Introduction: Navigating the Global Market for custom leather dies

Navigating the global market for custom leather dies presents a unique challenge for B2B buyers seeking efficiency and precision in their leather production processes. Whether you are a manufacturer in Vietnam or a craftsman in Germany, sourcing high-quality custom leather dies is essential to streamline operations and enhance product consistency. This comprehensive guide delves into the myriad aspects of custom leather dies, including various types available, their applications across different sectors, and critical insights on supplier vetting and cost considerations.

Understanding the landscape of custom leather dies is vital for making informed purchasing decisions. This guide empowers international buyers by providing actionable insights into evaluating suppliers, ensuring that you choose partners who can meet your specific design and production needs. With a focus on diverse regions—Africa, South America, the Middle East, and Europe—this resource addresses local market conditions, regulatory considerations, and cultural nuances that may influence your sourcing strategy.

By exploring the essential components of the custom leather die market, you will be equipped to navigate complexities, mitigate risks, and ultimately enhance your production capabilities. Whether you are looking to cut costs, improve turnaround times, or innovate your product line, this guide serves as a valuable tool for maximizing your investment in custom leather dies.

Table Of Contents

- Top 5 Custom Leather Dies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather dies

- Understanding custom leather dies Types and Variations

- Key Industrial Applications of custom leather dies

- 3 Common User Pain Points for ‘custom leather dies’ & Their Solutions

- Strategic Material Selection Guide for custom leather dies

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather dies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather dies’

- Comprehensive Cost and Pricing Analysis for custom leather dies Sourcing

- Alternatives Analysis: Comparing custom leather dies With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather dies

- Navigating Market Dynamics and Sourcing Trends in the custom leather dies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather dies

- Strategic Sourcing Conclusion and Outlook for custom leather dies

- Important Disclaimer & Terms of Use

Understanding custom leather dies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

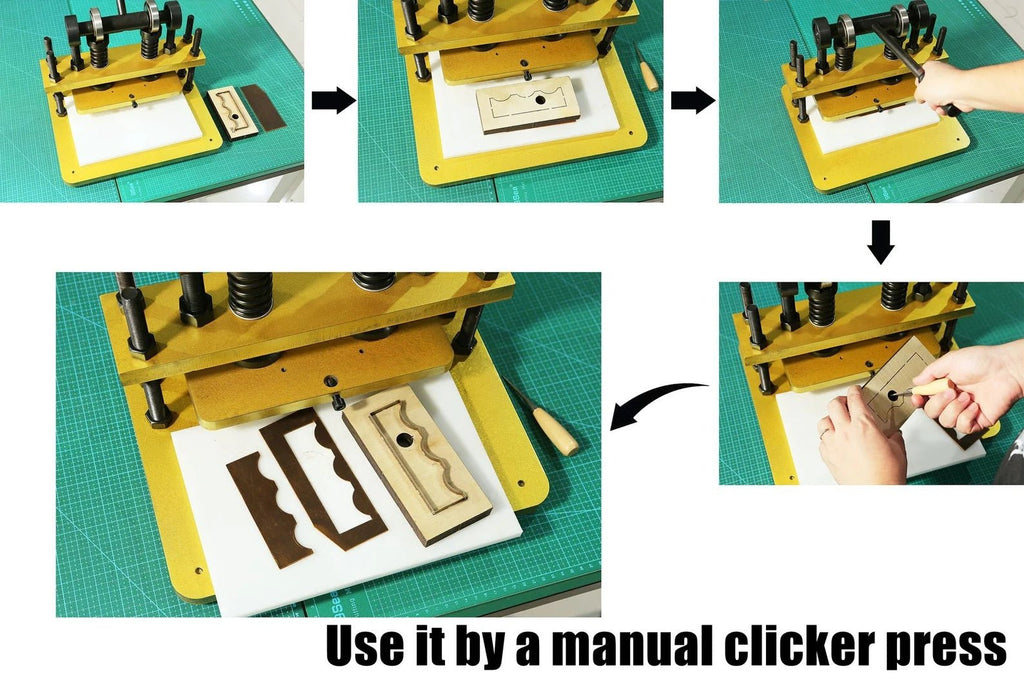

| Clicker Dies | Made from steel or polycarbonate; used in clicker presses | Mass production of leather goods | Pros: High efficiency, consistent cuts; Cons: Initial investment cost can be high. |

| Steel Rule Dies | Features a sharp steel blade; often mounted on acrylic | Custom shapes for various materials | Pros: High precision; Cons: Less durable for heavy use. |

| Custom Acrylic Mount Dies | Easy alignment and reduced waste; customizable designs | Crafting and prototyping | Pros: Quick turnaround; Cons: Limited to specific material thickness. |

| Laser-Cut Dies | Utilizes laser technology for intricate designs | High-detail applications | Pros: Extremely detailed cuts; Cons: Higher cost for complex designs. |

| Rotary Dies | Utilizes rotating blades for continuous cutting | High-volume production | Pros: Efficient for long runs; Cons: Not suitable for intricate designs. |

What Are Clicker Dies and Their B2B Applications?

Clicker dies are essential tools in the leather industry, designed for use with clicker presses. They are typically made from steel or polycarbonate, allowing for efficient mass production of leather goods such as wallets, bags, and accessories. The main advantage of using clicker dies is the speed and consistency they offer, drastically reducing labor time compared to manual cutting. B2B buyers should consider their production volume and budget, as the initial investment can be significant, but the long-term savings in labor and materials can be substantial.

How Do Steel Rule Dies Stand Out in Custom Leather Cutting?

Steel rule dies are characterized by their sharp steel blades, often mounted on acrylic for easy alignment. This type of die is versatile, suitable for cutting not only leather but also paper, felt, and other materials. Steel rule dies are advantageous for businesses looking to produce custom shapes with high precision. However, their durability can be a concern for high-volume operations, as they may wear out faster than other die types. B2B buyers should evaluate their production needs and material types when choosing steel rule dies.

Why Choose Custom Acrylic Mount Dies for Prototyping?

Custom acrylic mount dies offer a unique advantage in terms of ease of material alignment, which helps to minimize waste during the cutting process. This type of die is particularly suitable for crafting and prototyping, allowing businesses to experiment with designs before committing to larger production runs. The quick turnaround time for custom acrylic mount dies makes them appealing for businesses that require rapid development cycles. However, buyers should note that these dies are limited to specific material thicknesses, which could restrict their applications.

What Are the Benefits and Drawbacks of Laser-Cut Dies?

Laser-cut dies are ideal for businesses needing intricate designs and high-detail cuts. Utilizing advanced laser technology, these dies can produce complex patterns that are often impossible to achieve with traditional cutting methods. While the quality of the cuts is exceptional, the cost associated with laser-cut dies can be higher, especially for more complicated designs. B2B buyers should weigh the need for detail against their budget constraints when considering this option.

How Do Rotary Dies Enhance High-Volume Production?

Rotary dies are designed for continuous cutting, making them an excellent choice for high-volume production environments. They utilize rotating blades to efficiently cut through materials, which can be particularly beneficial for businesses producing large quantities of similar items. While rotary dies excel in efficiency, they may not be suitable for intricate designs or one-off projects. Buyers should assess their production goals and the complexity of their designs to determine if rotary dies meet their needs effectively.

Key Industrial Applications of custom leather dies

| Industry/Sector | Specific Application of custom leather dies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Production of handbags, wallets, and belts | Streamlined production, consistent quality, and reduced labor costs | Material compatibility, die precision, and lead time for orders |

| Automotive | Custom leather interiors and upholstery for vehicles | Enhanced aesthetics, durability, and customization options | Compliance with industry standards, material sourcing, and cost |

| Footwear | Manufacturing of leather shoes and boots | Increased production efficiency and design versatility | Design complexity, durability of dies, and minimum order quantities |

| Home Décor | Creation of leather furniture and decorative items | Unique product offerings and improved production turnaround | Custom design capabilities, material thickness, and pricing |

| Sports Equipment | Development of custom leather sports gear (e.g., gloves, pads) | Enhanced performance, comfort, and tailored fit | Specific material requirements, design accuracy, and lead times |

How Are Custom Leather Dies Used in the Fashion and Accessories Industry?

In the fashion and accessories sector, custom leather dies are essential for producing items like handbags, wallets, and belts. These dies allow manufacturers to cut leather into intricate shapes with precision, ensuring that each piece meets design specifications. This technology reduces labor costs and minimizes waste, particularly important for businesses aiming for sustainability. Buyers should focus on sourcing dies that are compatible with their specific leather types and that offer quick turnaround times for production to remain competitive in fast-paced fashion markets.

What Role Do Custom Leather Dies Play in the Automotive Sector?

The automotive industry utilizes custom leather dies for crafting high-quality interiors and upholstery. By employing these dies, manufacturers can achieve a high level of customization and durability, enhancing the overall aesthetic appeal of vehicles. The precision cutting ensures that materials fit perfectly, which is crucial for maintaining quality standards. When sourcing dies, businesses must consider compliance with automotive regulations, the ability to work with various leather grades, and the potential for bulk order pricing to optimize costs.

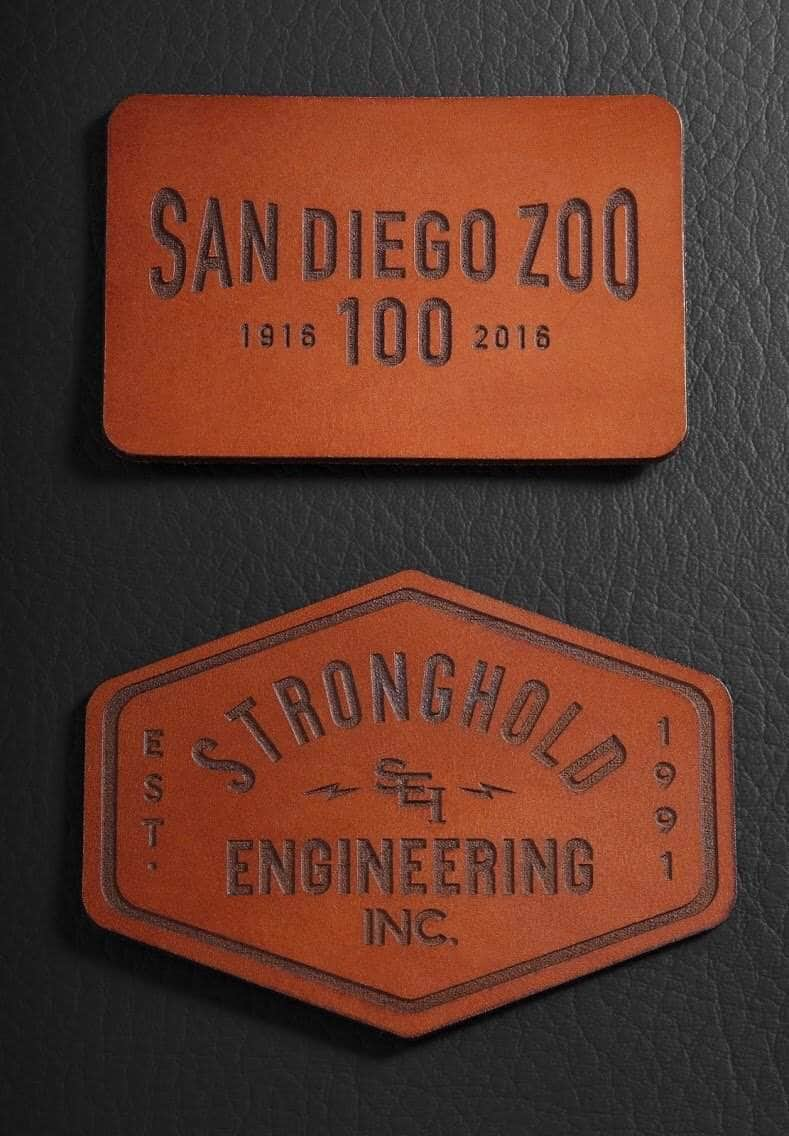

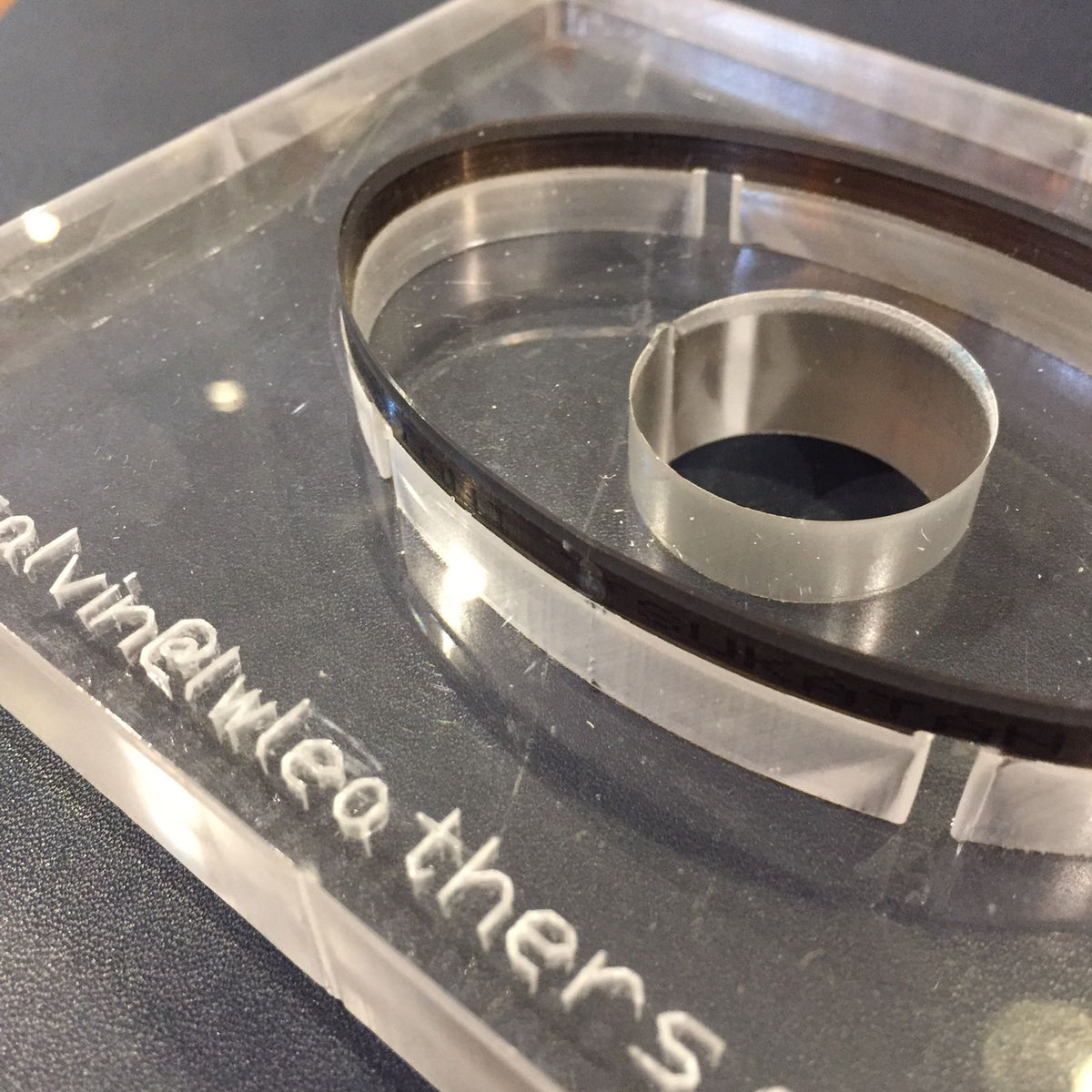

Illustrative image related to custom leather dies

How Are Custom Leather Dies Beneficial for Footwear Production?

In footwear manufacturing, custom leather dies facilitate the efficient production of shoes and boots by enabling the cutting of complex designs with high accuracy. This technology not only speeds up the production process but also allows for greater design flexibility, helping brands to innovate and differentiate their products. Buyers should evaluate the durability of the dies, as well as the ability to accommodate various leather thicknesses, to ensure they can meet their production needs without compromising quality.

What Advantages Do Custom Leather Dies Offer in Home Décor?

The home décor industry leverages custom leather dies for creating unique leather furniture and decorative items. These dies allow for precise cutting of leather, resulting in high-quality, aesthetically pleasing products that stand out in the market. Quick production turnaround times can significantly enhance a company’s ability to respond to market trends. When sourcing dies, businesses should consider the customization options available, the thickness of the leather that can be processed, and pricing structures that align with their production volumes.

How Are Custom Leather Dies Used in Sports Equipment Manufacturing?

In the sports equipment sector, custom leather dies are used to produce tailored items such as gloves and protective pads. The accuracy of these dies ensures that products fit comfortably and perform well, which is critical for athlete safety and performance. Buyers should prioritize sourcing dies that can handle specific material requirements and offer precision cutting for intricate designs. Additionally, understanding lead times and cost implications of bulk orders can help businesses manage their production schedules effectively.

Illustrative image related to custom leather dies

3 Common User Pain Points for ‘custom leather dies’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Cuts with Custom Leather Dies

The Problem: Many B2B buyers in the leather industry face challenges when it comes to achieving the precision required for their custom leather projects. Whether it’s for high-end fashion accessories or functional items like wallets and bags, the need for accuracy is paramount. Inconsistent cuts can lead to material wastage and ultimately affect the quality of the final product. Buyers often struggle to find dies that meet their exact specifications, leading to frustration and delays in production.

The Solution: To overcome this issue, buyers should focus on sourcing dies from reputable manufacturers who offer customization options tailored to specific project needs. When placing an order, provide detailed design files in formats like AI, PDF, or high-resolution JPEGs to ensure precision. Additionally, inquire about the tolerances offered by the manufacturer; a tolerance of ±0.2mm is ideal for most leather applications. Consider using manufacturers that provide a sample die for approval before full production. This allows you to test the die for accuracy and make adjustments if necessary, ensuring that your production runs smoothly and meets quality standards.

Scenario 2: Long Lead Times Causing Production Delays

The Problem: In the fast-paced world of B2B leather goods manufacturing, time is often of the essence. Buyers frequently encounter long lead times when ordering custom leather dies, which can stall production schedules and impact delivery commitments to clients. This is particularly problematic for businesses that require quick turnaround times for seasonal products or limited-edition releases.

The Solution: To mitigate lead times, buyers should prioritize suppliers who offer expedited services for custom die production. When reaching out to potential vendors, ask about their production timelines and the possibility of rush orders. Additionally, consider forming long-term partnerships with specific manufacturers to secure faster service based on past order history. Another effective strategy is to keep a stock of frequently used die designs on hand, allowing for immediate use without the wait for new orders. Establishing a streamlined communication process with suppliers can also help you stay informed about potential delays and plan accordingly.

Scenario 3: Cost Management for Custom Leather Die Production

The Problem: Managing costs is a critical concern for B2B buyers, especially in an industry where materials can be expensive and margins tight. Custom leather dies can vary significantly in price based on complexity and size, making it challenging for businesses to predict expenses accurately. Buyers often face unexpected costs, particularly when additional features like hole punches or intricate designs are involved, which can lead to budget overruns.

The Solution: To control costs effectively, buyers should engage in comprehensive upfront planning before placing orders. This includes developing a clear design brief that outlines all necessary features and specifications, allowing for accurate quotes from manufacturers. When requesting quotes, ask for a breakdown of costs associated with different design complexities and any optional features. It’s also beneficial to compare quotes from multiple suppliers to ensure competitive pricing. Additionally, consider bulk ordering dies for frequently used shapes, as many manufacturers offer discounts for larger quantities. Finally, keep track of your production needs and adjust orders based on seasonal demand to optimize your inventory and reduce costs over time.

By addressing these common pain points with practical solutions, B2B buyers can navigate the complexities of sourcing custom leather dies more effectively, ensuring smoother operations and higher-quality products.

Strategic Material Selection Guide for custom leather dies

What Are the Key Materials for Custom Leather Dies?

When selecting materials for custom leather dies, it is crucial to consider the properties and performance characteristics of each option. The most common materials include steel, polycarbonate, acrylic, and aluminum. Each material has unique advantages and disadvantages that can significantly affect the die’s performance, durability, and suitability for various applications.

How Does Steel Perform as a Material for Custom Leather Dies?

Steel is the traditional choice for custom leather dies due to its exceptional durability and strength. It can withstand high pressure and temperature, making it suitable for heavy-duty applications. Steel dies are resistant to wear and tear, allowing for consistent performance over time.

Pros: Steel dies are highly durable, providing longevity and reliability in production. They are also capable of cutting through thick leather and other materials with precision.

Cons: The primary drawback of steel is its cost, which can be higher than other materials. Additionally, manufacturing steel dies can be complex, requiring specialized machinery and expertise.

Illustrative image related to custom leather dies

For international buyers, compliance with standards such as ASTM or DIN for steel quality is essential. Buyers in regions like Europe may prefer steel dies due to their reliability, while those in Africa or South America may weigh cost considerations more heavily.

What Advantages Does Polycarbonate Offer for Custom Leather Dies?

Polycarbonate is a lightweight, high-impact plastic that is increasingly popular for custom leather dies. It is particularly useful for applications requiring intricate designs and detailed cuts.

Pros: Polycarbonate dies are less expensive than steel and easier to manufacture, allowing for faster turnaround times. Their lightweight nature makes them easier to handle and transport.

Cons: While polycarbonate is durable, it is not as strong as steel and may wear out faster under heavy use. It is also less suitable for cutting very thick materials.

International buyers should consider the specific applications they need the dies for. For example, regions with a focus on artisanal leather goods may benefit from the precision of polycarbonate, while mass production environments may prefer the durability of steel.

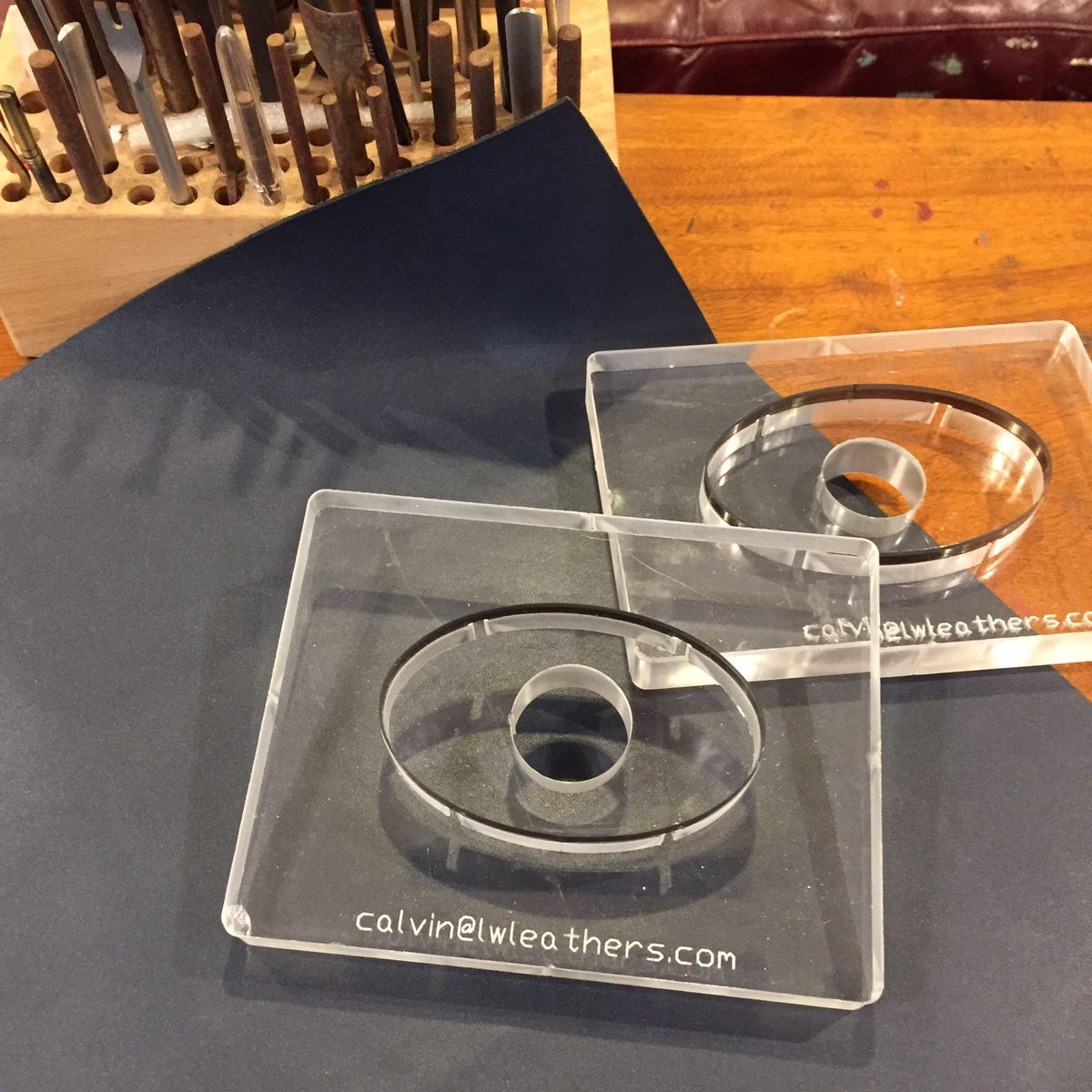

Illustrative image related to custom leather dies

How Does Acrylic Compare for Custom Leather Dies?

Acrylic is another material used for custom leather dies, particularly for applications that require alignment aids. Acrylic mounts can enhance the cutting process by providing a clear view of the material being cut.

Pros: Acrylic allows for easy alignment, which can reduce material waste. It is also relatively inexpensive and can be customized easily.

Cons: Acrylic dies may not withstand the same level of pressure as steel or polycarbonate, making them less suitable for heavy-duty applications. They can also be prone to scratching.

For buyers in the Middle East and Africa, the cost-effectiveness of acrylic might be appealing, especially for smaller operations. However, compliance with local manufacturing standards should be verified.

What Role Does Aluminum Play in Custom Leather Dies?

Aluminum is a lightweight metal often used for custom leather dies, especially in applications requiring moderate durability and precision.

Illustrative image related to custom leather dies

Pros: Aluminum is resistant to corrosion and is lighter than steel, making it easier to handle. It is also less expensive than steel while still providing decent durability.

Cons: Aluminum is not as strong as steel and may not be suitable for cutting very thick materials. Its lifespan may also be shorter under high-stress conditions.

International buyers from Europe, particularly Germany, may appreciate aluminum for its balance of cost and performance, while buyers in South America may focus on its lightweight advantages for shipping.

Summary Table of Material Selection for Custom Leather Dies

| Material | Typical Use Case for custom leather dies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty leather cutting for mass production | Exceptional durability and strength | Higher cost and complex manufacturing | High |

| Polycarbonate | Intricate designs and lightweight applications | Cost-effective and easy to manufacture | Less durable than steel | Medium |

| Acrylic | Applications requiring alignment aids | Easy alignment reduces waste | Prone to scratching and less durable | Low |

| Aluminum | Moderate durability applications | Lightweight and corrosion-resistant | Not suitable for very thick materials | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their custom leather die choices based on specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather dies

What Are the Key Stages in the Manufacturing Process of Custom Leather Dies?

The manufacturing of custom leather dies involves several crucial stages that ensure precision and quality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used and How Are They Prepared?

The foundation of any high-quality leather die is the selection of appropriate materials. Commonly used materials include steel for the cutting blades and polycarbonate or acrylic for mounts. The process begins with sourcing high-grade materials that meet industry standards for durability and performance.

Once materials are selected, they undergo various treatments to enhance their properties. For instance, steel blades may be heat-treated to improve hardness and wear resistance. Quality assurance begins at this stage with incoming quality control (IQC) checks to ensure that the materials meet specified standards.

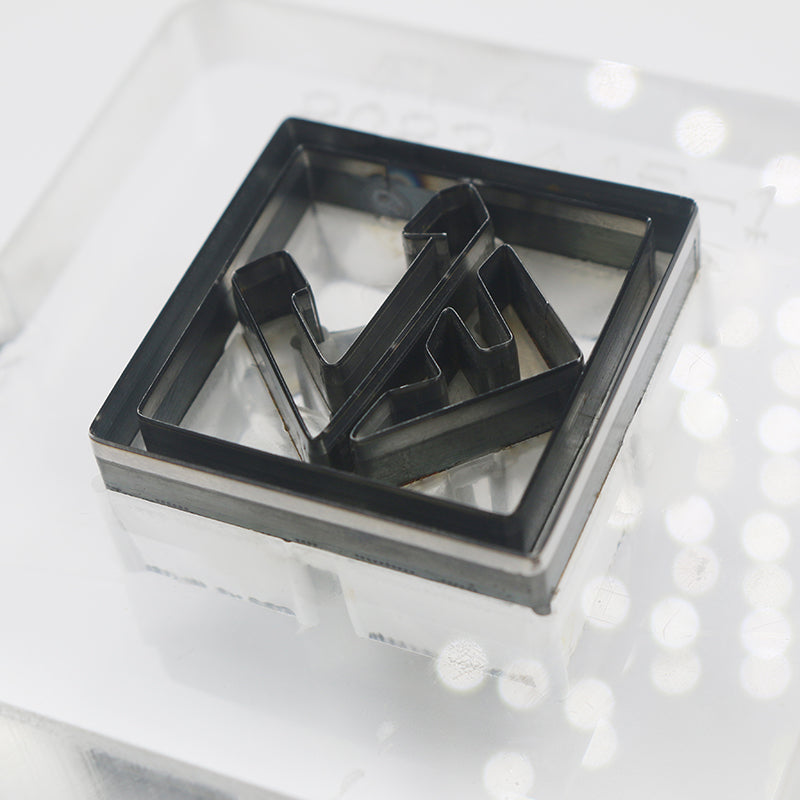

How Are Leather Dies Formed Using Advanced Techniques?

After preparation, the forming stage utilizes advanced techniques like laser cutting, CNC machining, and traditional die-making methods. Laser cutting offers high precision, allowing for intricate designs that can be replicated consistently. CNC machining provides a high level of automation and reduces human error, making it suitable for large production runs.

Traditional die-making involves manually crafting dies based on specific designs, which may be necessary for unique or complex shapes. This stage is critical for achieving the desired cut and ensuring that the die can perform effectively under operational conditions.

Illustrative image related to custom leather dies

What Is Involved in the Assembly and Finishing of Custom Leather Dies?

Once the components are formed, they undergo assembly, where the blades are affixed to their respective mounts. This stage requires meticulous attention to detail to ensure that all parts fit perfectly and operate smoothly. Any misalignment can lead to cutting inaccuracies, which can be costly for mass production.

The finishing stage includes polishing the blades to eliminate burrs and improve cutting quality. Additionally, dies may undergo surface treatments to prevent rust and enhance longevity. A thorough visual inspection is often conducted at this stage to catch any defects before the dies are shipped.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance is integral to the production of custom leather dies, ensuring that products meet international standards and customer expectations. B2B buyers should be aware of the various checkpoints and certifications involved in this process.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are critical for manufacturers of custom leather dies. This certification indicates that the manufacturer adheres to a quality management system that ensures continuous improvement and customer satisfaction. Additionally, other industry-specific certifications like CE (for safety) and API (for petroleum and natural gas) may also be relevant, depending on the application of the dies.

Illustrative image related to custom leather dies

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential for maintaining high standards throughout production. These checkpoints typically include:

- Incoming Quality Control (IQC): Assessing raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects early. This may involve regular measurements and inspections during die formation.

- Final Quality Control (FQC): Conducting thorough inspections of finished products, including dimensional accuracy, surface finish, and operational tests to ensure the dies function as intended.

B2B buyers should inquire about the specific QC processes employed by their suppliers and request documentation to verify compliance.

How Can B2B Buyers Verify the Quality Control Practices of Suppliers?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to mitigate risks associated with procurement.

Illustrative image related to custom leather dies

What Methods Can Be Used to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control practices. Buyers can schedule on-site visits to observe production processes, review quality control documentation, and assess compliance with international standards. It is advisable to involve a third-party inspection service to provide an unbiased evaluation.

What Types of Quality Reports Should Buyers Request?

Buyers should request detailed quality reports that document the results of inspections and tests conducted throughout the manufacturing process. These reports should include data on material compliance, production metrics, and any corrective actions taken in response to identified issues. This transparency helps build trust and assures buyers of the supplier’s commitment to quality.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Assurance?

International buyers must also consider specific nuances related to quality assurance that may vary by region. For example, different countries may have unique regulatory requirements or standards that affect the manufacturing and certification of leather dies. Understanding these can help buyers avoid compliance issues.

How Do Cultural Differences Impact Quality Expectations?

Cultural differences can also influence quality expectations and communication styles. Buyers should establish clear lines of communication and set explicit quality standards and expectations upfront. This proactive approach can help prevent misunderstandings and ensure that the final products meet the buyer’s requirements.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for custom leather dies equips B2B buyers with the knowledge needed to select reliable suppliers. By focusing on material preparation, forming techniques, assembly, and rigorous quality control, buyers can ensure that they receive high-quality products that meet their specific needs.

Illustrative image related to custom leather dies

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather dies’

Introduction

Navigating the procurement of custom leather dies can be a complex process, particularly for international B2B buyers. This checklist is designed to provide a structured approach, ensuring that you make informed decisions while sourcing custom leather dies that meet your specific needs. By following these steps, you can streamline your sourcing process, enhance your product quality, and ultimately improve your bottom line.

Step 1: Define Your Technical Specifications

Clearly outline the dimensions, shapes, and materials required for your custom leather dies. This step is crucial as it sets the foundation for the entire sourcing process. Consider the following details:

– Material Type: Determine if you need steel, polycarbonate, or another material based on durability and application.

– Design Complexity: Assess whether your designs require intricate details or simple shapes, as this will affect pricing and lead time.

Step 2: Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in custom leather dies. The right supplier can significantly impact your production efficiency. Look for:

– Industry Experience: Suppliers with a proven track record in the leather industry often understand the nuances of your requirements better.

– Location Considerations: Opt for suppliers who can meet your shipping needs, especially if you’re operating in regions like Africa or South America.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their manufacturing capabilities. This ensures they can deliver high-quality dies that meet your specifications. Key aspects to consider include:

– Production Volume: Verify if the supplier can handle your order size, especially if you require bulk production.

– Technology Utilization: Suppliers using advanced technology for die cutting can offer better precision and faster turnaround times.

Step 4: Request Samples

Always request samples of previous work to evaluate the quality of the dies. This step is critical to ensure that the supplier’s output aligns with your expectations. When reviewing samples, pay attention to:

– Cutting Accuracy: Check for clean edges and precise shapes.

– Material Quality: Assess whether the materials used meet your durability and performance standards.

Step 5: Understand Pricing Structures

Gain a clear understanding of the supplier’s pricing model. This will help you budget effectively and avoid unexpected costs. Be aware of:

– Base Costs vs. Additional Fees: Inquire about the base price for dies and any extra costs for customizations or expedited shipping.

– Bulk Discounts: Many suppliers offer discounts for larger orders, so clarify these terms upfront.

Step 6: Verify Supplier Certifications and Compliance

Ensure that the supplier adheres to relevant industry standards and certifications. This step is vital for maintaining quality and compliance with international regulations. Look for:

– ISO Certifications: These indicate a commitment to quality management systems.

– Sustainability Practices: Suppliers who prioritize eco-friendly materials and processes can enhance your brand’s reputation.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Ensure that you have established clear lines of communication with your supplier. Consider:

– Point of Contact: Designate a specific individual for ongoing correspondence to streamline communication.

– Regular Updates: Set expectations for progress updates, especially during the production phase, to avoid delays and misunderstandings.

By following this comprehensive checklist, B2B buyers can confidently source custom leather dies that align with their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for custom leather dies Sourcing

When sourcing custom leather dies, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This section outlines the various cost components, price influencers, and buyer tips to navigate the complexities of sourcing effectively.

Illustrative image related to custom leather dies

What Are the Key Cost Components in Custom Leather Die Production?

-

Materials: The cost of materials is a primary factor in the pricing of custom leather dies. Steel and polycarbonate are commonly used materials, with steel being more durable and typically more expensive. The choice of material can significantly impact the die’s longevity and performance.

-

Labor: Skilled labor is required to design and manufacture custom dies. The labor costs can vary depending on the complexity of the die and the expertise of the craftsmen. For intricate designs, expect higher labor charges due to the time and skill involved.

-

Manufacturing Overhead: This includes costs associated with the production facility, equipment maintenance, and utilities. Overhead can vary by region; for example, production in countries with higher labor costs, like Germany, may reflect increased overhead.

-

Tooling: Tooling costs cover the creation of the die itself, which can vary based on the die’s complexity and size. More complex shapes typically require more sophisticated tooling, leading to higher costs.

-

Quality Control (QC): Implementing rigorous quality control measures ensures the dies meet required specifications and standards. The cost of QC processes can add to the overall expense but is essential for maintaining product quality.

-

Logistics: Shipping and handling costs must also be considered, particularly for international buyers. Factors such as distance, shipping method, and customs duties can affect overall logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and supplier capabilities.

How Do Price Influencers Impact Custom Leather Die Sourcing?

-

Volume/MOQ: Many suppliers offer tiered pricing based on the minimum order quantity (MOQ). Larger orders often result in lower per-unit costs, making it advantageous for businesses planning to scale production.

-

Specifications and Customization: Custom specifications, including intricate designs or special features, can lead to higher costs. Clear communication of your requirements can help suppliers provide accurate quotes.

-

Material Quality and Certifications: The quality of materials used in the dies directly influences pricing. Additionally, certifications for materials (e.g., eco-friendly or compliance with specific industry standards) may come at a premium.

-

Supplier Factors: Supplier reliability, reputation, and location can impact pricing. Established suppliers with a track record of quality may charge more, while newer suppliers may offer competitive pricing to gain market share.

-

Incoterms: Understanding the Incoterms related to shipping can affect costs significantly. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) define who is responsible for various shipping costs and risks, influencing the total landed cost.

What Are the Best Negotiation Tips for B2B Buyers in Custom Leather Die Sourcing?

-

Leverage Volume Discounts: If planning to place large orders, negotiate for volume discounts. Suppliers are often willing to reduce prices for bulk purchases.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront cost but also the long-term value of the dies, including durability and the potential for reusability.

-

Explore Multiple Suppliers: Getting quotes from various suppliers can provide a clearer picture of the market rate and help in negotiations.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import duties, and tariffs that could affect overall costs.

-

Establish Long-Term Relationships: Building a good rapport with suppliers can lead to better pricing and terms in future transactions.

Conclusion

In summary, sourcing custom leather dies involves a multifaceted cost structure influenced by various factors. By understanding these components, international B2B buyers can make informed decisions that align with their production needs and budget constraints. Always remember to consider the total cost of ownership and explore negotiation opportunities to maximize value.

Alternatives Analysis: Comparing custom leather dies With Other Solutions

Understanding Alternatives to Custom Leather Dies

In the realm of leather crafting, custom leather dies are a popular choice for businesses seeking precision and efficiency in their production processes. However, there are alternative methods and technologies that may suit different operational needs. This section compares custom leather dies with other viable solutions, providing B2B buyers with insights to make informed decisions.

| Comparison Aspect | Custom Leather Dies | Laser Cutting Technology | Manual Cutting Tools |

|---|---|---|---|

| Performance | High precision; ideal for intricate designs | Extremely precise; versatile for various materials | Variable precision; dependent on skill level |

| Cost | $100 – $500+ per die; bulk discounts available | High initial investment; costs vary based on machine specs | Low upfront costs; minimal investment in tools |

| Ease of Implementation | Requires design and order process; setup needed | Requires technical knowledge; software for design needed | Straightforward; minimal training required |

| Maintenance | Low; durable if well cared for | Moderate; regular calibration needed | Minimal; mainly tool upkeep |

| Best Use Case | Mass production; consistent designs | Complex, detailed cuts across multiple materials | Small-scale projects; prototyping |

Pros and Cons of Laser Cutting Technology

Laser cutting technology offers a high degree of precision and versatility, making it an excellent alternative to custom leather dies. Its ability to cut through various materials, including leather, paper, and plastics, allows businesses to diversify their offerings. However, the initial investment in laser cutting machinery can be significant, which may not be feasible for all businesses, particularly small enterprises. Additionally, the technology requires a certain level of technical expertise, which can necessitate training for staff.

Pros and Cons of Manual Cutting Tools

Manual cutting tools represent a low-cost alternative for businesses that may not require the scale or precision that custom leather dies provide. They are easy to use, require minimal training, and can be an excellent choice for small-scale projects or prototyping. However, the performance heavily relies on the skill of the operator, which can lead to inconsistencies in the final product. This method is not ideal for mass production, as it can be time-consuming and labor-intensive.

Conclusion: How to Choose the Right Solution for Your Leather Crafting Needs

When deciding between custom leather dies, laser cutting technology, and manual cutting tools, B2B buyers should consider their specific operational requirements. If your business focuses on mass production with intricate designs, custom leather dies may be the best choice. Alternatively, if versatility and precision across multiple materials are paramount, investing in laser cutting technology could provide significant long-term value. For smaller projects or businesses just starting, manual cutting tools may suffice. Ultimately, evaluating the scale of your operations, budget constraints, and the complexity of your designs will guide you in selecting the most suitable solution for your leather crafting needs.

Essential Technical Properties and Trade Terminology for custom leather dies

What Are the Key Technical Properties of Custom Leather Dies?

Understanding the essential technical properties of custom leather dies is critical for B2B buyers aiming to enhance their production efficiency and product quality. Here are some key specifications to consider:

1. Material Grade

The material used for the die significantly impacts its durability and cutting efficiency. Common materials include steel and polycarbonate. Steel dies are known for their longevity and ability to cut through thicker materials, while polycarbonate offers a lightweight option with decent precision for less demanding applications. Choosing the right material based on your production needs ensures longevity and optimal performance.

2. Tolerance

Tolerance refers to the allowable deviation in the dimensions of the die. A typical tolerance for leather dies is around ±0.2 mm. This precision is crucial for maintaining consistency in mass production, as even minor deviations can lead to significant discrepancies in the final product. A tighter tolerance usually indicates a higher quality die, which is essential for intricate designs.

3. Cutting Depth

The effective cutting depth indicates how thick a material the die can cut. For example, many dies can effectively cut materials up to 8.8 mm thick. Understanding this specification helps buyers select dies that match the thickness of the leather or other materials they intend to use, ensuring they achieve clean cuts without damaging the die or material.

4. Die Height

The total height of the die, which typically includes both the cutting edge and any mounting materials, is an important consideration. For instance, a standard die height might be around 24 mm. This specification is vital for ensuring compatibility with the cutting press or machine being used, as improper heights can lead to ineffective cutting or even damage to the equipment.

Illustrative image related to custom leather dies

5. Customization Options

Buyers should also consider the customization options available for their dies, including the ability to add features like text engraving or varying blade shapes. Customization allows businesses to tailor dies to their specific production needs, enhancing the uniqueness of their products and improving market competitiveness.

What Are Common Trade Terms Related to Custom Leather Dies?

Familiarity with industry jargon can streamline communication and negotiations between buyers and suppliers. Here are some commonly used terms in the custom leather die market:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather dies, buyers may work directly with an OEM to create tailored solutions for their production needs, ensuring high-quality components that fit perfectly with existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their purchases efficiently. Many suppliers impose an MOQ to justify production costs, especially for custom dies, and knowing this helps in budgeting and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. For custom leather dies, buyers typically submit RFQs to compare pricing, capabilities, and lead times from various manufacturers, enabling informed purchasing decisions.

Illustrative image related to custom leather dies

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother trade relationships and clearer expectations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the final product. In the custom leather die industry, lead times can vary significantly based on design complexity and material availability. Understanding lead times aids in project planning and ensures timely delivery to meet production schedules.

Conclusion

By grasping the critical technical properties and common trade terminology related to custom leather dies, B2B buyers can make informed decisions that enhance their operational efficiency and product quality. This knowledge not only aids in selecting the right products but also facilitates smoother communication with suppliers, ultimately contributing to a more successful procurement process.

Illustrative image related to custom leather dies

Navigating Market Dynamics and Sourcing Trends in the custom leather dies Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Dies Sector?

The custom leather dies market is experiencing significant growth driven by several global factors. As the demand for personalized leather goods continues to rise, manufacturers are increasingly seeking efficient and precise cutting methods to streamline production. The trend towards mass customization allows businesses to offer unique products, which is especially appealing in markets across Africa, South America, the Middle East, and Europe. Technological advancements, such as the integration of CAD (Computer-Aided Design) software and CNC (Computer Numerical Control) machinery, enable more complex designs and higher production volumes, appealing to B2B buyers who prioritize efficiency and quality.

Emerging trends in sourcing include a shift towards online platforms that facilitate easier access to suppliers and more competitive pricing. International buyers are leveraging digital tools to compare products, request quotes, and place orders with minimal lead times. Additionally, there is a growing preference for polycarbonate and steel rule dies due to their durability and precision, which can significantly reduce material waste and improve overall production efficiency. As businesses focus on optimizing their supply chains, sourcing partnerships with manufacturers who offer quick turnaround times and customization options are becoming increasingly valuable.

How Does Sustainability and Ethical Sourcing Impact the Custom Leather Dies Industry?

Sustainability is becoming a critical consideration for B2B buyers in the custom leather dies sector. The environmental impact of leather production, including water usage and chemical waste, has prompted many companies to seek out ethical sourcing practices. Buyers are increasingly looking for suppliers that utilize environmentally friendly materials and production processes, such as vegetable-tanned leather or dies made from recycled materials. Certifications like the Leather Working Group’s (LWG) environmental audit are gaining traction, as they assure buyers that their suppliers adhere to sustainable practices.

Moreover, ethical sourcing is not just a trend; it has become a business imperative. Companies that prioritize sustainability can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers. This shift is pushing manufacturers to invest in greener technologies and practices, thereby aligning their operations with global sustainability goals. B2B buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability, as this can lead to long-term cost savings and improved compliance with international regulations.

What Is the Historical Context of Custom Leather Dies in B2B Markets?

The evolution of custom leather dies dates back several centuries, with traditional hand-cutting methods dominating the craft until the industrial revolution introduced mechanized processes. Early leather craftsmen relied on simple tools and templates, which limited the complexity and precision of their designs. However, the introduction of steel rule dies and later, clicker dies, revolutionized the industry by providing manufacturers with the ability to produce intricate shapes with high accuracy and efficiency.

Illustrative image related to custom leather dies

In recent decades, technological advancements such as laser cutting and CAD software have further transformed the sector, enabling the rapid prototyping of designs and the ability to cater to specific customer requests. This shift towards customization has been particularly beneficial for B2B buyers, as it allows for tailored solutions that meet diverse market demands. As the industry continues to evolve, the integration of advanced technologies and sustainable practices will likely shape the future of custom leather dies, creating new opportunities for international buyers looking to enhance their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather dies

-

How do I ensure the quality of custom leather dies before placing an order?

To ensure the quality of custom leather dies, request samples or prototypes from potential suppliers before committing to a bulk order. Evaluate the materials used—steel and polycarbonate are commonly recommended for durability and precision. Ask for details about their manufacturing process, including tolerances and quality control measures. Additionally, consider suppliers who offer a satisfaction guarantee or return policy to mitigate risks associated with quality. -

What is the best material for custom leather dies?

Steel and polycarbonate are among the best materials for custom leather dies. Steel offers durability and is ideal for intricate designs, while polycarbonate is lightweight and provides excellent precision for detailed cuts. When selecting a material, consider the type of leather you will be working with and the complexity of the shapes you need to cut. Discuss your specific needs with suppliers to determine the most suitable option. -

What are the minimum order quantities (MOQs) for custom leather dies?

Minimum order quantities (MOQs) for custom leather dies can vary significantly by supplier. Typically, many manufacturers require a minimum of 100 units for custom designs, especially for mass production. However, some may accept smaller orders for a higher price per unit. It’s advisable to discuss your project requirements upfront to negotiate MOQs that align with your business needs. -

How can I customize my design for a custom leather die?

To customize your design for a custom leather die, provide suppliers with high-quality digital files, such as .AI, .PDF, or .JPEG formats. If you have a rough sketch, include necessary dimensions and details about the design. Many suppliers offer design assistance, so don’t hesitate to ask for input on optimizing your design for production. Confirm the die’s capabilities, including cutting depth and material compatibility. -

What payment terms should I expect when ordering custom leather dies internationally?

Payment terms for international orders of custom leather dies typically vary by supplier. Common arrangements include upfront payment, a deposit followed by the balance upon delivery, or payment upon receipt of goods. Ensure to clarify these terms during negotiations, and consider using secure payment methods such as PayPal or letters of credit to protect your investment. Discuss any additional costs, such as shipping and customs duties, to avoid unexpected expenses. -

How do I vet suppliers for custom leather dies in international markets?

To vet suppliers for custom leather dies, conduct thorough research on their reputation and experience in the industry. Look for customer reviews, case studies, and references from previous clients. Verify their production capabilities and quality assurance practices. Additionally, consider visiting their facilities if possible or request virtual tours. Engaging in clear communication and asking specific questions about their processes will further ensure they meet your standards. -

What logistics considerations should I keep in mind when sourcing custom leather dies?

When sourcing custom leather dies, consider logistics factors such as shipping times, costs, and customs regulations for your specific region. Choose suppliers who can provide detailed shipping options, including express services for urgent orders. Factor in lead times for production and delivery, and ensure you understand any import duties or taxes that may apply. Building a relationship with a reliable logistics partner can streamline the process and prevent delays. -

How can I handle quality assurance for custom leather dies after receiving them?

Upon receiving your custom leather dies, conduct a thorough inspection to verify that they meet your specifications and quality standards. Check for any defects or discrepancies in the design and functionality. Testing the dies with sample leather can help assess their performance. If issues arise, communicate promptly with the supplier to address concerns, and keep detailed records of all correspondence for accountability. Establishing a quality assurance protocol will help maintain consistency in your production process.

Top 5 Custom Leather Dies Manufacturers & Suppliers List

1. Weaver Leather Supply – Clicker Dies & Sets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Clicker Dies & Sets – Weaver Leather Supply offers a variety of leather cutting dies made from steel and polycarbonate. These dies are designed for use with a clicker press, providing time savings, consistency, and ease in cutting complex shapes for leather projects. The selection includes popular in-stock leather cutting dies and options for custom polycarbonate leather cutting dies. Key products…

2. LW Leathers – Leather Die Cut with Acrylic Mount

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Leather Die Cut with Acrylic Mount for Leather Cutting and Paper Cutting”, “regular_price”: “US$138.00”, “available_sizes”: [“Up to 3×3 inch”, “Up to 4×4 inch”, “Up to 5×5 inch”, “Up to 6×6 inch”], “description”: “Custom made laser engraved leather die cut / steel rule die cut for cutting leather, paper, card stock, silicone, thin magnet etc. Acrylic mount steel rule die cut has …

3. DM Leather Studio – Custom Leather Cutting Dies

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: Custom leather cutting dies, Steel Die for cutting leather. Product Code: X09-LCD. Availability: Many in stock. Price: $2.00. Materials: wood, steel. Default height of the mold: 24mm (0.95in). Custom orders accepted for size adjustments, card slots, and construction rearrangements. Design file formats accepted: .ai, .eps, .pdf, .jpg, .png. Packaging includes foam for protection. Shipping options: …

4. USA Cutting Die – Custom Die Cutting Services

Domain: usacuttingdie.com

Registered: 2009 (16 years)

Introduction: Die cutting services for customers without a press, custom saddle dies, small key fobs, coaster dies.

5. Leather Stamp Maker – Custom Leather Cutting Dies

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Steel Leather Cutting Dies by Leather Stamp Maker, Made in the USA. Offers custom leather cutting dies, full letter sets, mini font sets, and custom fonts. Full sets include: trio of each letter A-Z, numbers 0-9, special characters, four blank spacers, stamping handle, and 4-inch holder. Mini sets include: full set of uppercase letters A-Z, stamping handle, and MDF organizing box. Custom fonts ava…

Strategic Sourcing Conclusion and Outlook for custom leather dies

The strategic sourcing of custom leather dies is essential for businesses aiming to enhance efficiency and quality in their production processes. By investing in high-quality cutting dies, companies can significantly reduce labor costs and time, while ensuring consistent and precise cuts across large volumes. This is particularly important for manufacturers in regions such as Africa, South America, the Middle East, and Europe, where competitive advantages can be gained through operational efficiency.

Moreover, the versatility of custom leather dies allows businesses to tailor their designs to meet market demands, fostering innovation and customer satisfaction. Utilizing local suppliers can further enhance supply chain resilience, reduce lead times, and lower shipping costs, making it a strategic choice for international buyers.

Looking ahead, it is crucial for B2B buyers to stay informed about advancements in die technology and material capabilities. Engaging with trusted suppliers who understand the unique challenges of your market will position your business for future success. We encourage you to explore partnerships that align with your sourcing strategies, ensuring you are well-equipped to meet the evolving needs of your customers. Embrace the potential of custom leather dies to drive your business forward in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather dies

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.