Introduction: Navigating the Global Market for the leather factory furniture

In the ever-evolving landscape of B2B commerce, sourcing high-quality leather factory furniture presents both opportunities and challenges for international buyers. With rising competition from global markets, particularly from manufacturers in Asia, understanding how to navigate these complexities is crucial. Whether you’re looking for bespoke leather seating solutions for luxury hotels or durable furniture for corporate offices, this guide will provide you with the insights needed to make informed purchasing decisions.

This comprehensive resource covers a wide range of essential topics, including the various types of leather furniture available, their applications across different industries, and effective strategies for vetting suppliers. Additionally, we delve into cost considerations, highlighting how to balance quality with budget constraints. For buyers from Africa, South America, the Middle East, and Europe—especially in key markets like Germany and Brazil—this guide is designed to empower your procurement process by equipping you with actionable insights and industry best practices.

By leveraging the information contained within this guide, you can confidently approach the global market for leather factory furniture, ensuring that your investment not only meets your aesthetic and functional needs but also aligns with your business objectives. Embrace the opportunity to elevate your offerings with quality leather furniture that resonates with your target audience.

Table Of Contents

- Top 4 The Leather Factory Furniture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for the leather factory furniture

- Understanding the leather factory furniture Types and Variations

- Key Industrial Applications of the leather factory furniture

- 3 Common User Pain Points for ‘the leather factory furniture’ & Their Solutions

- Strategic Material Selection Guide for the leather factory furniture

- In-depth Look: Manufacturing Processes and Quality Assurance for the leather factory furniture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘the leather factory furniture’

- Comprehensive Cost and Pricing Analysis for the leather factory furniture Sourcing

- Alternatives Analysis: Comparing the leather factory furniture With Other Solutions

- Essential Technical Properties and Trade Terminology for the leather factory furniture

- Navigating Market Dynamics and Sourcing Trends in the the leather factory furniture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of the leather factory furniture

- Strategic Sourcing Conclusion and Outlook for the leather factory furniture

- Important Disclaimer & Terms of Use

Understanding the leather factory furniture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Retains the natural grain, offering durability and beauty | High-end furniture retailers, luxury hotels | Pros: Long-lasting, unique appearance; Cons: Higher cost |

| Top-Grain Leather | Sanded and polished for a smoother finish | Office furniture, upscale residential | Pros: Soft feel, resistant to stains; Cons: Less durable than full-grain |

| Bonded Leather | Made from leather scraps and polyurethane | Budget-friendly furniture lines | Pros: Cost-effective, versatile; Cons: Less durable, may peel over time |

| Aniline Leather | Dyed with transparent dyes, showcasing natural texture | High-end retail, custom furniture | Pros: Rich colors, breathability; Cons: Sensitive to stains |

| Кожа нубук | Sanded to create a soft, velvety texture | Specialty furniture, high-end lounges | Pros: Luxurious feel, unique look; Cons: Requires careful maintenance |

What are the characteristics and applications of Full-Grain Leather in furniture?

Full-grain leather is highly regarded for its durability and natural beauty, as it retains the original grain of the hide. This type is often used in high-end furniture applications, including luxury hotels and premium retail environments. When sourcing full-grain leather furniture, B2B buyers should consider the authenticity and sourcing practices of the manufacturer, as well as the long-term value it provides despite a higher initial cost.

How does Top-Grain Leather compare to other types for business applications?

Top-grain leather is sanded and polished to achieve a smoother finish, making it a popular choice for office furniture and upscale residential settings. Its soft feel and resistance to stains make it appealing for businesses that prioritize aesthetics and functionality. B2B buyers should weigh the balance between comfort and durability, as top-grain leather may not offer the same lifespan as full-grain options, but it provides a more affordable luxury alternative.

What makes Bonded Leather a viable option for budget-conscious buyers?

Bonded leather is crafted from leather scraps bonded with polyurethane, making it a cost-effective choice for budget-friendly furniture lines. This type is suitable for various applications, including mass-market furniture and transitional spaces. While it offers versatility and affordability, buyers should be aware of its potential durability issues, as bonded leather may peel over time, impacting long-term value.

Why is Aniline Leather preferred in high-end furniture markets?

Aniline leather is dyed using transparent dyes that allow the natural texture of the hide to shine through, making it a favorite in high-end retail and custom furniture markets. This type is known for its rich colors and breathability, enhancing the overall aesthetic of luxury spaces. B2B buyers should consider the maintenance requirements, as aniline leather is more sensitive to stains, necessitating careful handling and cleaning.

What are the unique properties of Nubuck Leather for specialty furniture?

Nubuck leather, with its soft, velvety texture achieved through sanding, is often used in specialty furniture and high-end lounges. Its luxurious feel and unique appearance make it appealing for businesses aiming to create an upscale environment. However, B2B buyers should be prepared for the maintenance challenges associated with nubuck, as it requires careful cleaning and protection from moisture to maintain its aesthetic appeal.

Key Industrial Applications of the leather factory furniture

| Industry/Sector | Specific Application of the leather factory furniture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Custom leather seating for hotels and restaurants | Enhances guest experience and brand image with luxury appeal | Durability, ease of maintenance, and compliance with local regulations |

| Автомобили | Leather interiors for luxury vehicles | Elevates vehicle aesthetic and comfort, attracting premium clientele | Quality of leather, customization options, and supplier reliability |

| Office Furniture | Ergonomic leather office chairs and desks | Improves employee productivity and comfort, reducing fatigue | Ergonomic design standards, warranty, and environmental certifications |

| Retail | Leather display furniture for high-end boutiques | Attracts customers and showcases products elegantly | Design versatility, durability, and alignment with brand identity |

| Healthcare | Leather furniture for waiting areas and patient rooms | Provides a clean, professional appearance while ensuring comfort | Hygiene standards, ease of cleaning, and patient safety features |

How is Leather Factory Furniture Used in the Hospitality Sector?

In the hospitality industry, custom leather seating is extensively used in hotels and restaurants. This type of furniture not only enhances the aesthetic appeal but also contributes significantly to the overall guest experience. High-quality leather provides a luxurious feel, while durable finishes ensure longevity despite heavy usage. International buyers, particularly from regions like Africa and the Middle East, should consider sourcing options that comply with local regulations regarding fire safety and materials used in public spaces.

What Role Does Leather Furniture Play in the Automotive Industry?

Leather factory furniture is pivotal in the automotive sector, especially for luxury vehicles where leather interiors are a hallmark of comfort and style. This application not only elevates the vehicle’s aesthetic but also enhances customer satisfaction, appealing to premium clientele. Buyers from South America and Europe, particularly Germany, should prioritize the quality of leather and customization options to meet specific market demands, ensuring that they align with their brand’s identity and customer expectations.

Why is Ergonomic Leather Furniture Important for Office Spaces?

In corporate environments, ergonomic leather office chairs and desks are crucial for promoting employee productivity and well-being. These pieces not only offer comfort but also reduce fatigue during long working hours. For B2B buyers in Europe and Africa, it is essential to focus on ergonomic design standards and warranty options when sourcing such furniture, as these factors directly influence employee satisfaction and retention rates.

How Can Retailers Benefit from Leather Display Furniture?

For retailers, especially high-end boutiques, leather display furniture serves as a vital tool for attracting customers and effectively showcasing products. The elegance of leather furniture can significantly enhance the shopping experience, making products more appealing. When sourcing for this application, businesses should consider design versatility and durability to ensure that the furniture aligns with their brand identity and withstands the rigors of a retail environment.

What Are the Considerations for Leather Furniture in Healthcare Settings?

In healthcare, leather furniture is often utilized in waiting areas and patient rooms to provide a professional appearance while ensuring comfort. The choice of materials is critical, as hygiene standards and ease of cleaning are paramount in such environments. International buyers from the Middle East and Europe should ensure that their sourcing aligns with health regulations and patient safety features, maintaining the highest standards of care and comfort in their facilities.

3 Common User Pain Points for ‘the leather factory furniture’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Leather Products

The Problem: B2B buyers often face challenges when sourcing leather furniture due to varying quality standards. This issue is especially pronounced when dealing with international suppliers, where differences in material sourcing, processing, and craftsmanship can lead to inconsistent product quality. A buyer may receive leather pieces that look appealing in images but fail to meet durability or aesthetic expectations upon delivery, leading to dissatisfaction and potential financial loss.

The Solution: To ensure the quality of leather factory furniture, B2B buyers should implement a rigorous vetting process. Start by requesting samples of leather and furniture pieces before placing bulk orders. Assess the texture, grain, and color consistency of the leather. Moreover, establish clear quality benchmarks and communicate them with suppliers. Buyers should also ask for certifications regarding leather quality and sourcing, such as those from the Leather Working Group, which ensures responsible and sustainable practices. Additionally, consider visiting manufacturing facilities to observe production processes firsthand. This proactive approach can significantly mitigate the risk of receiving subpar products and enhance buyer confidence.

Scenario 2: Managing Supply Chain Disruptions

The Problem: Supply chain disruptions have become increasingly common in the furniture industry, particularly for leather products sourced internationally. B2B buyers may experience delays in delivery due to logistical challenges, customs issues, or raw material shortages. These delays can affect inventory management, sales forecasts, and ultimately customer satisfaction, leading to strained relationships with clients.

The Solution: To combat supply chain issues, B2B buyers should diversify their supplier base. Instead of relying on a single source, seek multiple suppliers from different regions, which can provide backup options in case of disruptions. Establishing strong relationships with local suppliers can also facilitate faster turnaround times and reduce reliance on international shipping. Furthermore, implementing an inventory management system that tracks stock levels and demand forecasts can help buyers maintain optimal inventory levels. This system should include lead time analysis for different suppliers, allowing buyers to plan orders more effectively and reduce the impact of unforeseen delays.

Scenario 3: Understanding Leather Types and Finishes

The Problem: The variety of leather types and finishes available can be overwhelming for B2B buyers. Different leathers (e.g., full-grain, top-grain, bonded) offer distinct characteristics in terms of durability, maintenance, and aesthetic appeal. Without a clear understanding of these differences, buyers risk selecting materials that do not align with their target market’s preferences or the intended use of the furniture, potentially harming their business reputation.

The Solution: To navigate the complexities of leather types, B2B buyers should invest in education about leather materials and finishes. This can be achieved through workshops, supplier training sessions, or online resources that explain the benefits and drawbacks of each leather type. Buyers should also consider collaborating with interior designers or consultants who specialize in leather furniture to gain insights into trends and consumer preferences. When specifying orders, create detailed product specifications that outline the desired leather type and finish, ensuring clarity in communication with suppliers. By becoming informed about the materials they are purchasing, buyers can make better decisions that align with their brand’s identity and customer expectations.

Strategic Material Selection Guide for the leather factory furniture

What Are the Key Materials Used in Leather Factory Furniture?

When selecting materials for leather factory furniture, it is essential to consider the properties, advantages, and limitations of each option. This guide analyzes four common materials: leather, wood, metal, and synthetic fabrics. Each material has unique characteristics that can influence the durability, aesthetic appeal, and overall performance of the furniture.

How Does Leather Perform in Furniture Manufacturing?

Leather is the primary material used in high-quality furniture. Its key properties include excellent durability, resistance to wear and tear, and a luxurious aesthetic. Leather can withstand varying temperatures and has a natural breathability that enhances comfort. However, it can be sensitive to moisture and requires regular maintenance to prevent drying and cracking.

Pros: Leather offers a timeless appeal and can improve with age, developing a unique patina. It is also easy to clean and resistant to allergens, making it suitable for various environments.

Cons: The cost of high-quality leather can be significant, and it may not be suitable for all budget ranges. Additionally, leather can be challenging to work with during manufacturing due to its need for specialized techniques.

For international buyers, compliance with environmental standards regarding leather sourcing is crucial, especially in regions like Europe where regulations are stringent. Buyers should also consider the ethical implications of leather sourcing in their purchasing decisions.

What Role Does Wood Play in Leather Furniture?

Wood is often used in the frames and structural components of leather furniture. Its key properties include strength, versatility, and aesthetic appeal. Different types of wood, such as hardwoods and softwoods, offer varying degrees of durability and resistance to warping.

Illustrative image related to the leather factory furniture

Pros: Wood provides a sturdy foundation for leather upholstery and can be finished in various ways to match design preferences. It is also relatively easy to work with in manufacturing.

Cons: Wood can be susceptible to moisture damage and may require treatments to enhance its durability. The cost can vary widely depending on the type of wood selected, with exotic woods being particularly expensive.

For international buyers, understanding local wood regulations and compliance with standards such as the Forest Stewardship Council (FSC) certification is vital. This ensures that the wood used is sustainably sourced, which is increasingly important in markets like Europe.

How Does Metal Enhance Leather Furniture Design?

Metal components are often used in the legs, frames, and accents of leather furniture. Key properties of metals such as steel and aluminum include high strength, corrosion resistance, and the ability to withstand heavy loads.

Illustrative image related to the leather factory furniture

Pros: Metal adds a modern aesthetic and can enhance the overall durability of the furniture. It is also resistant to pests and can be easily recycled, contributing to sustainability efforts.

Cons: Metal can be more expensive than other materials and may require specialized manufacturing processes. Additionally, it can be prone to scratching and denting, which may affect the furniture’s appearance over time.

International buyers should be aware of any metal compliance standards, such as ASTM or DIN, particularly regarding safety and environmental impact. This is especially relevant in regions like the Middle East, where specific regulations may apply.

What Are the Benefits of Synthetic Fabrics in Leather Furniture?

Synthetic fabrics, such as polyurethane or polyester, are increasingly used in leather furniture as an alternative or complement to natural leather. Their key properties include water resistance, ease of cleaning, and a wide range of colors and textures.

Pros: Synthetic fabrics are often more affordable than genuine leather and can mimic its appearance. They are also easier to maintain and can be produced in various styles to suit different markets.

Cons: While durable, synthetic materials may not offer the same level of comfort or longevity as natural leather. They can also have a negative environmental impact if not sourced responsibly.

For international buyers, understanding the environmental certifications associated with synthetic materials is critical. Compliance with standards such as REACH in Europe can help ensure that the materials used are safe and environmentally friendly.

Summary Table of Material Selection for Leather Factory Furniture

| Материал | Typical Use Case for the leather factory furniture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upholstery and surface finishes | Luxurious appearance and durability | High cost and maintenance requirements | Высокий |

| Wood | Structural frames and accents | Strong and versatile | Susceptible to moisture and variable cost | Medium |

| Metal | Frames and legs | High strength and modern aesthetic | Prone to scratching and higher cost | Medium to High |

| Synthetic Fabric | Upholstery alternative | Affordable and easy to maintain | May lack comfort and longevity | Low to Medium |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for leather factory furniture, ensuring informed decisions that align with their business needs and market demands.

Illustrative image related to the leather factory furniture

In-depth Look: Manufacturing Processes and Quality Assurance for the leather factory furniture

What Are the Main Stages of Manufacturing Leather Furniture?

Manufacturing leather furniture involves several critical stages, each designed to ensure quality and durability. The typical process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Furniture Production?

The first step in the manufacturing process is the preparation of leather hides. Quality leather is sourced from reputable suppliers, often adhering to strict international standards. Once sourced, hides undergo a rigorous inspection process to ensure they meet quality benchmarks.

After inspection, hides are treated through a tanning process, which can be vegetable-based or chrome-based, depending on the desired properties of the final product. Tanning not only preserves the leather but also enhances its flexibility and resistance to wear. This stage is crucial as it affects the overall texture, color, and longevity of the leather.

Illustrative image related to the leather factory furniture

What Techniques Are Used in Forming Leather Furniture?

The forming stage involves cutting and shaping the leather and other materials to create the various components of the furniture. Advanced techniques such as CAD (Computer-Aided Design) are often used to ensure precision in cutting patterns. This technology allows manufacturers to optimize material usage, minimizing waste and reducing costs.

Once cut, the leather pieces are shaped using molds and frames that provide the structure for sofas, chairs, and other types of furniture. This stage may also involve foam cushioning, which adds comfort and support. The integration of high-quality foams, which can be sourced from different regions like Europe or South America, enhances the product’s appeal.

How Is Leather Furniture Assembled?

Assembly is where the different components come together to form a complete piece of furniture. Skilled craftsmen or automated systems stitch the leather pieces, ensuring that seams are strong and visually appealing. Reinforcements may be added at stress points to enhance durability.

During assembly, quality checks are often performed to ensure that each piece meets design specifications. This might include measuring dimensions, inspecting stitching quality, and checking for any visible defects.

What Are the Key Finishing Processes for Leather Furniture?

Finishing processes play a vital role in the aesthetics and functionality of leather furniture. This stage includes dyeing, applying protective coatings, and polishing. High-quality finishes not only enhance the appearance but also provide resistance against stains and scratches.

Eco-friendly finishing options are increasingly popular, especially in markets like Europe, where consumers are more environmentally conscious. Manufacturers may adopt sustainable practices, such as using water-based dyes and finishes, to appeal to this demographic.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance in leather furniture manufacturing is paramount. International standards such as ISO 9001 set benchmarks for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific standards like CE marking indicate compliance with health, safety, and environmental protection legislation.

For B2B buyers, understanding these standards is crucial. They signify that the manufacturer adheres to recognized quality practices, which can impact the longevity and reliability of the furniture.

What Are the Key Quality Control Checkpoints in Leather Furniture Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process. The typical checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint occurs as materials arrive at the factory. Here, leather hides and other materials are inspected for defects and compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections ensure that each stage meets quality criteria. This may include checking stitching, alignment, and component assembly.

-

Final Quality Control (FQC): Once the furniture is assembled, a comprehensive inspection occurs. This includes assessing the overall appearance, functionality, and adherence to design specifications.

What Testing Methods Are Commonly Used in Leather Furniture Quality Assurance?

Several testing methods are employed to ensure the quality of leather furniture. These include:

-

Physical Tests: Assessing the strength, flexibility, and durability of leather through standardized tests helps determine how well the material will perform under everyday use.

-

Chemical Tests: Evaluating the leather for harmful substances ensures compliance with safety regulations, particularly important in markets like Europe, where regulations are stringent.

-

Aesthetic Tests: Visual inspections for color consistency, texture, and finish quality are critical to meet consumer expectations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure reliability. Here are effective strategies:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their quality control practices. This includes assessing their compliance with international standards and their internal QC processes.

-

Request Reports: Suppliers should provide detailed QC reports that outline testing methods, results, and any corrective actions taken. This transparency can build trust and confidence.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality standards. These services can conduct thorough inspections at various stages of production.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Cultural Expectations: Different markets may have varying expectations regarding quality and aesthetics. Understanding these cultural nuances can guide procurement decisions.

-

Regulatory Compliance: Each region may have unique regulations that suppliers must adhere to. Buyers should ensure that their suppliers comply with local laws, particularly concerning safety and environmental standards.

-

Communication Barriers: Clear communication is vital in international transactions. Establishing a strong relationship with suppliers can help mitigate misunderstandings related to quality standards.

By understanding the manufacturing processes and quality assurance measures in leather furniture production, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘the leather factory furniture’

To assist international B2B buyers in sourcing leather factory furniture effectively, this guide provides a structured approach. The checklist outlines essential steps to ensure you make informed decisions and secure high-quality products that meet your business needs.

Step 1: Identify Your Requirements

Clearly defining your needs is the first step in sourcing leather furniture. Consider the type of furniture required (e.g., sofas, chairs, or custom pieces) and the specifications regarding size, style, and leather quality. This step is crucial as it sets the foundation for your sourcing strategy and helps streamline your search for suppliers who can meet these criteria.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers in the leather furniture industry. Look for manufacturers with a good reputation, especially those who specialize in factory-direct sales to B2B clients. Utilize online platforms, trade shows, and industry publications to gather information.

- Key Resources:

- Industry-specific directories

- Trade associations

- B2B marketplaces

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their production capabilities and quality control processes. Ask for detailed information about their manufacturing processes, materials used, and compliance with international quality standards. This evaluation is vital to ensure that the supplier can consistently deliver products that meet your specifications.

- What to Check:

- Production capacity and lead times

- Quality assurance certifications (ISO, etc.)

Step 4: Request Samples

Always request samples before making a bulk purchase. This allows you to assess the quality of the leather, craftsmanship, and overall durability of the furniture. Analyzing samples helps you avoid costly mistakes and ensures that the products align with your expectations.

- Considerations:

- Evaluate the leather finish and texture

- Check for stitching quality and structural integrity

Step 5: Negotiate Terms and Pricing

Once you have shortlisted suppliers and evaluated their products, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget and seek to establish favorable terms that reflect the value of the products offered. Effective negotiation can lead to significant savings and better service conditions.

Illustrative image related to the leather factory furniture

- Key Points:

- Discuss bulk order discounts

- Clarify shipping and handling fees

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications that attest to their ethical sourcing and manufacturing practices. Certifications can include environmental standards, labor practices, and material quality. This step is crucial for maintaining compliance with regulations and enhancing your brand reputation.

- Important Certifications:

- Leather Working Group (LWG) for sustainable practices

- Global Organic Textile Standard (GOTS) for organic materials

Step 7: Establish a Communication Plan

Develop a communication strategy for ongoing engagement with your supplier. Establish clear channels for updates on production status, shipping, and potential issues. Effective communication fosters a strong partnership and ensures that any concerns are addressed promptly.

By following this practical sourcing checklist, B2B buyers can navigate the complexities of procuring leather factory furniture, ensuring they make informed decisions that benefit their business in the long term.

Comprehensive Cost and Pricing Analysis for the leather factory furniture Sourcing

What Are the Key Cost Components in Leather Furniture Manufacturing?

When evaluating the cost structure for sourcing leather furniture, several critical components must be taken into account.

-

Materials: The primary cost driver is the leather itself, which varies significantly based on quality, origin, and treatment. High-grade leathers from countries like Italy or Brazil typically command higher prices. Additionally, other materials such as wood, foam, and metal hardware contribute to overall costs.

-

Labor: Skilled labor is essential in leather furniture manufacturing. Artisans trained in cutting, stitching, and finishing leather contribute to the quality and durability of the final product. Labor costs can fluctuate depending on the region and the complexity of the designs.

-

Manufacturing Overhead: This includes costs associated with the factory operations, such as utilities, rent, and maintenance of machinery. Efficient overhead management can lead to significant savings.

-

Tooling: Custom designs often require specialized tools or molds, which can lead to increased initial costs. However, these costs can be amortized over larger production runs, making them more manageable.

-

Quality Control (QC): Ensuring that each piece meets high standards involves additional costs, but this investment is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs are particularly significant for international buyers. Factors such as distance, shipping method, and tariffs can greatly influence final pricing.

-

Margin: Manufacturers typically apply a markup to cover costs and ensure profitability. This margin can vary widely based on market conditions and competition.

How Do Price Influencers Affect Leather Furniture Sourcing?

Several factors influence the final pricing of leather furniture, making it essential for buyers to understand these nuances.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases usually result in lower per-unit costs. Establishing a solid relationship with suppliers may also provide leverage for negotiating better terms.

-

Specifications and Customization: Custom designs require additional resources, both in terms of time and materials. Buyers should be aware that bespoke options will significantly impact pricing.

-

Material Quality and Certifications: Higher-quality materials or those certified for sustainability and environmental impact can increase costs. However, these investments may lead to higher customer satisfaction and loyalty.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers with proven track records may charge a premium but often provide better quality assurance.

-

Incoterms: Understanding international shipping terms is crucial for cost management. Different Incoterms dictate who bears the risk and cost at various stages of the shipping process, impacting overall pricing.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers from regions such as Africa, South America, the Middle East, and Europe, strategic negotiation and thorough understanding of cost factors are vital.

-

Total Cost of Ownership (TCO): Consider not just the purchase price, but also shipping, import duties, and potential maintenance costs. A lower upfront price may not always be the best deal in the long run.

-

Leverage Relationships: Build strong relationships with suppliers. A trustworthy partnership can lead to better pricing, favorable terms, and priority during peak times.

-

Stay Informed on Market Trends: Keeping abreast of market fluctuations and competitor pricing can provide leverage during negotiations. Being informed allows buyers to negotiate effectively and avoid overpaying.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide a better understanding of the market and enable more informed negotiations.

-

Be Flexible with Specifications: If possible, consider adjusting your specifications or exploring alternative materials. This flexibility can lead to significant cost savings.

Заключение

Sourcing leather furniture involves navigating a complex landscape of costs and pricing factors. By understanding the intricacies of the cost structure and leveraging negotiation strategies, international B2B buyers can make informed decisions that align with their business objectives. Keep in mind that prices can vary widely based on numerous factors, and buyers should always approach negotiations with a clear understanding of their total cost of ownership.

Alternatives Analysis: Comparing the leather factory furniture With Other Solutions

Exploring Alternatives to Leather Factory Furniture for B2B Buyers

In the competitive landscape of furniture manufacturing, it is essential for B2B buyers to evaluate various options available in the market. While leather factory furniture has long been a staple for its durability and aesthetic appeal, alternative solutions are emerging, driven by technological advancements, changing consumer preferences, and economic factors. This analysis will compare leather factory furniture with two viable alternatives: high-quality synthetic leather furniture and wooden furniture, providing insights into their respective advantages and disadvantages.

Illustrative image related to the leather factory furniture

| Comparison Aspect | The Leather Factory Furniture | High-Quality Synthetic Leather Furniture | Wooden Furniture |

|---|---|---|---|

| Performance | Durable, luxurious feel | Good durability, less authentic feel | Highly durable, timeless appeal |

| Cost | Higher initial investment | Generally lower cost | Mid to high cost, varies widely |

| Ease of Implementation | Requires skilled artisans | Easier to mass-produce | Labor-intensive, varies by design |

| Maintenance | Requires regular conditioning | Easy to clean, less maintenance needed | Requires periodic sealing/finishing |

| Best Use Case | Luxury markets, high-end retail | Budget-conscious consumers, commercial spaces | Eco-friendly markets, classic designs |

What Are the Advantages and Disadvantages of High-Quality Synthetic Leather Furniture?

High-quality synthetic leather furniture presents a compelling alternative, especially for budget-conscious buyers. These products often mimic the look and feel of genuine leather while offering lower costs and easier maintenance. They are also more resistant to stains and spills, making them suitable for commercial environments. However, synthetic leather may lack the authentic feel and longevity of natural leather, which can be a deal-breaker for luxury markets.

How Does Wooden Furniture Compare to Leather Factory Furniture?

Wooden furniture is another traditional alternative, known for its durability and classic aesthetic. It offers a timeless appeal and can be crafted into a variety of designs, catering to diverse customer preferences. Wooden pieces can also be more environmentally friendly, especially when sourced from sustainable forests. However, the cost can vary significantly based on the type of wood and craftsmanship involved. Maintenance is also a consideration, as wooden furniture often requires regular sealing and care to preserve its appearance.

How Should B2B Buyers Decide on the Right Furniture Solution?

When selecting the right furniture solution, B2B buyers must consider their specific needs, including budget constraints, target market, and desired brand image. Leather factory furniture is ideal for businesses aiming to position themselves in the luxury segment, while synthetic leather may appeal to cost-sensitive customers. Wooden furniture could be the best choice for businesses emphasizing sustainability and craftsmanship. Ultimately, a thorough understanding of these alternatives will empower buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for the leather factory furniture

What Are the Key Technical Properties of Leather Factory Furniture?

When sourcing leather factory furniture, understanding the technical specifications is crucial for making informed purchasing decisions. Below are some essential properties to consider:

1. Material Grade

Material grade refers to the quality and classification of leather used in manufacturing furniture. Common grades include full-grain, top-grain, corrected grain, and bonded leather. Higher-grade leather, such as full-grain, offers superior durability, natural aesthetics, and breathability, making it ideal for high-end products. For B2B buyers, selecting the right material grade impacts both the longevity of the furniture and customer satisfaction.

Illustrative image related to the leather factory furniture

2. Tolerance Levels

Tolerance levels indicate the acceptable variations in the dimensions and characteristics of the furniture pieces. In leather furniture production, these tolerances are crucial for ensuring that individual components fit together correctly, which affects both the aesthetics and functionality of the final product. Understanding tolerance levels helps buyers ensure that their orders meet specific requirements and reduces the risk of costly returns or modifications.

3. Finish Type

The finish type applied to leather furniture can significantly affect its appearance and durability. Common finishes include aniline, semi-aniline, and pigmented leather. Aniline finishes provide a natural look and feel but may be less resistant to stains, while pigmented finishes offer greater protection against wear. B2B buyers should evaluate the intended use and environment of the furniture to select the appropriate finish type for their needs.

4. Frame Construction

The frame construction is vital for the structural integrity and longevity of leather furniture. Common materials include hardwoods, plywood, and engineered wood. A well-constructed frame supports the leather upholstery and enhances overall durability. For B2B buyers, investing in furniture with a robust frame construction can minimize maintenance costs and improve customer satisfaction over time.

5. Fire Retardancy Standards

Fire retardancy standards ensure that the furniture meets safety regulations regarding flammability. These standards can vary by region, so it’s essential for B2B buyers to confirm compliance with local regulations. Choosing fire-retardant materials not only enhances safety but can also be a selling point when marketing to safety-conscious consumers.

What Are Common Trade Terms in the Leather Furniture Industry?

Familiarity with industry jargon can streamline negotiations and improve communication between buyers and suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather furniture industry, an OEM might manufacture leather components that are then assembled into finished furniture by another brand. Understanding OEM relationships can help B2B buyers identify quality suppliers and streamline their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it impacts inventory levels and cash flow. Knowing the MOQ helps businesses plan their purchases effectively and avoid overstocking or stockouts.

Illustrative image related to the leather factory furniture

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. In the leather furniture sector, an RFQ can include details about materials, designs, and quantities. Utilizing RFQs can help B2B buyers compare offers from multiple suppliers, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They specify how costs, risks, and responsibilities are divided during shipping. For B2B buyers importing leather furniture, understanding Incoterms is essential for calculating total landed costs and ensuring smooth logistics.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is received. In the context of leather furniture, lead times can vary based on customization, production schedules, and shipping. Knowing the lead time is crucial for B2B buyers to manage inventory and meet customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the leather furniture market more effectively, making choices that align with their business goals and customer needs.

Navigating Market Dynamics and Sourcing Trends in the the leather factory furniture Sector

What Are the Current Market Dynamics and Key Trends in the Leather Factory Furniture Sector?

The leather factory furniture sector is experiencing significant transformation driven by global economic shifts, changing consumer preferences, and technological advancements. Key market drivers include the rising demand for premium and sustainable furniture, especially in emerging markets across Africa and South America. B2B buyers in these regions are increasingly seeking high-quality leather products that not only meet aesthetic desires but also align with their ethical standards.

Emerging sourcing trends are heavily influenced by the digital transformation of the furniture supply chain. Technologies such as AI and IoT are enhancing inventory management, enabling real-time tracking, and improving customer relationship management. Furthermore, e-commerce platforms are becoming essential for B2B transactions, allowing international buyers to access a wider range of products and suppliers with greater ease.

Additionally, the market is witnessing a shift towards customization, where buyers are looking for tailored solutions that reflect their specific brand identity. This trend is particularly pronounced in Europe, with countries like Germany leading the way in demanding bespoke designs. The competitive landscape is also evolving, as traditional manufacturers face challenges from lower-cost imports, particularly from Asia. Therefore, international buyers must remain agile and informed to navigate these dynamics effectively.

How Is Sustainability and Ethical Sourcing Impacting the Leather Factory Furniture Market?

Sustainability has become a cornerstone of the leather factory furniture market, with an increasing emphasis on ethical sourcing practices. The environmental impact of leather production is under scrutiny, prompting manufacturers to adopt more sustainable practices. This includes sourcing hides from suppliers that adhere to ethical treatment of animals and ensuring that chemical processes used in tanning are environmentally friendly.

For B2B buyers, aligning with suppliers who prioritize sustainability not only enhances brand reputation but also meets the growing consumer demand for eco-friendly products. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming critical indicators of a supplier’s commitment to ethical sourcing. These certifications assure buyers that the materials used in their products are produced responsibly, reducing the overall carbon footprint.

Moreover, the trend towards using alternative materials, such as plant-based leathers or recycled materials, is gaining traction. Buyers who embrace these innovations can differentiate themselves in the market, appealing to a more environmentally conscious clientele. By prioritizing sustainability in their sourcing strategies, international B2B buyers can contribute to a more responsible leather industry while also driving business growth.

Illustrative image related to the leather factory furniture

What Is the Historical Context of the Leather Factory Furniture Sector?

The leather factory furniture sector has a rich history that dates back centuries, evolving from artisanal craftsmanship to large-scale industrial production. In the early 20th century, leather furniture became synonymous with luxury, particularly in Western markets. As demand surged, manufacturers began to establish factories that could produce leather goods at scale, leading to innovations in tanning and upholstery techniques.

However, the late 20th century saw significant challenges as globalization introduced competition from lower-cost markets, particularly in Asia. Many traditional manufacturers struggled to adapt, resulting in a wave of bankruptcies and closures. This shift has compelled the industry to refocus on quality, design, and sustainability, paving the way for a more resilient and innovative sector.

Today, the leather factory furniture market is characterized by a blend of tradition and modernity, with a growing emphasis on custom designs and sustainable practices. B2B buyers must understand this historical context to appreciate the current landscape and make informed sourcing decisions that resonate with evolving market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of the leather factory furniture

-

How do I ensure quality when sourcing leather furniture from factories?

To ensure quality, conduct thorough research on potential suppliers, focusing on their manufacturing processes and material sourcing. Request samples to evaluate the craftsmanship and leather quality. Additionally, ask for certifications that guarantee compliance with international standards. Establish a clear quality assurance (QA) protocol that includes inspections at various stages of production. Building a strong relationship with suppliers can also facilitate open communication regarding quality expectations. -

What are the typical minimum order quantities (MOQ) for leather furniture?

MOQs for leather furniture can vary significantly based on the supplier and the specific product type. Generally, you might expect MOQs to range from 50 to 100 units for standard designs. Custom designs typically have higher MOQs due to the extra resources required for production. When negotiating with suppliers, discuss flexibility in order quantities, especially if you are a new buyer. Some manufacturers may offer lower MOQs to build relationships with new clients. -

What payment terms should I expect when purchasing leather furniture internationally?

Payment terms can differ widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer more flexible terms, such as letter of credit (LC) arrangements, especially for larger orders. Always clarify payment terms upfront, and consider using secure payment methods to protect your investment. Establishing trust through transparent communication can also lead to better payment options in future transactions. -

How can I customize leather furniture to meet my specific needs?

Most manufacturers offer a range of customization options, including size, style, leather type, and color. To begin, provide detailed specifications and design preferences to the supplier. Some factories may have design consultants to assist with the customization process. Be prepared to discuss lead times, as custom orders may require longer production periods. Reviewing prototypes or samples before final production can help ensure that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing leather furniture?

Logistics is crucial when importing leather furniture, as it involves shipping, customs clearance, and delivery. Choose a reliable freight forwarder with experience in handling furniture shipments. Understand the shipping terms (e.g., FOB, CIF) and factor in costs like tariffs and insurance. Be aware of the customs regulations in your country to avoid delays. Planning your logistics carefully can save time and money, ensuring a smooth import process. -

How do I vet suppliers for leather factory furniture?

Vetting suppliers involves assessing their reputation, production capabilities, and compliance with international standards. Start by checking online reviews and industry references. Request factory visits or virtual tours to observe their operations firsthand. Additionally, verify their certifications and inquire about their experience in exporting to your region. Establishing a strong rapport can also provide insights into their reliability and commitment to quality. -

What are the trends in leather furniture that I should be aware of?

Current trends in leather furniture include a focus on sustainability, with many manufacturers sourcing eco-friendly materials and employing responsible production methods. Additionally, minimalist and multifunctional designs are gaining popularity, catering to modern consumer preferences. Customization options are also increasingly in demand, allowing buyers to create unique pieces that reflect their brand identity. Staying informed about these trends can help you make strategic purchasing decisions that resonate with your target market. -

How can I effectively communicate my needs to a leather furniture supplier?

Clear and effective communication is key to successful supplier relationships. Begin by preparing a detailed brief outlining your requirements, including design specifications, quantities, and timelines. Utilize visual aids like sketches or reference images to convey your vision. Establish regular check-ins throughout the production process to address any concerns or adjustments. Building a collaborative relationship fosters trust and ensures that your needs are met throughout the sourcing process.

Top 4 The Leather Factory Furniture Manufacturers & Suppliers List

1. Leathersofa – Alexandria Sectional

Domain: leathersofaco.com

Registered: 2004 (21 years)

Введение: [{‘name’: ‘Alexandria Sectional (Left Arm Loveseat + Left Arm Right Chaise Sofa)’, ‘base_leather’: ‘Sooner Golden Tan’, ‘price’: ‘$9,200.00’, ‘description’: ‘Few designs offer a more perfect balance of style and comfort than the Alexandria. This contemporary off the floor silhouette features a beautifully sculpted frame and soft.’}, {‘name’: ‘Roma – Sofa with Power RA/LA Incliners & Power Headrest…

2. Leather Furniture CA – Anniversary Sale

Domain: leatherfurnitureca.com

Registered: 2009 (16 years)

Введение: Celebrating 22nd Anniversary with a huge floor sample sale. Upholstery Styles: Transitional Frames, Traditional Frames, Modern Frames, Power & Manual Reclining Seating, Home Theater, Accent Chairs, Dining Chairs, Bar Stools, Sleeper Sofas & Bed Frames, Upholstered Accents, Recliners & Massage Chairs. Services offered: Foam Replacement, Interior Design, Leather & Fabric Cleaning, Redye/Repair/Resto…

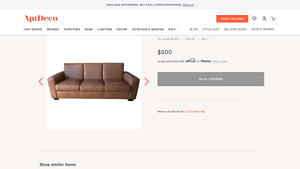

3. The Leather Factory – Leather Sofa

Domain: aptdeco.com

Registered: 2012 (13 years)

Введение: {“Product Name”:”The Leather Factory Leather Sofa”,”Seller”:”Leilani”,”Condition”:”Used – Good: Minor blemishes that most people won’t notice”,”Age”:”4 + Years Old”,”Overall Dimensions”:{“Width”:”86 inches”,”Height”:”36 inches”,”Depth”:”36 inches”},”Est. Retail Price”:”$2,400″,”Current Price”:”$500″,”Discount”:”79% off”,”Sustainability Impact”:”158 LBS OF CO2 OFFSET, 57 CARS REMOVED, 13 TREES PLAN…

4. Factory Direct – High Quality Leather Sectionals

Domain: reddit.com

Registered: 2005 (20 years)

Введение: Factory Direct Leather Furniture, high quality leather sectional, custom order options, links to manufacturers selling direct.

Strategic Sourcing Conclusion and Outlook for the leather factory furniture

In the competitive landscape of leather factory furniture, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging a diverse supplier network and staying attuned to market trends, businesses can navigate challenges such as rising costs and increasing competition from low-cost manufacturers. The insights drawn from recent industry shifts underscore the importance of selecting suppliers who not only provide quality materials but also demonstrate flexibility and responsiveness to market changes.

Furthermore, the focus on customization and craftsmanship is essential for differentiating products in an increasingly saturated market. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who emphasize sustainable practices and superior craftsmanship, as these factors resonate with today’s discerning consumers.

Looking ahead, the leather furniture market presents opportunities for growth and innovation. International buyers are encouraged to explore emerging markets and trends while fostering relationships that align with their strategic objectives. By investing in strategic sourcing now, businesses can position themselves for long-term success, ensuring they meet the evolving demands of their customer base while staying ahead of the competition.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.