Catalog

Material Insight: Reconstituted Leather

B2B Product Guide: Reconstituted Leather

Reconstituted leather is a high-performance material engineered from genuine leather fibers combined with bonding agents to create a durable, consistent, and sustainable alternative to solid leather. This material retains the natural characteristics of real leather—such as breathability and texture—while offering enhanced uniformity, cost-efficiency, and environmental benefits. It is widely used in furniture, automotive interiors, footwear, and accessories where performance, aesthetics, and sustainability are key.

Faux leather, particularly reconstituted leather, is the best choice for these applications due to its balanced combination of authenticity and functionality. Unlike synthetic leather made entirely from polymers, reconstituted leather incorporates up to 50% genuine leather content, reducing waste and leveraging the inherent qualities of natural hide. It delivers excellent abrasion resistance, dimensional stability, and a soft hand feel, making it ideal for high-use environments. Additionally, its production process aligns with eco-conscious manufacturing standards—minimizing environmental impact without compromising on quality or design flexibility.

WINIW is a leading innovator in synthetic leather solutions with over 20 years of industry expertise. Specializing in high-quality reconstituted and microfiber leather, WINIW serves global B2B clients across furniture, transportation, electronics, and lifestyle sectors. Our commitment to sustainability, performance, and customization enables partners to meet evolving market demands with materials that are both responsible and reliable. Backed by advanced R&D, international certifications, and eco-friendly production practices, WINIW delivers tailored solutions that support long-term business growth and environmental stewardship.

Technical Performance & Standards

WINIW Reconstituted Leather: Technical Product Guide for B2B Applications

WINIW reconstituted leather delivers premium performance and sustainability for demanding industrial applications. Engineered from meticulously processed natural leather fibers bonded with certified eco-friendly polyurethane, our material offers a compelling alternative to both full-grain leather and standard synthetics. It provides exceptional value without compromising on quality, durability, or environmental responsibility, making it ideal for furniture, automotive interiors, luggage, and technical goods manufacturing.

Key Technical Advantages

- Superior Cost-Effectiveness: Utilizes up to 90% pre-consumer leather waste (shavings, splits), significantly reducing raw material costs versus virgin leather while maintaining high performance. Lower waste generation during cutting compared to natural leather translates to higher yield and reduced production costs for manufacturers.

- Enhanced Durability: Features a tightly bonded fiber matrix and advanced PU coating, delivering exceptional resistance to abrasion (>50,000 double rubs ASTM D4060), tearing (Tear Strength > 35 N/mm ISO 1767), and seam strength. Superior colorfastness to light (ISO 105-B02 > Grade 4) and crocking ensures longevity in high-use environments.

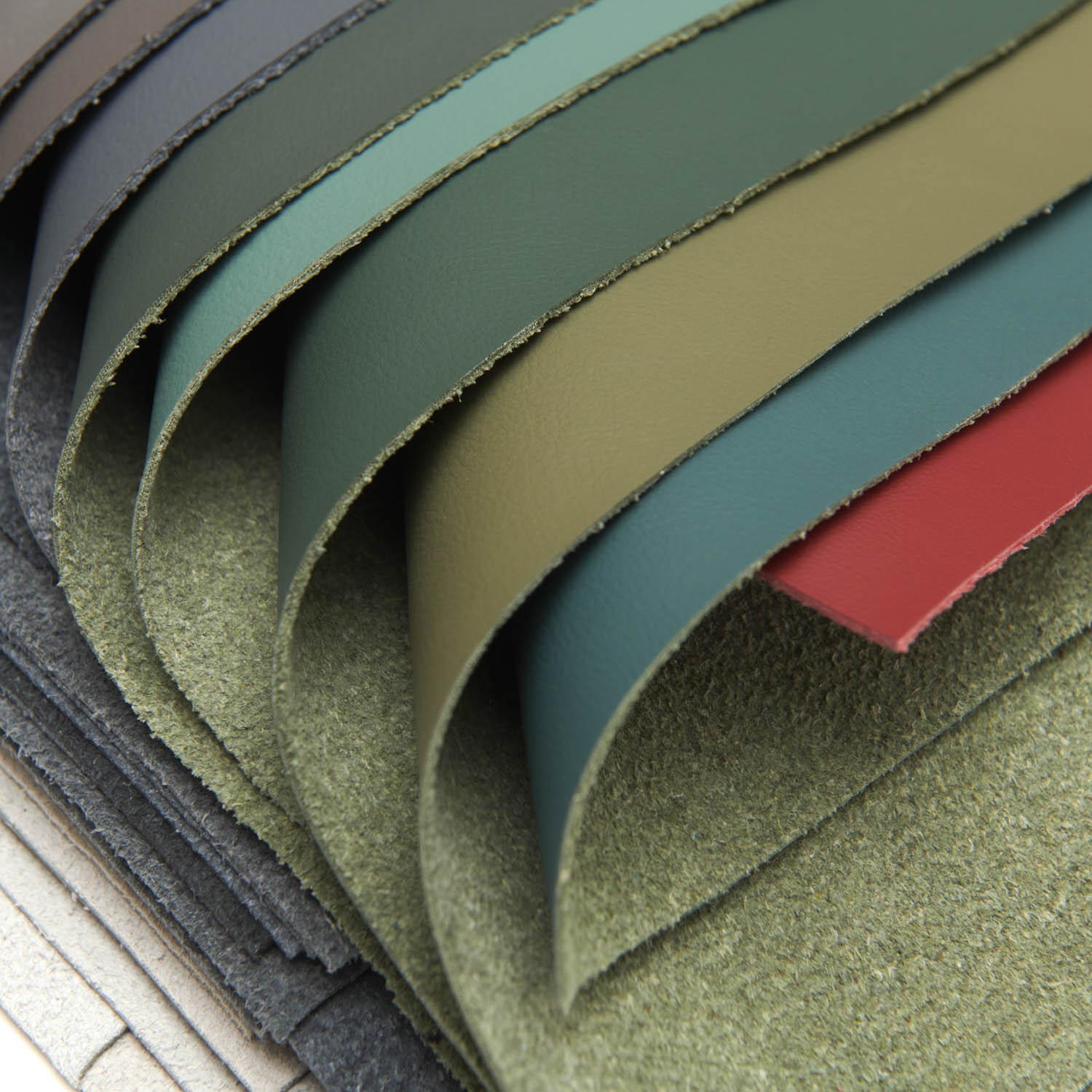

- Extensive Customizable Colors: Achieves precise, consistent color matching across large production runs using REACH-compliant dyes and pigments. Capable of replicating any Pantone reference or custom shade with high accuracy (ΔE < 1.5). Offers matte, semi-gloss, and full-gloss finishes to meet specific design requirements.

- Guaranteed REACH Compliance: Formulated exclusively with substances approved under EU REACH Regulation (EC) No 1907/2006 Annex XIV and XVII. Regularly tested by accredited third-party labs (SGS, Intertek) for restricted substances (AZO dyes, PCP, formaldehyde, heavy metals), ensuring safety for workers and end-users.

- Rigorous Quality Assurance (ISO 9001 Certified): Manufactured under a certified ISO 9001:2015 quality management system. Every batch undergoes stringent in-line and final inspection for thickness consistency, color uniformity, physical properties, and surface defects, guaranteeing reliable performance and batch-to-batch reproducibility.

Technical Specifications Overview

| Property | Test Method | Standard Requirement | WINIW Performance |

|---|---|---|---|

| Thickness | ISO 2418 | 0.8 – 2.5 mm | 0.9 – 2.2 mm (±0.1 mm) |

| Weight (g/m²) | ISO 2417 | 600 – 1200 | 750 – 1100 (Customizable) |

| Tensile Strength | ISO 1767 | > 20 N/mm | 25 – 32 N/mm |

| Tear Strength | ISO 1767 | > 30 N/mm | 35 – 45 N/mm |

| Seam Strength | ISO 1767 Annex B | > 150 N | 180 – 250 N |

| Martindale Abrasion | ISO 12947-2 | > 30,000 rubs | 50,000 – 100,000 rubs |

| Colorfastness to Light | ISO 105-B02 | > Grade 4 | Grade 5 – 6 |

| Colorfastness to Rubbing | ISO 11640 (Dry) | > Grade 4 | Grade 4 – 5 |

| REACH SVHC Screening | EC 1907/2006 | None Detected | Compliant (Report on Request) |

| Formaldehyde Content | EN ISO 17226-1 | < 60 mg/kg | < 20 mg/kg |

WINIW reconstituted leather provides the authentic look and feel of premium leather with the consistency, sustainability, and cost control essential for B2B manufacturing. Our commitment to rigorous quality standards (ISO 9001), full REACH compliance, and advanced engineering ensures a reliable, high-performance material that supports your brand’s sustainability goals and bottom line. Partner with WINIW for a durable, customizable, and responsibly sourced leather solution.

Why Choose Synthetic over Real Leather

B2B Product Guide: Reconstituted Leather vs. Real Leather

In the manufacturing and design sectors, selecting the right leather material is critical for balancing performance, cost, and sustainability. Two primary options dominate the market: real leather and reconstituted leather. Understanding their differences helps businesses make informed sourcing decisions aligned with product requirements and corporate sustainability goals.

Overview of Materials

- Real Leather is made directly from animal hides (typically bovine) that undergo tanning and finishing processes. It is valued for its natural grain, durability, and premium aesthetic.

- Reconstituted Leather, also known as recycled or bonded leather, is produced by combining leather fibers (often post-industrial scraps) with polyurethane or latex binders. The mixture is then laminated onto a backing material and embossed to mimic natural leather grain.

While both materials offer a leather-like appearance, their performance characteristics and environmental impacts differ significantly.

Key Differences

- Source Material: Real leather uses full hides; reconstituted leather utilizes shredded leather waste bound with synthetic resins.

- Consistency: Reconstituted leather offers uniform texture and color, while real leather may have natural variations and markings.

- Приложения: Real leather is preferred for high-end furniture, luxury automotive interiors, and premium footwear. Reconstituted leather is often used in mid-range furniture, accessories, and eco-conscious product lines.

- Sustainability: Reconstituted leather reduces waste by repurposing leather scraps, contributing to circular economy practices. However, the synthetic binders may affect biodegradability.

Comparative Analysis

| Feature | Real Leather | Reconstituted Leather |

|---|---|---|

| Cost | Высокий | Moderate to Low |

| Долговечность | High (long lifespan, ages well) | Moderate (prone to cracking over time) |

| Eco-friendliness | Moderate (resource-intensive tanning, but biodegradable) | High (uses waste material, lower carbon footprint) |

Considerations for B2B Buyers

- Cost Efficiency: Reconstituted leather offers a cost-effective alternative without sacrificing visual appeal, ideal for volume production.

- Durability Requirements: For products requiring long-term wear resistance, real leather remains the superior choice.

- Sustainability Goals: Brands committed to reducing environmental impact may favor reconstituted leather due to its waste-reduction benefits and lower resource consumption.

- Certifications: Look for reconstituted leather products with eco-labels (e.g., OEKO-TEX®, ISO 14001) to ensure responsible production practices.

At WINIW, we specialize in high-performance synthetic and reconstituted leather solutions that combine durability, aesthetics, and environmental responsibility—ideal for forward-thinking B2B partners in furniture, transportation, and lifestyle industries.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a premier global manufacturer of high-performance synthetic leather, engineered specifically for demanding B2B applications. Our operational scale and commitment to quality assurance provide unparalleled reliability for international partners in furniture, automotive, fashion, and technical textiles.

Core Manufacturing Capabilities

Our vertically integrated production ecosystem ensures end-to-end control over quality, sustainability, and innovation:

– 100,000 sqm Advanced Manufacturing Facility: One of Asia’s largest dedicated synthetic leather production campuses, featuring automated coating lines, precision embossing systems, and dedicated R&D pilot plants for rapid prototyping.

– Dedicated 60+ Member R&D Team: Comprising material scientists and application engineers focused on developing eco-conscious solutions, including water-based PU, recycled content formulations (up to 40% PCR), and bio-based alternatives compliant with global environmental standards.

– Strict Multi-Stage Quality Control: Every batch undergoes 18+ validation checkpoints, from raw material traceability to final product testing for color fastness (ISO 105), abrasion resistance (Martindale >50,000 cycles), and eco-toxicology (OEKO-TEX® STANDARD 100, REACH SVHC screening).

Global Supply Chain Assurance

WINIW delivers consistent quality to regulated markets through:

– Certified Sustainable Operations: ISO 14001 environmental management, ZDHC MRSL compliance, and annual third-party audits verifying reduced water consumption (40% below industry avg.) and VOC-free processes.

– Established Global Logistics: Direct export partnerships serving Tier-1 clients across Europe (Germany, Italy, Sweden) and North America (USA, Canada), with regional warehousing reducing lead times by 30%.

– Regulatory Adherence: All products meet EU REACH, CPSIA, and California Proposition 65 requirements, with full documentation packages for seamless customs clearance.

WINIW’s infrastructure transforms synthetic leather from a commodity into a strategic asset—combining industrial-scale output with precision engineering for brands committed to performance and planetary responsibility. Partner with us to integrate traceable, high-specification materials into your supply chain with zero compromise.

Contact Us for Samples

B2B Product Guide: Reconstituted Leather by WINIW

WINIW specializes in high-performance, eco-friendly reconstituted leather solutions designed for forward-thinking brands across the furniture, automotive, apparel, and accessories industries. Our reconstituted leather combines sustainable manufacturing practices with premium aesthetics and durability, offering a responsible alternative to traditional leather without compromising on quality.

Reconstituted leather from WINIW is engineered by bonding natural leather fibers with advanced synthetic resins, resulting in a consistent, versatile material that retains the authentic look and feel of genuine leather. This innovative process maximizes raw material efficiency, reduces waste, and supports circular economy goals—making it an ideal choice for environmentally conscious manufacturers.

Key Benefits of WINIW Reconstituted Leather:

- High breathability and soft hand feel for superior comfort

- Excellent abrasion and tear resistance for long-term durability

- Consistent thickness and grain for streamlined production

- Customizable thickness, color, texture, and finishing options

- Lower environmental impact compared to full-grain leather

- Compliant with REACH, RoHS, and other international safety standards

Typical Applications:

- Upholstered furniture and seating

- Automotive interiors (door panels, armrests, dash trims)

- Footwear and fashion accessories

- Bookbinding and luxury packaging

- Workwear and protective gear

Technical Specifications (Standard Grade):

| Property | Технические характеристики |

|---|---|

| Thickness Range | 0.8 mm – 3.0 mm |

| Base Material | Recycled leather fibers + PU/PVC |

| Backing Options | Cotton, polyester, or non-woven |

| Width Range | Up to 137 cm (54 inches) |

| Roll Length | 30–50 meters per roll |

| Color Fastness | ≥ Grade 4 (ISO 105-B02) |

| Martindale Abrasion | 20,000–50,000 cycles |

WINIW’s reconstituted leather is part of our broader commitment to sustainable material innovation. By repurposing post-industrial leather waste, we help reduce landfill burden and conserve natural resources—supporting your brand’s ESG and net-zero objectives.

Request Free Samples

Evaluate the quality and versatility of WINIW reconstituted leather in your own applications. Free samples are available upon request for qualified B2B partners.

Contact our materials team today:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.