Introduction: Navigating the Global Market for faux suede

In today’s competitive landscape, sourcing high-quality faux suede presents a significant challenge for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. With a plethora of options available, the need for reliable information on product types, applications, and supplier vetting is paramount. This guide aims to navigate the complexities of the global faux suede market, offering insights into various types of faux suede, their diverse applications—from upholstery and fashion to event decor—and essential considerations for evaluating suppliers.

Buyers will gain a comprehensive understanding of the factors influencing cost, including material quality, production methods, and shipping logistics. Furthermore, this guide will empower businesses to make informed purchasing decisions by providing actionable insights into market trends and best practices. Whether you are a buyer in Germany looking for innovative upholstery solutions or a supplier in Brazil aiming to expand your product offerings, this resource will serve as a vital tool for navigating the faux suede landscape. By equipping buyers with the knowledge needed to assess quality and sustainability, this guide fosters confidence in sourcing decisions, ultimately driving successful business outcomes in the global marketplace.

Table Of Contents

- Top 6 Faux Suede Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux suede

- Understanding faux suede Types and Variations

- Key Industrial Applications of faux suede

- 3 Common User Pain Points for ‘faux suede’ & Their Solutions

- Strategic Material Selection Guide for faux suede

- In-depth Look: Manufacturing Processes and Quality Assurance for faux suede

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux suede’

- Comprehensive Cost and Pricing Analysis for faux suede Sourcing

- Alternatives Analysis: Comparing faux suede With Other Solutions

- Essential Technical Properties and Trade Terminology for faux suede

- Navigating Market Dynamics and Sourcing Trends in the faux suede Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux suede

- Strategic Sourcing Conclusion and Outlook for faux suede

- Important Disclaimer & Terms of Use

Understanding faux suede Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microsuede | Soft, napped finish; lightweight and durable | Upholstery, fashion, bags, and costumes | Pros: Affordable, versatile; Cons: Limited cleaning options (dry clean only) |

| Ultrasuede | High-end look; thicker and more luxurious | Automotive interiors, high-end upholstery | Pros: Premium appearance, stain-resistant; Cons: Higher cost compared to other faux suedes |

| Faux Suede Leather | Leather-like texture; water-resistant | Footwear, bags, and outdoor gear | Pros: Durable, easy to clean; Cons: Can be less breathable than fabric versions |

| Faux Microfiber Suede | Ultra-soft and fine texture; highly durable | Apparel, home décor, and bedding | Pros: Soft feel, stain-resistant; Cons: May be pricier than standard faux suede |

| Eco-Friendly Faux Suede | Made from recycled materials; sustainable | Eco-conscious fashion and upholstery | Pros: Environmentally friendly; Cons: Availability may vary depending on suppliers |

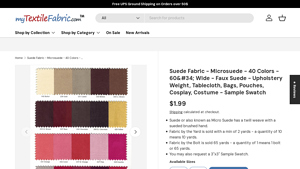

What Are the Key Characteristics of Microsuede?

Microsuede is a popular faux suede variant known for its soft, napped finish and lightweight, durable nature. It is made from polyester fibers, making it an excellent choice for various applications, including upholstery, fashion items, bags, and costumes. B2B buyers should note that while microsuede is versatile and affordable, it requires dry cleaning, limiting its appeal for high-traffic items. When sourcing microsuede, consider color options and fabric weight to ensure it meets your specific needs.

How Does Ultrasuede Stand Out in the Market?

Ultrasuede is a premium faux suede that provides a thicker, more luxurious feel compared to its counterparts. It is often used in automotive interiors and high-end upholstery due to its superior durability and stain resistance. For B2B buyers, the investment in ultrasuede can yield a high return in terms of customer satisfaction and brand reputation. However, its higher price point may require justification in budget-sensitive projects. Suppliers should ensure consistent quality and color matching, as these are critical factors for buyers.

Illustrative image related to faux suede

What Are the Advantages of Faux Suede Leather?

Faux suede leather mimics the look and feel of genuine leather while being more affordable and easier to clean. Its water-resistant properties make it ideal for footwear, bags, and outdoor gear. B2B buyers must consider the balance between durability and breathability when selecting this material. While faux suede leather is generally more durable, it may not offer the same breathability as fabric versions, which could be a consideration for apparel applications.

Why Choose Faux Microfiber Suede for Your Business?

Faux microfiber suede boasts an ultra-soft texture and exceptional durability, making it suitable for apparel, home décor, and bedding. This material is often stain-resistant, which adds to its appeal for B2B buyers looking for easy-to-maintain options. However, it may come at a higher price point than standard faux suede. Buyers should weigh the cost against the benefits of softness and longevity, especially in competitive markets where quality can influence purchasing decisions.

What Makes Eco-Friendly Faux Suede a Smart Choice?

Eco-friendly faux suede is crafted from recycled materials, appealing to environmentally conscious brands and consumers. Its applications often include eco-friendly fashion and upholstery, making it an excellent choice for businesses that prioritize sustainability. While this variant supports green initiatives, availability can be inconsistent, which may pose challenges for B2B buyers. Establishing relationships with reliable suppliers is crucial to ensure a steady supply of eco-friendly options.

Key Industrial Applications of faux suede

| Industry/Sector | Specific Application of faux suede | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Clothing and Accessories | Offers a stylish alternative to leather, appealing to eco-conscious consumers. | Look for color variety, fabric weight, and durability. |

| Автомобили | Upholstery and Interior Design | Enhances vehicle aesthetics while being cost-effective and easy to maintain. | Ensure compliance with automotive standards and certifications. |

| Home Furnishings | Upholstery for Furniture | Provides a luxurious feel at a lower cost than natural suede, catering to budget-conscious consumers. | Check for stain resistance and cleaning requirements. |

| Event Management | Tablecloths and Drapery | Adds elegance to events while being lightweight and easy to transport. | Consider color options and fabric weight for durability. |

| Craft and DIY | Costumes and Craft Projects | Versatile for various projects, allowing creativity without the high costs of genuine suede. | Assess fabric availability and ease of cutting and sewing. |

How is Faux Suede Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, faux suede is widely used for clothing and accessories, providing a sustainable alternative to leather. The soft texture and availability in multiple colors appeal to eco-conscious consumers. Businesses benefit from faux suede’s cost-effectiveness, allowing them to offer stylish products without compromising on quality. International buyers should prioritize sourcing options that guarantee consistent color and fabric weight, as variations can affect the final product’s appeal.

What Role Does Faux Suede Play in Automotive Upholstery?

Faux suede is increasingly popular in the automotive industry for upholstery and interior design. It enhances vehicle aesthetics while being more affordable than genuine leather, making it an attractive option for manufacturers and consumers alike. Additionally, faux suede is easier to clean and maintain, addressing durability concerns. Buyers should consider sourcing faux suede that meets automotive industry standards, ensuring compliance with safety and environmental regulations.

How is Faux Suede Beneficial in Home Furnishings?

In the home furnishings sector, faux suede is utilized for upholstery on furniture, providing a luxurious feel without the high price tag associated with natural suede. This material caters to budget-conscious consumers looking for stylish options. Its stain resistance and ease of cleaning further enhance its appeal in residential applications. B2B buyers should focus on sourcing durable faux suede that meets specific cleaning and maintenance requirements to ensure long-lasting products.

Illustrative image related to faux suede

Why is Faux Suede Popular in Event Management?

Faux suede serves as an elegant choice for tablecloths and drapery in the event management industry. Its lightweight nature makes it easy to transport and set up, while its luxurious appearance enhances the overall ambiance of events. Businesses benefit from the affordability of faux suede, allowing them to offer high-quality decor at competitive prices. Buyers should evaluate color options and fabric weight to ensure that the materials can withstand various event settings.

How is Faux Suede Used in Craft and DIY Projects?

Faux suede is a versatile material for craft and DIY projects, including costumes and various creative endeavors. Its affordability and ease of use make it a favorite among hobbyists and professional crafters alike. This fabric allows for a wide range of applications, from simple accessories to elaborate costumes. When sourcing faux suede for crafting, buyers should assess fabric availability and ensure that it can be easily cut and sewn without fraying.

3 Common User Pain Points for ‘faux suede’ & Their Solutions

Scenario 1: Sourcing Quality Faux Suede for Diverse Applications

The Problem: B2B buyers often struggle to find a reliable source for high-quality faux suede that meets specific project requirements. Given the variety of applications—from upholstery to fashion—buyers may encounter issues with material durability, color consistency, and texture. For example, a buyer sourcing faux suede for a high-end furniture line may receive samples that look different from the actual product due to dye lot variations, leading to potential mismatches in customer expectations and product quality.

Illustrative image related to faux suede

The Solution: To overcome these sourcing challenges, buyers should establish strong relationships with manufacturers or suppliers who offer comprehensive product specifications, including information on dye lots and fabric weight. Requesting sample swatches before placing bulk orders is crucial, as it allows buyers to verify texture and color accuracy. Additionally, conducting due diligence on suppliers by checking reviews and case studies can help assess their reliability and product quality. Buyers should also consider ordering a small batch first to evaluate the performance of the faux suede in real-world applications before committing to larger orders.

Scenario 2: Managing Care Instructions for Faux Suede Products

The Problem: Faux suede is often marketed as a low-maintenance alternative to genuine leather, but improper care can lead to significant issues such as staining, matting, or loss of texture. B2B buyers, especially those in the fashion and upholstery sectors, may find that customers are unaware of proper cleaning methods, leading to complaints and returns. For example, a buyer might receive feedback from clients about their faux suede products looking worn out after only a few uses, which can damage their brand reputation.

The Solution: To address care-related concerns, buyers should proactively educate their customers about the specific cleaning and maintenance requirements for faux suede. Providing clear care instructions with each purchase, including recommendations for dry cleaning and avoiding machine washing, can significantly enhance product longevity. Additionally, creating online resources, such as care guides or videos, can help customers understand the best practices for maintaining their faux suede products. Buyers may also consider offering complementary care products, such as fabric protectors, to enhance the customer experience and satisfaction.

Scenario 3: Addressing Environmental Concerns with Faux Suede Materials

The Problem: As sustainability becomes increasingly important, B2B buyers face pressure to source materials that are environmentally friendly. Faux suede, primarily made from polyester, raises concerns about its environmental impact, particularly in regions where eco-consciousness is growing, such as Europe and parts of South America. Buyers may struggle to find faux suede options that align with their sustainability goals while also meeting quality and performance standards.

Illustrative image related to faux suede

The Solution: To mitigate environmental concerns, buyers should seek out suppliers that offer eco-friendly alternatives to traditional faux suede, such as those made from recycled materials or produced using sustainable practices. Engaging in conversations with manufacturers about their sourcing and production methods can provide insights into the environmental impact of the materials. Furthermore, buyers can leverage certifications or labels that signify sustainable practices, making it easier to communicate the eco-friendliness of their products to their customers. By prioritizing sustainability in their sourcing strategy, buyers can not only meet market demands but also enhance their brand’s reputation as an environmentally responsible choice.

Strategic Material Selection Guide for faux suede

When selecting materials for faux suede, B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Here, we analyze four common materials used in the production of faux suede, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Polyester Faux Suede?

Polyester is the most common material used in faux suede production due to its versatility and cost-effectiveness. It offers a soft, velvety texture that mimics genuine suede while providing durability and resistance to wear. Polyester faux suede typically has a weight of around 225 grams per square meter, making it suitable for various applications, including upholstery, fashion, and accessories.

Pros: Polyester faux suede is lightweight, easy to clean, and resistant to fading and stains. It also retains its shape well under pressure, making it ideal for upholstery and other applications where durability is crucial.

Illustrative image related to faux suede

Cons: While it is generally durable, polyester can be less breathable than natural materials, which may affect comfort in clothing applications. Additionally, it may not perform as well in extreme temperatures compared to other materials.

Impact on Application: Polyester faux suede is compatible with a wide range of media, including dyeing and printing, allowing for vibrant colors and patterns. This adaptability is particularly beneficial for markets in Africa and South America, where colorful designs are often preferred.

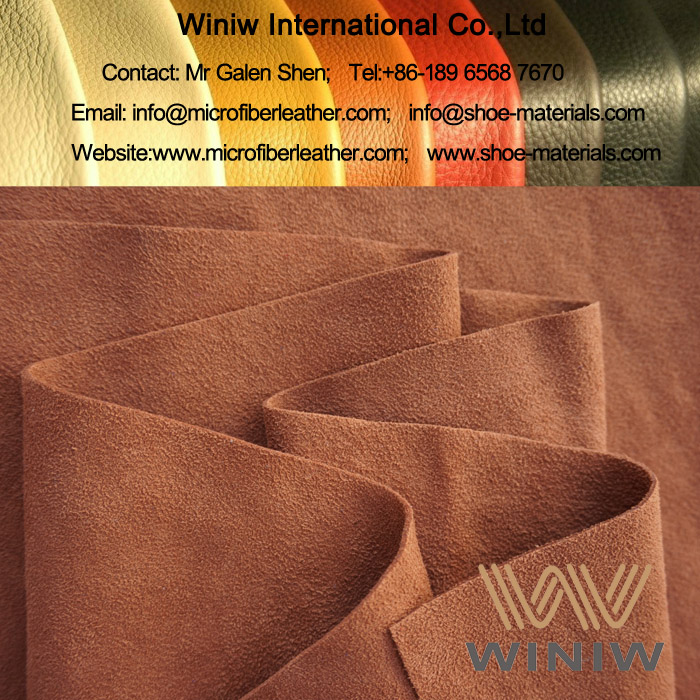

How Does Microfiber Compare in Faux Suede Applications?

Microfiber, a synthetic blend of polyester and polyamide, is another popular choice for faux suede. Its unique structure provides a soft, luxurious feel while enhancing durability and stain resistance.

Pros: Microfiber faux suede is exceptionally durable and offers superior resistance to wear and tear. It is also water-resistant, making it suitable for outdoor applications or environments with high humidity.

Cons: The manufacturing process for microfiber can be more complex, resulting in higher production costs. Additionally, while it is generally easy to clean, it may require special care to maintain its appearance over time.

Impact on Application: Microfiber’s water resistance makes it ideal for applications in the Middle East, where humidity and heat can be significant factors. Its softness and luxurious feel also align with European markets that prioritize high-quality materials.

What Are the Benefits of Nylon Faux Suede?

Nylon is less common than polyester and microfiber but offers unique advantages for faux suede applications. It is known for its strength and resilience, making it suitable for heavy-duty applications.

Pros: Nylon faux suede is highly durable and resistant to abrasion, making it ideal for products that undergo heavy use, such as automotive upholstery and outdoor furniture.

Cons: The cost of nylon is typically higher than polyester, which may deter some buyers. Additionally, it can be less flexible, which may limit its use in fashion applications.

Impact on Application: Given its durability, nylon faux suede is particularly suited for industries in Europe that require long-lasting materials for high-traffic areas. Compliance with European standards for textiles can also be met with nylon products.

How Does Rayon Faux Suede Stand Out?

Rayon, a semi-synthetic fiber made from natural sources, provides a different texture and aesthetic compared to synthetic options. It offers a soft, luxurious feel that closely resembles natural suede.

Illustrative image related to faux suede

Pros: Rayon faux suede is highly breathable and has a beautiful drape, making it suitable for fashion applications. It also dyes well, allowing for a wide range of colors.

Cons: Rayon is less durable than synthetic options, making it less suitable for high-wear applications. It is also more prone to wrinkling and may require more maintenance.

Impact on Application: Rayon faux suede is particularly appealing in fashion markets across Africa and South America, where aesthetics and comfort are paramount. However, buyers should be aware of care requirements to ensure longevity.

Summary Table of Material Selection for Faux Suede

| Материал | Typical Use Case for faux suede | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Upholstery, fashion accessories | Cost-effective and durable | Less breathable than natural materials | Низкий |

| Микрофибра | Outdoor furniture, automotive | Water-resistant and highly durable | Higher production costs | Medium |

| Nylon | Heavy-duty applications | Excellent abrasion resistance | Higher cost and less flexibility | Высокий |

| Rayon | Fashion apparel | Soft, luxurious feel and breathability | Less durable and prone to wrinkling | Medium |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that align with their product requirements and market preferences, ensuring successful procurement and application of faux suede materials.

Illustrative image related to faux suede

In-depth Look: Manufacturing Processes and Quality Assurance for faux suede

What Are the Key Stages in the Manufacturing Process of Faux Suede?

Faux suede, often made from polyester or other synthetic fibers, undergoes a meticulous manufacturing process that ensures a high-quality product suitable for various applications such as upholstery, fashion, and accessories. The typical manufacturing process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Faux Suede Production?

The manufacturing process begins with material preparation, where polyester fibers are sourced and treated. These fibers are often produced through polymerization, followed by spinning into yarn. The yarn is then woven or knitted into a base fabric. For faux suede, a twill weave is commonly employed, creating a soft, textured surface that mimics the feel of genuine suede.

Pre-dyeing treatments may also be applied to enhance the fabric’s texture and prepare it for dyeing. This step is crucial for achieving vibrant colors and ensuring that they adhere well to the fabric.

Illustrative image related to faux suede

What Techniques Are Used in Forming Faux Suede?

Once the material is prepared, it moves on to the forming stage. This involves several key techniques:

-

Weaving or Knitting: Depending on the desired end product, the polyester yarn is woven or knitted into a fabric. The choice of technique affects the fabric’s weight, drape, and overall feel.

-

Brushing: After weaving, the fabric undergoes a brushing process to create the characteristic soft and fuzzy texture of suede. This is typically done using specialized machines that raise the fibers, giving the fabric its napped finish.

-

Dyeing: The fabric is then dyed using various methods, including continuous dyeing or batch dyeing, to achieve the desired color. Advanced dyeing techniques ensure that the colors are consistent and vibrant across different batches.

How Does the Assembly Process Work for Faux Suede Products?

In the assembly stage, the finished fabric is cut into the required shapes and sizes for specific applications. This could include upholstery pieces, garments, or accessories. The assembly process may involve sewing, gluing, or bonding, depending on the final product’s design and functionality.

Quality control checkpoints are crucial during this stage to ensure that the cut pieces meet design specifications and that there are no defects in the fabric.

What Finishing Techniques Are Applied to Faux Suede?

The final stage is finishing, where various treatments are applied to enhance the fabric’s durability and appearance. Common finishing processes include:

-

Coating: A protective coating may be applied to improve water resistance and stain repellency, making faux suede more suitable for everyday use.

-

Calendering: This technique involves passing the fabric through heated rollers to achieve a smooth finish and improve its overall feel.

-

Quality Inspection: The finished fabric is subject to a thorough quality inspection to ensure it meets industry standards before being shipped to buyers.

What Quality Assurance Measures Are Essential for Faux Suede?

Quality assurance (QA) is crucial in the faux suede manufacturing process to ensure that the final product meets international standards and buyer expectations. Key QA measures include adherence to recognized international standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE for products sold within the European Union.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of production to monitor and verify the quality of the fabric:

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): During production, continuous monitoring occurs to catch any issues early. This includes checking the consistency of the weave, color, and texture.

-

Final Quality Control (FQC): After finishing, a thorough inspection is conducted to assess the overall quality of the faux suede, ensuring it meets all design and functional specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those sourcing from international markets, should take proactive steps to verify their suppliers’ quality control processes:

-

Audits: Conducting audits of the manufacturing facilities can provide insights into the supplier’s QA processes and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QC measures, including defect rates and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the product quality and compliance with specifications before shipment.

What Nuances Should International Buyers Consider in Quality Certification?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is vital. Different regions may have varying standards and regulations that impact product acceptance.

-

Regional Compliance: Buyers should ensure that the faux suede products comply with local regulations, such as REACH in Europe, which addresses the safe use of chemicals.

-

Cultural Preferences: Different markets may have specific preferences for texture, color, and durability. Understanding these preferences can help in selecting the right supplier and product.

-

Logistical Considerations: Factors such as shipping times, customs regulations, and tariffs can affect the overall cost and delivery of faux suede products. Buyers should factor these into their sourcing strategy to avoid delays and additional costs.

In conclusion, the manufacturing processes and quality assurance measures for faux suede are complex yet essential for delivering a high-quality product. B2B buyers must be diligent in understanding these processes and verifying their suppliers to ensure they receive products that meet their standards and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux suede’

When sourcing faux suede, especially for B2B purposes, having a structured approach can significantly streamline the process. This guide provides a comprehensive checklist to help you navigate the complexities of procuring faux suede efficiently and effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications of the faux suede you need. Consider factors such as fabric weight, texture, color options, and intended applications, whether for upholstery, fashion, or other uses. This clarity will ensure that suppliers can meet your specific requirements and help you avoid costly mistakes.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reliable suppliers of faux suede. Look for manufacturers with a proven track record in the industry, particularly those with experience serving markets similar to yours. Utilize online directories, trade shows, and industry associations to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications and Standards

Verify that potential suppliers adhere to relevant quality standards and certifications. This may include ISO certifications, compliance with environmental regulations, and ethical sourcing practices. Ensuring that suppliers meet these standards not only protects your brand but also enhances your product’s marketability.

- Tip: Request documentation that outlines their compliance with industry standards, especially if you plan to sell in regulated markets.

Step 4: Request Samples and Test Quality

Before making a bulk order, request samples of the faux suede to assess its quality firsthand. Evaluate the texture, durability, and color fidelity of the samples provided. This step is crucial to confirm that the material meets your expectations and is suitable for your intended applications.

- Tip: Pay attention to the cleaning instructions and maintenance needs, as these will affect the end-user experience.

Step 5: Negotiate Terms and Pricing

Once you have shortlisted suppliers, initiate discussions regarding pricing, payment terms, and delivery schedules. Be transparent about your budget and requirements, and don’t hesitate to negotiate to secure the best possible deal. Remember to consider factors such as minimum order quantities and shipping costs when evaluating overall pricing.

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for ongoing dialogue with your suppliers to ensure you can address any issues that may arise promptly. Regular updates on production timelines and potential delays can help manage expectations and foster a positive working relationship.

Step 7: Finalize Contracts and Place Orders

After agreeing on terms, ensure that all agreements are documented in a formal contract. This should outline the specifications, pricing, delivery timelines, and any penalties for non-compliance. Once both parties are satisfied with the contract, proceed to place your order, ensuring to keep copies of all correspondence for future reference.

Following this structured checklist will help you navigate the sourcing of faux suede with confidence, ensuring that you select the right materials for your business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for faux suede Sourcing

What Are the Key Cost Components in Faux Suede Sourcing?

When sourcing faux suede, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: Faux suede is typically made from polyester, which is relatively cost-effective compared to natural suede. Prices can vary based on the quality of the polyester and any special treatments applied for durability or aesthetics.

-

Labor: Labor costs can differ significantly depending on the country of production. Regions with lower labor costs may offer competitive pricing but could also lead to variations in quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production facilities may help lower these costs, impacting overall pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or specific color variations. These costs are usually amortized over larger production runs.

-

Quality Control (QC): Ensuring product consistency is crucial, especially for international buyers. Investment in QC processes will influence the final pricing but is necessary to minimize returns and maintain customer satisfaction.

-

Logistics: Shipping costs can vary based on distance, volume, and the chosen shipping method. Understanding the Incoterms used in the transaction will clarify responsibilities and potential hidden costs.

-

Margin: Suppliers will incorporate a margin to ensure profitability. This margin can vary widely based on market demand and competition.

How Do Price Influencers Affect Faux Suede Costs?

Several factors influence the pricing of faux suede that international B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Negotiating the MOQ can be beneficial for cost efficiency.

-

Specifications and Customization: Custom colors, textures, or additional treatments can increase costs. Buyers should assess whether the added features justify the price increase.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., eco-friendly or hypoallergenic) can impact pricing. Buyers should evaluate the importance of these factors in their sourcing decisions.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) can help buyers anticipate total costs, including shipping and insurance. This knowledge is crucial for budgeting.

What Tips Can Help B2B Buyers Negotiate Better Prices for Faux Suede?

To maximize value and minimize costs when sourcing faux suede, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Flexibility on both sides can lead to favorable agreements.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with the product, such as durability, maintenance, and potential returns. A higher upfront cost may be justified by lower long-term expenses.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import tariffs, and local regulations can impact overall costs. Buyers should conduct thorough market research to understand these factors.

-

Request Samples: Before committing to large orders, request samples to assess quality. This step can prevent costly mistakes and ensure that the product meets expectations.

-

Build Relationships: Establishing a solid relationship with suppliers can lead to better pricing and service over time. Loyal customers may receive preferential pricing or terms.

Disclaimer

Prices for faux suede can vary widely based on the factors discussed above. The information provided is indicative and should be verified with suppliers for the most accurate and current pricing. Always conduct due diligence when sourcing materials internationally.

Alternatives Analysis: Comparing faux suede With Other Solutions

When considering materials for upholstery, fashion, or various industrial applications, faux suede stands out for its luxurious feel and versatility. However, it is essential to evaluate alternatives that may offer distinct advantages depending on specific project requirements. Below, we compare faux suede against two viable alternatives: genuine suede and synthetic leather.

| Comparison Aspect | Faux Suede | Genuine Suede | Синтетическая кожа |

|---|---|---|---|

| Performance | Soft, durable, and stain-resistant | Soft, luxurious, but less durable | Highly durable and water-resistant |

| Cost | Generally lower than genuine suede | Higher due to animal sourcing | Typically mid-range, varies by quality |

| Ease of Implementation | Easy to cut and sew | Requires specialized tools and techniques | Easy to work with, similar to faux suede |

| Maintenance | Easy to clean, often machine washable | Requires careful cleaning, prone to staining | Easy to clean, often wipeable |

| Best Use Case | Fashion, upholstery, event décor | High-end fashion, luxury items | Casual wear, upholstery, automotive |

What Are the Advantages and Disadvantages of Genuine Suede Compared to Faux Suede?

Genuine suede is renowned for its luxurious texture and breathability, making it a preferred choice in high-end fashion and upscale upholstery. Its softness and natural appearance can create a compelling aesthetic. However, it comes with several drawbacks: genuine suede is significantly more expensive due to the cost of animal hides and requires more careful maintenance. It is prone to staining and can lose its appeal if not cared for properly, making it less suitable for everyday applications.

How Does Synthetic Leather Compare with Faux Suede in Terms of Functionality?

Synthetic leather, often known as vegan leather, is a popular alternative to both faux suede and genuine suede. It boasts high durability and water resistance, making it ideal for applications in automotive interiors and everyday wear. Synthetic leather is generally easier to clean, requiring only a simple wipe-down. However, it may lack the soft, plush feel of faux suede and can be less breathable. Additionally, while it may mimic the appearance of leather, it does not always provide the same luxurious aesthetic that some buyers may desire.

Illustrative image related to faux suede

Making the Right Choice: How Can B2B Buyers Decide Between Faux Suede and Its Alternatives?

For B2B buyers, the decision on whether to choose faux suede, genuine suede, or synthetic leather should be guided by the specific requirements of their projects. If cost-effectiveness and ease of maintenance are primary concerns, faux suede is an excellent choice. Conversely, buyers seeking a luxury product for high-end applications may opt for genuine suede despite its higher price. On the other hand, for those requiring durability and water resistance, synthetic leather offers a practical solution. Ultimately, aligning the material choice with the intended use case, budget, and maintenance capabilities will lead to the best decision for any business application.

Essential Technical Properties and Trade Terminology for faux suede

What Are the Key Technical Properties of Faux Suede?

Faux suede, also known as microsuede, is a synthetic fabric designed to mimic the softness and appearance of natural suede. Understanding its technical properties is crucial for B2B buyers looking to make informed decisions regarding procurement, applications, and overall quality.

1. Material Composition

Faux suede is primarily made from 100% polyester fibers. This composition not only provides a soft, velvety feel but also contributes to its durability and ease of maintenance. For businesses, knowing the material grade helps in assessing the fabric’s performance in various applications, from upholstery to fashion.

2. Fabric Weight

Typically, faux suede has a weight of approximately 225 grams per square meter (GSM). This weight indicates the fabric’s density and sturdiness, which is important for applications requiring durability, such as furniture upholstery and heavy-duty bags. Buyers should consider fabric weight when evaluating the suitability for their specific needs.

3. Width of the Fabric

Faux suede is commonly available in widths of 58 to 60 inches. The width is essential for calculating the amount of fabric required for a project. For B2B transactions, understanding fabric width allows for better planning in production runs and minimizing waste.

4. Cleaning and Maintenance

Most faux suede products are designated as “dry clean only.” This specification is critical for businesses to communicate to their end customers, ensuring that the longevity of the product is maintained. The cleaning requirements can also influence the choice of fabric for certain applications, particularly in industries like hospitality and automotive.

Illustrative image related to faux suede

5. Colorfastness

Faux suede is available in a wide range of colors, but colorfastness is a vital property that indicates how well the fabric retains its color after exposure to light and washing. For B2B buyers, confirming colorfastness is essential to prevent dissatisfaction from end-users, especially in fashion and home décor sectors.

6. Tensile Strength

Tensile strength measures how much pulling force the fabric can withstand before breaking. This property is crucial for applications that require durability, such as bags and garments. Buyers should prioritize tensile strength specifications to ensure the chosen fabric meets the demands of their products.

What Are Common Trade Terms in the Faux Suede Industry?

Navigating the faux suede market involves familiarity with specific trade terminology that can influence purchasing and supply chain decisions.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. For faux suede suppliers, understanding OEM relationships can help in tailoring products to meet specific client requirements, enhancing collaboration in production.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management. It can also affect the decision to enter into partnerships with suppliers based on their production capabilities.

Illustrative image related to faux suede

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing, terms, and conditions for specific products. For faux suede, submitting an RFQ helps buyers obtain competitive pricing and ensures transparency in supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for B2B buyers to understand shipping costs, insurance, and liability during transit.

5. Dye Lot

Dye lot refers to a batch of fabric dyed at the same time, which can result in color variations. Awareness of dye lot variations is essential for buyers to ensure consistency in fabric color across orders, particularly for large production runs.

6. Lead Time

Lead time is the duration from placing an order to receiving the product. Understanding lead times helps businesses plan their inventory and production schedules effectively, reducing the risk of stockouts or excess inventory.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when sourcing faux suede, ensuring they meet their specific needs and those of their end customers.

Navigating Market Dynamics and Sourcing Trends in the faux suede Sector

What Are the Current Market Dynamics and Key Trends in the Faux Suede Sector?

The faux suede market is experiencing a robust growth trajectory, driven by increasing consumer preference for sustainable and cruelty-free materials. As global awareness around environmental issues rises, faux suede has become a favored alternative to traditional leather, particularly in regions like Europe and North America. This trend is mirrored in emerging markets in Africa and South America, where the demand for versatile, cost-effective materials is escalating. Additionally, the rise of e-commerce platforms is facilitating easier access to faux suede, allowing B2B buyers to source materials from a wider array of suppliers.

In terms of technology, advancements in manufacturing processes are enhancing the quality and durability of faux suede fabrics. Innovations such as digital printing and eco-friendly dyeing techniques are becoming standard, providing businesses with the opportunity to offer more customized and vibrant products. Moreover, the integration of artificial intelligence in supply chain management is optimizing sourcing strategies, enabling companies to predict market demands more accurately and streamline their inventory management.

International buyers are also observing a shift towards more collaborative sourcing practices, where partnerships with suppliers are prioritized over transactional relationships. This approach fosters transparency and trust, essential elements in today’s competitive landscape. As businesses seek to differentiate themselves, the importance of unique offerings—such as diverse color palettes and textures—continues to rise, making faux suede a viable option for various applications, including fashion, upholstery, and event decor.

How Is Sustainability Impacting Sourcing Trends in the Faux Suede Industry?

Sustainability and ethical sourcing are at the forefront of the faux suede sector, reflecting a broader shift in consumer expectations and regulatory pressures. The environmental impact of traditional leather production—characterized by high water usage and chemical pollution—has propelled the faux suede market forward. International buyers are increasingly seeking suppliers who prioritize sustainable practices, such as utilizing recycled materials or adhering to stringent environmental standards.

Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® are gaining traction among suppliers, providing buyers with a means to verify the sustainability claims of materials. These certifications not only enhance brand reputation but also align with the growing consumer demand for ethically produced goods. Furthermore, the use of plant-based or biodegradable materials in faux suede production is emerging, appealing to environmentally conscious brands looking to reduce their carbon footprint.

Ethical supply chains are also being emphasized, with buyers encouraged to engage suppliers who uphold fair labor practices and transparency. This not only mitigates reputational risks but also fosters a more equitable market environment. As sustainability becomes a non-negotiable aspect of sourcing strategies, businesses that embrace these principles are likely to gain a competitive edge in the faux suede market.

What Is the Evolution of Faux Suede in the B2B Market?

The evolution of faux suede can be traced back to the late 20th century when synthetic textiles began to gain popularity as alternatives to natural materials. Initially, faux suede was primarily seen as a budget-friendly option for consumers seeking leather-like aesthetics without the associated costs. However, as technological advancements improved the quality of synthetic fibers, faux suede evolved into a desirable material in its own right.

By the early 2000s, the introduction of microsuede—a softer, more durable version of traditional faux suede—further cemented the material’s status in the fashion and upholstery markets. Today, faux suede is not just about affordability; it represents a commitment to sustainability and ethical production. As the market continues to grow, innovations in production and a strong focus on eco-friendly practices are shaping the future of faux suede, establishing it as a mainstay in B2B sourcing strategies across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of faux suede

-

How do I choose the right type of faux suede for my project?

Choosing the right faux suede involves considering the intended application, such as upholstery, fashion, or accessories. Assess the fabric’s weight, texture, and durability based on your needs. For instance, heavier weights are suitable for upholstery, while lighter options work well for garments. Additionally, consider color options and finishes, as these can significantly impact the final product’s appearance. Always request samples to evaluate the fabric’s quality and ensure it meets your specific requirements. -

What are the minimum order quantities (MOQs) for faux suede?

Minimum order quantities (MOQs) for faux suede can vary widely among suppliers. Typically, MOQs may range from as low as 10 yards for smaller manufacturers to 100 yards or more for larger suppliers. It’s crucial to communicate your needs with potential suppliers early in the negotiation process. If your order falls below their MOQ, inquire about the possibility of combining orders or sourcing from alternative suppliers who accommodate smaller quantities. -

What payment terms should I expect when sourcing faux suede internationally?

When sourcing faux suede internationally, payment terms can vary significantly. Common practices include upfront payment, partial payment before shipment, or net 30/60 terms after delivery. Discussing payment methods like wire transfers, letters of credit, or online payment platforms is essential for security. Always ensure that you clarify and document the agreed terms in your purchase order to avoid misunderstandings. -

How can I ensure the quality of faux suede before placing a large order?

To ensure quality, request fabric samples before committing to a bulk order. Evaluate the samples for texture, color consistency, and durability. Additionally, inquire about the supplier’s quality assurance processes, such as testing for colorfastness and abrasion resistance. Consider conducting a factory audit or using third-party inspection services to verify manufacturing standards and quality control practices. -

What are the best shipping options for importing faux suede?

Shipping options for importing faux suede typically include air freight and sea freight. Air freight is faster but more expensive, ideal for urgent orders. Sea freight is cost-effective for larger shipments but may take longer. Consider the trade-off between cost and delivery time based on your inventory needs. Always check with your supplier about shipping terms and whether they can handle logistics or if you need to engage a freight forwarder. -

Are there customization options available for faux suede?

Many suppliers offer customization options for faux suede, including bespoke colors, textures, and finishes. Discuss your specific requirements with potential suppliers to determine what is feasible. Custom orders may have different MOQs and lead times, so factor these into your planning. Be prepared to provide detailed specifications and possibly pay a premium for tailored solutions. -

What are the common uses for faux suede in various industries?

Faux suede is versatile, commonly used in fashion, upholstery, automotive interiors, and home décor. In fashion, it’s popular for garments, bags, and accessories due to its soft texture and appearance. In upholstery, faux suede offers durability and easy maintenance, making it suitable for furniture and drapery. Understanding your target market’s needs can help you leverage faux suede’s attributes effectively. -

How do I vet suppliers when sourcing faux suede internationally?

Vetting suppliers is crucial to ensure reliability and quality. Start by checking their credentials, certifications, and industry reputation. Request references from previous clients and review their product samples. It’s beneficial to visit the manufacturing facility if possible or arrange for third-party audits. Additionally, assess their communication responsiveness and willingness to accommodate your specific needs, which can indicate their overall professionalism and service quality.

Top 6 Faux Suede Manufacturers & Suppliers List

1. My Textile Fabric – Suede Fabric – Microsuede

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Введение: {“Product Name”: “Suede Fabric – Microsuede”,”Colors Available”: 40,”Width”: “60 inches”,”Type”: “Faux Suede”,”Uses”: [“Upholstery”,”Tablecloth”,”Bags”,”Pouches”,”Cosplay”,”Costume”],”Sample Swatch Size”: “3×3 inches”,”Price per Sample Swatch”: “$1.99″,”Fabric Weight”: “Approximately 225 grams per square meter”,”Fabric Content”: “100% Polyester”,”Cleaning Instructions”: “Dry Clean Only”,”Shipping”…

2. Otokomaeken – Faux Suede Fabric

Domain: en.otokomaeken.com

Registered: 2014 (11 years)

Введение: Faux suede is a fabric that mimics the texture of real suede leather, created artificially from polyester or acrylic fabric. It is lightweight, durable, easy to care for, and reasonably priced compared to natural suede. However, it has a disadvantage of degradation over time due to hydrolysis of polyurethane, typically occurring around three years after manufacture.

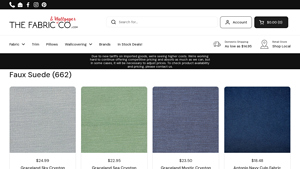

3. The Fabric Co – Faux Suede

Domain: thefabricco.com

Registered: 2000 (25 years)

Введение: Faux Suede (662) $24.99 Graceland Sky Crypton Fabric $22.95 Graceland Sea Crypton Fabric $23.50 Graceland Mystic Crypton Fabric $18.48 Antonio Navy Culp Fabric $23.02 Abbington Seven Sea Culp Fabric $24.99 Graceland Chambray Crypton Fabric $22.95 Graceland Buff Crypton Fabric $24.99 Graceland Sorrell Crypton Fabric $24.99 Graceland Snow Crypton Fabric $18.48 Antonio Goldenrod Culp Fabric $18.48 An…

4. Levi – Faux Suede Trucker

Domain: reddit.com

Registered: 2005 (20 years)

Введение: Faux suede trucker from Levi, faux suede bombers from Abercrombie, longevity of faux suede mentioned as 2 years, concerns about rayon safety.

5. CNC Fabrics – Faux Suede

Domain: cncfabrics.com

Введение: Faux Suede fabric, high quality, smooth fuzzy finish, flexible, easy to care for, heavyweight, suitable for apparel (pants, skirts, jackets, gloves, handbags) and upholstery (chair and couch coverings, pillows). Available in various colors and prints. Free samples upon request. Products include Aqua Suede Print, Black Faux Suede, Charcoal Faux Suede, Cinnabar Red Faux Suede, Dark Teal Suede Print,…

6. Lots of Fabric – Faux Suede Collection

Domain: lotsofabric.com

Registered: 2007 (18 years)

Введение: Faux Suede fabrics available in 9 variations. Prices range from $8.38 to $24.98. Specific products include: imgB720 ($21.98), imgB723 ($23.98), imgB546 ($24.98), img9398 ($20.98), img9466 ($21.98), img7059 ($16.98), img6534 ($18.98, on sale for $11.38), img4302 ($16.98), img3064 ($13.98, on sale for $8.38).

Strategic Sourcing Conclusion and Outlook for faux suede

In conclusion, the strategic sourcing of faux suede presents significant opportunities for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. This versatile material, available in a multitude of colors and weights, caters to a wide range of applications from upholstery to fashion. Its durability and aesthetic appeal make faux suede a compelling alternative to genuine leather, aligning with the growing demand for sustainable and ethical sourcing practices.

By leveraging strategic sourcing, businesses can secure competitive pricing, ensure quality control, and foster long-term relationships with suppliers. Emphasizing the importance of obtaining sample swatches before large orders can mitigate risks associated with dye lot variations and material specifications, ultimately leading to enhanced customer satisfaction.

As the global market continues to evolve, staying informed about trends and innovations in faux suede will be crucial for maintaining a competitive edge. International buyers are encouraged to explore partnerships with reputable suppliers who can meet their specific needs. Embrace the future of sourcing by integrating faux suede into your product offerings, and watch your business thrive in the ever-expanding landscape of sustainable textiles.

Illustrative image related to faux suede

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.