Introduction: Navigating the Global Market for how to make a leather dog collar

In the competitive landscape of pet accessories, sourcing high-quality leather dog collars presents a unique challenge for international B2B buyers. With a growing demand for durable, stylish, and comfortable collars, businesses must navigate various factors, from material selection to supplier reliability. This comprehensive guide on how to make a leather dog collar addresses these complexities by providing actionable insights into the types of leather available, the tools and techniques required for production, and best practices for supplier vetting.

Buyers will explore the different applications of leather collars, including decorative and functional options, ensuring they meet diverse customer needs across various markets. The guide also delves into cost considerations, helping businesses make informed purchasing decisions that align with their budget and quality standards.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—with a particular focus on markets like Nigeria and Brazil—this resource empowers them to confidently navigate the global market for leather dog collars. Whether you’re looking to enhance your product line or establish new supplier relationships, this guide is an essential tool for fostering success in the pet accessory industry.

Table Of Contents

- Top 5 How To Make A Leather Dog Collar Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather dog collar

- Understanding how to make a leather dog collar Types and Variations

- Key Industrial Applications of how to make a leather dog collar

- 3 Common User Pain Points for ‘how to make a leather dog collar’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather dog collar

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather dog collar

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather dog collar’

- Comprehensive Cost and Pricing Analysis for how to make a leather dog collar Sourcing

- Alternatives Analysis: Comparing how to make a leather dog collar With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather dog collar

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather dog collar Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather dog collar

- Strategic Sourcing Conclusion and Outlook for how to make a leather dog collar

- Important Disclaimer & Terms of Use

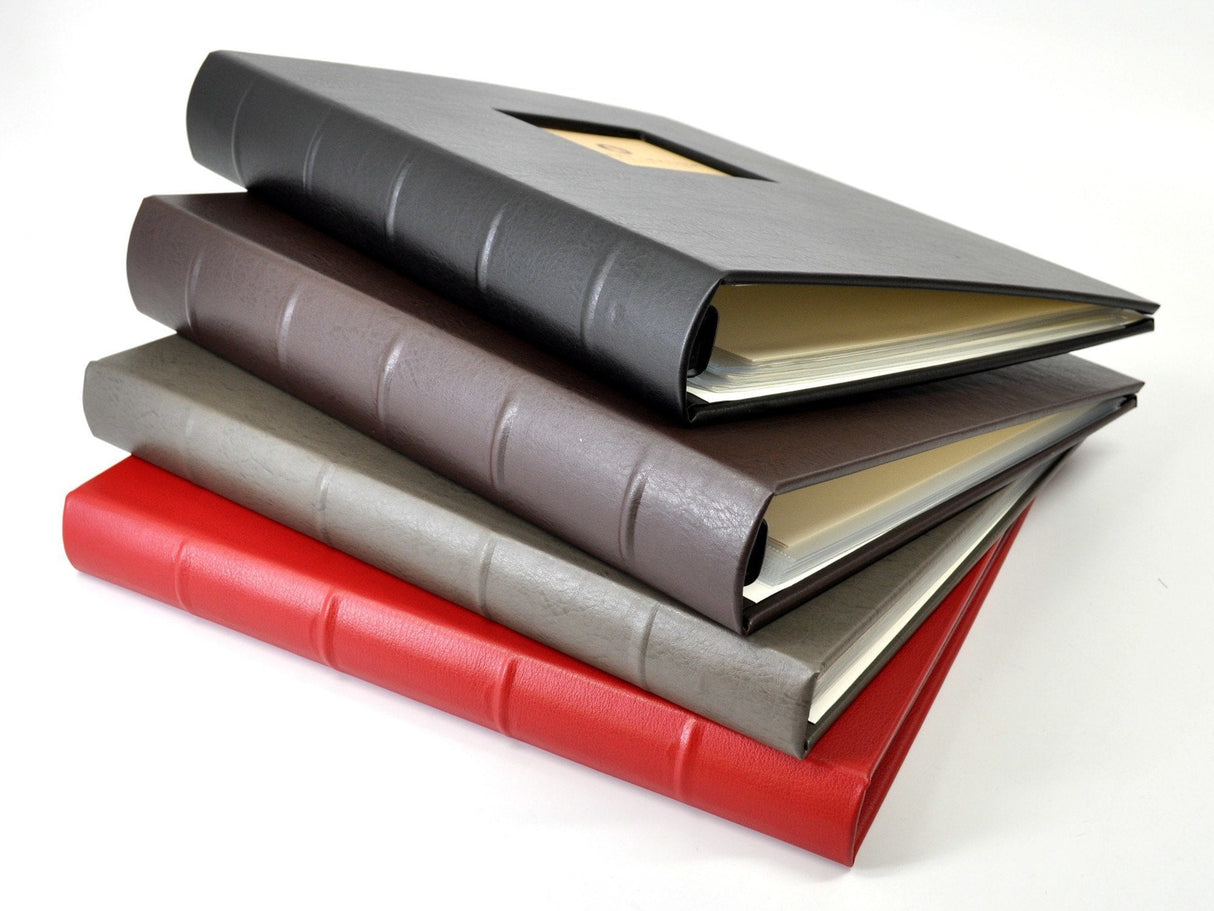

Understanding how to make a leather dog collar Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Buckle Collar | Features a traditional buckle and adjustable holes. | Pet retail, e-commerce platforms. | Pros: Cost-effective, easy to produce. Cons: Limited customization options. |

| Martingale Collar | Designed to tighten when pulled, preventing escape. | Specialized pet stores, training facilities. | Pros: Enhances control during training. Cons: Requires proper sizing to avoid discomfort. |

| Personalized Collar | Customizable with names or designs, often embossed. | Boutique shops, online custom orders. | Pros: High customer appeal, unique offerings. Cons: Longer production times, higher costs. |

| Reflective Collar | Incorporates reflective materials for visibility. | Outdoor gear retailers, safety-focused brands. | Pros: Increases safety during night walks. Cons: May require specific materials, increasing costs. |

| Decorative Stamped Collar | Features artistic designs stamped into the leather. | Artisan markets, craft fairs, bespoke retailers. | Pros: Unique aesthetic appeal, high-end market potential. Cons: Labor-intensive, may require skilled artisans. |

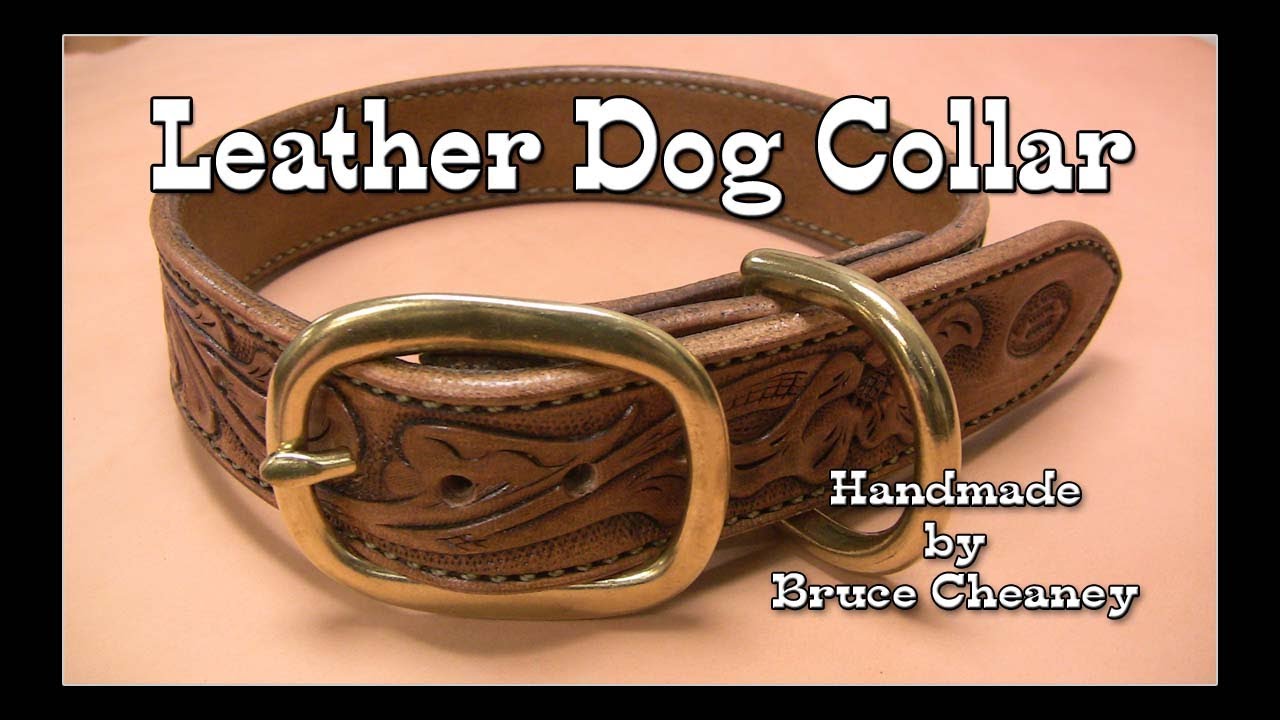

What are the Key Characteristics of a Standard Buckle Collar?

The standard buckle collar is the most basic form of leather dog collar, featuring an adjustable design with holes for fitting. This type is typically made from durable leather and is easy to mass-produce, making it a staple in pet retail and online marketplaces. For B2B buyers, this collar offers a cost-effective solution with a reliable profit margin. However, its lack of customization options may limit appeal in niche markets seeking unique products.

How Does a Martingale Collar Differ from Traditional Collars?

Martingale collars are designed to tighten when the dog pulls, providing better control without choking. This feature makes them particularly suitable for training purposes and is popular among specialized pet stores and training facilities. B2B buyers should consider the importance of proper sizing and comfort, as an ill-fitting martingale can lead to discomfort for the dog. While they may have a slightly higher price point, their effectiveness can justify the investment.

What are the Benefits of Offering Personalized Collars?

Personalized collars allow for customization, including names or unique designs, often achieved through embossing techniques. This type appeals to consumers looking for distinctive products, making it ideal for boutique shops and online custom order platforms. B2B buyers should be aware of the longer production times and higher costs associated with personalization, but the potential for higher price points and customer loyalty can offset these challenges.

Why Choose Reflective Collars for Safety?

Reflective collars incorporate materials that enhance visibility during nighttime walks, making them an essential product for outdoor gear retailers and safety-focused brands. They cater to a growing market segment that prioritizes pet safety. B2B buyers should note the necessity for specific materials, which may increase production costs. However, the demand for safety products can lead to a strong return on investment.

What Makes Decorative Stamped Collars a Unique Offering?

Decorative stamped collars feature artistic designs that enhance the aesthetic appeal of the product. This type is often found in artisan markets and craft fairs, targeting consumers looking for unique, high-quality items. B2B buyers should consider the labor-intensive nature of this collar type, which may require skilled artisans for production. While potentially higher in cost, the unique selling proposition can attract a premium customer base, justifying the investment.

Illustrative image related to how to make a leather dog collar

Key Industrial Applications of how to make a leather dog collar

| Industry/Sector | Specific Application of how to make a leather dog collar | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Accessories Retail | Custom leather dog collars for retail sale | Differentiation in product offerings; potential for premium pricing | Sourcing high-quality leather and unique designs; local craftsmanship |

| Veterinary Services | Durable collars for post-surgery recovery | Enhanced patient care; reduced risk of collar-related injuries | Compliance with veterinary standards; easy cleaning and maintenance |

| Dog Training Facilities | Training collars with adjustable features | Improved training effectiveness; increased client satisfaction | Adjustable sizing options; durable materials to withstand wear |

| E-commerce Platforms | Online sales of DIY leather dog collar kits | Growing demand for personalized pet products; increased online sales | Effective packaging; clear instructions for DIY assembly |

| Fashion and Lifestyle Brands | Fashion-forward leather dog collars | Expansion of product line; appeal to luxury pet owners | Trend analysis; collaboration with designers for unique styles |

How Can Custom Leather Dog Collars Benefit Pet Accessory Retailers?

In the pet accessories retail sector, custom leather dog collars provide a unique selling proposition. Retailers can offer personalized designs that cater to specific customer preferences, allowing for premium pricing. Additionally, sourcing high-quality leather from local tanneries can enhance the perceived value of the product. Retailers should consider the latest trends in pet fashion to stay competitive and ensure that their offerings resonate with their target market.

What Role Do Durable Collars Play in Veterinary Services?

Veterinary services can utilize durable leather dog collars for post-surgery recovery, providing a safer alternative to traditional collars. These collars can reduce the risk of injuries associated with conventional options, enhancing overall patient care. For international buyers, it is crucial to ensure compliance with veterinary standards and ease of cleaning, making leather a practical choice for recovery purposes.

How Can Dog Training Facilities Benefit from Adjustable Leather Collars?

Dog training facilities can incorporate adjustable leather collars into their training programs, providing a versatile option that meets the needs of various dog sizes. These collars can enhance training effectiveness and improve client satisfaction by ensuring comfort and safety during sessions. Buyers should focus on sourcing collars that are both durable and adjustable, allowing for easy modifications as dogs grow or change in size.

Why Are DIY Leather Dog Collar Kits Popular on E-commerce Platforms?

E-commerce platforms can capitalize on the growing trend of DIY projects by offering leather dog collar kits. These kits cater to pet owners looking for personalized products, allowing them to engage in the crafting process. Effective packaging and clear instructions are essential for these kits to ensure customer satisfaction. Sellers should also consider the environmental impact of their materials, appealing to eco-conscious consumers.

How Can Fashion and Lifestyle Brands Leverage Unique Leather Dog Collars?

Fashion and lifestyle brands can expand their product lines by introducing fashion-forward leather dog collars. These collars can appeal to luxury pet owners seeking stylish accessories for their pets. Collaborating with designers to create unique styles can differentiate brands in a crowded marketplace. Key considerations include trend analysis and sourcing high-quality materials that reflect the brand’s image and values.

Illustrative image related to how to make a leather dog collar

3 Common User Pain Points for ‘how to make a leather dog collar’ & Their Solutions

Scenario 1: Sourcing Quality Leather Materials for Dog Collars

The Problem: Many B2B buyers, especially those in regions such as Africa and South America, struggle to find high-quality leather suitable for making durable dog collars. Genuine leather can vary significantly in quality, and the risk of sourcing inferior materials can lead to products that do not meet customer expectations. This challenge is compounded by a lack of access to reliable suppliers and the difficulty of assessing leather quality without direct sampling.

The Solution: To address this issue, buyers should establish relationships with reputable leather suppliers who specialize in pet products. Conduct thorough research to identify suppliers that offer full-grain or vegetable-tanned leather, as these materials provide superior durability and comfort for pets. Buyers can also request samples before making large orders to ensure that the leather meets their quality standards. Joining local leatherworking communities or online forums can provide insights and recommendations on trustworthy suppliers. Additionally, leveraging trade shows and industry expos can facilitate direct connections with manufacturers, allowing buyers to negotiate better terms and potentially reduce costs through bulk purchasing.

Scenario 2: Understanding the Tools Required for Leather Collar Production

The Problem: A common pain point for B2B buyers entering the leather collar-making market is the overwhelming variety of tools needed for production. Inexperienced buyers may find it challenging to determine which tools are essential versus optional, leading to unnecessary expenses or incomplete setups that hinder production efficiency. This confusion can result in delays and increased production costs.

The Solution: Buyers should create a comprehensive checklist of essential tools before starting their production process. Key tools for making leather dog collars include a leather strap cutter, hole punch, and edge beveler. To minimize costs, buyers can consider purchasing second-hand tools or exploring local leatherworking groups where they might borrow or share equipment. Furthermore, investing in a starter kit from reputable suppliers can streamline the procurement process and ensure that buyers have all necessary tools without overspending. Educational resources, such as online tutorials or workshops, can also help buyers understand the proper use of each tool, enhancing their skill set and improving production quality.

Scenario 3: Navigating the Challenges of Leather Dyeing and Finishing

The Problem: Buyers often face difficulties when dyeing and finishing leather collars, which can impact the aesthetics and durability of the final product. Variations in dye absorption, the risk of uneven coloring, and the selection of appropriate sealants can lead to inconsistencies that affect customer satisfaction. Additionally, the lack of proper ventilation and safety measures during the dyeing process can pose health risks to workers.

The Solution: To overcome these challenges, buyers should prioritize the use of high-quality dyes specifically designed for leather. Conducting tests on scrap pieces of leather can help establish the best techniques for achieving even coloration. It is crucial to follow the manufacturer’s instructions regarding dye application and drying times to ensure consistent results. Implementing safety protocols, such as working in well-ventilated areas and using protective gear, will safeguard workers during the dyeing process. Furthermore, offering training sessions for staff on best practices in dyeing and finishing techniques can enhance product quality and reduce waste, ultimately leading to higher customer satisfaction and repeat business.

Strategic Material Selection Guide for how to make a leather dog collar

What Are the Key Properties of Different Leather Types for Dog Collars?

When selecting materials for crafting leather dog collars, various types of leather come into play, each with distinct properties and suitability for different applications. Understanding these materials is crucial for B2B buyers looking to source the best options for their markets.

1. Full Grain Leather

Key Properties: Full grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. It is highly durable, resistant to wear and tear, and develops a rich patina over time. Its breathability and moisture-wicking properties make it suitable for various climates.

Pros & Cons: The primary advantage of full grain leather is its longevity and aesthetic appeal, making it ideal for high-end dog collars. However, it is more expensive than other types of leather, which can impact profit margins. Manufacturing complexity is moderate, as it requires skilled labor to work with this material.

Impact on Application: Full grain leather is well-suited for collars that need to withstand outdoor conditions. Its moisture resistance helps prevent mold and mildew, making it ideal for humid climates.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local climate conditions when selecting full grain leather, as its properties can vary based on humidity. Compliance with international leather standards (e.g., ASTM) is essential for ensuring product quality.

2. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is treated with natural tannins from plant sources, making it eco-friendly. It is less durable than full grain leather but offers good flexibility and can be dyed easily.

Pros & Cons: The key advantage of vegetable-tanned leather is its sustainability and the ability to customize colors and finishes. However, it may not be as water-resistant as other leather types, which can limit its use in wet environments. The manufacturing process is less complex, making it a cost-effective option.

Illustrative image related to how to make a leather dog collar

Impact on Application: This type of leather is ideal for decorative collars that may not be exposed to harsh conditions. Its ability to absorb dyes allows for creative designs, appealing to niche markets.

Considerations for International Buyers: Buyers should ensure that the vegetable tanning process complies with local environmental regulations, particularly in Europe, where strict standards exist. Additionally, they should consider the availability of local suppliers for consistent sourcing.

3. Genuine Leather

Key Properties: Genuine leather is made from the lower layers of the hide and is often corrected to remove imperfections. It is less durable than full grain and vegetable-tanned leather but is more affordable.

Pros & Cons: The affordability of genuine leather makes it attractive for mass production. However, its lower quality and durability can lead to shorter product lifespans, which may affect customer satisfaction. The manufacturing process is straightforward, allowing for quick production.

Illustrative image related to how to make a leather dog collar

Impact on Application: Genuine leather is suitable for budget-friendly collars aimed at a broader market. However, its susceptibility to wear and tear means it may not be suitable for active dogs.

Considerations for International Buyers: B2B buyers should be cautious about sourcing genuine leather, as quality can vary significantly. Understanding local market preferences for quality can help in making informed purchasing decisions.

4. Suede Leather

Key Properties: Suede leather, made from the underside of the hide, is soft and flexible but less durable than other types. It has a unique texture that is appealing for fashion-oriented products.

Pros & Cons: The softness of suede makes it comfortable for dogs, but it is prone to staining and water damage. This limits its use in practical applications. Manufacturing suede requires specialized techniques, which can increase costs.

Impact on Application: Suede is best for decorative collars that are not intended for heavy use. Its aesthetic appeal can attract customers looking for stylish options.

Considerations for International Buyers: Buyers should consider the climate when sourcing suede, as it may not perform well in humid or wet conditions. Compliance with local standards for leather products is also crucial.

Summary Table of Material Selection for Leather Dog Collars

| Material | Typical Use Case for how to make a leather dog collar | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end, durable collars | Exceptional durability and aesthetics | Higher cost | High |

| Vegetable-Tanned Leather | Decorative collars | Eco-friendly and customizable | Less water resistance | Medium |

| Genuine Leather | Budget-friendly collars | Affordable for mass production | Lower durability | Low |

| Suede Leather | Fashion-oriented decorative collars | Soft and comfortable | Prone to staining and water damage | Medium |

This analysis provides a comprehensive overview of the key materials for crafting leather dog collars, helping international B2B buyers make informed sourcing decisions based on their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather dog collar

What Are the Main Stages of the Manufacturing Process for Leather Dog Collars?

The manufacturing process for leather dog collars consists of several critical stages, each requiring specialized techniques and tools to ensure high-quality output. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to how to make a leather dog collar

How Is Material Prepared for Leather Dog Collars?

The first step in the manufacturing process involves sourcing high-quality leather. Full-grain leather is preferred for its durability and aesthetic appeal. Suppliers should provide documentation confirming the leather’s grade and source, as well as any relevant certifications. Following procurement, the leather undergoes cleaning and conditioning to remove any contaminants that could affect the final product.

Once cleaned, the leather is cut into strips using a leather strap cutter, ensuring that the dimensions meet industry standards. This step may involve pre-cutting for common sizes to streamline production. The cutting process should be monitored to maintain consistency in size and shape, as this directly impacts the collar’s fit and comfort.

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping the leather into the desired collar profile. Techniques such as edge beveling, hole punching, and decorative stamping may be applied. Each of these processes requires precision tools, including a mallet, oblong hole punch, and stamping tools.

Illustrative image related to how to make a leather dog collar

Edge beveling is particularly crucial for preventing fraying and ensuring comfort for the dog. Quality assurance during this stage can be achieved by inspecting the edges for uniformity and smoothness. Additionally, any stamping should be executed with care to maintain the design integrity and aesthetic appeal.

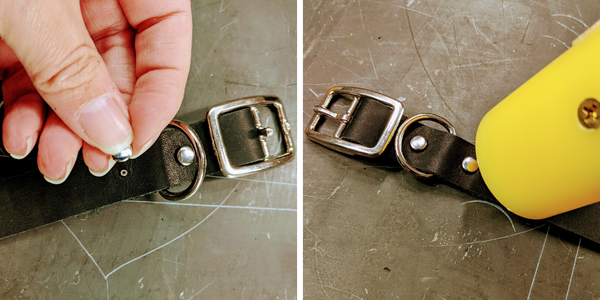

How Is the Assembly Process Conducted?

During assembly, various components such as buckles, D-rings, and Chicago screws are attached to the leather. This step requires meticulous attention to detail, as proper assembly affects both functionality and durability. Quality checks should occur at this stage to ensure that all components are securely fastened and that the collar can withstand the wear and tear of daily use.

The assembly process also includes verifying that the collars meet the required sizes and that the hole placements allow for adjustability. Any discrepancies at this stage can lead to product returns and negatively impact brand reputation.

Illustrative image related to how to make a leather dog collar

What Finishing Techniques Are Applied to Leather Dog Collars?

Finishing is the final stage of production, where the collar receives dye, sealant, and any additional treatments. The choice of dye can affect not only the appearance but also the longevity of the collar. Quality control during this stage is vital, as improper dyeing can lead to uneven coloring or fading over time.

After dyeing, the collar should be sealed to protect it from moisture and dirt. This step may involve the application of a water-resistant sealant, which must be thoroughly tested to ensure it meets international standards. The finished product should undergo a final inspection to confirm that it meets all aesthetic and functional requirements before packaging.

How Is Quality Assurance Implemented in Leather Dog Collar Production?

Quality assurance is essential in the manufacturing process to ensure that products meet international standards and customer expectations. Various methodologies and checkpoints are utilized throughout the production process.

What Are the Relevant International Standards for Leather Dog Collars?

Adhering to international standards, such as ISO 9001 for quality management systems, is crucial for maintaining consistent quality. These standards outline a framework for process improvement and customer satisfaction, guiding manufacturers in implementing effective quality control measures.

In addition to ISO standards, industry-specific certifications like CE marking may be relevant, particularly if the collars are sold in markets that require compliance with safety regulations. Understanding these standards can help B2B buyers assess the credibility of their suppliers.

What Are the Key Quality Control Checkpoints in Production?

Quality control checkpoints should be established at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Inspections during the manufacturing process help identify defects early, allowing for immediate corrections.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures that it meets all design and functional requirements.

By implementing these checkpoints, manufacturers can significantly reduce the risk of defects and enhance overall product quality.

What Common Testing Methods Are Used in Quality Assurance?

Common testing methods for leather dog collars include tensile strength tests, colorfastness tests, and wear resistance tests. These assessments provide valuable insights into the durability and usability of the collars. B2B buyers should inquire about the specific testing methods employed by their suppliers to ensure compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

- Conduct Audits: Regular audits of manufacturing facilities can reveal insights into the production process and adherence to quality standards.

- Request Quality Reports: Suppliers should provide detailed reports outlining their quality control processes, testing results, and compliance with international standards.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s quality control measures and overall product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. This includes understanding local regulations, cultural expectations, and market demands that may affect product quality.

Illustrative image related to how to make a leather dog collar

Additionally, buyers should be cautious about differences in manufacturing practices and quality standards in various regions. Establishing clear communication and setting expectations with suppliers is crucial for a successful partnership.

Conclusion

The manufacturing process and quality assurance of leather dog collars are multifaceted and require attention to detail at every stage. For B2B buyers, understanding these processes and implementing effective quality control measures is key to ensuring they receive high-quality products that meet market demands. By leveraging international standards and establishing robust verification processes, businesses can foster successful relationships with their suppliers, ensuring consistent quality and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather dog collar’

Introduction

Creating high-quality leather dog collars requires careful planning and sourcing. This guide serves as a comprehensive checklist for B2B buyers looking to procure the necessary materials and tools, ensuring that the final product meets both quality and safety standards. By following these steps, you can streamline your sourcing process and enhance your production capabilities.

Step 1: Identify Material Requirements

Before sourcing, define the types of leather and other materials you will use. Full-grain leather is recommended due to its durability and aesthetic appeal. Look for suppliers who provide:

– Natural Cowhide Leather or Veg-tan Leather: Ensure the leather is at least two grades higher than genuine leather for optimal quality.

– Water-Resistant Sealants: This enhances the longevity of the collars, especially in varied climates.

Illustrative image related to how to make a leather dog collar

Step 2: Source Reliable Tools

Gather the essential tools required for collar production. Investing in quality tools will facilitate efficient manufacturing and improve the final product’s finish. Consider sourcing:

– Leather Mallets and Punches: These are crucial for accurately shaping and assembling collars.

– Edge Bevelers and Slickers: They enhance comfort by smoothing edges, which is vital for customer satisfaction.

Step 3: Select a Trustworthy Supplier

Evaluate potential suppliers based on their reputation and reliability. This step is crucial to ensure consistent quality and timely deliveries. Key factors to assess include:

– Supplier Certifications: Verify if they adhere to international quality standards.

– Customer Reviews: Seek testimonials from other businesses in your region to gauge their experiences.

Step 4: Request Samples for Quality Assurance

Before placing a bulk order, always request samples of both materials and tools. This allows you to assess the quality firsthand. Pay attention to:

– Leather Texture and Finish: Ensure it meets your specifications for durability and aesthetics.

– Tool Performance: Check if the tools are ergonomic and efficient for leatherworking tasks.

Step 5: Understand Local Regulations

Familiarize yourself with any regulations regarding the production and sale of pet products in your target markets. Compliance is essential to avoid legal issues. Consider:

– Import Regulations: Ensure that all materials meet the import standards of your country.

– Safety Standards: Research requirements specific to pet products, ensuring that materials are safe for animal use.

Step 6: Plan for Logistics and Supply Chain

Consider the logistics of sourcing materials, including shipping times and costs. Efficient logistics will affect your production timeline. Focus on:

– Shipping Options: Evaluate both local and international shipping options for cost-effectiveness and reliability.

– Inventory Management: Implement systems for tracking stock levels to prevent production delays.

Step 7: Establish a Feedback Loop

Once production begins, create a system for gathering feedback from your customers. This will help you refine your products over time. Include:

– Customer Surveys: Solicit input on collar design, comfort, and durability.

– Market Trends: Stay updated on industry trends to adapt your offerings to consumer preferences.

By following this checklist, B2B buyers can effectively source the necessary materials and tools for producing high-quality leather dog collars, ensuring a successful manufacturing process that meets market demand.

Illustrative image related to how to make a leather dog collar

Comprehensive Cost and Pricing Analysis for how to make a leather dog collar Sourcing

What Are the Key Cost Components for Making Leather Dog Collars?

When analyzing the cost structure for producing leather dog collars, several key components must be considered. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

-

Materials: The cost of raw materials is significant, particularly the type of leather used. Full grain leather is preferred for its durability and aesthetic appeal, but it comes at a higher price compared to lower grades like genuine leather. Additional materials such as buckles, D-rings, screws, dyes, and sealants must also be factored in. Pricing for these components can vary widely depending on quality and supplier.

-

Labor: Labor costs will depend on the region and the skill level required for the production process. Skilled artisans may demand higher wages, but their expertise can lead to a superior product, justifying the investment.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient operations can help reduce these overheads, but they are essential for maintaining quality production.

-

Tooling: Initial setup costs for tools can be high, especially for specialized equipment like leather punches and cutting machines. However, these tools have long-term usability, so spreading the cost over multiple production runs can improve overall profitability.

-

Quality Control (QC): Implementing a robust QC process ensures that products meet customer expectations and compliance standards. While this may increase costs upfront, it can reduce returns and enhance customer satisfaction in the long run.

-

Logistics: Shipping costs can vary based on destination, volume, and chosen Incoterms. International shipments may require additional customs duties and taxes, impacting overall pricing.

-

Margin: The desired profit margin will dictate the final pricing strategy. It is crucial to balance competitiveness with profitability, particularly in diverse markets.

How Do Price Influencers Impact the Cost of Leather Dog Collars?

Several factors can influence pricing strategies in the leather collar market. Understanding these can help international buyers make informed decisions.

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often qualify for discounts, making it essential for buyers to consider their inventory needs.

-

Specifications and Customization: Custom designs or specific materials can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials Quality and Certifications: Higher-quality materials often come with certifications, which can affect pricing. Buyers should assess whether the added cost aligns with their target market’s expectations.

-

Supplier Factors: Supplier reputation, reliability, and location can impact pricing. Establishing strong relationships with suppliers can lead to better pricing negotiations and consistent quality.

-

Incoterms: Understanding shipping terms is crucial for managing costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) affect who bears the shipping costs and can influence overall pricing.

What Tips Can Help Buyers Navigate Cost-Efficiency in Leather Collar Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigating costs effectively is crucial.

-

Negotiation: Cultivating strong relationships with suppliers can lead to better negotiation outcomes. Don’t hesitate to ask for volume discounts or flexible payment terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential resale value. Opt for suppliers who provide quality products that minimize long-term costs.

-

Pricing Nuances: Be aware of regional price variations. Factors such as local demand, economic conditions, and import tariffs can affect pricing, making thorough market research essential.

-

Quality Assessment: Always request samples to assess quality before placing larger orders. This can help prevent costly mistakes and ensure that the products meet your specifications.

Disclaimer on Indicative Prices

Pricing for leather dog collars can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing aligned with their specific needs.

Illustrative image related to how to make a leather dog collar

Alternatives Analysis: Comparing how to make a leather dog collar With Other Solutions

Introduction to Alternatives in Dog Collar Production

When considering the creation of leather dog collars, it’s crucial for B2B buyers to explore various methods that can meet their business needs effectively. While crafting collars from leather offers unique customization and quality, alternative solutions may provide different benefits in terms of performance, cost, and ease of implementation. This analysis will compare the traditional leather collar-making process with two viable alternatives: synthetic dog collars and pre-made leather collars.

Comparison Table

| Comparison Aspect | How To Make A Leather Dog Collar | Synthetic Dog Collar | Pre-Made Leather Collar |

|---|---|---|---|

| Performance | High durability, customizable fit | Moderate durability, varies by material | High durability, ready-to-use |

| Cost | Moderate (materials & tools) | Low to moderate (mass-produced) | High (brand premium) |

| Ease of Implementation | Requires skill and tools | Easy (no special tools needed) | Very easy (ready to sell) |

| Maintenance | Requires regular care | Low maintenance | Moderate (depends on quality) |

| Best Use Case | Custom orders, artisanal appeal | Mass-market, budget-friendly | Premium retail, brand loyalty |

Detailed Breakdown of Alternatives

Synthetic Dog Collar

Synthetic collars, often made from materials like nylon or polyester, present a budget-friendly option for businesses focused on mass production. They are generally lightweight, resistant to wear and tear, and available in a wide variety of colors and styles. However, while synthetic collars can be easier to produce and maintain, they may not match the durability and aesthetic appeal of leather collars. Additionally, they often lack the customizability that leather provides, which can be a disadvantage for businesses looking to offer unique products.

Pre-Made Leather Collar

Pre-made leather collars offer an attractive alternative for businesses seeking to minimize production time and labor costs. These collars come ready-to-sell and often feature high-quality craftsmanship. They appeal to customers who desire the luxurious feel of leather without the wait or effort involved in making a collar from scratch. However, the downside is that pre-made collars may carry a premium price tag, which can affect profit margins. Furthermore, they limit the opportunity for customization, which could alienate customers looking for personalized products.

Conclusion: Choosing the Right Solution for Your Business

For B2B buyers, the decision on which method to pursue for dog collar production hinges on specific business goals and target markets. If customization and artisanal quality are key selling points, the leather collar-making process may be the best choice. Conversely, for businesses focused on volume sales and cost-effectiveness, synthetic collars could provide a viable solution. Pre-made leather collars can serve as an excellent option for retailers looking to offer high-quality products quickly. Ultimately, understanding the unique needs of your customer base will guide the selection of the most suitable production method.

Essential Technical Properties and Trade Terminology for how to make a leather dog collar

What Are the Key Technical Properties in Leather Dog Collar Manufacturing?

When considering the production of leather dog collars, understanding the technical properties of materials and components is essential for ensuring quality and durability. Below are critical specifications that are vital for B2B buyers in the leather goods industry:

-

Material Grade

The quality of leather used directly impacts the collar’s durability and aesthetics. Full grain leather is the highest quality, derived from the top layer of the hide, retaining its natural texture and strength. Conversely, genuine leather is a lower-grade material that may not withstand wear over time. Selecting the appropriate grade is crucial for meeting customer expectations and ensuring product longevity. -

Thickness

Leather thickness is measured in ounces or millimeters. A standard thickness for dog collars ranges from 8 to 10 ounces (approximately 3.2 to 4 mm). Thicker leather offers greater strength and resistance to wear, which is particularly important for larger breeds. B2B buyers should specify thickness requirements based on the target market to ensure safety and comfort for the end-user. -

Dye and Finish Quality

The dye used can affect the collar’s appearance and longevity. High-quality dyes, such as antique leather dyes, penetrate deeply and provide a rich color that enhances the leather’s natural grain. Additionally, a protective finish or sealant is vital for water and UV resistance, prolonging the product’s life. Understanding these qualities aids in selecting suppliers that meet industry standards. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in the dimensions of a collar. For example, if a collar is meant to fit a 1-inch buckle, a tolerance of ±0.1 inches is acceptable. Maintaining tight tolerances ensures a proper fit and functionality, which is crucial for customer satisfaction. Buyers should communicate tolerance specifications clearly to manufacturers to minimize production errors. -

Durability Testing

Durability testing measures how well a collar can withstand stress and wear over time. Common tests include tensile strength and abrasion resistance. For B2B buyers, understanding the results of these tests is essential for ensuring that the collars will perform well under various conditions, especially for active dog breeds.

What Are the Common Trade Terminology Terms Related to Leather Dog Collar Production?

Navigating the leather goods market requires familiarity with specific jargon that can impact negotiations and supply chain management. Here are key trade terms relevant to the production of leather dog collars:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are sold by another company under its brand name. In the context of leather collars, a B2B buyer may partner with an OEM to produce custom designs, ensuring product exclusivity while leveraging the OEM’s manufacturing expertise. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of units that a supplier is willing to produce or sell. Understanding MOQ is essential for B2B buyers to gauge production feasibility and cost-effectiveness. For smaller businesses, negotiating lower MOQs can facilitate entry into the market without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing and terms for specific products. In the leather collar industry, an RFQ should detail specifications, materials, and quantities, allowing suppliers to provide accurate quotes. This process is vital for budget planning and supplier selection. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps B2B buyers manage shipping costs and risks effectively when sourcing leather collars globally. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished product. In the leather goods industry, lead times can vary significantly based on production capacity and supplier reliability. B2B buyers should account for lead times when planning inventory and product launches to ensure timely delivery to customers.

In summary, familiarity with technical specifications and industry terminology is crucial for B2B buyers in the leather dog collar market. This knowledge facilitates informed decision-making, effective supplier negotiations, and ultimately, the delivery of high-quality products to end consumers.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather dog collar Sector

What Are the Key Trends Influencing the Leather Dog Collar Market?

The leather dog collar market is experiencing a significant transformation driven by global trends and consumer preferences. In recent years, there has been a marked increase in demand for personalized and customizable pet products. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are seeking unique designs that reflect individual pet personalities. This trend is complemented by advancements in B2B technologies, such as e-commerce platforms and digital design tools, enabling manufacturers to cater to specific consumer needs effectively.

Additionally, the rise of online marketplaces has expanded access to global suppliers, allowing B2B buyers to source high-quality materials from various regions. This shift is creating opportunities for local artisans and small businesses in countries like Nigeria and Brazil, where traditional craftsmanship can be highlighted. Furthermore, the market is witnessing a growing interest in functional designs that enhance the safety and comfort of pets, pushing manufacturers to innovate in areas like adjustable sizing and durable materials.

Illustrative image related to how to make a leather dog collar

How Is Sustainability Reshaping the Leather Dog Collar Industry?

Sustainability and ethical sourcing are increasingly becoming central to the leather dog collar market. The environmental impact of traditional leather production has raised concerns among consumers and businesses alike. Consequently, B2B buyers are prioritizing suppliers who adhere to sustainable practices, such as sourcing leather from eco-friendly tanneries that use vegetable tanning processes. This method not only reduces harmful chemicals but also appeals to environmentally conscious consumers.

Moreover, certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction. These certifications assure buyers that the products meet stringent environmental and ethical standards. As a result, businesses that invest in sustainable sourcing practices are likely to gain a competitive edge in the marketplace. By promoting eco-friendly materials and processes, companies can enhance their brand reputation and align with the values of modern consumers who prioritize sustainability.

What Historical Context Is Relevant for B2B Buyers in the Leather Dog Collar Market?

The leather dog collar has evolved significantly over the years, transitioning from a purely functional item to a fashion statement for pet owners. Historically, leather collars were primarily used for controlling and securing pets. However, as pet ownership has grown globally, particularly in urban areas, collars have become a means for pet owners to express their style and their pets’ personalities.

This evolution has opened new avenues for B2B buyers to explore diverse product offerings, such as decorative collars that incorporate various materials, colors, and designs. Additionally, the historical craftsmanship involved in leatherworking has seen a resurgence, with many buyers seeking artisanal products that reflect traditional techniques. This blend of history and modernity creates a unique market dynamic, offering numerous opportunities for B2B buyers to source innovative and culturally rich products.

In conclusion, understanding these market dynamics, trends, and historical contexts will empower international B2B buyers to make informed decisions in the leather dog collar sector, ultimately driving growth and sustainability in their business operations.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather dog collar

-

How do I choose the right leather for making dog collars?

Selecting the appropriate leather is crucial for durability and comfort. Full grain leather is recommended for its strength and natural finish. Veg-tan leather is another excellent choice as it can be easily dyed and shaped. When sourcing leather, consider the thickness and width based on your design and the size of the dogs you’re targeting. Establish relationships with suppliers who can provide consistent quality and various grades of leather, and always request samples to assess the material before committing to larger orders. -

What is the best type of dye for leather dog collars?

Antique leather dyes are popular due to their aesthetic appeal, as they enhance the natural grain and provide a rich color that deepens in the crevices. For B2B buyers, sourcing high-quality dyes from reputable suppliers ensures consistency and vibrancy in your products. Additionally, consider water-resistant dyes that can withstand wear and tear, especially for collars used in outdoor environments. Always conduct a small test on scrap leather to ensure compatibility with your chosen leather and desired finish. -

How can I ensure the quality of my leather dog collars?

Implementing a stringent quality assurance (QA) process is vital. Begin by establishing clear specifications for materials, craftsmanship, and finishes. Regularly inspect samples from your suppliers and conduct random checks during production. Collaborating with experienced artisans or manufacturers who understand leatherwork can enhance the quality of the final product. Additionally, consider customer feedback as a valuable tool for continuous improvement in your collar designs. -

What are the typical minimum order quantities (MOQs) for leather dog collars?

MOQs can vary significantly depending on the supplier and the complexity of the collar design. For custom designs, MOQs may start from 50 to 100 units, while standard designs may have lower thresholds. When negotiating with suppliers, clarify their MOQ policies and explore options for smaller initial orders to test the market. This approach can mitigate risk while allowing you to gauge demand before committing to larger productions. -

How do I find reliable suppliers for leather dog collars?

To find trustworthy suppliers, start by researching online marketplaces and industry trade shows, which often feature verified manufacturers. Networking within leatherworking communities can also yield recommendations. Evaluate potential suppliers based on their experience, production capacity, and customer reviews. Always request samples and visit facilities if possible to assess their practices firsthand. Establishing a long-term relationship with a reliable supplier can ensure consistent quality and timely deliveries. -

What logistics considerations should I keep in mind for importing leather dog collars?

When importing collars, consider customs regulations, tariffs, and shipping logistics specific to your region. Partnering with a logistics provider experienced in handling leather goods can streamline the process. Ensure your paperwork is in order, including invoices, packing lists, and certificates of origin. Additionally, factor in lead times for production and shipping to maintain an efficient supply chain and meet customer demand. -

What customization options are available for leather dog collars?

Customization can enhance your product’s appeal. Options include varying widths, lengths, colors, and finishes, as well as the addition of personalized elements like names or patterns. Discuss your ideas with suppliers to understand their capabilities and any limitations. Offering a range of customizable features can differentiate your brand in the market and cater to diverse customer preferences, ultimately driving sales. -

What payment terms should I negotiate with suppliers for leather dog collars?

Negotiating favorable payment terms is essential for managing cash flow. Common practices include 30% upfront payment with the balance due upon delivery or net 30/60 days post-invoice. Consider utilizing letters of credit for larger transactions to mitigate risks. Establishing clear payment terms can foster trust and ensure smooth transactions. Always communicate openly with suppliers about your financial capabilities and negotiate terms that work for both parties.

Top 5 How To Make A Leather Dog Collar Manufacturers & Suppliers List

1. Instructables – Leather Dog Collar

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather Dog Collar made from full grain leather, specifically natural cowhide or veg-tan leather. Requires materials such as a belt buckle, Chicago screws, D-rings, Gum Tragacanth, leather deglazer, and antique leather dye. Suggested tools include a hole punch, leather mallet, oblong leather punch, granite slab, swivel knife, edge beveler, edge slicker, leather shaver, bone folder, decorative stam…

2. Cory’s Leathercraft – Handmade Dog Collar

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Leather dog collar made by user Cory, who is new to Leathercraft. The collar was created for his best friend and the process is shared in a video tutorial.

3. Leatherworker – Rolled Leather Dog Leads

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Rolled leather dog leads; traditional method involves multiple steps; alternative method includes sewing a thin piece of leather around a cord or rope; Al Stohlman’s book “The Art of Handsewing Leather” provides instructions for making traditional rounds by hand; discussions on techniques and tools for sewing rounds.

4. Tandy Leather – Personalized Dog Collars

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Personalized Dog Collars, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Doberman Chat – Leather Craft Essentials

Domain: doberman-chat.com

Registered: 2008 (17 years)

Introduction: 1. 6′ long lead with a blood knot on each end requires close to 7′ strip. 2. Latigo vs. Veg tan: Latigo is preconditioned but stiff; Veg tan offers more options for dyeing and stamping. 3. Tool for cutting strips is called a strap cutter, priced around $33.20 at Tandy Leather. 4. Procedure for Veg tan: dye first, then conditioner, then finish if needed. 5. Cost range for dyes and conditioners avai…

Strategic Sourcing Conclusion and Outlook for how to make a leather dog collar

In summary, the process of creating leather dog collars presents significant opportunities for B2B buyers looking to enhance their product offerings. By strategically sourcing high-quality materials such as full-grain or vegetable-tanned leather, businesses can ensure durability and appeal, catering to the growing demand for premium pet products. Additionally, investing in the right tools and leveraging local craftsmanship can reduce costs while fostering community engagement, particularly in regions like Africa, South America, the Middle East, and Europe.

As the pet industry continues to expand globally, the potential for innovation in design and customization is immense. Businesses should consider diversifying their product lines by incorporating unique features or eco-friendly materials, appealing to the environmentally conscious consumer.

Illustrative image related to how to make a leather dog collar

Looking ahead, now is the time for international B2B buyers to explore partnerships with local artisans and suppliers. This not only strengthens supply chains but also enhances brand authenticity. Embrace the craftsmanship of leather dog collars and position your business at the forefront of this lucrative market, ensuring you meet the evolving preferences of pet owners worldwide. Take action today to capitalize on these opportunities and drive growth in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make a leather dog collar

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.