Introduction: Navigating the Global Market for printed leather fabric

In today’s competitive landscape, sourcing high-quality printed leather fabric poses a significant challenge for international B2B buyers. The demand for unique, vibrant, and durable materials is on the rise, particularly in industries such as fashion, automotive, and interior design. This guide addresses the critical aspects of sourcing printed leather fabric, offering insights into various types, applications, and the nuances of supplier vetting. With a focus on empowering buyers from diverse markets—including Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Brazil—this resource aims to simplify the purchasing process.

Navigating the complexities of global suppliers can be daunting, especially when considering factors like cost, quality, and compliance with international standards. This comprehensive guide will equip you with the knowledge to make informed decisions, from understanding different printed leather options to evaluating supplier reliability. We delve into practical applications, ensuring you can leverage printed leather fabric effectively in your projects. Furthermore, the guide provides actionable tips on negotiating prices and establishing long-term partnerships with suppliers, ultimately enhancing your procurement strategy.

By harnessing the insights provided, you will be better positioned to meet market demands and elevate your product offerings, ensuring you stand out in a crowded marketplace. Whether you’re looking to create bespoke items or bulk orders, this guide is your key to success in the dynamic world of printed leather fabric.

Table Of Contents

- Top 6 Printed Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for printed leather fabric

- Understanding printed leather fabric Types and Variations

- Key Industrial Applications of printed leather fabric

- 3 Common User Pain Points for ‘printed leather fabric’ & Their Solutions

- Strategic Material Selection Guide for printed leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for printed leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leather fabric’

- Comprehensive Cost and Pricing Analysis for printed leather fabric Sourcing

- Alternatives Analysis: Comparing printed leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for printed leather fabric

- Navigating Market Dynamics and Sourcing Trends in the printed leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of printed leather fabric

- Strategic Sourcing Conclusion and Outlook for printed leather fabric

- Important Disclaimer & Terms of Use

Understanding printed leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Printed Faux Leather | Pliable, vibrant, and easy to sew; often made from synthetic materials. | Fashion accessories, upholstery, bags | Pros: Cost-effective, easy to maintain. Cons: Less durable than genuine leather. |

| Embossed Leather | Features raised patterns or textures, mimicking exotic skins like crocodile or snake. | High-end fashion, luxury goods | Pros: Affordable alternative to exotic leathers. Cons: May lack the authenticity of real leather. |

| Digital Printed Leather | Utilizes advanced printing technology for intricate designs and colors. | Custom applications, branding | Pros: Unlimited design possibilities, quick turnaround. Cons: Potential for fading over time. |

| Suede Printed Leather | Soft texture with printed patterns; often used for apparel and accessories. | Footwear, fashion apparel | Pros: Soft and luxurious feel. Cons: Can be challenging to clean and maintain. |

| Holographic Leather | Reflective surface with dynamic color changes; often used in trendy designs. | Fashion, promotional items | Pros: Eye-catching and unique. Cons: May be perceived as less professional in some industries. |

What Are the Key Characteristics of Printed Faux Leather?

Printed faux leather is a synthetic alternative to genuine leather, offering a pliable and vibrant option for various applications. It is particularly suited for fashion accessories, upholstery, and bags due to its easy sewability and maintenance. B2B buyers should consider the cost-effectiveness of this material, especially when targeting budget-conscious markets. However, it’s essential to note that while it provides a visually appealing option, it may not offer the same durability as genuine leather, which could impact long-term use in high-wear environments.

How Does Embossed Leather Stand Out in the Market?

Embossed leather is characterized by its raised patterns that replicate the textures of exotic skins, such as crocodile or snake. This type of leather is commonly used in high-end fashion and luxury goods, providing an elegant appearance at a lower cost than genuine exotic leathers. For B2B buyers, embossed leather presents an opportunity to offer products that appeal to consumers seeking luxury without the associated price tag. However, authenticity may be a concern for some buyers, as embossed options can sometimes lack the unique characteristics of real animal skins.

What Advantages Does Digital Printed Leather Offer to Businesses?

Digital printed leather utilizes advanced printing technology to create intricate designs and vibrant colors, making it an ideal choice for custom applications and branding efforts. This type of leather allows for unlimited design possibilities, enabling businesses to tailor products to specific market demands quickly. B2B buyers should consider the quick turnaround times associated with digital printing, which can significantly enhance product offerings. However, potential fading over time may be a concern, necessitating discussions about longevity and care with suppliers.

Why Choose Suede Printed Leather for Fashion Applications?

Suede printed leather is known for its soft texture and luxurious feel, making it a popular choice for footwear and fashion apparel. This type of leather can be printed with various patterns, adding a unique touch to standard designs. B2B buyers should evaluate the appeal of suede for fashion-forward markets, as its tactile quality can elevate product offerings. However, the cleaning and maintenance challenges associated with suede may deter some manufacturers, so it’s essential to communicate care instructions clearly to end consumers.

What Makes Holographic Leather a Trendy Option?

Holographic leather features a reflective surface that changes color and appearance based on the angle of light, making it a trendy choice for fashion and promotional items. This eye-catching material can help brands stand out in competitive markets, especially among younger consumers. B2B buyers considering holographic leather should weigh its uniqueness against potential perceptions of professionalism in various industries. While it can attract attention, it may not always fit the branding needs of more traditional markets.

Illustrative image related to printed leather fabric

Key Industrial Applications of printed leather fabric

| Industry/Sector | Specific Application of Printed Leather Fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Handbags, wallets, and belts | Enhances product appeal with vibrant designs | Durability, print quality, and compliance with regulations |

| Automotive | Interior upholstery for vehicles | Provides aesthetic appeal and durability | Fire resistance, colorfastness, and eco-friendliness |

| Furniture | Upholstery for sofas and chairs | Combines luxury with easy maintenance | Material thickness, texture, and stain resistance |

| Home Decor | Decorative items and wall art | Adds a unique aesthetic to interior spaces | Design variety, customization options, and sourcing logistics |

| Footwear | Fashionable shoes and boots | Appeals to trend-conscious consumers | Comfort, flexibility, and breathability |

How is Printed Leather Fabric Used in the Fashion & Accessories Industry?

In the fashion and accessories sector, printed leather fabric is widely utilized for producing handbags, wallets, and belts. The vibrant patterns and textures enhance the aesthetic appeal of products, making them more attractive to consumers. For international buyers, especially from regions like Africa and Europe, sourcing printed leather that meets durability standards while offering unique designs is crucial. Buyers should consider factors such as print quality and compliance with local regulations to ensure a successful market entry.

What Role Does Printed Leather Fabric Play in Automotive Applications?

In the automotive industry, printed leather fabric is essential for vehicle interiors, including seats and door panels. This material not only elevates the visual appeal of vehicles but also provides durability and ease of maintenance. Buyers from the Middle East and South America must prioritize fire resistance and colorfastness when sourcing printed leather for automotive applications. Ensuring that the material meets stringent automotive standards is key to maintaining safety and quality.

How is Printed Leather Fabric Applied in Furniture Design?

Printed leather fabric finds significant use in the furniture industry, particularly for upholstery on sofas and chairs. It combines luxury with practicality, offering a stylish yet easy-to-clean option for residential and commercial spaces. Buyers should focus on material thickness and texture, as these factors influence both comfort and longevity. Additionally, sourcing materials that resist stains and wear is essential for ensuring customer satisfaction and repeat business.

What Are the Benefits of Using Printed Leather Fabric in Home Decor?

In home decor, printed leather fabric is employed in decorative items and wall art, adding a unique touch to interior spaces. Its versatility allows for a wide range of designs, catering to various aesthetic preferences. International buyers should consider the variety of designs available and the customization options offered by suppliers. Efficient sourcing logistics are also critical, ensuring timely delivery and consistent quality to meet market demands.

How is Printed Leather Fabric Transforming the Footwear Industry?

The footwear industry leverages printed leather fabric to create fashionable shoes and boots that appeal to trend-conscious consumers. This material offers flexibility and comfort, making it ideal for various footwear designs. Buyers should prioritize sourcing leather that balances style with functionality, focusing on breathability and wear resistance. Understanding regional trends and consumer preferences will aid in selecting the right printed leather options for successful product launches.

Illustrative image related to printed leather fabric

3 Common User Pain Points for ‘printed leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Printed Leather Fabric for Diverse Applications

The Problem: B2B buyers often struggle to find reliable suppliers that offer high-quality printed leather fabric suitable for various applications, such as fashion, upholstery, or accessories. Many suppliers provide inconsistent quality, leading to issues such as fading prints, peeling, or material that doesn’t hold up under stress. This inconsistency can result in rejected shipments, wasted resources, and ultimately dissatisfied customers, which is detrimental to any business’s reputation.

The Solution: To overcome this challenge, buyers should establish a rigorous supplier vetting process. This includes requesting samples of printed leather fabric before committing to larger orders. Look for suppliers that provide detailed specifications, including material composition, print durability, and care instructions. Additionally, leveraging platforms that specialize in B2B transactions can help connect buyers with reputable suppliers who have a proven track record. Conducting thorough research and reading reviews from other businesses can also provide insights into a supplier’s reliability and product quality. Finally, consider building long-term relationships with selected suppliers to ensure consistency and reliability in future orders.

Scenario 2: Managing Color and Print Consistency Across Batches

The Problem: One of the significant pain points for buyers is the inconsistency in color and print quality when ordering multiple batches of printed leather fabric. Variations can occur due to different production runs or changes in dye lots, leading to mismatched materials in products. This inconsistency can disrupt production schedules and complicate inventory management, especially for businesses that require precise color matching for their collections.

The Solution: To mitigate this issue, buyers should implement a standardized color and print matching process. Requesting a Pantone color reference from the supplier can ensure that all subsequent orders match the original sample. Additionally, establishing a clear agreement regarding print techniques and materials used can help maintain consistency across batches. Before large-scale production, it’s beneficial to conduct a pilot run of the fabric to verify that the colors and prints align with expectations. Regular communication with the supplier regarding any changes in their processes can also help preemptively address potential discrepancies.

Scenario 3: Ensuring Sustainability and Ethical Sourcing of Printed Leather Fabric

The Problem: Increasingly, B2B buyers are faced with the challenge of sourcing printed leather fabric that meets sustainability and ethical standards. Many businesses are now under pressure from consumers to ensure their products are made with environmentally friendly materials and practices. Finding suppliers who adhere to these standards without compromising on quality can be a daunting task, particularly in regions where regulations may vary significantly.

The Solution: To navigate this challenge, buyers should prioritize suppliers who have transparent sourcing and manufacturing processes. This can be achieved by requesting certifications that demonstrate adherence to environmental and ethical standards, such as OEKO-TEX or Global Organic Textile Standard (GOTS). Engaging in direct conversations with suppliers about their sourcing practices and sustainability initiatives can also provide valuable insights. Additionally, consider diversifying your supplier base to include those specializing in sustainable materials, which can not only enhance your product offerings but also align your brand with responsible practices. By investing in sustainable printed leather fabric, companies can enhance their brand reputation and appeal to eco-conscious consumers.

Strategic Material Selection Guide for printed leather fabric

What Are the Key Materials Used in Printed Leather Fabric?

When selecting printed leather fabric for various applications, understanding the properties and implications of different materials is crucial for B2B buyers. Here, we analyze four common materials used in printed leather fabrics: polyurethane (PU) leather, polyvinyl chloride (PVC) leather, genuine leather, and eco-leather.

Illustrative image related to printed leather fabric

How Does Polyurethane (PU) Leather Perform in Printed Applications?

Polyurethane leather, often referred to as PU leather, is a synthetic alternative to genuine leather. It boasts excellent flexibility and a soft texture, making it suitable for a wide range of applications, including upholstery, bags, and fashion accessories. PU leather is resistant to fading and cracking, which enhances its durability under various environmental conditions.

Pros: PU leather is lightweight, easy to clean, and can be produced in a variety of colors and patterns. It is also more cost-effective than genuine leather, making it an attractive option for budget-conscious projects.

Cons: However, PU leather may not be as durable as genuine leather in high-wear applications. Its resistance to extreme temperatures and pressure is moderate, which can limit its use in certain industrial settings.

Illustrative image related to printed leather fabric

International Considerations: Buyers from regions like Africa and the Middle East should ensure that PU leather complies with local regulations regarding chemical emissions and environmental impact, as some manufacturing processes may not meet stringent standards.

What About Polyvinyl Chloride (PVC) Leather?

PVC leather is another synthetic option that is widely used in the market. It is known for its high durability and resistance to water and stains, making it ideal for outdoor applications and environments where moisture is a concern.

Pros: PVC leather is highly versatile and can be produced in a variety of finishes, including glossy and matte. Its cost is generally low, making it a popular choice for mass-produced items.

Cons: On the downside, PVC leather can be less breathable compared to PU leather, which may not be suitable for clothing applications. Additionally, it can be less environmentally friendly due to the chemicals involved in its production.

International Considerations: B2B buyers should verify compliance with international standards such as ASTM and REACH, especially in Europe, where regulations around PVC use are becoming stricter.

How Does Genuine Leather Compare in Printed Leather Fabric?

Genuine leather is a natural material that offers unparalleled durability and a luxurious aesthetic. It is often used in high-end products such as luxury handbags and premium upholstery.

Pros: The main advantage of genuine leather is its longevity and ability to develop a unique patina over time. It also offers excellent breathability and comfort, making it suitable for wearable items.

Illustrative image related to printed leather fabric

Cons: However, genuine leather is typically more expensive than synthetic alternatives and may require more complex manufacturing processes. Additionally, it is less resistant to water and stains unless treated.

International Considerations: Buyers should consider ethical sourcing and compliance with animal welfare standards, especially in markets like Europe, where consumers are increasingly concerned about sustainability.

What Is Eco-Leather and Its Role in Printed Leather Fabric?

Eco-leather refers to leather that is produced using environmentally friendly processes, often involving vegetable tanning methods. It aims to reduce the environmental impact associated with traditional leather production.

Pros: Eco-leather is a sustainable choice that appeals to environmentally conscious consumers. It often retains the desirable qualities of genuine leather while minimizing harmful environmental effects.

Cons: The main limitation of eco-leather is its higher cost and potentially limited availability compared to conventional leather options. It may also have variable quality based on the tanning process used.

Illustrative image related to printed leather fabric

International Considerations: For buyers in regions like South America, where sustainability is a growing concern, ensuring that eco-leather meets local environmental regulations can enhance marketability.

Summary Table of Material Selection for Printed Leather Fabric

| Material | Typical Use Case for printed leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Upholstery, bags, fashion accessories | Flexible, easy to clean | Less durable in high-wear applications | Medium |

| Polyvinyl Chloride (PVC) | Outdoor furniture, automotive interiors | Highly durable, water-resistant | Less breathable, environmental concerns | Low |

| Genuine Leather | Luxury handbags, premium upholstery | Unmatched durability and aesthetics | Higher cost, requires complex manufacturing | High |

| Eco-Leather | Sustainable fashion, eco-friendly products | Environmentally friendly | Higher cost, variable quality | Medium to High |

This guide serves as a strategic resource for international B2B buyers, helping them navigate the complexities of material selection in printed leather fabrics while considering performance, cost, and compliance with regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for printed leather fabric

What Are the Key Stages in the Manufacturing Process of Printed Leather Fabric?

The production of printed leather fabric is a multifaceted process that involves several critical stages, ensuring that the final product meets the aesthetic and functional requirements of B2B buyers. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Printed Leather Fabric Production?

The first step in manufacturing printed leather fabric is material preparation. This involves selecting high-quality leather or faux leather substrates that will serve as the base for printing. The materials are then treated to enhance their properties; for example, they may undergo processes such as tanning, dyeing, and conditioning to ensure they are suitable for printing. Special attention is given to surface texture and flexibility, which are vital for the fabric’s end-use, whether for fashion, upholstery, or accessories.

What Techniques Are Employed in the Forming Stage?

Once the material is prepared, the next stage is forming, which typically involves cutting the leather into specific shapes that align with design specifications. Advanced techniques such as laser cutting or die-cutting may be employed to ensure precision. During this phase, manufacturers also consider how the printed designs will align with the fabric’s texture and color, which can significantly impact the visual appeal of the finished product.

How Is Assembly Conducted for Printed Leather Products?

After forming, the assembly stage begins. This involves stitching or bonding the cut pieces together to create the final product. Manufacturers may use various techniques such as ultrasonic welding or heat sealing to ensure strong bonds while maintaining the aesthetic quality of the fabric. This stage is crucial for products like bags or upholstery, where durability is essential. Quality stitching is not only a functional requirement but also a design element that can enhance the product’s overall appeal.

What Finishing Processes Are Used for Printed Leather Fabric?

The final stage is finishing, where the printed leather undergoes various treatments to enhance its appearance and durability. This includes applying protective coatings, adding embossing, or implementing special printing techniques such as digital printing or screen printing. The finishing process ensures that the fabric is not only visually striking but also resistant to wear, water, and other environmental factors. The choice of finishing techniques can also affect the tactile qualities of the fabric, making it essential for manufacturers to align these with the end-use requirements.

What Quality Control Measures Are Essential for Printed Leather Fabric?

Quality assurance (QA) is a critical aspect of the manufacturing process for printed leather fabric. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain high-quality production practices. This section outlines the key checkpoints and testing methods integral to effective quality control.

Illustrative image related to printed leather fabric

How Are International Standards Applied in Quality Control?

Compliance with international standards like ISO 9001 provides a framework for maintaining quality throughout the manufacturing process. This standard emphasizes a systematic approach to managing processes and improving customer satisfaction. For B2B buyers, verifying that a supplier adheres to these standards is vital, as it reflects their commitment to quality.

In addition to ISO standards, industry-specific certifications such as CE and API may be relevant, particularly for products that will be used in specialized applications or markets. These certifications ensure that the products meet specific safety, health, and environmental requirements.

What Are the Key Quality Control Checkpoints?

Quality control in printed leather fabric production typically involves several checkpoints:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for defects before production begins. This includes checking the quality of leather, inks, and other components to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as dye consistency, print alignment, and material integrity are monitored. This proactive approach helps identify issues early in the production process, allowing for timely corrections.

-

Final Quality Control (FQC): After the finishing stage, the final products undergo comprehensive testing for quality assurance. This includes visual inspections, physical tests for durability, and sometimes chemical testing for safety compliance.

What Testing Methods Are Commonly Used in Quality Control?

Several testing methods are employed to ensure the quality of printed leather fabric, including:

-

Colorfastness Testing: Assesses how well the fabric retains its color when exposed to light, water, and abrasion. This is crucial for products that will be used in varying environmental conditions.

-

Tensile Strength Testing: Measures the fabric’s ability to withstand pulling forces, ensuring it can endure the stresses of everyday use.

-

Flexural Testing: Evaluates the fabric’s flexibility and how it performs under repeated bending, which is important for products like bags and upholstery.

-

Chemical Resistance Testing: Determines how well the fabric can resist stains and degradation from chemicals, which is essential for longevity and maintenance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are effective methods to achieve this:

What Role Do Audits Play in Supplier Quality Verification?

Conducting supplier audits is an effective way to assess compliance with quality standards. Audits can be performed by the buyer’s quality assurance team or through third-party inspection agencies. These audits typically evaluate the manufacturer’s processes, documentation, and adherence to quality standards, providing a comprehensive view of their quality management system.

How Can Buyers Request Quality Control Reports?

Buyers should actively request quality control reports from suppliers, which should detail the results of various quality tests conducted during production. These reports serve as tangible evidence of the manufacturer’s commitment to quality and compliance with international standards.

Why Is Third-Party Inspection Important?

Engaging third-party inspection services can add an additional layer of assurance. These independent agencies can conduct random inspections at various stages of production to verify compliance with the agreed-upon specifications and standards. This practice is particularly beneficial for international transactions, where buyers may have limited oversight of the production process.

What Are the Nuances of Quality Control for International Buyers?

Understanding the nuances of quality control is essential for B2B buyers, particularly in international markets. Factors such as cultural differences, varying standards, and local regulations can impact the quality assurance process. Buyers should be aware of these differences and establish clear communication channels with suppliers to ensure alignment on quality expectations.

In conclusion, the manufacturing process and quality assurance of printed leather fabric involve intricate procedures and rigorous quality checks. By understanding these processes, B2B buyers can make informed decisions and establish reliable partnerships with suppliers, ensuring high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leather fabric’

Introduction

This guide is designed to assist B2B buyers in the effective procurement of printed leather fabric. By following these steps, you will ensure a streamlined sourcing process, allowing you to secure high-quality materials while minimizing risks. Understanding the key elements in sourcing will enhance your decision-making and contribute to the success of your business.

Illustrative image related to printed leather fabric

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before approaching suppliers. This includes determining the type of printed leather fabric required, such as faux leather, cowhide, or specialty embossed options. Additionally, specify the weight, thickness, and desired finishes to ensure compatibility with your intended applications, whether for fashion, upholstery, or accessories.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in printed leather fabrics. Utilize industry-specific platforms, trade shows, and B2B marketplaces to compile a list of reputable manufacturers. Pay attention to their production capabilities, experience in the market, and geographic location, as these factors can influence lead times and shipping costs.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify the certifications and compliance of your potential suppliers. Look for certifications that ensure quality standards, such as ISO 9001 or environmental compliance like REACH or RoHS. This step is crucial for ensuring that the materials meet international regulations and standards, which can significantly impact your brand reputation.

Step 4: Request Samples for Quality Assessment

Always request samples of the printed leather fabric before placing a bulk order. This allows you to assess the quality, texture, color vibrancy, and print accuracy firsthand. Evaluate the sample under different lighting conditions and alongside other materials to ensure it meets your design and quality expectations.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget constraints while also considering the quality of the materials. Establishing favorable terms can lead to long-term partnerships, so ensure both parties are aligned on expectations.

Illustrative image related to printed leather fabric

Step 6: Assess Production and Delivery Capabilities

Inquire about the supplier’s production capacity and delivery timelines. Understanding their workflow and any potential bottlenecks can help you avoid delays in your supply chain. Ask about their ability to scale production if your demand increases or if you require custom designs in the future.

Step 7: Finalize Contracts and Place Orders

After all evaluations and negotiations, finalize the contracts with the selected supplier. Ensure that all agreed terms, including pricing, delivery schedules, and quality standards, are documented. This step is vital to protect both parties and create a clear framework for the business relationship moving forward.

By following this structured sourcing checklist, B2B buyers can navigate the complexities of procuring printed leather fabric with confidence, ensuring they secure high-quality materials that meet their specific needs.

Illustrative image related to printed leather fabric

Comprehensive Cost and Pricing Analysis for printed leather fabric Sourcing

Understanding the cost structure and pricing factors of printed leather fabric is essential for B2B buyers, especially when sourcing from diverse regions like Africa, South America, the Middle East, and Europe. This analysis will break down the key components influencing costs and pricing, as well as provide actionable insights for effective sourcing.

What Are the Key Cost Components in Printed Leather Fabric Sourcing?

The total cost of printed leather fabric is composed of several critical elements:

-

Materials: The primary cost driver is the quality and type of raw materials used. High-quality leather or faux leather, as well as specialized inks for printing, significantly affect the final price. For instance, exotic prints may require more expensive substrates or finishing techniques.

-

Labor: Labor costs vary by region and can be influenced by the skill level required for manufacturing. Countries with lower labor costs may offer competitive pricing; however, the quality of craftsmanship should not be overlooked, as it can impact the overall durability and aesthetic appeal of the product.

-

Manufacturing Overhead: This includes utilities, rent, and other fixed costs incurred during production. Efficient manufacturing processes can reduce overhead, while outdated machinery or practices may increase costs.

-

Tooling: For customized designs, tooling costs can be significant. Buyers should consider whether the supplier has the capability to produce bespoke prints and what associated costs will be incurred.

-

Quality Control (QC): Implementing rigorous quality control measures ensures that the printed leather meets specified standards. This can add to the overall cost but is essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary widely based on the origin of the materials and the destination market. International shipping often involves tariffs and duties that should be accounted for in the total cost.

-

Margin: Suppliers typically apply a markup to cover their costs and profit margin. Understanding a supplier’s margin expectations can aid in negotiations.

What Influences Pricing in Printed Leather Fabric?

Several factors can influence the pricing of printed leather fabric:

-

Volume/MOQ: Bulk orders usually benefit from lower per-unit prices. Understanding a supplier’s minimum order quantities (MOQ) is crucial for cost-effective sourcing.

-

Specifications and Customization: Custom designs or high-spec materials can lead to increased costs. Buyers should weigh the benefits of unique designs against their budget constraints.

-

Quality and Certifications: Premium products often come with certifications (e.g., eco-friendly, hypoallergenic) that may justify higher prices. Buyers should evaluate the importance of these certifications for their market.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more but offer better quality and service.

-

Incoterms: The terms of shipping and delivery (e.g., FOB, CIF) can affect pricing. Buyers should be clear about who bears the risk and costs at each stage of the shipping process.

How Can Buyers Effectively Negotiate Prices for Printed Leather Fabric?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Understand Total Cost of Ownership: Consider not just the unit price, but also logistics, duties, and potential waste during production. This holistic view can guide negotiation strategies.

-

Leverage Volume Discounts: If planning to order in bulk, communicate this to suppliers early in negotiations to secure better pricing.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage in negotiations. It also allows buyers to compare quality and services.

-

Build Long-term Relationships: Establishing a strong partnership with suppliers can lead to better terms and pricing over time. Trust and reliability often result in favorable negotiations.

-

Stay Informed on Market Trends: Keeping abreast of market conditions, material availability, and pricing trends can provide insights that strengthen your negotiation position.

Conclusion

The landscape of printed leather fabric sourcing is complex, influenced by various cost components and pricing factors. By understanding these elements, B2B buyers can make informed decisions, ensuring they achieve the best value while meeting their quality standards. Always remember that prices may fluctuate based on market conditions, so staying adaptable and informed is key.

Illustrative image related to printed leather fabric

Alternatives Analysis: Comparing printed leather fabric With Other Solutions

Exploring Alternatives to Printed Leather Fabric

As the demand for versatile and stylish materials grows across various industries, B2B buyers are increasingly seeking alternatives to printed leather fabric. This section explores comparable solutions that offer unique benefits and potential drawbacks, helping businesses make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Printed Leather Fabric | Faux Leather (PU) | Textiles with Print (Cotton/Polyester) |

|---|---|---|---|

| Performance | Durable, water-resistant | Generally durable, less so than leather | Varies greatly; may not be water-resistant |

| Cost | Moderate to high | Generally lower than leather | Usually lower than both printed leather and faux leather |

| Ease of Implementation | Requires specialized tools for cutting and sewing | Easy to cut and sew, compatible with most machines | Easy to handle, widely available materials |

| Maintenance | Requires care to avoid wear | Low maintenance, easy to clean | Typically machine washable but may fade over time |

| Best Use Case | High-end fashion, upholstery | Everyday items like bags, wallets | Casual apparel, home decor |

Detailed Breakdown of Alternatives

Faux Leather (PU)

Faux leather, made from polyurethane (PU), presents a compelling alternative to printed leather fabric. It mimics the look and feel of genuine leather while offering a more budget-friendly option. Its ease of use makes it suitable for a range of applications, from fashion accessories to furniture upholstery. However, while faux leather is generally durable, it may not withstand the same level of wear and tear as printed leather, particularly in high-use environments. Additionally, faux leather can be less breathable, making it less comfortable for apparel.

Textiles with Print (Cotton/Polyester)

Textiles, particularly cotton and polyester blends, offer a lightweight and often more affordable alternative to printed leather fabric. These materials are highly versatile and available in a multitude of prints and colors. They are easy to cut and sew, making them accessible for a wide range of projects. However, they may not provide the same durability or water resistance as leather or faux leather, which can limit their use in certain applications, especially in outdoor or high-moisture environments. Additionally, printed textiles can fade with washing over time, which may impact their aesthetic appeal.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for your project, it’s essential to consider factors such as performance, cost, and intended use. Printed leather fabric is ideal for high-end applications requiring durability and a premium look, while faux leather offers a budget-friendly alternative with ease of use. On the other hand, printed textiles provide versatility and affordability for casual applications. By carefully assessing your specific requirements, including the nature of the end product and budget constraints, you can make an informed decision that aligns with your business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for printed leather fabric

What Are the Key Technical Properties of Printed Leather Fabric?

Understanding the essential technical properties of printed leather fabric is crucial for B2B buyers looking to make informed purchasing decisions. Here are the key specifications to consider:

Illustrative image related to printed leather fabric

-

Material Composition

The primary materials used in printed leather fabric can range from genuine leather to synthetic alternatives like polyurethane (PU) and polyvinyl chloride (PVC). Each material offers distinct advantages in terms of durability, cost, and environmental impact. For instance, PU leather tends to be more environmentally friendly than PVC and is often favored for high-quality applications. -

Thickness

Thickness is a critical specification that impacts the fabric’s durability and usability. Printed leather typically ranges from 0.5mm to 2mm in thickness. Thicker materials are generally more robust and suitable for heavy-duty applications, such as upholstery, while thinner fabrics are ideal for lightweight products like bags and accessories. Buyers should consider the intended use when selecting thickness. -

Tensile Strength

This property measures the fabric’s ability to withstand tension without breaking. It is crucial for applications where the material will experience stress, such as in bags or clothing. A tensile strength of at least 200 N (Newtons) is advisable for most commercial uses. Understanding tensile strength can help buyers evaluate the longevity and reliability of the product. -

Colorfastness

Colorfastness refers to the fabric’s ability to retain its color when exposed to light, washing, or other environmental factors. A high colorfastness rating (4-5 on the AATCC scale) ensures that the vibrant prints remain intact over time, which is essential for maintaining product quality and customer satisfaction. Buyers should inquire about colorfastness ratings to ensure the longevity of the printed designs. -

Flame Resistance

This specification indicates how well the fabric resists ignition and burning. In industries such as automotive and furniture, flame-resistant properties are vital for safety compliance. Buyers should look for printed leather fabrics that meet relevant safety standards, such as the BS EN 1021 standard for upholstery, to ensure compliance with regulations. -

Water Resistance

Water resistance is another essential property, particularly for applications exposed to moisture. A water-resistant rating (often measured in hydrostatic head) helps determine how well the fabric will perform in wet conditions. Fabrics with a rating of 1,500 mm or higher are generally considered suitable for outdoor applications.

Which Trade Terminology Should B2B Buyers Know for Printed Leather Fabric?

Familiarity with industry terminology can streamline communication and enhance negotiations. Here are some common terms every B2B buyer should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of printed leather, an OEM may supply customized materials for branded products, making it essential for buyers to clarify specifications and expectations. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory and cash flow effectively. Some suppliers may have flexible MOQs for new customers, while others may enforce strict limits based on production capabilities. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing and terms for specific products. Buyers should provide detailed specifications in their RFQ to receive accurate quotes, including material type, thickness, and any required certifications. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs and risks associated with transportation. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for inventory management, especially in industries where timely delivery is critical. Buyers should always confirm lead times with suppliers to plan accordingly. -

Certification Standards

Certifications such as ISO 9001 or OEKO-TEX indicate compliance with quality and safety standards. Buyers should verify that the printed leather fabric meets relevant certification requirements to ensure product quality and sustainability.

By grasping these essential technical properties and industry terminology, B2B buyers can make informed choices when sourcing printed leather fabric, ultimately leading to successful partnerships and high-quality products.

Navigating Market Dynamics and Sourcing Trends in the printed leather fabric Sector

What Are the Key Drivers and Trends Influencing the Printed Leather Fabric Market?

The printed leather fabric market is currently experiencing transformative dynamics fueled by several global drivers. Growing demand for innovative and aesthetically pleasing materials in various industries, including fashion, automotive, and upholstery, is a significant factor. The rise of e-commerce and digital platforms has also enabled international B2B buyers to access a broader range of products from suppliers worldwide, enhancing competition and driving down prices. Moreover, technological advancements in printing techniques have improved the quality and durability of printed leather fabrics, making them more appealing to manufacturers and designers.

In regions like Africa and South America, the market is further buoyed by a burgeoning middle class with increasing disposable incomes, leading to higher consumption rates of luxury and designer goods. In contrast, the Middle East and Europe are witnessing a shift towards unique, personalized products, prompting manufacturers to invest in custom printing technologies. Key trends include the use of digital printing for more intricate designs and sustainable practices, aligning with consumer preferences for environmentally friendly options.

Illustrative image related to printed leather fabric

How Does Sustainability and Ethical Sourcing Impact the Printed Leather Fabric Industry?

Sustainability and ethical sourcing have become paramount in the printed leather fabric sector, reflecting a growing awareness of environmental impacts. Traditional leather production is often criticized for its ecological footprint, particularly regarding water usage and chemical waste. As a result, many B2B buyers are now prioritizing suppliers that adopt sustainable practices, such as using eco-friendly dyes and tanning processes.

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are increasingly sought after, ensuring that products meet stringent environmental and safety criteria. Buyers are encouraged to engage with manufacturers who demonstrate transparency in their supply chains, as this not only mitigates risks associated with unethical labor practices but also enhances brand reputation. Emphasizing sustainable materials and practices can also lead to competitive advantages in a market that increasingly values corporate social responsibility.

What Is the Historical Context of Printed Leather Fabric in B2B Markets?

The printed leather fabric sector has evolved significantly over the past few decades. Initially, leather was primarily used in its natural form, valued for durability and craftsmanship. However, with the advent of synthetic materials in the late 20th century, printed leather began to emerge as a popular alternative, especially in fashion and accessories.

The introduction of digital printing technology revolutionized the industry, allowing for intricate designs and patterns that were previously unattainable. This innovation not only expanded the creative possibilities for designers but also reduced waste associated with traditional printing methods. Today, printed leather is synonymous with versatility and style, catering to a diverse array of applications, from high-end fashion to everyday consumer goods. As the market continues to grow, understanding its historical context helps B2B buyers appreciate the transformative journey of this material and its potential for future innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of printed leather fabric

-

How do I choose the right printed leather fabric for my project?

Choosing the right printed leather fabric involves considering the intended application, durability requirements, and aesthetic preferences. Assess the texture, flexibility, and print quality to ensure it aligns with your product’s purpose, whether it’s for fashion items, upholstery, or accessories. Request samples from suppliers to evaluate the fabric’s performance and appearance firsthand. Also, consider the environmental conditions in which the product will be used, as certain materials may perform better in specific climates. -

What types of printed leather fabrics are available for B2B buyers?

Printed leather fabrics come in various types, including faux leather, embossed leather, and traditional leather with printed designs. Faux leather is often more cost-effective and easier to maintain, while embossed options can provide a unique texture. Additionally, many suppliers offer customization options, allowing you to select specific patterns, colors, and finishes that suit your brand identity. Research suppliers who specialize in diverse collections to find the best fit for your needs. -

What are the minimum order quantities (MOQs) for printed leather fabric?

Minimum order quantities can vary significantly depending on the supplier and the type of printed leather fabric. Typically, MOQs may range from 50 to 500 meters or more. It’s essential to confirm MOQs directly with suppliers, as they may offer flexibility for larger orders or special projects. If you are looking for lower quantities, consider sourcing from suppliers who cater specifically to small businesses or start-ups. -

What payment terms should I expect when sourcing printed leather fabric internationally?

Payment terms for international orders can differ based on the supplier’s policies and your negotiation skills. Common arrangements include upfront payments, partial payments, or payment upon delivery. It’s advisable to establish clear terms in your contract, including payment methods (e.g., bank transfer, letter of credit) and timelines. Ensure to discuss currency exchange rates and any additional fees associated with international transactions to avoid surprises. -

How can I ensure quality assurance when sourcing printed leather fabric?

Quality assurance can be maintained by implementing a multi-step process that includes supplier vetting, sample evaluations, and third-party inspections. Begin by researching potential suppliers, checking their certifications, and reviewing past client feedback. Request samples to assess the fabric’s quality and performance. Additionally, consider hiring a quality assurance service to inspect products before shipment, ensuring they meet your specifications and standards. -

What logistics considerations should I take into account when importing printed leather fabric?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose between air freight for speed and sea freight for cost-effectiveness based on your urgency and budget. Familiarize yourself with the customs clearance process in your country, including required documentation and tariffs. Collaborating with a freight forwarder can streamline the logistics process, ensuring a smooth import experience. -

How can I customize printed leather fabric for my brand?

Customization options for printed leather fabric often include selecting specific designs, colors, and finishes. Many suppliers offer services for creating unique prints or embossing logos onto the fabric. Communicate your design requirements clearly, providing detailed specifications and mock-ups when possible. Be prepared for potential lead times associated with custom orders, and confirm the minimum order quantities that apply to customized products. -

What are the trends in printed leather fabric for B2B buyers?

Current trends in printed leather fabric include sustainability, unique textures, and vibrant patterns. Eco-friendly materials and production processes are increasingly popular, appealing to environmentally conscious brands. Additionally, bold prints and textured finishes are gaining traction in the fashion and interior design industries. Staying updated on these trends through industry publications and trade shows can help you make informed sourcing decisions that resonate with your target market.

Top 6 Printed Leather Fabric Manufacturers & Suppliers List

1. Zipper Valley – Printed Faux Leather

Domain: zippervalley.com

Registered: 2020 (5 years)

Introduction: Printed Faux Leather is pliable, vibrant, and bursting with personality. It is easy to cut and sews beautifully on domestic machines. Suitable for bags, wallets, key fobs, embroidery, and other creative projects. Available styles include Witch, Please; Spook-tacular; Fab-boo-lous; Cool Cats; Butterfly Dance; Japanese Arch; Flower Basket; Butterfly Conservatory; Love On The Brain; Travel Time; Clas…

2. Buy Leather Online – Printed Leather Hides

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Printed leather hides are characterized by a design or texture on the surface, suitable for various leather goods including bags, wallets, shoes, and more. The product range includes 79 items with prices ranging from $10.00 to $330.00. Available colors include white, beige, red, green, blue, brown, and many others. The leather types include bovine grain leather, lambskin, goatskin, and pigskin. Th…

3. Bags of Love – Custom Printed Leather Solutions

Domain: bagsoflove.com

Registered: 2003 (22 years)

Introduction: Printed Leather | Digital Printing on Leather. Options include: 100% Real Leather Printing ($26.25, ships in 2-3 days), Custom Printed Faux Leather (Vegan Leather Printing, $37.50, ships in 1-2 days), Fire-Rated Suede Printing (Vegan alternative, $23.98, ships in 1-2 days), Leather Swing Tags 10Pk (100% real leather, $29.95, ships in 1-2 days), Leather Swatch Pack ($1.95, ready same day), Real Lea…

4. Weaver Leather Supply – Embossed Leather Collection

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘Embossed Leather, 2/3 oz., Carbon Fiber Print’, ‘price’: ‘From $27.50’, ‘availability’: ‘Unavailable’}, {‘name’: ‘Embossed Leather, 2-3 oz., Woven Cognac’, ‘price’: ‘From $39.00’, ‘availability’: ‘Unavailable’}, {‘name’: ‘Embossed Leather, 2-3 oz., Southwest’, ‘price’: ‘From $37.70’, ‘availability’: ‘Unavailable’}, {‘name’: ‘Embossed Leather, 2-3 oz., Ostrich Cognac’, ‘price’: ‘From $39…

5. Nature’s Fabrics – Custom Printed Faux Leather Vinyl

Domain: naturesfabrics.com

Registered: 2009 (16 years)

Introduction: This company, Nature’s Fabrics – Custom Printed Faux Leather Vinyl, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

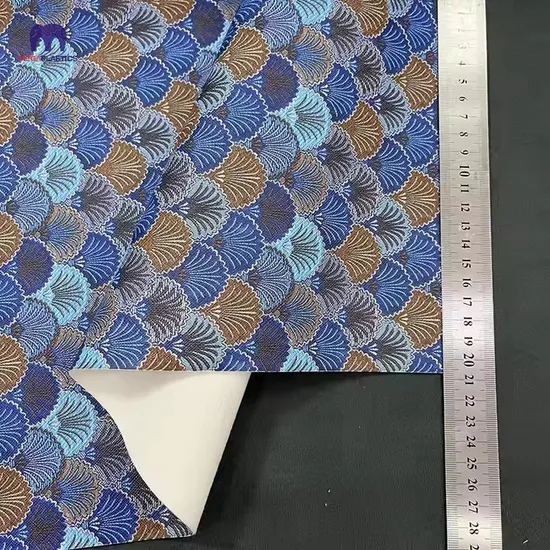

6. GVT Fast – Custom Printed Leather

Domain: gvtfast.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Custom Printed Leather”, “price_range”: “€100,00 – €190,00”, “VAT”: “22% not included”, “leather_types”: [{“type”: “Whole white chrome-tanned calfskin”, “thickness”: “1.4-1.6 mm”}, {“type”: “Half calf vegetable tanned”, “thickness”: “2.0-2.2 mm”}], “printing_options”: [{“size”: “60×60 cm panel”}, {“size”: “Allover”}], “suggested_use”: [“Leathergoods”, “Small leathergoods”], “tann…

Strategic Sourcing Conclusion and Outlook for printed leather fabric

In today’s competitive landscape, the value of strategic sourcing for printed leather fabric cannot be overstated. By leveraging quality materials that combine aesthetic appeal with functional performance, businesses can differentiate themselves in the marketplace. Buyers are encouraged to explore diverse offerings, from vibrant printed faux leather to sophisticated embossed hides, ensuring that their product lines resonate with their target audiences.

Illustrative image related to printed leather fabric

Strategic sourcing not only enhances product quality but also optimizes supply chain efficiency, ultimately leading to cost reductions. For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding regional trends and preferences is crucial. This insight allows companies to align their sourcing strategies with market demands, fostering stronger relationships with suppliers.

As we look to the future, the printed leather fabric market is poised for growth, driven by innovation and sustainability. B2B buyers are urged to stay ahead of trends, engage with suppliers who prioritize ethical practices, and invest in high-quality materials that reflect consumer preferences. Embrace the opportunity to elevate your product offerings and drive business success through strategic sourcing today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to printed leather fabric