Introduction: Navigating the Global Market for synthetic suede material

Navigating the global market for synthetic suede material presents unique challenges for international B2B buyers, especially when it comes to sourcing high-quality materials that align with diverse application needs. With its luxurious feel and versatile uses ranging from upholstery to fashion accessories, synthetic suede is increasingly in demand across various sectors. However, identifying reliable suppliers, understanding material specifications, and evaluating cost-effectiveness can prove daunting in a competitive landscape.

This comprehensive guide delves into the multifaceted world of synthetic suede, offering valuable insights into the different types available, their applications in various industries, and critical supplier vetting processes. We will explore cost considerations and trends that influence pricing, ensuring that you are well-equipped to make informed purchasing decisions. This guide is tailored specifically for international buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia.

By providing a thorough understanding of synthetic suede materials and their market dynamics, this resource empowers you to navigate sourcing challenges confidently, ensuring you can secure the best quality products at competitive prices while meeting the unique demands of your business.

Table Of Contents

- Top 7 Synthetic Suede Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for synthetic suede material

- Understanding synthetic suede material Types and Variations

- Key Industrial Applications of synthetic suede material

- 3 Common User Pain Points for ‘synthetic suede material’ & Their Solutions

- Strategic Material Selection Guide for synthetic suede material

- In-depth Look: Manufacturing Processes and Quality Assurance for synthetic suede material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic suede material’

- Comprehensive Cost and Pricing Analysis for synthetic suede material Sourcing

- Alternatives Analysis: Comparing synthetic suede material With Other Solutions

- Essential Technical Properties and Trade Terminology for synthetic suede material

- Navigating Market Dynamics and Sourcing Trends in the synthetic suede material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of synthetic suede material

- Strategic Sourcing Conclusion and Outlook for synthetic suede material

- Important Disclaimer & Terms of Use

Understanding synthetic suede material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microsuede | Soft, brushed finish; lightweight; high durability | Upholstery, fashion accessories, costumes | Pros: Soft texture, variety of colors; Cons: Non-stretchable, requires dry cleaning |

| Ultrasuede | More resilient, water-resistant, and stain-resistant | Automotive interiors, high-end upholstery | Pros: Easy to clean, long-lasting; Cons: Higher cost compared to standard suede |

| Eco-suede | Made from recycled materials; eco-friendly | Sustainable fashion, eco-conscious products | Pros: Environmentally friendly; Cons: Limited color options, may have a higher price point |

| Faux suede | Synthetic fibers with a suede-like appearance | Footwear, bags, and home decor | Pros: Affordable, easy to maintain; Cons: May not have the same texture as real suede |

| Performance suede | Enhanced durability and resistance to wear | Outdoor gear, heavy-use furniture | Pros: Extremely durable, versatile; Cons: Heavier weight, may sacrifice softness |

What Are the Key Characteristics of Microsuede?

Microsuede is a popular choice among B2B buyers due to its soft, brushed texture and lightweight nature. This synthetic material is made from tightly woven polyester fibers, providing a luxurious feel similar to genuine suede. Its durability makes it suitable for various applications, including upholstery for furniture, fashion accessories, and costumes. However, it is important for buyers to note that microsuede is non-stretchable and requires dry cleaning, which may affect maintenance costs.

How Does Ultrasuede Differ from Other Synthetic Suede Types?

Ultrasuede stands out for its enhanced resilience, water resistance, and stain resistance, making it ideal for high-demand applications like automotive interiors and high-end upholstery. This material is constructed using advanced technology that enhances its durability while maintaining a soft texture. B2B buyers appreciate that ultrasuede is easy to clean and long-lasting, although it typically comes at a higher price point compared to standard synthetic suedes, which should be considered in budget planning.

What Makes Eco-suede a Sustainable Choice?

Eco-suede is crafted from recycled materials, positioning it as an environmentally friendly option for B2B buyers focused on sustainability. This material is suitable for applications in sustainable fashion and eco-conscious products. While eco-suede provides a green alternative, buyers should be aware of its limited color options and potentially higher price point, which may affect their purchasing decisions depending on project requirements.

Why Choose Faux Suede for Affordable Options?

Faux suede, made from synthetic fibers, offers a cost-effective alternative to genuine suede while providing a similar appearance. This material is widely used in the production of footwear, bags, and home decor items. B2B buyers favor faux suede for its affordability and ease of maintenance; however, it may not replicate the texture of real suede as closely as other synthetic options, which could be a consideration for projects demanding a high-end look.

What Are the Benefits of Performance Suede?

Performance suede is engineered for maximum durability and wear resistance, making it an excellent choice for outdoor gear and heavy-use furniture. This type of synthetic suede can withstand harsh conditions while maintaining a stylish appearance. B2B buyers value performance suede for its versatility and longevity, although it may be heavier and sacrifice some softness compared to other options. Understanding these characteristics can help businesses make informed decisions based on their specific needs.

Key Industrial Applications of synthetic suede material

| Industry/Sector | Specific Application of synthetic suede material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Clothing and Accessories | Offers a luxurious feel at a lower cost compared to leather, appealing to eco-conscious consumers. | Ensure color consistency and fabric weight; consider regional preferences for styles. |

| Автомобили | Upholstery and Interior Design | Provides a durable and aesthetically pleasing alternative to leather, enhancing vehicle interiors. | Look for UV resistance and easy maintenance features; verify compliance with automotive standards. |

| Furniture and Home Décor | Upholstery for Sofas and Chairs | Combines comfort with durability, making it ideal for high-traffic areas. | Assess fire-retardant properties and stain resistance; consider bulk purchasing options. |

| Events and Exhibitions | Decorative Elements and Event Furnishings | Enhances visual appeal while being cost-effective for temporary setups. | Focus on lightweight options for transport; inquire about customization capabilities. |

| Sports and Outdoor Gear | Gear and Apparel for Outdoor Activities | Provides moisture-wicking properties and breathability, essential for active wear. | Check for water resistance and durability; ensure compliance with environmental regulations. |

How is Synthetic Suede Material Utilized in the Fashion and Apparel Industry?

In the fashion and apparel sector, synthetic suede material is extensively used for creating clothing and accessories, offering a luxurious feel that mimics real leather at a fraction of the cost. This appeals to a growing demographic of eco-conscious consumers looking for sustainable alternatives. International buyers need to consider factors such as color consistency and fabric weight, as regional fashion trends can vary significantly.

What Are the Benefits of Using Synthetic Suede in Automotive Upholstery?

Automotive manufacturers and suppliers leverage synthetic suede for upholstery and interior design, providing a durable and visually appealing alternative to traditional leather. This material enhances the overall aesthetic of vehicle interiors while being easier to maintain. B2B buyers should focus on sourcing options that include UV resistance and compliance with automotive standards, ensuring longevity and safety in their products.

Why is Synthetic Suede Preferred for Furniture and Home Décor?

In the furniture and home décor industry, synthetic suede is favored for upholstery on sofas and chairs due to its combination of comfort and durability. This makes it particularly suitable for high-traffic areas in homes and commercial spaces. Buyers should evaluate the fabric’s fire-retardant properties and stain resistance, as these features are crucial for meeting safety regulations and ensuring longevity.

How is Synthetic Suede Used in Events and Exhibitions?

For the events and exhibitions sector, synthetic suede is employed in decorative elements and event furnishings, enhancing the visual appeal of setups while remaining cost-effective for temporary installations. Its lightweight nature makes it easy to transport and set up. Buyers should prioritize sourcing lightweight options and inquire about customization capabilities to align with specific event themes.

What Applications Exist for Synthetic Suede in Sports and Outdoor Gear?

In the sports and outdoor gear industry, synthetic suede is utilized for gear and apparel designed for outdoor activities, thanks to its moisture-wicking properties and breathability. This is essential for active wear that needs to perform well under various conditions. B2B buyers must ensure that the material meets water resistance standards and complies with environmental regulations, particularly in regions with strict sustainability mandates.

3 Common User Pain Points for ‘synthetic suede material’ & Their Solutions

Scenario 1: Difficulty in Color Consistency Across Batches

The Problem: B2B buyers often face challenges related to color consistency when ordering synthetic suede material. Different dye lots can lead to variations in color, which can significantly impact the aesthetics of the final product. This inconsistency can be particularly problematic for businesses that require uniformity, such as fashion brands or upholstery manufacturers, where mismatched colors may lead to customer dissatisfaction and increased production costs.

The Solution: To mitigate color inconsistency, buyers should prioritize sourcing from suppliers that provide detailed color matching and dye lot information. Requesting a sample swatch before placing a bulk order is crucial to ensure the desired color meets expectations. Additionally, establishing a strong relationship with suppliers can facilitate better communication regarding dye lots and future orders. Buyers should also consider maintaining a dedicated inventory of specific dye lots for ongoing projects, ensuring that any subsequent orders match the original specifications. Implementing a quality control process to inspect incoming materials can further help identify discrepancies early on.

Illustrative image related to synthetic suede material

Scenario 2: Concerns About Durability and Maintenance

The Problem: Another common pain point for B2B buyers is the perceived durability and maintenance requirements of synthetic suede material. Many businesses, especially in the furniture and automotive sectors, worry that synthetic suede may not hold up against wear and tear, or that it may require complicated cleaning procedures that could deter customers.

The Solution: To address these concerns, buyers should thoroughly research the specific types of synthetic suede available, as there are many variations with differing levels of durability and maintenance requirements. Opting for high-quality synthetic suede that is treated for stain resistance and water repellency can significantly enhance longevity. It’s also advisable to provide clear care instructions to end customers, emphasizing that many synthetic suedes can be spot-cleaned or brushed to maintain appearance without the need for professional cleaning. Buyers may also consider offering warranties or guarantees on products made from synthetic suede, which can reassure customers about their durability.

Scenario 3: Sourcing Challenges in Global Markets

The Problem: Sourcing synthetic suede material can become a logistical challenge, especially for B2B buyers operating in diverse international markets such as Africa, South America, the Middle East, and Europe. Issues such as fluctuating shipping costs, import regulations, and supplier reliability can complicate the procurement process, leading to delays and increased expenses.

The Solution: To streamline sourcing, buyers should develop a multi-supplier strategy, allowing them to diversify their supply chain and reduce dependency on a single source. This approach can help mitigate risks associated with supplier reliability and shipping disruptions. Additionally, utilizing platforms that specialize in connecting B2B buyers with reputable suppliers across different regions can enhance sourcing efficiency. Buyers should also stay informed about international trade regulations and tariffs that may affect their orders, enabling them to plan accordingly. Establishing a strong logistics partner who understands the nuances of international shipping can further enhance supply chain resilience, ensuring that synthetic suede materials arrive on time and within budget.

Strategic Material Selection Guide for synthetic suede material

What are the Key Properties of Common Synthetic Suede Materials?

When selecting synthetic suede materials for various applications, it’s essential to understand the key properties of the most common types. Below are analyses of four prevalent materials used in synthetic suede production: Microfiber, Polyester, Polyurethane (PU), and Nylon. Each material has unique characteristics that influence its performance, durability, and suitability for different applications.

How Does Microfiber Perform as a Synthetic Suede Material?

Microfiber is a finely woven synthetic fabric made from polyester and polyamide. It boasts excellent durability, softness, and moisture-wicking properties. Microfiber can withstand high temperatures and is resistant to fading, making it suitable for upholstery and fashion applications.

Pros: Microfiber is lightweight, easy to clean, and offers a luxurious feel. It is also highly resistant to stains and water, which enhances its longevity in consumer products.

Cons: While microfiber is durable, it can be more expensive than other synthetic options. Additionally, it may require special care to maintain its appearance, as it can attract dust and lint.

Impact on Application: Microfiber is compatible with a wide range of media, including upholstery, clothing, and accessories. Its softness makes it a preferred choice in high-end fashion and interior design.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure that the microfiber meets local textile regulations, such as Oeko-Tex certification for harmful substances.

What Advantages Does Polyester Offer in Synthetic Suede?

Polyester is a versatile synthetic material widely used in various applications, including synthetic suede. It is known for its strength, resistance to shrinking and stretching, and quick-drying properties.

Pros: Polyester is relatively inexpensive and easy to manufacture, making it a cost-effective choice for large-scale production. It also offers good color retention and durability.

Cons: While durable, polyester may not provide the same luxurious feel as microfiber or natural suede. It can also be less breathable, which may limit its use in certain applications.

Impact on Application: Polyester synthetic suede is commonly used in fashion, upholstery, and accessories. Its affordability makes it suitable for mass-market products.

Considerations for International Buyers: Buyers should be aware of the global standards for polyester production, including compliance with ASTM and DIN regulations, especially in Europe.

How Does Polyurethane (PU) Compare in Synthetic Suede Selection?

Polyurethane (PU) is a synthetic polymer that mimics the look and feel of leather. PU synthetic suede is known for its flexibility and resistance to wear and tear.

Pros: PU offers a high-quality appearance that closely resembles genuine suede, making it popular in fashion and luxury goods. It is also more environmentally friendly than PVC alternatives.

Cons: PU can be less durable than microfiber and may not withstand extreme temperatures as well. It can also be susceptible to cracking over time.

Illustrative image related to synthetic suede material

Impact on Application: PU synthetic suede is ideal for high-end applications, including automotive interiors and luxury fashion. Its aesthetic appeal makes it a preferred choice for premium products.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the environmental regulations surrounding PU production, particularly regarding sustainability and waste management.

What Role Does Nylon Play in Synthetic Suede Applications?

Nylon is another synthetic material used in the production of suede-like fabrics. It is known for its strength, elasticity, and resistance to abrasion.

Pros: Nylon is highly durable and offers excellent resistance to tearing and fraying. Its elasticity makes it suitable for applications requiring stretch, such as activewear.

Cons: Nylon can be more expensive than polyester and may not provide the same soft texture as other synthetic suedes. It can also be prone to static electricity.

Illustrative image related to synthetic suede material

Impact on Application: Nylon synthetic suede is commonly used in outdoor gear, upholstery, and fashion items that require durability and flexibility.

Considerations for International Buyers: Buyers should ensure compliance with international textile standards and consider the environmental impact of nylon production, particularly in regions with stringent regulations.

Summary Table of Synthetic Suede Materials

| Материал | Typical Use Case for synthetic suede material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Микрофибра | Upholstery, fashion, accessories | Luxurious feel and durability | Higher cost, requires special care | Высокий |

| Polyester | Mass-market fashion, upholstery | Cost-effective and durable | Less luxurious feel, less breathable | Низкий |

| Polyurethane | Luxury fashion, automotive interiors | High-quality appearance | Less durable, can crack over time | Medium |

| Nylon | Outdoor gear, activewear, upholstery | Excellent durability and elasticity | Higher cost, prone to static | Medium |

This strategic material selection guide provides critical insights for B2B buyers in diverse regions, helping them make informed decisions when sourcing synthetic suede materials.

Illustrative image related to synthetic suede material

In-depth Look: Manufacturing Processes and Quality Assurance for synthetic suede material

What Are the Main Stages in the Manufacturing Process of Synthetic Suede Material?

The manufacturing process of synthetic suede material involves several key stages, each critical to achieving the desired quality and characteristics of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing synthetic suede for various applications, such as upholstery, fashion, and automotive interiors.

Material Preparation: What Raw Materials Are Used?

The first step in producing synthetic suede is the selection and preparation of raw materials. Typically, the primary component is polyester, which is favored for its durability, softness, and ease of dyeing. The polyester fibers undergo a rigorous quality check to ensure they meet industry standards. This includes assessing fiber length, strength, and color consistency.

In some cases, additives may be incorporated to enhance the fabric’s properties, such as anti-microbial agents for improved hygiene or UV stabilizers for better color retention. The blending of these materials is done in controlled environments to minimize contamination and ensure uniformity.

How Is the Forming Process Executed?

Once the materials are prepared, the next stage is forming. This process typically involves spinning the polyester fibers into yarns, which are then woven or knitted into fabric. The weaving technique most commonly used for synthetic suede is the twill weave, which provides a soft, brushed finish that mimics the texture of natural suede.

Illustrative image related to synthetic suede material

During this stage, manufacturers may also apply various treatments to enhance the fabric’s tactile qualities and appearance. Techniques such as shearing and brushing are employed to create the signature napped surface of synthetic suede. The fabric is then heat-set to stabilize its structure, ensuring it retains its shape and texture during subsequent processing.

What Finishing Techniques Are Commonly Used?

Finishing is a crucial stage in the manufacturing of synthetic suede. It involves several processes aimed at improving the fabric’s aesthetic appeal and functional performance. Common finishing techniques include dyeing, where the fabric is colored using eco-friendly dyes that meet international environmental standards.

Additionally, coatings may be applied to enhance water resistance, stain repellency, or flame retardancy, depending on the intended application of the synthetic suede. This stage also includes final inspections to ensure the fabric meets quality specifications before it is packaged for distribution.

How Is Quality Assurance Implemented in Synthetic Suede Manufacturing?

Quality assurance (QA) is vital in the synthetic suede manufacturing process, ensuring that products meet both international standards and customer expectations. Manufacturers typically adhere to various quality management systems, with ISO 9001 being one of the most recognized frameworks.

What Are the Key International and Industry-Specific Standards?

ISO 9001 outlines requirements for a quality management system, focusing on continuous improvement and customer satisfaction. For synthetic suede, compliance with CE marking may be required in Europe, indicating that the product meets health, safety, and environmental protection standards. In specific applications, such as automotive interiors, adherence to API (American Petroleum Institute) standards may also be necessary.

What Are the Critical Quality Control Checkpoints?

Quality control (QC) in synthetic suede manufacturing is often segmented into three main checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt. Suppliers must provide certificates of compliance, and materials are sampled for testing against predefined specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production parameters. This can include checking fabric weight, color fastness, and texture consistency. Any deviations from established standards are corrected immediately to prevent defects.

-

Final Quality Control (FQC): Before packaging, the finished synthetic suede undergoes thorough testing. This includes visual inspections for defects and physical tests for durability, softness, and color retention. Only products that pass these checks are approved for shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers adhere to strict QC practices. This can be accomplished through several actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities helps verify compliance with quality standards. Audits should assess both the processes and the equipment used in production.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can provide insights into the manufacturer’s QC processes, including test results and any corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspectors can add an extra layer of assurance. These inspectors can perform random checks and validate that the products meet the specified standards before shipment.

What Nuances Should International B2B Buyers Consider?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, it is essential to understand the nuances of QC and certification requirements that may vary by region.

-

Cultural and Regulatory Differences: Awareness of local regulations concerning textile imports is crucial. For instance, some countries may have stricter regulations on chemical treatments used in fabric production, necessitating additional certifications.

-

Logistical Considerations: International shipping can introduce challenges in maintaining product integrity. B2B buyers should work closely with suppliers to ensure that products are packaged correctly and protected against environmental factors during transit.

-

Language Barriers: Communication can be a hurdle in verifying quality standards. It is advisable to have bilingual representatives or translators involved in negotiations and contract discussions to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance measures associated with synthetic suede, B2B buyers can make more informed decisions, ensuring they source high-quality materials that meet their business needs and comply with relevant standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic suede material’

To successfully procure synthetic suede material, it’s essential to follow a structured approach that ensures quality, cost-effectiveness, and supplier reliability. This checklist serves as a practical guide for B2B buyers in various regions, including Africa, South America, the Middle East, and Europe, to streamline their sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the synthetic suede material you require. This includes determining the desired fabric weight, texture, color options, and specific uses (e.g., upholstery, fashion, or automotive applications). Having precise specifications helps suppliers provide accurate samples and quotes, minimizing misunderstandings later in the procurement process.

Step 2: Research Potential Suppliers

Thorough research is crucial to identify reliable suppliers. Look for manufacturers with a proven track record in producing synthetic suede materials. Utilize online platforms, industry trade shows, and networks to gather information. Pay attention to:

– Supplier Reviews: Check testimonials and ratings from previous buyers.

– Industry Experience: Suppliers with extensive experience in your specific market may better understand your requirements.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management systems or certifications specific to environmental standards. This step ensures that the supplier adheres to industry standards, which is crucial for maintaining the quality and sustainability of your products. Additionally, inquire about their manufacturing processes and whether they comply with local regulations.

Step 4: Request Samples and Conduct Quality Checks

Always request samples of the synthetic suede material before placing a large order. This allows you to assess the quality, texture, and color accuracy firsthand. When evaluating samples, consider:

– Durability: Test the fabric for wear and tear.

– Color Consistency: Compare the sample with your specifications to ensure it meets your expectations.

Step 5: Negotiate Pricing and Payment Terms

Once you are satisfied with the supplier’s quality, engage in negotiations regarding pricing and payment terms. Ensure that you discuss bulk order discounts, shipping costs, and payment methods. Aim for terms that are favorable to your cash flow while ensuring the supplier’s reliability in fulfilling orders.

Step 6: Confirm Shipping and Delivery Timelines

Clarify the shipping methods and delivery timelines with your chosen supplier. Understanding these logistics is critical to your project timelines and inventory management. Look for suppliers who offer tracking options and ensure they have a robust logistics process to prevent delays.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership. Establish a clear communication plan that outlines how often you will check in with the supplier and the preferred channels (e.g., email, phone, or messaging apps). Regular updates can help address any issues promptly and foster a long-term relationship.

By following this checklist, B2B buyers can enhance their sourcing strategy for synthetic suede material, ensuring they partner with reliable suppliers while meeting their specific material needs effectively.

Illustrative image related to synthetic suede material

Comprehensive Cost and Pricing Analysis for synthetic suede material Sourcing

What Are the Key Cost Components in Synthetic Suede Material Sourcing?

When sourcing synthetic suede materials, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: Synthetic suede is predominantly made from polyester, which can vary in price based on quality and sourcing location. The cost of raw materials can fluctuate based on global demand and supply chain conditions.

-

Labor: Labor costs will depend on the region of manufacturing. For instance, countries with lower labor costs may offer more competitive pricing, but this can sometimes impact the quality of the final product.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses that contribute to the production process. Efficient production methods can help reduce these costs, benefiting buyers.

-

Tooling: Initial setup costs for machinery and molds can be significant, especially for custom designs. Buyers should consider these costs, particularly when ordering unique or complex specifications.

-

Quality Control (QC): Implementing robust QC processes ensures that the materials meet specified standards, which can add to costs but ultimately protects against defects and returns.

-

Logistics: Shipping costs can vary widely based on distance, shipping methods, and the volume of the order. Incoterms play a crucial role in determining who bears these costs.

-

Margin: Suppliers will add a markup to cover their costs and profit, which can vary significantly based on market competition and the perceived value of the product.

How Do Price Influencers Affect Synthetic Suede Material Costs?

Several factors influence the pricing of synthetic suede materials:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. Establishing a long-term relationship with suppliers can help negotiate better terms.

-

Specifications and Customization: Custom colors, textures, or treatments can increase costs. Be clear about your requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific certifications (e.g., eco-friendly or hypoallergenic) can command premium pricing.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms is critical. For instance, choosing FOB (Free On Board) may result in different cost implications compared to DDP (Delivered Duty Paid).

What Are the Best Buyer Tips for Cost-Efficiency in Synthetic Suede Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing structures. Leveraging your purchasing power can lead to significant discounts, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also logistics, storage, and handling costs. A cheaper material may result in higher TCO if it requires frequent replacement.

-

Understand Pricing Nuances: International markets may have different pricing dynamics. Stay informed about local economic conditions, tariffs, and trade agreements that may affect costs.

-

Request Samples: Always ask for samples before placing large orders. This helps ensure the quality meets your standards and can prevent costly mistakes.

-

Stay Informed on Market Trends: Keep abreast of industry trends, including shifts in raw material prices and supply chain disruptions, which can influence future pricing.

Disclaimer on Indicative Prices

While the insights and guidelines provided aim to offer clarity on synthetic suede material sourcing, prices can vary widely based on market conditions, negotiation outcomes, and specific buyer requirements. Always seek updated quotes from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing synthetic suede material With Other Solutions

Understanding Alternatives to Synthetic Suede Material

In the pursuit of high-quality textiles, businesses often explore various material options to fulfill their needs. Synthetic suede, known for its luxurious feel and versatility, is a popular choice; however, there are other alternatives that might better suit specific applications. This section compares synthetic suede with two viable alternatives: genuine suede leather and microfiber fabric. Each option presents unique advantages and disadvantages that can influence decision-making for international B2B buyers.

| Comparison Aspect | Synthetic Suede Material | Genuine Suede Leather | Microfiber Fabric |

|---|---|---|---|

| Performance | Soft, durable, and water-resistant; mimics the look and feel of real suede | High durability; natural breathability but susceptible to water damage | Highly durable, stain-resistant, and easy to clean; soft texture |

| Cost | Generally lower cost ($8.99 per yard) | Higher cost due to sourcing and processing | Moderate cost, usually lower than suede leather but higher than synthetic suede |

| Ease of Implementation | Easy to cut and sew; requires basic sewing skills | Requires specialized tools for cutting and sewing | Very easy to work with; compatible with standard sewing techniques |

| Maintenance | Dry clean only; may require special care | Needs regular conditioning and protection from water | Machine washable; easy to maintain and clean |

| Best Use Case | Upholstery, fashion accessories, and event decor | High-end fashion items, luxury upholstery | Everyday items, sportswear, and cleaning products |

In-Depth Analysis of Alternatives

Genuine Suede Leather

Genuine suede leather is a natural material that offers superior durability and a luxurious aesthetic. Its breathability makes it ideal for clothing and footwear, providing comfort and style. However, it is significantly more expensive than synthetic alternatives, which can be a barrier for budget-conscious buyers. Additionally, genuine suede requires careful maintenance, including regular conditioning to prevent water damage and maintain its appearance. This makes it less practical for high-usage items or environments where exposure to moisture is likely.

Microfiber Fabric

Microfiber is a synthetic textile known for its exceptional durability and stain resistance. It offers a soft texture similar to suede but at a lower price point, making it an attractive option for businesses looking for quality without the premium cost. Microfiber is incredibly easy to maintain; it can be machine washed and dried without losing its integrity. However, it may not provide the same high-end look as synthetic suede or genuine suede leather, which can be a consideration for luxury applications. Its versatility makes it suitable for a range of products, from clothing to cleaning supplies.

Making the Right Choice for Your Business Needs

Choosing between synthetic suede and its alternatives depends on various factors, including budget, intended use, and maintenance preferences. For high-end products where aesthetics and durability are paramount, genuine suede might be the best option despite its higher cost and care requirements. Conversely, if affordability and ease of maintenance are critical, synthetic suede or microfiber fabric could be more suitable. B2B buyers should evaluate their specific needs, considering the performance characteristics and cost implications of each material to ensure they select the best solution for their projects.

Essential Technical Properties and Trade Terminology for synthetic suede material

What Are the Key Technical Properties of Synthetic Suede Material?

Understanding the essential technical properties of synthetic suede is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

Illustrative image related to synthetic suede material

-

Material Composition

– Synthetic suede is predominantly made from 100% polyester fibers. The choice of material affects durability, texture, and overall performance. Polyester offers a soft feel similar to natural suede while providing enhanced resistance to stains and fading, making it ideal for various applications, including upholstery and fashion. -

Fabric Weight

– Typically measured in grams per square meter (gsm), fabric weight influences the material’s thickness and durability. A common weight for synthetic suede is around 225 gsm. Heavier fabrics are often more durable and suitable for high-traffic areas, while lighter weights may be more appropriate for fashion applications. B2B buyers should select weight according to the intended use. -

Width and Length

– Synthetic suede is generally available in widths of 58 to 60 inches. Understanding the roll dimensions helps in calculating material requirements for large projects, reducing waste, and ensuring optimal production efficiency. Buyers should also be aware of minimum order quantities (MOQ) to align with their project needs. -

Color Fastness

– This property refers to the resistance of the fabric to fading or discoloration when exposed to light, washing, or rubbing. Synthetic suede often has high color fastness ratings, making it suitable for products that require longevity and aesthetic appeal, such as clothing and home decor. -

Cleaning and Maintenance

– Synthetic suede typically requires dry cleaning, which is essential for maintaining its appearance and integrity. Understanding cleaning requirements is vital for B2B buyers, especially in industries like hospitality or event planning, where fabric maintenance can significantly impact product lifespan and customer satisfaction.

What Trade Terminology Should B2B Buyers Know About Synthetic Suede Material?

Familiarity with industry jargon can streamline communications and negotiations. Here are some common trade terms relevant to synthetic suede:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of synthetic suede, OEMs may supply fabric to brands that incorporate it into their products, such as handbags or upholstery. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest amount of product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to ensure they can meet production needs without overcommitting to inventory. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and other information for specific products. This is particularly useful when sourcing synthetic suede from multiple vendors, allowing buyers to compare costs and terms efficiently. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers navigate shipping, insurance, and risk management related to synthetic suede procurement. -

Dye Lot Variations

– This term refers to the differences in color that can occur between different batches of dyed fabric. B2B buyers should be aware of dye lot variations when ordering synthetic suede, as this can affect color consistency across large orders. -

Sustainability Certification

– This refers to the verification that a product meets specific environmental or ethical standards. With increasing demand for sustainable materials, B2B buyers should inquire about sustainability certifications related to synthetic suede to align with consumer expectations and corporate social responsibility goals.

By understanding these properties and terms, B2B buyers can enhance their sourcing strategies, ensuring they procure the right synthetic suede materials that meet their business needs effectively.

Navigating Market Dynamics and Sourcing Trends in the synthetic suede material Sector

What Are the Current Market Dynamics and Key Trends in the Synthetic Suede Material Sector?

The synthetic suede material market is witnessing a surge driven by the increasing demand for versatile, cost-effective, and eco-friendly alternatives to natural leather. Globally, the shift towards sustainable fashion has propelled synthetic suede into the spotlight, with buyers from Africa, South America, the Middle East, and Europe, particularly Germany and Saudi Arabia, showing heightened interest. The fabric’s soft texture and durability make it a popular choice across various applications, including upholstery, fashion apparel, and accessories.

Emerging technologies are reshaping sourcing strategies in this sector. Innovations in manufacturing processes are enhancing the quality and variety of synthetic suede materials available, enabling suppliers to offer a wider range of colors and textures. Additionally, digital platforms are streamlining procurement processes, allowing B2B buyers to source materials directly from manufacturers, thereby reducing lead times and costs. As buyers increasingly prioritize transparency, suppliers that adopt digital tools to provide detailed information about their production processes stand to gain a competitive edge.

How Does Sustainability and Ethical Sourcing Impact the Synthetic Suede Material Sector?

Sustainability has become a cornerstone of sourcing strategies in the synthetic suede market. As environmental concerns grow, B2B buyers are compelled to consider the ecological impact of their procurement decisions. Synthetic suede, primarily made from polyester, can be produced using recycled materials, significantly reducing waste and resource consumption. This aligns with global efforts to promote circular economies and minimize the fashion industry’s carbon footprint.

Illustrative image related to synthetic suede material

Moreover, ethical sourcing practices are gaining traction. Buyers are increasingly demanding transparency in supply chains, seeking suppliers that adhere to fair labor practices and environmentally responsible production methods. Certifications such as Global Recycle Standard (GRS) and Oeko-Tex Standard 100 are becoming essential criteria for B2B buyers when evaluating potential suppliers. These certifications not only validate the sustainability claims of synthetic suede manufacturers but also enhance brand reputation among environmentally conscious consumers.

What Is the Historical Context Behind the Synthetic Suede Material’s Evolution?

The evolution of synthetic suede can be traced back to the mid-20th century, when manufacturers sought to create a viable alternative to natural suede that offered similar aesthetics without the associated costs and ethical concerns. Early iterations of synthetic suede were primarily made from polyester and polyurethane, but advancements in technology have significantly improved their quality and performance. Today, synthetic suede is not only favored for its affordability but also for its adaptability to various applications, meeting the diverse needs of international B2B buyers.

In summary, understanding the market dynamics, sustainability considerations, and the historical evolution of synthetic suede is essential for B2B buyers looking to navigate this thriving sector effectively. By aligning with suppliers who prioritize innovation and ethical practices, buyers can ensure their procurement strategies meet both business objectives and consumer expectations.

Illustrative image related to synthetic suede material

Frequently Asked Questions (FAQs) for B2B Buyers of synthetic suede material

-

How do I ensure the quality of synthetic suede material when sourcing?

To ensure the quality of synthetic suede material, request detailed specifications from suppliers, including fabric weight, fiber content, and manufacturing processes. It’s advisable to ask for sample swatches to assess texture, color accuracy, and durability. Additionally, consider suppliers with quality certifications or established reputations in the industry. Conducting a factory audit can further verify their production capabilities and quality control processes. -

What is the best synthetic suede for upholstery applications?

For upholstery applications, look for synthetic suede that offers high durability and resistance to wear and tear. Microfiber suede, often made from polyester, is an excellent choice as it mimics the softness of real suede while being more resistant to stains and easier to clean. Ensure the material has a suitable weight (around 225 grams per square meter) for upholstery, as this contributes to longevity and performance in high-use areas. -

What are the typical minimum order quantities (MOQ) for synthetic suede?

Minimum order quantities for synthetic suede can vary significantly among suppliers. Generally, MOQs may range from 10 to 50 yards, depending on the manufacturer and the specific product. Some suppliers may offer smaller quantities for sample orders, while bulk purchases often yield better pricing. Always confirm the MOQ before placing an order to avoid unexpected costs. -

How can I customize synthetic suede products to meet my needs?

Customization options for synthetic suede typically include color selection, fabric weight, and texture variations. Many suppliers offer a range of colors and finishes, allowing you to tailor products to your specific requirements. To initiate customization, communicate your needs clearly to the supplier and inquire about their capabilities regarding dyeing, pattern printing, or embossing. Ensure you receive a prototype or sample before finalizing your order. -

What payment terms should I expect when sourcing synthetic suede internationally?

Payment terms can vary based on supplier policies and your negotiation skills. Common options include upfront payment, a 30% deposit with the balance due upon shipment, or payment via letter of credit. It’s essential to clarify payment methods accepted by the supplier, such as bank transfers, PayPal, or credit cards. Understanding these terms upfront can help prevent misunderstandings and ensure smooth transactions. -

What logistics considerations should I keep in mind for international shipping of synthetic suede?

When sourcing synthetic suede internationally, consider logistics factors like shipping costs, delivery times, and customs duties. Partnering with a reliable freight forwarder can help navigate shipping regulations and ensure timely delivery. Be aware of the incoterms (International Commercial Terms) used in your agreement, as they define the responsibilities of both parties regarding shipping, insurance, and risk management. -

How do I vet suppliers for synthetic suede materials?

Vetting suppliers is crucial for ensuring reliability and product quality. Start by researching potential suppliers through trade platforms or industry directories. Request references from previous clients and check for reviews or testimonials. Consider conducting a factory visit or utilizing third-party inspection services to assess their operations and compliance with quality standards. Certifications like ISO can also indicate a supplier’s commitment to quality. -

What quality assurance measures should I implement when purchasing synthetic suede?

Implementing quality assurance measures involves establishing clear standards for your materials and communicating them to your supplier. Request regular quality checks during production and upon shipment. Consider third-party inspections to verify compliance with your specifications. Additionally, develop a return policy for defective materials and ensure that the supplier is aware of your expectations regarding dye lot variations and potential color discrepancies.

Top 7 Synthetic Suede Material Manufacturers & Suppliers List

1. My Textile Fabric – Suede & Microsuede Fabrics

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Введение: Suede Fabric | Microsuede | 40 Colors | 60″ Wide | Faux Suede | Upholstery Weight, Tablecloth, Bags, Pouches, Cosplay, Costume | Continuous Yards | $8.99 per yard | Minimum order of 2 yards | Fabric by the Bolt sold in 65 yards | 100% Polyester | Fabric Weight: Approximately 225 grams per square meter | Fabric Width: 58/60″ | Dry Clean Only | Imported | Ships from Los Angeles, California within 1-…

2. Decorative Fabrics Direct – Faux Suede Upholstery Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Введение: Faux Suede Upholstery Fabric – Microsuede Fabric

– Material: Typically 100% polyester, resembling genuine suede

– Type: Lightweight faux suede made from micro denier fibers

– Durability: More durable than real suede, less expensive, easy to care for

– Texture: Soft and supple

– Available in a variety of colors

– Order by the yard at distributor wholesale prices

– Product examples:

1. BERKLEY FIE…

3. Fashion Fabric LA – Performance Faux Suede Microfiber

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Введение: Performance Faux Suede Microfiber Fabric – Sold By The Yard

4. Fabric Wholesale Direct – Suede Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Введение: Suede Fabric available for purchase online by the yard at Fabric Wholesale Direct. Free shipping on orders over $99. Various fabric types, applications, contents, colors, patterns, and characteristics available. Suede fabric can be used for apparel, upholstery, and various home decor projects.

5. Bryden Apparel – Suede Fabrics

Domain: brydenapparel.com

Registered: 2013 (12 years)

Введение: Suede fabrics are leather made from the underside of animal skin, primarily from goats or lambs, featuring a napped and fuzzy finish. They are known for their unique, soft, and delicate feel, often associated with high-end luxury. Characteristics include durability, smooth texture, and pliability. Suede can be genuine (from animals like sheepskin, pigskin, cowhide, and deerskin) or synthetic (such…

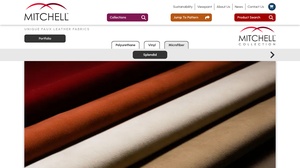

6. Mitchell Faux Leathers – Splendid Faux Suede Fabric

Domain: mitchellfauxleathers.com

Registered: 2011 (14 years)

Введение: Splendid is a faux suede fabric that mimics the look and feel of lamb skin gloves. It features a surface made from a blend of acrylic and nylon with a brushed finish resembling suede leather. The backing consists of a polyester and cotton blend. Splendid offers the softness and pliability of real suede but is more durable, resistant to stains and liquids, and can be cleaned with warm water and mil…

7. SewGuide – Synthetic Faux-Suede Alternatives

Domain: sewguide.com

Registered: 2016 (9 years)

Введение: Synthetic Faux-Suede Material: Alternatives to Suede Leather. Types of suede-like materials include Synthetic suede with backing, Ultrasuede, Alcantara, Nonwoven Suede, Sueded silk, and sueded cotton. Advantages of faux-suede: high quality, durable, affordable, lightweight, pliable, easy to wash, non-permeable to water, does not produce lint, and colors are steadfast. Disadvantages: not water-abso…

Strategic Sourcing Conclusion and Outlook for synthetic suede material

What Are the Key Takeaways for B2B Buyers of Synthetic Suede Material?

As the demand for synthetic suede material continues to grow across various industries, strategic sourcing emerges as a vital approach for international B2B buyers. Key takeaways include the importance of evaluating suppliers based on quality, availability, and customization options. Buyers should prioritize sourcing from manufacturers that offer a diverse range of colors and weights, ensuring the material meets specific project requirements. Additionally, understanding the fabric’s cleaning and maintenance needs is crucial for ensuring longevity and customer satisfaction.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in strategic sourcing not only enhances product quality but also fosters stronger supplier relationships, which can lead to better pricing and improved service levels. This is especially pertinent for buyers from regions such as Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly. By leveraging local suppliers and understanding regional trends, businesses can position themselves to respond quickly to market demands.

What Does the Future Hold for Synthetic Suede Material?

Looking ahead, the synthetic suede market is expected to innovate further, with advancements in sustainability and production techniques. B2B buyers are encouraged to stay informed about emerging trends and technologies that can enhance product offerings. By proactively engaging with suppliers and exploring new sourcing opportunities, businesses can secure a competitive advantage in this evolving landscape. Embrace the potential of synthetic suede material to elevate your product lines and meet the diverse needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.