Introduction: Navigating the Global Market for leather belt hole maker

In the fast-evolving global market for leather goods, the demand for reliable and efficient leather belt hole makers has surged, presenting both opportunities and challenges for international B2B buyers. Sourcing high-quality leather hole punches that ensure precision and durability can be a daunting task, particularly for businesses in diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Nigeria. This guide aims to demystify the complexities involved in selecting the right leather belt hole maker, offering insights into various types, applications, and essential features that can significantly impact production efficiency.

Throughout this comprehensive resource, we will explore the different categories of leather hole makers—from single tube punches to multi-size rotary options—and their respective uses in leather crafting. Additionally, we will provide strategies for vetting suppliers, ensuring you partner with reputable manufacturers who adhere to quality standards. Understanding cost factors and market trends will further empower you to make informed purchasing decisions that align with your business objectives.

By equipping you with the knowledge needed to navigate this specialized market, this guide serves as a valuable tool for international buyers seeking to enhance their leather production capabilities while minimizing risks associated with sourcing. Embrace the insights shared herein to elevate your purchasing strategy and secure the best leather belt hole maker for your operational needs.

Table Of Contents

- Top 3 Leather Belt Hole Maker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather belt hole maker

- Understanding leather belt hole maker Types and Variations

- Key Industrial Applications of leather belt hole maker

- 3 Common User Pain Points for ‘leather belt hole maker’ & Their Solutions

- Strategic Material Selection Guide for leather belt hole maker

- In-depth Look: Manufacturing Processes and Quality Assurance for leather belt hole maker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather belt hole maker’

- Comprehensive Cost and Pricing Analysis for leather belt hole maker Sourcing

- Alternatives Analysis: Comparing leather belt hole maker With Other Solutions

- Essential Technical Properties and Trade Terminology for leather belt hole maker

- Navigating Market Dynamics and Sourcing Trends in the leather belt hole maker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather belt hole maker

- Strategic Sourcing Conclusion and Outlook for leather belt hole maker

- Important Disclaimer & Terms of Use

Understanding leather belt hole maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Hole Punch | Adjustable size settings, plier-like design | Leather goods manufacturing | Pros: Versatile for multiple hole sizes; easy to use. Cons: Limited reach for deep holes. |

| Drive Hole Punch | Solid construction, requires mallet for use | High-volume leather crafting | Pros: Efficient for thick materials; durable. Cons: Requires more physical strength. |

| Strap End Punch | Specifically designed for finishing belt ends | Custom belt production | Pros: Creates professional finishes; various shapes available. Cons: Limited to end use only. |

| Oblong Hole Punch | Unique oblong shape for specific applications | Belt strap adjustments | Pros: Ideal for specific fastening needs; provides unique hole shapes. Cons: Niche application limits versatility. |

| Multi-Punch Set | Contains various sizes in one set, interchangeable components | Small-scale leather crafting | Pros: Cost-effective; comprehensive tool for beginners. Cons: Quality may vary by manufacturer. |

What Are the Characteristics of a Rotary Hole Punch?

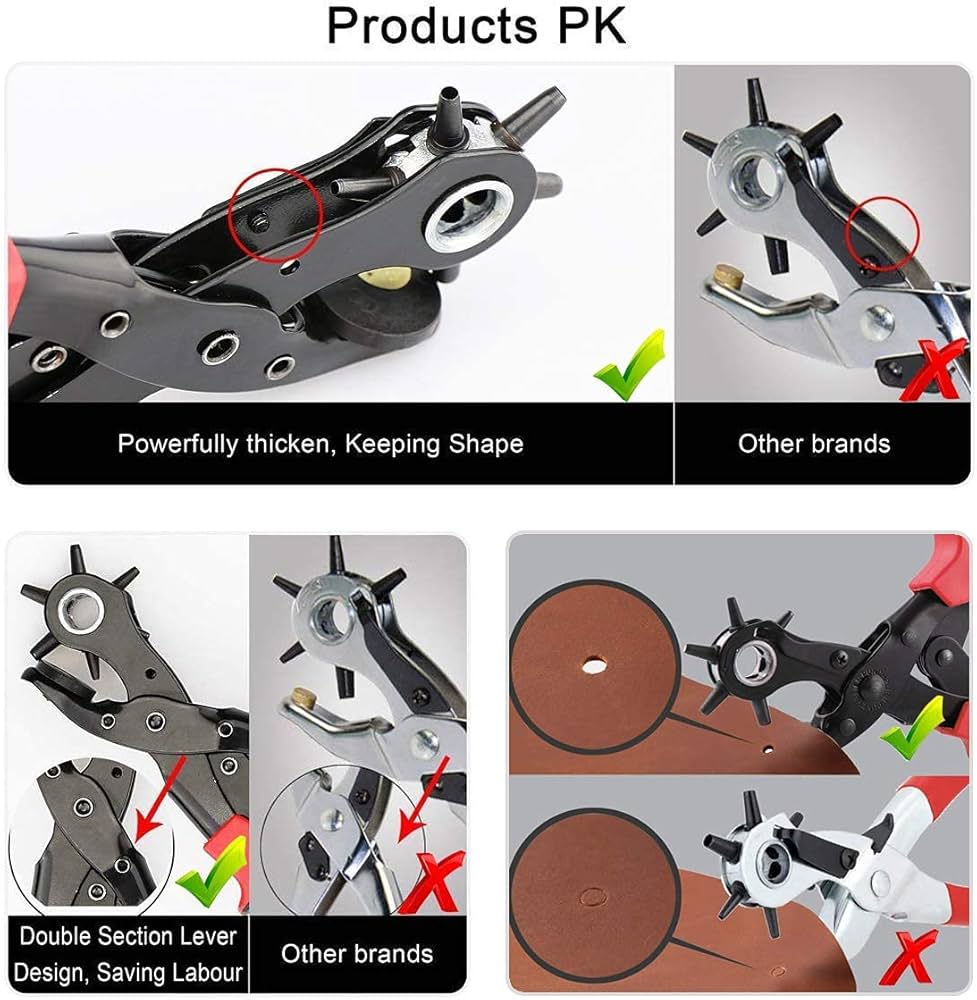

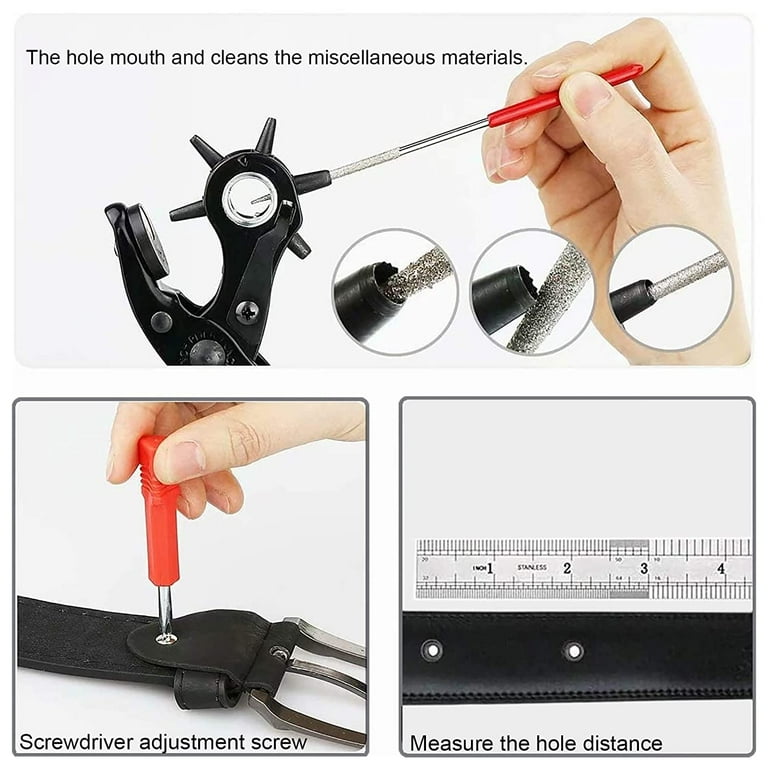

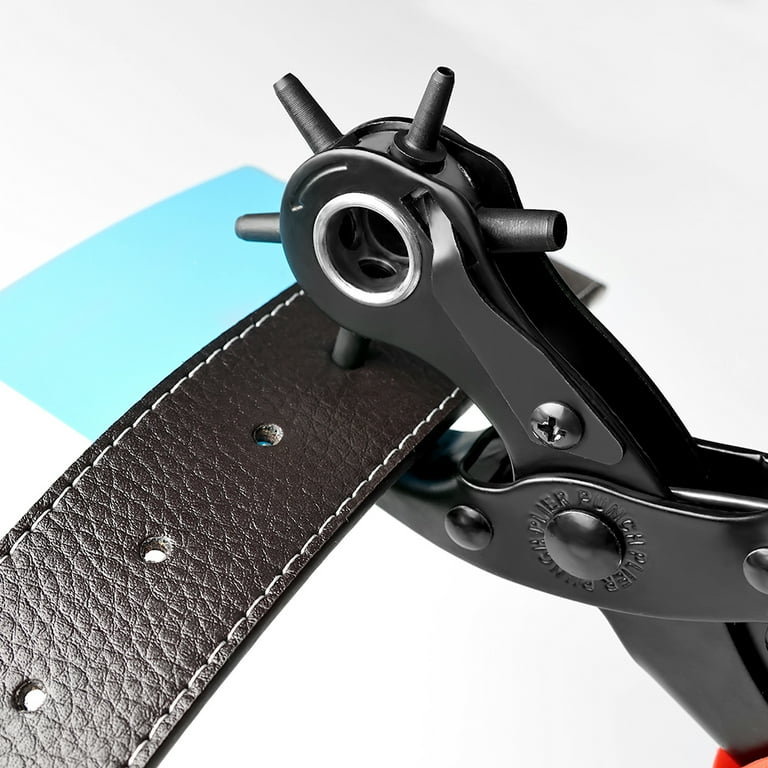

The rotary hole punch is a versatile tool featuring an adjustable wheel that allows users to select different hole sizes easily. Designed like a pair of pliers, it is ideal for making multiple holes in a single operation, making it a popular choice among leather goods manufacturers. When considering a rotary punch, B2B buyers should assess the tool’s build quality and ease of adjustment to ensure it meets production demands efficiently.

Why Choose a Drive Hole Punch for High-Volume Work?

Drive hole punches are robust tools that require a mallet for operation, making them suitable for high-volume leather crafting. They excel at punching through thick leather, which is essential for durable products. Buyers should consider the weight and material of the punch, as heavier models can provide better results with less effort. This tool is ideal for businesses that prioritize durability and efficiency in their production processes.

How Does a Strap End Punch Enhance Custom Belt Production?

Strap end punches are specialized tools designed to finish the ends of belts, creating a polished look. They come in various shapes to suit different design requirements, making them indispensable for custom belt production. B2B buyers should evaluate the range of shapes and sizes available to ensure they can meet client specifications effectively. This tool is particularly useful for businesses focused on high-quality craftsmanship.

What Are the Advantages of Using an Oblong Hole Punch?

Oblong hole punches feature a unique design tailored for specific fastening applications, such as belt strap adjustments. Their shape allows for a more secure fit of buckles and other components, enhancing the functionality of leather products. For B2B buyers, understanding the specific applications of oblong punches is crucial, as they may not be as versatile as other types. However, they are essential for businesses that require precise fastening solutions.

Why Consider a Multi-Punch Set for Small-Scale Crafting?

Multi-punch sets offer a comprehensive solution for small-scale leather crafting, featuring various sizes in one package. This cost-effective option is particularly beneficial for startups or businesses looking to diversify their product offerings without significant upfront investment. Buyers should consider the quality of the punches included in the set, as this can impact their overall effectiveness and longevity. A well-rounded set can significantly enhance a business’s crafting capabilities.

Key Industrial Applications of leather belt hole maker

| Industry/Sector | Specific Application of leather belt hole maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Creating custom belts and accessories | Enhances product differentiation and customization options | Quality of materials, variety of hole sizes, durability of tools |

| Leather Goods Manufacturing | Mass production of leather goods like bags and wallets | Increases efficiency and consistency in production processes | Cost-effectiveness, reliability of supply, compliance with standards |

| Автомобили | Manufacturing leather car interiors and seat covers | Improves aesthetics and comfort in vehicles | Compatibility with various leather thicknesses, precision of holes |

| Craft & Hobby | DIY projects and leather crafting | Enables hobbyists to create personalized leather items | Range of punch sizes, ease of use, availability of replacement parts |

| Industrial Upholstery | Upholstering furniture with leather | Enhances product durability and visual appeal | Heavy-duty options, ability to handle thick materials, sourcing support |

How is a leather belt hole maker utilized in the fashion and apparel industry?

In the fashion and apparel sector, leather belt hole makers are essential for creating custom belts and accessories. These tools allow manufacturers to create various hole sizes for buckle adjustments, enabling a perfect fit. This capability enhances product differentiation, allowing brands to offer personalized options that cater to specific customer preferences. International buyers, particularly from regions like Africa and Europe, should prioritize tools that provide durability and precision to maintain high-quality standards in their product offerings.

What role does a leather belt hole maker play in leather goods manufacturing?

In leather goods manufacturing, these tools streamline the mass production process of items such as bags and wallets. By providing consistent hole sizes and precise placements, leather belt hole makers enhance production efficiency and reduce waste. This is particularly valuable for businesses aiming for high output while maintaining quality. Buyers in South America and the Middle East should consider the reliability of the supplier and the availability of various sizes to meet diverse production needs.

Illustrative image related to leather belt hole maker

How is a leather belt hole maker beneficial in the automotive industry?

Within the automotive sector, leather belt hole makers are crucial for crafting leather interiors and seat covers. These tools ensure that holes for stitching or securing components are accurately placed, improving both the aesthetics and comfort of the vehicle. For international buyers, particularly in regions like Saudi Arabia, sourcing options that accommodate different leather thicknesses and provide precision is vital to meet industry standards and consumer expectations.

Why is a leather belt hole maker important for craft and hobby applications?

For craft and hobbyists, leather belt hole makers are indispensable for DIY projects. They enable enthusiasts to create personalized leather items, fostering creativity and self-expression. The ability to punch holes accurately allows for intricate designs and functional pieces, such as wallets or bags. Buyers should look for user-friendly options with a variety of punch sizes to cater to different project requirements, ensuring that they can easily adapt to varying designs.

How does a leather belt hole maker enhance industrial upholstery processes?

In industrial upholstery, leather belt hole makers facilitate the process of upholstering furniture with leather. They ensure that holes for securing leather are precisely placed, enhancing both the durability and visual appeal of the final product. Businesses should prioritize sourcing heavy-duty options capable of handling thick materials, ensuring longevity in their upholstery projects. Additionally, buyers should consider sourcing support and technical assistance from suppliers to optimize their use of these tools.

Illustrative image related to leather belt hole maker

3 Common User Pain Points for ‘leather belt hole maker’ & Their Solutions

Scenario 1: Difficulty in Achieving Precise Hole Placement

The Problem: A common challenge for B2B buyers in the leatherworking industry is achieving precise hole placement for belt adjustments. Inconsistencies can lead to wasted materials and compromised product quality, resulting in customer dissatisfaction. Buyers often face frustration when using standard leather hole makers that do not allow for accurate adjustments, particularly in thicker leather where the punch may slip or fail to create a clean hole.

The Solution: To overcome this issue, buyers should invest in high-quality, adjustable leather belt hole makers designed specifically for precision. Tools like revolving hole punches allow for easy size adjustments and can accommodate various thicknesses of leather. It’s advisable to choose models with a locking mechanism to ensure stability during use. Additionally, setting up a dedicated work surface with a cutting pad can help maintain the integrity of the leather while ensuring that the punch remains aligned correctly. Regularly maintaining the tools by lubricating the moving parts and using beeswax can enhance performance and prolong the lifespan of the hole maker.

Scenario 2: Inefficiency in Production Due to Limited Tool Versatility

The Problem: Many B2B buyers struggle with the inefficiency of using multiple tools for different hole sizes and types. This limitation not only increases the time spent on each project but can also lead to errors when switching between tools. Manufacturers often find themselves hampered by the need to stock various punch sizes, which complicates inventory management and incurs additional costs.

The Solution: A strategic solution involves sourcing multifunctional leather belt hole makers that incorporate various punch sizes and types within a single tool. Buyers should look for rotary punch sets that come with interchangeable heads, allowing for both round and oblong holes as needed. This versatility not only streamlines production processes but also reduces the need for multiple tools, simplifying inventory management. Furthermore, investing in durable, high-quality tools from reputable manufacturers can provide long-term cost savings by minimizing the frequency of replacements.

Scenario 3: Tool Durability and Maintenance Challenges

The Problem: Another significant pain point for B2B buyers is the durability and maintenance of leather belt hole makers. Tools that wear out quickly or require frequent repairs can disrupt production schedules, leading to increased downtime and operational costs. Buyers may experience frustration when the quality of their punches diminishes, resulting in poor hole quality and additional rework.

The Solution: To mitigate these challenges, buyers should prioritize investing in premium, heavy-duty leather hole makers known for their durability. Tools manufactured from high-quality materials such as stainless steel or hardened alloys will withstand regular use and provide consistent performance. Additionally, implementing a regular maintenance schedule is crucial. This includes cleaning the tools after each use, checking for any signs of wear, and replacing components as necessary. Buyers should also consider using protective mallets to minimize impact damage during use, which can help preserve the tool’s integrity over time. By focusing on quality and maintenance, businesses can enhance the longevity and effectiveness of their leather hole makers, ultimately contributing to better production outcomes.

Strategic Material Selection Guide for leather belt hole maker

What Materials Are Commonly Used for Leather Belt Hole Makers?

When selecting materials for leather belt hole makers, it’s essential to consider the properties, advantages, and limitations of each option. Here, we analyze four common materials: steel, aluminum, brass, and plastic. Each material has unique characteristics that influence performance, durability, and suitability for specific applications.

How Does Steel Perform in Leather Belt Hole Makers?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high pressure and is resistant to deformation under stress, which is crucial for making precise holes in thick leather.

Pros & Cons: The main advantage of steel is its longevity; tools made from steel can last for years with proper maintenance. However, steel is susceptible to corrosion if not properly treated, which can be a concern in humid environments. Additionally, manufacturing steel tools can be complex, leading to higher production costs.

Impact on Application: Steel’s compatibility with various leather types makes it ideal for professional leatherworking. However, users must ensure that the tools are well-maintained to prevent rust, especially in regions with high humidity, such as parts of Africa and the Middle East.

What Advantages Does Aluminum Offer for Leather Belt Hole Makers?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. These properties make aluminum tools easy to handle and suitable for prolonged use without causing fatigue.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which enhances maneuverability. However, aluminum is not as strong as steel, making it less suitable for heavy-duty applications. The manufacturing process for aluminum can be less complex, potentially lowering costs.

Impact on Application: Aluminum tools are particularly beneficial in regions where weight is a concern, such as for mobile leatherworkers or in markets with less robust infrastructure. However, buyers should be cautious about using aluminum for thicker leather, as it may not provide the necessary strength.

Why Choose Brass for Leather Belt Hole Makers?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and aesthetic appeal. It offers good machinability and can withstand moderate pressure.

Pros & Cons: Brass tools are durable and resistant to tarnishing, which is ideal for maintaining a professional appearance. However, they can be more expensive than steel and aluminum, which may deter budget-conscious buyers. Additionally, brass is softer than steel, making it less suitable for high-impact applications.

Impact on Application: Brass tools are often favored for their aesthetic qualities in high-end leather goods. Buyers in markets like Europe may prefer brass tools for their visual appeal, but they should consider the cost implications.

How Does Plastic Compare in Leather Belt Hole Makers?

Key Properties: Plastic is lightweight, resistant to corrosion, and can be manufactured in various colors and shapes. It is less durable than metal but can be designed for specific applications.

Pros & Cons: The main advantage of plastic tools is their cost-effectiveness and versatility. However, they are generally less durable and may not withstand heavy use, making them suitable primarily for hobbyists rather than professional leatherworkers.

Impact on Application: Plastic tools can be appealing to new entrants in the leatherworking market, especially in regions like South America where budget constraints may be significant. However, users should be aware of the limitations in terms of durability and performance.

Summary Table of Material Selection for Leather Belt Hole Makers

| Материал | Typical Use Case for leather belt hole maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty leatherworking | Exceptional durability | Susceptible to corrosion | Высокий |

| Aluminum | Lightweight, mobile applications | Easy to handle | Less strength for heavy-duty use | Medium |

| Brass | High-end leather goods | Corrosion-resistant and attractive | Higher cost and softer material | Высокий |

| Plastic | Hobbyist and budget applications | Cost-effective and versatile | Less durable for professional use | Низкий |

This material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions based on specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for leather belt hole maker

What Are the Main Stages in the Manufacturing Process of Leather Belt Hole Makers?

The manufacturing process of leather belt hole makers involves several critical stages that ensure the final product meets quality and performance standards.

Material Preparation

The initial stage focuses on selecting high-quality materials, which typically include durable metals such as stainless steel or high-carbon steel. The choice of material is crucial, as it affects the longevity and effectiveness of the hole maker. Manufacturers often source these materials from reputable suppliers, ensuring they meet specific mechanical properties suited for leatherworking. Before the manufacturing process begins, the materials undergo a thorough inspection to detect any defects or inconsistencies.

Illustrative image related to leather belt hole maker

Forming Techniques

After material preparation, the next step is forming the components of the leather hole maker. This process often involves techniques such as stamping, forging, or machining.

-

Stamping is commonly used for creating uniform shapes and sizes for the punches. High-precision stamping machines are employed to ensure that each piece is identical, reducing variability in production.

-

Forging involves shaping the metal through compressive forces, enhancing its strength and durability. This method is particularly effective for producing heavy-duty leather hole makers designed for high-volume usage.

-

Machining processes, including drilling and grinding, are used to refine the edges and surfaces of the tools, ensuring they are sharp and ready for precise leatherwork.

Assembly Process

Once the components are formed, they are assembled. This stage may involve attaching handles to punches or combining multiple tools into a single, multifunctional device.

-

Manual assembly is often employed for higher-end products, allowing for greater attention to detail. Skilled workers ensure that each tool operates smoothly, checking for alignment and functionality.

-

Automated assembly lines are utilized for mass production, enhancing efficiency while maintaining quality.

Finishing Touches

The final stage in manufacturing is finishing, which enhances the appearance and usability of the leather belt hole maker. This process may include:

-

Surface treatment, such as coating or polishing, to prevent rust and improve aesthetic appeal.

-

Quality checks during this stage ensure that every tool adheres to the specified dimensions and functionality. Any defective products are removed from the line for rework or scrapping.

What Quality Control Measures Are Critical for Leather Belt Hole Makers?

Quality control (QC) is paramount in the production of leather belt hole makers, as it directly influences customer satisfaction and product reliability.

What International Standards Should Manufacturers Comply With?

B2B buyers should look for suppliers who comply with international quality standards such as ISO 9001, which outlines requirements for quality management systems. This certification indicates that the manufacturer consistently provides products that meet customer and regulatory requirements.

Illustrative image related to leather belt hole maker

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) may be relevant, particularly for markets in Europe. These certifications ensure that products meet safety and environmental protection standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential for maintaining high production standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Any non-conforming materials are rejected.

-

In-Process Quality Control (IPQC): Conducted throughout the manufacturing process, IPQC involves monitoring production processes and conducting regular inspections to catch defects early.

-

Final Quality Control (FQC): This final inspection occurs before products are packaged and shipped. It includes functionality tests, dimensional checks, and visual inspections to ensure each tool meets quality standards.

Which Testing Methods Are Commonly Used?

Manufacturers employ various testing methods to verify the performance and durability of leather belt hole makers. Common testing methods include:

-

Functional Testing: Assessing the tool’s ability to punch holes through different leather thicknesses without deformation.

-

Durability Testing: Subjecting tools to repeated use to evaluate wear and tear over time.

-

Material Testing: Analyzing the metal’s hardness and tensile strength to ensure it can withstand regular use without breaking or bending.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should actively engage with suppliers to verify their quality control processes. Here are some effective strategies:

What Role Do Audits and Reports Play?

Conducting audits is one of the most effective ways to assess a supplier’s quality control measures. Buyers can request regular quality reports that detail inspection results, non-conformance rates, and corrective actions taken.

- On-site audits provide deeper insights into the manufacturing process, allowing buyers to evaluate the actual working conditions and practices.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can enhance trust in the supplier’s quality assurance practices. Independent inspectors can provide unbiased evaluations of the manufacturing process and product quality, ensuring compliance with international standards.

What Are the Unique QC Considerations for International B2B Buyers?

When sourcing leather belt hole makers internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider the following:

-

Import Regulations: Different countries have varying regulations regarding the import of tools and equipment. Understanding these can help avoid compliance issues upon arrival.

-

Cultural Differences: Recognizing that quality perceptions may differ across cultures can aid in establishing clear expectations and communication with suppliers.

-

Logistical Challenges: Considerations regarding shipping, customs, and tariffs can impact delivery timelines and costs. Working with suppliers familiar with international logistics can mitigate these issues.

In conclusion, understanding the manufacturing processes and quality assurance measures for leather belt hole makers is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control practices, buyers can ensure they source reliable and durable tools for their leatherworking needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather belt hole maker’

In today’s competitive leather goods market, sourcing the right leather belt hole maker is crucial for maintaining product quality and operational efficiency. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications of the leather belt hole maker you require. Consider factors such as the size of holes needed, the thickness of the leather you’ll be working with, and the types of materials the punch will handle. This clarity will streamline your discussions with suppliers and ensure you select a tool that meets your production needs.

Step 2: Research Available Types of Hole Makers

Familiarize yourself with the various types of leather hole makers available in the market. Options include revolving punches, drive punches, and rotary hole punchers, each suited for different applications. Understanding these tools will enable you to choose one that aligns with your specific leatherworking requirements and enhances your production efficiency.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, product catalogs, and customer references, particularly from businesses in your industry or region. This will help you gauge the supplier’s reliability, product quality, and customer service capabilities, ensuring you partner with a trustworthy provider.

Step 4: Check for Quality Certifications

Ensure that your potential suppliers hold relevant quality certifications. Look for ISO certifications or compliance with international standards, which indicate that the supplier adheres to rigorous quality control processes. This step is vital for ensuring the longevity and performance of the leather hole makers you intend to purchase.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the leather belt hole makers you are considering. Testing these samples on the actual leather materials you use will provide insight into their performance, durability, and ease of use. This hands-on evaluation can prevent costly mistakes and ensure that the tools meet your expectations.

Illustrative image related to leather belt hole maker

Step 6: Negotiate Terms and Pricing

Once you’ve identified a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the total cost of ownership, including shipping and potential tariffs, is crucial, especially for international transactions. Aim for mutually beneficial terms that reflect the quality and reliability of the products.

Step 7: Establish a Long-term Relationship

After completing your purchase, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to better service, priority support, and potential discounts on future orders. A strong partnership can enhance your supply chain resilience and open doors for collaboration on new projects.

By following this checklist, B2B buyers can ensure a strategic approach to sourcing leather belt hole makers, ultimately contributing to improved product quality and operational efficiency in their leather goods production.

Comprehensive Cost and Pricing Analysis for leather belt hole maker Sourcing

What Are the Key Cost Components in Leather Belt Hole Maker Sourcing?

When sourcing leather belt hole makers, it’s crucial to understand the various cost components involved. These typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

Materials are foundational to the cost structure. High-quality steel or specialized alloys are often used for the punch heads, while the handles may be made from durable plastics or wood. The choice of materials directly impacts both performance and pricing.

Illustrative image related to leather belt hole maker

Labor costs can vary significantly depending on the region of production. For instance, labor in Asian countries may be more cost-effective than in Europe, affecting the final pricing of the product.

Manufacturing overhead encompasses expenses such as utilities, rent, and equipment maintenance, which can differ based on the location and scale of operations.

Tooling is another important cost factor. Custom tooling for unique designs can escalate initial costs, but it can also enhance production efficiency in the long run.

Quality control processes are essential to ensure the functionality and durability of the punches. Stringent QC measures can increase costs but are vital for maintaining product integrity.

Logistics costs involve shipping, handling, and import duties, which can fluctuate based on the destination country and the chosen Incoterms. Finally, the supplier’s margin is added to cover their operational costs and profit.

How Do Pricing Influencers Affect Leather Belt Hole Maker Costs?

Several factors can influence the pricing of leather belt hole makers, including volume or minimum order quantities (MOQs), specifications or customization needs, material quality, and certifications.

Volume/MOQ plays a significant role in pricing; larger orders typically secure lower per-unit costs due to economies of scale. Conversely, smaller orders may face higher prices, as fixed costs are distributed over fewer units.

Specifications and customization can also lead to price variations. Customized punches designed for specific applications may incur additional tooling and design costs.

Сайт quality of materials used affects the durability and performance of the tools, with higher-quality materials resulting in higher prices. Certifications related to safety and environmental standards can further influence costs.

Supplier factors, such as reputation and reliability, can also impact pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better support and reliability.

Incoterms determine the responsibilities of buyers and sellers regarding shipping and logistics, influencing overall costs. Familiarity with these terms can help buyers understand their total financial commitment.

What Are the Best Practices for Negotiating Leather Belt Hole Maker Prices?

B2B buyers should adopt strategic approaches when negotiating prices for leather belt hole makers. Understanding the Total Cost of Ownership (TCO) is vital. This includes not only the purchase price but also maintenance, operational efficiency, and potential downtime costs.

Negotiation strategies should be informed by market research. Buyers should compare prices from multiple suppliers and consider requesting samples to assess quality before committing to larger orders.

Illustrative image related to leather belt hole maker

Additionally, leveraging long-term relationships with suppliers can lead to better pricing and terms. Suppliers value repeat business and may be more willing to offer discounts or favorable terms to loyal customers.

Buyers in regions like Africa, South America, the Middle East, and Europe should also be aware of pricing nuances specific to their markets. Factors such as import tariffs, currency fluctuations, and local competition can affect pricing structures.

What Should International Buyers Consider When Sourcing Leather Belt Hole Makers?

International buyers must navigate various challenges when sourcing leather belt hole makers. Understanding local regulations and compliance standards is essential, as different countries may have varying requirements for imported tools.

Logistics and shipping can also be complex. International buyers should ensure they have a clear understanding of shipping costs, delivery timelines, and potential delays at customs.

Lastly, buyers should be cautious of indicative pricing. Prices may fluctuate based on market conditions, and it is advisable to obtain formal quotes before making purchasing decisions. By keeping these factors in mind, buyers can make informed decisions that optimize their sourcing strategies.

Illustrative image related to leather belt hole maker

Alternatives Analysis: Comparing leather belt hole maker With Other Solutions

Exploring Alternatives for Leather Belt Hole Making Solutions

In the leatherworking industry, the need for precision and efficiency is paramount. While leather belt hole makers are popular tools, various alternatives exist that cater to different production needs and budgets. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational goals.

| Comparison Aspect | Leather Belt Hole Maker | Manual Leather Punch | Rotary Hole Punch |

|---|---|---|---|

| Performance | High precision for consistent hole sizes | Moderate, varies with user skill | High, can punch multiple holes quickly |

| Cost | Moderate to high, depending on brand and features | Low, affordable for small-scale use | Moderate, offers a range of prices |

| Ease of Implementation | Simple setup, minimal training needed | Requires skill for best results | User-friendly, quick to switch sizes |

| Maintenance | Low, occasional cleaning required | Moderate, needs sharpening and care | Low, durable with minimal upkeep |

| Best Use Case | High-volume production with uniform quality | Small-scale or hobbyist projects | Versatile use, suitable for varied leather thicknesses |

What Are the Advantages and Disadvantages of Manual Leather Punches?

Manual leather punches are a traditional alternative that involves striking a punch with a mallet to create holes. This method is favored for its simplicity and low cost, making it accessible for small businesses or hobbyists. However, the performance heavily relies on the user’s skill; inconsistent pressure can lead to uneven holes. Furthermore, while these tools are affordable, they may require regular maintenance, including sharpening, to ensure optimal performance over time.

How Does a Rotary Hole Punch Compare?

Rotary hole punches offer a blend of convenience and efficiency, making them suitable for both small and larger projects. This tool allows users to punch multiple holes quickly by simply rotating the punch to the desired size. Its ease of use means that even those with limited experience can achieve professional results. However, rotary punches may struggle with thicker leather, requiring more effort and sometimes leading to uneven results if not handled properly. Additionally, while they are generally durable, they may incur higher costs than manual punches.

Conclusion: Which Leather Hole Making Solution is Right for Your Business?

When choosing the right solution for leather hole making, B2B buyers should consider their specific operational needs. For high-volume production environments, a leather belt hole maker may be the best choice due to its precision and efficiency. Conversely, for smaller-scale operations or hobbyist projects, manual leather punches can provide a cost-effective solution. Meanwhile, rotary hole punches offer versatility and ease of use, making them ideal for businesses that require flexibility in their leatherworking tasks. By assessing factors such as performance, cost, and best use case, buyers can select the most suitable tool that aligns with their business objectives and enhances their productivity.

Illustrative image related to leather belt hole maker

Essential Technical Properties and Trade Terminology for leather belt hole maker

What Are the Key Technical Properties of Leather Belt Hole Makers?

When sourcing leather belt hole makers, understanding their technical specifications can significantly influence product quality and operational efficiency. Here are several critical properties to consider:

-

Material Grade

The material used in the construction of leather hole makers is crucial for durability and performance. High-grade steel, for instance, is commonly employed for its strength and resistance to wear. A higher material grade often translates to a longer lifespan and less frequent replacements, which can reduce overall operational costs for manufacturers. -

Cutting Edge Design

The design of the cutting edge impacts the efficiency and precision of hole making. A sharp, well-engineered edge minimizes the force required to punch through leather, ensuring clean cuts. This is particularly important in high-volume production environments where consistency and quality are paramount. -

Punch Size Range

The versatility of a leather belt hole maker is often determined by the range of punch sizes available. Tools that offer multiple sizes allow manufacturers to accommodate various leather thicknesses and hole diameters. This flexibility can enhance productivity by reducing the need for multiple tools for different applications. -

Ergonomic Design

Ergonomics plays a vital role in the usability of leather hole makers. Tools designed with comfortable grips and balanced weight distribution minimize user fatigue, particularly in environments where repetitive motions are common. Investing in ergonomic tools can lead to improved worker satisfaction and efficiency. -

Tolerances

Tolerance levels indicate the acceptable range of deviation in dimensions for the tool’s components. High precision in tolerances ensures that the hole maker performs reliably, producing consistent results. This is particularly essential for businesses that require exact specifications for their products, such as high-end leather goods. -

Durability Ratings

Evaluating the durability of leather hole makers can help buyers assess their long-term viability. Tools with high durability ratings are less prone to breakage and wear, making them a more economical choice over time. This is especially relevant for B2B buyers looking for tools that withstand heavy usage in manufacturing settings.

What Are Common Trade Terms Used in the Leather Industry?

Understanding industry terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some key terms relevant to leather belt hole makers:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the leather industry, OEMs often produce tools or components that are branded and sold by other companies. Understanding OEM relationships can help buyers identify quality manufacturers and negotiate terms. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cash flow. Buyers should be aware of MOQs to ensure they can meet supply needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare offers from multiple suppliers and make informed decisions based on cost and service quality. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border transactions, as they clarify costs and risks associated with shipping. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. For businesses relying on timely delivery for production schedules, understanding lead times is crucial for planning and operational efficiency. -

Warranty Period

A warranty period is the timeframe during which a supplier guarantees the performance of their product. Knowing the warranty terms can provide assurance regarding product quality and recourse in case of defects, which is vital for maintaining operational integrity.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and overall business success in the leather industry.

Navigating Market Dynamics and Sourcing Trends in the leather belt hole maker Sector

What Are the Current Market Dynamics and Key Trends in the Leather Belt Hole Maker Sector?

The leather belt hole maker sector is experiencing a transformative phase driven by several global factors. Increasing demand for customized leather goods, especially in emerging markets like Africa and South America, fuels the growth of tools and machinery designed for precision and efficiency in leather crafting. International buyers are gravitating towards innovative technologies such as CNC machinery and automated punching systems that enhance production capabilities and reduce labor costs. Additionally, the rise of e-commerce platforms facilitates access to a broader range of suppliers and products, enabling buyers to source high-quality leather hole makers from various regions, including Europe and the Middle East.

Illustrative image related to leather belt hole maker

Sourcing trends are also shifting towards multi-functional tools that offer versatility, catering to diverse leather projects. This trend is particularly relevant for B2B buyers in regions like Saudi Arabia and Nigeria, where leatherworking is integral to local craftsmanship. Moreover, there is a noticeable shift towards manufacturers that emphasize durability and ease of use, reflecting the needs of both hobbyists and professional leatherworkers. As such, suppliers that offer a comprehensive range of products—including revolving punches, oblong punches, and specialized sets—are well-positioned to capture the attention of international buyers looking for reliable and effective solutions.

How Is Sustainability and Ethical Sourcing Impacting the Leather Belt Hole Maker Sector?

Sustainability is becoming a focal point in the leather industry, with B2B buyers increasingly prioritizing eco-friendly sourcing practices. The environmental impact of leather production, from animal husbandry to chemical processing, necessitates a shift towards more sustainable methods. This has led to a growing interest in suppliers that utilize vegetable-tanned leather and environmentally friendly dyes, which are perceived as less harmful to the ecosystem.

Ethical supply chains are essential for building trust and long-term relationships with international buyers. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) not only assure buyers of the environmental responsibility of their suppliers but also enhance their brand image in an increasingly conscious market. Furthermore, the use of recycled materials and innovations in synthetic leather alternatives are gaining traction, providing buyers with options that align with their sustainability goals. As buyers from regions like Europe and the Middle East become more discerning, suppliers who adopt sustainable practices will likely gain a competitive edge.

How Has the Leather Belt Hole Maker Sector Evolved Over Time?

The evolution of the leather belt hole maker sector reflects broader technological advancements and shifts in consumer preferences. Historically, leather hole-making tools were rudimentary, relying on manual methods that required significant skill and labor. However, the introduction of mechanized tools in the 20th century revolutionized the industry, improving efficiency and consistency in hole-making processes.

In recent years, the sector has embraced digital technology, with CNC machines and automated systems enabling precise hole placement and customization. This evolution is particularly significant for B2B buyers seeking to enhance their production capabilities. As the market continues to evolve, the emphasis on quality, sustainability, and ethical sourcing is likely to shape the future of leather crafting, making it essential for suppliers to adapt and innovate in response to these changing dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of leather belt hole maker

-

1. How do I choose the right leather belt hole maker for my business?

Selecting the appropriate leather belt hole maker depends on your specific needs, including the types of leather you work with and the volume of production. Consider factors like the size range of holes needed, the thickness of the leather, and whether you require a manual or powered tool. For high-volume production, a heavy-duty revolving punch may be ideal, while smaller operations might benefit from a compact rotary punch. Always check for compatibility with your existing tools and the quality of the materials used in the punch. -

2. What are the key features to look for in a leather hole punch?

When sourcing a leather hole punch, prioritize features such as durability, ease of use, and versatility. Look for tools made from high-quality materials that can withstand repeated use without dulling or breaking. Adjustable hole sizes are beneficial for various applications, while ergonomic designs can reduce fatigue during extended use. Additionally, consider whether the punch allows for easy maintenance, such as replacing worn components, to ensure longevity in your operations. -

3. What is the typical minimum order quantity (MOQ) for leather belt hole makers?

Minimum order quantities can vary significantly between suppliers and regions. Generally, you might expect MOQs to range from 50 to 500 units, depending on the manufacturer and the complexity of the tool. Larger suppliers might offer lower MOQs for standard items, while custom orders or specialized tools may require higher quantities. Always discuss your needs with potential suppliers to negotiate terms that suit your business model. -

4. How can I ensure the quality of leather belt hole makers from international suppliers?

To guarantee quality when sourcing from international suppliers, conduct thorough vetting processes. Request product samples and certifications to assess the materials and craftsmanship. Utilize third-party inspection services to evaluate products before shipment. Establish clear quality assurance protocols and maintain open communication with suppliers to address any concerns promptly. Additionally, consider suppliers with good reviews and a proven track record in the industry. -

5. What are the best payment terms for international orders of leather tools?

Payment terms for international orders often include options such as advance payment, letter of credit, or payment upon delivery. It’s crucial to negotiate terms that mitigate risk while ensuring supplier commitment. For larger orders, consider using escrow services to protect your investment until the products are received and verified. Always clarify currency exchange rates, transaction fees, and payment timelines to avoid unexpected costs. -

6. How do I handle logistics and shipping for leather hole makers?

Managing logistics for importing leather hole makers involves selecting reliable shipping methods and understanding customs regulations in your country. Work with freight forwarders who specialize in handling tools and equipment to streamline the process. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared in advance to avoid delays at customs. Additionally, factor in shipping insurance to protect against loss or damage during transit. -

7. Can I customize leather belt hole makers for my brand?

Many manufacturers offer customization options for leather belt hole makers, allowing you to add your logo or specific design features. When discussing customization, communicate your requirements clearly, including the desired materials, sizes, and branding elements. Be prepared for potential minimum order quantities and longer lead times for custom products. Customization can enhance your brand’s visibility and differentiate your products in the market. -

8. What after-sales support should I expect from a leather hole punch supplier?

After-sales support varies by supplier, but reputable manufacturers typically offer warranties on their products and assistance with repairs or replacements. Inquire about the availability of spare parts and technical support for troubleshooting issues. A good supplier will provide guidance on proper maintenance and usage to prolong the life of your tools. Establishing a solid relationship with your supplier can facilitate ongoing support and communication for future orders.

Top 3 Leather Belt Hole Maker Manufacturers & Suppliers List

1. Buckleguy – BG Straight Leather Slot

Domain: buckleguy.com

Registered: 2002 (23 years)

Введение: Buckleguy offers a variety of leather hole and end punches, manufactured by C.S. Osborne in the US. The product range includes multi-size strap end punches suitable for leather straps and bag ends, commonly referred to as revolving belt hole punches. Key products include:

– BG Straight Leather Slot Punch (Sizes: 1/8″ to 1″) priced between $7.67 – $21.84

– BG Card Slot Punch (Sizes: 5mm to 87mm) …

2. Weaver Leather Supply – Leather Hole Punch Tools

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Введение: Leather Hole Punch Tools & Sets – Weaver Leather Supply offers a variety of leather punch tools including leather hole punches, oblong leather punches, leather stitching punches, leather corner punches, and more. The selection includes revolving & rotary punches, single tube & card slot punches, strap end punches, button hole punches, and various sizes of oblong, oval, and round hole punch sets. K…

3. Knipex – Best Handheld Hole Punch

Domain: reddit.com

Registered: 2005 (20 years)

Введение: Handheld hole punch recommended by users includes: 1. Knipex – mentioned as the best owned by a user. 2. Leather Hole Puncher Hand Punching Machine Manual Press Puncher – requires a punch set, praised for its performance. 3. WUTA punches – used with the manual press puncher, requires some modification to fit. 4. OWDEN 9 Pieces Hollow Punch Set (1/8″-1/2″) – comes with a free cutting mat, highly re…

Strategic Sourcing Conclusion and Outlook for leather belt hole maker

How Can Strategic Sourcing Enhance Your Leather Belt Hole Maker Procurement?

In conclusion, the strategic sourcing of leather belt hole makers is crucial for international B2B buyers seeking high-quality, durable, and efficient tools. By understanding the diverse options available—from heavy-duty revolving punches to multi-size punch sets—buyers can ensure they select tools that align with their specific production needs. Key takeaways include the importance of sourcing from reputable manufacturers known for their craftsmanship, as well as the value of investing in versatile tools that enhance productivity and reduce downtime.

As businesses in regions such as Africa, South America, the Middle East, and Europe (e.g., Saudi Arabia, Nigeria) continue to grow, the demand for reliable leatherworking tools will only increase. Strategic sourcing not only fosters competitive pricing but also strengthens supplier relationships, leading to long-term benefits.

To stay ahead in this evolving market, we encourage buyers to assess their current sourcing strategies and explore partnerships with established suppliers who can provide innovative solutions. Embrace the future of leather craftsmanship by making informed sourcing decisions today—your business’s success depends on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.