Introduction: Navigating the Global Market for custom leather lifting belt

In the competitive landscape of fitness equipment, sourcing high-quality custom leather lifting belts poses a significant challenge for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. The demand for personalized, durable lifting belts is on the rise as gyms and fitness enthusiasts increasingly seek products that combine functionality with style. This comprehensive guide aims to navigate the complexities of the global market for custom leather lifting belts, offering insights into various types, applications, and the intricacies of supplier vetting.

Understanding the nuances of material quality, design options, and cost structures is crucial for making informed purchasing decisions. This guide empowers international buyers by providing a detailed analysis of the factors that influence the selection of custom leather lifting belts, including performance benefits, customization options, and compliance with regional standards. Additionally, it highlights key suppliers renowned for their craftsmanship and reliability, ensuring that businesses can connect with manufacturers who meet their specific needs.

By equipping B2B buyers with actionable insights and expert recommendations, this guide serves as a vital resource for those looking to enhance their product offerings in the fitness sector. Whether you are sourcing for retail or equipping a commercial gym, understanding the market dynamics and leveraging the right partnerships will be pivotal to your success.

Table Of Contents

- Top 6 Custom Leather Lifting Belt Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather lifting belt

- Understanding custom leather lifting belt Types and Variations

- Key Industrial Applications of custom leather lifting belt

- 3 Common User Pain Points for ‘custom leather lifting belt’ & Their Solutions

- Strategic Material Selection Guide for custom leather lifting belt

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather lifting belt

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather lifting belt’

- Comprehensive Cost and Pricing Analysis for custom leather lifting belt Sourcing

- Alternatives Analysis: Comparing custom leather lifting belt With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather lifting belt

- Navigating Market Dynamics and Sourcing Trends in the custom leather lifting belt Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather lifting belt

- Strategic Sourcing Conclusion and Outlook for custom leather lifting belt

- Important Disclaimer & Terms of Use

Understanding custom leather lifting belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Lever Belts | Quick-release lever mechanism, adjustable fit | Powerlifting, competitive lifting | Pros: Easy to adjust, secure fit. Cons: Can be bulkier than traditional belts. |

| Custom Dyed Belts | Unique color options and artistic designs | Branding, promotional events | Pros: High visual appeal, personalization. Cons: May require longer production times. |

| Standard Custom Belts | Basic leather construction with customizable sizing | General gym use, fitness training | Pros: Cost-effective, versatile. Cons: Limited customization compared to other types. |

| Exotic Leather Belts | Made from premium materials like gator or ostrich | Luxury fitness markets, high-end gyms | Pros: Distinctive style, high durability. Cons: Higher price point, niche market appeal. |

| Custom Embroidered Belts | Personalized embroidery options for branding | Corporate gifting, team sports | Pros: Enhances brand visibility, unique designs. Cons: Potentially longer lead times for production. |

What Are the Characteristics and Suitability of Custom Lever Belts?

Custom lever belts are designed with a quick-release lever mechanism, allowing for easy adjustment and a secure fit during heavy lifts. They are particularly suited for powerlifters and athletes in competitive settings where stability and safety are paramount. B2B buyers should consider the fit and comfort level, as well as the belt’s material quality to ensure it meets the rigorous demands of their clientele.

How Do Custom Dyed Belts Enhance Branding Opportunities?

Custom dyed belts offer a unique aesthetic with a variety of color options and artistic designs, making them ideal for branding purposes or promotional events. They allow businesses to create visually striking products that stand out in the market. Buyers should evaluate the production timelines and the potential for increased customer engagement through distinctive designs when considering these belts.

What Are the Benefits of Standard Custom Belts for General Use?

Standard custom belts are typically made from durable leather and offer customizable sizing options. They cater to a broad audience, including casual gym-goers and fitness enthusiasts. B2B buyers will find these belts to be cost-effective, making them a suitable choice for bulk orders while still providing a level of personalization that appeals to a wide customer base.

Why Choose Exotic Leather Belts for Luxury Markets?

Exotic leather belts, crafted from premium materials such as gator or ostrich, cater to high-end fitness markets and luxury gyms. Their unique appearance and durability make them appealing to consumers seeking exclusivity in their fitness gear. Buyers should be prepared for a higher price point and consider the niche market appeal when incorporating these products into their offerings.

How Do Custom Embroidered Belts Improve Team Spirit and Brand Visibility?

Custom embroidered belts allow for personalization through unique embroidery options, making them excellent for corporate gifting or team sports. They enhance brand visibility and foster a sense of unity among team members. B2B buyers should consider the lead times for production and the impact of branding on customer loyalty when selecting these belts for promotional purposes.

Key Industrial Applications of custom leather lifting belt

| Industry/Sector | Specific Application of custom leather lifting belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness & Wellness | Used by personal trainers and fitness enthusiasts for weightlifting and strength training | Enhances performance and safety during heavy lifts, promoting client retention and satisfaction | Durability, customization options, and compliance with international quality standards |

| Competitive Sports | Utilized by powerlifters and bodybuilders in competitions | Provides critical support and boosts confidence, improving performance outcomes | Certification for competitive use, material quality, and branding opportunities |

| Rehabilitation & Therapy | Employed in physical therapy settings for strength recovery programs | Aids in safe lifting techniques, reducing injury risk and promoting faster recovery | Ergonomic design, adjustability, and compatibility with therapy protocols |

| Industrial Training | Incorporated in training programs for manual labor and construction workers | Increases safety awareness and reduces workplace injuries, fostering a culture of safety | Compliance with safety regulations, bulk purchasing options, and supplier reliability |

| Fashion & Lifestyle | Customized for athletes and fitness influencers as fashion statements | Differentiates brands and enhances marketability through unique designs | Trend alignment, customization capabilities, and material sourcing for sustainable practices |

How is the Custom Leather Lifting Belt Used in the Fitness & Wellness Sector?

In the fitness and wellness sector, custom leather lifting belts are essential for personal trainers and fitness enthusiasts engaged in weightlifting and strength training. These belts provide critical support for the lower back and core, allowing users to lift heavier weights safely. For international buyers, particularly from regions like Africa and South America, sourcing high-quality, durable belts that meet local fitness trends is crucial. Customization options, such as personalized embroidery or color choices, can also enhance brand loyalty and client satisfaction.

What Role Does the Custom Leather Lifting Belt Play in Competitive Sports?

In competitive sports, particularly powerlifting and bodybuilding, custom leather lifting belts are indispensable. They offer the necessary support to maintain proper posture and reduce injury risk during high-stakes lifts. For buyers in Europe and the Middle East, ensuring that these belts meet competitive standards is vital. Additionally, the ability to brand these belts with logos can serve as a marketing tool, enhancing visibility during competitions and events.

How is the Custom Leather Lifting Belt Beneficial in Rehabilitation & Therapy?

Custom leather lifting belts find significant application in rehabilitation and therapy settings, where they are used to assist patients in strength recovery programs. These belts help patients perform lifting exercises safely, minimizing the risk of re-injury. For international buyers, especially in emerging markets, sourcing belts that are ergonomically designed and adjustable is essential for accommodating diverse patient needs and ensuring compliance with therapy protocols.

Why is the Custom Leather Lifting Belt Important in Industrial Training?

In industrial training, custom leather lifting belts are integrated into programs aimed at manual labor and construction workers. These belts promote safe lifting techniques and increase awareness of workplace safety, thus reducing the incidence of injuries. Buyers in regions with robust industrial sectors must consider compliance with local safety regulations when sourcing these belts. Bulk purchasing options and supplier reliability are also critical factors for businesses looking to equip their workforce effectively.

How Does the Custom Leather Lifting Belt Cater to Fashion & Lifestyle Trends?

Custom leather lifting belts are increasingly viewed as fashion statements among athletes and fitness influencers. They not only serve a functional purpose but also allow individuals to express their personal style. For B2B buyers focused on fashion and lifestyle, aligning with current trends and offering customization capabilities is essential for market differentiation. Sustainable material sourcing can also enhance brand appeal in a market that values eco-friendly practices.

3 Common User Pain Points for ‘custom leather lifting belt’ & Their Solutions

Scenario 1: Sourcing High-Quality Custom Leather Lifting Belts for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality custom leather lifting belts that meet the varying demands of their target markets, especially when dealing with international customers from regions like Africa, South America, the Middle East, and Europe. Many suppliers may offer low-cost options, but these can compromise on quality and durability. This inconsistency can lead to customer dissatisfaction, product returns, and potential damage to a company’s reputation.

The Solution: To ensure a reliable supply of high-quality custom leather lifting belts, B2B buyers should establish partnerships with reputable manufacturers known for their craftsmanship and commitment to quality. Conduct thorough research to identify suppliers that provide detailed product specifications, including leather quality, stitching techniques, and customization options. Request samples before placing bulk orders to assess the belts’ durability and comfort. Additionally, consider manufacturers that provide testimonials or case studies from other international buyers to validate their reliability. By prioritizing quality over cost and building solid relationships with trustworthy suppliers, businesses can enhance their product offerings and ensure customer satisfaction.

Scenario 2: Customization Challenges for Different User Needs

The Problem: Another common pain point for B2B buyers is the challenge of offering customization options that cater to a wide range of user preferences and requirements. Different markets may have specific demands regarding colors, styles, sizes, and even branding elements. If a supplier cannot accommodate these variations, it can lead to lost sales opportunities and an inability to meet customer expectations.

The Solution: To address this issue, B2B buyers should collaborate with manufacturers that offer extensive customization capabilities. This includes not only a variety of color and design options but also the ability to add logos, names, or other personal touches. When negotiating with suppliers, inquire about their customization processes, lead times, and minimum order quantities for bespoke designs. Establishing a clear communication channel with the manufacturer can also facilitate the design process, ensuring that the final product aligns with the buyer’s vision and meets the specific needs of their clientele. Offering a wider range of customizable options can significantly enhance market appeal and customer retention.

Scenario 3: Understanding Regulatory Compliance and Quality Standards

The Problem: Navigating regulatory compliance and quality standards can be particularly daunting for B2B buyers, especially when sourcing custom leather lifting belts for international markets. Different countries may have varying regulations regarding materials used, safety standards, and labeling requirements. This lack of clarity can lead to compliance issues, fines, or even the rejection of goods at customs.

The Solution: B2B buyers should proactively familiarize themselves with the regulatory requirements specific to the regions they intend to sell in. This may involve researching local laws or consulting with legal experts who specialize in international trade. When selecting suppliers, prioritize those who are knowledgeable about compliance and can provide documentation that confirms their products meet relevant safety and quality standards. Additionally, consider requesting certifications or test results for materials used in the belts, such as leather quality and chemical safety. By staying informed and partnering with compliant suppliers, buyers can mitigate risks and ensure smooth transactions across borders, ultimately enhancing their business’s credibility in the global market.

Strategic Material Selection Guide for custom leather lifting belt

What Are the Key Materials Used in Custom Leather Lifting Belts?

When selecting materials for custom leather lifting belts, it’s crucial to understand the properties, advantages, and limitations of each option. This analysis will focus on four common materials: full-grain leather, top-grain leather, synthetic leather, and suede leather. Each material has unique characteristics that can influence performance, durability, and suitability for international markets.

How Does Full-Grain Leather Perform in Custom Leather Lifting Belts?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, providing exceptional durability and breathability. Full-grain leather can withstand high temperatures and pressures, making it ideal for heavy lifting. However, it can be more expensive and may require more complex manufacturing techniques due to its thickness.

Pros:

– Extremely durable and long-lasting

– Excellent breathability and moisture-wicking properties

– Develops a unique patina over time

Cons:

– Higher cost compared to other materials

– Requires specialized craftsmanship

For international buyers, particularly in regions with high humidity like parts of Africa and South America, full-grain leather’s breathability can be a significant advantage. Compliance with quality standards such as ASTM for leather goods is crucial to ensure product reliability.

What Are the Benefits of Top-Grain Leather for Lifting Belts?

Top-grain leather is slightly less durable than full-grain leather but offers a more uniform appearance. It is sanded and finished to remove imperfections, making it more aesthetically appealing. This material is also resistant to moisture and can handle moderate pressure, making it suitable for lifting applications.

Pros:

– More affordable than full-grain leather

– Attractive finish with fewer blemishes

– Good resistance to moisture

Cons:

– Less durable than full-grain leather

– Can wear out faster under heavy use

For B2B buyers in the Middle East and Europe, where style and appearance may be prioritized, top-grain leather provides a balance between cost and aesthetics. Ensuring that the leather meets local standards for quality and environmental impact is essential.

How Does Synthetic Leather Compare in Terms of Performance?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to natural leather. It is lightweight, easy to clean, and resistant to moisture and stains. However, synthetic leather may not provide the same level of breathability and durability as genuine leather.

Pros:

– Cost-effective and lightweight

– Easy to maintain and clean

– Resistant to moisture and stains

Cons:

– Less durable than natural leather

– May not provide the same level of support during heavy lifting

For buyers in regions like South America, where budget constraints may be a concern, synthetic leather can be an appealing option. However, it’s crucial to verify that the synthetic materials comply with international standards for safety and environmental sustainability.

What Role Does Suede Leather Play in Custom Lifting Belts?

Suede leather, characterized by its soft and textured finish, offers a unique aesthetic appeal. While it provides decent grip and comfort, it is less durable than full-grain or top-grain leather. Suede is also more susceptible to moisture damage, which can limit its effectiveness in high-performance lifting scenarios.

Pros:

– Soft and comfortable feel

– Unique aesthetic appeal

– Good grip during lifting

Cons:

– Less durable than other leather types

– Susceptible to moisture and stains

For international buyers, particularly in humid climates, the use of suede may require additional care and maintenance. Ensuring that suede belts are treated for water resistance can enhance their usability in various environments.

Summary of Material Selection for Custom Leather Lifting Belts

| Материал | Typical Use Case for Custom Leather Lifting Belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-performance lifting in competitive settings | Exceptional durability and breathability | Higher cost, requires craftsmanship | Высокий |

| Top-Grain Leather | General lifting and fitness applications | Attractive finish, moisture-resistant | Less durable than full-grain | Medium |

| Синтетическая кожа | Budget-friendly lifting options | Lightweight, easy to maintain | Less durable, lower breathability | Низкий |

| Suede Leather | Casual lifting and aesthetic-focused applications | Soft feel, good grip | Susceptible to moisture damage | Medium |

This guide provides a comprehensive overview of materials suitable for custom leather lifting belts, aiding international B2B buyers in making informed decisions based on performance, cost, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather lifting belt

What Are the Key Stages in the Manufacturing Process of Custom Leather Lifting Belts?

The manufacturing process of custom leather lifting belts involves several critical stages that ensure the final product meets the high standards expected by athletes and fitness enthusiasts. Understanding these stages can help B2B buyers make informed purchasing decisions.

Material Preparation: What Types of Leather Are Used?

The first stage in the manufacturing process is material preparation. High-quality leather is paramount for the durability and performance of lifting belts. Common types of leather used include full-grain, top-grain, and suede. Full-grain leather, known for its strength and breathability, is often preferred for its ability to withstand heavy use and provide optimal support. In addition to leather, manufacturers may use synthetic materials for added flexibility and moisture resistance.

Once the leather is selected, it undergoes a treatment process to enhance its durability. This may include tanning, which helps preserve the leather and improve its resistance to wear and tear. The leather is then cut into the required shapes and sizes, ensuring precision to fit various customer specifications.

How Is the Forming Process Conducted?

The forming stage involves shaping the leather into the desired belt configuration. This process typically uses a combination of handcrafting and machinery. Skilled artisans may hand-stitch or machine-stitch the leather, depending on the design requirements. This stage is critical for ensuring that the belt provides the right amount of support and comfort.

Manufacturers often use techniques such as heat molding to create a contoured fit that conforms to the wearer’s body. This is particularly important for lifting belts, as a snug fit can enhance stability during heavy lifting. Additionally, custom designs may be embossed or printed onto the leather, allowing for branding or personalization.

What Happens During the Assembly and Finishing Stages?

Once the leather pieces are formed, they are assembled. This involves attaching the buckle, which can vary in style—lever, prong, or quick-release—depending on customer preferences. The assembly process may also include adding padding or lining materials to enhance comfort and reduce chafing during use.

The finishing stage is where the belt is polished and treated for aesthetic and functional purposes. This may involve applying conditioners or sealants to protect the leather from moisture and dirt. Final quality checks occur during this stage to ensure that the belt meets the desired specifications before packaging.

What Quality Assurance Measures Are Commonly Employed?

Quality assurance is critical in the manufacturing of custom leather lifting belts. To ensure that products meet international standards, manufacturers typically adhere to several quality control measures.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with key international quality standards such as ISO 9001, which specifies requirements for quality management systems. Compliance with these standards indicates that the manufacturer has established processes to ensure consistent quality and customer satisfaction.

In addition to ISO standards, certain industry-specific certifications may apply, such as CE marking for products sold in the European Economic Area, or API standards for specific applications. Buyers should verify that their suppliers comply with these standards to ensure product safety and reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications. This helps prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor compliance with quality standards. This includes checking stitching quality, leather thickness, and overall craftsmanship.

-

Final Quality Control (FQC): Before the products are packaged, a thorough inspection is performed to confirm that each belt meets the required quality standards. This may include stress testing the belts to ensure they can withstand the pressures of lifting.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control processes.

What Should Buyers Look for in Supplier Audits and Reports?

Requesting audits and quality control reports from suppliers can provide insight into their manufacturing practices. A reputable supplier should be willing to share documentation that outlines their QC processes and any certifications they hold.

Additionally, buyers can conduct on-site inspections to observe the manufacturing process firsthand. This allows buyers to assess the working conditions, equipment quality, and overall adherence to quality standards.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further validate a supplier’s quality assurance practices. These independent organizations can conduct comprehensive assessments of the manufacturing facilities and processes, providing unbiased reports on compliance with international standards.

What Are the Unique Quality Control Considerations for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, there are specific quality control nuances to consider.

How Do Cultural and Regulatory Differences Impact Quality Standards?

Cultural differences and varying regulatory requirements can influence quality standards across regions. Buyers should familiarize themselves with local regulations and expectations, which can differ significantly from one country to another.

For instance, some regions may have stricter guidelines regarding material sourcing and labor practices. Understanding these nuances can help buyers select suppliers that align with their values and compliance requirements.

What Should Buyers Consider Regarding Shipping and Handling?

Lastly, B2B buyers must consider the impact of shipping and handling on product quality. Ensuring that suppliers have robust packaging and shipping practices is essential to prevent damage during transport. Buyers should inquire about how products are packaged and whether suppliers have insurance or guarantees for damaged goods.

By understanding the manufacturing processes and quality assurance measures associated with custom leather lifting belts, B2B buyers can make informed decisions, ensuring they partner with reliable manufacturers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather lifting belt’

In the competitive market for custom leather lifting belts, B2B buyers must navigate a series of crucial steps to ensure they procure high-quality products that meet their specific needs. This guide provides a comprehensive checklist to help you make informed decisions while sourcing custom lifting belts.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline the technical specifications of the lifting belts you need. This includes the type of leather, thickness, width, and any specific design elements such as color or embroidery. Clear specifications not only streamline your communication with suppliers but also ensure that the final product aligns with your brand and functional requirements.

- Key Considerations:

- Determine the intended use (e.g., powerlifting, bodybuilding).

- Consider ergonomic features that enhance performance and comfort.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in custom leather lifting belts. Look for manufacturers with a solid track record in producing high-quality products and positive reviews from other businesses.

- Important Actions:

- Use online directories and trade shows to find suppliers.

- Check for industry certifications and quality assurance processes.

Step 3: Evaluate Supplier Capabilities

Once you have a list of potential suppliers, assess their capabilities to meet your specifications. This includes evaluating their production methods, customization options, and lead times.

- What to Look For:

- The range of customization options available (e.g., sizes, colors, logos).

- Production capacity to meet your order volume and deadlines.

Step 4: Request Samples

Before making a bulk purchase, it is prudent to request samples from your shortlisted suppliers. Evaluating samples allows you to assess the quality of materials and craftsmanship firsthand.

- Sample Evaluation Criteria:

- Durability and comfort of the belt when worn.

- Quality of stitching and overall finish.

Step 5: Verify Supplier Certifications

Ensuring that your chosen supplier adheres to industry standards is critical for maintaining quality and compliance. Verify any relevant certifications, such as ISO or safety standards, which can indicate a commitment to quality manufacturing processes.

- Why This Matters:

- Certifications can help mitigate risks associated with product quality and safety.

- They enhance your credibility when marketing the lifting belts.

Step 6: Negotiate Terms and Pricing

Engage in discussions about pricing, payment terms, and order quantities. Understanding the cost structure is vital for budgeting and profitability.

- Negotiation Tips:

- Inquire about bulk order discounts and shipping options.

- Ensure clarity on return policies and warranty terms.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your supplier to ensure that any issues or questions can be addressed promptly.

- Best Practices:

- Use dedicated project management tools for tracking progress.

- Schedule regular check-ins to review production updates.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom leather lifting belts, ensuring they partner with reliable suppliers and receive products that meet their exact specifications.

Comprehensive Cost and Pricing Analysis for custom leather lifting belt Sourcing

What Are the Key Cost Components for Custom Leather Lifting Belts?

The cost structure for sourcing custom leather lifting belts is multifaceted, encompassing various components that directly influence the final pricing. Key cost components include:

-

Materials: The choice of leather significantly affects costs. High-quality, durable leather, such as full-grain or top-grain, tends to be more expensive than synthetic alternatives. Specialty materials, like exotic leathers, can further increase the price.

-

Labor: Handcrafted belts require skilled artisans, which can lead to higher labor costs. Labor intensity varies based on the level of customization and the complexity of the design.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. For custom products, the overhead can be higher due to the need for specialized equipment.

-

Tooling: Custom tooling for unique designs or logos adds to initial costs. These one-time expenses can be amortized over larger production runs, making it essential to consider the volume of orders.

-

Quality Control (QC): Rigorous QC processes ensure that the belts meet specified standards. This can include inspections during various production stages, contributing to overall costs.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and volume. International shipments may incur additional fees, including customs duties and taxes.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. This can vary based on market positioning, brand reputation, and demand.

How Do Price Influencers Affect the Cost of Custom Leather Lifting Belts?

Several factors influence the pricing of custom leather lifting belts:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect the unit price. Larger orders often lead to bulk pricing discounts, making it crucial for buyers to assess their purchasing strategies.

-

Specifications and Customization: The extent of customization—such as specific sizes, colors, and embroidery—can raise costs. More intricate designs require additional time and resources, affecting the overall price.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., eco-friendly or compliance with specific industry standards) may increase costs but can enhance the product’s marketability.

-

Supplier Factors: Supplier reputation, experience, and location also play roles in pricing. Established suppliers with a track record of quality and reliability may charge a premium.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is vital, as they determine responsibility for shipping costs, insurance, and risk during transit.

What Buyer Tips Can Help Negotiate Better Prices for Custom Leather Lifting Belts?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize their sourcing process:

-

Negotiate Volume Discounts: Leverage larger order sizes to negotiate lower prices per unit. Establishing long-term relationships with suppliers can also yield better pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential tariffs, and maintenance costs. A lower upfront cost may not always translate to savings in the long run.

-

Be Aware of Pricing Nuances: Regional economic conditions can impact pricing. For instance, currency fluctuations or trade agreements may affect costs for buyers in different markets.

-

Clarify Customization Costs: Ensure clarity on what customization entails and any associated costs. Sometimes, suppliers may offer package deals that can reduce overall expenses.

-

Understand Shipping Implications: Familiarize yourself with the shipping process and associated costs. Opting for different shipping methods can lead to significant savings, especially for larger orders.

Заключение

Understanding the cost structure and pricing factors associated with custom leather lifting belts is essential for B2B buyers. By being informed about the various components and price influencers, buyers can make strategic decisions that not only optimize costs but also enhance the value derived from their investments. Always remember that indicative prices may vary based on supplier negotiations and market conditions, so conducting thorough research and analysis is key to successful sourcing.

Alternatives Analysis: Comparing custom leather lifting belt With Other Solutions

Introduction to Alternatives in Weightlifting Solutions

In the world of weightlifting, the choice of equipment significantly impacts performance, safety, and comfort. While custom leather lifting belts are a popular option for many athletes, several alternatives exist that offer different benefits and features. Understanding these alternatives can help B2B buyers make informed decisions based on their specific needs, budget, and operational context.

Comparison Table

| Comparison Aspect | Custom Leather Lifting Belt | Nylon Weightlifting Belt | Lever Action Weightlifting Belt |

|---|---|---|---|

| Performance | High support; enhances core stability; durable | Moderate support; flexible; less rigid | Excellent support; quick adjustments; very durable |

| Cost | Higher investment ($120 – $250) | Lower cost ($30 – $100) | Mid-range ($60 – $150) |

| Ease of Implementation | Requires sizing; typically custom-made | Standard sizes; readily available | Requires sizing; can be customized |

| Maintenance | Requires regular conditioning; more durable | Minimal maintenance; lightweight | Low maintenance; very durable |

| Best Use Case | Professional athletes; heavy lifting; powerlifting | General fitness; CrossFit; casual lifters | Powerlifting; competitive lifting; heavy usage |

Detailed Breakdown of Alternatives

Nylon Weightlifting Belt

Nylon weightlifting belts are lightweight and often more affordable than their leather counterparts. They provide moderate support and flexibility, making them suitable for various activities, including CrossFit and general fitness training. The ease of finding standard sizes makes them accessible for casual lifters. However, they may not offer the same level of core stability or durability under heavy loads, which could lead to safety concerns for serious athletes.

Lever Action Weightlifting Belt

Lever action belts provide a unique mechanism that allows for quick adjustments, making them user-friendly, especially in competitive environments. They offer excellent support and can be very durable, suitable for powerlifting and other strength training disciplines. While they typically fall in the mid-range price category, their effective design and functionality make them a strong choice for serious lifters. However, they may require specific sizing and might not offer the same level of customization as leather belts.

Conclusion: Choosing the Right Weightlifting Solution for Your Business

For B2B buyers, selecting the right lifting belt hinges on a clear understanding of their specific use cases and the preferences of their clientele. Custom leather lifting belts are ideal for professional athletes seeking durability and high performance, while nylon belts serve well for general fitness enthusiasts looking for affordability and flexibility. Lever action belts stand out for their ease of adjustment and robust support, making them suitable for competitive lifters. Ultimately, the decision should align with the target market’s needs, budget constraints, and the level of commitment to weightlifting activities.

Essential Technical Properties and Trade Terminology for custom leather lifting belt

What Are the Key Technical Properties of Custom Leather Lifting Belts?

When sourcing custom leather lifting belts, understanding specific technical properties is crucial for ensuring product quality and compliance with industry standards. Here are some essential specifications to consider:

1. Material Grade

The quality of leather used in lifting belts significantly impacts durability and performance. Full-grain leather, often regarded as the highest quality, offers superior strength and longevity. It retains natural characteristics and breathability, making it ideal for heavy lifting. B2B buyers should prioritize suppliers that specify the type of leather and its grade, as this directly influences product reliability.

2. Thickness

The thickness of the leather belt, typically measured in millimeters (mm), affects both comfort and support. Most high-quality lifting belts range from 10mm to 13mm thick. A thicker belt provides more stability and support during heavy lifts, which can be a deciding factor for serious athletes and fitness enthusiasts. Buyers should verify the thickness to ensure it meets their specific lifting requirements.

3. Width

Lifting belts usually come in various widths, commonly 4 inches (10 cm) or 6 inches (15 cm). A wider belt offers more coverage and support for the lower back, distributing pressure more evenly across the torso. Buyers should assess the target audience’s preferences, as some lifters may prefer a narrower belt for flexibility.

4. Stitching and Reinforcement

The stitching quality is a critical indicator of durability. Double or triple stitching is recommended for lifting belts to withstand heavy loads without fraying or breaking. Reinforced edges can also improve longevity. B2B buyers should inquire about the stitching techniques employed by manufacturers to ensure the product can endure rigorous use.

5. Buckle Type

The type of buckle used in lifting belts (lever, prong, or Velcro) affects usability and adjustment. Lever buckles provide quick adjustments and a secure fit, which is preferred by many powerlifters. Prong buckles offer a classic option with customizable tightness, while Velcro allows for easy adjustments. Buyers should consider the preferences of their customer base when selecting buckle types.

6. Weight Capacity

Understanding the weight capacity of a lifting belt is essential for safety and performance. Most belts are designed to support a specific maximum weight, which should be clearly indicated by the manufacturer. B2B buyers should ensure that the belts they source can accommodate the lifting needs of their end-users, particularly in competitive settings.

What Are Common Trade Terms Related to Custom Leather Lifting Belts?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another brand’s name. Understanding OEM relationships can help buyers identify reliable suppliers who adhere to quality standards and specifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to produce or sell. Buyers need to be aware of MOQs to manage inventory and cost-effectiveness, especially when entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing information for specific products. Including detailed specifications in an RFQ can help ensure accurate quotes and streamline the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms is essential for avoiding misunderstandings and ensuring compliance with trade regulations.

5. Customization Options

This term refers to the range of personalization available for lifting belts, including color, size, and design elements. Understanding the customization process can help buyers better meet the specific needs of their customers.

6. Lead Time

Lead time is the duration between placing an order and receiving the product. Knowing the lead times for custom leather lifting belts is crucial for inventory planning and meeting customer demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather lifting belts, ultimately enhancing their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the custom leather lifting belt Sector

What Are the Key Market Trends Driving the Custom Leather Lifting Belt Sector?

The global custom leather lifting belt market is experiencing significant growth, driven by increasing participation in fitness and strength training across various demographics. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where fitness culture is evolving rapidly. The demand for personalized and high-quality products is on the rise, as consumers seek belts that not only provide functionality but also reflect their individual style.

Emerging technologies in the manufacturing process, such as advanced leather tanning and digital customization tools, are reshaping sourcing practices. B2B buyers can now leverage these innovations to create unique products that cater to specific market demands. For instance, customization options that allow for embroidery, color selection, and the use of exotic materials are becoming increasingly popular. Additionally, the integration of e-commerce platforms facilitates easier access to suppliers and enables international buyers to source products directly from manufacturers, streamlining the procurement process.

Market dynamics are also influenced by the rise of social media, where influencers and athletes showcase their gear, creating aspirational demand. As a result, manufacturers are focusing on branding and storytelling to connect with their audience, which can be a crucial factor for B2B buyers looking to stock their shelves with sought-after products.

How Is Sustainability and Ethical Sourcing Shaping the Custom Leather Lifting Belt Industry?

Sustainability is no longer a niche concern; it has become a critical factor influencing purchasing decisions in the custom leather lifting belt sector. Environmental impact considerations are driving brands to adopt ethical sourcing practices and utilize eco-friendly materials. Buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainability through certifications and transparent supply chains.

The use of ‘green’ materials, such as vegetable-tanned leather and recycled components, is gaining traction. These materials not only reduce environmental impact but also appeal to a growing demographic of eco-conscious consumers. For B2B buyers, partnering with manufacturers that prioritize ethical practices can enhance brand reputation and customer loyalty, particularly in markets where consumers are increasingly aware of sustainability issues.

Furthermore, ethical sourcing can mitigate risks associated with supply chain disruptions and regulatory compliance. By ensuring that suppliers adhere to fair labor practices and environmental standards, businesses can safeguard their operations against potential backlash from unethical sourcing practices.

What Is the Historical Context Behind the Rise of Custom Leather Lifting Belts?

The evolution of custom leather lifting belts can be traced back to the late 20th century, when the fitness industry began to flourish. Initially, weightlifting belts were primarily utilitarian, designed to provide support during heavy lifts. However, as the fitness culture grew, so did the demand for personalized and aesthetically pleasing gear.

The 1980s and 1990s saw the emergence of brands that specialized in handcrafted leather products, catering to athletes and fitness enthusiasts who desired both functionality and style. This period marked the beginning of customization in weightlifting belts, with consumers seeking unique designs that reflected their personalities.

In recent years, the advent of e-commerce and advanced manufacturing techniques has further propelled the growth of the custom leather lifting belt market. Today, brands are not only focusing on performance but also on creating belts that resonate with the identity of the user, solidifying their place in both the fitness and fashion industries. B2B buyers can benefit from this rich history by sourcing products that not only meet performance standards but also align with evolving consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather lifting belt

-

How do I select the right custom leather lifting belt supplier?

Selecting a reliable supplier for custom leather lifting belts involves thorough research and vetting. Start by checking the supplier’s reputation through online reviews and industry referrals. Evaluate their production capabilities, including the materials used and customization options available. Request samples to assess quality firsthand. Additionally, inquire about their experience with international shipping and compliance with trade regulations in your region. Establish communication to ensure they understand your needs and can meet your timeline and budget requirements. -

What are the key customization options available for leather lifting belts?

Custom leather lifting belts offer a variety of personalization options. Buyers can typically choose the type of leather, colors, stitching styles, and buckle designs. Some suppliers allow for custom logos or embroidery to enhance brand visibility. It’s also possible to select the thickness and width of the belt to suit different lifting styles. Discuss your specific requirements with the supplier to ensure the final product aligns with your brand identity and performance needs. -

What are the minimum order quantities (MOQs) for custom leather lifting belts?

Minimum order quantities can vary significantly among suppliers, often influenced by the complexity of customization and production capabilities. Generally, MOQs for custom leather lifting belts can range from 50 to 100 units. It’s essential to communicate your needs upfront, as some suppliers may offer flexibility for first-time buyers or bulk orders. Understanding MOQs will help you better plan your inventory and cash flow while ensuring you meet market demand. -

What payment terms should I expect when ordering custom lifting belts?

Payment terms for custom lifting belts typically involve an upfront deposit, often ranging from 30% to 50% of the total order value. The remaining balance is usually due prior to shipment. Some suppliers may offer flexible payment options, including letters of credit or escrow services for larger orders. Always clarify payment terms before finalizing the order to avoid any misunderstandings and to ensure compliance with your company’s financial policies. -

How can I ensure quality assurance for my custom lifting belts?

To ensure quality assurance, request a detailed quality control process from your supplier. This may include material inspections, craftsmanship evaluations, and compliance with industry standards. It’s beneficial to establish clear specifications and expectations in your purchase order. Consider visiting the manufacturing facility, if feasible, or requesting regular updates and photos during production. Implementing a final inspection before shipment can also help mitigate any potential issues with quality. -

What logistics considerations should I be aware of when importing lifting belts?

When importing custom leather lifting belts, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder who understands the intricacies of international shipping. Be aware of any import duties or taxes applicable in your country, as these can affect overall costs. Additionally, ensure that your supplier provides all necessary documentation for customs clearance to avoid delays or additional charges. -

How do I handle potential disputes with my supplier?

Handling disputes with your supplier requires a proactive approach. Start by maintaining open lines of communication to address issues as they arise. Document all agreements, correspondence, and transaction details for reference. If a dispute escalates, refer to the terms outlined in your purchase agreement, including any arbitration or mediation clauses. Building a strong relationship with your supplier can also facilitate smoother resolutions, as mutual trust often helps in conflict management. -

What are the benefits of using custom leather lifting belts for my business?

Custom leather lifting belts can significantly enhance your brand’s reputation and customer loyalty. They provide a high-quality, durable product that appeals to fitness enthusiasts, athletes, and professionals. By offering customization options, you can cater to diverse consumer preferences, setting your products apart from competitors. Additionally, the ability to incorporate branding elements can increase visibility and market presence, making custom belts a strategic investment for your business.

Top 6 Custom Leather Lifting Belt Manufacturers & Suppliers List

1. Pioneer Fit – Custom Dyed Weightlifting Belts

Domain: pioneerfit.com

Registered: 2019 (6 years)

Введение: Pioneer Custom Dyed, Special Design & Art Weightlifting Belts; In stock and ready to ship; Free shipping on US domestic orders over $300; Various styles including Lever Belts, Powerlifting Belts, Training Belts, and more; Closure options: Single Prong, Double Prong, Standard Lever, PAL V2 Lever; Belt thickness options: 6.5mm, 8.5mm, 10mm, 13mm; Belt width options: 2.5″, 3″, 4″; Size range: XS (22″…

2. Iron Attitude – Custom Weightlifting Belts

Domain: ironattitudebelts.com

Registered: 2014 (11 years)

Введение: Custom Weightlifting Belts by Iron Attitude are 100% handcrafted in the USA and fully customizable. Options include:

– Men’s Standard Custom Belts starting at $125

– Men’s Exotic Custom Belts starting at $135

– Women’s Standard Custom Belts starting at $115

– Women’s Exotic Custom Belts starting at $125

Features include:

– Real leather with high-quality embroidery

– Over a dozen base colors…

3. Aesthreadics – Custom Weight Lifting Belts

Domain: aesthreadics.com

Registered: 2014 (11 years)

Введение: Aesthreadics offers a variety of custom weight lifting belts and fitness gear, including: 1. Custom Tapered Weight Lifting Belts (Custom Color and Engraved Designs) 2. Model 23 Premium Tapered Weight Lifting Belts (Custom Color and Engraved Designs) 3. Custom Powerlifting Weight Belts (Custom Color and Engraved Designs) 4. Custom Lever Weight Lifting Belts (Custom Color and Engraved Designs) 5. St…

4. Gunsmith Fitness – Bespoke Custom Weightlifting Belt

Domain: gunsmithfitness.com

Registered: 2015 (10 years)

Введение: Custom Weight Lifting Belts | Leather Personalized Powerlifting Belts

– Product Name: Bespoke Custom Weightlifting Belt

– Sale Price: €121,95

– Regular Price: (not specified)

– Rating: 4.8 out of 5 based on 61 reviews

– Features:

– Premium materials and build quality

– Fully customizable design (shape, thickness, leather colors, buckle type, rivet color, embroidery/printing)

– Unique, made …

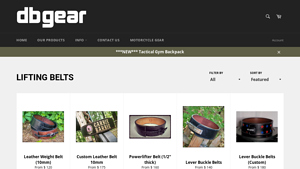

5. DB Gear – Leather Weight Belts

Domain: dbgear.net

Registered: 2016 (9 years)

Введение: Lifting Belts: Leather Weight Belt (10mm) from $120, Custom Leather Belt (10mm) from $175, Powerlifter Belt (1/2″ thick) from $160, Lever Buckle Belts from $140, Lever Buckle Belts (Custom) from $180, Leather foamcore belt from $115, Tapered Leather Belts from $125, Prong Buckle Belts from $135, Foam Core Belts on sale from $50, VEGAN Leather Custom Belt from $110, Leather strap retainer $10, Cust…

6. Pioneer – Custom Leather Weightlifting Belt

Domain: reddit.com

Registered: 2005 (20 years)

Введение: Custom weightlifting belt, all leather, 10mm thick, 4 inches wide. Suggested brands include Pioneer and Gunsmithfitness.com, which offers high-quality custom lifting belts with various options for leather, stitching, and edge finish.

Strategic Sourcing Conclusion and Outlook for custom leather lifting belt

How Can Strategic Sourcing Enhance Your Custom Leather Lifting Belt Procurement?

In conclusion, effective strategic sourcing of custom leather lifting belts can significantly enhance your procurement process, ensuring quality, durability, and unique branding opportunities. As the demand for personalized fitness equipment continues to rise, aligning with reputable manufacturers who prioritize craftsmanship and customer service is paramount. Buyers should focus on suppliers that offer comprehensive customization options, reflecting both brand identity and functional requirements, which can be a decisive factor in competitive markets.

Furthermore, understanding regional trends and preferences in Africa, South America, the Middle East, and Europe can help in selecting the right products that resonate with local consumers. Engaging with manufacturers that provide clear communication, reliable shipping, and post-purchase support can foster long-term partnerships and facilitate market entry strategies.

As you look to the future, consider leveraging the insights gained from this guide to make informed decisions that not only meet your immediate needs but also position your business for growth in the evolving fitness landscape. Start exploring partnerships today that will elevate your brand and strengthen your market presence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.