Catalog

Material Insight: Leather Cloth Material

B2B Product Guide: Understanding Leather Cloth Material

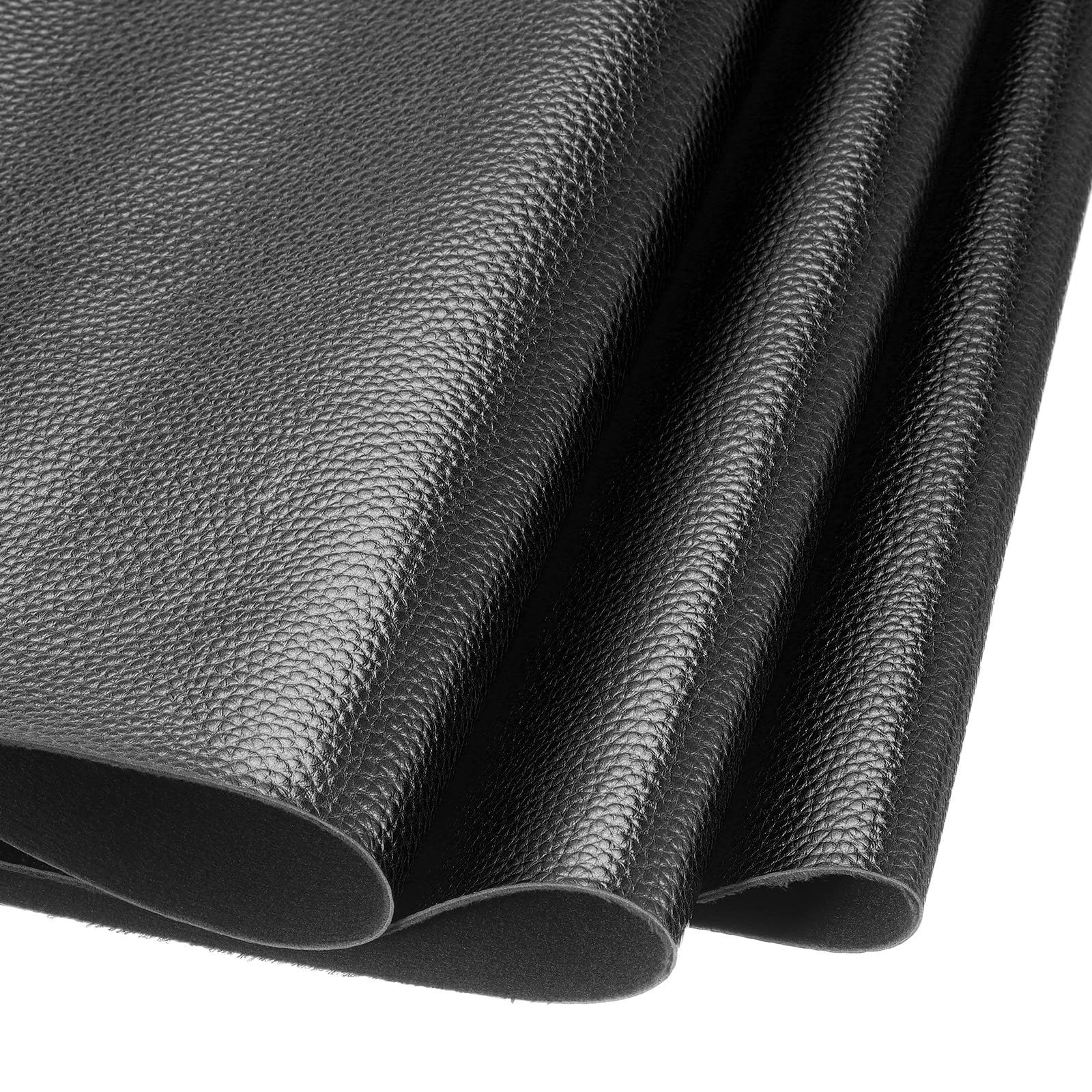

Leather cloth material—often referred to as coated fabric or engineered leather substrate—represents a critical category of performance textiles designed for demanding applications where durability, aesthetics, and functionality intersect. Unlike traditional leather, this category encompasses synthetic or composite fabrics engineered with polyurethane (PU), polyvinyl chloride (PVC), or bio-based coatings laminated onto textile backings (e.g., polyester, cotton, or recycled fibers). It is widely specified across upholstery, automotive interiors, luggage, footwear, and technical goods requiring consistent texture, tear resistance, and design versatility.

Why Faux Leather is the Optimal Choice for Leather Cloth Applications

Faux leather outperforms traditional materials in modern B2B contexts due to its engineered precision and alignment with evolving market demands. Key advantages include:

– Consistent Quality & Scalability: Eliminates natural hide variations, ensuring uniform color, texture, and thickness across large production runs—critical for brand consistency in mass manufacturing.

– Enhanced Durability: Engineered to resist abrasion, UV degradation, and microbial growth, extending product lifecycle in high-use environments (e.g., commercial furniture or automotive seating).

– Sustainability Compliance: Offers traceable eco-credentials through recycled content, water-based coatings, and VOC-free processes—meeting stringent global regulations (REACH, OEKO-TEX®) without compromising performance.

– Design Flexibility: Enables infinite customization in color, embossing, and tactile finishes, accelerating time-to-market for innovative product lines.

– Ethical & Cost Efficiency: Avoids animal-derived materials while reducing waste and long-term costs via higher yield rates and simplified supply chains.

Introducing WINIW: Your Trusted Partner in Advanced Synthetic Leather

With over 20 years of specialized expertise, WINIW has pioneered sustainable synthetic leather solutions for global B2B manufacturers seeking performance without compromise. We engineer every LEATHER CLOTH™ product through a rigorous R&D framework focused on:

– Eco-Innovation: Our proprietary EcoCalm™ and BioFlex™ technologies integrate 30–50% recycled content and plant-based polymers, achieving ISO 14001-certified production with 60% lower carbon footprint vs. conventional synthetics.

– Application-Specific Engineering: From high-abrasion automotive grade (50,000+ double-rubs) to ultra-soft apparel textiles, our materials are validated for real-world industrial use.

– End-to-End Collaboration: Partner with us for technical co-development, rapid prototyping, and compliance documentation tailored to your regional and sector requirements.

In an era where sustainability drives procurement decisions, WINIW’s LEATHER CLOTH™ delivers the durability, ethics, and innovation modern businesses require—proven across 10,000+ global client projects. Let’s redefine performance, responsibly.

Technical Performance & Standards

WINIW Leather Cloth Material – B2B Product Guide

WINIW’s leather cloth material is engineered for performance-driven industries seeking a sustainable, high-quality alternative to genuine leather. Designed with precision and manufactured under stringent quality standards, this synthetic leather offers a compelling combination of cost-efficiency, durability, and customization, making it ideal for automotive interiors, furniture, luggage, footwear, and technical applications.

Built on a foundation of innovation and environmental responsibility, WINIW’s leather cloth material delivers consistent performance while meeting global regulatory requirements. It is especially suited for B2B partners aiming to reduce material costs without compromising on aesthetics or longevity.

Key Technical Advantages

-

Cost-Effective Solution: Offers significant cost savings compared to genuine leather while maintaining a premium look and feel. Reduces dependency on volatile raw material markets and minimizes waste during cutting and processing.

-

Exceptional Durability: Reinforced with high-tenacity polyester or nylon backings, the material exhibits superior abrasion resistance, tear strength, and dimensional stability. Suitable for high-wear applications with long lifecycle demands.

-

Customizable Colors & Finishes: Available in a wide spectrum of standard colors, with full capability for custom color matching (Pantone, RAL, etc.). Surface textures can be tailored—matte, glossy, embossed, or soft-touch—to meet specific design and functional needs.

-

REACH Compliant: Fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensuring the absence of harmful substances. Safe for use in consumer and industrial products across European markets.

-

ISO9001-Certified Production: Manufactured in facilities certified under ISO 9001 quality management standards, guaranteeing consistent product quality, traceability, and continuous improvement in production processes.

-

Eco-Friendly Profile: Utilizes water-based polyurethane (PU) coatings and low-VOC formulations, reducing environmental impact during production and end-of-life disposal.

Technical Specifications

| Property | Технические характеристики |

|---|---|

| Base Material | Knitted or woven polyester/nylon fabric |

| Coating Type | Water-based PU or PVC-free alternatives |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight | 200 – 500 g/m² (depending on construction) |

| Tensile Strength | ≥ 80 N/5cm (warp and weft) |

| Elongation at Break | ≤ 25% |

| Abrasion Resistance | ≥ 30,000 cycles (Martindale, dry) |

| Color Fastness to Rubbing | Grade 4–5 (dry), Grade 4 (wet) |

| Color Fastness to Light | ≥ Grade 6 (after 40 hrs Xenon exposure) |

| Cold Crack Resistance | Passes at -20°C |

| REACH Compliance | Yes (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, texture, thickness, roll width (1.37m, 1.5m standard) |

WINIW’s leather cloth material supports scalable B2B supply chains with batch consistency, fast turnaround, and technical documentation for compliance auditing. By integrating advanced materials science with sustainable manufacturing, WINIW enables brands to deliver premium products responsibly and cost-effectively.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather for Industrial Applications

As a B2B solutions provider, WINIW delivers high-performance materials engineered for durability, sustainability, and cost-efficiency. Understanding the core differences between synthetic leather (“leather cloth material”) and real leather is critical for informed procurement decisions. Below is a technical comparison focused on key operational metrics for commercial use.

Key Differentiators

- Material Composition: Synthetic leather utilizes polymer bases (e.g., PU, PVC) with non-woven or knit substrates, while real leather is derived from tanned animal hides.

- Consistency: Synthetic leather offers uniform texture, color, and thickness; real leather exhibits natural variations (scars, grain differences).

- Ethical & Regulatory Compliance: Synthetic leather eliminates animal welfare concerns and aligns with global restrictions on chromium-tanned hides (e.g., EU REACH).

- Lead Times: Synthetic leather enables faster production cycles due to standardized manufacturing; real leather requires lengthy tanning and grading.

Performance & Sustainability Comparison

| Metric | Synthetic Leather (WINIW Standard) | Real Leather (Full-Grain) |

|---|---|---|

| Cost (USD/sq ft) | $3.50 – $8.00 | $12.00 – $25.00+ |

| Durability (Martindale Abrasion) | 50,000+ cycles (industrial grade) | 25,000 – 40,000 cycles |

| Eco-Friendliness | • 60% lower water usage vs. tanning • 100% chrome-free • Up to 40% recycled content (WINIW EcoLine) |

• High water/chemical consumption • Chromium pollution risk • Limited recycled potential |

Why Choose WINIW Synthetic Leather for B2B Applications

- Supply Chain Resilience: Avoid hide market volatility and ethical audits; consistent global availability.

- Customization: Tailor thickness (0.6mm–1.8mm), breathability, and fire resistance (e.g., CA TB 117-2013) for automotive, furniture, or luggage.

- Circular Economy Support: Our EcoLine series uses post-consumer recycled polyester and waterless dyeing, reducing carbon footprint by 30% vs. conventional synthetics.

- Total Cost of Ownership: Lower material waste (predictable yields), reduced maintenance, and extended product lifecycle offset initial pricing gaps.

For industries prioritizing ESG compliance without sacrificing performance, WINIW synthetic leather delivers a future-proof alternative. Request our technical datasheets for abrasion, lightfastness, and chemical resistance testing protocols.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our large-scale manufacturing capabilities, deep technical expertise, and commitment to quality have positioned us as a trusted supplier across diverse industries including automotive, furniture, fashion, and sports.

Our production is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive factory integrates advanced automation with precision engineering to ensure consistent output, high production capacity, and efficient lead times—critical for meeting the demands of international partners and large-volume orders.

Key strengths of the WINIW factory include:

-

Advanced R&D Team: A dedicated research and development team of over 100 professionals drives continuous innovation. We focus on developing sustainable materials, including water-based, solvent-free, and recycled synthetic leather solutions that align with global environmental standards.

-

Strict Quality Control (QC): Every stage of production follows a rigorous QC protocol. From raw material inspection to finished product testing, we adhere to ISO 9001 standards and conduct performance tests for abrasion resistance, color fastness, tensile strength, and eco-compliance (REACH, RoHS, OEKO-TEX®).

-

Sustainable Manufacturing: Our facility is equipped with energy-efficient production lines and eco-conscious waste management systems. We prioritize low-carbon processes and have achieved certifications including ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health & Safety).

-

Global Export Network: WINIW exports to over 50 countries, with a strong market presence in Europe and the USA. Our logistics network ensures reliable delivery, and our compliance with regional regulatory requirements simplifies cross-border procurement for partners.

By combining scale, innovation, and sustainability, WINIW delivers synthetic leather solutions that meet the highest international standards—supporting brands in achieving both performance goals and environmental responsibility.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Leather Cloth Material for Sustainable B2B Applications

WINIW Microfiber Leather represents the pinnacle of eco-conscious, high-performance synthetic leather cloth material engineered specifically for demanding commercial and industrial applications. As a leader in sustainable material innovation, we deliver exceptional durability, design flexibility, and environmental responsibility without compromising on luxury aesthetics. Our solution is trusted by global manufacturers in furniture, automotive, fashion, and technical textiles seeking reliable, scalable, and planet-positive alternatives to traditional leather and inferior synthetics.

Why WINIW Microfiber Leather Cloth Material?

- Unmatched Eco-Credentials: Manufactured using water-based, solvent-free processes and 30%+ recycled content. Certified by OEKO-TEX® STANDARD 100 (Class I) and Global Recycled Standard (GRS), ensuring zero toxic residues and traceable circularity.

- Industrial-Grade Durability: Engineered for 50,000+ double-rub cycles (Martindale), superior tear strength (>45 N), and UV resistance (ISO 105-B02: Grade 7-8), guaranteeing longevity in high-traffic environments.

- Design Versatility: Available in 12+ base weights (0.6–1.8mm), 200+ stock colors, and customizable textures (suede, pebble, exotic embosses). Compatible with laser cutting, ultrasonic welding, and digital printing.

- Cost-Efficient Scalability: Roll widths up to 1.8m with consistent color/texture batch-to-batch, reducing waste and accelerating production timelines versus natural leather.

- End-of-Life Responsibility: Fully recyclable through WINIW’s take-back program, supporting true circular economy integration.

Performance Comparison: WINIW vs. Conventional Materials

| Параметр | WINIW Microfiber Leather | Standard PU Leather | Genuine Leather |

|---|---|---|---|

| Состав | Recycled PET + PU (solvent-free) | Virgin PVC/PU + DMF solvents | Animal hide + heavy tanning chemicals |

| Eco-Impact (CO2e) | 30% lower footprint | High emissions | Highest emissions (livestock + tanning) |

| Abrasion Resistance | 50,000+ cycles | 15,000–25,000 cycles | Varies (30,000–50,000 cycles) |

| Water Absorption | <5% (hydrophobic) | 15–25% | 20–30% (requires sealing) |

| Customization Lead Time | 15–20 days (small MOQs) | 30–45 days | 60+ days (hide variability) |

Ideal Applications Across Industries

- Furniture & Contract Interiors: High-resilience upholstery for sofas, chairs, and hotel lobbies (meets CA TB 117-2013, BS 5852).

- Automotive Interiors: Seamless door panels, seats, and dashboards with low VOC emissions (<10μg/g) and temperature stability (-30°C to 85°C).

- Fashion & Accessories: Lightweight, flexible material for bags, footwear, and apparel with superior drape and stitchability.

- Technical Textiles: Marine, aviation, and healthcare applications requiring antimicrobial properties (ISO 22196) and easy cleanability.

Commitment to Sustainable Partnership

WINIW operates a closed-loop production system powered by 100% renewable energy, diverting 12,000+ tons of plastic waste annually from landfills. Our quality control adheres to ISO 9001:2015 standards, with real-time batch traceability via blockchain technology.

Request Free Samples for Your Next Project

Experience WINIW’s premium leather cloth material firsthand. Our technical team provides full application support—from material selection to production integration—to ensure seamless adoption.

→ Contact WINIW Marketing: MKT88@MicrofiberLeather.com

Free physical samples available for qualified B2B partners. Specify your industry, application, and required specs for tailored recommendations.

WINIW: Engineering Sustainable Luxury for a Responsible Future.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.