Introduction: Navigating the Global Market for tooled leather fabric

In the quest to source tooled leather fabric, international B2B buyers often face the challenge of navigating a complex global market filled with varying quality, styles, and applications. Understanding how to effectively procure this unique material is essential for businesses looking to enhance their product offerings, whether for upholstery, fashion accessories, or home decor. This comprehensive guide delves into the diverse types of tooled leather fabric available, including genuine leather and high-quality faux options, alongside their respective applications across multiple industries.

Moreover, we will provide insights on the essential considerations for vetting suppliers, ensuring that your procurement process is both efficient and cost-effective. Buyers will learn about pricing structures, minimum order quantities, and shipping logistics, which are crucial for making informed purchasing decisions. With a focus on the needs of businesses in Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—this guide aims to empower decision-makers with actionable insights and strategies.

By the end of this guide, you will be equipped with the knowledge to confidently navigate the tooled leather fabric market, enabling you to select the right products that align with your business goals and customer expectations. Let’s embark on this journey to streamline your sourcing process and elevate your product line with quality tooled leather fabric.

Table Of Contents

- Top 6 Tooled Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tooled leather fabric

- Understanding tooled leather fabric Types and Variations

- Key Industrial Applications of tooled leather fabric

- 3 Common User Pain Points for ‘tooled leather fabric’ & Their Solutions

- Strategic Material Selection Guide for tooled leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for tooled leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tooled leather fabric’

- Comprehensive Cost and Pricing Analysis for tooled leather fabric Sourcing

- Alternatives Analysis: Comparing tooled leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for tooled leather fabric

- Navigating Market Dynamics and Sourcing Trends in the tooled leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tooled leather fabric

- Strategic Sourcing Conclusion and Outlook for tooled leather fabric

- Important Disclaimer & Terms of Use

Understanding tooled leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Tooled Leather | Authentic leather with intricate designs and textures. | High-end upholstery, luxury goods, fashion | Pros: Durable, timeless appeal. Cons: Higher cost, maintenance required. |

| Faux Tooled Leather | Synthetic material mimicking the appearance of real leather. | Affordable upholstery, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less durability, may lack authenticity. |

| Embossed Leather | Leather treated with heat and pressure to create patterns. | Automotive interiors, furniture upholstery | Pros: Versatile, various designs available. Cons: Can be less breathable than genuine leather. |

| Tooled Fabric (Cotton/Poly) | Fabric printed with tooled leather designs, lightweight. | Home decor, crafts, apparel | Pros: Lightweight, wide range of designs. Cons: Less durable than leather, may fade over time. |

| PU Faux Leather | Polyurethane material that offers a leather-like finish. | Fashion, upholstery, bags | Pros: Water-resistant, easy maintenance. Cons: Environmental concerns, may not age well. |

What are the Key Characteristics of Genuine Tooled Leather?

Genuine tooled leather is crafted from high-quality animal hides, showcasing intricate designs that are often hand-tooled. Its luxurious feel and unique textures make it ideal for high-end applications such as upscale furniture, luxury handbags, and bespoke fashion items. B2B buyers should consider the longevity and aesthetic appeal of genuine leather, but be prepared for a higher initial investment and ongoing care requirements to maintain its appearance.

How Does Faux Tooled Leather Compare in Terms of Cost and Durability?

Faux tooled leather is a synthetic alternative designed to replicate the look of genuine leather while being more budget-friendly. It is commonly used in affordable upholstery projects and fashion accessories. While it offers easy maintenance and a wide variety of designs, buyers should be aware that it may not provide the same durability or authentic feel as genuine leather. This option is ideal for businesses targeting cost-conscious consumers without compromising on style.

What are the Advantages of Embossed Leather for B2B Buyers?

Embossed leather is produced through a process that uses heat and pressure to create unique patterns, making it a versatile choice for various applications, including automotive interiors and furniture. This type of leather allows for a diverse range of designs, appealing to buyers looking for customization options. However, it may be less breathable than traditional leather, which could impact comfort in specific applications. Buyers should weigh the benefits of design flexibility against the potential trade-offs in comfort.

Why Choose Tooled Fabric for Home Decor and Crafts?

Tooled fabric, often made from cotton or polyester, features printed designs that mimic the appearance of tooled leather. This lightweight option is popular for home decor items, crafts, and apparel. B2B buyers appreciate the extensive range of designs available, but should note that while these fabrics are cost-effective, they may not offer the durability or longevity of leather options. This makes them suitable for projects where style is prioritized over ruggedness.

What Makes PU Faux Leather an Attractive Option for Various Applications?

PU faux leather is a polyurethane-based material that provides a leather-like finish, making it a popular choice for fashion items, upholstery, and bags. Its water-resistant properties and ease of maintenance are significant advantages for businesses that require practical solutions. However, environmental concerns regarding synthetic materials may affect purchasing decisions. B2B buyers should consider their target market’s values and preferences when opting for PU faux leather in their product lines.

Key Industrial Applications of tooled leather fabric

| Industry/Sector | Specific Application of tooled leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhances aesthetic appeal and durability of products | Ensure high-quality leather and customization options |

| Fashion and Accessories | Handbags and wallets | Offers unique designs that cater to luxury markets | Look for sustainable sourcing and trending designs |

| Автомобили | Interior upholstery for vehicles | Increases resale value and enhances user experience | Consider weather resistance and durability specifications |

| Home Decor | Wall coverings and decorative accents | Adds a luxurious touch to interiors | Evaluate design options and compatibility with existing decor |

| Crafts and DIY Projects | Custom craft projects | Encourages creativity and personalization | Source versatile materials that can be easily manipulated |

How is tooled leather fabric utilized in the furniture manufacturing sector?

In the furniture manufacturing industry, tooled leather fabric is primarily used for upholstery on sofas and chairs. This fabric not only enhances the aesthetic appeal of furniture but also provides durability that meets consumer expectations for longevity. Manufacturers often seek high-quality leather that can withstand wear and tear while allowing for customization in design and color. International buyers, particularly from regions like Europe and the Middle East, may prioritize sourcing materials that comply with local regulations on sustainability and quality standards.

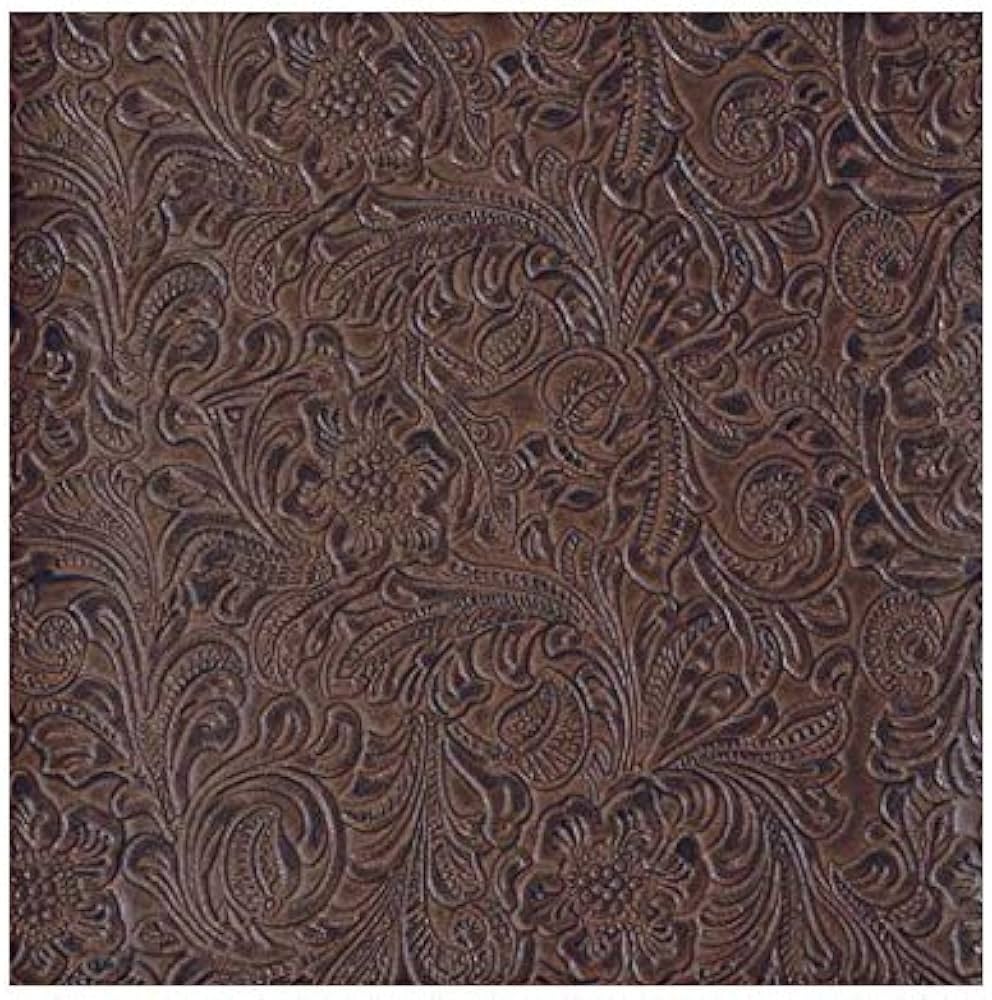

Illustrative image related to tooled leather fabric

What role does tooled leather fabric play in the fashion and accessories market?

In the fashion and accessories sector, tooled leather fabric is favored for crafting high-end handbags and wallets. The unique designs and textures offered by tooled leather resonate well with luxury consumers, helping brands differentiate their products in a competitive market. When sourcing, businesses should focus on sustainable practices and the latest design trends to appeal to environmentally conscious consumers. Buyers from South America and Africa may also look for suppliers who can provide a range of styles that reflect local cultural influences.

How is tooled leather fabric beneficial for automotive applications?

Automotive manufacturers utilize tooled leather fabric for interior upholstery, enhancing both the aesthetic and functional aspects of vehicles. This application not only boosts the vehicle’s resale value but also improves the overall user experience, making it a preferred choice for luxury vehicles. Key considerations for sourcing include the fabric’s resistance to weather and wear, as well as compliance with automotive industry standards. Buyers from regions such as the Middle East may prioritize materials that can withstand extreme temperatures.

In what ways is tooled leather fabric applied in home decor?

In the home decor industry, tooled leather fabric is commonly used for wall coverings and decorative accents, adding a touch of luxury to residential and commercial spaces. This fabric can transform ordinary interiors into sophisticated environments, appealing to a wide range of consumers. When sourcing, businesses should evaluate the design options available, ensuring compatibility with existing decor styles. Buyers from Europe may particularly seek out innovative designs that align with contemporary trends.

How does tooled leather fabric encourage creativity in crafts and DIY projects?

For crafts and DIY enthusiasts, tooled leather fabric serves as a versatile material for various custom projects. Its unique texture and design allow crafters to create personalized items, fostering creativity and individual expression. Suppliers should focus on offering materials that are easy to manipulate and come in various colors and patterns to cater to diverse crafting needs. International buyers, especially from Africa and South America, may look for materials that reflect local artistic styles and traditions, enhancing the cultural relevance of their projects.

3 Common User Pain Points for ‘tooled leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Tooled Leather Fabric for Diverse Applications

The Problem: B2B buyers often face the challenge of sourcing high-quality tooled leather fabric that meets their specific design needs and durability requirements. With a myriad of suppliers offering different qualities, it can be overwhelming to determine which products truly deliver on quality and authenticity. Buyers may also struggle with verifying the material’s specifications, such as its thickness, composition, and durability ratings, leading to potential mismatches in their projects.

The Solution: To effectively source tooled leather fabric, buyers should prioritize establishing relationships with reputable suppliers who provide comprehensive product specifications and samples. Engaging with manufacturers that offer transparency about their sourcing and production processes can ensure buyers receive authentic materials. Additionally, utilizing industry-specific trade shows or online platforms to connect with vetted suppliers can streamline the sourcing process. Requesting material samples before making bulk purchases is also essential; this allows buyers to assess the texture, weight, and overall quality of the fabric in real-world applications. By focusing on suppliers known for their craftsmanship and reliability, buyers can confidently select materials that align with their project requirements.

Scenario 2: Managing Inventory and Reducing Waste with Tooled Leather Fabric

The Problem: Many B2B buyers in sectors such as upholstery and fashion struggle with inventory management when dealing with tooled leather fabric. The unique patterns and designs often mean that cutting and usage must be meticulously planned to avoid waste. Miscalculations can lead to over-purchasing or insufficient material, resulting in increased costs and delays in production timelines.

The Solution: To mitigate these challenges, buyers should implement a detailed inventory management system that tracks the usage and cut plans for tooled leather fabric. Using digital tools or software that allows for precise measurements and layout designs can help optimize the cutting process. Furthermore, establishing a standard protocol for estimating fabric requirements based on project dimensions can reduce waste significantly. Buyers might also consider collaborating with suppliers who offer flexible minimum order quantities, allowing them to purchase only what they need for specific projects. Incorporating sustainable practices, such as recycling scraps or donating leftover materials, can also enhance a company’s reputation while minimizing waste.

Scenario 3: Overcoming Design Limitations with Tooled Leather Fabric

The Problem: Buyers often encounter design limitations when working with tooled leather fabric, especially when trying to innovate or create custom designs. The traditional look of tooled leather may not always align with modern aesthetics or client preferences, making it difficult for businesses to meet the evolving demands of their customers.

The Solution: To overcome design limitations, buyers should consider collaborating with fabric designers or artists who specialize in modern interpretations of tooled leather. This could involve commissioning unique patterns or exploring digital printing techniques that allow for customization on the fabric. Additionally, buyers can experiment with combining tooled leather fabric with other materials, such as textiles or faux leathers, to create hybrid designs that appeal to contemporary tastes. Engaging in market research to identify current trends and customer preferences can also guide buyers in selecting designs that resonate with their target audience. By embracing innovation and customization, businesses can expand their offerings and attract a broader customer base.

Strategic Material Selection Guide for tooled leather fabric

What Are the Key Materials Used in Tooled Leather Fabric?

When selecting tooled leather fabric for various applications, understanding the properties, advantages, and limitations of different materials is crucial for B2B buyers. Here, we analyze four common materials used in tooled leather fabric: genuine leather, PU (polyurethane) faux leather, cotton canvas, and embossed vinyl.

How Does Genuine Leather Perform as Tooled Leather Fabric?

Genuine leather is prized for its durability and luxurious appearance. It typically exhibits excellent temperature resistance and can withstand significant wear and tear, making it suitable for high-use applications like upholstery and fashion accessories. However, genuine leather can be costly and may require special care to maintain its appearance.

Illustrative image related to tooled leather fabric

Pros: High durability, natural aesthetic, excellent temperature resistance.

Cons: Higher cost, requires maintenance, potential for variability in quality.

Impact on Application: Ideal for luxury items, but may not be suitable for budget-conscious projects.

Considerations for International Buyers: Compliance with leather sourcing regulations and standards (e.g., REACH in Europe) is essential, as well as understanding local market preferences for leather types.

What Advantages Does PU Faux Leather Offer?

PU faux leather is a synthetic alternative that mimics the look of genuine leather while offering lower production costs. It is lightweight, easy to clean, and often more resistant to stains and spills. However, it may not have the same level of durability as genuine leather and can be less breathable.

Pros: Cost-effective, easy maintenance, consistent quality.

Cons: Lower durability compared to genuine leather, potential for peeling over time.

Impact on Application: Suitable for a variety of applications, including fashion and home decor, but may not withstand heavy use.

Considerations for International Buyers: Ensure compliance with material safety standards and certifications, especially in regions with strict environmental regulations.

How Does Cotton Canvas Fit into Tooled Leather Fabric Applications?

Cotton canvas is another option for tooled leather fabric, known for its versatility and affordability. It can be treated to mimic leather textures and is often used in upholstery and crafting. While it is not as durable as leather, it is breathable and can be printed with various designs.

Illustrative image related to tooled leather fabric

Pros: Affordable, breathable, customizable with prints.

Cons: Lower durability and resistance to moisture, may require additional treatment for leather-like appearance.

Impact on Application: Best for casual applications and projects where cost is a concern.

Considerations for International Buyers: Familiarity with local fabric standards and preferences can enhance market entry strategies.

What Role Does Embossed Vinyl Play in Tooled Leather Fabric?

Embossed vinyl is a synthetic material that provides a leather-like appearance at a lower price point. It is often used in environments where moisture resistance is essential, such as in automotive interiors and outdoor furniture. While it is durable and easy to clean, it may lack the luxurious feel of genuine leather.

Pros: Water-resistant, easy to clean, cost-effective.

Cons: May not have the same aesthetic appeal as genuine leather, can be less breathable.

Impact on Application: Suitable for high-moisture environments and budget-friendly projects.

Considerations for International Buyers: Understanding the local demand for synthetic versus natural materials can inform purchasing decisions.

Summary of Material Properties for Tooled Leather Fabric

| Материал | Typical Use Case for tooled leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end upholstery, fashion accessories | High durability and aesthetic appeal | Expensive and requires maintenance | Высокий |

| PU Faux Leather | Fashion, home decor, and light upholstery | Cost-effective and easy to clean | Less durable than genuine leather | Medium |

| Cotton Canvas | Casual upholstery, crafting | Affordable and customizable | Lower durability and moisture resistance | Низкий |

| Embossed Vinyl | Automotive interiors, outdoor furniture | Water-resistant and easy to clean | Lacks luxury feel of genuine leather | Medium |

This guide provides a comprehensive overview of the materials commonly used in tooled leather fabric, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for tooled leather fabric

What Are the Main Stages of Manufacturing Tooled Leather Fabric?

The production of tooled leather fabric involves several critical stages, each of which contributes to the final product’s quality and durability. Understanding these stages helps B2B buyers ensure they are sourcing from reputable suppliers who adhere to best practices.

Material Preparation: What Is the Importance of Choosing the Right Leather?

The first step in the manufacturing process is the selection and preparation of the leather. Typically, high-quality cowhide is used due to its durability and ability to hold intricate tooling designs. The leather is sourced from tanneries that meet international standards.

Once the leather is sourced, it undergoes a conditioning process to enhance flexibility and prevent cracking. This may involve soaking in oils or waxes. Buyers should inquire about the tanning methods used—vegetable tanning is preferred for eco-friendliness, while chrome tanning is known for its efficiency and durability.

How Is Tooled Leather Fabric Formed?

Forming is the next stage, where the prepared leather is shaped into the desired form. This involves several techniques, including:

Illustrative image related to tooled leather fabric

- Tooling: This is the process of creating designs or patterns on the leather surface. Skilled artisans use various tools to emboss intricate designs, which adds aesthetic value.

- Cutting: After tooling, the leather is cut into specific shapes and sizes based on the end product requirements. Precision in cutting is vital to ensure consistency and reduce waste.

- Stitching: In many cases, leather pieces are stitched together. This requires specialized sewing machines that can handle thick materials, ensuring strong seams.

What Are the Final Touches in the Finishing Stage?

The finishing stage is crucial for enhancing the leather’s appearance and longevity. This may involve:

- Dyeing: Applying color to the leather can be done through various methods, including aniline dyeing, which allows the natural grain to show through while providing color.

- Sealing: A protective finish is often applied to increase water resistance and protect against wear and tear. This can include waxes or acrylic coatings.

The finishing stage is where quality can significantly vary; thus, B2B buyers should ask about the specific finishes used and their properties.

What Quality Assurance Practices Are Essential for Tooled Leather Fabric?

Quality assurance is a cornerstone of the manufacturing process, ensuring that the final product meets both aesthetic and functional standards. Understanding these practices is vital for B2B buyers looking to maintain high standards in their supply chains.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are crucial in manufacturing tooled leather fabric. ISO 9001 focuses on quality management systems and ensures that manufacturers maintain consistent quality throughout their processes. Additionally, industry-specific certifications like CE (Conformité Européenne) indicate compliance with European health and safety standards.

For buyers from regions like Africa, South America, the Middle East, and Europe, ensuring that suppliers have these certifications can minimize risks associated with quality and compliance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality Control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival. The focus is on ensuring that the leather meets specified standards and is free from defects.

-

In-Process Quality Control (IPQC): During production, periodic checks are performed to ensure that each stage of the process adheres to quality standards. This includes monitoring tooling accuracy, stitching integrity, and finishing quality.

-

Final Quality Control (FQC): Before shipment, the finished products undergo a comprehensive inspection. This includes checking for defects, measuring dimensions, and ensuring that the product meets customer specifications.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is essential for maintaining product standards. Here are several actionable steps:

-

Conduct Audits: Regularly auditing suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their quality management systems and compliance with international standards.

-

Request Quality Reports: Suppliers should be able to provide documentation that details their quality control processes, including results from IQC, IPQC, and FQC checks.

-

Third-Party Inspections: Engaging independent third-party inspection services can help verify that the supplier meets industry standards. This adds an extra layer of assurance for buyers, particularly those operating in diverse markets.

-

Certifications and Compliance: Always check for relevant certifications and ensure they are up-to-date. This can include not just ISO and CE, but also compliance with local regulations in the buyer’s region.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, understanding the nuances of quality control is critical. Differences in manufacturing standards, cultural practices, and legal requirements can complicate sourcing decisions.

B2B buyers should be aware of the following:

-

Local Regulations: Different countries have unique regulations regarding leather production and importation. Understanding these can prevent compliance issues.

-

Cultural Expectations: The perception of quality can vary across cultures. For instance, European buyers may prioritize craftsmanship, while buyers in other regions might focus more on durability and cost-effectiveness.

-

Supply Chain Transparency: The complexity of global supply chains necessitates a clear understanding of each supplier’s role and their adherence to quality standards. Establishing direct communication with suppliers can help clarify expectations and quality requirements.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices related to tooled leather fabric is essential for B2B buyers. By focusing on the details of material selection, manufacturing stages, and quality control measures, buyers can make informed decisions that align with their business objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tooled leather fabric’

When sourcing tooled leather fabric, it’s essential to follow a structured approach to ensure quality, compliance, and suitability for your specific needs. This checklist will guide you through the necessary steps to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the tooled leather fabric you need. Consider factors such as thickness, texture, and pattern.

– Why It Matters: Clearly defined specifications help streamline the sourcing process and ensure that the materials meet your project’s demands.

– What to Look For: Check if the fabric is suitable for its intended use, whether it be upholstery, fashion accessories, or home decor.

Step 2: Research Market Trends

Stay updated on current trends in the tooled leather market. Understand what styles, colors, and textures are in demand.

– Why It Matters: Knowing market trends will help you select products that appeal to your target audience and enhance your competitive edge.

– What to Look For: Look for reports, articles, and industry insights that highlight emerging trends in fabric design and usage.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product samples, and references from other buyers.

– Why It Matters: Vetting suppliers ensures that you are partnering with reliable sources who can deliver quality products consistently.

– What to Look For: Focus on suppliers’ reputations, years in business, and any certifications that may indicate quality standards.

Step 4: Request Samples

Always ask for fabric samples before placing a bulk order. This allows you to assess the quality, feel, and appearance of the tooled leather fabric firsthand.

– Why It Matters: Samples help mitigate risks associated with purchasing large quantities without prior inspection.

– What to Look For: Check for color consistency, texture, and durability of the material in real-life applications.

Step 5: Verify Compliance with Regulations

Ensure that the tooled leather fabric complies with local and international regulations, including environmental and safety standards.

– Why It Matters: Compliance helps avoid legal issues and ensures that your products are safe for consumers.

– What to Look For: Inquire about certifications related to the fabric, such as those indicating low chemical emissions or sustainability practices.

Step 6: Assess Pricing and Payment Terms

Compare pricing from different suppliers and understand their payment terms. Look for bulk discounts or favorable credit terms.

– Why It Matters: Understanding pricing structures helps you stay within budget while ensuring quality.

– What to Look For: Consider not only the unit price but also shipping costs, lead times, and payment flexibility.

Step 7: Establish a Communication Plan

Set up clear lines of communication with your chosen supplier for ongoing support and issue resolution.

– Why It Matters: Effective communication fosters a strong partnership and facilitates quick responses to any challenges that may arise.

– What to Look For: Identify key contacts within the supplier’s organization and establish preferred methods for communication, whether through email, phone, or messaging platforms.

Illustrative image related to tooled leather fabric

By following these steps, you can navigate the complexities of sourcing tooled leather fabric effectively, ensuring that you find the right materials for your business needs while building strong supplier relationships.

Comprehensive Cost and Pricing Analysis for tooled leather fabric Sourcing

What Are the Key Cost Components in Sourcing Tooled Leather Fabric?

When sourcing tooled leather fabric, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The choice of base material significantly influences costs. Genuine leather is typically more expensive than synthetic alternatives, such as PU or PVC. Additionally, the quality of the leather, including its tanning process and finish, can further affect pricing.

-

Labor: Labor costs vary based on the complexity of the tooling process. Skilled artisans are often needed for high-quality tooled leather, which can drive up labor expenses. In regions where labor is less expensive, such as parts of South America or Southeast Asia, buyers may find more competitive pricing.

-

Manufacturing Overhead: This encompasses the costs associated with running the manufacturing facility, including utilities, equipment maintenance, and administrative expenses. Facilities that utilize advanced technology may have higher overhead but can produce more consistent quality.

-

Tooling: The setup costs for creating custom designs or patterns can be significant. This includes the initial investment in tools and molds, which is often amortized over larger production runs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the final product meets the required specifications. This may add to the overall cost but is essential for maintaining product integrity, especially for international buyers who may face stringent quality standards.

-

Logistics: Transportation costs vary significantly based on the origin of the fabric and the destination. International shipping, customs duties, and insurance must be factored into the total cost. Incoterms can also dictate who bears these costs, impacting overall pricing.

-

Margin: Suppliers will typically add a profit margin based on their operational costs, market demand, and competitive landscape. Understanding the typical margins in different markets can aid in negotiation.

How Do Price Influencers Affect Sourcing Decisions for Tooled Leather Fabric?

Several factors can influence the price of tooled leather fabric:

-

Volume/MOQ: Minimum order quantities can significantly affect pricing. Larger orders often yield discounts, so buyers should assess their needs carefully to maximize cost-efficiency.

-

Specifications and Customization: Custom designs or specific requirements may lead to increased costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher quality materials or those with certifications (e.g., eco-friendly or fair trade) will typically command higher prices. Buyers should evaluate whether the added cost aligns with their brand values and customer expectations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their experience and quality assurance, while newer suppliers may offer lower prices to build their client base.

-

Incoterms: Understanding the terms of shipping and delivery can affect the final cost. Buyers should clarify responsibilities for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing Tooled Leather Fabric?

B2B buyers should consider the following strategies to optimize their sourcing experience:

-

Negotiation: Building strong relationships with suppliers can facilitate better negotiation outcomes. Open discussions about pricing, payment terms, and delivery schedules can lead to mutually beneficial arrangements.

-

Cost-Efficiency: Assessing the Total Cost of Ownership (TCO) is essential. This includes not just the purchase price but also shipping, handling, and potential returns. A lower upfront cost may not always equate to better value in the long run.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences. Currency fluctuations, import tariffs, and local market conditions can impact final pricing.

-

Due Diligence: Conducting thorough research on suppliers, including reviews and references, can help mitigate risks. Requesting samples can also provide insights into material quality and craftsmanship.

Disclaimer

The prices and cost components discussed are indicative and may vary based on current market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to obtain accurate quotes tailored to your needs.

Alternatives Analysis: Comparing tooled leather fabric With Other Solutions

Understanding Alternatives to Tooled Leather Fabric

When evaluating materials for upholstery, décor, or fashion accessories, tooled leather fabric stands out for its unique aesthetic and durability. However, various alternatives can also meet specific needs while offering different advantages. This analysis aims to provide B2B buyers with a comparative overview of tooled leather fabric against viable alternatives such as faux leather and embossed vinyl.

| Comparison Aspect | Tooled Leather Fabric | Искусственная кожа | Embossed Vinyl |

|---|---|---|---|

| Performance | High durability; age beautifully | Moderate durability; less breathable | Highly durable; resistant to stains |

| Cost | Generally higher due to quality | More cost-effective; varies widely | Often lower than leather options |

| Ease of Implementation | Requires skilled craftsmanship | Easy to work with; widely available | Simple to cut and sew |

| Maintenance | Requires conditioning; sensitive to moisture | Wipe clean; less care needed | Easy maintenance; wipe with damp cloth |

| Best Use Case | High-end upholstery and accessories | Budget-friendly fashion items | Commercial upholstery and crafts |

What Are the Advantages and Disadvantages of Faux Leather?

Faux leather, made from synthetic materials, is a popular alternative to tooled leather fabric. Its cost-effectiveness makes it an attractive option for businesses looking to minimize expenses while still offering stylish products. Faux leather is relatively easy to work with, allowing for quick production times. However, it lacks the breathability and longevity of real leather, which may be a concern for high-end applications. While it can imitate the look of tooled leather, it may not achieve the same level of authenticity or durability over time.

How Does Embossed Vinyl Compare to Tooled Leather Fabric?

Embossed vinyl is another viable alternative that provides a unique texture similar to that of tooled leather. It is generally more affordable and is well-suited for commercial applications due to its resistance to stains and easy maintenance. This makes it ideal for high-traffic areas and projects requiring durability. However, embossed vinyl may not possess the same luxurious feel or aesthetic appeal as genuine leather, which could affect its desirability for upscale markets.

Making the Right Choice: What Should B2B Buyers Consider?

When selecting between tooled leather fabric and its alternatives, B2B buyers must assess their specific needs. Considerations such as the intended application, budget constraints, and desired aesthetic quality will guide decision-making. For high-end products where durability and authenticity are paramount, tooled leather fabric may be the best choice despite its higher cost. Conversely, for businesses focused on budget-friendly options that still offer style, faux leather or embossed vinyl could be more suitable. Understanding these variables will empower buyers to make informed choices that align with their brand and market demands.

Essential Technical Properties and Trade Terminology for tooled leather fabric

What Are the Key Technical Properties of Tooled Leather Fabric?

When sourcing tooled leather fabric, understanding its technical properties is crucial for making informed purchasing decisions. Below are essential specifications to consider:

-

Material Composition: Tooled leather fabric can be made from various materials, including genuine leather, synthetic leather (PU or PVC), or cotton with a leather-like finish. The choice of material affects the fabric’s durability, texture, and application. For example, genuine leather offers superior durability and aesthetic appeal, while synthetic options can be more cost-effective and easier to maintain.

-

Weight and Thickness: The weight of tooled leather fabric is typically measured in ounces per yard, while thickness is expressed in millimeters. A heavier fabric (e.g., 28 oz per yard) is more suitable for upholstery, while lighter weights (e.g., 8-10 oz) might be ideal for fashion accessories. Understanding these metrics helps buyers select the right fabric for specific applications.

-

Double Rub Count: This metric indicates the fabric’s durability, measured by how many times it can withstand abrasion before showing wear. A double rub count of over 50,000 is considered excellent for upholstery, making it suitable for high-traffic areas. This property is essential for B2B buyers looking for long-lasting materials for furniture or automotive applications.

-

UV Resistance: This property measures the fabric’s ability to withstand fading when exposed to sunlight. UV-resistant tooled leather is particularly important for outdoor applications or items exposed to natural light. Ensuring UV resistance can prolong the life of the product and maintain its aesthetic quality.

-

Flame Retardancy: Some tooled leather fabrics are treated to be flame retardant, which is crucial for applications in public spaces or where safety regulations are stringent. Knowing whether a fabric meets fire safety standards is essential for compliance and risk management.

-

Care Instructions: Different tooled leather fabrics require various maintenance methods. Some may be wipe-clean while others might need more specialized care. Understanding care requirements helps businesses minimize long-term costs associated with maintenance and replacement.

What Common Trade Terms Should Buyers Know When Purchasing Tooled Leather Fabric?

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are key terms to understand:

Illustrative image related to tooled leather fabric

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. In the context of tooled leather fabric, an OEM might produce custom designs for brands in the fashion or upholstery sectors.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest order quantity a supplier will accept. Understanding MOQs is vital for buyers to ensure that they can meet their production needs without overcommitting financially.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers should prepare detailed RFQs to facilitate accurate and competitive bids from manufacturers.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) dictate shipping responsibilities and costs, which are crucial for international transactions.

-

Lead Time: This term refers to the time from placing an order to delivery. Understanding lead times helps businesses plan their production schedules and manage inventory effectively.

-

Colorfastness: This property measures the fabric’s resistance to fading or running when exposed to moisture, light, or abrasion. It is a critical factor for buyers concerned about the longevity and appearance of their products.

By comprehensively understanding these technical properties and trade terms, B2B buyers can navigate the tooled leather fabric market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the tooled leather fabric Sector

Market Overview & Key Trends

The global market for tooled leather fabric is witnessing significant growth, driven by rising consumer demand for unique, artisanal products across various sectors, including fashion, upholstery, and home décor. Notably, the trend towards personalization and customization in products has led to an increased interest in tooled leather, which offers a distinct aesthetic appeal. Emerging technologies, such as digital printing and advanced embossing techniques, are reshaping the sourcing landscape, enabling suppliers to provide bespoke designs tailored to specific buyer requirements.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. The European market, for instance, is leaning heavily towards high-quality, sustainable materials, whereas African and South American markets are increasingly embracing both traditional craftsmanship and modern manufacturing methods. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers across borders, allowing buyers to explore a wider range of products and suppliers than ever before.

Moreover, the COVID-19 pandemic has accelerated the adoption of digital sourcing strategies. B2B buyers are now more inclined to engage in virtual showrooms and online trade fairs, making it imperative for suppliers to enhance their digital presence. As the market evolves, being adaptable and responsive to these trends will be key for buyers looking to establish long-term partnerships.

Illustrative image related to tooled leather fabric

Sustainability & Ethical Sourcing in B2B

In today’s environmentally conscious landscape, sustainability and ethical sourcing have become paramount for B2B buyers in the tooled leather fabric sector. The production of leather, even when tooled, has significant environmental implications, including high water usage and pollution from tanning processes. Consequently, buyers are increasingly prioritizing suppliers who utilize eco-friendly practices, such as vegetable tanning, which minimizes harmful chemical usage and waste.

Furthermore, the demand for transparency in supply chains is on the rise. Buyers are seeking partners who can provide clear information about the sourcing and production of their materials, including certifications that verify sustainable practices. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification are becoming essential in distinguishing responsible suppliers from less scrupulous ones.

Investing in sustainable materials not only aligns with global sustainability goals but also resonates with consumers who are willing to pay a premium for ethically sourced products. As the demand for tooled leather fabric grows, so does the opportunity for suppliers to differentiate themselves through their commitment to sustainable practices, ensuring long-term success in the market.

Brief Evolution/History

The history of tooled leather fabric can be traced back to ancient civilizations, where leather was adorned with intricate designs to signify status and craftsmanship. Initially used primarily for functional purposes, such as armor and footwear, the art of leather tooling has evolved into a decorative craft celebrated in various cultures worldwide.

In the modern context, tooled leather gained popularity during the 19th century with the rise of the Arts and Crafts movement, which emphasized artisanal production and quality materials. Today, it is not only a staple in traditional artisan workshops but also increasingly integrated into contemporary design, appealing to a wide array of markets, from luxury fashion brands to home décor manufacturers. This evolution reflects a blend of heritage and innovation, providing B2B buyers with diverse sourcing opportunities that cater to both traditional and modern aesthetics.

Frequently Asked Questions (FAQs) for B2B Buyers of tooled leather fabric

-

How do I ensure the quality of tooled leather fabric before purchasing?

To ensure the quality of tooled leather fabric, request samples from potential suppliers before making bulk orders. Evaluate the texture, durability, and appearance of the samples to determine if they meet your standards. Additionally, inquire about the manufacturing process, material sourcing, and any quality assurance measures they implement. Certifications or compliance with international standards can also provide reassurance about the fabric’s quality. -

What are the most popular uses for tooled leather fabric in B2B applications?

Tooled leather fabric is versatile and commonly used in various industries. It is ideal for upholstery in furniture, automotive interiors, and fashion accessories such as handbags and wallets. Additionally, it is popular in home decor items like cushions and wall coverings. Understanding your target market’s preferences can help you select the most suitable styles and colors for your specific applications. -

What is the minimum order quantity (MOQ) for tooled leather fabric?

Minimum order quantities for tooled leather fabric can vary significantly between suppliers. Typically, you may encounter MOQs ranging from 10 to 50 yards or more, depending on the supplier’s production capabilities and the type of fabric. Always confirm MOQs before finalizing your supplier to ensure they align with your project requirements and budget. -

How do I vet potential suppliers of tooled leather fabric?

To vet potential suppliers, start by researching their reputation through online reviews and testimonials. Look for suppliers with a proven track record in the industry and verify their certifications. Request references from previous clients and inquire about their production capabilities, lead times, and payment terms. A reliable supplier should also be responsive to inquiries and transparent about their processes. -

What payment terms are typical for international orders of tooled leather fabric?

Payment terms for international orders often include options like wire transfers, letters of credit, or PayPal. Standard terms may require a deposit (e.g., 30-50%) upfront, with the balance due upon shipment or delivery. Always negotiate terms that are favorable to your business while ensuring that they align with the supplier’s policies. Make sure to clarify any additional fees related to currency conversion or transaction processing. -

How can I customize tooled leather fabric for my specific needs?

Customization options for tooled leather fabric may include design alterations, color variations, and embossed patterns. Many suppliers offer services to create bespoke designs based on your specifications. When considering customization, provide clear guidelines and examples to your supplier. Be aware that customized orders may require higher MOQs and longer lead times. -

What logistics considerations should I keep in mind when sourcing tooled leather fabric internationally?

When sourcing tooled leather fabric internationally, consider shipping methods, costs, and delivery timelines. Ensure that your supplier has reliable logistics partners and can provide information on shipping options, including air freight for quicker delivery or sea freight for cost savings. Additionally, factor in customs duties, taxes, and potential delays due to border regulations when planning your order. -

What quality assurance practices should I implement when receiving shipments of tooled leather fabric?

Upon receiving shipments of tooled leather fabric, conduct a thorough inspection to verify that the quantity and quality match your order specifications. Check for defects, color consistency, and overall workmanship. Establish a clear process for reporting discrepancies to the supplier, and consider implementing a quality control checklist to streamline this process. Consistent QA practices can help maintain product standards and foster strong supplier relationships.

Top 6 Tooled Leather Fabric Manufacturers & Suppliers List

1. Spoonflower – Custom Fabric & Home Decor

Domain: spoonflower.com

Registered: 2005 (20 years)

Введение: Tooled-leather designs available in fabric by the yard, fabric by the meter, wallpaper, and home decor items such as curtains, bedding, pillows, and dining products. Supports Spoonflower’s community of artists. Custom design upload option available.

2. SW Decoratives – Tooled Leather Look Fabric

Domain: swdecoratives.com

Registered: 1997 (28 years)

Введение: {“product_name”: “Tooled Leather Look – Cream Fabric”, “product_code”: “1121620”, “description”: “Beautiful replication of actual tooled leather.”, “material”: “100% cotton”, “width”: “44/45 inches”, “minimum_cut”: “half yard”, “fat_quarter_available”: “18” X 22″”, “contact_phone_1”: “505-821-7400”, “contact_phone_2”: “800-530-8995”, “location”: “965 HWY 550 S. Ste. C, Bernalillo, NM 87004”, “esta…

3. Barbarossa Leather – Tropical Tooled Collection

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Введение: Collection: Tropical Tooled

Inspired by: Art Nouveau imagery

Design Features: Wispy scrolls, visual interest, calming effect

Технические характеристики:

– Raw Material: Bovine hide

– Weight: 2.5 – 3.5 oz.

– Type: Embossed Leather

– Hide Size: Full 40-50 sqft.

– Thickness: 1.0 – 1.4mm

– Flammability: Meets CA 117E

Available Colors:

– Tropical Tooled #18 Turquoise Brown

– Tropical Tooled #19 Brown Sugar

– Tropi…

4. Michael Miller – Tooled Leather COTTON Fabric

Domain: sewbaditsgood.com

Registered: 2016 (9 years)

Введение: {“product_name”: “Tooled Leather COTTON Fabric – Mahogany”, “brand”: “Michael Miller”, “description”: “This is cotton fabric printed to look like leather. It is NOT real leather.”, “price”: “$6.29 USD”, “material”: “100% Cotton”, “collection”: “Big Sky Collection”, “sizes_available”: {“1/2 yard”: “18” x 43″”, “1 yard”: “36” x 43″”, “2 yards”: “72” x 43″”, “3 yards”: “108” x 43″”, “4 yards”: “144” …

5. Facebook – Tooled Leather Fabric

6. Etsy – Tooled Leather Fabric

Domain: etsy.com

Registered: 2004 (21 years)

Введение: This company, Etsy – Tooled Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tooled leather fabric

In conclusion, strategic sourcing of tooled leather fabric presents a multitude of opportunities for international B2B buyers. The diverse applications—from upholstery to fashion accessories—highlight the versatility of this material, making it a valuable addition to product lines across various industries. Buyers should prioritize suppliers who demonstrate a commitment to quality and sustainability, as these factors increasingly influence purchasing decisions in global markets.

Moreover, leveraging technology to source materials efficiently can enhance competitive advantage. By utilizing platforms that offer customizable options, such as bespoke designs or eco-friendly alternatives, businesses can cater to the unique preferences of their target markets in Africa, South America, the Middle East, and Europe.

As we look forward, the demand for tooled leather fabric is expected to grow, fueled by trends in home decor and fashion that favor artisanal, high-quality materials. International buyers are encouraged to stay ahead of these trends by forging strong partnerships with reputable suppliers and exploring innovative sourcing strategies. Embrace the potential of tooled leather fabric to elevate your offerings and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to tooled leather fabric

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.