Introduction: Navigating the Global Market for synthetic shammy leather

In an increasingly competitive global market, sourcing high-quality synthetic shammy leather presents both opportunities and challenges for international B2B buyers. This innovative material, celebrated for its superior absorbency and versatility, has become essential in various industries, from automotive detailing to household cleaning. As businesses in regions such as Africa, South America, the Middle East, and Europe (including Nigeria and Germany) seek reliable suppliers, understanding the nuances of synthetic shammy leather is crucial for making informed purchasing decisions.

This comprehensive guide delves into the different types of synthetic shammy leather, exploring their unique properties and applications across diverse sectors. It will also address the critical aspects of supplier vetting, ensuring that buyers can identify trustworthy manufacturers who meet their quality standards. Cost considerations are another vital component, as understanding pricing structures can significantly impact budgeting and profitability.

By equipping B2B buyers with actionable insights and expert recommendations, this guide empowers companies to navigate the complexities of sourcing synthetic shammy leather effectively. With a focus on practical solutions and strategic decision-making, readers will gain the confidence needed to enhance their procurement processes and ultimately improve their operational efficiency. Embrace this opportunity to elevate your business by leveraging the advantages of synthetic shammy leather in your supply chain.

Table Of Contents

- Top 2 Synthetic Shammy Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for synthetic shammy leather

- Understanding synthetic shammy leather Types and Variations

- Key Industrial Applications of synthetic shammy leather

- 3 Common User Pain Points for ‘synthetic shammy leather’ & Their Solutions

- Strategic Material Selection Guide for synthetic shammy leather

- In-depth Look: Manufacturing Processes and Quality Assurance for synthetic shammy leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic shammy leather’

- Comprehensive Cost and Pricing Analysis for synthetic shammy leather Sourcing

- Alternatives Analysis: Comparing synthetic shammy leather With Other Solutions

- Essential Technical Properties and Trade Terminology for synthetic shammy leather

- Navigating Market Dynamics and Sourcing Trends in the synthetic shammy leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of synthetic shammy leather

- Strategic Sourcing Conclusion and Outlook for synthetic shammy leather

- Important Disclaimer & Terms of Use

Understanding synthetic shammy leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

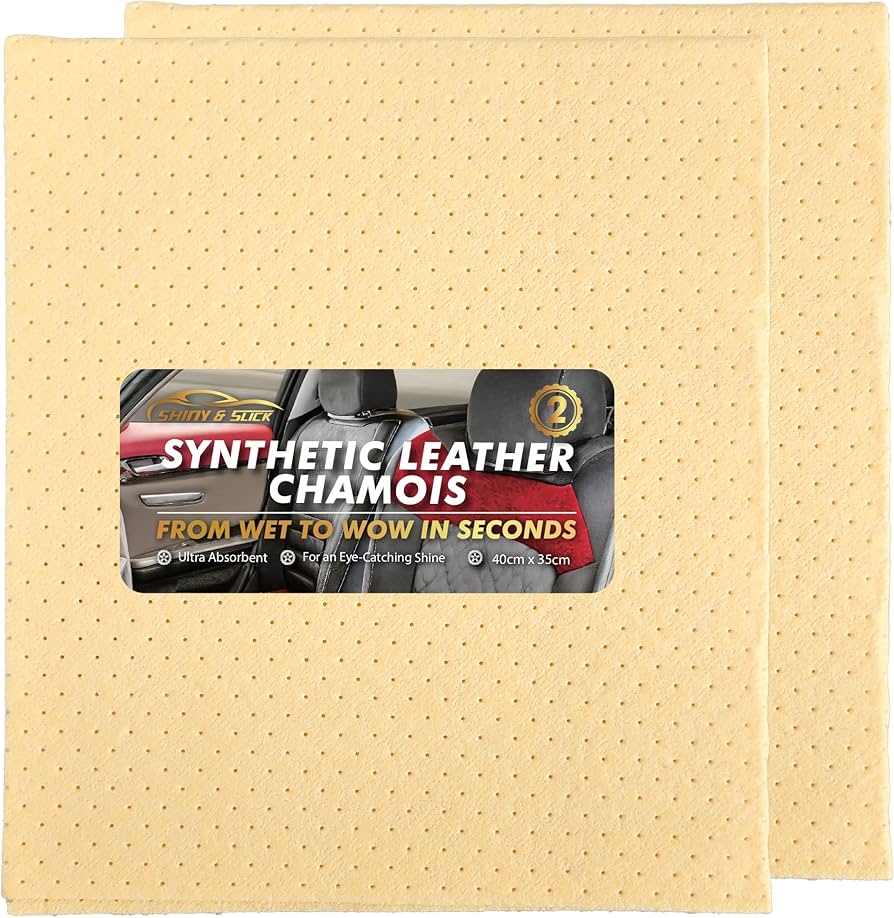

| Perforated Synthetic Microfiber | High absorbency with evenly placed perforations | Automotive detailing, industrial cleaning | Pros: Excellent drying performance; machine washable. Cons: May require careful handling to avoid tearing. |

| Jumbo Synthetic Chamois | Larger size for extensive drying areas | Car washes, marine applications, large surfaces | Pros: Saves time due to size; highly absorbent. Cons: Can be cumbersome for smaller tasks. |

| PVA (Polyvinyl Alcohol) | Soft, durable, and non-abrasive with dual textures | Professional detailing, household cleaning | Pros: Gentle on surfaces; minimizes streaks. Cons: Requires rinsing before first use; specific care needed. |

| Non-Woven Synthetic Chamois | Lightweight and flexible, often with a dimpled surface | General cleaning, automotive, and household use | Pros: Versatile and easy to store. Cons: May not be as durable as other types. |

| Eco-Friendly Synthetic Chamois | Made from recycled materials, biodegradable options | Green cleaning services, eco-conscious markets | Pros: Sustainable choice; appealing to eco-friendly brands. Cons: May have higher upfront costs. |

What Are the Characteristics of Perforated Synthetic Microfiber Chamois?

Perforated synthetic microfiber chamois are engineered for superior absorbency, utilizing evenly spaced perforations that enhance liquid retention. Ideal for automotive detailing and industrial cleaning, these chamois are lightweight and machine washable, making them a practical choice for businesses requiring frequent use. Buyers should consider their drying efficiency and ease of maintenance, but be cautious about potential tearing during intensive tasks.

How Does the Jumbo Synthetic Chamois Stand Out?

The jumbo synthetic chamois is designed to cover larger surfaces, making it particularly beneficial for car washes and marine applications. With dimensions that exceed standard sizes, it offers a time-saving solution for drying vehicles and other large items. While its size provides exceptional drying capabilities, buyers should assess whether it aligns with their operational scale, as it may be less convenient for smaller jobs.

What Are the Benefits of PVA Synthetic Chamois?

PVA (Polyvinyl Alcohol) chamois are known for their soft texture and non-abrasive quality, making them suitable for professional detailing and household cleaning. They feature dual surfaces—one smooth and one dimpled—allowing users to select the best option for their specific needs. However, these chamois require proper rinsing before first use and careful maintenance to ensure longevity, which should be factored into purchasing decisions.

Why Choose Non-Woven Synthetic Chamois?

Non-woven synthetic chamois offer flexibility and lightweight convenience, making them ideal for general cleaning tasks in both automotive and household settings. Their dimpled surfaces enhance absorption while remaining easy to store. However, buyers should be aware that these chamois may not match the durability of other types, which could affect long-term cost efficiency.

What Are the Advantages of Eco-Friendly Synthetic Chamois?

Eco-friendly synthetic chamois made from recycled materials provide a sustainable alternative for businesses focused on environmental responsibility. These options appeal to green cleaning services and eco-conscious markets, offering biodegradability without sacrificing performance. While they may come at a higher upfront cost, the long-term benefits of aligning with sustainable practices can enhance brand reputation and customer loyalty.

Key Industrial Applications of synthetic shammy leather

| Industry/Sector | Specific Application of synthetic shammy leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Автомобили | Vehicle drying and detailing tools | Enhances efficiency in car washes and detailing services | Look for high absorbency, durability, and machine washability. |

| Marine | Drying and maintaining boats and watercraft | Protects surfaces from water spots and corrosion | Ensure the material is resistant to mold and mildew. |

| Household Cleaning | Multi-surface cleaning and drying solutions | Reduces time and labor in cleaning tasks | Prioritize non-abrasive properties and ease of maintenance. |

| Sports and Recreation | Equipment drying and maintenance | Extends the lifespan of gear and enhances performance | Seek lightweight options that are easy to transport. |

| Hospitality | Cleaning and drying linens, furniture, and surfaces | Ensures a pristine appearance and hygiene in establishments | Consider eco-friendly materials for sustainability. |

How is Synthetic Shammy Leather Used in the Automotive Industry?

In the automotive sector, synthetic shammy leather serves as an essential tool for vehicle drying and detailing. Its high absorbency allows for quick drying of cars, trucks, and SUVs, reducing the time spent on detailing services. This efficiency is critical for businesses that aim to provide fast turnaround times to customers. Buyers should prioritize products that are durable, machine washable, and resistant to wear, ensuring they can withstand frequent use without degrading.

What Role Does Synthetic Shammy Leather Play in Marine Applications?

For marine applications, synthetic shammy leather is invaluable in maintaining boats and watercraft. It effectively dries surfaces to prevent water spots and corrosion, which can be detrimental to the longevity of marine equipment. In regions with high humidity, such as parts of Africa and South America, the mold and mildew-resistant properties of synthetic shammy leather are particularly important. Buyers in this sector should focus on sourcing materials that are specifically designed for marine use to ensure maximum performance and durability.

How Can Synthetic Shammy Leather Improve Household Cleaning Efficiency?

In the realm of household cleaning, synthetic shammy leather is utilized for multi-surface cleaning and drying. Its versatility allows it to be used on various surfaces, from countertops to windows, making it an ideal solution for both residential and commercial cleaning services. The non-abrasive nature of synthetic shammy leather ensures that surfaces remain scratch-free while achieving a streak-free finish. Buyers should consider ease of maintenance and the product’s lifespan when sourcing for cleaning applications.

Why is Synthetic Shammy Leather Important for Sports and Recreation?

In the sports and recreation industry, synthetic shammy leather is used for drying and maintaining sports equipment, such as bicycles and surfboards. Its lightweight and absorbent qualities make it easy to carry and use, ensuring that gear is quickly dried after use, which extends its lifespan and enhances performance. International buyers should look for products that offer high absorbency and durability to meet the rigorous demands of outdoor activities.

How Does Synthetic Shammy Leather Benefit the Hospitality Sector?

Within the hospitality industry, synthetic shammy leather is employed for cleaning and drying linens, furniture, and various surfaces. Its ability to provide a clean and hygienic appearance is crucial for maintaining high standards in hotels and restaurants. As sustainability becomes increasingly important, buyers should consider eco-friendly options that align with their corporate social responsibility goals, ensuring that the sourcing of synthetic shammy leather supports environmental initiatives.

3 Common User Pain Points for ‘synthetic shammy leather’ & Their Solutions

Scenario 1: Difficulty in Ensuring Consistent Quality

The Problem: B2B buyers often face challenges when sourcing synthetic shammy leather, particularly regarding quality consistency. Variations in manufacturing processes can lead to discrepancies in absorbency, durability, and overall performance. Buyers may receive products that do not meet their specifications, leading to customer dissatisfaction and increased return rates. This inconsistency can be particularly problematic for businesses that rely on synthetic shammy leather for high-stakes applications, such as automotive detailing or professional cleaning services.

The Solution: To mitigate these quality concerns, buyers should establish strong relationships with reputable suppliers who prioritize quality control. Requesting samples from multiple suppliers can help assess the absorbency, texture, and durability of the materials. Additionally, buyers should inquire about the manufacturing standards and certifications of the products. Specifying clear quality benchmarks in purchase agreements can also ensure that the delivered products consistently meet the expected standards. Regular audits of suppliers and their manufacturing processes can further help maintain quality consistency.

Scenario 2: Challenges with Proper Care and Maintenance

The Problem: Many B2B buyers are unaware of the specific care requirements for synthetic shammy leather, leading to premature degradation of the product. Improper washing techniques, use of harsh chemicals, or failure to store the shammy correctly can result in reduced lifespan and effectiveness. This lack of knowledge can be particularly detrimental for businesses, as they may face increased costs associated with frequent replacements and lost productivity during downtimes.

The Solution: Buyers should educate themselves and their teams on the proper care and maintenance of synthetic shammy leather. Providing detailed care instructions—such as avoiding bleach and fabric softeners, washing on a gentle cycle, and air drying the shammy—can significantly extend its lifespan. Additionally, creating a maintenance schedule can help ensure that all team members are consistently following the recommended care practices. Investing in training sessions on how to use and care for synthetic shammy leather can also enhance overall effectiveness, ensuring that products remain in top condition for longer periods.

Scenario 3: Limited Versatility in Application

The Problem: B2B buyers may find that their synthetic shammy leather products are limited in versatility, restricting their use to specific applications. For example, some shammies may work well for automotive detailing but perform poorly on delicate surfaces like glass or furniture. This lack of adaptability can result in buyers needing to maintain multiple types of cleaning products, increasing inventory costs and complicating storage.

Illustrative image related to synthetic shammy leather

The Solution: To address this issue, buyers should seek out synthetic shammy leather products that are designed with versatility in mind. When sourcing, look for options that are explicitly marketed for multiple applications, such as automotive, household, and industrial cleaning. Products with dual textures, such as one side being smooth and the other dimpled, can cater to various surface needs without requiring multiple products. Moreover, providing clear usage guidelines for each application can help teams maximize the effectiveness of the shammy across different tasks. By choosing multifunctional products, buyers can streamline their operations and reduce the need for excessive inventory, ultimately saving costs and improving efficiency.

Strategic Material Selection Guide for synthetic shammy leather

When selecting materials for synthetic shammy leather, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Below is an analysis of three common materials used in synthetic shammy leather production, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyvinyl Alcohol (PVA) in Synthetic Shammy Leather?

Polyvinyl Alcohol (PVA) is a widely used material in synthetic shammy leather due to its high absorbency and durability. PVA can withstand high temperatures and has excellent resistance to mold and mildew, making it suitable for various drying applications. Its non-abrasive nature ensures that it does not scratch surfaces, which is particularly important for automotive and household uses.

Pros: PVA is highly absorbent, capable of soaking up several times its weight in water. It is also machine washable, making it easy to maintain.

Cons: However, PVA can be more expensive than other materials and may require specific handling to avoid damage during washing.

Impact on Application: PVA is ideal for drying vehicles, household items, and even pets, making it versatile across different markets.

Considerations for International Buyers: Buyers should ensure that PVA products comply with local regulations regarding chemical safety and environmental impact, particularly in regions with stringent standards like Germany.

How Does Microfiber Compare as a Material for Synthetic Shammy Leather?

Microfiber is another popular choice for synthetic shammy leather, known for its fine fibers that enhance absorbency and softness. It can effectively trap dirt and dust, making it suitable for cleaning and drying applications.

Pros: Microfiber is lightweight, highly durable, and resistant to wear and tear. It is also cost-effective, making it a popular choice for mass production.

Cons: On the downside, microfiber may not have the same level of absorbency as PVA and can retain odors if not cleaned properly.

Impact on Application: Microfiber is excellent for automotive detailing, household cleaning, and industrial applications where a gentle touch is required.

Considerations for International Buyers: Compliance with ASTM and ISO standards for textile products is essential, especially for buyers in Europe and the Middle East.

What Are the Benefits and Limitations of Synthetic Leather (PU) in Shammy Production?

Polyurethane (PU) synthetic leather is often used in the production of shammy leather for its aesthetic appeal and versatility. PU can mimic the look and feel of natural leather while providing water resistance.

Pros: PU is available in various textures and colors, allowing for customization. It is also generally more affordable than natural leather and offers good durability.

Illustrative image related to synthetic shammy leather

Cons: However, PU may not be as absorbent as PVA or microfiber, and its performance can degrade under extreme temperatures.

Impact on Application: PU is suitable for applications where appearance is essential, such as fashion accessories or decorative items.

Considerations for International Buyers: Buyers should verify that PU products meet local environmental regulations, particularly concerning VOC emissions.

Summary Table of Material Selection for Synthetic Shammy Leather

| Материал | Typical Use Case for synthetic shammy leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Alcohol (PVA) | Automotive drying, household cleaning | Highly absorbent and durable | More expensive, requires careful handling | Высокий |

| Микрофибра | Cleaning, automotive detailing | Lightweight, durable, cost-effective | May retain odors if not cleaned properly | Medium |

| Polyurethane (PU) | Fashion accessories, decorative items | Customizable appearance, affordable | Less absorbent, performance may degrade in extreme temperatures | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of different materials used in synthetic shammy leather. By understanding these factors, buyers can make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for synthetic shammy leather

What Are the Key Stages in the Manufacturing Process of Synthetic Shammy Leather?

The manufacturing of synthetic shammy leather involves several critical stages, each designed to ensure the final product meets high standards of quality and performance.

Illustrative image related to synthetic shammy leather

1. Material Preparation

The process begins with sourcing high-quality synthetic materials, predominantly polyvinyl alcohol (PVA) or microfiber blends. These materials are selected for their absorbent properties, durability, and softness. Before production, the raw materials undergo thorough testing to confirm they meet specified standards for chemical composition and performance. This stage is crucial for ensuring the final product has the desired characteristics such as absorbency, softness, and longevity.

2. Forming and Shaping

Once the materials are prepared, they are cut and shaped into the desired dimensions. This can involve various techniques, such as die-cutting or laser-cutting, to achieve precise sizes and shapes. For products like perforated synthetic shammy leather, additional processes include the creation of perforations, which enhance absorbency and drying efficiency. This stage often utilizes advanced machinery that allows for high precision and minimizes waste.

3. Assembly

After shaping, the synthetic materials are assembled into the final product. This may involve techniques such as stitching or bonding, depending on the design requirements. For instance, some products may have edgeless designs that require specific bonding techniques to ensure durability and prevent fraying. The assembly process is critical as it affects both the aesthetic and functional qualities of the shammy leather.

4. Finishing

The finishing stage includes treatments that enhance the product’s performance, such as applying anti-microbial coatings to prevent mold and mildew growth. Additionally, products may undergo a quality inspection to ensure they meet the required specifications. This stage often includes testing for texture, absorbency, and durability, ensuring that the final shammy leather is not only visually appealing but also functional.

Illustrative image related to synthetic shammy leather

What Quality Assurance Measures Are Essential for Synthetic Shammy Leather?

Quality assurance is integral to the manufacturing process of synthetic shammy leather, ensuring products meet international standards and customer expectations.

Relevant International Standards for Quality Assurance

B2B buyers should be aware of key international standards that govern the quality of synthetic shammy leather. ISO 9001 is a widely recognized quality management standard that ensures organizations consistently meet customer and regulatory requirements. Compliance with this standard indicates a commitment to quality and continuous improvement.

Additionally, specific industry certifications such as CE (Conformité Européenne) for products marketed in Europe and API (American Petroleum Institute) for products used in industrial applications may also be relevant. These certifications can provide further assurance of product quality and safety.

What Are the Checkpoints in Quality Control?

Quality control (QC) is structured through various checkpoints during the manufacturing process, including:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. IQC ensures that only materials meeting predetermined standards enter the production process.

-

In-Process Quality Control (IPQC): Throughout manufacturing, various inspections are conducted to monitor the production process. This may include checking for consistency in material properties and adherence to specifications at each stage of production.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure they meet all quality and performance standards. This stage often involves rigorous testing of absorbency, durability, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital to ensure product reliability.

Conducting Audits and Inspections

Buyers can conduct on-site audits to evaluate a supplier’s manufacturing processes and quality control measures. This hands-on approach allows buyers to assess compliance with international standards and ensure that best practices are being followed. Regular audits can also help build a strong partnership based on transparency and trust.

Requesting Quality Control Reports

Suppliers should provide comprehensive QC reports detailing the results of various inspections and tests conducted during the manufacturing process. These reports can offer insights into the consistency of product quality and any corrective actions taken to address issues.

Engaging Third-Party Inspectors

For buyers who may not have the capacity to conduct in-house audits, engaging third-party inspection services can be an effective alternative. These independent organizations can perform thorough evaluations of the supplier’s facilities, processes, and products, providing an unbiased assessment of quality.

Illustrative image related to synthetic shammy leather

What Are the Nuances in Quality Control for International B2B Buyers?

B2B buyers operating in different regions must be aware of specific nuances that may affect quality control practices. For example, regulatory requirements may vary significantly between countries, influencing the types of certifications needed for import/export.

Moreover, cultural differences can impact supplier communication and expectations regarding quality. Establishing clear communication channels and understanding local practices can help mitigate misunderstandings and ensure that quality standards are consistently met.

In summary, the manufacturing processes and quality assurance measures for synthetic shammy leather are complex yet essential for delivering high-quality products. By understanding these processes and engaging in proactive quality verification, B2B buyers can make informed purchasing decisions that align with their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic shammy leather’

This guide provides a step-by-step checklist for B2B buyers looking to procure synthetic shammy leather. With the increasing demand for high-quality synthetic materials in various industries, it is essential to approach sourcing with a strategic mindset. This checklist will help you navigate the process efficiently, ensuring you select the best products and suppliers.

Illustrative image related to synthetic shammy leather

Step 1: Define Your Technical Specifications

Clearly outline your requirements. Before reaching out to suppliers, establish the specific properties you need in synthetic shammy leather, such as thickness, texture, absorbency, and durability. This clarity will help you communicate effectively with potential suppliers and ensure that the products you receive meet your expectations.

- Consider intended use: Will the material be used for automotive applications, cleaning products, or other purposes?

- Check industry standards: Research common specifications in your industry to ensure compliance.

Step 2: Research Potential Suppliers

Identify reputable suppliers. Conduct thorough research to compile a list of potential suppliers. Look for companies with a proven track record in manufacturing synthetic materials, especially those that specialize in shammy leather.

- Use industry directories: Resources like trade associations or online marketplaces can help you discover reliable suppliers.

- Leverage reviews and testimonials: Check for feedback from other B2B buyers to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify supplier credentials. It’s crucial to ensure that your potential suppliers hold relevant certifications that demonstrate their commitment to quality and sustainability. Look for ISO certifications or compliance with environmental standards.

- Ask for documentation: Request copies of certifications and quality assurance processes.

- Assess their production practices: Understanding their manufacturing methods can provide insight into the quality and sustainability of the materials.

Step 4: Request Samples for Testing

Obtain product samples. Before making a bulk order, request samples of the synthetic shammy leather from your shortlisted suppliers. This step allows you to evaluate the material’s quality, texture, and performance in real-world applications.

Illustrative image related to synthetic shammy leather

- Test for absorbency and durability: Conduct tests to see how well the material performs under typical usage conditions.

- Compare across suppliers: Assess samples side by side to make an informed decision.

Step 5: Negotiate Terms and Pricing

Engage in discussions about pricing and terms. Once you’ve selected a supplier, initiate negotiations on pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms that benefit both parties.

- Understand market pricing: Research industry pricing standards to ensure you’re negotiating from a knowledgeable position.

- Discuss bulk order discounts: If planning for large orders, inquire about potential discounts or incentives.

Step 6: Assess Logistics and Delivery Options

Evaluate shipping and delivery logistics. Discuss shipping terms, lead times, and delivery methods with your supplier. Understanding logistics will help you plan for inventory needs and manage supply chain efficiency.

- Inquire about shipping costs: Factor these into your total cost analysis.

- Check for tracking and support: Ensure the supplier provides tracking for shipments and is available for support during the delivery process.

Step 7: Establish a Long-Term Relationship

Build a partnership with your supplier. Once you’ve successfully sourced synthetic shammy leather, consider establishing a long-term relationship with the supplier. This can lead to better pricing, priority service, and collaborative innovations in future projects.

- Communicate regularly: Maintain open lines of communication to address any issues or changes in requirements.

- Provide feedback: Share your experiences to help the supplier improve their offerings and service.

By following this checklist, B2B buyers can streamline their sourcing process for synthetic shammy leather and ensure they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for synthetic shammy leather Sourcing

What Are the Key Cost Components in Sourcing Synthetic Shammy Leather?

When sourcing synthetic shammy leather, understanding the cost structure is essential for effective budgeting and price negotiations. The primary cost components include:

Illustrative image related to synthetic shammy leather

-

Materials: The core ingredient in synthetic shammy leather is often a blend of microfiber or PVA (Polyvinyl Alcohol). The quality and type of materials directly affect the price. Higher-grade materials offer better absorbency and durability, which can justify a higher cost.

-

Labor: Labor costs can vary significantly based on the region of production. Countries with lower labor costs may provide a competitive edge, but this could also influence the quality of craftsmanship. It’s important to assess labor conditions and skill levels in the manufacturing country.

-

Manufacturing Overhead: This includes costs related to utilities, factory rent, and maintenance. Efficient manufacturing processes can lower these overheads, contributing to a more competitive pricing structure.

-

Tooling: Initial tooling costs can be substantial, especially if custom designs or specifications are requested. These costs are typically amortized over larger production runs, making it critical to consider the volume of your order.

-

Quality Control (QC): Ensuring the product meets specific quality standards incurs additional costs. Rigorous QC processes are vital, particularly for international shipments, where compliance with various regulations is mandatory.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and Incoterms. Understanding these factors is crucial for estimating total costs accurately.

-

Margin: Suppliers will typically include a profit margin that varies based on market competition and perceived value. This margin can be negotiated, especially for larger orders or long-term contracts.

How Do Price Influencers Affect the Cost of Synthetic Shammy Leather?

Several factors can influence the pricing of synthetic shammy leather:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for businesses anticipating high demand.

-

Specifications and Customization: Custom designs or specialized features (e.g., unique dimensions, branding, or packaging) can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Premium materials and certifications (e.g., eco-friendly or hypoallergenic) typically command higher prices. Buyers should consider whether these attributes align with their target market’s preferences.

-

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers may offer higher quality and more consistent products, justifying a premium price.

-

Incoterms: The chosen Incoterms can significantly affect logistics costs. Understanding who bears the risk and cost during transportation can help buyers make more informed decisions.

What Are Some Tips for Negotiating Prices for Synthetic Shammy Leather?

Effective negotiation strategies can lead to significant savings:

-

Understand Total Cost of Ownership (TCO): Assess not just the purchase price but also the long-term costs associated with maintenance, durability, and replacement. A higher upfront cost may be justified by lower long-term expenses.

-

Leverage Volume Discounts: When placing larger orders, use the opportunity to negotiate better rates. Suppliers are often willing to reduce prices for significant commitments.

-

Request Samples: Before finalizing an order, request samples to evaluate quality. This helps in making informed decisions and can serve as leverage during negotiations.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures influenced by local economies, tariffs, and shipping costs. Understanding these nuances is particularly important for buyers from Africa, South America, the Middle East, and Europe.

-

Build Relationships: Developing long-term relationships with suppliers can lead to better pricing and terms. Trust can facilitate negotiations and yield more favorable conditions over time.

Заключение

While pricing for synthetic shammy leather is influenced by a multitude of factors, a comprehensive understanding of cost components and price influencers can empower international B2B buyers to make informed purchasing decisions. Always remember that prices are indicative and subject to change based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing synthetic shammy leather With Other Solutions

Exploring Alternatives to Synthetic Shammy Leather: A Comprehensive Comparison

In the quest for effective drying solutions, synthetic shammy leather has emerged as a popular choice. However, it is essential for B2B buyers to consider viable alternatives that may better suit their specific needs. This analysis compares synthetic shammy leather with two notable alternatives: traditional cotton towels and perforated synthetic microfiber chamois. Each option has unique characteristics that can affect performance, cost, ease of implementation, and maintenance.

| Comparison Aspect | Synthetic Shammy Leather | Traditional Cotton Towels | Perforated Synthetic Microfiber Chamois |

|---|---|---|---|

| Performance | Highly absorbent, dries quickly, minimizes streaks | Good absorbency, but can leave lint and streaks | Excellent absorbency, superior drying speed, streak-free finish |

| Cost | Moderate price point | Generally lower cost | Moderate price point |

| Ease of Implementation | Ready to use; no special preparation needed | Widely available, easy to use | Requires initial rinsing for optimal performance |

| Maintenance | Machine washable, durable | Machine washable, prone to wear and tear | Machine washable, quick to clean and dry |

| Best Use Case | Ideal for automotive and delicate surfaces | Suitable for general household cleaning | Excellent for automotive detailing and multi-surface drying |

What Are the Advantages and Disadvantages of Traditional Cotton Towels?

Traditional cotton towels are a ubiquitous choice in households and businesses alike. They offer decent absorbency and are readily available, making them an accessible option for many. However, they often fall short in terms of drying speed and may leave lint or streaks on surfaces. Their lifespan can be shorter than synthetic options, especially when subjected to frequent washing, leading to higher long-term replacement costs. For general cleaning tasks, they may suffice, but for specialized applications like automotive detailing, they may not be the best fit.

How Does Perforated Synthetic Microfiber Chamois Compare?

Perforated synthetic microfiber chamois, such as the Holey Shammy, provide an innovative solution that excels in both absorbency and drying efficiency. They are designed with evenly placed perforations, allowing for rapid moisture removal and a streak-free finish. Their versatility makes them suitable for a range of applications, from drying vehicles to cleaning delicate surfaces. While they may require an initial rinse before use, their ease of cleaning afterward makes them a favorite among professionals. The only downside might be their higher upfront cost compared to traditional towels, but the performance benefits often justify this investment.

Illustrative image related to synthetic shammy leather

Conclusion: How to Choose the Right Drying Solution for Your Business Needs

When selecting a drying solution, B2B buyers must weigh the specific needs of their operations against the characteristics of each option. Synthetic shammy leather provides a balance of performance and durability, making it ideal for applications requiring meticulous care. Traditional cotton towels are cost-effective but may not meet the demands of high-performance tasks. In contrast, perforated synthetic microfiber chamois offer superior absorbency and efficiency, which can enhance productivity in professional settings. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for synthetic shammy leather

What Are the Key Technical Properties of Synthetic Shammy Leather?

When sourcing synthetic shammy leather, understanding its technical specifications is crucial for making informed purchasing decisions. Here are several critical properties to consider:

1. Material Composition

Synthetic shammy leather is typically made from high-quality materials like Polyvinyl Alcohol (PVA) or microfiber blends. The choice of material affects durability, absorbency, and usability across various applications. PVA, for instance, is known for its superior absorption capabilities, making it ideal for drying tasks. Buyers should assess the composition to ensure the product meets their specific needs.

2. Weight and Thickness

The weight, often measured in grams per square meter (GSM), indicates the density and absorbency of the shammy leather. A higher GSM, such as 300 GSM, suggests a thicker and more absorbent product, suitable for heavy-duty applications. Understanding weight and thickness helps buyers gauge the product’s effectiveness in their intended use, whether for automotive detailing or household cleaning.

3. Size and Dimensions

Synthetic shammy leather comes in various sizes, with common dimensions ranging from 15″x25″ to jumbo sizes exceeding 5 square feet. The size affects the coverage area during drying or cleaning tasks. Buyers should choose dimensions that align with their operational needs, ensuring efficiency in both commercial and industrial applications.

4. Edge Type

The edge type of synthetic shammy leather can be either edgeless or hemmed. Edgeless designs minimize the risk of scratching surfaces, making them preferable for delicate finishes like automotive paint. Selecting the right edge type is vital for buyers who prioritize surface protection in their operations.

5. Machine Washability

Many synthetic shammy leathers are machine washable, allowing for easy maintenance and prolonged use. This feature is particularly important for businesses that require frequent cleaning and reuse of their drying tools. Buyers should confirm the care instructions to ensure the product can withstand regular washing without degradation.

Which Trade Terminology Should B2B Buyers Understand in Synthetic Shammy Leather Sourcing?

Navigating the B2B landscape requires familiarity with specific trade terms. Here are some essential jargon relevant to synthetic shammy leather:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of synthetic shammy leather, OEM suppliers may offer customized products tailored to specific industry needs. Understanding OEM relationships can enhance procurement strategies for businesses looking for bespoke solutions.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory management and cash flow. Knowing the MOQ helps businesses plan their purchasing strategy, ensuring they meet supplier requirements without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should utilize RFQs to obtain competitive quotes for synthetic shammy leather. This process aids in evaluating suppliers and ensuring the best value for procurement.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined international trade terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in shipping arrangements. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and delivery timelines, particularly when sourcing products from international suppliers.

5. Lead Time

Lead time refers to the period between placing an order and receiving it. For synthetic shammy leather, understanding lead times is essential for inventory planning and ensuring timely delivery to meet customer demands. Buyers should inquire about lead times when negotiating terms with suppliers.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing synthetic shammy leather, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the synthetic shammy leather Sector

What Are the Current Market Dynamics and Key Trends in the Synthetic Shammy Leather Sector?

The synthetic shammy leather market is experiencing robust growth, driven by increasing demand across various sectors, including automotive, cleaning, and fashion. The proliferation of eco-friendly products is reshaping consumer preferences, with businesses seeking high-quality, durable alternatives to traditional materials. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are focusing on sourcing synthetic chamois that not only offer superior absorbency but also reduce environmental impact. Emerging trends include the adoption of advanced manufacturing technologies that improve product quality and reduce costs, making synthetic shammy leather more accessible.

Another key trend is the rise of e-commerce platforms that facilitate global sourcing, enabling buyers from diverse regions to connect with manufacturers and suppliers. The increased focus on customization is also noteworthy, as businesses look for products tailored to specific applications, such as automotive detailing or industrial cleaning. Furthermore, innovation in materials, including the development of advanced synthetic fibers that enhance performance, is likely to create new opportunities for B2B buyers.

How Is Sustainability Shaping the Sourcing of Synthetic Shammy Leather?

Sustainability is becoming a critical factor in the sourcing of synthetic shammy leather. With growing awareness of environmental issues, buyers are increasingly prioritizing products made from sustainable materials that minimize ecological footprints. The environmental impact of traditional leather production, including water usage and chemical treatments, is prompting many companies to seek synthetic alternatives that provide similar performance without the associated harm.

Ethical sourcing practices are gaining traction, with B2B buyers demanding transparency in supply chains. Certifications such as OEKO-TEX® and Global Recycled Standard (GRS) are becoming essential as they assure buyers of the sustainability and safety of materials used in synthetic chamois products. Moreover, the incorporation of recycled materials into synthetic shammy leather production is a trend that aligns with circular economy principles, appealing to environmentally conscious buyers. By prioritizing sustainable sourcing, businesses not only enhance their brand reputation but also contribute to a more responsible industry.

What Is the Evolution and History of Synthetic Shammy Leather in the B2B Context?

The evolution of synthetic shammy leather dates back to the mid-20th century when manufacturers sought alternatives to traditional animal hides. The introduction of synthetic materials like PVA (Polyvinyl Alcohol) marked a significant turning point, offering a more absorbent and durable option for various applications. Over the decades, advancements in textile technology have refined the production processes, resulting in high-quality products that rival their natural counterparts.

Initially, synthetic chamois were primarily used in automotive detailing and cleaning applications due to their superior absorbency and non-abrasive properties. However, as the market has expanded, these materials are now finding applications in fashion and home goods, further diversifying the sector. The continuous improvement in production techniques and material science suggests a bright future for synthetic shammy leather, making it an attractive option for B2B buyers looking for innovative and sustainable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of synthetic shammy leather

-

How do I choose the right synthetic shammy leather for my business needs?

Choosing the right synthetic shammy leather involves assessing your specific application requirements. Consider factors such as absorbency, durability, and size. For automotive use, a high GSM (grams per square meter) fabric is ideal for better absorption and longevity. Evaluate product specifications and samples from suppliers to ensure the material meets your quality standards. Additionally, assess versatility for other applications, like household cleaning or industrial use, to maximize your investment. -

What is the best synthetic shammy leather for automotive detailing?

For automotive detailing, look for synthetic shammy leather made from high-quality microfiber or PVA (Polyvinyl Alcohol). These materials provide superior absorbency and are gentle on surfaces, reducing the risk of scratches. A product with a larger size, like those measuring around 19.6 x 37.5 inches, can expedite the drying process. Ensure that the shammy is machine washable for easy maintenance, which is essential for businesses focusing on efficiency and cleanliness. -

What are the minimum order quantities (MOQs) for synthetic shammy leather?

Minimum order quantities for synthetic shammy leather can vary widely among suppliers, typically ranging from 100 to 1,000 pieces. Factors influencing MOQs include the supplier’s production capacity, customization options, and shipping logistics. When sourcing internationally, it’s essential to clarify MOQs upfront and consider the potential for bulk discounts. Suppliers may also offer flexibility for first-time buyers or long-term partnerships, so negotiating terms can be beneficial. -

How do I vet suppliers for synthetic shammy leather?

To vet suppliers effectively, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from other B2B buyers. Request samples to assess product quality firsthand and inquire about their manufacturing processes and materials used. Additionally, check for certifications, such as ISO or specific industry standards, which ensure compliance with quality and safety regulations. Establishing clear communication and responsiveness during initial interactions can also indicate the supplier’s reliability. -

What payment terms are typically available when sourcing synthetic shammy leather?

Payment terms for synthetic shammy leather can vary based on supplier policies and the nature of the transaction. Common options include payment in advance, net 30/60/90 days, and letter of credit. Negotiating favorable terms is crucial, especially for larger orders, to ensure cash flow management. It’s also important to understand any potential fees associated with international transactions, such as currency exchange rates or banking charges, to avoid unexpected costs. -

What quality assurance processes should I expect from suppliers?

Quality assurance processes vary by supplier but should include rigorous testing of materials for durability, absorbency, and performance. Look for suppliers who conduct inspections at different stages of production and offer warranties or guarantees on their products. Request documentation on quality control measures and certifications that validate their manufacturing standards. Engaging in regular communication about your quality expectations can also facilitate better outcomes and accountability. -

How can I ensure timely logistics and delivery for international orders?

To ensure timely logistics and delivery, work closely with suppliers who have established shipping protocols and partnerships with reliable freight forwarders. Discuss shipping timelines during negotiations and consider using Incoterms (International Commercial Terms) to clarify responsibilities for transportation costs and risks. Monitoring shipment progress through tracking systems can help mitigate delays. Additionally, factor in customs clearance times and local regulations in your planning to avoid unexpected hold-ups. -

What customization options are available for synthetic shammy leather products?

Customization options for synthetic shammy leather can include size, color, thickness, and branding elements such as logos or packaging. Many suppliers offer tailored solutions to meet specific business needs, so it’s beneficial to inquire about available options during initial discussions. Providing detailed specifications and discussing your target market can help suppliers suggest suitable customizations. Be sure to request prototypes before finalizing large orders to ensure the product aligns with your expectations.

Top 2 Synthetic Shammy Leather Manufacturers & Suppliers List

1. Chamois – Premium Leather

Domain: chamois.com

Registered: 1996 (29 years)

Введение: Chamois leather is a unique and natural product made from selected sheepskins that are 100% cod oil tanned, providing a luxurious, golden, soft finish. It can absorb six times its weight in water and is known for its quality, high performance, and durability. The leather can be cut into regular shapes or left as whole skins, individually sized and graded to meet market requirements. The Pittards D…

2. Reddit – The Absorber Synthetic Shami

Domain: reddit.com

Registered: 2005 (20 years)

Введение: The Absorber is a synthetic shami that is ten years old and has outlived two of the three cars it was purchased to dry.

Strategic Sourcing Conclusion and Outlook for synthetic shammy leather

In conclusion, strategic sourcing of synthetic shammy leather presents a unique opportunity for B2B buyers to enhance their product offerings while ensuring quality and efficiency. The versatility of synthetic shammies—ranging from automotive applications to household uses—demonstrates their broad market appeal. By partnering with reliable manufacturers, buyers can leverage superior absorbency, durability, and ease of maintenance, ultimately leading to higher customer satisfaction and repeat business.

As markets across Africa, South America, the Middle East, and Europe continue to evolve, the demand for innovative and sustainable materials will only grow. Investing in high-quality synthetic shammy leather not only aligns with contemporary consumer preferences but also positions businesses to capitalize on emerging trends in the automotive and cleaning sectors.

Illustrative image related to synthetic shammy leather

To stay competitive, international buyers should prioritize sourcing strategies that emphasize quality, cost-effectiveness, and adaptability. Engage with trusted suppliers to explore the latest advancements in synthetic materials and refine your product lineup. Embrace this opportunity to lead the charge in your market, meeting the growing demand for effective and eco-friendly solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.