Introduction: Navigating the Global Market for marine leather fabric

In today’s competitive marketplace, sourcing high-quality marine leather fabric presents a significant challenge for B2B buyers across the globe. As industries ranging from marine upholstery to automotive manufacturing seek durable, weather-resistant materials, the demand for marine leather fabric has surged. This guide is designed to navigate the complex landscape of marine leather fabric, offering insights into various types, applications, and the intricacies of supplier vetting.

International buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Brazil and Nigeria—will find value in this comprehensive resource. We explore the myriad applications of marine leather fabric, from boat interiors to outdoor furniture, while providing actionable strategies for assessing quality and pricing. Additionally, we delve into supplier reliability and the importance of certifications, helping buyers make informed decisions that align with their specific needs and budget constraints.

By equipping B2B buyers with the knowledge to identify reputable suppliers and understand market dynamics, this guide empowers businesses to enhance their product offerings with superior marine leather fabric. Whether you are looking to enhance your manufacturing capabilities or streamline your supply chain, the insights provided here will facilitate smarter purchasing decisions and drive business growth.

Table Of Contents

- Top 6 Marine Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for marine leather fabric

- Understanding marine leather fabric Types and Variations

- Key Industrial Applications of marine leather fabric

- 3 Common User Pain Points for ‘marine leather fabric’ & Their Solutions

- Strategic Material Selection Guide for marine leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for marine leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘marine leather fabric’

- Comprehensive Cost and Pricing Analysis for marine leather fabric Sourcing

- Alternatives Analysis: Comparing marine leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for marine leather fabric

- Navigating Market Dynamics and Sourcing Trends in the marine leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of marine leather fabric

- Strategic Sourcing Conclusion and Outlook for marine leather fabric

- Important Disclaimer & Terms of Use

Understanding marine leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Marine Vinyl | Waterproof, UV resistant, mold/mildew resistant | Boat upholstery, outdoor furniture, car seats | Pros: Durable, easy to clean; Cons: Can fade if not properly maintained. |

| Синтетическая кожа | Soft texture, available in various colors and patterns | Upholstery for marine and recreational vehicles | Pros: Aesthetic appeal, lightweight; Cons: Less durable than vinyl in harsh conditions. |

| Neoprene | High elasticity, excellent water resistance | Wetsuits, protective covers, marine gear | Pros: Flexible, comfortable; Cons: Limited color options, can be pricier. |

| PVC Fabric | Cost-effective, versatile, and easy to work with | Tarpaulins, boat covers, outdoor storage | Pros: Budget-friendly, lightweight; Cons: Less durable than higher-end materials. |

| Leatherette | Faux leather look, easy to clean | Upholstery for luxury boats, furniture | Pros: Stylish appearance, affordable; Cons: May not withstand extreme conditions. |

What are the Characteristics and Suitability of Marine Vinyl Fabric?

Marine vinyl fabric is a popular choice for its waterproof and UV-resistant properties, making it ideal for outdoor applications. It is highly durable, withstanding extensive wear and tear, which is crucial for environments exposed to moisture and sunlight. This type of fabric is commonly used for boat upholstery, outdoor furniture, and car seats, providing both functionality and aesthetic appeal. Buyers should consider the maintenance requirements, as prolonged exposure to sunlight without proper protection can lead to fading.

How Does Synthetic Leather Compare in Marine Applications?

Synthetic leather offers a soft texture and a wide range of colors and patterns, appealing to businesses looking for aesthetic versatility. It is suitable for upholstery in marine and recreational vehicles, providing a balance between comfort and style. However, while it provides a visually appealing option, synthetic leather may not offer the same level of durability as marine vinyl, particularly in extreme weather conditions. B2B buyers should weigh the importance of aesthetics against long-term durability when making purchasing decisions.

What Makes Neoprene Ideal for Marine Gear?

Neoprene is recognized for its high elasticity and excellent water resistance, making it a prime material for wetsuits and protective covers. Its flexibility provides comfort and ease of movement, which is essential for marine activities. However, neoprene typically comes in limited color options and can be more expensive than other materials, which may affect budget-conscious buyers. When sourcing neoprene, businesses should consider the specific requirements of the marine applications to ensure optimal performance.

Why Choose PVC Fabric for Cost-Effective Solutions?

PVC fabric is a cost-effective option that is versatile and easy to work with, making it a popular choice for tarpaulins, boat covers, and outdoor storage solutions. While it is lightweight and budget-friendly, its durability may not match that of higher-end materials like marine vinyl. B2B buyers looking for economical solutions should evaluate the trade-off between cost and long-term performance when considering PVC fabric for their marine needs.

What Advantages Does Leatherette Offer for Luxury Upholstery?

Leatherette provides a stylish faux leather look that is easy to clean, making it an attractive option for upholstery in luxury boats and furniture. Its affordability and aesthetic appeal make it a favored choice among businesses aiming to create a sophisticated look without the high costs associated with genuine leather. However, leatherette may not withstand extreme marine conditions as effectively as other materials, so buyers should assess the specific application requirements to ensure longevity and performance.

Key Industrial Applications of marine leather fabric

| Industry/Sector | Specific Application of marine leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine and Boating | Boat Upholstery | Enhances aesthetic appeal and durability of marine interiors. | Ensure UV resistance, waterproofing, and colorfastness. |

| Автомобили | Custom Vehicle Interiors | Provides luxury feel while being resistant to wear and tear. | Look for abrasion resistance and compliance with safety standards. |

| Hospitality | Restaurant and Bar Furniture | Offers a stylish, easy-to-clean surface for high-traffic areas. | Consider stain resistance and ease of maintenance. |

| Marine Accessories | Outdoor Gear and Equipment | Delivers durability and weather resistance for outdoor use. | Check for mold/mildew resistance and overall durability. |

| Fashion and Retail | Handbags and Accessories | Combines style with functionality, appealing to luxury markets. | Source materials that meet ethical standards and are sustainably produced. |

How is Marine Leather Fabric Used in the Marine and Boating Industry?

Marine leather fabric is primarily utilized for boat upholstery, enhancing the aesthetic appeal and comfort of marine interiors. This fabric is designed to withstand harsh marine environments, providing excellent UV resistance and waterproofing. For B2B buyers in regions like Africa or South America, sourcing high-quality marine leather that meets local climate challenges is crucial. Additionally, buyers should consider the fabric’s colorfastness to prevent fading from sun exposure, ensuring a long-lasting investment.

What Role Does Marine Leather Fabric Play in the Automotive Sector?

In the automotive industry, marine leather fabric is often used for custom vehicle interiors, providing a luxurious feel while ensuring durability against wear and tear. This fabric is particularly beneficial for high-end vehicles, where aesthetics and comfort are paramount. International B2B buyers, especially from Europe, should prioritize suppliers that offer abrasion-resistant materials compliant with safety standards, ensuring both style and functionality in their automotive applications.

How Can Marine Leather Fabric Enhance Hospitality Settings?

Marine leather fabric finds significant application in the hospitality sector, particularly in restaurant and bar furniture. Its stylish design and easy-to-clean surfaces make it ideal for high-traffic areas, where durability and maintenance are critical. For businesses in the Middle East, sourcing marine leather that is stain-resistant and easy to maintain can enhance customer experience while reducing long-term upkeep costs. Buyers should also evaluate the fabric’s color options to align with their brand aesthetics.

What Are the Benefits of Marine Leather Fabric for Outdoor Gear?

Marine leather fabric is essential for the production of outdoor gear and equipment, delivering durability and weather resistance that are vital for outdoor applications. This fabric ensures that products can withstand extreme conditions while maintaining their appearance and functionality. B2B buyers in regions with diverse climates, such as Brazil and Nigeria, must consider sourcing materials that offer mold and mildew resistance, as well as overall durability to ensure longevity in outdoor settings.

How is Marine Leather Fabric Used in Fashion and Retail?

In the fashion and retail sector, marine leather fabric is increasingly used in the production of handbags and accessories, merging style with functionality. This fabric appeals to luxury markets due to its unique texture and durability. For international B2B buyers, particularly those focused on sustainability, sourcing marine leather that meets ethical standards is essential. Buyers should also evaluate the fabric’s versatility in design to cater to various consumer preferences while maintaining quality.

3 Common User Pain Points for ‘marine leather fabric’ & Their Solutions

Scenario 1: Challenges with Quality Assurance in Sourcing Marine Leather Fabric

The Problem: B2B buyers often face difficulties in ensuring the quality of marine leather fabric before making bulk purchases. This is particularly critical for businesses in regions with less stringent quality control standards. Many suppliers may not provide adequate certifications, leading to concerns over durability, UV resistance, and overall performance. In sectors like boat manufacturing or upholstery for outdoor furniture, subpar materials can result in costly product failures and damage to brand reputation.

The Solution: To mitigate these risks, buyers should prioritize sourcing from reputable suppliers who provide third-party testing certifications. Request documentation such as UV resistance ratings, mold and mildew resistance tests, and durability assessments (e.g., double rub counts). Additionally, consider ordering small samples or swatches before committing to larger quantities. This allows for physical inspection of the material’s texture, color consistency, and overall quality. Engaging in direct communication with suppliers about their quality assurance processes will also help establish trust and ensure that the materials meet specific industry standards.

Scenario 2: Difficulty in Choosing the Right Marine Leather Fabric for Specific Applications

The Problem: Another common pain point is the confusion surrounding the selection of marine leather fabric suitable for specific applications, such as boat interiors, outdoor furniture, or automotive upholstery. With a wide variety of materials available, each with different properties (like water resistance, stretchability, and thickness), buyers often struggle to determine which fabric will meet their project’s requirements without compromising on durability and aesthetics.

The Solution: Buyers should start by conducting a thorough needs assessment for their specific applications. This includes understanding the environmental conditions the fabric will be exposed to, such as sunlight, moisture, and temperature fluctuations. After identifying these requirements, buyers can consult with fabric suppliers to obtain tailored recommendations. For instance, a fabric with high UV resistance and cold crack ratings is ideal for outdoor use, while a softer, more flexible option might be better suited for boat interiors. Additionally, leveraging product specifications, such as weight (measured in ounces) and stretch properties, can further guide the decision-making process.

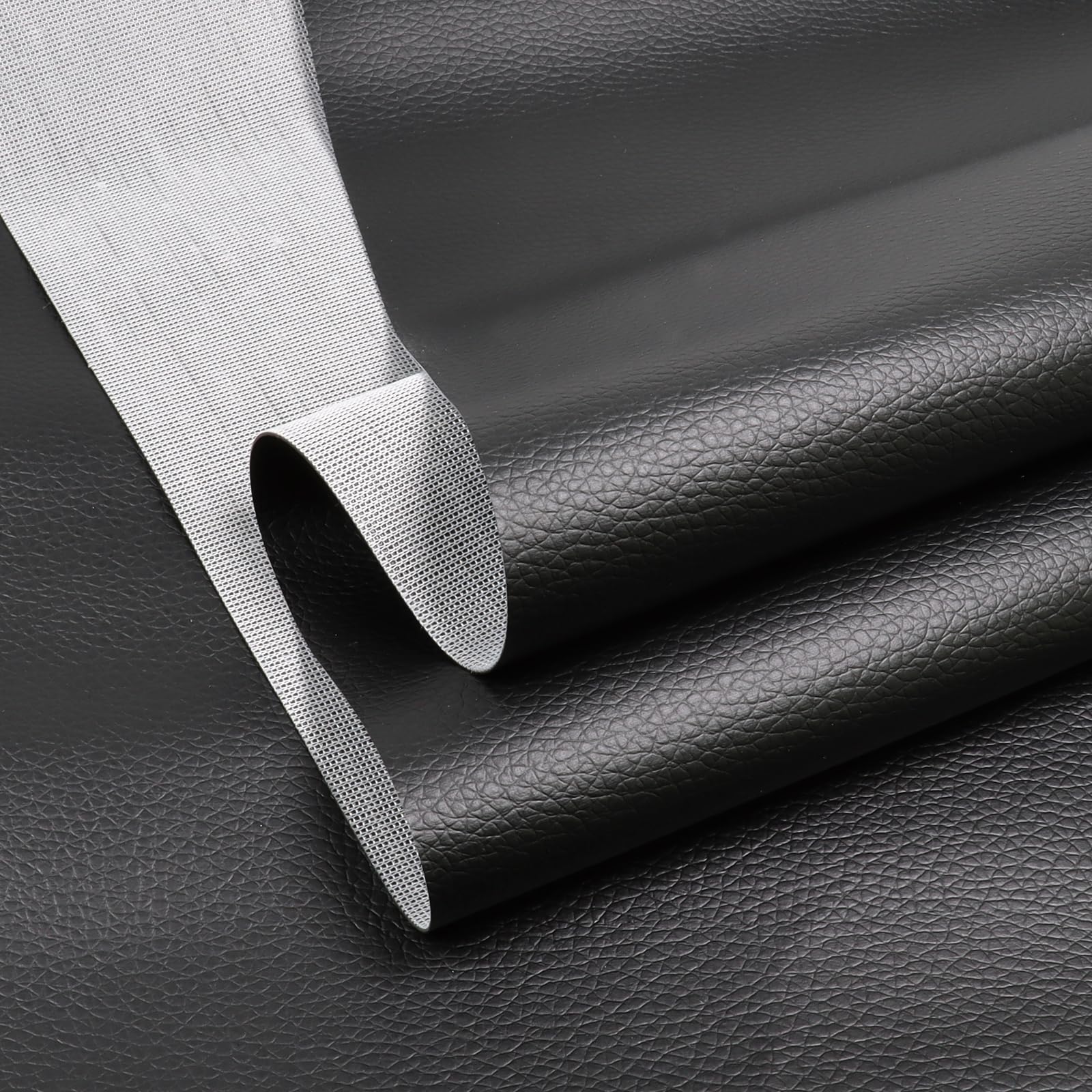

Illustrative image related to marine leather fabric

Scenario 3: Cost Management and Budget Constraints in Large-Scale Purchases

The Problem: Many B2B buyers encounter budget constraints when planning large-scale purchases of marine leather fabric. Fluctuations in raw material prices, shipping costs, and supplier pricing strategies can significantly impact overall project budgets. This is especially true for businesses in emerging markets where financial resources may be limited, leading to difficult choices between quality and affordability.

The Solution: To navigate these financial challenges, buyers should explore volume discount opportunities and establish long-term relationships with suppliers. Many suppliers offer tiered pricing based on order size, which can significantly reduce costs for bulk purchases. Additionally, buyers can consider negotiating payment terms or delivery schedules that align with their cash flow. Keeping an eye on market trends and seasonal sales can also provide cost-saving opportunities. Lastly, consider alternative materials or blends that maintain quality while offering a more budget-friendly price point without sacrificing performance.

Strategic Material Selection Guide for marine leather fabric

When selecting materials for marine leather fabric, it is crucial to evaluate various options based on their properties, advantages, and limitations. This analysis focuses on four common materials used in marine applications: PVC (Polyvinyl Chloride), PU (Polyurethane), Polyester, and Synthetic Leather. Each material has unique characteristics that cater to different needs in the marine industry.

What Are the Key Properties of PVC for Marine Leather Fabric?

PVC is a widely used material for marine leather fabric due to its excellent durability and water resistance. It typically has a temperature rating of -30°C to 70°C and is resistant to UV rays, making it suitable for outdoor applications. PVC is also resistant to mold and mildew, which is crucial for marine environments.

Pros and Cons of PVC

The primary advantage of PVC is its cost-effectiveness and high durability, which makes it suitable for a variety of marine applications. However, it can be less flexible compared to other materials, which may limit its application in intricate designs. Additionally, PVC can be less environmentally friendly, which may concern buyers focused on sustainability.

Illustrative image related to marine leather fabric

Impact on Application

PVC is compatible with various marine applications, including boat upholstery and outdoor furniture. Its resistance to saltwater and other harsh environments makes it a reliable choice for long-lasting performance.

How Does PU Compare to PVC in Marine Leather Fabric Applications?

Polyurethane (PU) is another popular choice for marine leather fabric. It offers superior flexibility and a softer feel compared to PVC, making it ideal for applications requiring a more luxurious finish. PU can withstand temperatures ranging from -20°C to 60°C and has good resistance to abrasion and UV exposure.

Pros and Cons of PU

The key advantage of PU is its aesthetic appeal and comfort, making it suitable for high-end applications. However, it tends to be more expensive than PVC and may require more complex manufacturing processes. Additionally, while PU is generally durable, it may not perform as well as PVC in extreme marine conditions.

Impact on Application

PU is often used in luxury boat interiors and high-end outdoor furniture. Its compatibility with various media, including water and UV rays, makes it a versatile option for premium applications.

What Role Does Polyester Play in Marine Leather Fabric?

Polyester is a synthetic fabric that offers excellent strength and resistance to stretching and shrinking. It is typically rated for temperatures from -20°C to 70°C and has good UV resistance. Polyester is often treated to enhance its water resistance, making it suitable for marine environments.

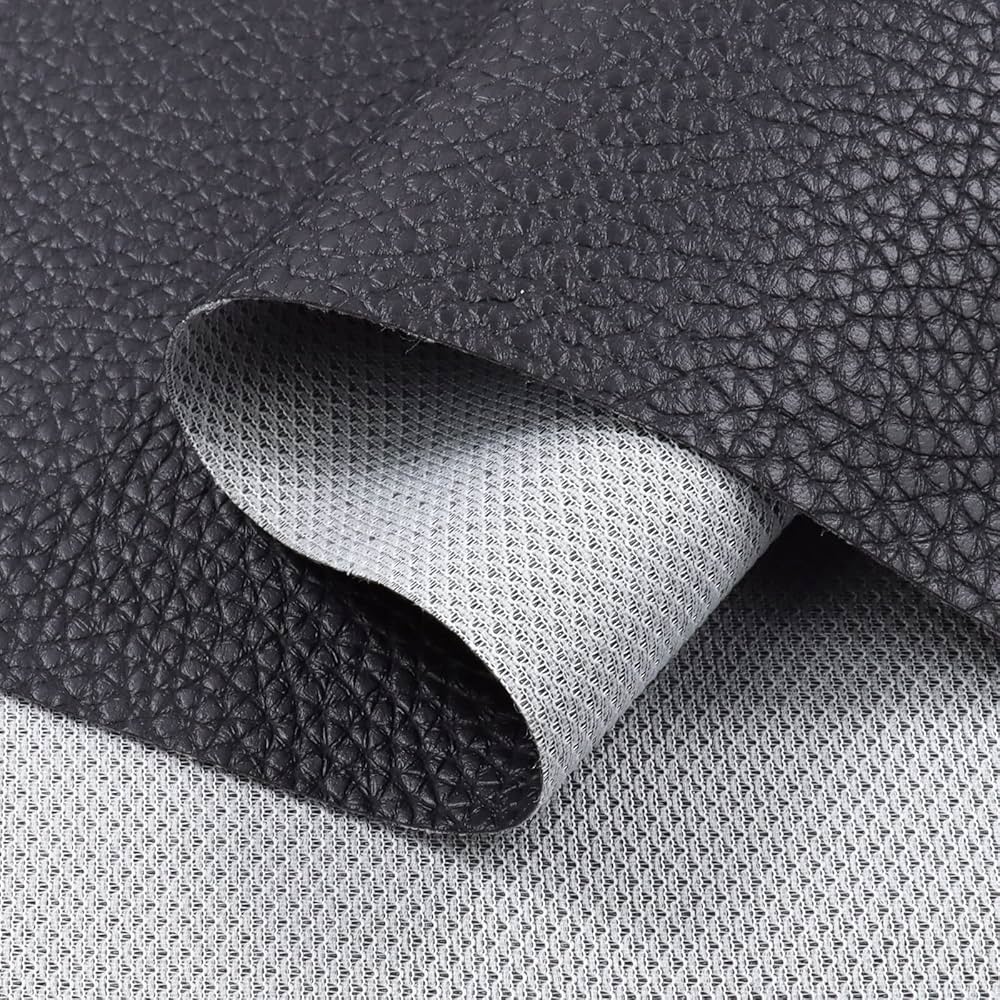

Illustrative image related to marine leather fabric

Pros and Cons of Polyester

The main advantage of polyester is its durability and resistance to fading, which is essential for outdoor applications. However, it can be less resistant to chemicals compared to PVC and PU, which may limit its use in specific marine applications. Additionally, polyester may require additional treatments to enhance its water resistance.

Impact on Application

Polyester is commonly used in marine upholstery and outdoor gear, where durability and resistance to environmental factors are critical. Its compatibility with various coatings makes it adaptable for different marine applications.

What Are the Benefits and Limitations of Synthetic Leather in Marine Applications?

Synthetic leather, often made from a combination of PVC and PU, offers a balance between durability and aesthetics. It typically has a temperature rating of -30°C to 60°C and is resistant to water and UV rays.

Pros and Cons of Synthetic Leather

The primary advantage of synthetic leather is its versatility and ability to mimic the look and feel of genuine leather while being more durable and easier to maintain. However, it can be more expensive than traditional PVC and may not offer the same level of breathability. Additionally, synthetic leather can be less environmentally friendly, which may be a concern for some buyers.

Impact on Application

Synthetic leather is ideal for high-end marine upholstery and accessories, providing a luxurious look while maintaining durability. Its compatibility with various marine environments makes it a strong contender for premium applications.

Illustrative image related to marine leather fabric

Summary Table of Marine Leather Fabric Materials

| Материал | Typical Use Case for marine leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Boat upholstery, outdoor furniture | Cost-effective and durable | Less flexible, environmentally unfriendly | Низкий |

| PU | Luxury boat interiors, high-end furniture | Superior flexibility and aesthetic appeal | More expensive, complex manufacturing | Высокий |

| Polyester | Marine upholstery, outdoor gear | Durable and resistant to fading | Less chemical resistance | Medium |

| Синтетическая кожа | High-end marine upholstery, accessories | Versatile and mimics genuine leather | Higher cost, less breathability | Medium to High |

This guide provides essential insights for B2B buyers in Africa, South America, the Middle East, and Europe, helping them make informed decisions about marine leather fabric materials that meet their specific needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for marine leather fabric

What Are the Main Stages in the Manufacturing Process of Marine Leather Fabric?

The manufacturing of marine leather fabric involves several critical stages that ensure the final product meets the high standards required for marine applications. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, often a combination of synthetic fibers and additives that enhance durability and resistance to environmental factors such as UV rays and moisture. Suppliers often use PVC or polyurethane (PU) as the base material, which is then treated to be waterproof and resistant to mold and mildew.

-

Forming: During this stage, the prepared materials undergo processes such as extrusion and calendering. In extrusion, the material is melted and forced through a die to create sheets of fabric. Calendering involves passing the material through rollers to achieve the desired thickness and finish. This stage is crucial as it determines the fabric’s flexibility and strength.

-

Assembly: After forming, the fabric may be cut into specific shapes and sizes based on customer requirements. This step often includes stitching, where reinforced seams are created to enhance durability. Some manufacturers incorporate additional layers or backing materials for added strength, particularly for high-stress applications like boat seating.

-

Finishing: The final stage involves applying coatings or treatments to enhance the fabric’s performance. This can include UV protection, anti-microbial treatments, and protective finishes that increase resistance to scratching and staining. Quality finishing processes ensure the fabric maintains its aesthetic appeal while providing longevity in harsh marine environments.

How Is Quality Assurance Implemented During Marine Leather Fabric Production?

Quality assurance (QA) is a fundamental aspect of marine leather fabric production, ensuring that the materials meet international standards and customer specifications. This involves the application of various quality control (QC) methodologies throughout the manufacturing process.

Illustrative image related to marine leather fabric

-

International and Industry-Specific Standards: Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for quality management systems. Additionally, industry-specific standards like CE marking for safety and compliance, and API standards for materials used in marine applications, are critical. These certifications not only guarantee product quality but also enhance marketability in international markets.

-

Quality Control Checkpoints: QC checkpoints are integrated into the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

– IQC: This involves inspecting raw materials upon arrival to ensure they meet specified requirements before production begins.

– IPQC: During production, regular inspections are conducted to monitor processes and detect any deviations from quality standards.

– FQC: The final inspection ensures that the finished product meets all specifications, including dimensional accuracy, color consistency, and functional performance. -

Common Testing Methods for Marine Leather Fabric: Various testing methods are employed to assess the quality and performance of marine leather fabric. These include:

– Tensile Strength Testing: Measures the fabric’s resistance to breaking under tension.

– Abrasion Resistance Testing: Evaluates how well the fabric withstands wear and tear.

– Waterproof Testing: Assesses the fabric’s ability to repel water, crucial for marine applications.

– UV Resistance Testing: Determines how well the fabric maintains its color and integrity when exposed to sunlight.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to ensure product reliability. Here are several strategies to achieve this:

-

Conducting Supplier Audits: Regular audits can help assess a supplier’s manufacturing processes and QC practices. Buyers can schedule on-site visits to evaluate the production environment, machinery, and adherence to QA protocols.

-

Requesting Quality Reports: Suppliers should provide comprehensive quality reports that detail testing results, compliance with international standards, and any certifications obtained. This documentation can help buyers make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services often conduct random inspections during various production stages and verify compliance with quality standards.

-

Understanding QC and Certification Nuances: International buyers should be aware of the specific quality control requirements and certifications relevant to their region. For instance, standards may differ significantly between regions like Africa and Europe, impacting the acceptance of products in local markets. Buyers should ensure that suppliers are familiar with these requirements and can provide the necessary documentation.

What Are the Benefits of Stringent Quality Control in Marine Leather Fabric Production?

Implementing stringent quality control measures not only benefits manufacturers but also provides significant advantages to B2B buyers:

-

Enhanced Product Reliability: High-quality marine leather fabric reduces the risk of product failure in harsh marine environments, ensuring long-term performance and customer satisfaction.

-

Reduced Returns and Complaints: By ensuring that products meet quality standards before reaching the market, manufacturers can minimize the frequency of returns and customer complaints, leading to improved relationships and brand loyalty.

-

Competitive Advantage: Suppliers that maintain rigorous quality control processes can differentiate themselves in the market, attracting more buyers and potentially allowing for premium pricing due to perceived value.

-

Sustainability and Compliance: Adhering to quality standards often goes hand-in-hand with sustainable practices, which are increasingly important to consumers. Suppliers that demonstrate compliance with environmental standards can enhance their reputation and appeal to eco-conscious buyers.

In summary, understanding the manufacturing processes and quality assurance practices for marine leather fabric is crucial for B2B buyers. By focusing on these elements, buyers can ensure they source high-quality materials that meet the demands of their specific applications, ultimately leading to better business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘marine leather fabric’

The following guide provides a systematic approach for B2B buyers looking to procure marine leather fabric. This checklist outlines essential steps to ensure informed decision-making and successful sourcing.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the marine leather fabric meets your project’s requirements. Consider factors such as weight, thickness, and UV resistance, as these attributes will influence durability and performance. Additionally, identify the intended use, whether for boat upholstery, outdoor furniture, or marine applications, to guide your selection.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing can help you make informed purchasing decisions. Investigate the average costs of marine leather fabric within your target regions, such as Africa and South America, and compare these prices against your budget. Consider subscribing to industry reports or newsletters to stay updated on fluctuations in material costs and emerging trends.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, case studies, and references from other buyers in your industry. Look for suppliers who can provide certifications for their products, such as UV protection and mold resistance, which are critical for marine applications.

- Tip: Check online reviews and ratings from previous clients to gauge supplier performance and customer service.

Step 4: Request Samples for Quality Assessment

Always request samples of marine leather fabric before finalizing your order. This allows you to assess the material’s texture, durability, and color accuracy firsthand. Evaluate the samples for key performance indicators, such as water resistance and UV stability, to ensure they meet your project needs.

Illustrative image related to marine leather fabric

- Action: Conduct a stress test on samples to verify their strength and flexibility, especially if the fabric will be used in high-wear applications.

Step 5: Verify Compliance with Industry Standards

Ensure that the marine leather fabric complies with relevant industry standards and regulations. This includes checking for certifications like CPSIA compliance, which guarantees that the fabric is free from harmful substances. Compliance not only impacts safety but can also influence your brand’s reputation in the market.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, it is crucial to negotiate favorable terms and conditions. Discuss pricing, payment terms, and delivery timelines to avoid future misunderstandings. Ensure that the contract includes warranty information and returns policy, particularly regarding defects or non-compliance with specifications.

- Consider: Discuss bulk purchasing discounts or long-term partnership benefits to enhance cost-effectiveness.

Step 7: Plan for Logistics and Distribution

Finally, develop a comprehensive logistics plan for transporting the marine leather fabric from the supplier to your location. Consider factors such as shipping costs, customs regulations, and potential delays. Collaborate with your supply chain team to ensure timely delivery and inventory management upon receipt.

By following these steps, B2B buyers can effectively source marine leather fabric that meets their specific needs while ensuring quality, compliance, and value.

Comprehensive Cost and Pricing Analysis for marine leather fabric Sourcing

What Are the Key Cost Components in Sourcing Marine Leather Fabric?

When considering the sourcing of marine leather fabric, it is crucial to understand the various cost components involved. These typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to marine leather fabric

-

Materials: The primary cost driver is the quality of the marine leather fabric itself. Prices can vary significantly based on the type of vinyl or leather used, with premium options costing more due to their enhanced durability and UV resistance. For instance, marine vinyl can range from approximately $10 to $15 per yard depending on its specifications and certifications.

-

Labor: Labor costs include the wages paid to skilled workers involved in the production process. In regions with higher labor costs, such as Europe, this can significantly influence the overall pricing structure. Conversely, countries with lower labor costs may offer more competitive rates.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, facility maintenance, and equipment depreciation. Effective management of these overheads can help suppliers offer more competitive pricing.

-

Tooling: Initial setup costs for specialized manufacturing equipment can be substantial, particularly for custom orders. If a buyer requires unique specifications, these costs should be factored into the overall pricing.

-

Quality Control (QC): Ensuring that the fabric meets industry standards is vital, especially for marine applications where durability is critical. QC processes may add to the cost but are essential for maintaining product integrity.

-

Logistics: Shipping and handling expenses can vary based on distance, shipping method, and packaging requirements. For international buyers, understanding these costs is crucial to avoid unexpected expenses.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure business sustainability. The margin can vary widely based on market conditions and supplier reputation.

How Do Price Influencers Affect Marine Leather Fabric Costs?

Several factors can influence the pricing of marine leather fabric:

-

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Suppliers may offer tiered pricing based on the minimum order quantity (MOQ), incentivizing larger orders.

-

Specifications and Customization: Customized fabrics with specific colors, patterns, or additional features (like UV resistance) tend to be more expensive than standard options. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: Fabrics that are certified for safety and durability (e.g., CPSIA compliant) often command higher prices. Buyers should consider whether these certifications are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can significantly impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence the total cost. For instance, terms that include shipping and handling may provide clarity on overall expenses, while Ex-Works terms may lead to additional logistics costs for the buyer.

What Buyer Tips Should Be Considered for Cost-Efficiency?

To optimize cost-efficiency in sourcing marine leather fabric, consider the following strategies:

-

Negotiation: Always negotiate prices and terms with suppliers. Establishing a strong relationship can lead to better pricing and terms over time.

-

Total Cost of Ownership: Beyond the initial purchase price, evaluate the total cost of ownership, which includes shipping, storage, and maintenance costs. A lower upfront price may not always equate to overall savings.

-

Pricing Nuances for International Buyers: When sourcing from suppliers in different regions, be mindful of currency fluctuations, tariffs, and import duties. These can significantly alter the final cost.

-

Requesting Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure the fabric meets your specifications.

-

Understanding Market Trends: Stay informed about market trends that may affect supply and demand. Price fluctuations can occur due to seasonal changes, economic conditions, or shifts in consumer preferences.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on supplier, region, and market conditions. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure the best pricing for their specific needs.

Alternatives Analysis: Comparing marine leather fabric With Other Solutions

Introduction: Understanding Alternative Solutions for Marine Leather Fabric

As businesses explore options for marine upholstery and applications, understanding the available alternatives to marine leather fabric is crucial. While marine leather fabric offers unique benefits such as durability and aesthetic appeal, other materials like marine vinyl fabric and synthetic leather also present viable options. This analysis will compare these alternatives based on performance, cost, ease of implementation, maintenance, and best use cases, enabling B2B buyers to make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | Marine Leather Fabric | Marine Vinyl Fabric | Синтетическая кожа |

|---|---|---|---|

| Performance | Highly durable, water-resistant, and UV-protected | Excellent abrasion resistance, water-resistant | Good durability, less UV resistance than marine leather |

| Cost | Premium pricing, typically higher than alternatives | More affordable; prices range from $10 to $15 per yard | Mid-range pricing, generally less than marine leather |

| Ease of Implementation | Moderate; requires skilled labor for installation | Easy to work with, can be sewn or stapled | Generally easy to install, versatile for various applications |

| Maintenance | Requires regular cleaning and protection from harsh elements | Low maintenance; easy to clean | Moderate maintenance; cleaning with mild detergent recommended |

| Best Use Case | High-end marine vessels and luxury applications | Boat upholstery, furniture, and outdoor settings | Automotive interiors, budget-conscious projects, and versatile furniture |

Detailed Breakdown of Alternatives

Marine Vinyl Fabric

Marine vinyl fabric is a popular alternative due to its affordability and excellent performance in marine environments. With a price point typically ranging from $10 to $15 per yard, it provides a cost-effective solution without compromising on durability. Marine vinyl is easy to install, making it suitable for various applications, including boat upholstery and outdoor furniture. However, while it boasts significant abrasion resistance and water resistance, it may not match the premium feel and aesthetic of marine leather fabric, which could be a deciding factor for high-end projects.

Синтетическая кожа

Synthetic leather, often referred to as faux leather, is another alternative that offers a good balance of cost and functionality. Its pricing is usually mid-range, making it accessible for businesses seeking a budget-friendly option. Synthetic leather is versatile and easy to work with, which can reduce labor costs during installation. However, it generally has lower UV resistance compared to marine leather and may not perform as well in extreme marine conditions. This makes it less suitable for high-end marine applications but an excellent choice for automotive interiors and projects requiring versatility.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for marine applications, B2B buyers should carefully evaluate their specific needs, including budget constraints, desired performance characteristics, and aesthetic preferences. Marine leather fabric is ideal for high-end applications requiring durability and luxury, while marine vinyl fabric and synthetic leather provide excellent alternatives for cost-sensitive projects without sacrificing functionality. By assessing the key aspects outlined in this analysis, businesses can make informed decisions that enhance their product offerings and meet customer expectations effectively.

Essential Technical Properties and Trade Terminology for marine leather fabric

What Are the Key Technical Properties of Marine Leather Fabric?

When considering marine leather fabric for B2B procurement, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications:

-

Material Grade

Marine leather fabric typically consists of high-grade synthetic materials, such as PVC or polyurethane. The grade affects durability, UV resistance, and overall performance in marine environments. Higher-grade materials ensure longevity and reduced maintenance costs, making them a wise investment for manufacturers and suppliers in marine upholstery and related industries. -

Weight and Thickness

The weight of marine leather fabric is often measured in ounces per square yard. A common weight is 30 oz., which provides a balance between durability and flexibility. Thickness, usually around 0.95 mm, influences the fabric’s resistance to wear and tear. For B2B buyers, selecting the right weight and thickness is crucial for specific applications, as it affects the fabric’s ease of handling and sewing. -

Water Resistance

A hallmark of marine leather fabric is its waterproof nature, which is critical for preventing moisture damage in marine environments. This property ensures that the fabric maintains its integrity and aesthetic appeal over time, reducing the risk of costly replacements. Understanding the water resistance rating can help buyers evaluate the fabric’s suitability for different applications, such as boat interiors and outdoor furniture. -

UV Resistance

UV-treated marine leather fabric is designed to withstand prolonged exposure to sunlight without fading or degrading. This characteristic is vital for outdoor applications, where exposure to harsh weather conditions is inevitable. Buyers should look for fabrics tested against UV standards, as this can significantly extend the life of the product, offering better value over time. -

Abrasion Resistance

The durability of marine leather fabric is often quantified by the double rub count, which indicates how many rubs the material can withstand before showing signs of wear. A higher count (e.g., 250,000) signifies superior resistance to abrasion, making it ideal for high-traffic areas. B2B purchasers should prioritize fabrics with high abrasion resistance to ensure longevity in their products.

What Are Common Trade Terms Used in Marine Leather Fabric Procurement?

Understanding industry terminology is equally important for effective communication and negotiation in the B2B space. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of marine leather, an OEM might design specific upholstery solutions that utilize the fabric. Understanding OEM relationships can help buyers identify potential partners for custom projects. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and pricing strategies. Knowing the MOQ allows businesses to plan their orders according to budget and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a formal process through which a buyer solicits price quotes from suppliers for specific products or services. For marine leather fabric, an RFQ can help buyers compare prices and terms across different vendors, ensuring they make cost-effective decisions. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms helps B2B buyers manage shipping, insurance, and liability, which is crucial for importing marine leather fabric from overseas suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the marine leather fabric industry, lead times can vary significantly based on customization and supplier location. Accurate knowledge of lead times aids in better project planning and inventory management. -

Warranty and Guarantee

A warranty provides assurance from the supplier regarding the quality and durability of the marine leather fabric. Understanding warranty terms is essential for buyers as it impacts long-term satisfaction and potential return on investment. This is particularly important in marine applications where fabric performance is crucial.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing marine leather fabric more effectively, ensuring they select the right products for their needs while optimizing costs and quality.

Navigating Market Dynamics and Sourcing Trends in the marine leather fabric Sector

What Are the Key Trends Driving the Marine Leather Fabric Market?

The marine leather fabric sector is witnessing a dynamic shift fueled by several global drivers. Increasing demand for durable and weather-resistant materials in marine applications is at the forefront, driven by the growing recreational boating industry and marine tourism. Additionally, innovations in manufacturing technologies, such as digital printing and advanced coating techniques, are enhancing product offerings and customization options for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Emerging B2B tech trends include the rise of e-commerce platforms that facilitate direct sourcing, enabling buyers to access a wider range of products with competitive pricing. Moreover, supply chain transparency is becoming crucial, as buyers seek detailed information about product origins and manufacturing processes. Companies that leverage data analytics for inventory management and trend forecasting are better positioned to respond to market fluctuations, thereby enhancing their competitive edge.

Another critical aspect is the increasing emphasis on quality standards. Buyers are looking for marine leather fabrics that not only meet aesthetic requirements but also demonstrate superior durability and resistance to environmental factors. This trend is particularly relevant for markets in Brazil and Nigeria, where climatic conditions demand robust solutions.

How Is Sustainability Influencing Sourcing Decisions in the Marine Leather Fabric Sector?

Sustainability is no longer a niche concern; it has become a central pillar in B2B sourcing strategies. The environmental impact of marine leather fabric production is significant, prompting buyers to prioritize suppliers with sustainable practices. This includes the use of eco-friendly materials, such as recycled plastics and organic compounds, which reduce the ecological footprint of the products.

Illustrative image related to marine leather fabric

Ethical sourcing is equally important, as companies increasingly face scrutiny regarding their supply chains. Buyers are now seeking partners who can provide certifications that validate their commitment to sustainability and ethical practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 offer assurance that the materials are free from harmful substances and produced in environmentally friendly facilities.

Moreover, sustainable practices can translate into economic benefits, as consumers are more willing to pay a premium for products that align with their values. For international buyers in regions like the Middle East and South America, partnering with manufacturers that prioritize sustainability can enhance brand reputation and customer loyalty, driving long-term success.

What Is the Historical Context of Marine Leather Fabric in B2B Markets?

The evolution of marine leather fabric has been shaped by both technological advancements and changing consumer preferences. Initially, traditional leather was predominantly used in marine applications; however, the advent of synthetic materials offered a more practical solution. Marine vinyl fabrics emerged as a popular alternative due to their superior durability, waterproof properties, and ease of maintenance.

Over the years, the industry has seen significant innovation, leading to the development of advanced marine-grade vinyls that combine aesthetic appeal with high performance. These products are now engineered to withstand extreme weather conditions, making them suitable for a wide range of applications, from boat upholstery to outdoor furniture. As the market continues to evolve, the focus on sustainability and ethical sourcing is likely to shape the future of marine leather fabric, aligning with the broader trends in global manufacturing and consumer behavior.

In summary, navigating the marine leather fabric sector requires an understanding of market dynamics, a commitment to sustainability, and a keen awareness of historical trends that inform current sourcing strategies. By prioritizing these aspects, B2B buyers can make informed decisions that enhance their competitive positioning in a rapidly changing landscape.

Illustrative image related to marine leather fabric

Frequently Asked Questions (FAQs) for B2B Buyers of marine leather fabric

1. How do I choose the right marine leather fabric for my project?

Selecting the appropriate marine leather fabric involves considering several factors. First, assess the intended application—whether for boat upholstery, furniture, or outdoor gear. Look for materials that are waterproof, UV resistant, and mold/mildew resistant to ensure durability in marine environments. Additionally, consider the fabric’s weight and thickness; heavier materials are generally more durable but may be more challenging to work with. Finally, review color options and patterns that align with your brand identity or project aesthetic.

2. What are the customization options available for marine leather fabric?

Many suppliers offer customization options for marine leather fabric, including color selection, texture, and even patterns. You may also be able to request specific dimensions or roll lengths tailored to your needs. It’s advisable to discuss your requirements directly with suppliers to explore available options and any associated costs. Some manufacturers also provide samples to help you make informed decisions before placing a bulk order.

3. What are the minimum order quantities (MOQs) for marine leather fabric?

Minimum order quantities for marine leather fabric can vary significantly depending on the supplier and your specific requirements. Typically, MOQs range from as low as 10 yards to over 100 yards. When sourcing, inquire about the MOQ as it can affect your overall budget and inventory management. Some suppliers may offer flexible MOQs for established customers or larger projects, so it’s worth negotiating based on your needs.

4. How can I vet suppliers of marine leather fabric?

To vet suppliers effectively, start by checking their reputation and customer reviews. Look for certifications that indicate quality standards, such as ISO or industry-specific certifications. Request references from previous clients and consider conducting factory visits if possible. Additionally, assess their responsiveness and willingness to provide samples, as this can reflect their commitment to customer service and product quality.

5. What payment terms should I expect when sourcing marine leather fabric?

Payment terms can vary widely among suppliers, but typical arrangements include upfront payments, deposits, or net payment terms (e.g., 30 days after delivery). It’s essential to clarify payment methods accepted, such as wire transfers, credit cards, or letters of credit. Negotiating favorable terms can help manage cash flow, so don’t hesitate to discuss options that may suit your financial strategy.

Illustrative image related to marine leather fabric

6. How do I ensure quality assurance when purchasing marine leather fabric?

To ensure quality, establish clear specifications and standards before placing an order. Request samples to evaluate the fabric’s texture, color, and durability. Many suppliers offer third-party testing to confirm that their products meet industry standards for UV resistance and mold resistance. Additionally, consider implementing a quality control process that includes inspections upon receipt of the goods to verify that they meet your expectations.

7. What logistics considerations should I keep in mind when importing marine leather fabric?

When importing marine leather fabric, consider shipping costs, delivery times, and customs regulations. Ensure your supplier can provide the necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. It’s also advisable to work with a logistics partner familiar with international trade to navigate potential challenges related to tariffs or import restrictions in your country.

8. How can I address issues with my marine leather fabric order?

If issues arise with your order, such as defects or incorrect quantities, contact your supplier promptly to discuss the situation. Most reputable suppliers have return and exchange policies in place. Document any issues with photos and provide detailed descriptions to facilitate the resolution process. Understanding the supplier’s warranty and return policies upfront can also guide you in addressing problems effectively.

Top 6 Marine Leather Fabric Manufacturers & Suppliers List

1. Sunbrella – Horizon Marine Vinyl

Domain: sunbrella.com

Registered: 1995 (30 years)

Введение: Product Name: Sunbrella Horizon Marine Vinyl

Type: Marine Vinyl Upholstery

Key Features:

– Ultra-soft and comfortable

– Knit-backed construction with 4-way stretch and recovery

– Mold and mildew resistant

– UV fading resistant

– Industry-leading 3-year limited warranty against microbial pinking

– Comprehensive 5-year limited product and labor warranty

– Seamlessly matches color system used in Sunb…

2. KOVI Fabrics – Marine Vinyl Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Введение: Marine Vinyl Fabric – Heavy duty marine vinyl that withstands the elements. KOVI Fabrics offers a wide selection of marine-grade vinyl fabric suitable for boat upholstery, including boat seats, cushions, and covers. Features include waterproof, mildew resistant, UV resistant, and highly durable against salt water damage. Available in various colors and patterns, including solid colors and textures…

3. Sailrite – Premium Marine Vinyl Upholstery

Domain: sailrite.com

Registered: 1996 (29 years)

Введение: Premium Marine Vinyl Fabric | Durable & Weather-Resistant Upholstery. Add a high-end look to your boat’s upholstery and seating with quality marine vinyl upholstery. Sailrite stocks hundreds of name-brand vinyl upholstery fabrics sold by the yard and ready to ship. Fabric samples available.

4. Naugahyde – Marine Vinyl Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Введение: Marine Vinyl Fabric & Upholstery, Marine Grade Faux Leather, Upholstery Fabric, Available by the yard or roll, Wholesale prices, Brands: Naugahyde, Omnova, Spradling, Nassimi, Color options: Blue, White, Black, Gray, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, Yellow, Gold, Price range: $10.54 – $33.80 per yard, Stock availability: Various yards in stock for each product.

5. Marine Leather – Full-Grain Leather for High-End Spaces

Domain: marineleather.it

Registered: 2005 (20 years)

Введение: Full-grain leather for high-end spaces; available in various colors including White, Cream, Brown, Bordeaux, Red, Yellow, Pink, Purple, Blue, Green, Grey, and Black. Product types include Plain, Embossed, Woven, Tubular, 3D Effect, Inlay art, Digital printed, Embroidery, Pleated, Laser work, and Interlaced by hand. Accessories include Baskets, Cushions, Poufs, Trays, Tissue boxes, Coasters, and Ha…

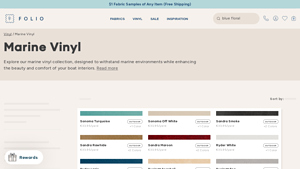

6. Folio Fabrics – Marine Vinyl Upholstery

Domain: foliofabrics.com

Registered: 2013 (12 years)

Введение: Marine Vinyl Fabric designed for boat upholstery, crafted from durable materials such as PVC and marine-grade vinyl. Features include exceptional durability, weather resistance, easy maintenance, and stain resistance. Available in various textures, colors, and designs. Regular price: $36-$38 per yard. Options include colors like Sonoma Turquoise, Sonoma Off White, Sandra Smoke, Ryder White, Pucket…

Strategic Sourcing Conclusion and Outlook for marine leather fabric

As the demand for marine leather fabric continues to grow, strategic sourcing remains crucial for international B2B buyers looking to capitalize on emerging markets in Africa, South America, the Middle East, and Europe. The versatility and durability of marine vinyl fabrics, coupled with competitive pricing and a wide range of color options, present significant opportunities for businesses in various sectors, including boating, hospitality, and automotive.

By prioritizing quality and supplier reliability, buyers can ensure they are not only meeting current market needs but also positioning themselves for future trends. Investing in marine leather fabric that is UV treated, mold resistant, and compliant with safety standards will enhance product longevity and customer satisfaction, ultimately driving repeat business.

Illustrative image related to marine leather fabric

Looking ahead, it is essential for B2B buyers to stay informed about technological advancements and sustainability practices within the marine fabric industry. Collaborating with trusted suppliers and leveraging bulk purchasing strategies can further optimize cost-efficiency. Take action now to explore your options in marine leather fabric and secure a competitive edge in your marketplace. The future of your business depends on the quality and reliability of your sourcing decisions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.