent regulations and consumer expectations demand transparency in supply chains.

Illustrative image related to custom leather craft

How Is Sustainability and Ethical Sourcing Shaping the Custom Leather Craft Industry?

The environmental impact of leather production is under scrutiny, prompting B2B buyers to consider sustainability in their sourcing decisions. Traditional leather tanning processes can be harmful to ecosystems due to the chemicals used. Therefore, many companies are adopting greener practices, such as vegetable tanning, which minimizes harmful emissions and waste.

Ethical sourcing is becoming a cornerstone of procurement strategies. Buyers are increasingly looking for suppliers who can demonstrate a commitment to fair labor practices and animal welfare. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction, as they provide assurance regarding the environmental and ethical standards upheld by manufacturers.

For international buyers, particularly those in the Middle East and Europe, aligning with suppliers that prioritize sustainability not only enhances brand reputation but also meets the growing consumer demand for responsible products. This shift not only contributes to a healthier planet but also fosters loyalty among increasingly eco-conscious consumers.

How Has the Custom Leather Craft Sector Evolved Over Time?

The custom leather craft sector has a rich history, evolving from traditional artisanal practices to a modern industry characterized by innovation and technology. Initially, leather crafting was a localized trade, with artisans creating bespoke items for individual customers. As industrialization took hold in the 19th century, mass production methods began to dominate, leading to a decline in custom craftsmanship.

Illustrative image related to custom leather craft

However, in recent decades, there has been a resurgence of interest in handcrafted leather goods. This revival is fueled by a growing appreciation for artisanal skills and the desire for unique, high-quality products. Today, the sector combines traditional craftsmanship with modern design and sustainable practices, appealing to a diverse global audience. B2B buyers are increasingly recognizing the value of sourcing from companies that honor this heritage while also embracing innovation. This evolution signifies a vibrant market that balances craftsmanship with modern consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather craft

-

1. How do I ensure the quality of custom leather craft products from suppliers?

To ensure quality, start by vetting potential suppliers through verified references and customer testimonials. Request samples of their products to assess material quality and craftsmanship. It’s also beneficial to inquire about their manufacturing processes, quality assurance protocols, and any certifications they hold. Establishing a clear communication channel for quality expectations and conducting periodic quality checks can further safeguard your interests. -

2. What is the best way to customize leather products for my business needs?

The best way to customize leather products is to work closely with your supplier from the beginning. Discuss your specific requirements, including design, color, size, and functionality. Many suppliers offer customization options like embossing, branding, or tailored pocket designs. Make sure to provide detailed specifications and visual references, and request prototypes to refine the final product before bulk production. -

3. What are the typical minimum order quantities (MOQs) for custom leather craft?

Minimum order quantities for custom leather craft can vary significantly based on the supplier and the complexity of the product. Generally, MOQs can range from 50 to several hundred units. It is crucial to discuss your needs with suppliers upfront, as some may be flexible on MOQs for first-time orders or ongoing partnerships. Always clarify this aspect in your negotiations to avoid unexpected costs. -

4. What payment terms should I expect when sourcing custom leather products?

Payment terms can vary widely depending on the supplier and the order size. Common practices include a deposit (often 30-50%) upfront, with the balance due upon completion or before shipment. Some suppliers may offer net payment terms, allowing a period for payment after delivery. It’s essential to establish clear payment terms in your contract to avoid misunderstandings and ensure cash flow management. -

5. How can I effectively communicate my design requirements for custom leather products?

Effective communication begins with clarity. Provide your supplier with detailed specifications, including drawings, color swatches, and material samples. Utilize visual aids like mood boards to convey your vision. Regular check-ins during the design process can help address any questions or adjustments. A collaborative approach fosters better understanding and ensures the final product aligns with your expectations. -

6. What logistics considerations should I keep in mind when importing leather products?

When importing leather products, consider shipping methods, transit times, and customs regulations specific to your country. Research duty rates and import taxes that may apply to leather goods. It’s advisable to work with a logistics partner experienced in international trade to navigate documentation and compliance requirements. Plan for potential delays, especially during peak seasons, to ensure timely delivery. -

7. How do I evaluate the reliability of a custom leather craft supplier?

To evaluate reliability, start by researching the supplier’s reputation through online reviews, industry forums, and trade associations. Request client references and case studies to assess their track record. Additionally, consider their production capacity and lead times to ensure they can meet your demands. A supplier with a transparent communication style and a willingness to collaborate is often more reliable. -

8. What are the common challenges faced in sourcing custom leather craft internationally?

Common challenges include language barriers, differing quality standards, and varying lead times. Additionally, navigating customs regulations and tariffs can complicate logistics. To mitigate these issues, maintain open communication with your supplier and consider working with a local agent who understands the market dynamics. It’s beneficial to establish clear contracts and engage in regular follow-ups throughout the sourcing process.

Top 5 Custom Leather Craft Manufacturers & Suppliers List

1. CLC – Tool Carriers and Tech Gear

Domain: goclc.com

Registered: 2007 (18 years)

Introduction: Products: Tool Carriers, CLC Tech Gear™, Molded Base Bags, Nail and Tool Bags, Softside Tool Carriers, Tool Pouches, Work Gear, Aprons and Combos, Belts and Suspenders, Canvas, CLC Signature, CLC Signature Elite, Climate Gear®, Hi-Viz® Gear, Strap-It™ Tie-Downs, Tool Holders, Tool Lanyards, Knee Protection, Work Gloves (including Automotive Gloves, Chemical/Disposables Gloves, Flexgrip 363 Gloves,…

2. Custom Leathercraft – Zip Pouch for Electricians

Domain: custom-leathercraft.com

Registered: 2025 (0 years)

Introduction: {“products”:[{“name”:”Zippered Professional Electricians Tool Pouch”,”description”:”21 Pocket, Black suede leather tool pouch for organizing electrician tools. Zippered for security, durable for job sites, ensures easy access and professional efficiency.”},{“name”:”20 Inch, Open Top, Soft Sided Tool Box”,”description”:”27 Pockets, ample storage with an open-top design for easy access, perfect for …

3. Custom Leather Craft – Multi-Compartment Tool Carrier

Domain: colsafety.com

Registered: 2012 (13 years)

Introduction: This company, Custom Leather Craft – Multi-Compartment Tool Carrier, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Custom LeatherCraft – 10 Pocket Carpenter’s Nail and Tool Bag

Domain: timothystoolbox.com

Registered: 2018 (7 years)

Introduction: Custom LeatherCraft (CLC) products available at Timothy’s Toolbox include various tool bags, such as the 10 Pocket Carpenter’s Nail and Tool Bag (Model: 179354). The collection features a range of items designed for durability and functionality, catering to professionals in the construction and woodworking industries. Products are sorted by availability and can be filtered by price and popularity.

5. CLC Work Gear – Innovative Tool Storage Solutions

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, CLC Work Gear – Innovative Tool Storage Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather craft

As the demand for high-quality custom leather craft continues to rise globally, strategic sourcing becomes essential for B2B buyers looking to optimize their procurement processes. By leveraging partnerships with reputable manufacturers, businesses can ensure access to durable, versatile products that enhance operational efficiency. Custom LeatherCraft exemplifies this through its commitment to quality, organization, and comfort, providing tools that cater specifically to contractors, electricians, and DIY enthusiasts.

Investing in reliable leather goods not only improves workflow but also fosters brand loyalty among customers who value quality craftsmanship. International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize sourcing strategies that emphasize durability and functionality. The insights gained from evaluating supplier capabilities can lead to informed decisions that align with market demands.

Looking ahead, the landscape of custom leather craft will evolve with innovations in materials and design. Embrace these changes by establishing strong supplier relationships and remaining adaptable to new trends. For B2B buyers, the opportunity to elevate their product offerings is ripe—seize it by exploring the robust capabilities of custom leather craft manufacturers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather craft

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.