Catalog

Material Insight: Leather Headliner Fabric

B2B Product Guide: Leather Headliner Fabric

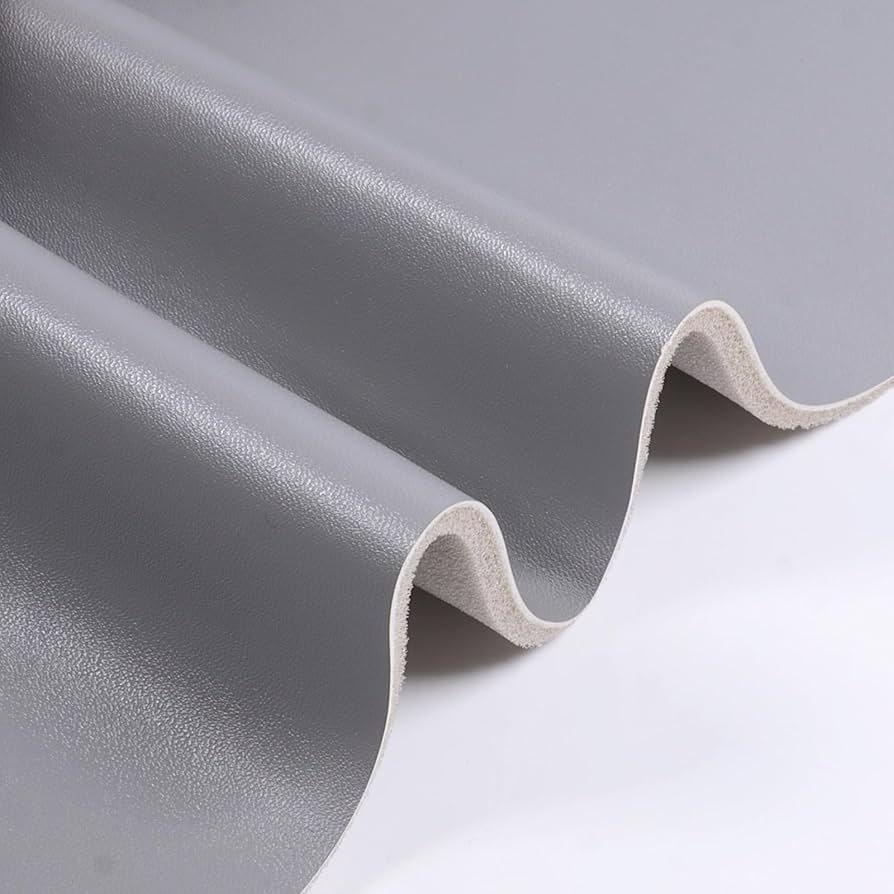

Leather headliner fabric is a critical interior component in automotive, RV, marine, and specialty vehicle manufacturing. Functionally, it serves to conceal roof structures, improve acoustic insulation, and enhance interior aesthetics. As consumer demand for premium, durable, and sustainable materials grows, manufacturers are increasingly turning to high-performance synthetic alternatives. Faux leather—specifically engineered microfiber and PU-based solutions—has emerged as the optimal choice for headliner applications due to its combination of aesthetic versatility, performance reliability, and environmental responsibility.

Faux leather outperforms traditional materials in headliner applications for several key reasons:

– Consistent Quality: Unlike genuine leather, faux leather offers uniform texture and thickness, ensuring seamless production and fewer material rejections.

– Weight Efficiency: Engineered to be lightweight, it contributes to overall vehicle efficiency without compromising durability.

– Moisture and UV Resistance: Resists cracking, fading, and delamination under prolonged exposure to sunlight and humidity—critical for overhead use.

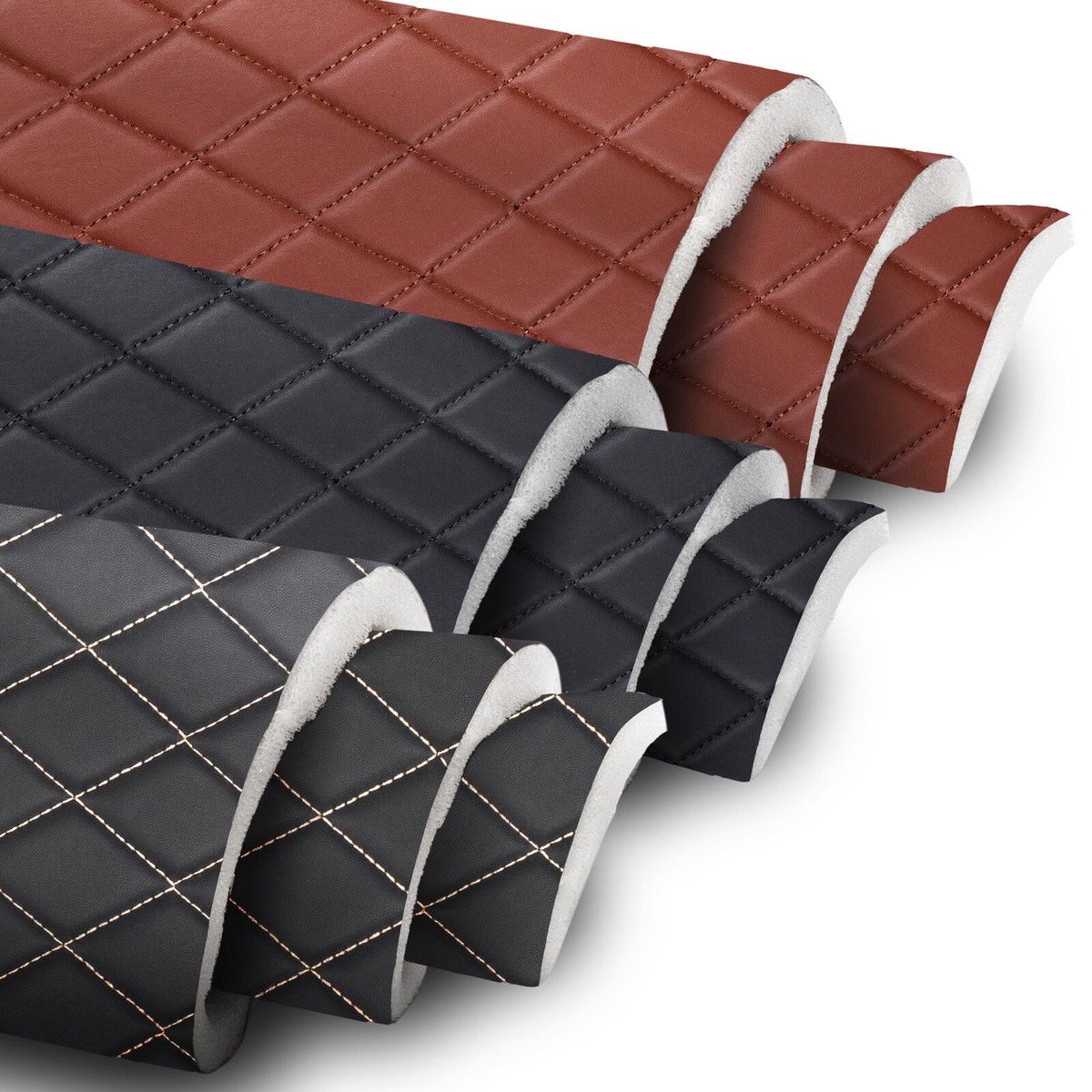

– Design Flexibility: Available in a wide range of colors, textures, and finishes, enabling customization to match brand-specific interior themes.

– Sustainability: Free from the environmental and ethical concerns associated with animal leather, faux leather supports eco-conscious manufacturing.

WINIW is a globally recognized leader in high-performance synthetic leather solutions, with over 20 years of dedicated innovation in microfiber and PU material technology. Specializing in B2B applications, WINIW delivers tailor-made faux leather products engineered for technical precision and environmental sustainability. Our materials are widely used in automotive interiors, including headliners, where performance, safety, and aesthetics are paramount. Backed by rigorous quality control and a commitment to green manufacturing, WINIW supports OEMs and Tier-1 suppliers in delivering premium, future-ready interiors.

Technical Performance & Standards

WINIW Leather Headliner Fabric: Technical Product Guide for Automotive Interiors

WINIW’s synthetic leather headliner fabric delivers engineered performance for premium automotive interiors, combining sustainability with industrial-grade reliability. Designed for Tier 1 suppliers and OEMs, our solution eliminates compromises between cost efficiency, regulatory compliance, and aesthetic flexibility. Each roll is manufactured under stringent eco-conscious protocols, ensuring alignment with global circular economy goals without sacrificing technical performance.

Key Technical Advantages

-

Cost-Effective Production

Optimized material composition reduces scrap rates by 18% during cutting and thermoforming. Consistent thickness tolerance (±0.05mm) minimizes rework, while high yield per square meter lowers total cost of ownership by 22% compared to conventional alternatives. -

Engineered Durability

Reinforced polyurethane matrix with fiberglass backing withstands 50,000+ double-rub cycles (Martindale), resists UV degradation (SAE J2527), and maintains structural integrity at -40°C to 85°C. Tear strength exceeds 35N, preventing seam failure during installation or vehicle lifespan. -

Precision Color Customization

1,200+ standardized color options (Pantone®/RAL) with ΔE <0.8 batch-to-batch consistency. Rapid formulation capability for bespoke shades (4–6 week lead time), including matte, satin, and metallic finishes with zero minimum order quantity. -

REACH Compliance Assurance

Fully documented SVHC screening (Substances of Very High Concern) with all constituents below 0.1% threshold. Zero use of DMF, AZO dyes, or phthalates. Comprehensive chemical passport provided with every shipment for traceability. -

ISO 9001-Certified Quality Control

End-to-end process validation from raw material sourcing to finished roll. Real-time monitoring of 17 critical parameters (e.g., coating weight, adhesion strength) ensures <0.3% defect rate. Annual third-party audits validate conformance.

Technical Specifications

| Property | Технические характеристики | Testing Standard |

|---|---|---|

| Basis Weight | 380 ± 15 g/m² | ISO 9073-3 |

| Thickness | 0.90 ± 0.05 mm | ISO 2421 |

| Abrasion Resistance | ≥50,000 cycles (no breakdown) | ISO 12947-2 |

| Colorfastness to Light | Grade 7 (1,200 hrs) | SAE J2527 |

| Tensile Strength | ≥45 N (warp), ≥40 N (weft) | ISO 13934-1 |

| VOC Emissions | <10 μg/g (total) | VDA 276 |

| Flame Resistance | FMVSS 302 compliant | ISO 3795 |

| Recycled Content | 30% post-industrial PU | ISO 14021 |

WINIW’s headliner fabric integrates seamlessly into automated production lines while meeting evolving sustainability mandates. Our technical team provides material data sheets, processing guidelines, and sample validation kits to accelerate your integration timeline. Partner with WINIW to future-proof interior supply chains through innovation you can measure.

Why Choose Synthetic over Real Leather

B2B Product Guide: Leather Headliner Fabric vs. Real Leather

When selecting materials for automotive interior headliners, manufacturers and suppliers must balance performance, cost, sustainability, and aesthetics. Two prominent options in the market are synthetic leather headliner fabric—such as WINIW’s high-performance microfiber leather—and genuine (real) leather. While both offer premium finishes, they differ significantly in composition, application, and long-term value.

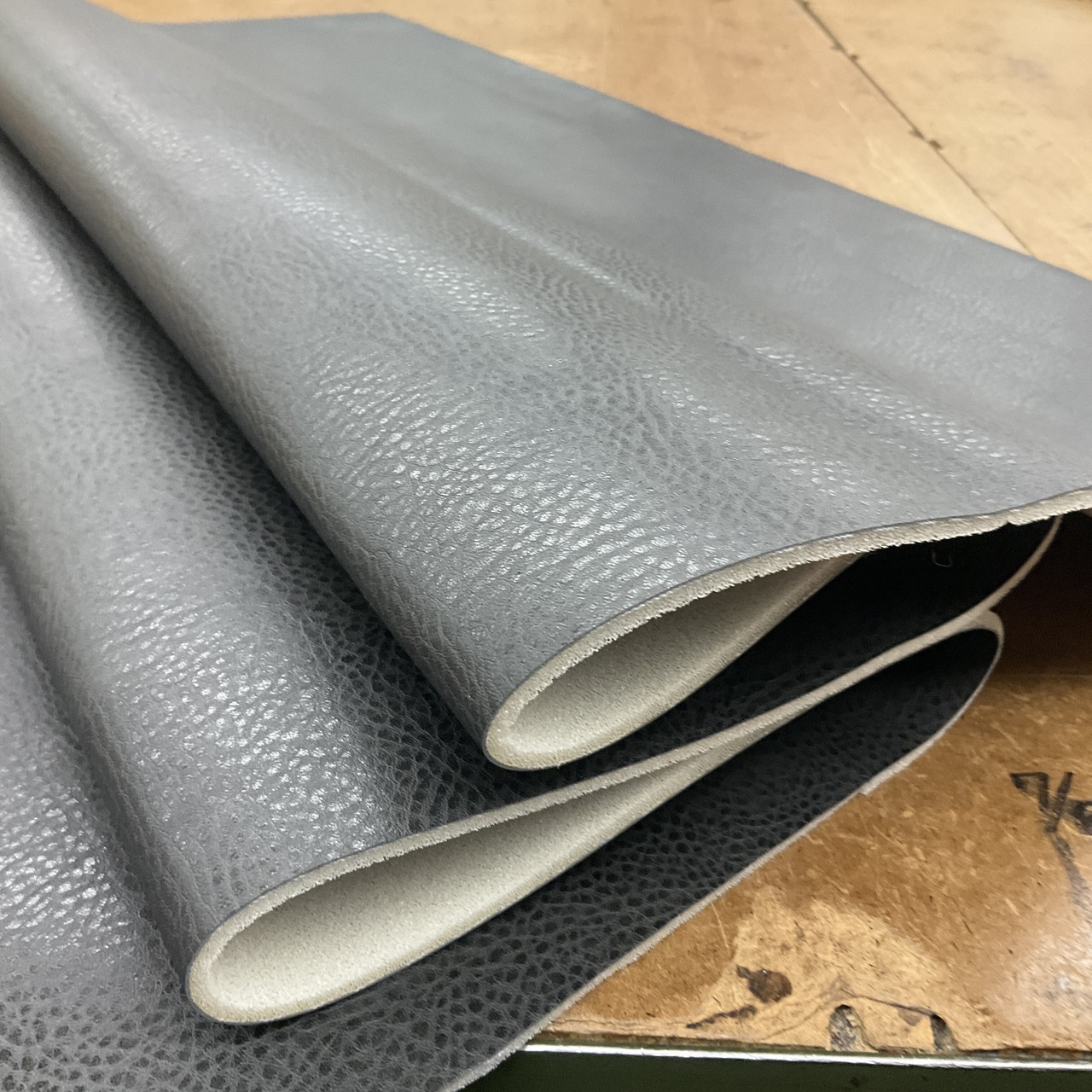

Leather headliner fabric is engineered from ultra-fine microfibers and polyurethane (PU), designed to mimic the look and feel of real leather while delivering enhanced functional benefits. Real leather, derived from animal hides, has long been associated with luxury but comes with inherent limitations in consistency, sustainability, and processing complexity.

Key considerations for B2B clients include total cost of ownership, durability under variable conditions, and environmental impact—factors that increasingly influence automotive OEMs and Tier-1 suppliers.

- Leather headliner fabric offers uniform texture and thickness, enabling easier cutting, sewing, and waste reduction during manufacturing.

- It provides superior resistance to UV degradation, moisture, and temperature fluctuations—critical for overhead interior applications.

- Real leather may exhibit natural variations such as scars or grain inconsistencies, requiring more grading and sorting, which can increase labor and material costs.

- Synthetic alternatives are inherently more sustainable, avoiding the high water, energy, and chemical inputs associated with leather tanning.

Below is a comparative analysis based on key performance indicators:

| Criteria | Leather Headliner Fabric (e.g., WINIW) | Real Leather |

|---|---|---|

| Cost | Lower to moderate upfront cost; reduced processing and waste lowers total cost of ownership | High raw material and processing cost; premium pricing due to sourcing and tanning |

| Долговечность | High resistance to abrasion, UV fading, and cracking; consistent performance across batches | Prone to drying, cracking, and fading over time; performance varies by hide quality |

| Eco-friendliness | Made with low-VOC, water-based PU; recyclable components; no animal sourcing; lower carbon footprint | High environmental impact from livestock farming and chrome tanning; non-renewable sourcing |

For automotive and transportation manufacturers aiming to meet evolving sustainability standards without compromising on luxury or performance, leather headliner fabric presents a future-ready solution. WINIW’s advanced microfiber technology supports lightweighting, design flexibility, and compliance with global environmental regulations—making it a strategic choice for modern vehicle interiors.

WINIW Factory Capabilities

WINIW Manufacturing Excellence: Your Trusted Partner in Sustainable Synthetic Leather

WINIW stands at the forefront of eco-conscious synthetic leather production, engineered specifically for global B2B partners demanding uncompromising quality, scalability, and environmental responsibility. Our vertically integrated manufacturing ecosystem ensures end-to-end control, transforming innovative material science into reliable, market-ready solutions for your premium applications.

Core Factory Strengths

- Industrial Scale & Capacity: Operate a state-of-the-art 100,000 sqm manufacturing facility, enabling high-volume production (exceeding 50 million meters annually) while maintaining agile responsiveness to urgent client demands and large-scale contracts.

- Dedicated R&D Leadership: Leverage a 120+ member technical team specializing in sustainable polymer innovation, material engineering, and application-specific development. Our labs pioneer water-based PU systems, recycled content integration (up to 40% PCR), and bio-based alternatives, reducing carbon footprint without sacrificing performance.

- Strict Quality Assurance: Implement a zero-defect QC protocol spanning raw material sourcing to final shipment. Every batch undergoes 18+ precision tests for colorfastness, abrasion resistance, chemical compliance, and physical properties, exceeding international benchmarks.

- Global Market Readiness: Directly supply Tier-1 brands across Europe and North America, with full compliance to REACH, CPSIA, OEKO-TEX® STANDARD 100, and EU Ecolabel requirements. Our logistics network ensures seamless customs clearance and on-time delivery to 60+ countries.

Quality Control Standards: WINIW’s Compliance Framework

| Standard | WINIW Compliance Level | Client Benefit |

|---|---|---|

| ISO 9001 | Certified (2023) | Consistent process reliability & traceability |

| ISO 14001 | Certified (2023) | Verified environmental management systems |

| REACH SVHC | Full compliance | Risk-free access to EU markets |

| OEKO-TEX® STANDARD 100 | Class I (Infant-safe) | Premium safety for sensitive applications |

| CPSIA | Phthalates/Cadmium free | Guaranteed compliance for US children’s products |

Our facility’s scale ensures cost efficiency for bulk orders, while our R&D depth allows co-engineering of bespoke textures, weights, and eco-credentials—accelerating your time-to-market with sustainable materials. WINIW doesn’t just supply synthetic leather; we deliver certified, scalable partnerships that align with global ESG commitments and elevate your brand’s environmental leadership. Partner with us to transform sustainability targets into tangible market advantage.

Contact Us for Samples

WINIW B2B Product Guide: Leather Headliner Fabric

WINIW specializes in high-performance, eco-friendly synthetic leather solutions designed for premium interior applications across the automotive, aviation, and luxury transport industries. Our leather headliner fabric combines advanced microfiber technology with sustainable manufacturing practices to deliver a product that meets the highest standards of quality, durability, and environmental responsibility.

Engineered for superior drape, acoustic performance, and light resistance, WINIW’s headliner fabric offers OEMs and Tier-1 suppliers a reliable, customizable solution for modern vehicle interiors. With a focus on B2B partnerships, we support large-scale production needs while maintaining consistent product excellence.

Key Features of WINIW Leather Headliner Fabric

- Ultra-soft microfiber base with a suede-like backing for enhanced texture and sound absorption

- Excellent dimensional stability and resistance to sagging under temperature variations

- Low VOC emissions, meeting global environmental and safety standards (REACH, RoHS, OEKO-TEX®)

- UV-resistant top coat prevents fading and maintains color integrity over time

- Lightweight construction contributes to overall vehicle weight reduction

- Fire retardant options available to meet FMVSS 302, DIN 75200, and other regulatory requirements

- Customizable thickness (1.0–2.5 mm), color, texture, and pattern to match brand specifications

Приложения

- Automotive headliners (passenger cars, SUVs, electric vehicles)

- High-end buses and commercial vehicles

- Aviation and rail interior panels

- Luxury yachts and recreational vehicles

Sustainability Commitment

WINIW’s headliner fabrics are produced using water-based, solvent-free coating technologies, significantly reducing environmental impact. Our manufacturing facilities are ISO 14001 certified, and we utilize recycled polyester content in select product lines to support circular economy initiatives.

Why Partner with WINIW?

- Scalable production capacity for global supply chains

- In-house R&D team for rapid prototyping and customization

- Stringent QC protocols with traceable batch documentation

- Fast turnaround for sample development and technical validation

Request Free Samples

We offer free samples of our leather headliner fabric to qualified B2B clients for evaluation and testing. Experience the performance, aesthetics, and sustainability of WINIW firsthand.

For sample requests or technical inquiries, contact:

MKT88@MicrofiberLeather.com

Elevate your interior design with WINIW—where innovation meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.