Introduction: Navigating the Global Market for belt types

In the ever-evolving global marketplace, sourcing the right belt types can be a daunting challenge for international B2B buyers. Whether you’re looking to outfit a fashion retail line or supply industrial applications, understanding the diverse range of belt types is crucial for making informed purchasing decisions. This comprehensive guide will delve into various belt categories—from full-grain leather and vegan options to specialized industrial belts—highlighting their unique applications and benefits.

As a B2B buyer, you will gain insights into the critical aspects of supplier vetting, cost considerations, and market trends tailored specifically for regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Vietnam. By exploring factors such as material quality, durability, and style, you will be equipped to select the most suitable belts for your business needs.

Ultimately, this guide serves as an invaluable resource that empowers you to navigate the complexities of the global belt market confidently. With the right knowledge and strategies, you can streamline your sourcing process, enhance your product offerings, and stay ahead of the competition.

Table Of Contents

- Top 3 Belt Types Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for belt types

- Understanding belt types Types and Variations

- Key Industrial Applications of belt types

- 3 Common User Pain Points for ‘belt types’ & Their Solutions

- Strategic Material Selection Guide for belt types

- In-depth Look: Manufacturing Processes and Quality Assurance for belt types

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt types’

- Comprehensive Cost and Pricing Analysis for belt types Sourcing

- Alternatives Analysis: Comparing belt types With Other Solutions

- Essential Technical Properties and Trade Terminology for belt types

- Navigating Market Dynamics and Sourcing Trends in the belt types Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of belt types

- Strategic Sourcing Conclusion and Outlook for belt types

- Important Disclaimer & Terms of Use

Understanding belt types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather Belt | Top layer cowhide, natural finish, high durability | Corporate attire, formal events | Pros: Long-lasting, classic aesthetic. Cons: Higher cost than synthetic options. |

| Braided Leather Belt | Interwoven strips of leather, flexible design | Casual wear, outdoor events | Pros: Stylish, adds texture. Cons: Less durable in wet conditions. |

| Reversible Belt | Two-sided design (often black and brown) | Travel, versatile wardrobe solutions | Pros: Cost-effective, space-saving. Cons: Quality can vary significantly. |

| Vegan Leather Belt | Made from sustainable materials, cruelty-free | Eco-friendly brands, casual wear | Pros: Ethical choice, lightweight. Cons: May not have the same durability as leather. |

| Military Belt | Thick, sturdy material with a simple buckle | Outdoor activities, tactical use | Pros: Extremely durable, functional. Cons: Limited style appeal for formal settings. |

What Are the Key Characteristics of Full-Grain Leather Belts for B2B Buyers?

Full-grain leather belts are crafted from the top layer of cowhide, retaining the natural grain and texture. This type of belt is renowned for its durability and ability to age gracefully, making it suitable for corporate attire and formal events. B2B buyers should consider the investment value, as these belts often outlast cheaper alternatives. However, the higher price point may be a concern for budget-conscious companies.

How Do Braided Leather Belts Fit into the B2B Market?

Braided leather belts feature interwoven strips of leather, offering a flexible and stylish option for casual wear and outdoor events. Their unique design adds a touch of flair to standard outfits, making them appealing for companies focused on branding through employee attire. While these belts are visually appealing, buyers should be aware of their reduced durability in wet conditions, which may affect longevity in certain climates.

Why Are Reversible Belts Popular Among B2B Buyers?

Reversible belts present a versatile solution, featuring two sides—commonly one black and one brown—allowing for easy color coordination with outfits. This design is particularly beneficial for businesses that prioritize travel or minimalistic wardrobes. B2B purchasers should consider the cost-effectiveness and space-saving benefits of this option. However, the quality of reversible belts can vary, and buyers should seek reputable suppliers to ensure longevity.

What Advantages Do Vegan Leather Belts Offer for Ethical Brands?

Vegan leather belts are made from sustainable materials such as recycled plastics or plant-based alternatives, appealing to eco-conscious brands. They are lightweight and cruelty-free, aligning with the values of many modern businesses. B2B buyers should assess the durability of these belts, as they may not match the lifespan of traditional leather. Still, they present a compelling option for companies looking to enhance their environmental responsibility.

How Do Military Belts Serve Specific B2B Needs?

Military belts are constructed from robust materials designed for extreme durability and functionality, making them ideal for outdoor activities and tactical applications. They are often favored by companies in the security or outdoor sectors. While their practicality is a significant advantage, B2B buyers should note that military belts may lack the style required for formal or corporate settings, limiting their versatility.

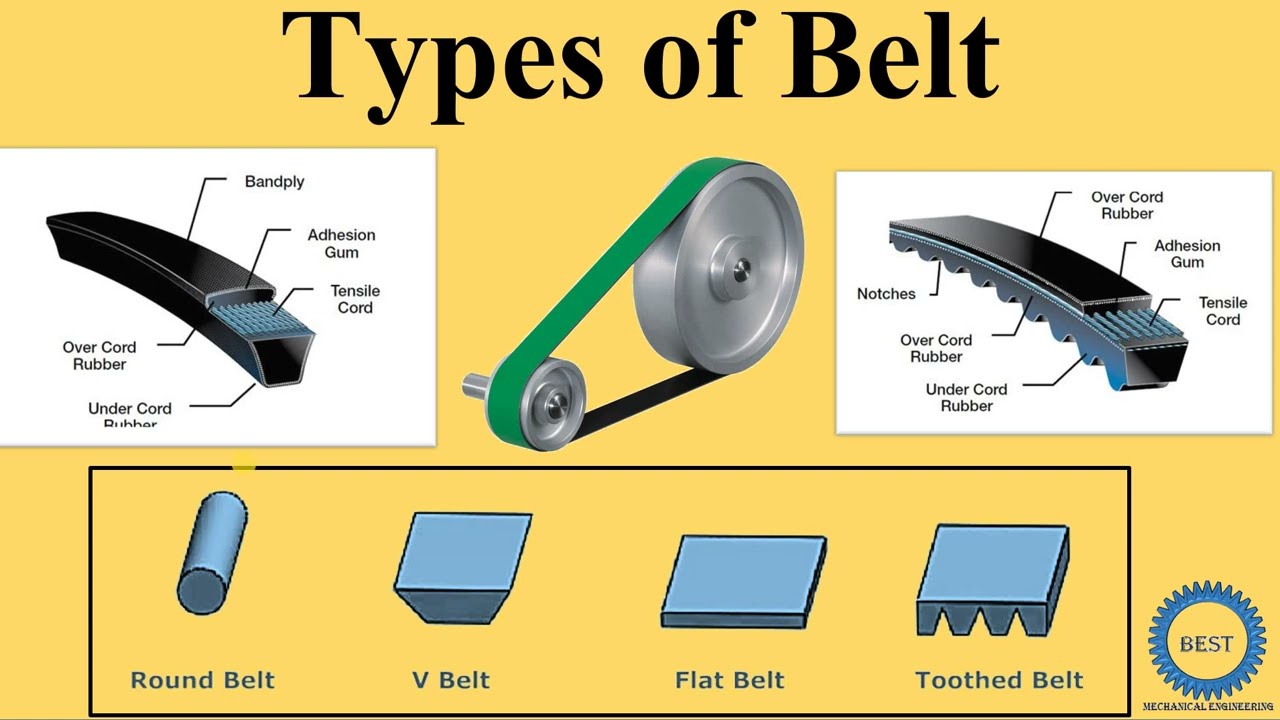

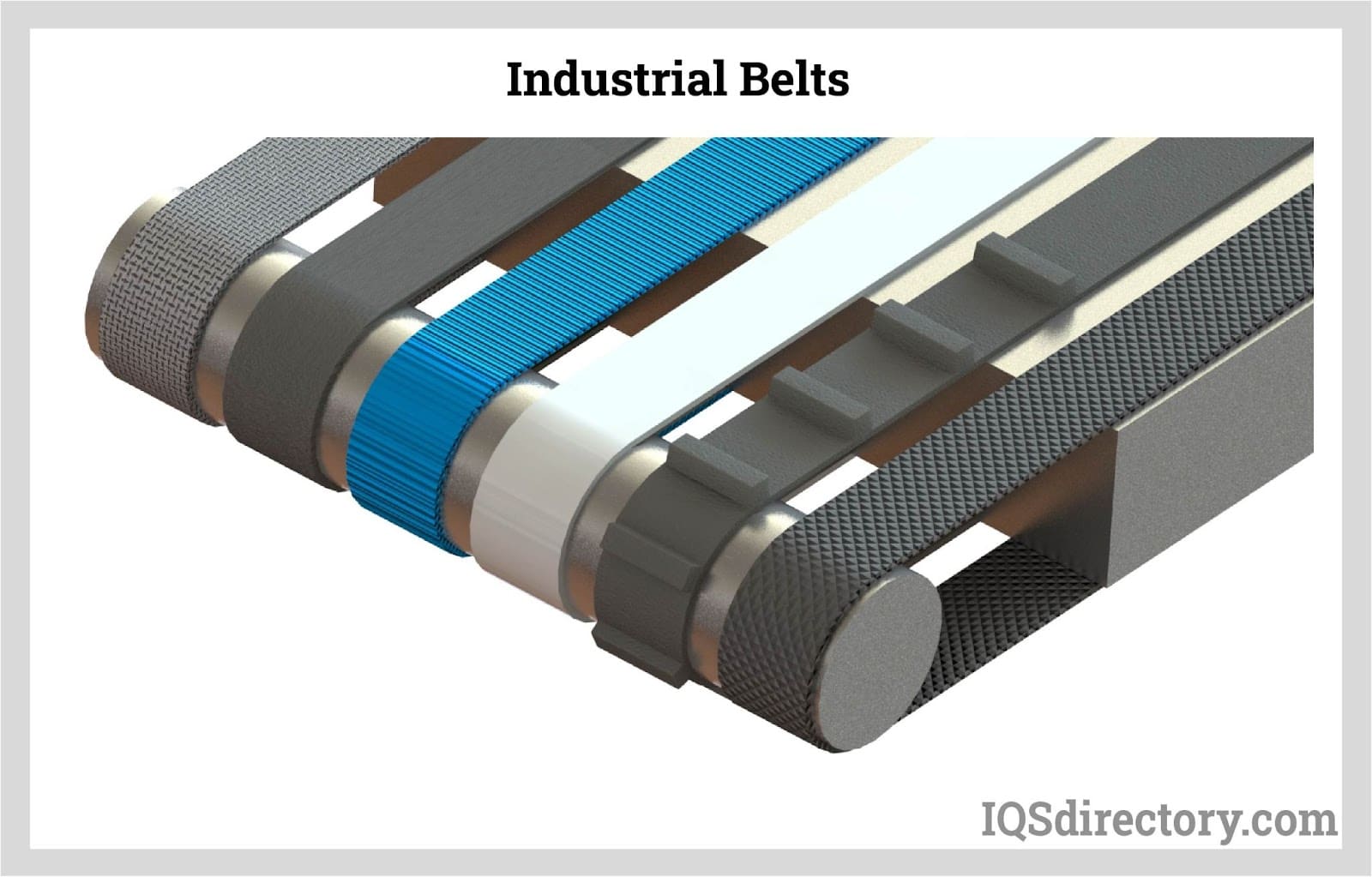

Key Industrial Applications of belt types

| Industry/Sector | Specific Application of belt types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

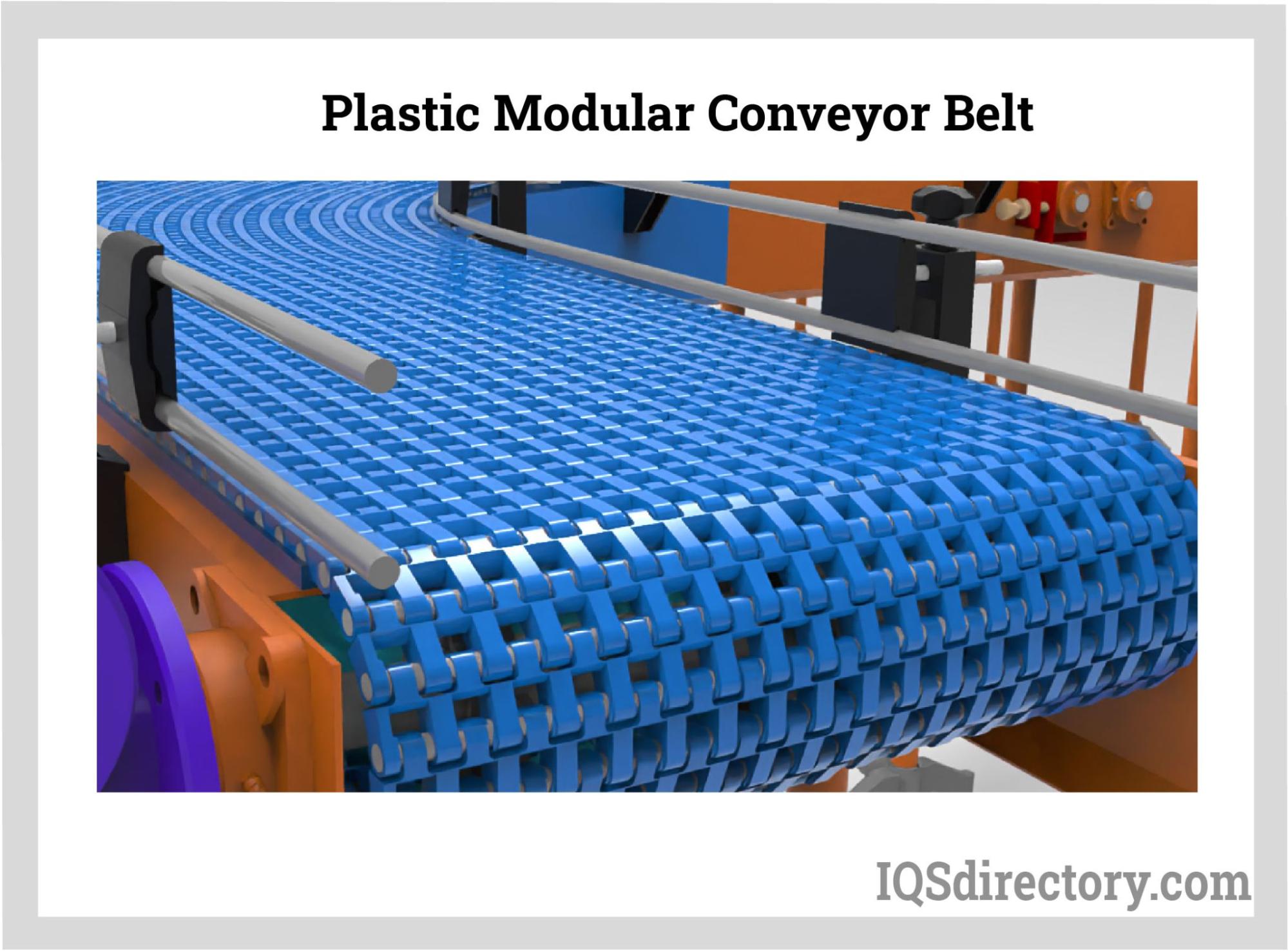

| Manufacturing | Conveyor Belts in Production Lines | Increases efficiency and reduces downtime | Material durability, resistance to wear, and customization options |

| Agriculture | Agricultural Belts for Machinery | Enhances equipment performance and longevity | Compatibility with existing machinery, weather resistance, and maintenance support |

| Mining and Quarrying | Heavy-Duty Mining Belts | Ensures safe and efficient material transport | Load capacity, abrasion resistance, and supplier reliability |

| Automotive | Timing Belts in Engine Systems | Improves engine efficiency and performance | Precision engineering, compatibility with vehicle models, and quality certifications |

| Food Processing | Food-Grade Conveyor Belts | Meets hygiene standards and enhances safety | Compliance with food safety regulations, ease of cleaning, and material certifications |

How Are Belt Types Utilized in Manufacturing and What Benefits Do They Offer?

In the manufacturing sector, conveyor belts are essential for streamlining production lines. They facilitate the movement of materials and finished products, significantly increasing operational efficiency and minimizing downtime. Buyers from various regions, including Africa and Europe, must consider the durability of materials used in these belts, as well as their resistance to wear and tear. Customization options can also be critical, allowing businesses to tailor solutions to specific production needs.

What Role Do Agricultural Belts Play in Enhancing Equipment Performance?

In agriculture, belts are integral to the functionality of machinery such as tractors and harvesters. Agricultural belts must withstand harsh environmental conditions while providing reliable performance. Businesses benefit from enhanced equipment longevity and reliability, which translates to reduced maintenance costs. Buyers should ensure compatibility with existing machinery and inquire about weather-resistant materials to avoid frequent replacements.

How Do Heavy-Duty Mining Belts Ensure Safety and Efficiency?

In the mining and quarrying industries, heavy-duty belts are crucial for transporting materials safely and efficiently. These belts must be designed to handle significant loads and resist abrasion caused by rough materials. The value for businesses lies in their ability to maintain productivity while ensuring worker safety. International buyers should prioritize suppliers with proven reliability and experience in providing belts that meet industry-specific load capacities and durability standards.

Why Are Timing Belts Essential in Automotive Applications?

Timing belts play a critical role in automotive engine systems, ensuring that engine components operate in sync for optimal performance. The benefits include improved engine efficiency and reduced wear on parts, leading to longer vehicle lifespans. Buyers, especially those in Europe, should focus on precision engineering and compatibility with various vehicle models when sourcing these belts, as well as ensuring that suppliers meet quality certifications.

How Do Food-Grade Conveyor Belts Meet Safety Standards in Food Processing?

In food processing, the use of food-grade conveyor belts is essential for maintaining hygiene and safety standards. These belts facilitate the movement of food products while ensuring compliance with strict regulations. The value for businesses includes enhanced safety and reduced risk of contamination. Buyers must consider materials that are easy to clean and compliant with food safety regulations, as well as the availability of certifications that guarantee product safety.

3 Common User Pain Points for ‘belt types’ & Their Solutions

Scenario 1: Sourcing Quality Belts for Diverse Markets

The Problem:

B2B buyers often face significant challenges when sourcing belts suitable for various markets, particularly when considering the unique demands of regions like Africa, South America, the Middle East, and Europe. The quality expectations can vary drastically across these regions. For instance, while a durable leather belt may be a hit in European markets, buyers in Africa might prioritize affordability and adaptability to local climates. Additionally, factors such as import tariffs, shipping costs, and varying consumer preferences complicate the sourcing process, leading to frustration and potential financial loss.

The Solution:

To navigate these challenges effectively, B2B buyers should conduct thorough market research to understand the specific needs and preferences of their target demographics. Engaging with local distributors can provide insights into regional trends, enabling buyers to tailor their product offerings. Establishing relationships with multiple suppliers can also enhance flexibility, allowing for a diverse range of belt types that cater to different tastes and budgets. When selecting suppliers, it is crucial to assess their quality control measures and production capabilities to ensure that the belts meet the necessary standards for durability and style. Consider requesting samples to evaluate the products firsthand before making bulk purchases.

Scenario 2: Managing Inventory for Seasonal Demand Fluctuations

The Problem:

Another prevalent pain point for B2B buyers is managing inventory levels, particularly during seasonal demand fluctuations. For instance, demand for fashionable belts may spike during the back-to-school season or holiday festivities, while it may dwindle in off-peak months. This inconsistency can lead to either overstocking—resulting in increased holding costs—or stockouts, which can damage customer relationships and sales opportunities. Such challenges are particularly pronounced in regions with distinct seasonal variations.

The Solution:

To address this issue, B2B buyers should implement a robust inventory management system that leverages data analytics to forecast demand accurately. Utilizing historical sales data and market trends can help predict which belt types will be in demand during specific seasons. This proactive approach allows for timely reordering and minimizes excess inventory. Additionally, establishing flexible agreements with suppliers can provide the option to adjust orders based on real-time demand, ensuring that stock levels are optimized. Collaborating with logistics partners who can offer rapid shipping solutions will also help meet unexpected surges in demand without excessive inventory buildup.

Scenario 3: Ensuring Compliance with Regional Regulations

The Problem:

B2B buyers often encounter regulatory compliance issues when sourcing and selling belt types, particularly in international markets. Different countries have specific regulations regarding materials, manufacturing processes, and labeling requirements. For example, EU regulations may restrict the use of certain synthetic materials or mandate specific safety standards, while regulations in South America may focus on environmental sustainability. Non-compliance can lead to legal repercussions, fines, and damage to a company’s reputation.

The Solution:

To mitigate compliance risks, B2B buyers should stay informed about the regulations governing the countries they operate in. This can be achieved by consulting with legal experts or compliance specialists who are knowledgeable about international trade laws and product safety standards. Buyers should also prioritize sourcing belts from manufacturers who adhere to best practices in material sourcing and production. Requesting certification documents and testing results can help ensure that the products meet required standards. Establishing a compliance checklist tailored to each target market can further streamline the sourcing process, ensuring that all products meet local regulations before entering the market.

Strategic Material Selection Guide for belt types

What Are the Key Properties of Common Belt Materials?

When selecting belts for various applications, understanding the properties of the materials used is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in belt types, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

Illustrative image related to belt types

1. Leather

Key Properties: Leather is known for its durability, flexibility, and resistance to wear and tear. It performs well in a range of temperatures, maintaining its integrity under moderate heat. However, it can be susceptible to moisture and requires proper care to avoid deterioration.

Pros & Cons: Leather belts offer a classic aesthetic and can last for years with proper maintenance. However, they can be more expensive compared to synthetic alternatives and may not be suitable for environments with high humidity or exposure to chemicals.

Impact on Application: Leather is often used in fashion and formal settings, making it ideal for belts in retail and luxury markets. Its compatibility with various clothing styles enhances its appeal.

Considerations for International Buyers: Buyers from regions with diverse climates, such as Africa and the Middle East, should consider the leather’s treatment process to ensure it can withstand local conditions. Compliance with international standards like ASTM for leather quality can also influence purchasing decisions.

Illustrative image related to belt types

2. Synthetic Fabrics (e.g., Polyester, Nylon)

Key Properties: Synthetic fabrics are lightweight, resistant to moisture, and offer excellent tensile strength. They can withstand a wide range of temperatures and are often treated to enhance UV resistance.

Pros & Cons: These materials are generally more affordable than leather and can be produced in various colors and patterns. However, they may lack the luxurious feel of leather and can degrade under prolonged exposure to UV light.

Impact on Application: Synthetic belts are widely used in casual wear, outdoor activities, and industrial applications. Their versatility makes them suitable for various markets, including fashion and workwear.

Considerations for International Buyers: Buyers should ensure that synthetic materials meet local environmental regulations, especially in Europe, where there are strict guidelines regarding the use of certain chemicals in textiles.

Illustrative image related to belt types

3. Rubber

Key Properties: Rubber belts are known for their excellent elasticity and resistance to abrasion. They perform well under high-pressure conditions and can maintain their shape across a wide temperature range.

Pros & Cons: Rubber belts are durable and provide good grip, making them ideal for industrial applications. However, they can be less aesthetically pleasing for fashion applications and may have a shorter lifespan when exposed to extreme temperatures.

Impact on Application: These belts are commonly used in machinery and automotive applications where flexibility and strength are essential. They are also suitable for heavy-duty tasks.

Considerations for International Buyers: Buyers should be aware of the specific rubber grades and their compliance with industry standards such as DIN or JIS, particularly in the automotive sector.

4. Vegan Leather

Key Properties: Vegan leather, often made from polyurethane or other synthetic materials, mimics the look and feel of real leather while being more environmentally friendly. It is generally resistant to water and easy to clean.

Pros & Cons: This material offers a cruelty-free alternative to traditional leather and is often more affordable. However, it may not be as durable as genuine leather and can show wear more quickly.

Impact on Application: Vegan leather is increasingly popular in fashion-forward markets, appealing to eco-conscious consumers. It is suitable for casual and formal wear alike.

Considerations for International Buyers: Buyers should verify the sourcing and production practices of vegan leather to ensure they align with ethical standards. Compliance with environmental regulations is also crucial, particularly in Europe.

Summary Table of Material Selection for Belt Types

| Material | Typical Use Case for belt types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Fashion and formal wear | Durability and classic aesthetic | Higher cost and moisture sensitivity | High |

| Synthetic Fabrics | Casual and industrial applications | Affordability and versatility | Less luxurious feel | Medium |

| Rubber | Machinery and automotive applications | Excellent elasticity and strength | Aesthetic limitations | Medium |

| Vegan Leather | Fashion and eco-friendly markets | Cruelty-free and easy maintenance | Potentially lower durability | Medium |

This analysis provides a comprehensive overview of material selection for belt types, enabling international B2B buyers to make informed decisions that align with their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for belt types

What Are the Main Stages of the Manufacturing Process for Different Belt Types?

The manufacturing of belts encompasses several key stages, each critical to ensuring the final product meets quality and functionality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The choice of material greatly influences the belt’s durability and application. Common materials include leather, synthetic fabrics, and metal. For leather belts, full-grain or top-grain leather is often selected for its strength and aesthetic appeal. Materials undergo processes like tanning and dyeing to enhance their properties. Synthetic materials may require treatments to improve flexibility, water resistance, or durability.

-

Forming: In this stage, the prepared materials are shaped into the desired belt form. Techniques vary based on the material. For leather, cutting is performed using dies to ensure precise shapes and sizes. Synthetic belts may be extruded or woven, depending on the design. Advanced technologies such as laser cutting are increasingly used for precision and efficiency.

-

Assembly: This stage involves attaching components such as buckles, loops, and decorative elements. Quality control is vital here to ensure all components fit correctly. For example, metal buckles may be riveted or stitched onto leather belts. Automated assembly lines can enhance production speed while maintaining consistency.

-

Finishing: The final step includes processes like polishing, coating, and packaging. Leather belts may be conditioned with oils or waxes to enhance their appearance and longevity. Synthetic belts might undergo additional treatments for UV resistance or colorfastness. Proper packaging ensures that the belts are protected during shipping and storage.

How Is Quality Assurance Implemented During Belt Manufacturing?

Quality assurance (QA) is crucial in the belt manufacturing process, ensuring that products meet both customer expectations and regulatory standards. Implementing a robust QA system involves adherence to international standards, systematic checkpoints, and various testing methods.

-

What International Standards Are Relevant for Belt Quality Assurance?

B2B buyers should look for suppliers who comply with international quality standards, such as ISO 9001, which outlines requirements for a quality management system (QMS). Industry-specific certifications, such as CE marking for European markets or API standards for industrial applications, are also significant. These certifications indicate that the manufacturer adheres to internationally recognized safety and quality practices. -

What Are the Key Quality Control Checkpoints in Belt Manufacturing?

Quality control is typically divided into three checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. For leather, this may include checks for grain quality and tanning consistency. For synthetic materials, tests may include checking tensile strength and elasticity.

-

In-Process Quality Control (IPQC): During production, various parameters are monitored to prevent defects. This includes checking the alignment of components during assembly and ensuring that the forming process maintains consistency across batches. Regular audits during this phase can help identify potential issues early.

-

Final Quality Control (FQC): After assembly, belts undergo final inspections to verify that they meet all design specifications and quality standards. Common tests include stress tests, colorfastness assessments, and durability evaluations.

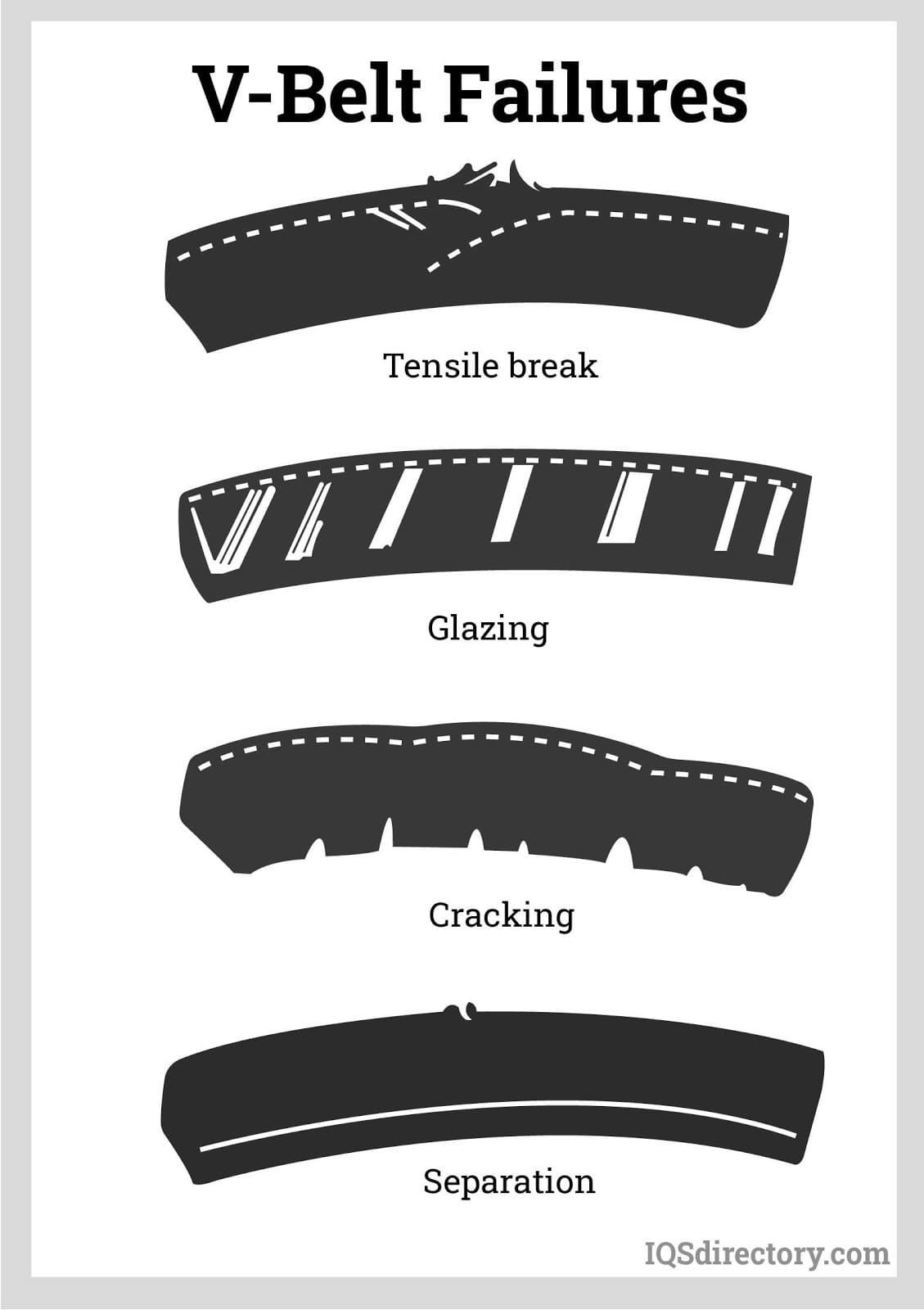

What Testing Methods Are Commonly Used in Belt Quality Assurance?

Testing methods vary based on the material and intended use of the belt. Common testing methods include:

Illustrative image related to belt types

- Tensile Testing: Measures the strength and elasticity of materials to ensure they can withstand the required loads.

- Colorfastness Testing: Assesses how well the color of the belt holds up against washing and exposure to light, especially important for synthetic materials.

- Abrasion Resistance Testing: Evaluates how well the material withstands wear and tear over time.

- Flexibility Testing: Determines how well the belt material bends and flexes without cracking or breaking.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe, should employ several strategies to verify the quality control measures of potential suppliers.

-

Conducting Audits: Regular audits of the manufacturing facility can provide insights into the operational practices and adherence to quality standards. Buyers may choose to conduct these audits themselves or hire third-party auditing firms.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC results. These reports often include data on defect rates, testing outcomes, and compliance with international standards.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can verify that the products meet specified standards before shipping.

-

Understanding Certification Nuances: Different regions may have varying requirements for certifications. Buyers should familiarize themselves with these nuances to ensure compliance with local regulations, particularly when importing goods.

What Are the Challenges in Quality Assurance for International B2B Buyers?

International B2B buyers may face specific challenges when it comes to quality assurance in the belt manufacturing sector. These challenges include:

- Cultural Differences: Different regions may have varying approaches to quality and manufacturing practices, necessitating a deeper understanding of local standards and expectations.

- Logistical Issues: Shipping delays or customs inspections can impact the timely delivery of products. This necessitates robust communication and planning with suppliers.

- Regulatory Compliance: Ensuring compliance with multiple international standards can be complex. Buyers must remain informed about the regulations applicable in their regions.

Conclusion

Manufacturing belts involves a detailed process that emphasizes quality assurance at every stage. By understanding the manufacturing processes, relevant quality standards, and methods of verification, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only helps in securing high-quality products but also fosters long-term business relationships across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt types’

When sourcing different types of belts for your business, a structured approach can streamline the process and ensure you make informed decisions. This checklist is designed to guide international B2B buyers through each essential step, from defining requirements to selecting the right supplier.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure the belts meet your operational needs. Consider factors such as material (e.g., leather, vegan leather, or fabric), design (e.g., braided, reversible), and functional requirements (e.g., width, length, or buckle type). This clarity will help you communicate effectively with suppliers and avoid misunderstandings.

Illustrative image related to belt types

Step 2: Research Market Trends and Requirements

Understanding market trends can provide insights into customer preferences and emerging styles. Research popular belt types in your target markets, such as Africa, South America, the Middle East, and Europe. Pay attention to regional preferences, such as eco-friendly materials or specific design aesthetics that resonate with local consumers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, certifications, and references from previous clients within your industry. Look for suppliers who specialize in the specific belt types you require, and assess their capacity to meet your order volume and delivery timelines.

- Sub-bullet: Verify that they comply with international quality standards.

- Sub-bullet: Ask for samples to assess the quality firsthand.

Step 4: Assess Production Capabilities

Understanding a supplier’s production capabilities is key to ensuring they can meet your needs. Inquire about their manufacturing processes, technology, and lead times. A supplier with modern equipment and skilled labor is more likely to produce high-quality belts that align with your specifications.

Illustrative image related to belt types

Step 5: Negotiate Terms and Conditions

Once you’ve identified potential suppliers, negotiate terms that align with your business objectives. This includes pricing, payment terms, minimum order quantities, and delivery schedules. A clear agreement will prevent potential disputes and help establish a positive working relationship.

Step 6: Review Quality Assurance Processes

Quality assurance is vital in the belt manufacturing process. Inquire about the supplier’s quality control measures, testing protocols, and any certifications they hold. A robust quality assurance process ensures that the belts will perform as expected and meet the durability standards required in your market.

Step 7: Establish a Communication Plan

Effective communication is essential for successful sourcing. Set up a communication plan that includes regular updates on production, shipping timelines, and any potential issues. Establishing a point of contact within the supplier’s organization can facilitate smoother interactions and quicker resolutions to any challenges that arise.

By following this checklist, B2B buyers can navigate the sourcing process for various belt types with confidence, ensuring they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for belt types Sourcing

What Are the Key Cost Components in Belt Manufacturing?

When sourcing belts, understanding the cost structure is critical for effective budgeting and negotiation. The main cost components include:

-

Materials: The choice of materials significantly impacts the cost. Full-grain leather, for instance, is typically more expensive than synthetic alternatives due to its durability and quality. Other materials like vegan leather or fabric can vary widely in price, depending on their sourcing and production methods.

-

Labor: Labor costs are influenced by the complexity of the design and the skill level required for production. Handmade or artisanal belts, for instance, may command higher labor costs compared to mass-produced options.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, equipment maintenance, and administrative expenses. Efficient operations can help reduce overhead costs, benefiting buyers in the long run.

-

Tooling: Custom tooling for unique designs or specifications can add to initial costs. Buyers should consider whether the investment in tooling aligns with their anticipated order volume.

-

Quality Control (QC): Implementing stringent QC processes ensures product consistency and quality, but it also adds to overall costs. Buyers should evaluate the supplier’s QC measures as part of their sourcing strategy.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors like the shipping method, destination, and Incoterms will influence logistics costs.

-

Margin: Suppliers will build in their profit margin, which varies widely based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Belt Sourcing?

Several factors influence pricing that B2B buyers should be aware of:

-

Volume/MOQ: Minimum order quantities (MOQs) can impact pricing. Suppliers often provide discounts for larger orders, so buyers should evaluate their purchasing strategy to optimize costs.

-

Specifications/Customization: Custom designs or specific materials can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Higher quality belts or those meeting specific industry certifications (such as ISO) generally come at a premium. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Engaging with reputable suppliers may yield better quality and service but could also come with higher costs.

-

Incoterms: Understanding Incoterms is essential for calculating total landed costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, impacting the overall price.

What Are Effective Buyer Tips for Negotiating Belt Prices?

International B2B buyers should adopt specific strategies to enhance their sourcing efficiency:

-

Negotiation: Leverage bulk purchasing and long-term contracts to negotiate better pricing. Suppliers may be willing to offer discounts for guaranteed orders over time.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and potential replacement costs. A higher upfront investment in quality belts can lead to lower long-term costs.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and import duties that can affect final costs. It’s advisable to conduct thorough market research and potentially consult local experts to navigate these complexities.

-

Supplier Diversification: Engaging multiple suppliers can foster competitive pricing and mitigate risks associated with dependency on a single source.

What Should Buyers Remember About Indicative Prices?

While indicative pricing can provide a useful benchmark, it’s essential to recognize that actual costs may vary based on specific requirements, market conditions, and negotiations. Buyers should always seek detailed quotes and clarify all terms before finalizing any agreements to ensure transparency and alignment with their expectations.

Alternatives Analysis: Comparing belt types With Other Solutions

Understanding Alternatives to Belt Types in the B2B Market

When evaluating belt types for various applications, it’s essential to consider viable alternatives that may offer comparable functionalities. In sectors such as fashion, manufacturing, or logistics, different solutions can address the same needs, whether for securing items, enhancing aesthetics, or providing support. This analysis will compare various belt types against alternative solutions, highlighting key performance indicators relevant to international B2B buyers.

Comparison Table

| Comparison Aspect | Belt Types | Alternative 1: Suspenders | Alternative 2: Garter Straps |

|---|---|---|---|

| Performance | Provides reliable support; versatile for various styles | Excellent for holding up trousers without tightening around the waist | Keeps stockings in place, ideal for formal wear |

| Cost | Ranges from economical to premium based on materials | Generally low-cost, depending on fabric and brand | Moderate cost, often higher for designer options |

| Ease of Implementation | Simple to wear and adjust | Easy to use but may require adjustments throughout the day | Requires specific clothing and can be less convenient |

| Maintenance | Generally low; leather requires conditioning | Minimal, machine washable options available | Requires careful washing to maintain elasticity |

| Best Use Case | Everyday wear, formal occasions, and fashion statements | Casual and formal trousers, especially for larger sizes | Formal wear, specifically with stockings for women |

Detailed Breakdown of Alternatives

Suspenders

Suspenders are an excellent alternative for those seeking a functional yet stylish solution to keep trousers in place. They distribute weight evenly across the shoulders, alleviating pressure on the waist. This makes them particularly appealing for individuals who find belts uncomfortable or restrictive. Suspenders are generally cost-effective and come in various materials and styles, suitable for both casual and formal settings. However, they may require regular adjustments, which could be a drawback for some users.

Garter Straps

Garter straps serve a niche but essential role in the fashion industry, primarily used to keep stockings in place. These straps can add a layer of elegance to formal attire, particularly in settings such as weddings or evening events. While they offer a unique aesthetic and functionality, they are often less practical for everyday use. The maintenance of garter straps can be more demanding, as they require careful washing and handling to maintain their elasticity and shape.

Illustrative image related to belt types

Conclusion: Choosing the Right Solution for Your Needs

When selecting between belt types and their alternatives, B2B buyers should consider the specific requirements of their target market. Factors such as performance, cost, and maintenance will vary based on the intended use case. For example, if comfort and style are priorities for a formal event, suspenders or garter straps may provide the desired aesthetic while offering functional support. Conversely, if versatility and durability are essential for everyday applications, traditional belt types may be the better choice. Ultimately, understanding the unique benefits of each option will empower buyers to make informed decisions that align with their business needs and customer expectations.

Essential Technical Properties and Trade Terminology for belt types

What Are the Key Technical Properties of Different Belt Types?

When selecting belts for industrial applications, understanding specific technical properties is crucial. Here are some essential specifications to consider:

-

Material Grade

The material grade refers to the quality and type of material used in the belt’s construction, such as leather, synthetic, or reinforced fabrics. Higher-grade materials typically offer better durability, resistance to wear, and performance under stress. For B2B buyers, selecting the appropriate material grade can significantly impact the longevity and reliability of the belt in operational settings. -

Belt Thickness

Belt thickness is a critical factor that influences the strength and flexibility of the belt. Thicker belts can handle heavier loads and provide more stability, while thinner belts may be more suitable for lighter applications. Buyers should assess the required thickness based on the specific application to ensure optimal performance and safety. -

Load Capacity

This specification indicates the maximum weight a belt can support without compromising its integrity. Load capacity is vital for applications in manufacturing, logistics, or any environment where belts are subjected to heavy loads. Understanding load capacity helps buyers choose belts that meet their operational demands without risking failure. -

Tolerance Levels

Tolerance levels define the allowable variations in dimensions and properties of the belt. This includes length, width, and material thickness. In B2B contexts, precise tolerances are essential for ensuring compatibility with machinery and equipment, thereby minimizing operational disruptions. -

Resistance Properties

Resistance properties, such as abrasion, chemical, and temperature resistance, determine how well a belt can withstand various environmental factors. For instance, belts used in food processing must meet stringent hygiene and chemical resistance standards. Buyers should evaluate these properties based on the operational environment to ensure the belt performs effectively under specific conditions.

What Are Common Trade Terms Related to Belt Types?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of belts, an OEM might manufacture belts that are then branded and sold by another company. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management. Suppliers often set MOQs to cover production costs, and buyers should negotiate these terms to align with their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. In the context of belts, an RFQ allows buyers to compare prices, quality, and delivery options from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. These terms outline who is responsible for costs, risks, and logistics during transportation. For international B2B buyers, understanding Incoterms is essential for managing shipping logistics and ensuring compliance with global trade regulations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is particularly important for businesses that rely on timely deliveries to maintain production schedules. Buyers should clarify lead times with suppliers to ensure they can meet their operational timelines.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing belts, ultimately enhancing their operational efficiency and supply chain management.

Navigating Market Dynamics and Sourcing Trends in the belt types Sector

What Are the Current Market Dynamics and Key Trends Affecting the Belt Types Sector?

The global belt types market is witnessing a dynamic shift influenced by several key factors. One significant driver is the increasing demand for fashion accessories that blend functionality with style. As consumers across Africa, South America, the Middle East, and Europe become more fashion-conscious, B2B buyers are compelled to offer a diverse range of belt types, from classic leather to innovative vegan materials. Additionally, the rise of e-commerce has made it easier for manufacturers and suppliers to reach international markets, allowing for more competitive pricing and expanded product offerings.

Emerging technologies are also reshaping sourcing trends within the belt types sector. Innovations such as digital supply chain management and data analytics are enhancing the efficiency of procurement processes. B2B buyers can leverage these technologies to streamline operations, reduce lead times, and improve inventory management. Furthermore, the trend toward customization is gaining traction, with buyers seeking bespoke solutions that cater to regional preferences and cultural nuances. This demand for personalized products is particularly pronounced in markets like Germany and Vietnam, where consumers value unique styles that reflect their identity.

How Is Sustainability Influencing Sourcing Decisions in the Belt Types Sector?

Sustainability is no longer a niche consideration; it has become a critical factor in the sourcing decisions of B2B buyers in the belt types sector. The environmental impact of manufacturing processes, particularly those involving leather and synthetic materials, has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who utilize eco-friendly materials, such as recycled plastics or plant-based leathers, and those who implement sustainable production methods.

Ethical sourcing is also gaining importance, as consumers demand transparency regarding the origins of their products. Certifications like Global Organic Textile Standard (GOTS) and Fair Trade are becoming essential for brands aiming to build trust with environmentally conscious consumers. For international buyers, aligning with suppliers who meet these standards not only helps mitigate environmental risks but also enhances brand reputation. Emphasizing sustainable practices can also open doors to new markets, particularly in regions where consumers are increasingly aware of and concerned about environmental issues.

What Is the Historical Context of Belt Types and Their Evolution?

The evolution of belts dates back to ancient civilizations, where they served both practical and decorative purposes. Initially, belts were primarily functional, used to secure garments or carry tools. However, over the centuries, they have transformed into essential fashion accessories that reflect personal style and cultural identity. From the gladiatorial belts of ancient Rome to the ornate embroidered belts of various cultures, the significance of belts has continually evolved.

In recent years, the belt types sector has embraced innovation, with advancements in materials and design. The introduction of vegan leather and tech-infused belts illustrates how the industry adapts to contemporary consumer demands. As B2B buyers navigate this landscape, understanding the historical context can provide insights into consumer preferences and market trends, allowing them to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of belt types

-

How do I choose the right belt type for my business needs?

Choosing the right belt type involves understanding your target market and the specific applications of the belts. Consider factors such as material, durability, and style preferences. For instance, full-grain leather belts may appeal to high-end retailers, while vegan options could attract eco-conscious consumers. Engage with suppliers to explore different styles, and request samples to assess quality before making a bulk purchase. Conduct market research to identify trending styles in your region, ensuring your selection aligns with consumer preferences. -

What are the best materials for belts in the current market?

The best materials for belts depend on the intended use and target demographic. Full-grain leather is popular for its durability and luxury appeal, while synthetic options like vegan leather are gaining traction for ethical considerations. Additionally, braided leather offers a unique aesthetic, and canvas materials are favored for casual styles. Evaluate the market trends in your region—such as sustainability in Europe or affordability in Africa—to determine which materials will resonate with your customers. -

What customization options are available for belt orders?

Customization options vary by supplier but typically include choices in color, material, buckle type, and size. Many manufacturers also offer personalized branding, such as embossed logos or custom packaging, which can enhance brand visibility. Discuss your specific requirements with potential suppliers to see if they can accommodate your needs, including minimum order quantities (MOQs) for custom designs. Ensure to request samples of customized products to verify quality before placing larger orders. -

How can I verify the reliability of a belt supplier?

To verify a supplier’s reliability, conduct thorough due diligence, including checking their business licenses, certifications, and customer reviews. Request references from previous clients and consider visiting their production facilities if feasible. Additionally, assess their responsiveness to inquiries and willingness to provide product samples. Joining trade associations or attending industry trade shows can also offer insights into reputable suppliers. Establish clear communication and expectations regarding quality and delivery timelines. -

What are typical minimum order quantities (MOQs) for belt products?

Minimum order quantities can vary significantly based on the supplier and the type of belt being ordered. For standard styles, MOQs might range from 100 to 500 units, while custom designs may require higher quantities, often starting at 500 to 1,000 units. Discuss MOQs upfront with suppliers to ensure they align with your business needs and budget. If you are a smaller business, consider negotiating lower MOQs for initial orders or exploring suppliers that cater to smaller enterprises. -

What payment terms should I expect when sourcing belts internationally?

Payment terms can differ widely among suppliers but typically include options like advance payments, letters of credit, or payment upon delivery. For international transactions, it’s common to negotiate a 30-50% deposit with the balance due before shipment. Be cautious of suppliers requesting full payment upfront, especially if they are new or unverified. Always ensure that payment terms are documented in your contract to avoid misunderstandings and protect your investment. -

How do I ensure quality assurance for my belt orders?

To ensure quality assurance, establish clear specifications for your belt orders, including materials, dimensions, and finishing details. Request samples before committing to larger orders to evaluate craftsmanship and material quality. Many suppliers offer quality control inspections, so discuss this option to confirm that products meet your standards before shipment. Additionally, consider third-party inspection services to conduct quality checks at the factory if you are placing a large or critical order. -

What logistics considerations should I keep in mind for international shipping of belts?

When shipping belts internationally, consider factors such as shipping costs, delivery times, and customs regulations in your target market. Engage with logistics partners experienced in international shipping to navigate potential challenges. Ensure your supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin. Additionally, factor in shipping insurance to protect your investment during transit and choose reliable shipping methods that align with your delivery timelines.

Top 3 Belt Types Manufacturers & Suppliers List

1. GRIP6 – Modern Adjustable Belts

Domain: grip6.com

Registered: 2012 (13 years)

Introduction: GRIP6 offers modern, high-quality belts that excel in both functionality and style. Key features include: 1. Slide Belt Innovation: Infinite adjustability with a sleek, minimalist appearance. 2. Durable Materials: Aerospace-grade aluminum buckles and military-grade webbing ensure long-lasting performance. 3. TSA Compliance: Options like the Forged Carbon Fiber Belt are ideal for frequent travelers…

2. AutoZone – Types of Engine Belts

Domain: autozone.com

Registered: 1995 (30 years)

Introduction: Types of Engine Belts: 1. Serpentine Belts: – Drives multiple components (alternator, power steering pump, air conditioning compressor) – Lasts between 50,000 to 100,000 miles – Regular inspection for cracks, glazing, or fraying is essential. 2. Timing Belts: – Synchronizes crankshaft and camshaft movement – Critical for valve and piston movement – Replacement interval: 60,000 to 100,000 miles – N…

3. Obscure Belts – High Quality Leather Belts

Domain: obscurebelts.com

Registered: 2005 (20 years)

Introduction: High quality leather belts are made using full grain leather from a double butt cut hide in 8.5 – 9.5 ounce thickness. The main types of leather used in belt making include: 1. Full-grain leather – known for durability, style, eco-friendly qualities, and natural variation. 2. Corrected grain leather – a type of top grain leather that is sanded and embossed for a uniform appearance. 3. Split grain …

Strategic Sourcing Conclusion and Outlook for belt types

In the competitive landscape of international business, understanding the diverse types of belts and their applications is crucial for strategic sourcing. From full-grain leather belts that exemplify durability and elegance to innovative vegan options appealing to eco-conscious consumers, each belt type serves specific market needs. Buyers should prioritize quality, supplier reliability, and ethical sourcing practices to enhance brand reputation and customer satisfaction.

Illustrative image related to belt types

The value of strategic sourcing lies in its ability to streamline procurement processes, reduce costs, and foster long-term partnerships with manufacturers. By leveraging local and international suppliers, businesses can access a broader range of materials and styles, catering to diverse consumer preferences across regions, including Africa, South America, the Middle East, and Europe.

As the belt market evolves, staying attuned to trends such as sustainability and customization will be vital. B2B buyers are encouraged to explore innovative sourcing strategies and maintain agility in their supply chains. Engaging with suppliers who share a commitment to quality and ethical practices will not only enhance product offerings but also position brands favorably in an increasingly conscious marketplace. Embrace these insights to drive your sourcing strategy forward and capitalize on emerging opportunities in the belt industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to belt types