Introduction: Navigating the Global Market for oil on leather

In the dynamic landscape of international trade, sourcing quality oil for leather applications presents a unique set of challenges for B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, understanding the nuances of oil treatments for leather goods is essential for maintaining product integrity and enhancing durability. This comprehensive guide delves into the multifaceted world of oil on leather, exploring various types of oils, their applications in leather care, and the best practices for sourcing these materials effectively.

From identifying the right suppliers to understanding cost implications, this resource equips international buyers with actionable insights that empower informed purchasing decisions. The guide highlights critical factors to consider when vetting suppliers, ensuring you can confidently select partners who meet your quality and sustainability standards. With a focus on practical applications and market trends, this guide also addresses the specific needs of diverse markets, including the unique preferences and challenges faced by buyers from countries like Nigeria and Vietnam.

By leveraging the knowledge contained within this guide, B2B buyers can navigate the complexities of the oil on leather market, ultimately enhancing their product offerings and fostering long-term supplier relationships. Prepare to elevate your sourcing strategy and unlock the potential of high-quality leather care solutions.

Table Of Contents

- Top 6 Oil On Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for oil on leather

- Understanding oil on leather Types and Variations

- Key Industrial Applications of oil on leather

- 3 Common User Pain Points for ‘oil on leather’ & Their Solutions

- Strategic Material Selection Guide for oil on leather

- In-depth Look: Manufacturing Processes and Quality Assurance for oil on leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil on leather’

- Comprehensive Cost and Pricing Analysis for oil on leather Sourcing

- Alternatives Analysis: Comparing oil on leather With Other Solutions

- Essential Technical Properties and Trade Terminology for oil on leather

- Navigating Market Dynamics and Sourcing Trends in the oil on leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of oil on leather

- Strategic Sourcing Conclusion and Outlook for oil on leather

- Important Disclaimer & Terms of Use

Understanding oil on leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Neatsfoot Oil | Derived from animal fats, enhances flexibility | Leather goods manufacturing | Pros: Excellent conditioning; Cons: May darken leather. |

| Mink Oil | Rich in fatty acids, water-resistant | Outdoor gear and footwear | Pros: Provides waterproofing; Cons: Can be greasy if over-applied. |

| Olive Oil | Natural and readily available, mild conditioning | Craft leather and small repairs | Pros: Eco-friendly; Cons: Shorter lifespan than synthetic oils. |

| Synthetic Leather Oil | Engineered for specific leather types, consistent | Automotive and upholstery sectors | Pros: Tailored for performance; Cons: Less traditional appeal. |

| Beeswax Leather Balm | Combines wax and oil for a protective layer | High-end leather products | Pros: Durable and water-resistant; Cons: Requires more effort to apply. |

What Are the Characteristics of Neatsfoot Oil and Its B2B Suitability?

Neatsfoot oil is a traditional leather conditioner derived from the rendered fat of cattle bones and feet. It is renowned for its ability to soften and preserve leather, making it ideal for manufacturers of leather goods such as saddles, belts, and bags. B2B buyers should consider its effectiveness in enhancing the flexibility of leather, but be cautious of its potential to darken lighter-colored leathers. This oil is particularly suitable for businesses prioritizing long-lasting leather quality.

Illustrative image related to oil on leather

How Does Mink Oil Benefit Outdoor Gear and Footwear?

Mink oil is a popular choice for waterproofing leather products, particularly in outdoor gear and footwear. Its unique composition, rich in fatty acids, creates a barrier against moisture while conditioning the leather. B2B buyers in sectors such as hiking and camping gear should appreciate its protective qualities, especially in wet conditions. However, they should also be aware that excessive application can lead to a greasy finish, potentially affecting product aesthetics.

Why Choose Olive Oil for Craft Leather and Small Repairs?

Olive oil is often favored for its natural properties and eco-friendliness, making it an attractive option for small-scale leather crafting and repairs. While it conditions leather effectively, enhancing its suppleness, its longevity is not as robust as synthetic alternatives. B2B buyers focused on sustainability and natural products may find olive oil appealing, but they should be prepared for more frequent reapplication compared to synthetic oils.

What Advantages Does Synthetic Leather Oil Offer in Automotive Applications?

Synthetic leather oils are specifically formulated for various types of leather, offering tailored conditioning and protection. They are commonly used in the automotive and upholstery sectors, where consistency and performance are critical. B2B buyers should appreciate the reliability of these oils in maintaining leather’s appearance and feel, but they may lack the traditional appeal of natural oils. Thus, businesses focused on modern leather applications may find synthetic options more suitable.

How Does Beeswax Leather Balm Provide Durability for High-End Products?

Beeswax leather balm combines the nourishing properties of oils with the protective qualities of wax, creating a durable barrier against moisture and dirt. It is particularly favored in high-end leather products, where aesthetics and longevity are paramount. B2B buyers should recognize the additional effort required for application, as it can be more labor-intensive than liquid oils. However, the long-lasting protection it offers makes it a worthwhile investment for luxury leather goods manufacturers.

Key Industrial Applications of oil on leather

| Industry/Sector | Specific Application of oil on leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Conditioning and preserving leather goods | Extends product lifespan, enhances appearance | Sourcing high-quality, non-toxic oils suitable for various leather types |

| Automotive | Leather seat treatment and maintenance | Improves comfort and durability of interiors | Compatibility with different leather grades, eco-friendly options available |

| Furniture & Upholstery | Leather sofa and chair care | Maintains aesthetic appeal, prevents cracking | Sourcing oils that are safe for household use and effective for large surfaces |

| Equestrian Equipment | Care for saddles and bridles | Enhances performance and longevity of gear | Oils that are safe for animal use, resistant to mold and mildew |

| Industrial Goods | Protective treatment for leather work gloves | Increases grip and wear resistance | Ensuring oils meet industry safety standards and are effective for heavy-duty use |

How is Oil on Leather Used in the Fashion & Accessories Industry?

In the fashion and accessories sector, oil is commonly used to condition and preserve leather goods, such as bags, belts, and shoes. This application helps to maintain the leather’s suppleness, preventing it from becoming dry and brittle. For B2B buyers, sourcing high-quality, non-toxic oils is essential to ensure compatibility with various leather types, maintaining the integrity and appearance of the products. Additionally, businesses should consider oils that enhance the natural look of the leather while providing necessary protection against environmental factors.

What Role Does Oil Play in Automotive Leather Care?

In the automotive industry, oil is applied to leather seats and interiors to enhance comfort and durability. Regular treatment with appropriate oils can prevent cracking and wear, significantly extending the life of the vehicle’s interior. Buyers in this sector must ensure that the oils sourced are compatible with different grades of leather and are eco-friendly, catering to the growing demand for sustainable practices in automotive manufacturing.

How is Oil Beneficial for Furniture & Upholstery?

For furniture and upholstery, oil is applied to leather sofas and chairs to maintain their aesthetic appeal and prevent cracking. This application is crucial for businesses that rely on high-quality furniture, as it keeps products looking new for longer. When sourcing oils, companies should prioritize those that are safe for household use and effective for treating large surfaces, ensuring a consistent finish across products.

Why is Oil Important for Equestrian Equipment Maintenance?

In the equestrian sector, oil is essential for the care of saddles and bridles, enhancing their performance and longevity. Regular oiling prevents the leather from becoming dry and ensures it remains flexible and strong, which is vital for safety and comfort during use. Buyers should look for oils that are safe for animal use, resistant to mold and mildew, and effective in various weather conditions to ensure the longevity of the equipment.

Illustrative image related to oil on leather

What is the Application of Oil in Industrial Goods?

In industrial settings, oil is used to treat leather work gloves, increasing grip and wear resistance. This application is particularly important in sectors where safety and durability are paramount, such as construction and manufacturing. When sourcing oils for this purpose, businesses must ensure that the products meet industry safety standards and are effective for heavy-duty use, providing reliable performance in challenging environments.

3 Common User Pain Points for ‘oil on leather’ & Their Solutions

Scenario 1: The Dilemma of Excessive Greasiness in Leather Goods

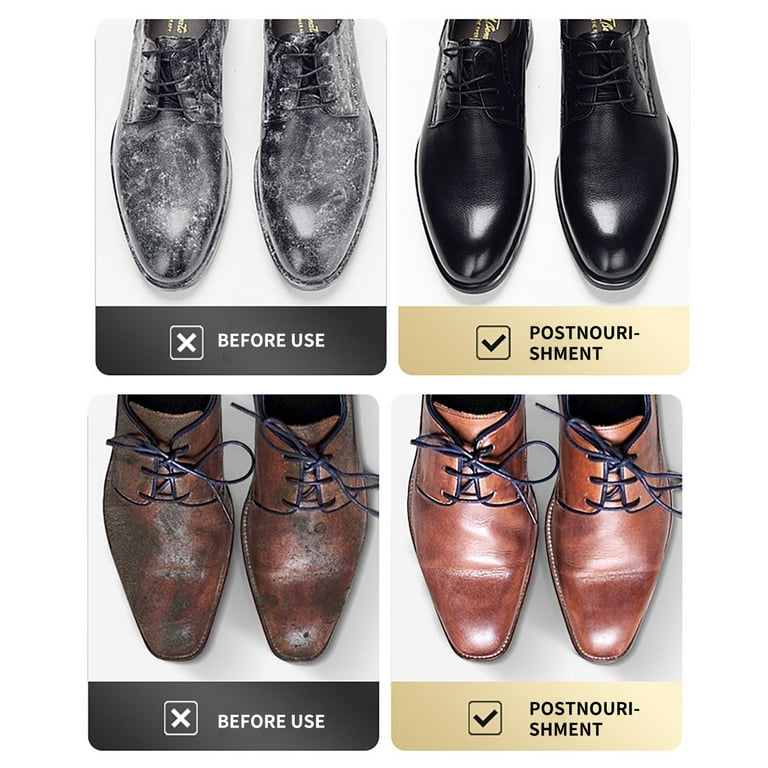

The Problem: B2B buyers often face the challenge of excessive greasiness when oil is applied to leather products, whether for conditioning or maintenance purposes. This can occur due to the use of inappropriate oils, improper application methods, or the natural oils from human hands transferring onto the leather. Such issues can lead to a tarnished appearance, creating a negative impression on customers, especially in high-stakes industries where aesthetics and professionalism are paramount. Buyers may find themselves needing to manage customer dissatisfaction and return rates due to these visible flaws.

The Solution: To combat the greasiness issue, it is essential to choose the right type of oil and application method. For conditioning leather, opt for oils specifically designed for leather care, such as neatsfoot oil or mink oil, as they penetrate the leather without leaving a greasy residue. Before application, test the oil on a small, inconspicuous area to ensure compatibility. When applying, use a soft, lint-free cloth to apply a thin layer evenly, allowing the leather to absorb the oil without over-saturation. Following this, buff the leather with a clean cloth to remove any excess oil, ensuring a polished look. Additionally, establishing a routine maintenance schedule will help in preserving the leather’s appearance and longevity, thereby reducing the risk of customer complaints.

Scenario 2: Stains and Marks from Oil Spills

The Problem: In sectors where leather goods are frequently used—such as hospitality or retail—accidental oil spills can occur, leaving unsightly stains. These marks can be particularly troublesome on high-end leather products, where the integrity of the material is crucial for brand image. B2B buyers may struggle with how to effectively remove these stains without damaging the leather, leading to increased costs in replacements or repairs and jeopardizing customer satisfaction.

The Solution: The first step in addressing oil stains is to act quickly. Blot the stain immediately with a paper towel to absorb as much oil as possible without rubbing it in further. Once the excess oil is removed, sprinkle baking soda or cornstarch over the stained area. These powders act as absorbents; leave them on for several hours or overnight. Afterward, gently brush off the powder with a soft brush. For persistent stains, a specialized leather cleaner can be used—ensure it’s pH-balanced and suitable for the type of leather. Apply it according to the manufacturer’s instructions, and always test on a hidden area first. Following the cleaning process, a good leather conditioner should be applied to restore moisture and prevent cracking, maintaining the product’s aesthetic and functional integrity.

Scenario 3: Long-Term Damage from Improper Oil Use

The Problem: Long-term users of leather products may unknowingly cause irreparable damage by using the wrong types of oil or applying oils too frequently. This can lead to issues such as darkening of the leather, loss of flexibility, or even mold growth in humid climates. For B2B buyers, understanding the long-term implications of oil usage is critical in maintaining their inventory and ensuring customer satisfaction, especially in markets where leather goods are a significant investment.

The Solution: To prevent long-term damage, it is crucial to adopt a proactive and informed approach to leather care. Buyers should first familiarize themselves with the specific leather types in their inventory and the appropriate oils for each. For instance, vegetable-tanned leather may require different care compared to chrome-tanned leather. Implement a clear guideline on how often to apply oils—typically, conditioning every six months is adequate for most leather products. Buyers should also ensure that any oil used is specifically designed for leather to avoid reactions that could cause discoloration or degradation. Educating staff on proper care and maintenance techniques can further enhance the longevity of the leather products and reduce the risk of costly replacements, ultimately leading to a more satisfied customer base.

Strategic Material Selection Guide for oil on leather

What Are the Key Materials Used for Oil on Leather Applications?

When selecting materials for oil on leather applications, it is essential to consider their properties, advantages, disadvantages, and suitability for specific markets. Here, we will analyze four common materials used in this context: vegetable oils, synthetic oils, animal fats, and waxes.

How Do Vegetable Oils Perform in Oil on Leather Applications?

Vegetable oils, such as olive oil and coconut oil, are often used for conditioning leather. Their natural composition allows them to penetrate the leather fibers, providing moisture and flexibility. The key advantage of vegetable oils is their eco-friendliness and non-toxic nature, making them suitable for various applications, including leather goods and upholstery.

However, vegetable oils can have a few drawbacks. They may not provide the same level of protection against water or stains as synthetic alternatives. Additionally, the application of vegetable oils can lead to a sticky residue if not properly absorbed, potentially affecting the leather’s appearance. For international buyers, especially in regions like Africa and South America, it’s crucial to consider local climate conditions, as high humidity can exacerbate the drawbacks of vegetable oils.

What Role Do Synthetic Oils Play in Leather Treatment?

Synthetic oils are engineered to provide superior performance in leather applications. They offer excellent resistance to water, stains, and UV light, making them ideal for outdoor leather products. Their temperature and pressure ratings are typically higher than those of natural oils, ensuring durability in harsh conditions.

On the downside, synthetic oils can be more expensive and may not be biodegradable, which raises environmental concerns. Additionally, some synthetic formulations may not be compatible with all leather types, necessitating careful selection. For B2B buyers in Europe, compliance with environmental regulations such as REACH is essential when considering synthetic oils.

How Do Animal Fats Compare in Leather Conditioning?

Animal fats, such as lanolin and tallow, have been traditional choices for leather treatment. They are effective in softening leather and providing a degree of water resistance. The key advantage of animal fats is their ability to nourish and preserve the leather, extending its lifespan.

However, animal fats can attract dirt and dust, leading to a need for more frequent cleaning. They may also present ethical concerns for some buyers, particularly in regions with strict animal welfare standards. Buyers in the Middle East and Africa should consider local preferences and ethical considerations when choosing animal-based products.

What Advantages Do Waxes Offer for Leather Protection?

Waxes, such as beeswax and paraffin, are commonly used in leather treatments to create a protective barrier against moisture and dirt. They are particularly effective for outdoor leather goods, providing excellent durability and resistance to wear and tear. Waxes can also enhance the aesthetic appeal of leather by giving it a rich sheen.

The main limitation of waxes is that they can make leather stiffer if applied excessively, which may not be suitable for all applications. Additionally, the manufacturing process for some wax-based products can be complex and costly. B2B buyers from Europe and South America should ensure compliance with local regulations regarding the use of animal-derived waxes.

Summary Table of Material Selection for Oil on Leather

| Material | Typical Use Case for oil on leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable Oils | Conditioning leather goods | Eco-friendly and non-toxic | May leave a sticky residue | Low |

| Synthetic Oils | Outdoor leather products | Excellent water and UV resistance | Higher cost and environmental concerns | High |

| Animal Fats | Softening and preserving leather | Nourishes and extends leather lifespan | Attracts dirt and ethical concerns | Medium |

| Waxes | Protective barrier for outdoor leather | Durable and enhances aesthetic appeal | Can stiffen leather if over-applied | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions based on the specific requirements of their markets and applications.

In-depth Look: Manufacturing Processes and Quality Assurance for oil on leather

What Are the Key Stages in the Manufacturing Process of Oil on Leather?

The production of oil-treated leather involves several critical stages, each designed to ensure high-quality output. Understanding these stages can help B2B buyers appreciate the craftsmanship and quality assurance involved in their sourcing decisions.

Material Preparation: Selecting the Right Hides

The first step in manufacturing oil on leather is the selection of high-quality hides. Typically, vegetable-tanned leather is favored for its durability and ability to absorb oils effectively. Suppliers often source hides from trusted tanneries that adhere to ethical and environmental standards. Key factors to consider include the hide’s thickness, grain quality, and absence of blemishes. For international buyers, verifying the origin and quality of hides can be facilitated through supplier certifications or direct audits.

Illustrative image related to oil on leather

Forming: Shaping the Leather

After selecting the hides, the forming stage begins. This involves cutting the leather into predetermined shapes according to the final product’s design specifications. Advanced cutting techniques, such as laser cutting, are increasingly common, offering precision and reducing waste. For B2B buyers, understanding the manufacturer’s cutting methods can provide insights into the efficiency and sustainability of the production process.

Assembly: Crafting the Final Product

The assembly stage involves stitching and assembling various leather components. Skilled artisans often perform this task to ensure durability and aesthetic appeal. The use of high-quality threads and adhesives is crucial, particularly for oil-treated leather, which must withstand various environmental conditions. Buyers should inquire about the artisans’ expertise and the assembly techniques employed, as these factors significantly impact the final product’s quality.

Finishing: The Application of Oils

Finishing is where the oil treatment occurs, enhancing the leather’s flexibility, water resistance, and overall appearance. Manufacturers typically apply natural oils, such as neatsfoot or olive oil, in controlled amounts to avoid over-saturation, which can lead to a sticky texture. The finishing process may also include buffing and polishing to achieve the desired sheen. Buyers should ask about the types of oils used and the specific techniques applied to ensure product longevity and aesthetic appeal.

Illustrative image related to oil on leather

What Quality Assurance Measures Are Essential for Oil on Leather?

Quality assurance (QA) is vital in the manufacturing of oil-treated leather, ensuring that products meet international standards and customer expectations. A well-defined QA process encompasses various checkpoints and testing methods.

What Are the Relevant International Standards for Leather Quality?

B2B buyers should be familiar with international standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) certifications for certain oil-related products may apply. Suppliers that adhere to these standards demonstrate a commitment to quality and safety, making them more reliable partners.

How Are Quality Checkpoints Implemented?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure product integrity:

-

Incoming Quality Control (IQC): Inspections at this stage focus on the quality of raw materials, including hides and oils. Buyers should verify that suppliers conduct thorough assessments of incoming materials.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects or deviations from specifications early on. This stage often involves visual inspections and measurements.

-

Final Quality Control (FQC): Before products are shipped, a final inspection ensures they meet all quality standards. This may include testing for durability, flexibility, and oil absorption. Buyers can request detailed FQC reports to confirm compliance.

What Common Testing Methods Are Used for Oil on Leather?

Testing methods are crucial in validating the quality of oil-treated leather. Common techniques include:

-

Physical Testing: This includes tensile strength tests to measure how much force the leather can withstand before breaking, as well as flexibility tests to assess how well the leather bends and flexes.

-

Chemical Testing: This examines the effects of oils on leather over time, determining how well the material retains its properties after exposure to various conditions.

-

Environmental Testing: Products may undergo tests to evaluate their performance under different humidity and temperature levels, ensuring they can withstand diverse climates, particularly relevant for buyers in regions like Africa and the Middle East.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain rigorous quality control standards, B2B buyers can take several proactive steps:

-

Supplier Audits: Conducting on-site audits allows buyers to observe manufacturing practices firsthand and assess compliance with quality standards.

-

Requesting Quality Reports: Suppliers should provide documentation that details their QA processes, including inspection results and certifications. Regular reports can help maintain transparency and trust.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an objective assessment of the supplier’s quality control processes. This is especially important for buyers from regions with varying standards of quality assurance.

What Nuances Should International Buyers Consider in Quality Control?

International buyers, particularly from diverse markets such as Africa, South America, and the Middle East, must navigate various nuances in quality control:

-

Cultural Differences: Understanding the cultural context of manufacturing practices can help buyers communicate expectations more effectively.

-

Regulatory Compliance: Different regions may have unique regulations regarding leather production and treatment. Buyers should ensure that suppliers comply with local laws and international standards.

-

Logistics and Supply Chain: Delays in shipping and customs can affect product quality. Buyers should establish clear communication channels with suppliers to address potential issues proactively.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for oil on leather is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil on leather’

Introduction

This practical sourcing guide is designed for B2B buyers interested in procuring oil for leather treatment. Understanding the nuances of oil selection is essential for maintaining the quality and longevity of leather products. This checklist will help you navigate the procurement process efficiently, ensuring you partner with reliable suppliers and select the right products for your needs.

Illustrative image related to oil on leather

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider the type of leather you are working with and the specific oil characteristics needed—such as viscosity, drying time, and compatibility with different leather finishes. This ensures that you select oils that will enhance, rather than damage, the leather.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in leather care products. Researching innovations such as plant-based oils or eco-friendly options can provide you with a competitive edge. Understanding market preferences can also help you align your procurement strategy with consumer demands, particularly in regions prioritizing sustainability.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service standards. Request company profiles, product samples, and references from existing customers. This step is critical to mitigate risks associated with subpar products that could lead to significant losses in both reputation and finances.

- Look for Certifications: Ensure suppliers have relevant certifications, such as ISO standards, which indicate a commitment to quality and safety.

- Assess Supply Chain Reliability: Investigate their logistics and delivery capabilities, especially if you require timely shipments for seasonal demands.

Step 4: Request Product Samples

Before making a bulk purchase, always request samples of the oils you are considering. Testing these samples on your leather products allows you to evaluate their effectiveness and compatibility firsthand. This step can prevent costly mistakes associated with unsuitable products.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and products, engage in negotiations to secure favorable pricing and terms. Discuss bulk order discounts, payment terms, and return policies. A well-negotiated contract can lead to substantial cost savings and a stronger business relationship.

Illustrative image related to oil on leather

Step 6: Verify Compliance with Local Regulations

Ensure that the oils you are sourcing comply with local and international regulations regarding chemical safety and environmental impact. This is particularly important in regions with stringent regulations, such as Europe. Non-compliance can result in significant penalties and disrupt your supply chain.

Step 7: Establish Quality Control Procedures

Implement quality control measures to regularly assess the oil’s performance once it is in use. This includes setting benchmarks for application methods and results, as well as establishing a feedback loop with your team. Consistent evaluation helps maintain product integrity and ensures that leather care standards are upheld.

By following these steps, B2B buyers can make informed decisions when sourcing oils for leather, ensuring the quality and durability of their products while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for oil on leather Sourcing

What Are the Key Cost Components in Sourcing Oil on Leather?

When sourcing oil on leather, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Illustrative image related to oil on leather

-

Materials: The quality of the leather and oil used significantly impacts costs. Premium materials often lead to higher prices, but they can also enhance product longevity and customer satisfaction.

-

Labor: Skilled labor is essential for the application of oil on leather, especially for high-quality finishes. Labor costs vary by region; for example, skilled artisans in Europe may command higher wages compared to those in certain parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these overheads.

-

Tooling: Specific tools or machinery may be required for oil application, which can involve significant upfront investment. Understanding the tooling costs is vital for both suppliers and buyers.

-

Quality Control (QC): Ensuring that the finished product meets quality standards incurs additional costs. Investing in robust QC processes can prevent costly returns or dissatisfaction down the line.

-

Logistics: Shipping costs can vary dramatically based on the destination and the chosen Incoterms. Understanding these logistics costs is crucial for accurate pricing.

-

Margin: Suppliers will include a profit margin on top of their costs. This margin varies based on market competition and product differentiation.

How Do Price Influencers Affect the Cost of Oil on Leather?

Several factors influence the pricing of oil on leather:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically result in lower per-unit costs due to economies of scale. B2B buyers should negotiate favorable terms, especially when committing to larger orders.

-

Specifications and Customization: Custom orders often lead to increased costs. Buyers should be clear about their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and certifications (like eco-friendly or sustainable sourcing) can drive up costs. However, these factors can also appeal to environmentally conscious consumers.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: Understanding the agreed-upon Incoterms is essential for calculating total landed costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect pricing and risk allocation.

What Are the Best Buyer Tips for Negotiating Oil on Leather Prices?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Leverage Total Cost of Ownership (TCO): Rather than focusing solely on the initial purchase price, consider the total cost over the product’s lifecycle, including maintenance and potential resale value.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can yield better prices and terms. Suppliers are often more willing to negotiate with buyers who they see as partners.

-

Understand Pricing Nuances: Be aware of the different pricing strategies suppliers may use, such as tiered pricing based on volume or discounts for early payments. Knowledge of these strategies can empower negotiations.

-

Conduct Market Research: Familiarize yourself with market trends, competitor pricing, and regional economic conditions. This information can provide leverage during negotiations.

-

Be Clear on Payment Terms: Discussing payment terms upfront can prevent misunderstandings later. Flexible payment options can sometimes lead to better pricing agreements.

Disclaimer for Indicative Prices

It is essential to note that the prices for oil on leather can fluctuate based on market conditions, material availability, and regional economic factors. Always consult with suppliers for the most accurate and up-to-date pricing tailored to your specific needs.

Alternatives Analysis: Comparing oil on leather With Other Solutions

In the realm of leather care and maintenance, it is essential for B2B buyers to evaluate various solutions to protect and enhance leather products. While using oil on leather is a common method, several alternatives can achieve similar results, each with distinct benefits and drawbacks. This section will delve into a comparative analysis of oil on leather against other viable methods, providing insights that can guide purchasing decisions.

Illustrative image related to oil on leather

| Comparison Aspect | Oil On Leather | Beeswax and Oil Mixture | Leather Conditioner |

|---|---|---|---|

| Performance | Effective for softening and moisturizing leather, but may darken the material. | Provides a protective layer, enhances water resistance, and adds shine. | Nourishes leather, improves flexibility, and prevents cracking. |

| Cost | Moderate; costs vary based on oil type (e.g., olive, mink). | Generally low; beeswax is inexpensive and widely available. | Varies; high-quality conditioners can be pricier but offer longer-lasting benefits. |

| Ease of Implementation | Requires careful application to avoid over-saturation. | Simple to apply; requires melting and mixing. | Easy to use; typically comes in a ready-to-apply form. |

| Maintenance | Needs reapplication every few months, depending on use and exposure. | Requires occasional reapplication, especially after exposure to water. | Maintenance frequency varies; generally less frequent than oil. |

| Best Use Case | Ideal for vintage or well-worn leather needing hydration. | Suitable for outdoor leather goods exposed to moisture. | Best for regular maintenance of new or lightly used leather items. |

What Are the Benefits and Drawbacks of Beeswax and Oil Mixture for Leather?

Using a beeswax and oil mixture offers a balanced approach to leather care. The combination creates a protective barrier that not only enhances the leather’s appearance but also improves its resistance to water and dirt. This method is particularly beneficial for outdoor leather items, such as jackets and bags, that face harsher environmental conditions. However, the preparation process requires melting the beeswax and mixing it with oil, which may not be convenient for all users. Additionally, while it provides excellent protection, it may not penetrate as deeply as oils, meaning it might not be as effective for deeply conditioning the leather.

How Does Leather Conditioner Compare to Oil on Leather?

Leather conditioners are designed specifically for nourishing and maintaining leather’s integrity. They typically contain a blend of natural oils and waxes that penetrate the leather, restoring moisture and flexibility. This method is particularly advantageous for new or lightly used leather products, as it helps prevent cracking and wear over time. While high-quality conditioners can be more expensive, their long-term benefits often justify the investment. However, they may not offer the same level of immediate shine or protective barrier as an oil or beeswax mixture, making it essential for buyers to consider their specific leather care needs.

How Can B2B Buyers Choose the Right Leather Care Solution?

When selecting a leather care solution, B2B buyers should assess their specific needs, including the type of leather, its current condition, and the environmental factors it will face. For those working with vintage or heavily-used leather, oil may be the best choice for deep conditioning. Conversely, if the leather will be exposed to moisture, a beeswax and oil mixture may provide the necessary protection. For routine maintenance of newer leather items, investing in a quality leather conditioner is advisable. Understanding these alternatives will empower buyers to make informed decisions that enhance the longevity and appearance of their leather products.

Essential Technical Properties and Trade Terminology for oil on leather

What Are the Key Technical Properties of Oil on Leather?

Understanding the technical specifications of oil-treated leather is crucial for B2B buyers. These properties impact the quality, durability, and usability of leather products across various applications.

1. Oil Content Percentage

The oil content percentage refers to the amount of oil incorporated into the leather during processing. Typically ranging from 5% to 15%, this specification affects the leather’s softness, flexibility, and resistance to moisture. A higher oil content generally increases the leather’s water resistance, making it suitable for items exposed to harsher environments, such as outdoor gear or workwear.

2. Durability Rating

Durability is a measure of how well the leather can withstand wear and tear over time. This property is often assessed using tests like the Martindale abrasion test, where the leather is subjected to friction until wear occurs. For B2B buyers, understanding the durability rating helps in selecting leather that meets specific performance requirements, particularly in high-use applications like furniture or automotive interiors.

3. Thickness (Gauge)

Leather thickness, measured in millimeters or ounces, significantly influences its strength and weight. For example, thicker leather is generally more robust and suitable for heavy-duty applications, while thinner leather is often preferred for softer, more flexible products. Buyers must consider the end use to determine the appropriate thickness required for their products.

4. Grain Type

The grain type defines the surface texture of the leather and can range from smooth to pebbled or even suede. Full-grain leather, which retains the original texture and imperfections of the hide, is highly regarded for its durability and aesthetic appeal. Understanding grain types helps buyers match products with their desired look and performance characteristics.

Illustrative image related to oil on leather

5. Water Resistance

Water resistance is a critical property for oil-treated leather, achieved through the oiling process. This property is vital for products intended for outdoor use or in damp conditions. Buyers should inquire about specific water resistance tests to ensure the leather meets their performance standards.

What Are Common Trade Terms Related to Oil on Leather?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand. In the leather industry, this term is crucial for buyers looking to source leather goods that can be branded under their label. Understanding OEM relationships can facilitate smoother procurement processes.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B transactions, as it affects inventory management and cash flow. Buyers should negotiate MOQs to align with their operational needs without incurring excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the leather industry, issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure the best possible deal. A well-crafted RFQ can streamline the procurement process significantly.

Illustrative image related to oil on leather

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is vital for B2B buyers, as they determine who bears the risk and costs associated with shipping, insurance, and customs duties. This knowledge can prevent misunderstandings and ensure smoother transactions.

5. Tannery Certification

Tannery certification refers to the accreditation of leather processing facilities based on environmental and quality standards. Certifications like LWG (Leather Working Group) ensure that the leather sourced is produced responsibly. Buyers should prioritize suppliers with recognized certifications to align with sustainability goals and quality expectations.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing oil-treated leather, ultimately enhancing their product offerings and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the oil on leather Sector

What Are the Current Trends in the Oil on Leather Market?

The global oil on leather market is experiencing a notable shift driven by various factors, including increasing demand for high-quality leather goods and the rising popularity of sustainable and ethically sourced materials. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for products that combine traditional craftsmanship with modern technology. Digital transformation is also influencing sourcing trends, with B2B platforms enabling more streamlined procurement processes. The use of data analytics in supply chain management is becoming more prevalent, allowing companies to better predict market demands and optimize inventory levels.

Moreover, the emergence of e-commerce has expanded market access for international buyers, enabling them to connect with suppliers from various parts of the world, including emerging markets. As buyers become more discerning, there is a growing emphasis on quality and durability, particularly in sectors like fashion, automotive, and furniture. This trend is further emphasized by the increasing consumer awareness regarding the lifecycle of leather products, pushing companies to adopt more sustainable practices.

How Is Sustainability Influencing the Oil on Leather Sector?

Sustainability has emerged as a central theme in the oil on leather sector. Environmental impacts from traditional leather production methods have led to a surge in demand for sustainable alternatives. B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing practices and demonstrate a commitment to minimizing their ecological footprint. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming critical benchmarks for discerning buyers.

The use of eco-friendly oils, such as vegetable-based or synthetic alternatives, is gaining traction as businesses seek to reduce the harmful effects of traditional oiling processes. Additionally, the concept of circular economy is being integrated into leather production, encouraging the recycling and repurposing of materials. This not only aligns with the values of eco-conscious consumers but also enhances brand reputation, making it a strategic advantage for companies looking to differentiate themselves in the marketplace.

What Is the Historical Context of Oil on Leather in B2B Transactions?

The use of oil on leather dates back centuries, with its origins rooted in the necessity of preserving and enhancing the durability of leather goods. Traditionally, oils were applied to leather to provide moisture, flexibility, and a rich finish, making it more appealing to consumers. Over time, as industrialization took hold, the methods of oiling leather evolved, leading to the development of various synthetic oils that offered improved performance.

In the contemporary B2B landscape, the historical significance of oil on leather is often viewed through the lens of quality assurance. Buyers now seek suppliers who not only understand the traditional practices but also innovate in their application to meet modern standards. This blend of heritage and innovation is crucial for businesses aiming to appeal to both traditional markets and the newer, sustainability-focused consumer base. Understanding this evolution helps international buyers appreciate the nuances of sourcing oil-treated leather products that meet their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of oil on leather

-

How do I remove oil stains from leather products?

To effectively remove oil stains from leather, start by blotting the excess oil with a clean, dry cloth to absorb as much as possible without rubbing. Then, sprinkle cornstarch or talcum powder over the stain and leave it for several hours or overnight to absorb the oil. Afterward, gently brush off the powder and, if necessary, use a leather cleaner specifically formulated for your type of leather. Always test any cleaning product on a hidden area first to avoid damage. -

What type of oil is best for conditioning leather?

The best oils for conditioning leather include neatsfoot oil, mink oil, and olive oil. Neatsfoot oil is favored for its deep conditioning properties, while mink oil offers water resistance and flexibility. Olive oil can be used in moderation, but it may darken the leather over time. When selecting an oil, consider the specific type of leather and its intended use to ensure optimal results without compromising quality. -

What are the key factors to consider when sourcing leather oil suppliers?

When sourcing suppliers for leather oil, prioritize their experience and reputation in the leather industry. Verify their compliance with international quality standards and regulations, as well as their ability to provide certifications for the products. Additionally, assess their customer service, lead times, and flexibility in order quantities. Engaging with suppliers who offer customization options can also enhance your product offerings. -

What are the minimum order quantities (MOQs) for leather oil suppliers?

Minimum order quantities (MOQs) for leather oil can vary significantly by supplier, ranging from small batches of a few liters to larger orders of hundreds of liters. Many suppliers may allow flexibility in MOQs for first-time buyers or long-term contracts. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that align with your business objectives, especially for international trade. -

What payment terms should I expect when purchasing leather oil internationally?

Payment terms for international leather oil purchases typically include options like Letter of Credit (LC), advance payment, or net 30/60 days after delivery. It’s crucial to establish clear payment terms that protect both parties, ensuring the supplier has confidence in your order and you have assurance of product quality. Always review the terms in the purchase agreement and consider using escrow services for larger transactions to mitigate risks. -

How can I ensure quality assurance (QA) for leather oil products?

To ensure quality assurance for leather oil, request samples before placing bulk orders. Evaluate the oil’s performance on various leather types and check for consistency in color and viscosity. Additionally, inquire about the supplier’s quality control processes, including testing methods and certifications. Regular audits and inspections can also help maintain product quality throughout the supply chain. -

What logistics considerations are important for importing leather oil?

When importing leather oil, consider logistics factors such as shipping methods, customs regulations, and lead times. Select a reliable freight forwarder familiar with hazardous materials if applicable, as some oils may be classified as such. Ensure compliance with local import regulations in your country to avoid delays. It’s advisable to plan for potential customs duties and taxes in your total cost analysis. -

How can I customize leather oil for specific applications?

Customizing leather oil involves adjusting the formulation to meet specific needs, such as different absorption rates or additional conditioning properties. Engage with suppliers who offer formulation services and discuss your requirements in detail. This can include selecting specific base oils, additives, or fragrances that align with your product line. Collaborating with a supplier on custom formulations can enhance your market differentiation and meet unique customer demands.

Top 6 Oil On Leather Manufacturers & Suppliers List

1. Reddit – Oils for Leathercraft

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Oils for leathercraft include various types with distinct pros and cons:

1. **Petroleum-based oils** (e.g., Mineral Oil, Baby Oil, Petroleum Jelly):

– Pros: Low cost, good availability, clear, softens leather, deep penetration, strong waterproofing.

– Cons: Clogs pores, can form a surface film, breaks down leather structure, environmental impacts, higher health risk (VOCs), may dry out o…

2. Vintage Leather – Premium Leather Goods

Domain: vintageleather.store

Registered: 2022 (3 years)

Introduction: Men’s and Women’s Leather Goods including Duffle Bags, Messenger Bags, Briefcases, Satchels, Backpacks, Laptop Bags, Camera Bags, Laptop Sleeves, Compendium, Notebook Cover, Toiletry Bags, Sling Bags, Wallets, Leather Journals, Wine Bags, Tobacco Pouches, Passport Wallets, Pencil Cases, Accessories, and Glass Cases. Gifts categorized for Him, Her, and under various price ranges. Free standard ship…

3. Steel Horse Leather – Stain Removal Tips

Domain: steelhorseleather.com

Registered: 2019 (6 years)

Introduction: This company, Steel Horse Leather – Stain Removal Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Otter Wax – Leather Oil

Domain: otterwax.com

Registered: 2011 (14 years)

Introduction: Otter Wax Leather Oil is a premium all-natural polishing conditioner designed to enhance natural shine, restore original color, and revitalize dehydrated leather. It is made from a balanced blend of high-oleic safflower oil, vitamin E, and sweet orange oils. The product is suitable for various leather items including sofas, boots, belts, bags, car seats, and gloves. It is free from harsh chemicals…

5. The Leather Colour Doctor – Essential Leather Care Products

Domain: theleathercolourdoctor.co.uk

Registered: 2017 (8 years)

Introduction: Leather Cleaning Products: Talcum powder, Corn starch, Baking soda, White vinegar, Lemon juice, Rubbing alcohol, Nail varnish remover, Dish soap, Leather cleaner, Leather conditioner/leather oil. Leather Types: Aniline Leather, Semi-Aniline Leather, Pigmented Leather, Suede, PU Leather. Recommended Methods: Dry powdered methods for Aniline and Suede; mild wet methods for Semi-Aniline; powdered, di…

6. Sarna Sports – Baseball Glove Care Products

Domain: sarnasports.com

Registered: 2024 (1 years)

Introduction: Sarna Baseball Official Site offers a variety of products including Baseball Glove Cleaners, Glove Conditioners, Glove Oils, Glove Tools & Kits, and Sneaker Cleaners. They provide free shipping to all continental U.S. states.

Strategic Sourcing Conclusion and Outlook for oil on leather

What Are the Key Insights for Strategic Sourcing of Oil on Leather?

In conclusion, the strategic sourcing of oils for leather treatment offers significant advantages for international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the various types of oils, such as olive and neatsfoot oil, allows businesses to select products that enhance leather’s durability and aesthetic appeal while also addressing specific local preferences.

Illustrative image related to oil on leather

Investing in high-quality oils not only extends the life of leather goods but also provides a competitive edge in the market by meeting rising consumer demand for sustainable and well-maintained leather products. Leveraging strategic sourcing practices ensures that buyers can negotiate favorable terms, maintain consistent supply chains, and mitigate risks associated with fluctuating oil prices.

As you consider your sourcing strategies, prioritize building relationships with reliable suppliers who understand your regional market dynamics. Embrace innovation in product offerings and stay informed about the latest trends in leather care. By doing so, you position your business for sustained growth and success in the vibrant global leather market. Take the next step today—evaluate your current sourcing strategies and explore new partnerships to enhance your leather offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.