Catalog

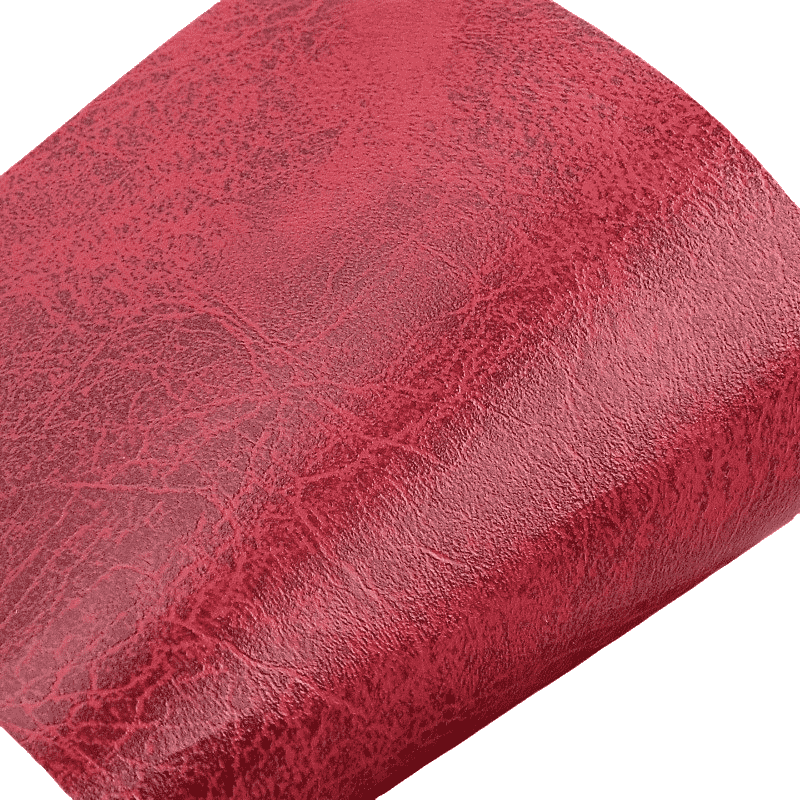

Material Insight: Printed Leatherette

B2B Product Guide: Printed Leatherette

Introduction to Printed Leatherette

Printed leatherette is a high-performance synthetic leather engineered to deliver the luxurious look and feel of genuine leather, enhanced with customizable surface designs through advanced printing technology. This versatile material is widely used across industries including automotive interiors, furniture, fashion accessories, and consumer electronics due to its consistent texture, design flexibility, and cost-efficiency. Through precision embossing and digital printing, manufacturers can replicate natural grain patterns or create unique, branded textures tailored to specific design requirements.

Why Faux Leather is the Best Choice for This Application

Faux leather—specifically high-grade polyurethane (PU) leatherette—offers significant advantages over natural leather in printed applications:

- Design Versatility: Faux leather provides a uniform surface ideal for high-resolution printing, enabling intricate patterns, logos, and colorways that are difficult or impossible to achieve with real leather.

- Consistency & Scalability: Unlike natural leather, which varies in grain and thickness, synthetic leatherette ensures batch-to-batch uniformity, essential for large-scale manufacturing and brand consistency.

- Sustainability: Faux leather reduces reliance on animal products and supports eco-conscious production. Modern PU leatherette, like WINIW’s formulations, is free from harmful solvents and meets global environmental standards.

- Durability & Performance: Printed leatherette can be engineered to resist abrasion, UV exposure, and staining—critical for applications in high-use environments such as automotive seating or commercial furniture.

- Cost-Effectiveness: With lower raw material and processing costs, printed leatherette delivers premium aesthetics at a fraction of the price of printed genuine leather.

Introducing WINIW: 20+ Years of Innovation in Synthetic Leather

WINIW is a trusted global leader in high-performance synthetic leather solutions, with over two decades of expertise in PU and microfiber leather development. We specialize in creating customized, eco-friendly leatherette materials that meet the rigorous demands of B2B clients across diverse sectors. Our commitment to innovation, sustainability, and quality has made us a preferred partner for brands seeking durable, aesthetically superior alternatives to natural leather.

Key strengths of WINIW include:

– Advanced printing and embossing technologies for photorealistic finishes

– Compliance with REACH, RoHS, and OEKO-TEX® standards

– In-house R&D for rapid prototyping and material customization

– Sustainable production processes with low-VOC emissions

With a focus on performance, aesthetics, and environmental responsibility, WINIW’s printed leatherette solutions empower businesses to deliver premium products—responsibly and efficiently.

Technical Performance & Standards

WINIW Printed Leatherette: Technical Product Guide for B2B Applications

WINIW Printed Leatherette delivers a premium, sustainable alternative to genuine leather, engineered specifically for demanding industrial and commercial applications. Our solution addresses critical pain points in upholstery, packaging, automotive interiors, and consumer goods manufacturing—offering consistent quality, reduced environmental impact, and significant supply chain advantages without compromising performance.

Core Technical Advantages

- Cost-Effectiveness: Eliminates volatility associated with natural leather sourcing. Our controlled synthetic production reduces material waste by up to 30% compared to leather cutting processes, while faster lead times (typically 15-20 days) minimize inventory costs. Lower maintenance requirements over the product lifecycle further enhance ROI.

- Superior Durability: Engineered with a high-density PU base layer and resilient printed surface. Resists cracking, peeling, and UV degradation (tested per ISO 105-B02, Grade 7-8). Withstands 50,000+ double rubs (Martindale, ASTM D4966), outperforming many coated fabrics in high-wear applications.

- Unmatched Color Customization: Utilizes advanced digital printing technology for limitless PMS color matching (ΔE < 1.5) and intricate pattern replication. Achieve consistent batch-to-batch color accuracy without minimum order quantities. Water-based, low-VOC inks ensure vibrancy while meeting strict eco-standards.

- REACH Compliance Guaranteed: All formulations are rigorously screened against the full REACH SVHC list (Annex XIV/XVII). Free from DMF, PAHs, azo dyes (BZ-100), and heavy metals (Cd, Pb, Hg, Cr⁶⁺). Full substance disclosure documentation available upon request.

- ISO 9001-Certified Quality Control: Integrated within WINIW’s end-to-end ISO 9001:2015 certified manufacturing system. Every batch undergoes 12+ in-process quality checkpoints, including thickness uniformity, bond strength, and colorfastness validation, ensuring zero-defect delivery.

Technical Specifications Overview

| Property | Технические характеристики | Testing Standard |

|---|---|---|

| Thickness Range | 0.6 mm – 1.2 mm | ISO 2427 |

| Weight | 280 g/m² – 450 g/m² | ISO 9073-3 |

| Tensile Strength | ≥ 60 N/5cm (MD & CD) | ISO 13934-1 |

| Tear Strength | ≥ 15 N (Elmendorf) | ISO 13937-3 |

| Martindale Abrasion | ≥ 50,000 rubs (no break) | ASTM D4966 |

| Colorfastness to Rubbing | ≥ Grade 4 (dry/wet) | ISO 105-X12 |

| Lightfastness | ≥ Grade 7 (100 hrs Xenon) | ISO 105-B02 |

| REACH Status | Fully Compliant (SVHC-free) | EC 1907/2006 |

| Fire Resistance | Meets FMVSS 302, CAL 117 (Optional) | ASTM D5116 |

WINIW Printed Leatherette merges industrial robustness with environmental responsibility. By replacing resource-intensive leather with a traceable, circular-economy-aligned material (containing up to 35% recycled content), we enable brands to meet ESG targets without sacrificing performance. Request our full technical dossier and sample swatch kit to validate specifications against your application requirements.

WINIW: Engineering Sustainable Surfaces for Industry.

Why Choose Synthetic over Real Leather

B2B Product Guide: Printed Leatherette vs. Real Leather

When selecting materials for upholstery, accessories, or interior design applications, businesses must balance aesthetics, performance, cost, and sustainability. Two commonly compared materials are printed leatherette and real leather. Each offers distinct advantages and trade-offs depending on the intended use and brand values.

Printed leatherette is a synthetic material engineered to mimic the look and texture of genuine leather. It is typically made from polyurethane (PU) or polyvinyl chloride (PVC) and undergoes a printing process to replicate natural leather grain patterns. Real leather, by contrast, is derived from animal hides—primarily bovine—and undergoes tanning and finishing processes to enhance durability and appearance.

While real leather is often associated with premium quality and longevity, printed leatherette provides a cost-effective and cruelty-free alternative that supports eco-conscious manufacturing when produced responsibly.

Key considerations for B2B buyers include:

- Cost Efficiency: Printed leatherette is significantly less expensive than real leather, both in raw material and processing costs.

- Consistency: Leatherette offers uniform color and texture across batches, ideal for large-scale production.

- Animal Welfare & Ethics: Leatherette is vegan and avoids the ethical concerns associated with animal sourcing.

- Environmental Impact: Advances in PU-based leatherette, such as water-based production and recycled content, have improved its sustainability profile.

- Durability & Maintenance: Real leather ages gracefully but is susceptible to moisture and UV damage. Leatherette resists fading and staining but may crack over time under stress.

- Customization: Leatherette allows for greater flexibility in color, pattern, and texture, including unique designs not possible with natural hides.

The following table compares printed leatherette and real leather across three critical business metrics:

| Criteria | Printed Leatherette | Real Leather |

|---|---|---|

| Cost | Low to moderate | Высокий |

| Долговечность | Moderate (5–7 years) | High (10–15+ years) |

| Eco-Friendliness | Moderate to high (especially with PU and recycled content) | Low to moderate (due to high water use, chemicals in tanning, and methane from livestock) |

WINIW’s printed leatherette solutions are designed for B2B clients seeking sustainable, high-performance materials without compromising on aesthetics. Our eco-friendly production processes minimize VOC emissions and utilize recyclable inputs, supporting your brand’s environmental goals.

For applications where long-term wear resistance and natural aging are priorities, real leather remains a viable option. However, for scalable, ethical, and cost-efficient manufacturing, printed leatherette presents a compelling alternative—particularly in automotive interiors, furniture, fashion accessories, and retail displays.

Choose the material that aligns with your product lifecycle, customer values, and sustainability commitments.

WINIW Factory Capabilities

WINIW Synthetic Leather: Global Manufacturing Excellence for B2B Partners

WINIW stands as a leading synthetic leather manufacturer, engineered to meet the exacting demands of global B2B clients in automotive, furniture, fashion, and technical textiles. Our vertically integrated production ecosystem ensures consistent quality, scalability, and innovation—backed by uncompromising environmental stewardship.

Core Manufacturing Capabilities

- 100,000 sqm Advanced Production Facility: One of Asia’s largest dedicated synthetic leather campuses, enabling annual output exceeding 150 million meters. Fully automated lines minimize waste while maximizing precision for bulk orders (MOQs starting at 1,000 meters).

- Dedicated R&D Team (50+ Specialists): In-house chemists, material scientists, and engineers develop eco-conscious solutions. 30% of annual revenue is reinvested into R&D, yielding 12+ patents yearly for water-based PU, recycled PET substrates, and bio-based polymers.

- Strict Multi-Stage Quality Control: Every meter undergoes 72-point validation, including:

- ISO 9001-certified processes from raw material sourcing to finished goods

- Real-time IoT monitoring of thickness, color fastness (≥4.5 on ISO 105-B02), and abrasion resistance

- Third-party compliance testing for REACH, OEKO-TEX® STANDARD 100, and Prop 65

Global Export Infrastructure

WINIW delivers certified sustainable materials to 40+ countries, with established logistics partnerships ensuring seamless entry into regulated markets:

| Key Region | Compliance Achieved | Lead Time (Standard Orders) |

|---|---|---|

| Europe | EU Ecolabel, ZDHC MRSL Conformant | 25-30 days |

| USA | CPSIA, California TB 117-2013 | 20-25 days |

| Asia-Pacific | Japan LAF, AS/NZS 4684 | 15-20 дней |

Our facility operates under ISO 14001 and ISO 50001 frameworks, utilizing solar energy (30% of total consumption) and closed-loop water systems to reduce ecological impact per production cycle by 40%. This commitment ensures your supply chain meets evolving ESG mandates while maintaining cost efficiency. Partner with WINIW for synthetic leather solutions where industrial scale, scientific rigor, and planetary responsibility converge.

Contact Us for Samples

WINIW B2B Product Guide: Printed Leatherette

WINIW specializes in high-performance, eco-friendly synthetic leather solutions designed for demanding industrial and commercial applications. Our printed leatherette combines durability, aesthetic versatility, and sustainable manufacturing practices—making it an ideal choice for forward-thinking brands across furniture, automotive, electronics, and consumer goods sectors.

Engineered for consistency and performance, WINIW printed leatherette offers a cost-effective alternative to genuine leather without compromising on quality or appearance. Our advanced coating and printing technologies enable precise replication of natural textures and custom designs, supporting brand differentiation and design innovation.

Key Features of WINIW Printed Leatherette

- Premium synthetic microfiber base with high tensile and tear strength

- UV-resistant surface printing for long-lasting color retention

- Available in a wide range of patterns, including leather grain, geometric, and custom designs

- Eco-conscious production: free from harmful solvents and heavy metals

- REACH and RoHS compliant; suitable for global market distribution

- Abrasion-resistant for high-use applications

- Dimensional stability and low elongation under stress

- Customizable thickness (0.6mm to 1.8mm) and roll width (up to 1.5m)

Typical Applications

- Upholstered furniture and modular seating

- Automotive interiors (door panels, armrests, consoles)

- Luggage, handbags, and fashion accessories

- Electronic device covers and protective cases

- Retail fixtures and display solutions

Technical Specifications (Standard Grade)

| Property | Технические характеристики |

|---|---|

| Thickness | 0.8 mm – 1.5 mm (customizable) |

| Width | Up to 1.5 meters |

| Weight | 280 – 420 g/m² |

| Tear Strength | ≥ 45 N (warp & weft) |

| Color Fastness (Rubbing) | ≥ Grade 4 (dry/wet) |

| Light Fastness | ≥ Grade 6 (after 40 hrs UV test) |

| Cold Crack Resistance | Passes at -20°C |

Why Choose WINIW Printed Leatherette?

- Rapid prototyping and short lead times for bulk orders

- Low MOQs to support startups and niche product lines

- Full customization: color, texture, print, and back-coating options

- Dedicated R&D team for performance-driven material innovation

- Sustainable supply chain with traceable raw materials

For product integration, technical support, or design collaboration, request free samples of our printed leatherette to evaluate performance and aesthetics in your application.

Contact our materials team today:

MKT88@MicrofiberLeather.com

Elevate your product design with sustainable, precision-engineered synthetic leather from WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.