Catalog

Material Insight: Leather Solutions

B2B Product Guide: Advanced Leather Solutions for Modern Manufacturing

In today’s demanding industrial landscape, material selection directly impacts product performance, sustainability compliance, and brand reputation. Natural leather, while traditional, presents significant challenges: inconsistent quality due to biological variability, ethical concerns in sourcing, vulnerability to environmental stressors, and growing regulatory pressures around deforestation and chemical use in tanning. These factors drive leading manufacturers across furniture, automotive, fashion, and technical textiles to seek superior alternatives. Engineered synthetic leather delivers not just a substitute, but a strategic upgrade—combining design flexibility, operational efficiency, and verifiable environmental responsibility.

Why Synthetic Leather is the Optimal Choice for Industrial Applications

- Consistent Performance & Quality: Eliminate batch variations inherent in natural hides. Achieve precise thickness, color fastness, abrasion resistance, and physical properties tailored to your exact specifications, every time.

- Enhanced Sustainability Profile: Avoid the high water consumption, toxic tanning chemicals (e.g., chromium), and land-use impacts of conventional leather. Modern synthetics utilize recycled content (PET, PU), bio-based polymers, and adhere to strict global standards (REACH, OEKO-TEX®).

- Design & Production Agility: Customize textures, weights, breathability, and performance additives (flame retardancy, antimicrobial) rapidly. Simplify cutting efficiency with uniform rolls, reducing waste and accelerating time-to-market.

- Ethical & Traceable Sourcing: Ensure full supply chain transparency and compliance with evolving ESG mandates, mitigating reputational risk associated with animal agriculture and opaque tannery practices.

- Cost Predictability: Stabilize input costs by removing dependency on volatile hide markets and complex, geographically concentrated tanning infrastructure.

Introducing WINIW: Your Trusted Partner in Advanced Material Innovation

WINIW has been a pioneer in high-performance synthetic leather solutions for over 20 years. We partner exclusively with B2B manufacturers who demand materials that excel in both function and responsibility. Our expertise isn’t just in production—it’s in solving your specific challenges:

- Deep Technical Partnership: Our R&D team collaborates closely with your engineers to develop formulations meeting exact industry standards (e.g., automotive OEM specs, furniture durability benchmarks).

- Eco-Conscious Manufacturing Leadership: We operate ISO 14001-certified facilities, utilize renewable energy where possible, and offer material lines with >30% recycled content and Cradle-to-Cradle® inspired design principles.

- Global Scale, Local Support: Leverage our international production network for reliable supply chain resilience, backed by regional technical service teams ensuring seamless integration into your processes.

- Future-Proof Innovation: Continuously advancing bio-based polymers, waterless coating technologies, and fully recyclable material systems to keep your products ahead of regulatory curves and consumer expectations.

Choosing WINIW means selecting a material science partner committed to delivering not just products, but sustainable competitive advantage. Let us help you transform your next-generation products with leather solutions engineered for excellence and responsibility.

Technical Performance & Standards

WINIW Synthetic Leather Solutions – B2B Product Guide

WINIW delivers high-performance synthetic leather solutions engineered for industrial and commercial applications across footwear, automotive interiors, furniture, and accessories. Our advanced manufacturing processes and commitment to quality ensure products that combine cost-efficiency with superior durability and environmental responsibility.

Technical Advantages

-

Cost-Effective Production: WINIW’s synthetic leather reduces material waste and production downtime. With consistent roll-to-roll quality and high yield rates, manufacturers benefit from lower total production costs compared to natural leather or lower-tier synthetics.

-

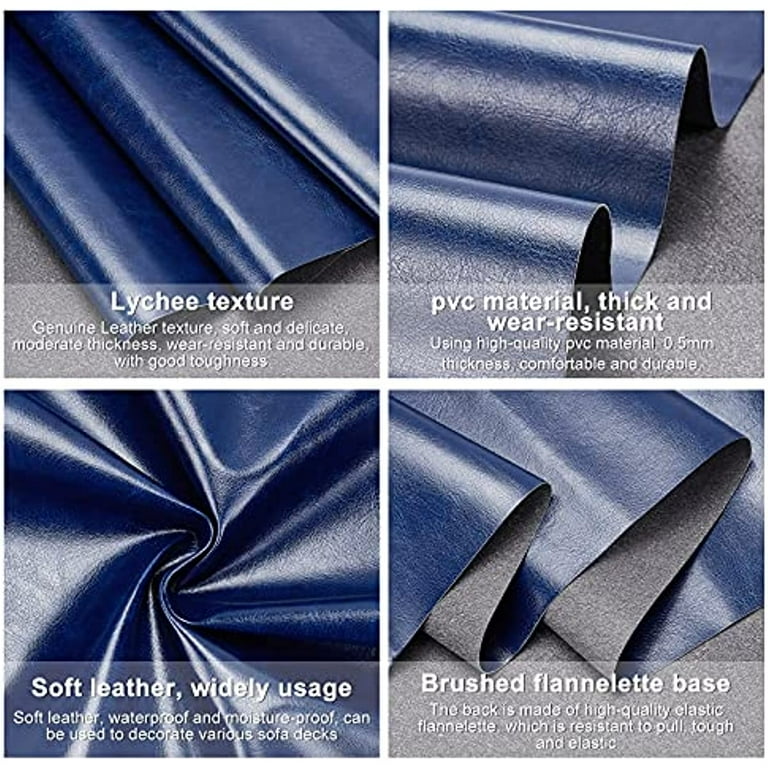

Enhanced Durability: Our polyurethane (PU) and polyvinyl chloride (PVC) formulations are reinforced with high-tenacity backings, delivering excellent abrasion resistance, tensile strength, and dimensional stability. WINIW materials withstand rigorous use in demanding environments.

-

Customizable Colors & Finishes: WINIW offers full color customization with batch-to-batch consistency. We support Pantone matching, digital color libraries, and custom embossing patterns to meet specific design and branding requirements.

-

REACH Compliant: All WINIW synthetic leather products comply with EU REACH regulations (EC 1907/2006), ensuring restricted substances are monitored and controlled. Our materials are free from SVHCs (Substances of Very High Concern) and meet global chemical safety standards.

-

ISO 9001 Certified Manufacturing: WINIW operates under an ISO 9001-certified quality management system, guaranteeing consistent product performance, traceability, and continuous improvement in every production cycle.

Product Specifications

| Property | Технические характеристики |

|---|---|

| Material Type | PU Leather, PVC Leather, Microfiber Synthetic |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Width (Roll) | 137 cm, 140 cm, 150 cm (standard) |

| Weight Range | 200 – 500 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale, EN ISO 12947) |

| Color Fastness to Rubbing | Grade 4–5 (dry & wet, ISO 105-X12) |

| Light Fastness | >4 (ISO 105-B02) |

| Tensile Strength | ≥ 25 N/cm (warp & weft) |

| Tear Strength | ≥ 10 N (ASTM D624) |

| Cold Crack Resistance | Passes -20°C (ISO 14363) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, texture, back fabric, roll size |

WINIW’s synthetic leather solutions are designed for B2B partners seeking reliable, scalable, and sustainable materials. With in-house R&D, agile production lines, and global logistics support, we help brands and manufacturers meet market demands efficiently—without compromising on quality or compliance.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Advanced Leather Solutions for Modern Manufacturing

WINIW delivers next-generation synthetic leather solutions engineered for performance, sustainability, and cost efficiency in demanding industrial applications. Our materials provide designers and manufacturers with consistent, traceable alternatives to traditional leather, aligning with evolving regulatory and consumer expectations for eco-conscious production. Below we objectively compare WINIW’s synthetic leather solutions against premium real leather across critical business metrics.

Key Comparison: WINIW Synthetic Leather vs. Premium Real Leather

| Attribute | WINIW Synthetic Leather | Premium Real Leather |

|---|---|---|

| Cost | 20-40% lower total landed cost; no seasonal price volatility, consistent yield (95%+ utilization) | Higher base cost; subject to livestock market fluctuations, significant waste (30-40% unusable hides) |

| Долговечность | Superior abrasion resistance (50,000+ double rubs), uniform thickness, 100% waterproof, UV-stable, colorfast | Variable grain integrity, susceptible to moisture damage, requires chemical treatments for water resistance, natural fading |

| Eco-Friendliness | Up to 90% lower carbon footprint, zero animal agriculture impact, OEKO-TEX® certified, 30-60% recycled content options, fully traceable supply chain | High water/land use, methane emissions from livestock, toxic tanning chemicals (unless vegetable-tanned), limited traceability |

Why WINIW Synthetic Leather Optimizes Your Production

- Supply Chain Resilience: Eliminate hide scarcity risks with on-demand production capacity; 8-12 week lead times vs. 6-18 months for premium hides.

- Design Precision: Achieve exact color/texture replication across batches; no natural defects requiring manual sorting.

- Regulatory Compliance: Meet REACH, CPSIA, and LEED standards out-of-the-box; no hazardous tanning residues.

- Waste Reduction: Laser-cut optimized nesting with near-zero material waste; compatible with automated cutting systems.

- End-of-Life Management: Recyclable through WINIW’s closed-loop program (where facilities exist); biodegradable variants in development.

Real leather retains niche value in ultra-luxury heritage goods but introduces significant cost volatility, ethical complexities, and performance limitations for scalable industrial use. WINIW’s solutions deliver predictable economics, engineered performance, and verifiable sustainability—critical advantages for forward-looking brands targeting conscious consumers and ESG-driven investors. Partner with us to future-proof your material strategy without compromising quality.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong focus on quality, sustainability, and technical excellence, WINIW serves a wide range of industries including automotive, furniture, fashion, and accessories.

The company operates from a state-of-the-art manufacturing facility spanning over 100,000 square meters. This large-scale production base integrates advanced automation and environmentally responsible processes to ensure consistent output and efficiency. The facility is designed to support high-volume production while maintaining flexibility for customized solutions tailored to client specifications.

Key strengths of WINIW’s manufacturing capabilities include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and sustainable development. The team continually advances product performance in areas such as abrasion resistance, color fastness, and eco-compliance.

- Implementation of a strict quality control (QC) system throughout every stage of production. Each batch undergoes rigorous testing for physical properties, chemical safety, and environmental standards, ensuring compliance with global regulations such as REACH, RoHS, and OEKO-TEX®.

- Full traceability and process monitoring enabled by smart manufacturing technologies, allowing for consistent product reliability and rapid response to quality feedback.

WINIW exports to key international markets, with established distribution and client partnerships across Europe and the USA. Our products meet the demanding standards of these regions, supported by certifications and a commitment to sustainable manufacturing practices.

The following table summarizes key aspects of WINIW’s factory capabilities:

| Feature | Технические характеристики |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 100+ engineers and technicians |

| Annual Production | Over 100 million meters |

| QC Standards | REACH, RoHS, OEKO-TEX®, ISO 9001 |

| Export Regions | Europe, USA, Japan, Southeast Asia |

| Sustainability Focus | Water-based PU, recycled content options |

With a proven track record in quality, innovation, and global logistics, WINIW is a trusted partner for brands seeking high-performance synthetic leather solutions with environmental integrity.

Contact Us for Samples

WINIW Premium Synthetic Leather: Engineered for Commercial Excellence

As a global leader in sustainable material innovation, WINIW delivers high-performance synthetic leather solutions engineered for demanding B2B applications. Our advanced microfiber technology combines uncompromising durability with rigorous environmental stewardship, providing manufacturers a responsible alternative to traditional leather without sacrificing aesthetics or function. Ideal for automotive interiors, furniture upholstery, and luxury goods, WINIW materials reduce supply chain volatility while meeting stringent industry compliance standards.

Why Partner with WINIW for Your Leather Solutions?

- Consistent Quality & Supply: Eliminate natural leather’s batch variations and ethical concerns with precision-engineered materials available year-round.

- Eco-Performance Leadership: 100% animal-free, OEKO-TEX® STANDARD 100 certified, and manufactured using water-based chemistry with 40% lower carbon footprint vs. conventional synthetics.

- Customization Agility: Tailor thickness (0.6–2.0mm), texture, color (Pantone-matched), and performance properties (abrasion resistance, UV stability) to exact project specifications.

- Cost Efficiency: Reduce waste by 30% with roll goods optimized for automated cutting systems and predictable long-term pricing.

WINIW Product Performance Comparison

| Feature | WINIW EcoLux™ Series | Conventional PU Leather | Genuine Leather |

|---|---|---|---|

| Abrasion Resistance | 50,000+ cycles | 15,000–25,000 cycles | 30,000–40,000 cycles |

| Tensile Strength | 35–45 MPa | 18–25 MPa | 20–30 MPa |

| Water Absorption | <5% (24hrs) | 15–25% (24hrs) | 10–15% (24hrs) |

| Recyclability | 100% closed-loop | Landfill-only | Limited |

| Lead Time | 2–4 weeks | 6–10 weeks | 8–12 weeks |

Industry-Specific Advantages

- Автомобили: Meets FMVSS 302 flammability standards; exceptional colorfastness for sun-exposed interiors; seamless integration with airbag deployment systems.

- Мебель: 300,000+ double-rub durability for high-traffic commercial seating; hypoallergenic and easy-clean surfaces ideal for healthcare/hospitality.

- Accessories: Ultra-lightweight (0.8mm) options for handbags/wallets with authentic drape and stitchability; resistant to plasticizer migration.

Commitment to Sustainable Manufacturing

WINIW’s ISO 14001-certified facilities utilize renewable energy and closed-loop water systems, ensuring every square meter supports your ESG goals. Our materials are PVC-free and phthalate-free, aligning with REACH, CAL TB 117, and LEED v4.1 requirements. Partner with us to future-proof your supply chain while exceeding consumer expectations for ethical luxury.

Elevate your product line with WINIW’s certified leather solutions—engineered for performance, designed for the planet.

Request technical datasheets or claim your free 30cm x 30cm sample kit today. Contact our Material Innovation Team:

MKT88@MicrofiberLeather.com

WINIW: Where Responsibility Meets Resilience

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.