Introduction: Navigating the Global Market for shammy cloth material

Navigating the global market for shammy cloth material presents a unique challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, such as Brazil and Saudi Arabia. The quest for high-quality, absorbent materials that meet diverse applications—from automotive care to textiles—can be daunting. This guide serves as a comprehensive resource, addressing critical factors such as types of shammy cloth, various applications, supplier vetting processes, and cost considerations.

In an ever-evolving marketplace, understanding the nuances of shammy cloth material is essential for making informed purchasing decisions. Buyers will gain insights into the differences between traditional and synthetic options, the fabric’s durability, and its practical uses across industries. Furthermore, we delve into the importance of sourcing reliable suppliers who adhere to quality standards, ensuring that businesses can maintain a competitive edge.

This guide empowers international B2B buyers by providing actionable insights and expert advice, enabling them to navigate the complexities of sourcing shammy cloth material effectively. Whether you are looking to enhance your product offerings or streamline your supply chain, this resource will equip you with the knowledge needed to make strategic decisions that drive success in the global market.

Table Of Contents

- Top 5 Shammy Cloth Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for shammy cloth material

- Understanding shammy cloth material Types and Variations

- Key Industrial Applications of shammy cloth material

- 3 Common User Pain Points for ‘shammy cloth material’ & Their Solutions

- Strategic Material Selection Guide for shammy cloth material

- In-depth Look: Manufacturing Processes and Quality Assurance for shammy cloth material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘shammy cloth material’

- Comprehensive Cost and Pricing Analysis for shammy cloth material Sourcing

- Alternatives Analysis: Comparing shammy cloth material With Other Solutions

- Essential Technical Properties and Trade Terminology for shammy cloth material

- Navigating Market Dynamics and Sourcing Trends in the shammy cloth material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shammy cloth material

- Strategic Sourcing Conclusion and Outlook for shammy cloth material

- Important Disclaimer & Terms of Use

Understanding shammy cloth material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Chamois | Made from animal hide; high absorbency | Automotive, luxury goods, apparel | Pros: Excellent absorbency, soft texture. Cons: Higher cost, ethical sourcing concerns. |

| Синтетическая замша | Made from microfiber; durable and lightweight | Cleaning, automotive, sports gear | Pros: Cost-effective, easy to maintain. Cons: May lack the luxury feel of natural options. |

| Cotton Chamois | Composed of cotton fibers; soft and breathable | Household cleaning, personal care | Pros: Eco-friendly, comfortable to use. Cons: Lower absorbency compared to synthetic options. |

| Suede Chamois | Soft, napped finish; luxurious feel | Fashion accessories, upholstery | Pros: Aesthetic appeal, soft texture. Cons: Requires careful maintenance to avoid damage. |

| Microfiber Chamois | Ultra-fine fibers; superior cleaning ability | Electronics, automotive, healthcare | Pros: High durability, excellent cleaning efficiency. Cons: Can be pricier than traditional options. |

What Are the Characteristics of Natural Chamois Cloth?

Natural chamois cloth is derived from the skin of the chamois animal, traditionally known for its exceptional absorbency and softness. This type of cloth is particularly favored in luxury automotive applications and high-end apparel due to its premium feel and performance. When considering a purchase, B2B buyers should evaluate the ethical sourcing of the hide and the potential for higher costs associated with natural materials.

How Does Synthetic Chamois Compare to Other Variants?

Synthetic chamois, commonly made from microfiber, offers a lightweight and durable alternative to natural chamois. It is widely used across various industries, including cleaning and automotive, due to its cost-effectiveness and ease of maintenance. Buyers should consider the long-term performance and lower initial investment, although they may sacrifice some of the luxury characteristics found in natural chamois.

Illustrative image related to shammy cloth material

Why Choose Cotton Chamois for Household Applications?

Cotton chamois is a popular choice for household cleaning and personal care products. Its breathable and soft nature makes it comfortable for users, while also being eco-friendly. However, B2B buyers should be aware that cotton chamois may not offer the same level of absorbency as synthetic options, making it less suitable for high-demand applications.

What Makes Suede Chamois Ideal for Fashion Accessories?

Suede chamois is characterized by its soft, napped finish, making it a luxurious option for fashion accessories and upholstery. While it offers an appealing aesthetic, it requires careful maintenance to prevent damage. Buyers should assess the potential for higher maintenance costs and the value it adds to their product lines when considering suede chamois.

How Does Microfiber Chamois Enhance Cleaning Efficiency?

Microfiber chamois is known for its ultra-fine fibers that provide superior cleaning capabilities, making it ideal for sensitive applications such as electronics and healthcare. Its durability and effectiveness make it a worthwhile investment for B2B buyers, although it may come at a higher price point compared to traditional cloths. Buyers should weigh the benefits of efficiency against the initial cost to determine the best fit for their needs.

Key Industrial Applications of shammy cloth material

| Industry/Sector | Specific Application of shammy cloth material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Автомобили | Vehicle detailing and cleaning | Efficient water absorption and scratch-free finish | Ensure high absorbency and softness; consider bulk sourcing options. |

| Hospitality | Cleaning and drying glassware and surfaces | Streak-free shine and reduced drying time | Look for durable, washable options; verify compliance with hygiene standards. |

| Manufacturing | Precision cleaning in electronics assembly | Non-abrasive, lint-free cleaning to prevent damage | Prioritize high-quality synthetic materials for reliability. |

| Sports and Fitness | Equipment maintenance and drying | Quick drying and maintenance of sports gear | Assess durability under heavy use; consider moisture-wicking properties. |

| Home Care | General cleaning and drying tasks | Versatile, reusable, and eco-friendly cleaning option | Evaluate for softness and absorbency; ensure compatibility with various surfaces. |

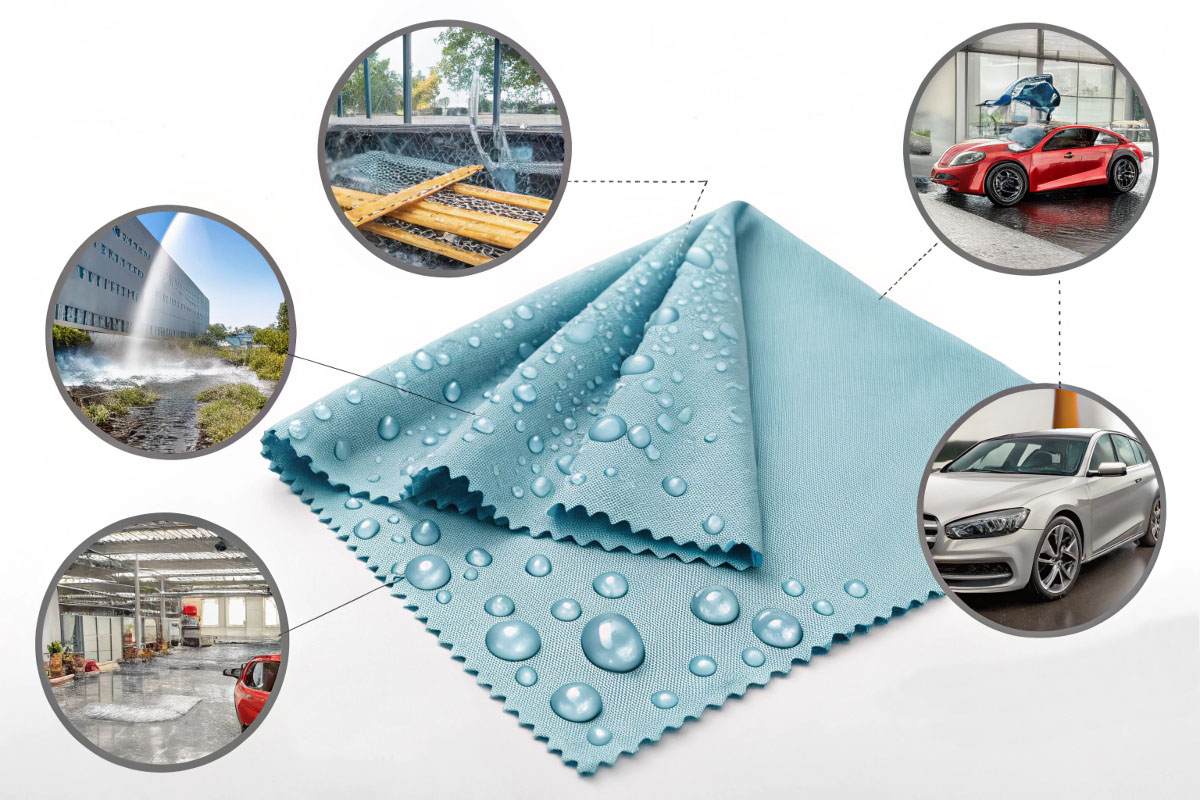

How is Shammy Cloth Material Used in the Automotive Industry?

In the automotive sector, shammy cloth material is extensively employed for vehicle detailing and cleaning. Its superior absorbency allows for efficient drying after washing, ensuring a streak-free finish that enhances the vehicle’s appearance. This application addresses the common issue of water spots and streaks that can detract from a car’s aesthetic. International buyers should focus on sourcing high-quality shammy cloth that offers both softness and durability, particularly for high-end vehicles where finish quality is paramount. Bulk purchasing options may provide cost savings and ensure a consistent supply.

Illustrative image related to shammy cloth material

Why is Shammy Cloth Essential in the Hospitality Sector?

Within the hospitality industry, shammy cloth is a preferred choice for cleaning and drying glassware, dishes, and surfaces. Its ability to deliver a streak-free shine significantly reduces the time staff spend on cleaning, enhancing operational efficiency. This is particularly beneficial in high-turnover settings such as restaurants and hotels. Buyers should ensure that the shammy cloth is durable enough to withstand frequent washing and adheres to hygiene standards, especially in regions with strict health regulations. Sourcing from reputable suppliers who prioritize quality will help maintain cleanliness and guest satisfaction.

What Role Does Shammy Cloth Play in Manufacturing?

In manufacturing, particularly in electronics assembly, shammy cloth is utilized for precision cleaning tasks. Its non-abrasive nature and lint-free characteristics make it ideal for cleaning sensitive electronic components without risking damage. This application helps prevent defects in products due to contaminants, thereby improving overall quality. Buyers in this sector should prioritize sourcing high-quality synthetic shammy materials that can endure rigorous cleaning processes while maintaining their effectiveness. Reliability in supply and material performance is crucial for manufacturers aiming to uphold high production standards.

How Can Shammy Cloth Benefit Sports and Fitness Industries?

In the sports and fitness industry, shammy cloth is widely used for maintaining equipment and drying gear. Its quick-drying properties help athletes keep their equipment in optimal condition, reducing the risk of mold and odors. This application addresses the challenge of maintaining hygiene and performance in athletic environments. When sourcing shammy cloth for this purpose, buyers should consider the durability of the material under heavy use and its moisture-wicking capabilities. Ensuring that the cloth can withstand rigorous cleaning and drying will enhance its value for fitness facilities and sports teams.

Why is Shammy Cloth a Versatile Choice for Home Care?

In home care, shammy cloth serves as a versatile tool for various cleaning and drying tasks, from wiping surfaces to drying dishes. Its eco-friendly nature, being reusable and machine washable, appeals to environmentally conscious consumers. This versatility addresses the need for effective cleaning solutions that minimize waste. Buyers should evaluate the softness and absorbency of the shammy cloth to ensure it is suitable for multiple surfaces without causing scratches. Sourcing options that guarantee quality and performance will provide significant value to households looking for reliable cleaning products.

3 Common User Pain Points for ‘shammy cloth material’ & Their Solutions

Scenario 1: Sourcing Quality Shammy Cloth for Diverse Applications

The Problem: B2B buyers often struggle to find suppliers that offer high-quality shammy cloth suitable for various industrial applications. With numerous manufacturers claiming to provide superior products, distinguishing between genuine high-performance shammy cloth and subpar alternatives can be daunting. Buyers may face issues such as inconsistent quality, inadequate absorbency, and durability concerns, which can affect their end products and customer satisfaction.

Illustrative image related to shammy cloth material

The Solution: To effectively source high-quality shammy cloth, buyers should prioritize suppliers with a proven track record and transparent manufacturing processes. Look for suppliers that provide detailed specifications regarding the fabric composition, absorbency rates, and intended applications. Consider requesting samples before committing to a bulk order, allowing you to assess the cloth’s performance firsthand. Additionally, engaging in direct communication with suppliers to understand their quality control measures and sourcing practices can help ensure that the shammy cloth meets your specific requirements. By building a relationship with trusted suppliers, you can also negotiate better terms and ensure a reliable supply chain.

Scenario 2: Maintaining Shammy Cloth for Longevity

The Problem: Many B2B buyers overlook the importance of proper care and maintenance of shammy cloth, leading to premature wear and reduced effectiveness. Buyers often encounter issues such as fabric stiffness, reduced absorbency, and unpleasant odors, which can significantly impact the usability of the cloth in professional settings.

The Solution: To maintain the integrity of shammy cloth, establish a routine care regimen that includes proper washing and drying techniques. Hand washing in lukewarm water with mild detergent is recommended to preserve the fabric’s softness. Avoid using bleach or fabric softeners, as they can damage the fibers. After washing, air drying the cloth is preferable to machine drying, which can lead to stiffness. Implementing these practices not only extends the lifespan of the shammy cloth but also ensures it performs effectively for various tasks, from automotive detailing to cleaning delicate surfaces. Additionally, providing training for staff on proper care techniques can enhance overall efficiency and reduce replacement costs.

Scenario 3: Understanding the Limitations of Shammy Cloth

The Problem: B2B buyers often face challenges when using shammy cloth in inappropriate applications, leading to dissatisfaction and wasted resources. For instance, while shammy cloth is excellent for drying and polishing, using it on rough or abrasive surfaces can result in damage to both the cloth and the surface being cleaned. This misunderstanding can lead to costly mistakes and negatively affect client relationships.

Illustrative image related to shammy cloth material

The Solution: To mitigate this issue, it’s crucial to educate buyers on the appropriate applications for shammy cloth. Providing detailed product guidelines that outline suitable uses can help buyers make informed decisions. For instance, shammy cloth is ideal for gentle drying of painted surfaces but should be avoided on textured or abrasive materials. Additionally, offering a variety of cloth options designed for specific tasks—such as heavier, more durable cloth for rough surfaces—can help buyers select the right product for their needs. Implementing a comprehensive product training program can also empower buyers to utilize shammy cloth effectively, enhancing user experience and customer satisfaction.

Strategic Material Selection Guide for shammy cloth material

What Are the Key Materials Used in Shammy Cloth Production?

When selecting shammy cloth materials for B2B applications, understanding the various options available is crucial. The choice of material directly impacts the performance, durability, and suitability for specific applications. Below, we analyze four common materials used in shammy cloth production: natural chamois leather, cotton chamois, synthetic chamois, and microfiber. Each material has distinct properties, benefits, and limitations that international buyers should consider.

How Does Natural Chamois Leather Perform as a Shammy Cloth Material?

Natural chamois leather, derived from the skin of the chamois goat, is known for its exceptional absorbency and softness. This material is highly effective in drying surfaces without leaving streaks, making it ideal for automotive and luxury applications. However, it is relatively expensive and may require more care to maintain its quality.

Illustrative image related to shammy cloth material

Pros:

– High absorbency and softness enhance user experience.

– Long-lasting when properly cared for, making it suitable for premium products.

Cons:

– Higher cost compared to synthetic options.

– Requires special cleaning and maintenance to preserve its properties.

What Are the Advantages of Cotton Chamois for Shammy Cloth Applications?

Cotton chamois is a popular alternative that offers a balance between performance and cost. This material is thicker and more resilient than traditional flannel, providing excellent absorbency while being softer to the touch. It is commonly used in automotive cleaning and waxing.

Pros:

– Cost-effective and widely available.

– Good absorbency and comfort make it suitable for various applications.

Illustrative image related to shammy cloth material

Cons:

– Durability may be lower than natural leather.

– Potential for shrinking or losing shape if not cared for properly.

How Does Synthetic Chamois Compare in Terms of Performance and Cost?

Synthetic chamois cloths are made from advanced polymers designed to mimic the properties of natural chamois. They offer superior absorbency and are often more durable than their natural counterparts. Synthetic options are typically more affordable and easier to clean.

Pros:

– High durability and resistance to tearing.

– Cost-effective, making it accessible for bulk purchases.

Cons:

– May not have the same luxurious feel as natural chamois.

– Environmental concerns regarding the production of synthetic materials.

What Role Does Microfiber Play in Shammy Cloth Material Selection?

Microfiber is another innovative option for shammy cloths. Composed of ultra-fine synthetic fibers, microfiber cloths are known for their exceptional cleaning capabilities and ability to trap dirt and moisture. They are highly versatile and can be used in various applications, from automotive to household cleaning.

Illustrative image related to shammy cloth material

Pros:

– Excellent cleaning efficiency and absorbency.

– Machine washable and quick-drying, enhancing convenience.

Cons:

– May be perceived as less durable over time compared to thicker materials.

– Quality can vary significantly between manufacturers.

Summary of Key Material Considerations for B2B Buyers

When selecting shammy cloth materials, international buyers must consider compliance with local standards and regulations (such as ASTM, DIN, or JIS) relevant to their specific markets. Buyers from Africa, South America, the Middle East, and Europe should also be aware of regional preferences for material durability, cost, and environmental impact.

| Материал | Typical Use Case for shammy cloth material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Chamois Leather | Luxury automotive detailing | Exceptional absorbency and softness | Higher cost and maintenance requirements | Высокий |

| Cotton Chamois | Automotive cleaning and waxing | Cost-effective with good absorbency | Durability may be lower than leather | Medium |

| Синтетическая замша | General cleaning applications | High durability and affordability | May lack the luxurious feel of leather | Низкий |

| Микрофибра | Versatile cleaning across industries | Excellent cleaning efficiency | Potential variability in quality | Medium |

This guide should assist B2B buyers in making informed decisions regarding shammy cloth materials, aligning with their specific needs and regional market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for shammy cloth material

What Are the Key Stages in the Manufacturing Process of Shammy Cloth Material?

The manufacturing process of shammy cloth, particularly the synthetic variants, involves several critical stages that ensure high quality and performance. Understanding these stages is essential for B2B buyers looking to source shammy cloth materials effectively.

Illustrative image related to shammy cloth material

Material Preparation: What Raw Materials Are Used?

The production of shammy cloth typically begins with the selection of high-quality raw materials. Modern shammy cloth is often made from synthetic fibers such as polyamide or polyester, which are known for their excellent absorbency and durability. These materials are chosen over traditional chamois leather due to their superior performance and lower environmental impact.

The initial step involves the careful preparation of these synthetic fibers. This includes processes like spinning and weaving, where the fibers are turned into a fabric that mimics the properties of traditional chamois. Quality control during this stage is crucial, as the consistency and uniformity of the fibers directly influence the final product’s performance.

Forming: How Is Shammy Cloth Shaped and Structured?

Once the material is prepared, the forming stage begins. Here, the fabric is cut to specific dimensions and shapes based on the intended end-use, whether for automotive cleaning, personal care, or industrial applications. Advanced techniques such as ultrasonic cutting may be employed to ensure clean edges without fraying.

During this stage, manufacturers may also apply treatments to enhance properties like absorbency and softness. For instance, a chemical finish may be applied to improve water retention or to add a layer of protection against wear and tear. This process requires precision, as any inconsistencies can lead to defects in the final product.

Illustrative image related to shammy cloth material

Assembly: What Does the Assembly Process Involve?

In the assembly phase, the various pieces of shammy cloth are stitched or bonded together if multiple layers or types of fabric are used. For example, some products may incorporate a combination of shammy cloth with other materials for added functionality, such as a non-slip backing for automotive applications.

Quality checks are integral during assembly, where manufacturers inspect the seams, stitching, and overall construction. Ensuring that the assembly meets industry standards helps prevent issues during the product’s lifecycle.

Finishing: How Are Shammy Cloth Products Finalized?

The finishing stage is where the shammy cloth is treated for final properties before packaging. This may include processes like dyeing, which can enhance the aesthetic appeal, and additional softening treatments that improve user experience. The finishing touches often determine the product’s marketability and usability.

Manufacturers may also implement a rigorous quality assurance protocol at this stage, ensuring that every piece meets established specifications before leaving the facility. This can involve visual inspections, tactile assessments, and even automated checks using technology.

What Quality Assurance Measures Are Essential for Shammy Cloth Material?

Quality assurance (QA) in the manufacturing of shammy cloth is vital for ensuring that the final products meet both industry and customer expectations. B2B buyers should be well-versed in the various QA measures that are commonly employed.

What International Standards Should Buyers Be Aware Of?

For shammy cloth manufacturers, adherence to international standards is crucial. ISO 9001, which outlines criteria for a quality management system, is commonly sought after. This certification ensures that manufacturers consistently produce quality products and improve processes.

Additionally, industry-specific certifications such as CE marking for compliance with European safety standards, or API standards for products used in industrial contexts, may also be relevant. Buyers should inquire about these certifications when assessing potential suppliers.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet quality standards. For synthetic fibers, this might include tests for tensile strength and absorbency.

-

In-Process Quality Control (IPQC): During production, random samples are taken to monitor quality at different stages. This can include checking the consistency of fabric thickness or the effectiveness of water repellency treatments.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted. This ensures that finished shammy cloths meet all specifications, such as size, color, and performance attributes.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some actionable steps:

-

Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows for firsthand assessment of manufacturing practices, equipment, and adherence to QA processes.

-

Quality Reports: Requesting quality assurance reports can provide insights into a supplier’s QC history and compliance with international standards. This documentation can include details on testing methods and results.

-

Third-Party Inspections: Engaging third-party inspection services can offer an objective evaluation of the manufacturing process and product quality. These services can be particularly beneficial for buyers located far from the manufacturing site.

What Nuances Should International Buyers Consider in Quality Control?

When sourcing shammy cloth material, international buyers must consider regional nuances in quality control practices. For example, in regions like Africa and South America, suppliers may have different capabilities and certifications compared to those in Europe or the Middle East.

Understanding local manufacturing standards, labor practices, and environmental regulations can significantly impact the procurement process. Buyers should also be aware of potential supply chain challenges, such as transportation delays or customs regulations, which can affect the timely delivery of quality products.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures related to shammy cloth material is crucial for B2B buyers. By focusing on the key stages of production and implementing effective quality control strategies, businesses can ensure they source high-quality materials that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shammy cloth material’

To assist international B2B buyers in sourcing shammy cloth material effectively, this step-by-step checklist is designed to guide you through the procurement process. Ensuring you make informed decisions will help you secure high-quality materials that meet your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for shammy cloth. Consider factors such as thickness, absorbency, texture, and durability. These specifications will help you communicate effectively with potential suppliers and ensure the material meets your operational needs.

- Толщина: Determine the desired weight of the fabric, which can affect its absorption capabilities.

- Absorbency: Specify the level of moisture absorption required for your intended use, whether for automotive cleaning, clothing, or other applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in shammy cloth material. Utilize online platforms, trade shows, and industry directories to compile a list of candidates.

- Online Platforms: Websites like Alibaba or industry-specific marketplaces can provide a wealth of options.

- Trade Shows: Attend relevant industry events to meet suppliers face-to-face and assess their products directly.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers to ensure they meet industry standards and regulations. This step is crucial for maintaining quality and sustainability in your supply chain.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance credentials that signify adherence to manufacturing standards.

- Sustainability Practices: If sustainability is important to your brand, inquire about eco-friendly practices and certifications.

Step 4: Request Samples

Always request samples from shortlisted suppliers before making a bulk purchase. This allows you to evaluate the quality and characteristics of the shammy cloth firsthand.

- Material Quality: Assess the softness, thickness, and absorbency of the fabric.

- Performance Testing: If applicable, test the samples in real-world scenarios to determine their effectiveness for your intended application.

Step 5: Compare Pricing and Terms

Once you have evaluated samples, compare pricing among suppliers while considering the total cost of ownership. Look beyond the initial price to include shipping, import duties, and potential tariffs.

- Volume Discounts: Inquire about bulk pricing or discounts for large orders.

- Payment Terms: Clarify payment terms, including deposits and payment schedules, to ensure they align with your cash flow.

Step 6: Negotiate Contracts

After selecting a supplier, negotiate contract terms that protect your interests. This includes delivery timelines, quality assurance measures, and penalties for non-compliance.

- Delivery Schedules: Establish clear timelines for when you expect to receive shipments.

- Quality Assurance: Specify quality checks and processes to address any defects or inconsistencies.

Step 7: Plan for Logistics

Finally, develop a logistics plan to manage the transportation and delivery of your shammy cloth. Consider factors such as shipping methods, storage conditions, and inventory management.

- Shipping Methods: Choose between air freight for speed or sea freight for cost-effectiveness based on your urgency.

- Storage Requirements: Ensure proper storage conditions to maintain the quality of the fabric until it is ready for use.

By following this comprehensive checklist, you can streamline the sourcing process for shammy cloth material, ensuring that you make well-informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for shammy cloth material Sourcing

What Are the Key Cost Components in Shammy Cloth Material Sourcing?

When sourcing shammy cloth material, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: The cost of raw materials is a significant factor, particularly as shammy cloth can be made from various fibers such as cotton or synthetic materials. The choice of material directly impacts both the quality and price. Higher-quality materials often command higher prices but can lead to greater customer satisfaction and lower return rates.

-

Labor: Labor costs vary by region and are influenced by local wage standards. Countries with lower labor costs may offer more competitive pricing, but it is essential to consider the trade-off with quality and craftsmanship.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and general operational costs. Efficient manufacturing processes can reduce overhead, translating to more competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom specifications. These costs are typically amortized over large production runs, so higher minimum order quantities (MOQs) can help spread these expenses and reduce per-unit costs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the final product meets the required standards. While this adds to the cost, it can prevent costly returns and enhance brand reputation in international markets.

-

Logistics: Shipping costs can vary dramatically based on distance, shipping method, and volume. Understanding the logistics involved in transporting materials from the supplier to your location is crucial for accurate cost estimation.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

What Influences the Pricing of Shammy Cloth Material?

Several factors can influence the pricing of shammy cloth material, which is particularly pertinent for international B2B buyers:

-

Volume/MOQ: Suppliers often provide discounts for larger orders. Understanding your needs and negotiating for an optimal MOQ can significantly impact pricing.

-

Specifications and Customization: Custom specifications, such as unique sizes, patterns, or colors, may incur additional costs. Buyers should weigh the benefits of customization against the potential increase in expense.

-

Materials: The quality of the raw materials plays a crucial role in pricing. Synthetic options may be cheaper but could compromise quality compared to natural fibers like cotton.

-

Quality Certifications: Products that meet specific quality certifications (e.g., ISO, Oeko-Tex) may come with higher costs but can enhance marketability and consumer trust.

-

Supplier Factors: Supplier reputation and reliability can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to attract business.

-

Incoterms: The terms of shipment (Incoterms) impact the final cost significantly. Buyers should be aware of which party is responsible for shipping costs, insurance, and customs duties to avoid unexpected expenses.

What Are Some Essential Buyer Tips for Cost-Efficiency?

To maximize value and minimize costs in sourcing shammy cloth material, consider the following tips:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially regarding MOQs and customization options. Effective negotiation can lead to substantial savings.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also other costs such as shipping, customs duties, and potential return costs. A lower upfront price may not always equate to lower overall expenses.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, trade tariffs, and local market dynamics that can affect costs.

-

Conduct Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower you during negotiations and help you identify the best sourcing strategies.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and preferential treatment in future transactions. Loyalty can also result in more favorable terms and improved service.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult with suppliers to obtain the most accurate and current pricing information.

Alternatives Analysis: Comparing shammy cloth material With Other Solutions

Exploring Alternatives to Shammy Cloth Material: A Comparative Analysis

In the world of cleaning and drying, shammy cloth material has long been a favored choice due to its unique properties. However, as the market evolves, various alternatives have emerged, each offering distinct advantages and drawbacks. This section provides a thorough comparison of shammy cloth material against two viable alternatives: microfiber cloths and cotton towels. This analysis will help B2B buyers make informed decisions based on their specific operational needs.

| Comparison Aspect | Shammy Cloth Material | Microfiber Cloths | Cotton Towels |

|---|---|---|---|

| Performance | High absorbency, non-abrasive | Superior absorbency and drying speed | Good absorbency, but less efficient |

| Cost | Moderate cost per piece | Generally low cost | Varies widely; can be low to high |

| Ease of Implementation | Simple to use, requires initial conditioning | Ready to use, easy to wash | Readily available, but may require more care |

| Maintenance | Requires careful washing to maintain quality | Machine washable, quick-drying | Machine washable, but can retain odors |

| Best Use Case | Ideal for delicate surfaces like cars | Excellent for various surfaces, including electronics | Versatile, suitable for general cleaning |

What Are the Advantages and Disadvantages of Microfiber Cloths?

Microfiber cloths are increasingly popular due to their exceptional cleaning performance. Composed of tiny fibers, they can effectively trap dirt and moisture, making them ideal for a wide range of applications, from cleaning electronics to polishing surfaces. The primary advantages include their high absorbency and quick-drying nature, which significantly reduces downtime. However, they may require specific washing instructions to avoid damage and can be less durable than shammy cloths over time, leading to potential replacements.

Why Choose Cotton Towels Over Shammy Cloth Material?

Cotton towels are a traditional cleaning solution that remains widely used due to their versatility and availability. They are effective for general cleaning and can be found in various sizes and weights, catering to different needs. While cotton towels can absorb moisture adequately, they do not dry as quickly as shammy cloths or microfiber cloths. Additionally, they may require more care to prevent odors and maintain cleanliness, which can be a downside for businesses looking for low-maintenance options.

Making the Right Choice: How to Select the Best Cleaning Solution for Your Needs

When deciding between shammy cloth material and its alternatives, consider the specific requirements of your operations. If you prioritize high absorbency and non-abrasive qualities, shammy cloth may be the best choice, especially for delicate surfaces. However, for broader cleaning applications, microfiber cloths could offer better performance and convenience. Cotton towels, while versatile, may be less efficient in specialized settings but can serve well for general cleaning tasks. Ultimately, understanding the unique attributes of each option will empower B2B buyers to select the most suitable solution for their cleaning and drying needs.

Essential Technical Properties and Trade Terminology for shammy cloth material

What are the Key Technical Properties of Shammy Cloth Material?

Shammy cloth, known for its superior absorbency and softness, has several critical technical properties that make it an essential choice for various applications. Understanding these properties is vital for B2B buyers to ensure they select the right material for their needs.

1. Material Composition

Shammy cloth is typically made from a combination of synthetic fibers, such as polyamide or polyester, and sometimes includes natural fibers like cotton. This blend enhances its durability and absorbency, making it suitable for tasks ranging from automotive detailing to household cleaning. The choice of material directly affects performance, so buyers should consider the intended use when evaluating options.

2. Absorbency Rate

The absorbency rate measures how much liquid the shammy cloth can hold relative to its weight. High-quality shammy cloth can absorb several times its weight in water, making it ideal for drying surfaces without leaving streaks. For B2B buyers, this property is crucial, especially in industries like automotive and hospitality, where efficiency and cleanliness are paramount.

3. Thickness and Weight

The thickness and weight of shammy cloth are important specifications that influence its usability and application. Thicker cloths often provide better durability and absorption but may be heavier and bulkier. Conversely, lighter options may be easier to handle but could compromise on absorbency. Buyers should assess the balance between these factors to select the most suitable product for their requirements.

Illustrative image related to shammy cloth material

4. Durability and Lifespan

Durability is a critical property that determines how long the shammy cloth will last under regular use. High-quality shammy cloth can withstand multiple washes and maintain its absorbency and softness. For B2B buyers, investing in durable materials can lead to reduced replacement costs and increased customer satisfaction.

5. Cleaning and Maintenance

Shammy cloth requires specific care to maintain its properties over time. Most products are machine washable, but some may require hand washing to preserve their quality. Understanding the cleaning instructions is essential for B2B buyers to ensure longevity and performance, especially in high-use environments.

What are Common Trade Terms Related to Shammy Cloth?

Navigating the B2B landscape involves familiarizing oneself with specific jargon and trade terms that are frequently used in transactions involving shammy cloth. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that may be marketed by another company. In the context of shammy cloth, it may refer to manufacturers that create specialized cloths for branded automotive or cleaning products. Understanding OEM relationships can help buyers identify potential suppliers who can provide customized solutions.

Illustrative image related to shammy cloth material

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it affects inventory management and purchasing decisions. Knowing the MOQ can help businesses plan their orders effectively, especially when entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a document that companies send to suppliers to request pricing for specific products or services. For buyers interested in shammy cloth, submitting an RFQ can yield competitive pricing and enable them to compare offers from different suppliers, ensuring the best value.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and risk transfer. Understanding these terms helps B2B buyers navigate logistics and compliance when sourcing shammy cloth from international suppliers.

Illustrative image related to shammy cloth material

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. For B2B buyers, knowing the lead time for shammy cloth can assist in inventory planning and ensuring timely delivery to customers.

6. Certification Standards

Certification standards refer to the various industry benchmarks that shammy cloth may meet, such as ISO or ASTM standards. These certifications can indicate quality and performance, providing assurance to buyers regarding the reliability of the products they are sourcing.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shammy cloth material, ensuring they meet their operational needs while optimizing their supply chain.

Navigating Market Dynamics and Sourcing Trends in the shammy cloth material Sector

What Are the Key Market Dynamics for Shammy Cloth Material in B2B Sourcing?

The shammy cloth material sector is experiencing a dynamic shift, influenced by a variety of global drivers. Increasing demand for high-performance cleaning materials in automotive, hospitality, and personal care sectors is propelling growth. The rise of e-commerce platforms has made it easier for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, to access a diverse range of suppliers. Additionally, advancements in synthetic fiber technology are leading to the development of improved chamois cloths that offer enhanced absorbency and durability, catering to the evolving preferences of end-users.

Illustrative image related to shammy cloth material

Emerging trends in B2B sourcing include the adoption of digital platforms for procurement, allowing buyers to compare products and suppliers more efficiently. Furthermore, the integration of smart technologies in manufacturing processes is optimizing production capabilities and reducing lead times. Buyers are also increasingly looking for suppliers who can provide transparency in their sourcing practices and product specifications, ensuring they receive high-quality materials that meet their requirements.

How Are Sustainability and Ethical Sourcing Impacting the Shammy Cloth Material Sector?

Sustainability has become a critical consideration in the sourcing of shammy cloth materials. As environmental concerns gain prominence, B2B buyers are prioritizing suppliers that demonstrate commitment to eco-friendly practices. The production of shammy cloths from sustainable materials, such as organic cotton or recycled fibers, is gaining traction. These options not only reduce the environmental impact but also appeal to consumers who are increasingly aware of their purchasing choices.

Moreover, establishing ethical supply chains is essential for building trust and brand reputation. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® serve as important indicators of a supplier’s commitment to sustainability and ethical practices. Buyers should actively seek partnerships with manufacturers who prioritize responsible sourcing, ensuring that their procurement aligns with broader corporate social responsibility goals.

What Is the Historical Context of Shammy Cloth Material Relevant to Today’s B2B Buyers?

The history of shammy cloth can be traced back to its origins in Europe, where it was initially made from the skin of the chamois goat. This traditional material was valued for its softness and absorbency, primarily used for gloves and other garments. Over time, the evolution of manufacturing processes led to the introduction of synthetic alternatives, which not only matched but often exceeded the performance of natural materials.

By the early 20th century, chamois cloth began to see widespread adoption in industrial applications, particularly in the automotive sector for cleaning and drying purposes. This historical context highlights the material’s adaptability and ongoing relevance in various industries. Today’s B2B buyers can benefit from this rich legacy, leveraging advancements in technology and sustainability to meet contemporary market demands while honoring the traditional craftsmanship that has defined the shammy cloth sector.

Illustrative image related to shammy cloth material

Frequently Asked Questions (FAQs) for B2B Buyers of shammy cloth material

-

How do I determine the quality of shammy cloth material?

To evaluate the quality of shammy cloth material, consider factors such as fiber composition, absorbency, texture, and durability. High-quality shammy cloth should be made from premium cotton or synthetic materials that offer superior absorbency and softness. Request samples from suppliers to assess the material firsthand. Additionally, check for certifications or quality assurance processes that ensure the cloth meets industry standards. Engaging with suppliers who have a solid reputation can also provide insights into the quality of their products. -

What is the best use for shammy cloth in various industries?

Shammy cloth is highly versatile and used across multiple industries. In automotive settings, it is ideal for drying and polishing surfaces due to its high absorbency and non-abrasive nature. In the fashion industry, it can be utilized for clothing, accessories, and home furnishings. Additionally, its micro-filtration properties make it suitable for applications in cleaning and medical sectors. Understanding your specific industry needs will help you identify the best type of shammy cloth for your applications. -

What customization options are available for shammy cloth orders?

Many suppliers offer customization options such as specific sizes, colors, and branding. You can request personalized printing or dyeing services to match your brand identity. Additionally, inquire about different fabric blends or finishes that may enhance functionality for your particular use case. Discussing your requirements with suppliers early in the negotiation process can help ensure that your order meets your specific needs. -

What are the typical minimum order quantities (MOQs) for shammy cloth?

Minimum order quantities for shammy cloth can vary significantly based on the supplier and the specific product. Generally, MOQs range from 500 to 1,000 meters for bulk orders. However, some suppliers may accommodate smaller orders, especially for customized products. It’s advisable to communicate your needs clearly to suppliers and explore options that may suit your business model, particularly if you are a smaller enterprise. -

What payment terms should I expect when sourcing shammy cloth internationally?

Payment terms for international orders typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for large orders or customization. It’s essential to clarify payment terms before finalizing the contract and to consider using secure payment methods to protect your transaction. Discussing and negotiating terms that align with your cash flow management can facilitate smoother transactions. -

How can I effectively vet suppliers of shammy cloth?

Vetting suppliers involves several steps to ensure reliability and product quality. Start by checking their reputation through online reviews, testimonials, and industry references. Request samples to assess the quality of their products. Investigate their production capabilities, lead times, and compliance with international standards. Engaging with suppliers who provide transparent communication and have a proven track record can enhance your sourcing experience and reduce risks. -

What logistics considerations should I keep in mind when importing shammy cloth?

When importing shammy cloth, consider shipping methods, customs regulations, and potential tariffs in your target market. Choose a reliable freight forwarder who can navigate logistics complexities and offer advice on documentation required for customs clearance. Ensure that you account for lead times and any potential delays that may arise during transit. Establishing a solid logistics plan can significantly impact the efficiency of your supply chain. -

What quality assurance practices should be in place for shammy cloth?

Quality assurance practices are crucial in maintaining the consistency and reliability of shammy cloth. Suppliers should implement rigorous testing procedures, including absorbency tests, abrasion resistance checks, and compliance with safety standards. Regular inspections during production and before shipment can help identify defects early. As a buyer, consider establishing a quality control agreement that outlines specific performance metrics and standards that the supplier must meet.

Top 5 Shammy Cloth Material Manufacturers & Suppliers List

1. Fabriclore – Chamois Fabric

Domain: fabriclore.com

Registered: 2015 (10 years)

Введение: Chamois fabric is made from cotton fibers and has a simple weave, resembling chamois leather. It is thicker, more resilient, and comfortable compared to flannel, commonly used for washing and waxing automobiles. Historically, chamois fabric originated in Europe, initially made from the skin of a goat-like animal called chamois, used for gloves. Modern chamois fabric features higher absorbency and …

2. Walmart – Secamax Orange Shammy Multipurpose Cleaning Cloth

Domain: walmart.com

Registered: 1995 (30 years)

Введение: This company, Walmart – Secamax Orange Shammy Multipurpose Cleaning Cloth, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Etsy – Chamois Cloth Fabric by the Yard

Domain: etsy.com

Registered: 2004 (21 years)

Введение: This company, Etsy – Chamois Cloth Fabric by the Yard, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Ultrafabrics® – Ultraleather® Chamois Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Введение: Ultrafabrics® Ultraleather® Chamois Fabric

5. Torque Detail – Microfiber Towels

Domain: torquedetail.com

Registered: 2018 (7 years)

Введение: Microfiber towels are superior for auto detailing due to their extreme absorbency, softness, and lint-free nature. A good-quality microfiber drying towel should have a minimum GSM of 250, with the best towels being 350 or more. Chamois, made from natural leather, are absorbent but not as effective as microfiber and can be stiff and difficult to use. Microfiber towels can hold up to seven times the…

Strategic Sourcing Conclusion and Outlook for shammy cloth material

In the realm of strategic sourcing for shammy cloth material, the importance of quality, versatility, and supplier reliability cannot be overstated. As B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe seek to enhance their product offerings, understanding the unique properties of shammy cloth—its absorbency, durability, and soft texture—becomes essential. Sourcing from reputable manufacturers ensures not only consistent quality but also opens avenues for customization, catering to specific market needs.

The global demand for eco-friendly and high-performance materials continues to rise, making shammy cloth an attractive choice for various applications, from automotive care to household cleaning and fashion accessories. Buyers should prioritize strategic partnerships with suppliers who emphasize sustainability and innovation, aligning with the growing consumer preference for environmentally responsible products.

Looking ahead, the potential for growth in this sector is significant. By proactively engaging with suppliers and exploring new markets, international buyers can position themselves at the forefront of the shammy cloth industry. Embrace this opportunity to elevate your sourcing strategy and drive your business forward in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.