Introduction: Navigating the Global Market for custom leather patches

In today’s competitive landscape, sourcing custom leather patches poses significant challenges for B2B buyers, particularly when navigating the diverse international market. As businesses in regions like Africa, South America, the Middle East, and Europe strive to enhance their brand identity, the demand for personalized, high-quality leather patches continues to rise. This comprehensive guide delves into the intricate world of custom leather patches, offering invaluable insights into various types, applications, and sourcing strategies.

From understanding different patch materials and designs to exploring the latest trends in customization, this guide equips buyers with the knowledge necessary to make informed purchasing decisions. It also provides essential criteria for vetting suppliers, ensuring that businesses can identify reliable partners capable of delivering quality products on time and within budget.

Whether you’re looking to create branded merchandise for promotional events or enhance the aesthetic appeal of products, this resource serves as your roadmap for successful procurement. By addressing key aspects such as cost analysis, production timelines, and the importance of sustainable sourcing practices, this guide empowers international B2B buyers to confidently navigate the complexities of the custom leather patch market, ultimately driving brand loyalty and customer engagement.

Table Of Contents

- Top 8 Custom Leather Patches Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather patches

- Understanding custom leather patches Types and Variations

- Key Industrial Applications of custom leather patches

- 3 Common User Pain Points for ‘custom leather patches’ & Their Solutions

- Strategic Material Selection Guide for custom leather patches

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather patches

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather patches’

- Comprehensive Cost and Pricing Analysis for custom leather patches Sourcing

- Alternatives Analysis: Comparing custom leather patches With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather patches

- Navigating Market Dynamics and Sourcing Trends in the custom leather patches Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather patches

- Strategic Sourcing Conclusion and Outlook for custom leather patches

- Important Disclaimer & Terms of Use

Understanding custom leather patches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Embroidered Leather Patches | Features intricate designs stitched onto leather. | Apparel, uniforms, promotional items. | Pros: High durability, customizable designs. Cons: Higher production time and cost. |

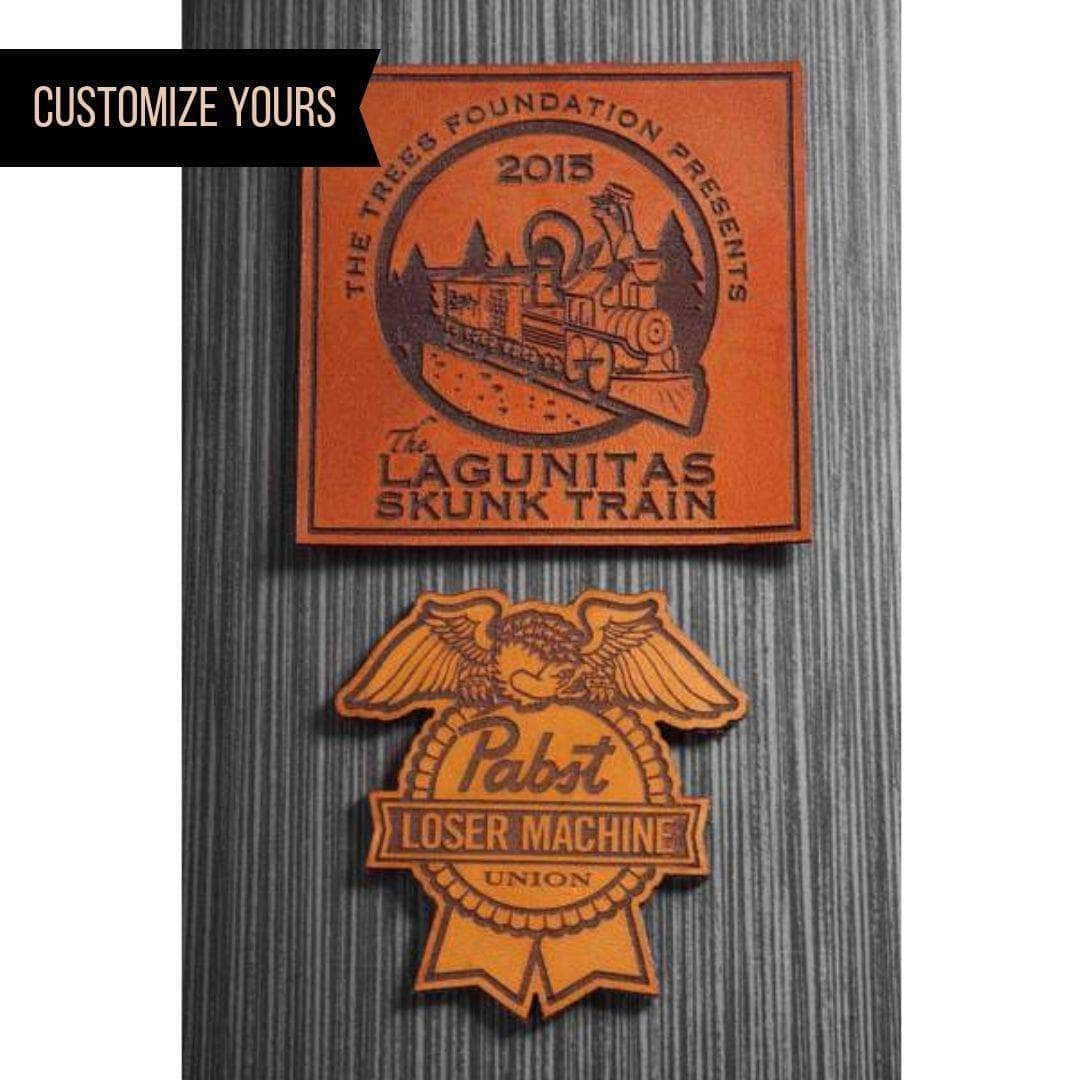

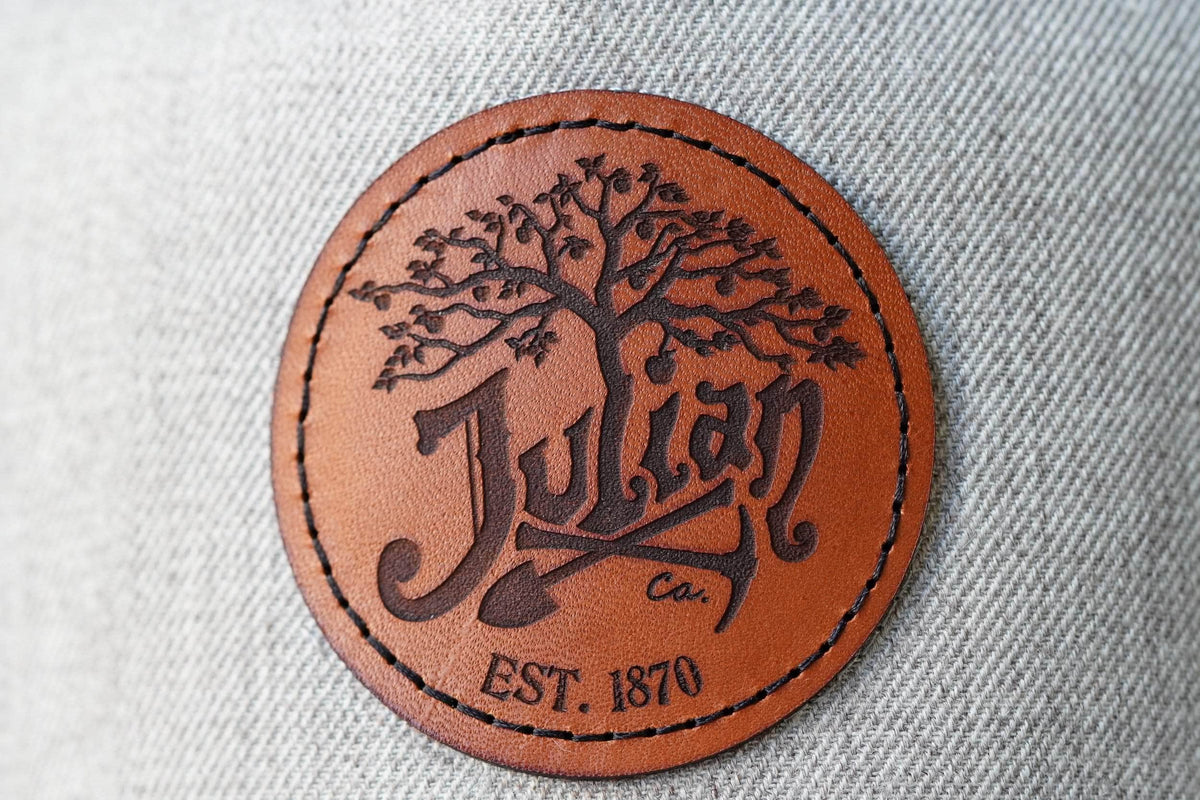

| Laser-Engraved Leather Patches | Uses precision laser technology for detailed engravings. | Corporate branding, personalized gifts. | Pros: Permanent designs, precise detail. Cons: Limited color options. |

| Iron-On Leather Patches | Backed with adhesive for easy application without sewing. | Casual wear, event merchandise. | Pros: Simple application, cost-effective. Cons: May not adhere well to all leather types. |

| Die-Cut Leather Patches | Cut into specific shapes, providing unique designs. | Fashion accessories, branding, and logos. | Pros: Unique shapes, strong visual impact. Cons: Can be more expensive due to custom cuts. |

| Hook-and-Loop Leather Patches | Equipped with Velcro for easy attachment and removal. | Tactical gear, outdoor apparel, and bags. | Pros: Reusable, versatile application. Cons: May wear out over time, requiring replacement. |

What Are the Key Characteristics of Embroidered Leather Patches?

Embroidered leather patches are characterized by their detailed stitching, which adds texture and depth to the design. These patches are highly durable, making them suitable for items that undergo regular wear and tear, such as uniforms and promotional apparel. When purchasing, businesses should consider the complexity of the design, as intricate patterns may lead to longer production times and higher costs.

Illustrative image related to custom leather patches

How Do Laser-Engraved Leather Patches Stand Out?

Laser-engraved leather patches utilize advanced laser technology to create precise and permanent engravings. This method is ideal for branding purposes, as logos and text can be intricately designed to maintain clarity over time. B2B buyers should focus on the material quality and the engraving depth, ensuring that the final product aligns with their branding needs while providing a professional appearance.

Why Choose Iron-On Leather Patches for Casual Applications?

Iron-on leather patches are designed for easy application, requiring no sewing, making them an attractive option for casual wear and event merchandise. Their adhesive backing allows for quick attachment, which is beneficial for businesses looking to produce items rapidly. However, buyers must be cautious about the type of leather, as not all materials will hold the adhesive effectively.

What Advantages Do Die-Cut Leather Patches Offer?

Die-cut leather patches are cut into specific shapes, providing a unique aesthetic that can enhance branding or fashion items. This type of patch is particularly effective for businesses wanting to make a strong visual impact with their logos or designs. However, the cost can be higher due to the custom cutting process, so businesses should evaluate their budget against the desired impact.

Illustrative image related to custom leather patches

When to Use Hook-and-Loop Leather Patches?

Hook-and-loop leather patches, commonly known as Velcro patches, offer the advantage of reusability, making them ideal for tactical gear or outdoor apparel where attachments may need to be changed frequently. Their versatility is a significant selling point for businesses that require adaptable solutions. However, potential buyers should be aware that the wear and tear on the Velcro may necessitate replacements, impacting long-term costs.

Key Industrial Applications of custom leather patches

| Industry/Sector | Specific Application of custom leather patches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom branding on jackets, hats, and bags | Enhances brand identity and creates unique fashion statements | Ensure high-quality leather, customization options, and durability |

| Outdoor Gear and Equipment | Patches for backpacks and camping gear | Increases product visibility and promotes brand loyalty | Look for weather-resistant materials and robust attachment methods |

| Automotive | Custom patches for car seat covers and interiors | Adds a personalized touch and can enhance resale value | Focus on compatibility with various materials and color matching |

| Corporate Gifts | Personalized patches for employee uniforms | Strengthens team spirit and enhances company image | Consider bulk pricing and quick turnaround times for events |

| Sports Teams | Team logo patches for jerseys and merchandise | Fosters team unity and enhances fan engagement | Ensure high visibility and durability for frequent wear and washing |

How Are Custom Leather Patches Used in the Fashion and Apparel Industry?

In the fashion and apparel industry, custom leather patches are utilized to add unique branding to various clothing items, such as jackets, hats, and bags. These patches allow brands to stand out in a crowded market, enhancing their identity and appeal. For international buyers, sourcing high-quality leather that meets local fashion standards is crucial, along with options for customization that reflect regional styles and preferences.

What Role Do Custom Leather Patches Play in Outdoor Gear and Equipment?

Custom leather patches are increasingly popular in the outdoor gear sector, particularly on backpacks and camping equipment. They serve not only as branding tools but also as functional elements that can withstand the rigors of outdoor use. Buyers should prioritize sourcing weather-resistant materials and robust attachment methods to ensure longevity, especially in challenging environments typical in regions like Africa and South America.

How Are Custom Leather Patches Beneficial in the Automotive Sector?

In the automotive industry, custom leather patches can be used on car seat covers and interiors to add a personalized touch. This application not only enhances the aesthetic appeal but can also improve resale value by making vehicles more unique. B2B buyers should focus on sourcing patches that are compatible with various materials used in car interiors, ensuring that colors and textures match existing designs.

Why Are Custom Leather Patches Important for Corporate Gifts?

Corporate gifts that include personalized leather patches for employee uniforms can significantly strengthen team spirit and enhance a company’s image. These patches can display logos or motivational messages, creating a sense of belonging among employees. For buyers, it is essential to consider bulk pricing options and quick turnaround times, especially when planning for events or employee recognition days.

Illustrative image related to custom leather patches

How Do Custom Leather Patches Foster Team Unity in Sports Teams?

Sports teams frequently use custom leather patches on jerseys and merchandise to foster unity and enhance fan engagement. These patches can display team logos, player names, or motivational slogans, making them an integral part of the team’s identity. Buyers should ensure that the patches are designed for durability, considering that they will undergo frequent wear and washing, particularly in competitive environments across Europe and the Middle East.

3 Common User Pain Points for ‘custom leather patches’ & Their Solutions

Scenario 1: Customization Limitations in Bulk Orders

The Problem: Many B2B buyers, especially those sourcing custom leather patches for promotional events or corporate branding, face challenges when it comes to customization options. They often find that suppliers have limited designs, colors, or sizes, which can hinder their ability to create unique patches that align with their brand identity. This limitation can lead to frustration, especially when trying to meet specific branding requirements for different markets or regions.

The Solution: To overcome this challenge, buyers should prioritize partnering with suppliers that offer extensive customization options. Look for manufacturers that provide a wide range of leather types, colors, and finishes, as well as various attachment methods (e.g., sew-on, iron-on, Velcro). When placing bulk orders, communicate your specific needs upfront and ask for digital mockups to visualize the final product before production begins. Additionally, consider suppliers that specialize in custom designs and can accommodate unique requests, ensuring your patches reflect your brand’s identity effectively. Establishing a solid relationship with a reliable supplier can also facilitate better communication regarding customization capabilities, allowing for a smoother ordering process.

Scenario 2: Quality Assurance and Material Concerns

The Problem: Quality control is a significant concern for B2B buyers when sourcing custom leather patches. Many buyers have reported receiving patches made from subpar materials that do not meet durability expectations or have inconsistent quality, leading to potential dissatisfaction among end-users. This is particularly important for businesses in sectors like apparel, outdoor gear, or promotional merchandise, where product quality directly impacts brand reputation.

The Solution: To ensure high-quality custom leather patches, buyers should conduct thorough research on potential suppliers before placing orders. Look for manufacturers with a proven track record of using premium materials, such as full-grain leather, which offers superior durability and aesthetic appeal. Request samples to evaluate the material quality and craftsmanship before committing to larger orders. Additionally, inquire about the supplier’s quality assurance processes, including how they handle defects or inconsistencies. Establishing clear quality benchmarks and expectations in your initial discussions can help mitigate risks associated with receiving inferior products.

Scenario 3: Long Lead Times Affecting Project Timelines

The Problem: B2B buyers often experience long lead times when ordering custom leather patches, which can disrupt project timelines, especially for events or product launches. Delays in production or shipping can result in missed deadlines, leading to financial losses and reputational damage. Buyers in regions like Africa or South America may face additional challenges due to logistical hurdles or customs regulations, exacerbating the issue.

The Solution: To combat long lead times, buyers should seek suppliers that offer transparent timelines and reliable shipping options. During the initial inquiry, ask for estimated production and delivery times, and ensure these align with your project deadlines. Consider suppliers that provide expedited shipping options or have local manufacturing capabilities to reduce transit times. When placing orders, factor in potential delays by allowing for a buffer period in your timeline. Engaging with suppliers who have efficient production processes and strong logistics partnerships can significantly reduce the risk of delays, ensuring your custom leather patches arrive on time for your events or launches.

Strategic Material Selection Guide for custom leather patches

What Are the Common Materials Used for Custom Leather Patches?

When selecting materials for custom leather patches, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. Here, we analyze four common materials: full-grain leather, top-grain leather, synthetic leather, and suede. Each material has unique characteristics that can influence the final product’s performance and suitability for various applications.

Illustrative image related to custom leather patches

How Does Full-Grain Leather Compare for Custom Patches?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, preserving the natural grain. This material exhibits excellent durability and breathability, making it resistant to wear and tear. Full-grain leather can withstand high temperatures and pressure, ensuring longevity in various applications.

Pros: Its natural look and feel enhance the aesthetic appeal of custom patches, making them suitable for high-end products. Additionally, full-grain leather develops a unique patina over time, adding character.

Cons: However, full-grain leather can be more expensive than other options, which may affect budget considerations for bulk orders. The manufacturing process is also more complex, requiring skilled artisans.

Impact on Application: Full-grain leather is ideal for premium products, such as jackets and bags, where durability and style are paramount.

Illustrative image related to custom leather patches

Considerations for International Buyers: Buyers from regions like Africa or South America should ensure compliance with local leather quality standards, such as ASTM or DIN, to avoid issues with import regulations.

What Are the Benefits of Top-Grain Leather for Custom Patches?

Top-grain leather is slightly less durable than full-grain but still offers a good balance of quality and cost. It is sanded and treated to remove imperfections, resulting in a smoother surface.

Pros: This material is more affordable than full-grain leather while still providing a premium look. It is also easier to work with during the manufacturing process, allowing for quicker production times.

Illustrative image related to custom leather patches

Cons: The downside is that top-grain leather is less resistant to scratches and wear compared to full-grain leather, which could affect its longevity in high-use applications.

Impact on Application: Top-grain leather is suitable for a variety of products, including apparel and accessories, where a balance of aesthetics and functionality is needed.

Considerations for International Buyers: Buyers should consider the availability of top-grain leather in their local markets and ensure it meets the necessary quality standards for their applications.

How Does Synthetic Leather Perform for Custom Leather Patches?

Synthetic leather, or faux leather, is made from plastic materials designed to mimic the look and feel of natural leather. It is increasingly popular due to its affordability and versatility.

Pros: Synthetic leather is highly resistant to water and stains, making it suitable for outdoor applications. It is also easier to clean and maintain compared to natural leather.

Illustrative image related to custom leather patches

Cons: However, synthetic leather lacks the breathability and durability of genuine leather, which may limit its use in high-end products. It also does not develop a patina, which can detract from its aesthetic appeal over time.

Impact on Application: This material is often used in budget-friendly products, such as promotional items or fashion accessories, where cost is a significant factor.

Considerations for International Buyers: Buyers should verify that synthetic leather complies with environmental regulations, especially in regions with strict standards for materials.

What Role Does Suede Play in Custom Leather Patches?

Suede is made from the underside of the animal hide, resulting in a soft, textured finish. It is often used in fashion applications due to its unique appearance.

Illustrative image related to custom leather patches

Pros: Suede offers a luxurious feel and is available in various colors, enhancing design flexibility. It is also relatively lightweight, making it suitable for apparel.

Cons: The main drawback is its susceptibility to stains and moisture, which can limit its use in certain environments. Additionally, suede requires more care in maintenance.

Impact on Application: Suede is best suited for fashion items and custom patches that prioritize aesthetics over durability.

Considerations for International Buyers: Buyers should consider the climatic conditions of their regions, as suede may not perform well in humid or wet environments.

Illustrative image related to custom leather patches

Summary Table of Material Selection for Custom Leather Patches

| Material | Typical Use Case for custom leather patches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Premium apparel, high-end bags | Exceptional durability and aesthetics | Higher cost, complex manufacturing | High |

| Top-Grain Leather | General apparel, accessories | Good balance of quality and cost | Less durable than full-grain | Medium |

| Synthetic Leather | Budget-friendly items, promotional products | Water-resistant and easy to maintain | Lacks durability and breathability | Low |

| Suede | Fashion items, luxury patches | Luxurious feel and design flexibility | Susceptible to stains and moisture | Medium |

This guide provides a comprehensive overview of the materials available for custom leather patches, helping international B2B buyers make informed decisions that align with their specific needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather patches

What Are the Key Stages in the Manufacturing Process of Custom Leather Patches?

The manufacturing of custom leather patches typically involves several crucial stages, each contributing to the final product’s quality and appeal. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Types of Leather Are Commonly Used?

The initial stage of the manufacturing process involves selecting and preparing the leather. Full-grain leather is a popular choice due to its durability and natural appearance. Other options include top-grain and suede leather, each offering different aesthetics and functional characteristics.

During material preparation, the leather is cut into sheets of the required size and shape. This process often utilizes advanced cutting techniques, such as laser cutting, which ensures precision and minimizes waste. Additionally, buyers can request specific finishes or treatments, such as dyeing or waterproofing, to enhance the leather’s performance based on its intended use.

2. Forming: How Are Custom Designs Created?

Once the leather is prepared, the next step is forming the patches according to custom designs. This involves either stamping, embossing, or engraving the desired logos or text onto the leather. Laser engraving is particularly popular for its ability to produce intricate designs that are permanent and resistant to fading.

Illustrative image related to custom leather patches

The forming stage may also include die-cutting, where patches are shaped into unique forms that align with the buyer’s branding requirements. This process is essential for creating distinctive patches that stand out, especially in competitive markets.

3. Assembly: How Are Patches Attached to Garments?

After forming, the patches are assembled and attached to their respective products. Depending on the application, there are several attachment methods available, including sewing, heat transfer, or using hook and loop fasteners. B2B buyers should consider the end-use of the patches when selecting an attachment method, as each has its pros and cons.

For instance, iron-on patches are convenient for quick applications but may not be suitable for high-stress areas. Conversely, sewn patches offer superior durability, making them ideal for workwear or outdoor gear.

4. Finishing: What Enhancements Are Applied?

The finishing stage involves applying any final treatments that enhance the patches’ aesthetics and longevity. This may include edge finishing to prevent fraying, applying protective coatings, or adding embellishments like embroidery or decorative stitching.

Illustrative image related to custom leather patches

Quality finishing not only improves the visual appeal of the patches but also contributes to their overall durability. Buyers should inquire about the specific finishing processes used by suppliers to ensure that the patches will meet their quality standards.

What Quality Assurance Measures Are Essential for Custom Leather Patches?

Quality assurance (QA) is a critical aspect of the manufacturing process for custom leather patches. Implementing robust QA measures ensures that products meet international standards and the specific expectations of B2B buyers.

1. What Are the Relevant International Standards for Leather Products?

For manufacturers, adhering to international standards such as ISO 9001 is essential. This certification indicates that a company has established a quality management system that consistently provides products that meet customer and regulatory requirements.

In addition to ISO standards, other certifications may apply, such as CE marking for compliance with European health, safety, and environmental protection standards, or API standards for certain industrial applications. B2B buyers should verify that their suppliers hold these certifications, as they reflect a commitment to quality.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints play a vital role throughout the manufacturing process. Key checkpoints include:

Illustrative image related to custom leather patches

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Buyers can request reports on IQC processes to verify the quality of materials used.

-

In-Process Quality Control (IPQC): During production, regular checks are performed to monitor the manufacturing processes and ensure adherence to quality standards. This may involve measuring dimensions, checking finishes, and testing attachment methods.

-

Final Quality Control (FQC): After production, a thorough inspection is conducted before shipment. This includes checking for defects, ensuring that design specifications are met, and confirming that the final product performs as intended.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that suppliers maintain high-quality standards:

-

Supplier Audits: Conducting on-site audits provides insight into a supplier’s manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline the QC processes, inspection results, and any corrective actions taken during production.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the products before shipment. This is particularly important for international transactions where buyers may not have the ability to inspect the products themselves.

What Are the Challenges and Considerations for International B2B Buyers?

When sourcing custom leather patches, international buyers face unique challenges, particularly in regions like Africa, South America, the Middle East, and Europe. Factors such as varying quality standards, logistical issues, and cultural differences can impact procurement.

1. Navigating Different Quality Standards

Buyers must be aware of the specific quality standards applicable in their regions. For instance, while ISO 9001 is recognized globally, regional standards may vary. Understanding these nuances can prevent compliance issues and ensure that products meet local regulations.

2. Logistics and Supply Chain Considerations

International shipping and logistics can complicate the procurement process. Delays, tariffs, and customs regulations may affect delivery timelines and costs. B2B buyers should work closely with suppliers to understand shipping options and potential challenges to ensure timely delivery.

3. Cultural Sensitivity and Communication

Cultural differences can impact negotiations and communication. Buyers should approach suppliers with an understanding of local customs and practices, fostering a collaborative relationship that can lead to better outcomes.

Illustrative image related to custom leather patches

By being informed about the manufacturing processes and quality assurance measures for custom leather patches, B2B buyers can make strategic decisions that enhance their product offerings and ensure customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather patches’

Introduction

This guide provides a comprehensive checklist for B2B buyers looking to source custom leather patches. Whether you are in the fashion industry, promotional products, or any sector requiring branding solutions, following these steps will help ensure that you select the right supplier and product to meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify your requirements. Consider the type of leather, size, shape, and design details of the patches you need.

– Material Considerations: Full-grain leather offers durability and a premium feel, while synthetic options may be more cost-effective.

– Design Complexity: Determine if you require simple designs or intricate laser engravings, as this will affect the production process and cost.

Illustrative image related to custom leather patches

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in custom leather patches. Look for companies that have a proven track record in your industry.

– Supplier Reviews: Check online reviews and testimonials to gauge customer satisfaction.

– Portfolio Evaluation: Examine their previous work to ensure they can deliver the quality and design you envision.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers hold relevant certifications and comply with international quality standards. This is crucial for ensuring product safety and consistency.

– ISO Certifications: Look for suppliers with ISO certifications, as they demonstrate a commitment to quality management.

– Sustainability Practices: Inquire about the sourcing of leather and whether the supplier adheres to environmentally friendly practices.

Step 4: Request Samples

Before placing a bulk order, request samples of the patches you’re considering. This step allows you to assess the quality and craftsmanship firsthand.

– Quality Assessment: Evaluate the texture, durability, and finish of the leather.

– Design Verification: Ensure that the design meets your expectations in terms of clarity and precision.

Step 5: Discuss Pricing and Minimum Order Quantities

Engage in discussions about pricing structures and minimum order quantities. Understanding the financial aspects upfront helps you budget effectively.

– Bulk Discounts: Inquire about price breaks for larger orders, which can significantly impact your overall costs.

– Hidden Fees: Be aware of any additional fees, such as setup or shipping costs, to avoid surprises later in the procurement process.

Step 6: Clarify Production and Delivery Timelines

Establish clear timelines for production and delivery. This step is essential to ensure that your patches arrive when needed, especially for events or promotional activities.

– Lead Times: Ask suppliers about their typical lead times and whether they can accommodate urgent requests.

– Shipping Options: Explore shipping methods and costs, particularly if you are sourcing from international suppliers.

Step 7: Review Contract Terms Carefully

Once you’ve chosen a supplier, review the contract terms meticulously before signing. This ensures that all agreed-upon details are documented and provides legal protection.

– Payment Terms: Clarify payment schedules and methods to avoid any misunderstandings.

– Return Policies: Understand the return or replacement policies in case the delivered patches do not meet your specifications.

By following this checklist, you can confidently navigate the sourcing process for custom leather patches, ensuring a successful partnership with your chosen supplier.

Comprehensive Cost and Pricing Analysis for custom leather patches Sourcing

What Are the Key Cost Components in Custom Leather Patches Sourcing?

When sourcing custom leather patches, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of leather significantly impacts the cost. Full-grain leather, known for its durability and aesthetic appeal, typically commands a higher price compared to bonded or synthetic leather. Additional materials for customization, such as threads for embroidery or adhesives for backing, also contribute to the overall material costs.

-

Labor: Labor costs vary based on the complexity of the design and the manufacturing processes involved. Skilled artisans may be required for intricate designs, which can increase labor costs. Conversely, simpler patches may require less skilled labor, reducing costs.

-

Manufacturing Overhead: This includes expenses related to running the production facility, such as utilities, equipment maintenance, and administrative costs. Efficient production processes can help minimize overhead.

-

Tooling: Custom molds or dies for specific designs incur tooling costs. These are often amortized over larger production runs, making them less impactful per unit for bulk orders.

-

Quality Control (QC): Implementing a robust QC process ensures that the patches meet quality standards. While this may introduce additional costs, it can prevent costly returns and maintain brand reputation.

-

Logistics: Transportation costs can vary based on the distance from the manufacturing facility to the buyer, as well as the chosen shipping method. International shipping may involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers will add a margin to cover their profit, which can vary widely based on market conditions and competitive landscape.

What Influences the Pricing of Custom Leather Patches?

Several factors influence the pricing of custom leather patches, which can be pivotal for B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Higher quantities typically reduce the per-unit cost. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom designs, sizes, and additional features like laser engraving or special finishes can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Premium materials and certifications (e.g., eco-friendly or fair-trade) may elevate costs. Buyers looking for high-quality patches should be prepared to invest more upfront for better longevity.

-

Supplier Factors: Supplier reputation, location, and production capabilities can impact pricing. Established suppliers may charge more due to perceived reliability and quality assurance.

-

Incoterms: The choice of Incoterms affects logistics costs and risks. Buyers should understand the implications of terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) to negotiate better shipping arrangements.

How Can Buyers Optimize Costs When Sourcing Custom Leather Patches?

To achieve cost-efficiency in sourcing custom leather patches, buyers should consider the following tips:

Illustrative image related to custom leather patches

-

Negotiate Effectively: Leverage volume commitments and long-term partnerships to negotiate better pricing. Understanding market rates can empower buyers during discussions.

-

Total Cost of Ownership: Evaluate the total cost of ownership, including shipping, customs duties, and potential returns. A lower initial price may not always equate to overall savings.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide insights into competitive pricing and help identify the best fit for quality and cost.

-

Consider Local Suppliers: For international buyers, sourcing from local manufacturers can reduce shipping costs and lead times, providing a competitive advantage.

-

Stay Informed on Market Trends: Understanding global market trends, particularly in regions like Africa, South America, the Middle East, and Europe, can help buyers anticipate price fluctuations and plan purchases accordingly.

Disclaimer on Indicative Prices

Prices for custom leather patches can vary widely based on the factors discussed. The examples provided are indicative and should be verified with suppliers for accurate quotes tailored to specific requirements.

Alternatives Analysis: Comparing custom leather patches With Other Solutions

When considering branding and personalization options for products, custom leather patches stand out for their aesthetic appeal and durability. However, businesses should evaluate alternatives that can also serve similar purposes. This section explores viable alternatives to custom leather patches, comparing their attributes to help B2B buyers make informed decisions.

| Comparison Aspect | Custom Leather Patches | Embroidered Patches | Printed Patches |

|---|---|---|---|

| Performance | High durability and premium feel | Good durability, vibrant colors | Moderate durability, may fade over time |

| Cost | Moderate to high ($9.00+) | Lower to moderate ($2.00 – $6.00) | Generally lower ($1.00 – $5.00) |

| Ease of Implementation | Requires sewing or iron-on method | Easy to attach, can be sewn or ironed | Simple application; often adhesive-backed |

| Maintenance | Low; may need occasional conditioning | Low; machine washable | Moderate; may require careful washing |

| Best Use Case | Fashion items, premium branding | Casual wear, team uniforms | Promotional items, event giveaways |

What Are the Benefits and Drawbacks of Embroidered Patches Compared to Custom Leather Patches?

Embroidered patches are a popular alternative, known for their vibrant colors and detailed designs. They typically offer a lower cost compared to leather patches, making them appealing for bulk orders. Their ease of application allows for quick attachment to a variety of fabrics. However, while they are durable, they may not match the premium feel of leather and can fade over time, which could affect brand perception. They are best suited for casual wear or team uniforms where cost efficiency is a priority.

Illustrative image related to custom leather patches

How Do Printed Patches Stack Up Against Custom Leather Patches?

Printed patches provide a cost-effective solution for businesses looking to create visually striking designs. They can reproduce intricate graphics and logos with high fidelity, making them suitable for promotional items and event giveaways. Their adhesive backing allows for easy application, which is a significant advantage for large-scale events. However, printed patches generally have a shorter lifespan and are more susceptible to wear and fading compared to custom leather options. They are best for temporary branding needs where budget constraints are a primary concern.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between custom leather patches and alternatives like embroidered or printed patches, B2B buyers should consider their specific branding goals, budget, and the intended use of the patches. If a premium, long-lasting impression is essential, custom leather patches are likely the best choice. However, for cost-sensitive projects or more casual applications, embroidered or printed patches may provide adequate solutions. Ultimately, understanding the unique attributes of each option will allow businesses to align their choice with their branding strategy effectively.

Essential Technical Properties and Trade Terminology for custom leather patches

What Are the Key Technical Properties of Custom Leather Patches?

When sourcing custom leather patches, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties that significantly impact the quality, durability, and suitability of leather patches for various applications.

1. Material Grade

The grade of leather, such as full-grain, top-grain, or genuine leather, determines the patch’s quality and durability. Full-grain leather, the highest quality, retains the natural texture and strength, making it ideal for high-end applications. Top-grain leather, while slightly less durable, offers a balance of cost and quality, suitable for everyday use. Genuine leather, often more affordable, is less durable but can be effective for promotional items. B2B buyers should consider the intended use of the patches to select the appropriate material grade.

Illustrative image related to custom leather patches

2. Thickness

Leather thickness, typically measured in ounces, is crucial for the patch’s durability and application method. Thicker patches are more robust and can withstand wear and tear, making them suitable for outdoor gear or heavy-duty applications. Conversely, thinner patches are more flexible and can be ideal for clothing or accessories where comfort is a priority. Understanding the thickness helps buyers align the product with their specific needs.

3. Customization Options

Customization capabilities, including engraving, embossing, or printing, enhance the uniqueness of leather patches. B2B buyers should evaluate the available customization options to ensure they can effectively showcase branding or logos. The choice of customization method can also influence the patch’s longevity and appearance, making it essential to consider how the customization will hold up over time.

4. Attachment Methods

Different attachment methods, such as sewing, iron-on, or hook and loop (Velcro), determine how the patches will be applied to garments or accessories. Each method has its pros and cons; for instance, sewing is the most durable but requires more labor, while iron-on is quicker but may not be as long-lasting. B2B buyers need to assess the application context to select the most suitable attachment method for their products.

5. Tolerance

Tolerance refers to the acceptable variation in size and shape during the manufacturing process. For custom leather patches, maintaining tight tolerances ensures consistency and quality, especially when producing large quantities. B2B buyers should inquire about the manufacturer’s tolerance standards to ensure the patches meet their specifications and quality expectations.

Illustrative image related to custom leather patches

What Are Common Trade Terms in the Custom Leather Patch Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the custom leather patch market. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of custom leather patches, an OEM might be a manufacturer that produces patches for brands that sell them under their own label. Understanding OEM relationships can help buyers identify reliable partners for their custom products.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of products that a supplier is willing to sell. For custom leather patches, MOQs can vary significantly based on the supplier and the complexity of the design. Buyers should clarify MOQs before placing orders to ensure they can meet their inventory needs without incurring excess costs.

Illustrative image related to custom leather patches

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the custom leather patch industry, an RFQ will typically include details about design specifications, materials, and quantities. This process is essential for obtaining competitive pricing and ensuring that suppliers can meet the buyer’s requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers for the delivery of goods. Understanding Incoterms is crucial for B2B buyers, especially when dealing with international suppliers, as they dictate who is responsible for shipping, insurance, and customs clearance.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the final product. In the custom leather patch industry, lead times can vary based on factors such as complexity of the design, quantity, and the manufacturer’s production schedule. Buyers should factor lead times into their planning to ensure timely delivery of products for events or promotions.

By understanding these key technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their custom leather patches meet their quality and branding needs.

Illustrative image related to custom leather patches

Navigating Market Dynamics and Sourcing Trends in the custom leather patches Sector

What Are the Key Market Drivers and Trends for Custom Leather Patches?

The custom leather patches market is experiencing significant growth, driven by a variety of global factors. Increased consumer demand for personalized products, especially in fashion and outdoor gear, has spurred manufacturers to offer a wider range of customizable options. This trend is particularly evident in regions like Africa, South America, the Middle East, and Europe, where brands are looking to differentiate themselves in competitive markets. Emerging technologies such as laser engraving and digital printing are enhancing the customization process, allowing for intricate designs and quicker turnaround times.

Additionally, B2B buyers are increasingly seeking suppliers who can offer scalable solutions without compromising quality. The rise of e-commerce platforms has streamlined the sourcing process, enabling buyers to access international suppliers with ease. In markets like Vietnam and Nigeria, local craftsmanship is being combined with modern manufacturing techniques, creating unique products that appeal to both domestic and international consumers. As a result, buyers are advised to keep an eye on suppliers who leverage technology for efficiency and quality assurance.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Patches Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the custom leather patches sector. The environmental impact of leather production has prompted many companies to seek alternatives that minimize harm to the planet. Sustainable leather options, such as vegetable-tanned leather, are gaining traction as buyers become more conscious of their choices. Additionally, suppliers that implement ethical supply chains and prioritize fair labor practices are increasingly favored by businesses looking to enhance their corporate social responsibility profiles.

Buyers should look for suppliers who offer certifications that verify sustainable practices, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications not only ensure compliance with environmental standards but also provide reassurance to consumers about the ethical considerations behind their purchases. Furthermore, the integration of recycled materials into the production of custom leather patches can appeal to eco-conscious buyers, making it a worthwhile investment for brands aiming to align with sustainability goals.

Illustrative image related to custom leather patches

How Has the Custom Leather Patches Market Evolved Over Time?

The custom leather patches market has evolved significantly from its origins, where patches primarily served functional purposes, such as mending or reinforcing clothing. As fashion trends shifted in the late 20th century, patches transformed into symbols of identity and personal expression, gaining popularity among various subcultures. The advent of digital technology has revolutionized the market, enabling intricate designs and mass customization that were previously unimaginable.

Today, custom leather patches are not just accessories; they have become a canvas for creativity, allowing brands and individuals alike to showcase their unique styles. This evolution reflects broader trends in consumer behavior, where personalization and quality craftsmanship are increasingly valued. As a result, the custom leather patches market is well-positioned to continue growing, driven by innovation and a demand for individuality.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather patches

-

How do I select the right supplier for custom leather patches?

Choosing the right supplier involves several key factors. First, evaluate their reputation by checking reviews and testimonials from previous clients. Next, assess their product quality by requesting samples, ensuring they meet your specifications. Additionally, verify their production capabilities, lead times, and minimum order quantities (MOQs) to align with your needs. Lastly, ensure clear communication regarding customization options, pricing, and logistics, particularly for international shipping, to avoid potential misunderstandings. -

What customization options are available for leather patches?

Customization options for leather patches are extensive. You can choose the size, shape, color, and type of leather used. Many suppliers offer options for embossing, laser engraving, or printing your logo or design onto the patch. Additionally, consider the attachment method—iron-on, sew-on, or Velcro—based on the intended use of the patch. Discuss your design requirements with the supplier to ensure they can accommodate your specific needs. -

What are the typical minimum order quantities (MOQs) for custom leather patches?

Minimum order quantities (MOQs) can vary significantly between suppliers. Generally, MOQs for custom leather patches range from 50 to 100 pieces, but some manufacturers may offer lower or higher quantities depending on their production capacity and your design complexity. It’s crucial to clarify MOQs during initial discussions to ensure they align with your purchasing needs and budget constraints. -

How can I ensure quality assurance for my custom leather patches?

To ensure quality assurance, collaborate closely with your supplier from the beginning. Request detailed product specifications and quality control measures they have in place. Establish a sampling process where you can review a prototype before full production. Additionally, inquire about their return or refund policies in case the final product does not meet agreed-upon standards. Regular communication throughout the production phase can also help identify and address potential issues early. -

What payment terms should I expect when sourcing custom leather patches?

Payment terms can vary widely among suppliers. Common practices include full payment upfront, a deposit followed by the balance upon completion, or net payment terms after delivery. As an international buyer, it’s essential to clarify payment methods accepted, such as credit card, bank transfer, or PayPal, and any associated fees. Understanding these terms early in the negotiation process can help prevent cash flow issues later on. -

What logistics considerations should I keep in mind when importing leather patches?

When importing custom leather patches, consider logistics aspects such as shipping methods, costs, and delivery timelines. Discuss with your supplier the best shipping options based on your location and urgency. Be aware of any customs duties and import regulations specific to your country that may affect delivery times and costs. It’s also wise to have a reliable freight forwarder to streamline the logistics process and ensure compliance with international trade laws. -

How do I handle language barriers when sourcing from international suppliers?

To navigate language barriers, consider working with suppliers that provide multilingual support or hiring a translator if necessary. Clear and concise communication is vital, so use simple language and avoid jargon. Visual aids, such as diagrams or images, can help convey your requirements more effectively. It may also be beneficial to establish a single point of contact within the supplier’s organization to streamline communication and reduce misunderstandings. -

What are the best practices for negotiating prices for bulk orders of custom leather patches?

When negotiating prices for bulk orders, research the market to understand standard pricing for similar products. Start by discussing your order volume and any potential long-term partnership, which can give you leverage. Be transparent about your budget constraints while expressing your interest in quality and service. Additionally, inquire about discounts for larger quantities or repeat orders, and consider discussing payment terms that might make the deal more appealing to both parties.

Top 8 Custom Leather Patches Manufacturers & Suppliers List

1. Oxand Pine – Custom Leather Patches

Domain: oxandpine.com

Registered: 2017 (8 years)

Introduction: Custom leather patches for all your projects! Handcrafted in the USA with 100% full grain leather. Personalization options available for logos, text, or initials. Prices start from $9.00. Available designs include American Flag, Arizona, Best Dad Ever, Bison, Bride (block and cursive), California Flag, Colorado Flag, Compass Rose, Cool Cat, Dad, Deer, Fish, Floral, Florida, Groom (block and cursiv…

2. Lazer Designs – Custom Laser Engraved Patches

Domain: lazerdesigns.com

Registered: 2002 (23 years)

Introduction: This company, Lazer Designs – Custom Laser Engraved Patches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Dekni Creations – Custom Leather Patches

Domain: deknicreations.com

Registered: 2011 (14 years)

Introduction: {“title”:”Custom Leather Patches – Engraved & USA Made”,”description”:”Custom Leather Patches made from premium full grain vegetable tanned leather, ideal for corporate gifting, company branding, or promotional events. Available for customization with your logo. Bulk discounts available. Made in the USA.”,”features”:[“Engraved leather patches”,”USA made”,”Premium full grain vegetable tanned leathe…

4. Stahls – Custom Leather Patches

Domain: stahls.com

Registered: 1996 (29 years)

Introduction: Custom Leather Patches for Apparel

– Material: Genuine leather

– Custom designs available

– Colors: Taupe, Caramel, Natural

– Ideal for: Hats, bags, heavy apparel (like outerwear not regularly laundered), and hard goods

– Application: Can be heat applied or stickered to any hard good

– Minimum order: 12 pieces

– Pre-production physical sample available for a fee (Limit QTY 1)

– Note: Etching depth…

5. Custom Woven Labels – Custom Leather Patches

Domain: customwovenlabels.com

Registered: 2004 (21 years)

Introduction: Custom leather patches for hats, jeans, and other apparel types. Made from high-quality genuine leather available in various colors. Options for embossing (raised) or debossing (pressed) designs. Ability to add a print color to specific areas. Sew-on patches with optional iron-on or peel & stick backing. Upload artwork for customization. Digital proof provided within 1 business day for approval. F…

6. Leather Patch Company – Custom Leather Patch Hats

Domain: leatherpatchcompany.com

Registered: 2017 (8 years)

Introduction: Authentic Leather Patch Hats, 100% Authentic Leather, Hand Stitched, Huge Hat Selection, Custom Patch Shapes, No Minimum Orders, Various Patch Shapes, Four Hide Colors: Natural Leather, Dark Brown Leather, Chestnut Leather, Black Leather, Customer Service Focus, Design-It-Yourself Option, Mock-Up Request Available.

7. MrPatch – Custom Leather Patches

Domain: mrpatch.com

Registered: 2010 (15 years)

Introduction: Leather patches: Custom-made leather patches available online. Ideal for premium clothing, accessories, and personalized gifts. Features include:

– Elegant and durable design with a natural texture.

– Unique patina that develops over time.

– Customization options: emboss, print, or embroider logos/designs.

– Delivery time: 14 working days from production approval.

– Minimum order: 10 pieces.

– Mea…

8. Etsy – Custom Leather Patches

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Custom Leather Patches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather patches

In the evolving landscape of custom leather patches, strategic sourcing emerges as a pivotal element for B2B buyers aiming to enhance their branding and product offerings. By leveraging high-quality materials and innovative customization options, businesses can differentiate themselves in competitive markets across Africa, South America, the Middle East, and Europe. The versatility of custom leather patches—from apparel to promotional items—provides a unique opportunity for companies to express individuality and foster brand loyalty.

Illustrative image related to custom leather patches

Key takeaways include the importance of understanding the sourcing process, selecting reliable suppliers, and considering factors such as customization capabilities, shipping logistics, and pricing structures. Engaging with manufacturers who prioritize quality and customer service can lead to long-term partnerships that drive business growth.

As you explore the potential of custom leather patches, consider how these products can not only enhance your brand’s aesthetic but also resonate with your target audience. The future of custom leather patches is bright, and with strategic sourcing, your business can stay ahead of trends and consumer demands. Embrace this opportunity to elevate your brand’s identity and connect with customers in meaningful ways. Start your journey today by reaching out to trusted suppliers and exploring the endless possibilities that custom leather patches offer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.