Introduction: Navigating the Global Market for white fake leather fabric

The global market for white fake leather fabric presents a unique challenge for international B2B buyers seeking quality and reliability. Sourcing this versatile material—popular for its durability and aesthetic appeal—can be daunting, especially when navigating diverse suppliers across regions like Africa, South America, the Middle East, and Europe, including key markets such as Nigeria and Germany. This guide aims to demystify the complexities of acquiring white fake leather fabric by offering an in-depth exploration of its types, applications, and the critical aspects of supplier vetting.

Understanding the various forms of white fake leather, from vinyl to polyurethane, is essential for making informed purchasing decisions. This guide will delve into the myriad applications, ranging from fashion and upholstery to automotive and home decor, ensuring that buyers can match their needs with the right product. Additionally, it will provide insights into cost considerations, helping buyers negotiate better deals and avoid common pitfalls.

By equipping B2B buyers with actionable information and expert advice, this guide empowers them to navigate the competitive landscape of white fake leather fabric confidently. With a focus on quality, sustainability, and supplier transparency, buyers can make strategic decisions that enhance their product offerings while optimizing their supply chain efficiency.

Table Of Contents

- Top 5 White Fake Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for white fake leather fabric

- Understanding white fake leather fabric Types and Variations

- Key Industrial Applications of white fake leather fabric

- 3 Common User Pain Points for ‘white fake leather fabric’ & Their Solutions

- Strategic Material Selection Guide for white fake leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for white fake leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘white fake leather fabric’

- Comprehensive Cost and Pricing Analysis for white fake leather fabric Sourcing

- Alternatives Analysis: Comparing white fake leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for white fake leather fabric

- Navigating Market Dynamics and Sourcing Trends in the white fake leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of white fake leather fabric

- Strategic Sourcing Conclusion and Outlook for white fake leather fabric

- Important Disclaimer & Terms of Use

Understanding white fake leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Faux Leather | Made from polyvinyl chloride, durable and waterproof | Upholstery, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less breathable than other materials. |

| PU Faux Leather | Made from polyurethane, softer and more flexible | Apparel, bags, furniture upholstery | Pros: Eco-friendly, resembles genuine leather. Cons: May not be as durable as PVC. |

| Искусственная кожа из микрофибры | Soft texture, mimics genuine leather closely | Automotive interiors, clothing | Pros: Breathable, resistant to stains. Cons: Higher cost compared to PVC. |

| Pearl White Faux Leather | Glossy finish, adds elegance to designs | Home decor, fashion items | Pros: Aesthetic appeal, versatile. Cons: Can be prone to scratches. |

| Eco-Friendly Faux Leather | Made from recycled materials, sustainable | Fashion, eco-conscious products | Pros: Sustainable, unique appearance. Cons: Availability may be limited. |

What are the characteristics of PVC Faux Leather?

PVC (polyvinyl chloride) faux leather is a synthetic material known for its durability and waterproof properties. It is commonly used in applications where cost-effectiveness and ease of maintenance are priorities, such as upholstery and fashion accessories. When purchasing PVC faux leather, B2B buyers should consider its resistance to wear and tear, but also note that it may lack breathability compared to other options, which could affect comfort in certain applications.

How does PU Faux Leather differ from other types?

PU (polyurethane) faux leather is recognized for its softer texture and greater flexibility compared to PVC. It is often used in apparel, bags, and furniture upholstery, where a more luxurious feel is desired. B2B buyers should consider the eco-friendly aspect of PU, as it is generally more sustainable than PVC. However, it may not provide the same level of durability, making it essential to evaluate the intended use and expected wear.

Why is Microfiber Faux Leather a preferred choice in certain industries?

Microfiber faux leather offers a soft texture that closely resembles genuine leather, making it a popular choice in automotive interiors and high-end clothing. Its breathability and resistance to stains are significant advantages for B2B buyers, especially in environments where comfort and cleanliness are paramount. The higher cost may be a consideration, but the long-term value often justifies the investment.

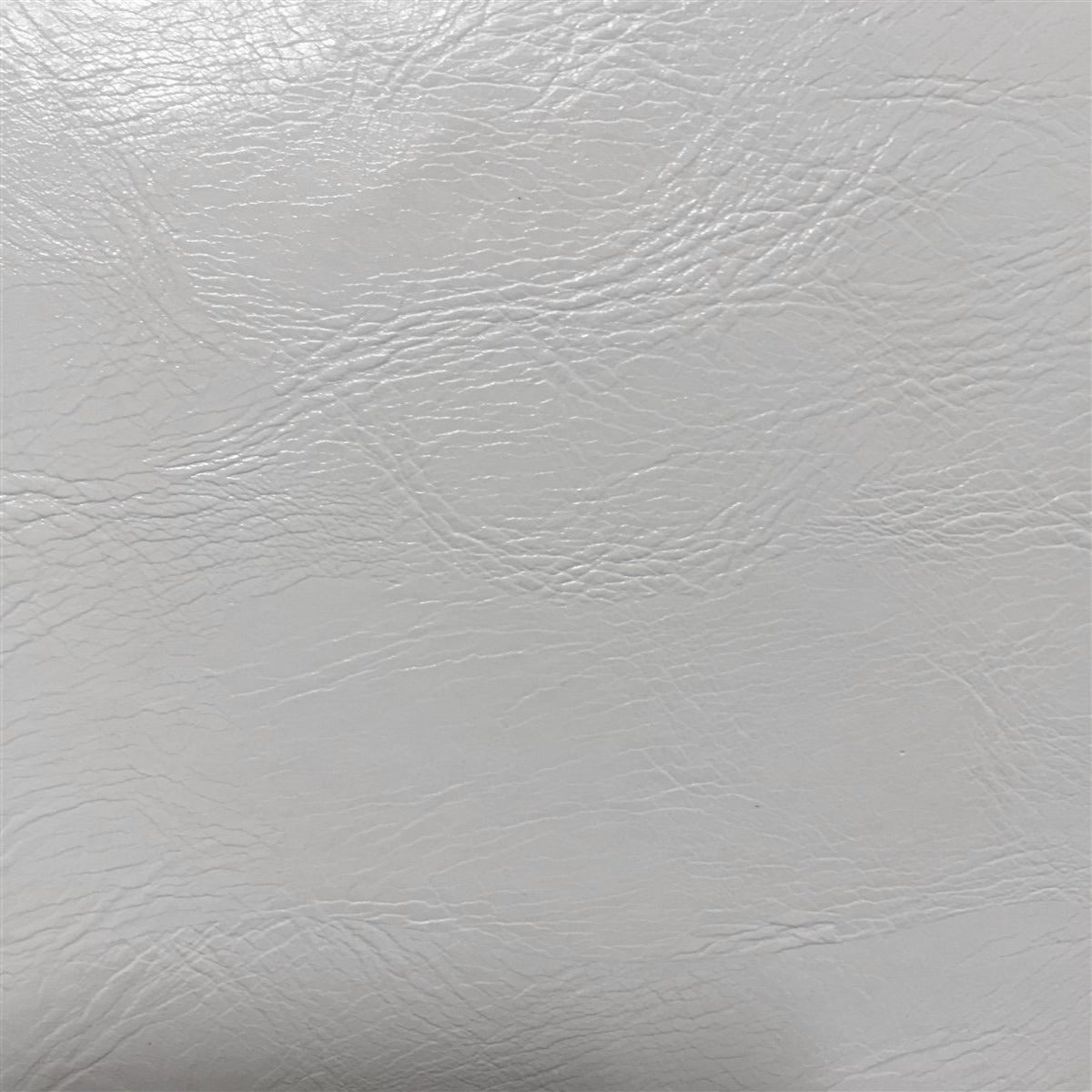

What applications benefit from Pearl White Faux Leather?

Pearl white faux leather is distinguished by its glossy finish, which adds an element of elegance to any design. It is commonly used in home décor and fashion items, appealing to buyers looking for aesthetic appeal. While it offers versatility, B2B buyers should be cautious of its susceptibility to scratches, which may require additional care in maintenance.

How does Eco-Friendly Faux Leather stand out in the market?

Eco-friendly faux leather is made from recycled materials, catering to the growing demand for sustainable products. This type is particularly appealing to businesses focused on eco-conscious fashion or lifestyle products. While it offers a unique appearance and aligns with sustainable practices, B2B buyers should be aware that availability may be limited, potentially impacting supply chain decisions.

Key Industrial Applications of white fake leather fabric

| Industry/Sector | Specific Application of white fake leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Jackets, belts, and footwear | High durability and aesthetic appeal | Ensure material meets fashion industry standards, such as eco-friendliness and compliance with safety regulations. |

| Furniture & Upholstery | Sofa and chair upholstery | Enhances luxury feel while being cost-effective | Source materials that are easy to clean and maintain, ensuring long-lasting quality. |

| Автомобили | Car interiors (seat covers, dashboards) | Provides a premium look and feel at a lower cost | Consider flame-retardant properties and compatibility with automotive standards. |

| Home Decor | Decorative cushions and throws | Adds elegance and versatility to home environments | Look for materials that are UV resistant and easy to maintain, suitable for various climates. |

| Health & Medical | Medical furniture coverings | Easy to sanitize and maintain hygiene standards | Ensure compliance with medical safety regulations and availability in bulk for larger orders. |

How is White Fake Leather Fabric Used in Fashion & Apparel?

In the fashion industry, white fake leather fabric is extensively used for crafting stylish jackets, belts, and footwear. This material provides a luxurious appearance while being more affordable than genuine leather, making it an attractive option for brands targeting budget-conscious consumers. For international buyers, especially in regions like Africa and South America, the ability to source eco-friendly and sustainable materials is crucial, as consumer preferences shift towards more responsible fashion choices. Additionally, compliance with safety regulations regarding chemical treatments is essential for brands aiming to sell in the European market.

What Role Does White Fake Leather Fabric Play in Furniture & Upholstery?

For the furniture and upholstery sector, white fake leather fabric serves as an ideal choice for creating sofas and chairs. Its durability and aesthetic appeal enhance the overall design, allowing manufacturers to offer high-end products at competitive prices. Buyers should prioritize sourcing materials that are easy to clean and resistant to wear and tear, particularly in regions with high humidity or exposure to sunlight, such as the Middle East. Understanding the local market’s preferences and ensuring the fabric’s compliance with health and safety standards can significantly impact business success.

Illustrative image related to white fake leather fabric

How is White Fake Leather Fabric Beneficial in Automotive Applications?

In the automotive industry, white fake leather fabric is commonly used for car interiors, including seat covers and dashboards. This material provides a premium look and feel while being more cost-effective than traditional leather. For international buyers, particularly in Europe, sourcing materials that meet stringent automotive standards for flame resistance and durability is vital. Additionally, understanding regional preferences for design and color can help manufacturers tailor their offerings to specific markets, enhancing customer satisfaction and brand loyalty.

Why is White Fake Leather Fabric Ideal for Home Decor?

White fake leather fabric is popular in home decor for decorative cushions and throws, adding elegance and versatility to living spaces. Its lightweight nature and ease of maintenance make it a preferred choice for interior designers and homeowners alike. Buyers should consider the fabric’s UV resistance, especially in sunny climates, to prevent fading. Moreover, sourcing from suppliers who can provide bulk orders ensures that businesses can meet demand while maintaining quality consistency.

What are the Advantages of White Fake Leather Fabric in Health & Medical Settings?

In the health and medical sector, white fake leather fabric is utilized for covering medical furniture, such as examination tables and waiting room chairs. Its easy-to-sanitize properties are crucial for maintaining hygiene standards in medical environments. International buyers, particularly those in Europe and the Middle East, should ensure that the materials comply with medical safety regulations and are available in bulk to meet the needs of larger facilities. Understanding the specific requirements for durability and ease of maintenance can also influence sourcing decisions effectively.

Illustrative image related to white fake leather fabric

3 Common User Pain Points for ‘white fake leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality White Fake Leather Fabric for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality white fake leather fabric that meets specific application needs. Variability in quality can lead to discrepancies in texture, durability, and finish, impacting the final product’s aesthetics and functionality. For instance, a manufacturer creating luxury handbags may find that a low-quality material results in a poor customer experience, leading to returns and damage to their brand reputation.

The Solution: To ensure the procurement of high-quality white fake leather, buyers should establish clear specifications based on end-use requirements. This includes assessing the fabric’s weight, thickness, and intended application—be it upholstery, fashion, or automotive. Partnering with reputable suppliers who offer product samples can provide firsthand insights into the material’s properties. Additionally, requesting certifications for eco-friendliness and manufacturing standards can help ensure that the sourced material aligns with the buyer’s ethical standards. Investing time in thorough supplier evaluation processes can pay off significantly in the long run, ensuring product quality and reducing the risk of dissatisfaction.

Scenario 2: Managing Inventory and Reducing Waste of White Fake Leather Fabric

The Problem: Many B2B buyers face challenges related to inventory management, particularly when dealing with synthetic materials like white fake leather fabric. Overstocking can lead to waste due to changes in design trends or consumer preferences, while understocking can cause project delays. Both scenarios can negatively affect cash flow and operational efficiency.

The Solution: Implementing a just-in-time (JIT) inventory management system can greatly alleviate these issues. By closely monitoring sales trends and customer demand, buyers can maintain optimal stock levels without overcommitting resources. Utilizing inventory management software that integrates with sales forecasts can provide data-driven insights, allowing for more accurate purchasing decisions. Additionally, establishing strong relationships with suppliers can facilitate quicker restocking, ensuring that materials are available when needed without requiring large upfront investments. This approach not only reduces waste but also enhances responsiveness to market changes.

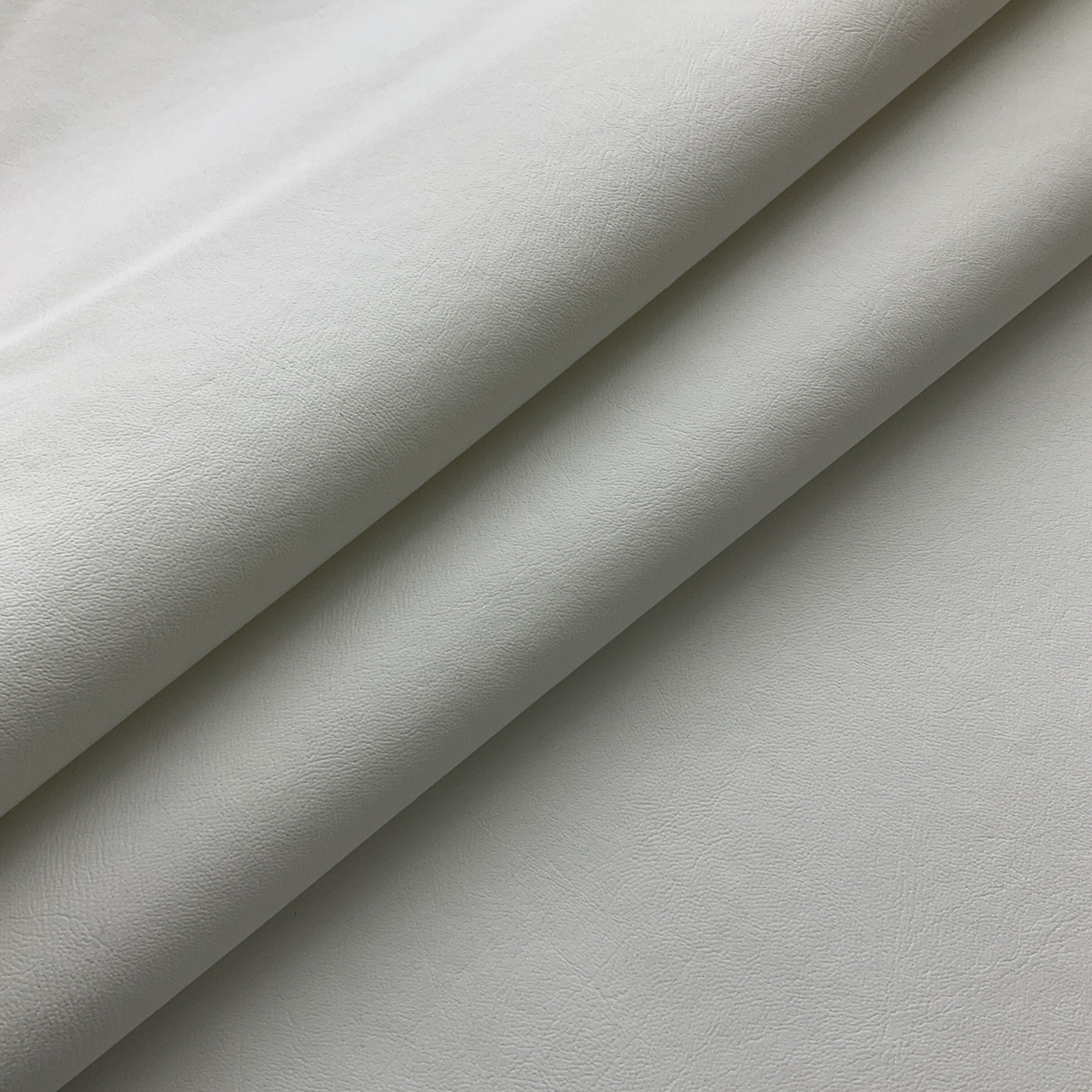

Scenario 3: Ensuring Color Consistency in White Fake Leather Fabric

The Problem: Color inconsistency is a common pain point for B2B buyers in various industries, particularly in fashion and interior design. White fake leather fabric can vary in shade and brightness across different batches, leading to mismatched products that fail to meet client expectations. This inconsistency can result in increased returns, customer dissatisfaction, and potential loss of contracts.

The Solution: To mitigate color inconsistency, buyers should insist on a color standardization process with their suppliers. Before placing bulk orders, requesting a lab-dip sample can help verify that the color meets specifications. Additionally, establishing a color approval process that includes all stakeholders can ensure alignment on color expectations throughout the supply chain. Suppliers should be encouraged to maintain stringent quality control measures during production to ensure batch consistency. Furthermore, keeping a color reference library can aid in future orders, ensuring that repeat purchases maintain the desired shade and finish. By prioritizing color consistency, buyers can enhance product quality and customer satisfaction, ultimately driving brand loyalty.

Strategic Material Selection Guide for white fake leather fabric

What are the Common Materials Used for White Fake Leather Fabric?

When selecting white fake leather fabric for various applications, understanding the underlying materials is crucial for B2B buyers. Here, we analyze four common materials used in white fake leather fabric, focusing on their properties, advantages, disadvantages, and considerations for international markets.

1. Polyurethane (PU) Leather

Key Properties:

Polyurethane leather, often referred to as PU leather, is a synthetic material known for its flexibility, durability, and resistance to wear and tear. It can withstand moderate temperatures and is generally resistant to moisture and stains.

Pros & Cons:

PU leather is relatively inexpensive compared to genuine leather, making it an attractive option for manufacturers. It is easy to clean and maintain, which is beneficial for consumer products. However, it may not be as durable as other synthetic options, particularly under extreme conditions, and can degrade faster when exposed to direct sunlight.

Impact on Application:

PU leather is widely used in apparel, upholstery, and accessories. Its compatibility with dyeing processes allows for vibrant colors, including bright white, which is essential for fashion-forward applications.

Considerations for International Buyers:

B2B buyers should ensure that PU leather complies with relevant standards such as REACH in Europe or similar regulations in other regions. Understanding local preferences for sustainability can also influence material selection.

2. Polyvinyl Chloride (PVC) Leather

Key Properties:

PVC leather is a robust synthetic material that offers excellent durability and resistance to environmental factors. It is less flexible than PU but provides superior waterproofing and UV resistance.

Pros & Cons:

The primary advantage of PVC leather is its cost-effectiveness and high durability, making it suitable for outdoor furniture and automotive applications. However, it can be less breathable than PU, leading to discomfort in clothing applications.

Illustrative image related to white fake leather fabric

Impact on Application:

PVC leather is ideal for applications requiring high durability and water resistance, such as marine upholstery and outdoor gear. Its ability to maintain a pristine appearance over time is a significant asset.

Considerations for International Buyers:

Buyers should be aware of the environmental impact of PVC, as it is less biodegradable than other materials. Compliance with local regulations regarding the use of PVC is essential, especially in European markets.

3. Microfiber Leather

Key Properties:

Microfiber leather is made from ultra-fine synthetic fibers, providing a soft texture that closely resembles genuine leather. It is lightweight, breathable, and offers good resistance to wear and tear.

Pros & Cons:

The main advantage of microfiber leather is its luxurious feel and appearance, making it popular in high-end applications. It is also easier to clean than traditional leather. However, it can be more expensive than PU and PVC options, which may impact budget considerations.

Impact on Application:

Microfiber leather is commonly used in high-quality fashion items, upholstery, and automotive interiors. Its compatibility with dyeing processes allows for vibrant colors, including white, which is essential for luxury branding.

Considerations for International Buyers:

Buyers should verify that microfiber leather meets international quality standards and certifications, such as ISO and ASTM. Additionally, understanding regional preferences for sustainability can influence purchasing decisions.

4. Recycled Leather

Key Properties:

Recycled leather is made from scraps of genuine leather that are reprocessed into a new material. It retains some characteristics of real leather, including durability and breathability, while being more environmentally friendly.

Pros & Cons:

The key advantage of recycled leather is its sustainability, appealing to eco-conscious consumers. However, its availability and consistency in quality can vary, potentially complicating sourcing efforts.

Illustrative image related to white fake leather fabric

Impact on Application:

Recycled leather is suitable for various applications, including fashion, upholstery, and accessories. Its unique texture can add value to products, particularly in markets focused on sustainability.

Considerations for International Buyers:

B2B buyers should ensure that recycled leather complies with local environmental regulations and standards. Understanding consumer trends toward sustainability can help inform purchasing decisions.

Summary Table of White Fake Leather Fabric Materials

| Материал | Typical Use Case for white fake leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) Leather | Apparel, upholstery, accessories | Cost-effective, easy to maintain | Less durable under extreme conditions | Низкий |

| Polyvinyl Chloride (PVC) Leather | Outdoor furniture, automotive | High durability, waterproof | Less breathable than other options | Низкий |

| Кожа из микрофибры | High-end fashion, automotive interiors | Luxurious feel, easy to clean | Higher cost than PU and PVC | Высокий |

| Recycled Leather | Fashion, upholstery, accessories | Sustainable, eco-friendly | Variable quality and availability | Medium |

This guide provides actionable insights for B2B buyers considering white fake leather fabric, ensuring informed decisions that align with market demands and compliance standards.

Illustrative image related to white fake leather fabric

In-depth Look: Manufacturing Processes and Quality Assurance for white fake leather fabric

What Are the Main Stages of Manufacturing White Fake Leather Fabric?

The manufacturing process of white fake leather fabric involves several key stages, ensuring both quality and functionality. Understanding these stages is crucial for B2B buyers looking to source high-quality materials.

Material Preparation: What Raw Materials Are Used?

The first stage of manufacturing white fake leather involves the selection and preparation of raw materials. Typically, the base materials used are polyurethane (PU) or polyvinyl chloride (PVC), which are chosen for their durability and flexibility. These synthetic polymers undergo a rigorous purification process to remove impurities that could affect the final product. The chosen materials are then compounded with colorants and additives, including UV stabilizers and anti-fungal agents, to enhance their performance characteristics and aesthetic appeal.

How Is the Forming Process Conducted?

Once the raw materials are prepared, they are subjected to a forming process. This involves spreading a mixture of the polymers onto a substrate, often a fabric backing such as polyester or cotton, to create a composite material. The application method can vary; common techniques include calendering, where the mixture is passed through rollers to achieve the desired thickness, and coating, which involves applying a liquid layer onto the substrate. The goal is to ensure uniform thickness and consistent texture across the fabric.

What Techniques Are Used During Assembly?

After forming, the next stage is assembly, where the sheets of faux leather are cut to size based on specifications. This stage may involve stitching or bonding layers together to create the final product. For white fake leather, special care is taken to maintain color consistency throughout the assembly process. Manufacturers often utilize advanced cutting technology such as laser cutting for precision and to minimize waste.

Illustrative image related to white fake leather fabric

How Is the Finishing Process Performed?

The finishing stage is vital for enhancing the aesthetic and functional properties of white fake leather fabric. This process typically includes surface treatments that can impart characteristics such as water resistance, anti-scratch properties, and a soft touch. Techniques like embossing or printing can also be applied to create unique textures or designs. Finally, the fabric is often treated with a protective coating to ensure longevity and ease of cleaning, which is particularly important for B2B buyers in sectors like furniture and automotive.

What Quality Control Measures Are Implemented in Production?

Quality assurance is critical in the manufacturing of white fake leather fabric. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This certification is particularly important for B2B buyers, as it demonstrates a commitment to quality and continuous improvement.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the production process, with specific checkpoints established at various stages:

Illustrative image related to white fake leather fabric

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet predetermined specifications. This step is crucial as the quality of raw materials directly affects the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at regular intervals to monitor quality. This includes checking the thickness, color consistency, and overall integrity of the fabric as it is formed and assembled.

-

Final Quality Control (FQC): Before the products are shipped, a comprehensive inspection is conducted. This involves checking for defects, measuring color accuracy, and ensuring that the fabric meets all specified standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability and compliance with local standards.

What Audits and Reports Should Be Requested?

Buyers should request detailed quality assurance reports from suppliers, which should include results from IQC, IPQC, and FQC stages. Additionally, it’s advisable to conduct periodic audits of the manufacturing facilities. This not only helps to assess compliance with international standards but also builds a strong relationship with the supplier based on transparency and trust.

How Do Third-Party Inspections Work?

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process. These services often include pre-shipment inspections, where experts verify that the goods meet specified quality standards before they leave the factory. This is particularly beneficial for buyers who may not have the capacity to conduct on-site inspections due to geographic constraints.

What Are the Common Testing Methods for White Fake Leather Fabric?

To ensure that white fake leather fabric meets specific performance criteria, various testing methods are employed:

-

Tensile Strength Testing: This measures the fabric’s resistance to being pulled apart, which is crucial for durability.

-

Color Fastness Testing: This evaluates how well the color holds up against washing, light, and rubbing, ensuring that the white remains vibrant over time.

-

Water Resistance Testing: This assesses the fabric’s ability to repel water, which is essential for applications in upholstery and fashion.

How Do International Standards Affect Quality Assurance?

International standards like CE marking and API certification may also be relevant depending on the end-use of the white fake leather fabric. CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area. For B2B buyers, especially in industries like automotive or construction, ensuring that suppliers meet these standards can mitigate risk and enhance product credibility in the market.

In conclusion, the manufacturing and quality assurance processes for white fake leather fabric are extensive and require a thorough understanding. B2B buyers must prioritize suppliers who implement rigorous QC measures, adhere to international standards, and are open to audits and inspections to ensure the highest quality materials for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘white fake leather fabric’

Введение

Sourcing white fake leather fabric for your business requires careful consideration and strategic planning. This guide provides a step-by-step checklist designed to help international B2B buyers navigate the procurement process efficiently, ensuring you secure high-quality materials that meet your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Consider factors such as the desired thickness, texture, and durability of the fabric. Additionally, determine if you require specific features such as water resistance or UV protection, which can significantly influence your product’s performance and longevity.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial to maintaining the quality of your products. Research potential suppliers by checking their online presence, customer reviews, and industry reputation. Look for suppliers who specialize in faux leather and have experience serving businesses in your target market, whether it’s in Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your potential suppliers hold necessary certifications and comply with industry standards. This may include ISO certifications, environmental compliance, and safety certifications. Ensuring that suppliers adhere to these standards not only mitigates risks but also enhances your brand’s credibility.

Step 4: Request Samples

Always request samples before placing a bulk order. Testing samples allows you to assess the quality, feel, and appearance of the fabric firsthand. Pay close attention to factors such as color consistency, texture, and overall finish, which are essential for ensuring customer satisfaction in your final products.

Step 5: Negotiate Pricing and Terms

Once you have evaluated potential suppliers and received samples, initiate negotiations. Discuss pricing, payment terms, and minimum order quantities. Be prepared to negotiate on delivery timelines and shipping costs, especially if you are sourcing from international suppliers. Establishing favorable terms can significantly impact your overall cost structure.

Step 6: Establish Communication Channels

Effective communication is key to successful sourcing. Ensure that you have established clear communication channels with your supplier. Utilize tools such as emails, instant messaging, or video calls to maintain regular updates and address any concerns promptly. A responsive supplier can greatly enhance your procurement experience.

Step 7: Conduct a Final Review

Before finalizing your order, conduct a thorough review of all agreements and documents. Ensure that all specifications, terms, and conditions are clearly outlined and agreed upon. This final review can prevent misunderstandings and discrepancies later in the sourcing process, safeguarding your investment.

By following this checklist, B2B buyers can streamline their sourcing process for white fake leather fabric, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for white fake leather fabric Sourcing

When sourcing white fake leather fabric, understanding the comprehensive cost structure is crucial for B2B buyers to make informed decisions. The cost components associated with this fabric include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

What Are the Key Cost Components for White Fake Leather Fabric?

-

Materials: The primary cost driver in sourcing white fake leather fabric is the raw materials used. Synthetic materials like polyurethane (PU) or polyvinyl chloride (PVC) often serve as the base. The price of these materials can fluctuate based on market demand, availability, and quality.

-

Labor: Labor costs encompass the wages paid to workers involved in the production process. This includes cutting, stitching, and finishing the fabric. In regions with lower labor costs, such as parts of Africa and South America, buyers might find more competitive pricing.

-

Manufacturing Overhead: This includes the costs associated with operating the manufacturing facility, such as utilities, rent, and equipment depreciation. Manufacturers with advanced technologies may charge higher overhead due to their investment in efficient production processes.

-

Tooling: The initial setup of machinery and tools for production can significantly influence costs. Custom designs or specifications may require additional tooling, which can lead to increased costs.

-

Quality Control (QC): Ensuring the fabric meets specific quality standards involves additional costs. This includes testing for durability, colorfastness, and compliance with safety regulations. Certifications can also add to the cost, especially for markets like Europe where standards are stringent.

-

Logistics: Transportation costs vary based on the distance between the manufacturer and the buyer. Factors such as shipping mode (air, sea, or land), fuel prices, and customs duties impact logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure sustainability. Margins can vary widely based on the supplier’s reputation and the complexity of the fabric.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence pricing and should be considered by buyers:

-

Volume/MOQ: Bulk orders often lead to discounts due to economies of scale. Understanding the minimum order quantities (MOQs) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom designs or specific fabric characteristics can increase costs. Buyers should clearly communicate their needs to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials or certifications that comply with international standards can increase the cost. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The supplier’s location, reliability, and experience can significantly influence pricing. Building long-term relationships with suppliers may lead to better pricing and service.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Different Incoterms (e.g., FOB, CIF) affect who pays for shipping, insurance, and tariffs, impacting the total cost.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

-

Negotiate Terms: Leverage your purchase volume to negotiate better prices and payment terms. Suppliers may be more willing to lower prices for larger commitments.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also logistics, maintenance, and potential waste costs over the fabric’s lifecycle.

-

Be Aware of Pricing Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider currency fluctuations, local tariffs, and import regulations, which can affect overall costs.

-

Build Relationships: Cultivating strong relationships with suppliers can lead to better pricing and priority service. Trust and reliability often result in more favorable terms.

Disclaimer for Indicative Prices

Pricing for white fake leather fabric can vary significantly based on the aforementioned factors. It is recommended that buyers conduct thorough market research and obtain multiple quotes to ensure competitive pricing and quality. Always verify current prices with suppliers, as market conditions can change rapidly.

Illustrative image related to white fake leather fabric

Alternatives Analysis: Comparing white fake leather fabric With Other Solutions

When considering the procurement of materials for various applications, white fake leather fabric stands out due to its versatility and aesthetic appeal. However, it’s essential to evaluate alternative solutions to ensure that buyers make informed decisions that align with their specific business needs. This section will compare white fake leather fabric with other viable options, highlighting key performance metrics, costs, and practical applications.

| Comparison Aspect | White Fake Leather Fabric | Natural Leather | PVC Vinyl |

|---|---|---|---|

| Performance | Durable, resistant to wear and tear, waterproof options available | Highly durable, offers breathability, natural aging | Good durability, resistant to moisture but less breathable |

| Cost | Moderate, varies by quality and supplier | Higher cost due to sourcing and tanning processes | Generally lower cost, widely available |

| Ease of Implementation | Easy to sew and manipulate, compatible with various applications | Requires specialized tools for cutting and stitching | Simple to work with, readily available in rolls |

| Maintenance | Low maintenance, easy to clean | Requires regular conditioning to maintain appearance | Low maintenance, easy to wipe clean |

| Best Use Case | Fashion items, upholstery, accessories | High-end fashion, luxury goods, durable upholstery | Budget-friendly upholstery, outdoor furniture |

What Are the Advantages and Disadvantages of Natural Leather Compared to White Fake Leather Fabric?

Natural leather is renowned for its durability and unique aesthetic appeal, making it a popular choice in high-end fashion and luxury goods. Its breathability and ability to age beautifully are significant advantages. However, the higher cost associated with sourcing and tanning natural leather can be a barrier for many businesses. Additionally, it requires regular maintenance to retain its quality, which may not be feasible for all applications.

How Does PVC Vinyl Stack Up Against White Fake Leather Fabric?

PVC vinyl presents a budget-friendly alternative to white fake leather fabric. It is widely available and easy to work with, making it a practical choice for various applications, including outdoor furniture and budget-conscious upholstery projects. While PVC vinyl is durable and moisture-resistant, it lacks the breathability of both white fake leather and natural leather. This can lead to discomfort in certain applications, particularly in fashion items where ventilation is critical.

How Can B2B Buyers Choose the Right Fabric Solution?

Selecting the right material depends largely on the specific requirements of the project at hand. Buyers should consider factors such as the intended use of the fabric, budget constraints, and maintenance capabilities. For instance, if the focus is on high-end fashion or luxury items, natural leather may be the best choice despite its higher cost. Conversely, if affordability and ease of maintenance are priorities, PVC vinyl or white fake leather fabric may be more suitable. Ultimately, understanding the unique properties and limitations of each option will empower B2B buyers to make informed choices that align with their business objectives.

Essential Technical Properties and Trade Terminology for white fake leather fabric

What Are the Essential Technical Properties of White Fake Leather Fabric?

When sourcing white fake leather fabric, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications:

Illustrative image related to white fake leather fabric

1. Material Composition

White fake leather, also known as synthetic leather, is typically made from a combination of polyurethane (PU) or polyvinyl chloride (PVC). The choice of material impacts the fabric’s durability, flexibility, and ease of maintenance. PU is often favored for its eco-friendliness and superior breathability, while PVC offers enhanced waterproof capabilities.

2. Thickness

Measured in millimeters (mm) or mils (thousandths of an inch), the thickness of the fabric affects its application. Thicker materials are generally more durable and suitable for upholstery, while thinner options are ideal for fashion applications such as garments and accessories. Understanding thickness ensures that buyers select the right product for their intended use.

3. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that the fabric can withstand before breaking. This property is crucial for assessing the longevity of the fabric in high-wear applications, such as furniture or automotive upholstery. Higher tensile strength indicates a more durable product, which is essential for B2B buyers seeking long-lasting materials.

4. Water Resistance

Many white fake leather fabrics are treated to be water-resistant or waterproof. This property is vital for applications in environments where moisture exposure is a concern, such as outdoor furniture or marine upholstery. Buyers should inquire about the water resistance level to ensure the fabric meets their specific needs.

5. UV Resistance

UV resistance is a critical property for fabrics exposed to sunlight. White fake leather that is UV-resistant will maintain its color and integrity over time, making it suitable for outdoor applications. This feature is particularly important for buyers in regions with high sun exposure, as it helps prevent fading and degradation.

6. Flame Retardancy

For certain applications, such as in public spaces or transportation, flame retardancy is a necessary property. Fabrics that meet specific fire safety standards can reduce the risk of ignition and slow down fire spread. B2B buyers should verify compliance with relevant safety regulations when selecting materials for such applications.

What Are Common Trade Terms Used in the White Fake Leather Fabric Industry?

In addition to technical specifications, familiarizing yourself with industry terminology can streamline the procurement process. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products to be sold under another company’s brand. In the context of fake leather fabric, an OEM may produce custom designs or specifications for brands looking to create unique products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it affects inventory management and cost efficiency. Suppliers often set MOQs to ensure profitability and justify production runs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other information for specific products. Buyers use RFQs to compare offers from multiple suppliers, ensuring they get the best possible deal. Including detailed specifications in the RFQ can lead to more accurate responses.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps clarify shipping, insurance, and payment responsibilities, which is crucial for smooth cross-border transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. It encompasses manufacturing time, shipping duration, and any potential delays. Buyers should consider lead times when planning inventory and production schedules to avoid disruptions.

6. Certification Standards

Certification standards, such as OEKO-TEX or REACH, indicate that the fabric meets specific safety and environmental criteria. B2B buyers should seek materials that are certified to ensure compliance with industry regulations and consumer safety standards.

Illustrative image related to white fake leather fabric

By understanding these essential properties and trade terms, B2B buyers can make informed decisions when sourcing white fake leather fabric, ultimately enhancing their purchasing strategies and product offerings.

Navigating Market Dynamics and Sourcing Trends in the white fake leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the White Fake Leather Fabric Sector?

The global market for white fake leather fabric is experiencing significant growth driven by several factors. Increasing demand for cost-effective and versatile materials across various industries, including fashion, automotive, and furniture, is at the forefront. This surge is particularly pronounced in regions such as Africa and South America, where the manufacturing sector is expanding rapidly. International buyers from these regions are increasingly looking for high-quality synthetic alternatives that mimic the aesthetics of genuine leather while offering greater durability and ease of maintenance.

Emerging B2B tech trends, such as digital sourcing platforms and AI-driven supply chain management, are reshaping how businesses engage with suppliers. These technologies facilitate real-time inventory tracking, enabling buyers to make informed purchasing decisions based on market demand and supply fluctuations. Furthermore, the rise of e-commerce platforms is allowing international buyers, particularly in Europe and the Middle East, to access a wider range of suppliers and products, enhancing competition and driving innovation in the white fake leather segment.

As consumer preferences shift towards sustainable and ethical options, the market dynamics are also adapting. Buyers are increasingly seeking products that align with their values, pushing manufacturers to prioritize eco-friendly materials and production processes. This trend is not only shaping product offerings but is also influencing pricing strategies and marketing approaches within the sector.

How Is Sustainability and Ethical Sourcing Shaping the White Fake Leather Fabric Market?

Sustainability has become a critical focus in the white fake leather fabric sector, driven by rising environmental concerns and consumer awareness. Traditional leather production is associated with significant environmental impacts, including deforestation and high water usage. In contrast, white fake leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), presents a more sustainable alternative when produced responsibly.

Illustrative image related to white fake leather fabric

B2B buyers are increasingly prioritizing ethical sourcing practices, emphasizing the importance of transparent supply chains. This includes ensuring that materials are sourced from suppliers that adhere to environmental regulations and labor rights standards. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are becoming essential in verifying the sustainability of materials used in the production of white fake leather fabrics.

Moreover, the demand for recycled and biodegradable options is on the rise. Companies that invest in innovative materials, such as bio-based synthetic leathers made from plant sources, are positioned to attract environmentally-conscious buyers. By aligning with these sustainability trends, businesses can not only meet regulatory requirements but also enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

What Has Been the Evolution of White Fake Leather Fabric in the B2B Space?

The evolution of white fake leather fabric has been marked by significant technological advancements and changing consumer preferences. Initially, synthetic leathers were primarily seen as low-cost alternatives to traditional leather, often lacking in durability and aesthetic appeal. However, advancements in manufacturing processes have led to the development of high-quality faux leathers that closely replicate the look and feel of genuine leather.

Over the past few decades, the rise of ethical consumerism has further transformed the market. As awareness of the environmental and ethical implications of leather production has grown, so too has the demand for sustainable alternatives. This shift has prompted manufacturers to innovate, leading to the creation of more versatile, durable, and eco-friendly options in the white fake leather category.

Today, the B2B landscape for white fake leather is characterized by a diverse range of applications, from fashion apparel to automotive interiors and furniture. The ongoing focus on sustainability and ethical sourcing is expected to continue driving innovations and shaping the future of this sector, providing ample opportunities for international buyers looking to align with modern consumer values.

Frequently Asked Questions (FAQs) for B2B Buyers of white fake leather fabric

-

How do I choose the right supplier for white fake leather fabric?

Selecting a reliable supplier for white fake leather fabric requires thorough research. Start by evaluating their reputation through online reviews and ratings. Ensure they have experience in international trade, especially in your target regions like Africa, South America, the Middle East, and Europe. Request samples to assess the quality of the material and inquire about their production capabilities, lead times, and certifications. Establish clear communication to gauge their responsiveness and willingness to meet your requirements. -

What are the common applications of white fake leather fabric in B2B sectors?

White fake leather fabric is versatile and widely used across various industries. In fashion, it serves for apparel items like jackets, bags, and shoes. In home decor, it can be utilized for upholstery, cushions, and curtains. Additionally, it finds applications in automotive interiors and event decorations. Understanding the specific needs of your target market will help you position this fabric effectively in your offerings. -

What customization options are available for white fake leather fabric?

Many suppliers offer customization options for white fake leather fabric, including thickness, texture, and finishes. You can also request specific treatments, such as waterproofing or UV resistance, depending on your intended application. Discuss your requirements with potential suppliers to determine their capabilities and minimum order quantities (MOQs) for customized products. Ensure that you receive samples before finalizing any orders to confirm that the customization meets your standards. -

What are typical minimum order quantities (MOQs) for white fake leather fabric?

MOQs for white fake leather fabric can vary significantly between suppliers, often ranging from 50 to 500 yards, depending on the manufacturer and customization options. When sourcing, inquire about the MOQ and negotiate based on your purchasing power and projected demand. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s essential to communicate your needs clearly. -

What payment terms should I expect when purchasing white fake leather fabric internationally?

Payment terms for international purchases of white fake leather fabric can vary by supplier. Common practices include a 30% deposit upon order confirmation, with the balance due before shipping. Some suppliers might offer credit terms or letters of credit, especially for established relationships. Always clarify payment terms upfront and consider using secure payment methods to protect your transaction. -

How can I ensure quality assurance (QA) for my white fake leather fabric orders?

To maintain quality assurance for your white fake leather fabric, establish a clear QA process with your supplier. Request detailed specifications and quality control measures they implement during production. Consider scheduling pre-shipment inspections or third-party quality checks to verify that the materials meet your standards before dispatch. Document all agreements regarding quality expectations to avoid disputes later. -

What logistics considerations should I keep in mind when importing white fake leather fabric?

When importing white fake leather fabric, consider logistics factors such as shipping methods, delivery times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders. Familiarize yourself with import duties and taxes in your country to budget appropriately. Collaborate with a freight forwarder experienced in textile imports to streamline the process and ensure compliance with all regulations. -

What are the environmental impacts of white fake leather fabric?

White fake leather fabric, especially when made from synthetic materials, can have environmental implications due to its production and disposal. Many suppliers are now focusing on sustainability by using eco-friendly materials and processes. When sourcing, inquire about the environmental policies of your suppliers and consider options made from recycled or biodegradable materials. This not only enhances your brand image but also meets the growing consumer demand for sustainable products.

Top 5 White Fake Leather Fabric Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Quality Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Введение: This company, Fabric Wholesale Direct – Quality Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Hobby Lobby – Pearl White Castello Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Введение: {“SKU”:”1347699″,”Original Price”:”$13.99 YDS”,”Description”:”Pearl White Castello Faux Leather Fabric is a charming fabric that includes a felt-like backing and a vinyl-like crackled texture across the front.”,”Available In”:”1-yard increments”,”Average Bolt Size”:”approximately 9 yards”,”Width”:”55 inches”,”Color”:”Pearl”,”Weight”:”Extra-Heavyweight”,”Content”:”100% Polyurethane”,”Flammability N…

3. Sallie Tomato – Faux Leather

Domain: sallietomato.com

Registered: 2015 (10 years)

Введение: Faux Leather by Sallie Tomato is a vegan alternative to leather or cork fabric, available in various textures including Weave, Pebble, Legacy, Shimmer, Crocodile, Alligator, Ostrich, and Rugged. Select Faux Leathers are offered in Lite Legacy, an ultra-thin material. The fabric is sold by quarter yard, with 66 products in total, featuring colors such as Beige, Black, Blue, Brown, Green, Grey, Navy…

4. Kiki Textiles – Faux Leather Fabric

Domain: kikitextiles.com

Registered: 2021 (4 years)

Введение: Faux leather (pleather) fabric by the yard available in various colors and styles. Key features include:

– Ethical and animal-friendly alternative to genuine leather.

– Advanced technology for realistic texture, sheen, and durability.

– Suitable for fashion (jackets, handbags, clothing), upholstery (furniture), and accessories (wallets, belts, shoes).

– Easy to clean and resistant to wear and tear…

5. Fabric Warehouse – Faux Leather Upholstery Fabric

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Введение: Faux Leather Upholstery Fabric by the yard, available in various styles including faux leather, pleather, vegan leather, synthetic leather, and simulated leather. Common patterns include ostrich, peacock, snake, crocodile, alligator, and cow. Fabric width is 54 inches. Ideal for upholstery projects such as stools, benches, and armchairs. Options include heavyweight and very heavyweight fabrics. Va…

Strategic Sourcing Conclusion and Outlook for white fake leather fabric

As the demand for sustainable and stylish materials rises, white fake leather fabric stands out as a versatile solution for various applications across industries. Its unique blend of durability and aesthetic appeal makes it an ideal choice for fashion, furniture, and automotive sectors. Strategic sourcing of this material not only ensures cost-effectiveness but also aligns with environmentally-conscious practices, which are increasingly important to consumers and businesses alike.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider leveraging the growing market for white fake leather. Establishing partnerships with reliable suppliers can enhance product offerings while also providing competitive advantages in pricing and quality. By focusing on sourcing strategies that prioritize sustainability and innovation, businesses can meet the evolving demands of their customers.

Looking ahead, the market for white fake leather fabric is expected to expand, driven by consumer preferences for cruelty-free and eco-friendly products. Now is the time to engage with suppliers who can provide high-quality materials that meet these standards. Embrace this opportunity to differentiate your product line and enhance your brand’s reputation by integrating white fake leather into your offerings.

Illustrative image related to white fake leather fabric

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.