Catalog

Material Insight: Suede Lining

B2B Product Guide: Premium Suede Lining Solutions

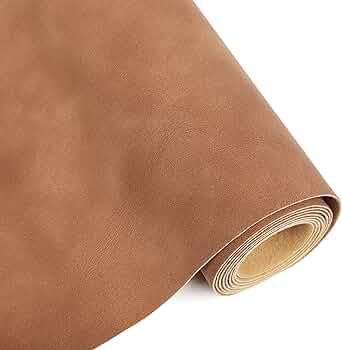

For discerning manufacturers of luxury handbags, footwear, apparel, and accessories, the interior finish defines the unspoken quality promise to the end consumer. Suede lining delivers an immediate tactile impression of sophistication and care. However, traditional genuine suede presents significant challenges for scalable, consistent, and responsible production. This is where high-performance faux suede lining emerges not just as an alternative, but as the superior strategic choice for forward-thinking brands.

Why Faux Leather is the Optimal Choice for Suede Lining Applications:

- Consistent Quality & Performance: Genuine suede suffers from natural hide variations, grain inconsistencies, and susceptibility to water spotting or staining. Faux suede lining offers uniform texture, color, and thickness roll-to-roll, ensuring predictable manufacturing and flawless end-product presentation every time.

- Enhanced Durability & Functionality: Unlike genuine suede, which can mat, crush, or degrade with moisture exposure, advanced faux suede linings are engineered for resilience. They resist abrasion, repel light moisture, and maintain their plush aesthetic through repeated use and handling – critical for high-value goods.

- Sustainable Production & Compliance: Genuine suede relies on resource-intensive tanning processes (often chrome-based) with significant water consumption and chemical waste. Eco-conscious faux suede linings eliminate these impacts, utilizing water-based PU systems, recycled content options (e.g., recycled PET backing), and achieving certifications like OEKO-TEX® STANDARD 100, ensuring safer products and simplified supply chain compliance.

- Cost Efficiency & Scalability: Volatile raw material costs and limited availability of premium genuine suede hides create budget and production uncertainties. Faux suede provides stable pricing, reliable large-scale availability, and reduced waste during cutting – optimizing your production economics without sacrificing perceived luxury.

- Design Freedom & Innovation: Faux suede technology allows for precise color matching, custom textures (ultra-soft napped finishes, subtle embossing), and integration of functional properties (anti-microbial, static control) impossible with natural materials, empowering unique brand differentiation.

Introducing WINIW: Your Trusted Partner in Advanced Synthetic Leather

For over 20 years, WINIW has been at the forefront of developing premium, sustainable synthetic leather solutions for global B2B clients. We specialize in engineering materials that don’t just mimic nature, but improve upon it – combining uncompromising aesthetics with performance, responsibility, and manufacturing efficiency. Our R&D-driven approach, vertically integrated production, and deep understanding of luxury segment demands enable us to deliver WINIW Suede Lining collections that set the industry benchmark. Partner with WINIW to transform your product interiors into a tangible expression of modern luxury, built on a foundation of innovation and environmental stewardship. Elevate the unspoken detail.

Technical Performance & Standards

WINIW Suede Lining – B2B Product Technical Guide

WINIW’s synthetic suede lining is engineered specifically for B2B manufacturers seeking a high-performance, sustainable, and cost-effective interior material. Designed to meet the rigorous demands of automotive, footwear, electronics, and luxury goods industries, WINIW’s suede lining combines advanced microfiber technology with eco-conscious manufacturing. This results in a premium textile alternative that outperforms traditional materials in durability, customization, and compliance.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s suede lining reduces overall material and processing costs. Its consistent quality minimizes waste during cutting and sewing, while its high yield per roll optimizes production efficiency. The material requires no additional coatings or treatments, lowering downstream processing expenses. -

Enhanced Durability

Constructed with high-tenacity polyester and polyurethane matrix, WINIW’s lining offers excellent abrasion resistance (tested up to 50,000+ double rubs), tear strength, and dimensional stability. It maintains integrity under repeated stress and adverse environmental conditions, including humidity and UV exposure. -

Customizable Color Options

Available in a full spectrum of standard and custom colors, WINIW supports Pantone Matching System (PMS) and customer-specific dye formulations. Color consistency is ensured across large production batches, supporting brand integrity and design flexibility. -

REACH-Compliant Chemistry

WINIW’s suede lining is manufactured without SVHCs (Substances of Very High Concern) and complies with EU REACH regulations. All chemical inputs are traceable and tested, ensuring safe handling and end-use in consumer products. -

ISO 9001-Certified Manufacturing

Produced in ISO 9001-certified facilities, WINIW’s quality management system ensures consistent product specifications, rigorous in-process inspections, and full batch traceability. This certification guarantees reliability and compliance for global supply chains.

Technical Specifications

| Property | Технические характеристики |

|---|---|

| Base Material | Split microfiber polyester + PU |

| Weight Range | 120 – 220 g/m² |

| Thickness | 0.8 – 1.6 mm |

| Abrasion Resistance | >50,000 double rubs (Martindale) |

| Color Fastness (Light) | Grade 4–5 (ISO 105-B02) |

| Color Fastness (Rubbing) | Dry: Grade 5, Wet: Grade 4–5 |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO 9001:2015 |

| Customization | Width up to 150 cm, custom colors, finishes |

| Environmental Profile | Low-VOC, recyclable packaging, reduced water usage in dyeing |

WINIW’s suede lining delivers a balanced performance profile ideal for high-volume, quality-driven industries. With scalable production capacity and responsive technical support, WINIW enables OEMs and designers to achieve premium aesthetics without compromising cost-efficiency or regulatory compliance.

Why Choose Synthetic over Real Leather

B2B Product Guide: Suede Lining (WINIW Microsuede) vs. Real Leather

Selecting the optimal lining material is critical for balancing performance, cost, and sustainability in premium goods manufacturing. As a leader in innovative synthetic leathers, WINIW provides this objective comparison to support informed material sourcing decisions. Understanding the distinct properties of WINIW Microsuede (our premium synthetic suede lining) versus traditional real leather is essential for optimizing product value and aligning with modern sustainability goals.

WINIW Microsuede delivers the luxurious hand feel and refined aesthetics of genuine suede while engineered for superior consistency and responsible production. Real leather, while possessing inherent natural qualities, presents significant variability and environmental considerations that impact supply chain reliability and lifecycle costs. The following comparison focuses on three core factors vital to B2B procurement:

- Cost Predictability: WINIW Microsuede offers stable pricing unaffected by hide grade fluctuations or tanning market volatility, enabling accurate long-term budgeting.

- Performance Consistency: Engineered for uniform thickness, color, and texture across all production runs, minimizing waste and rework during manufacturing.

- Sustainable Sourcing: Eliminates reliance on animal agriculture and utilizes processes with drastically reduced water consumption and chemical load compared to conventional leather tanning.

The table below details key comparative metrics:

| Attribute | Suede Lining (WINIW Microsuede) | Real Leather (Suede Finish) |

|---|---|---|

| Cost | 20-30% lower initial material cost. Highly predictable pricing. Lower processing costs (no conditioning, consistent cut yield). | Higher initial cost due to hide grading, tanning, and finishing. Significant price volatility based on hide quality and market supply. Higher processing costs (conditioning, variable cut yield). |

| Долговечность | Excellent abrasion resistance. Highly resistant to stains, moisture, and fading. Uniform performance. No conditioning required. Consistent texture across entire production run. | Moderate abrasion resistance; prone to crushing and water spotting. Requires regular conditioning to maintain suppleness. Susceptible to staining and fading. Performance varies significantly by hide origin and grade. |

| Eco-Friendliness | Made with up to 37% recycled PET content. Water-based, low-VOC production. Near-zero water consumption in manufacturing. OEKO-TEX® STANDARD 100 certified. Fully traceable supply chain. | High water consumption (15,000+ liters per hide). Heavy use of chromium and other toxic chemicals in tanning. Significant greenhouse gas emissions from livestock. Non-recyclable end-of-life in most cases. Supply chain traceability often limited. |

For manufacturers prioritizing supply chain resilience, consistent product quality, and demonstrable progress toward ESG targets, WINIW Microsuede presents a compelling, high-performance alternative to real leather lining. Its engineered properties directly address common pain points in luxury goods production – cost overruns from material waste, quality inconsistencies, and the growing imperative for verifiable sustainable materials. WINIW enables brands to deliver exceptional consumer experience while meeting rigorous environmental and ethical standards demanded by today’s conscious market. Consider your operational priorities and sustainability commitments when selecting the lining solution that best supports your brand’s future.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative and sustainable materials for global B2B clients. With a strong foundation in research, quality, and scale, WINIW delivers premium synthetic leather solutions tailored to diverse industry needs.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters. This large-scale production base integrates advanced automation and eco-friendly processes to ensure consistent output, high efficiency, and environmental responsibility.

Key strengths of WINIW’s factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and sustainable development

- Continuous investment in new technologies to meet evolving market demands, including water-based and recycled raw materials

- Strict quality control (QC) protocols implemented at every stage of production, from raw material inspection to final product testing

- Compliance with international standards such as REACH, RoHS, and OEKO-TEX® for product safety and environmental protection

WINIW’s products are exported globally, with a strong presence in Europe and the USA. Trusted by leading brands in furniture, automotive, fashion, and sports industries, WINIW maintains long-term partnerships through reliable supply, technical support, and customized material solutions.

The combination of scale, innovation, and quality positions WINIW as a preferred B2B partner for sustainable synthetic leather worldwide.

Contact Us for Samples

WINIW® Premium Synthetic Leather: Sustainable Performance for B2B Applications

WINIW® delivers high-performance, eco-conscious synthetic leather solutions engineered for durability, aesthetics, and responsible manufacturing. Our materials meet rigorous industrial standards while significantly reducing environmental impact, making us the preferred partner for forward-thinking brands in furniture, automotive, travel goods, and fashion accessories.

Core Advantages of WINIW® Synthetic Leather

- Superior Sustainability: Composed of 30-100% recycled polyester (including ocean-bound plastic) and plant-based polyurethane (bio-content up to 40%).

- Exceptional Durability: 50,000+ double rubs (Martindale), UV resistance (5,000+ hrs), and hydrolysis resistance for extended product lifecycles.

- Regulatory Compliance: OEKO-TEX® STANDARD 100 Class I, REACH SVHC compliant, and free from DMF, AZO dyes, and heavy metals.

- Design Flexibility: Custom thickness (0.6–1.2mm), widths (137–150cm), and textures (grain, nubuck, embossed) with rapid color matching (Pantone®).

- Resource Efficiency: 60% lower carbon footprint vs. traditional leather; manufactured in ISO 14001-certified facilities.

Technical Specifications Comparison

| Property | WINIW® Standard Eco | WINIW® Suede Lining | WINIW® Performance+ |

|---|---|---|---|

| Состав | 70% rPET / 30% PU | 100% rPET | 50% Bio-PU / 50% rPET |

| Thickness (mm) | 0.8 | 0.6 | 1.0 |

| Width (cm) | 140 | 137 | 150 |

| Abrasion Resistance | 50,000+ rubs | 30,000+ rubs | 100,000+ rubs |

| Eco-Certifications | GRS, OEKO-TEX® | GRS, OEKO-TEX® | GRS, OEKO-TEX®, USDA BioPreferred® |

| Primary Applications | Upholstery, Bags | Interior linings, Footwear | Automotive, High-wear furniture |

Why WINIW® Suede Lining?

Our ultra-soft, microfiber suede lining material solves critical challenges for premium product manufacturers:

– Weight Reduction: 25% lighter than conventional linings, enhancing portability in luggage and handbags.

– Moisture Management: Breathable structure wicks humidity, preventing odors in footwear and enclosed accessories.

– Waste Minimization: Seamless roll-to-roll production reduces cutting waste by up to 18% vs. woven fabrics.

– Luxury Feel: Consistent texture with no grain direction, eliminating fabric matching complexity during assembly.

– Circularity Ready: Fully recyclable via WINIW® Take-Back Program for closed-loop material recovery.

Sustainability Impact by the Numbers

- 1 sqm of WINIW® Suede Lining = 32 recycled PET bottles diverted from oceans

- Water Savings: 95% less water used vs. conventional suede production

- Carbon Reduction: 4.2 kg CO2e saved per linear meter vs. animal leather lining

Accelerate Your Sustainable Product Launch

WINIW® Suede Lining is engineered for brands committed to uncompromised quality and planet-positive innovation. Experience the tactile premium finish and operational efficiencies firsthand:

– Free physical samples available for qualified B2B partners (specify required width/thickness)

– Technical datasheets and eco-impact reports provided upon request

– Dedicated engineering support for seamless integration into your supply chain

Contact WINIW® Marketing for Suede Lining Solutions

→ Email: MKT88@MicrofiberLeather.com

→ Subject Line: “SUEDE LINING SAMPLE REQUEST – [Your Company Name]”

Free samples dispatched within 48 business hours for verified commercial projects.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.