Описание

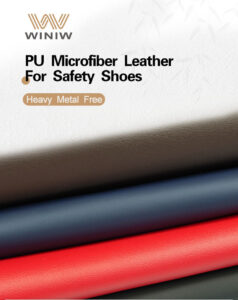

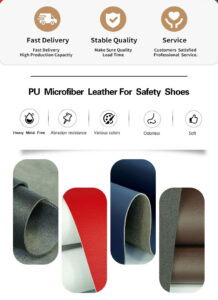

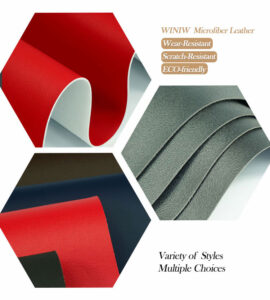

High-Performance Microfiber Leather for Safety Shoes by WINIW

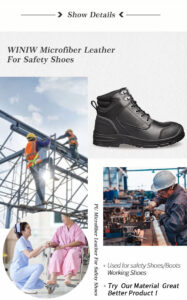

As a leading global manufacturer of advanced microfiber materials, WINIW has engineered a specialized High-Performance Кожа из микрофибры tailored explicitly for safety footwear—addressing the critical demands of industrial, construction, chemical, and high-temperature work environments. Unlike traditional genuine leather or low-grade synthetic alternatives, WINIW’s microfiber leather integrates cutting-edge fiber technology, premium polyurethane (PU) coatings, and strict quality control to deliver uncompromised safety, durability, and comfort. This product is designed to meet or exceed international safety standards such as ASTM F2413-18, ISO 20345, and EN 13832-1, making it the preferred choice for safety shoe brands prioritizing worker protection and long-term product performance. Производитель кожаного материалаWhether facing heavy abrasion, oil contamination, chemical exposure, or fire risks, WINIW’s microfiber leather ensures safety shoes maintain structural integrity while keeping wearers comfortable during extended shifts.

| Technical Parameter | Технические характеристики | Testing Standard |

|---|---|---|

| Material Composition | 80% Polyester Microfiber, 20% High-Grade PU Coating | ASTM D6291 |

| Thickness Range | 1.2–2.0mm (Customizable up to 3.0mm for heavy-duty use) | ASTM D1777 |

| Tensile Strength | ≥ 18MPa (Longitudinal); ≥ 16MPa (Transverse) | ASTM D412 |

| Abrasion Resistance | ≥ 50,000 Cycles (No visible wear or fiber breakage) | Martindale Method (ISO 12947-2) |

| Oil Resistance | Grade 4 (No swelling, discoloration, or stiffness after 24h immersion) | ISO 1817 |

| Flex Resistance | ≥ 200,000 Cycles (No cracks or delamination) | ASTM D2099 |

| Flame Retardancy | V-0 Rating (Self-extinguishing within 10s; no dripping) | UL94 / ASTM F2413-18 |

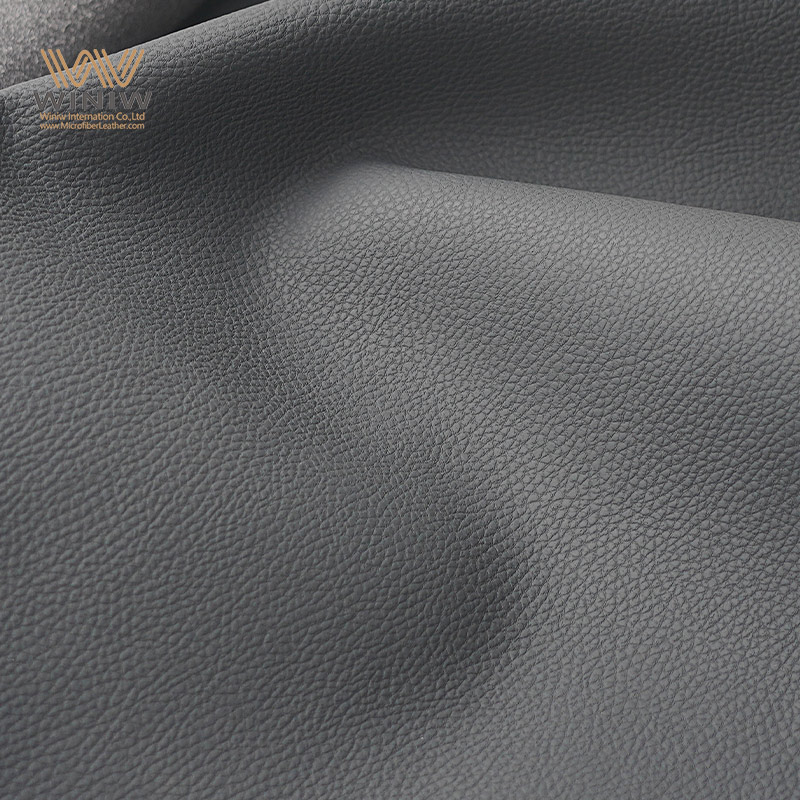

| Color Options | Black, Brown, Gray (Custom PANTONE colors available) | Visual Matching (ISO 105-A02) |

Standard High-Density Microfiber Leather for General Safety Footwear

1. Superior Abrasion Resistance for Extended Service Life

WINIW’s Standard High-Density variant features a tightly woven polyester microfiber base that withstands over 50,000 Martindale abrasion cycles—far exceeding the 30,000-cycle average of conventional synthetic leathers. Microfiber Leather Material ManufacturerThis density prevents fiber fraying or surface wear even in high-friction environments, such as construction sites where shoes rub against concrete or metal. The PU coating further reinforces the surface, creating a barrier against scuffs and scratches, ensuring safety shoes retain their protective structure for up to 2x longer than those using genuine leather.

2. Exceptional Tensile Strength for Impact Protection

With a longitudinal tensile strength of ≥ 18MPa, this microfiber leather resists tearing or stretching when subjected to sudden impacts—critical for safety shoes designed to shield against falling objects or heavy loads. WINIW’s proprietary bonding technology fuses the PU coating with individual microfibers, eliminating delamination (a common flaw in low-quality synthetics) and ensuring the material maintains its integrity even if the shoe’s upper is pulled or strained. This strength aligns with ASTM F2413-18 requirements for protective footwear, providing reliable defense in industrial settings.

3. Balanced Comfort and Breathability for All-Day Wear

Unlike rigid PVC or non-breathable rubber alternatives, WINIW’s microfiber leather incorporates a porous PU structure that allows air circulation while wicking away moisture. This design prevents foot perspiration buildup, reducing discomfort and the risk of bacterial growth during 8+ hour shifts. The material also offers mild flexibility, conforming to the foot’s shape without losing structural support—striking a balance between safety and wearability that genuine leather (often stiff when new) struggles to match.

Oil-Resistant Enhanced Microfiber Leather for Industrial & Chemical Environments

1. Advanced Oil Repellency to Block Chemical Penetration

Engineered for mechanical and chemical workshops, this variant features a modified PU coating with oil-repellent additives that achieve ISO 1817 Grade 4 resistance. It repels mineral oils, lubricants, and mild solvents, preventing the material from swelling, hardening, or losing elasticity—issues that render standard leather or synthetic shoes ineffective in oily environments. After 24 hours of immersion in industrial oil, WINIW’s oil-resistant leather retains 95% of its original tensile strength, ensuring safety shoes remain functional and protective.

2. Water Resistance Without Sacrificing Breathability

Complementing its oil resistance, this microfiber leather includes a nano-scale waterproof layer that repels water and aqueous solutions (e.g., cleaning chemicals) while preserving air permeability. Microfiber Leather Supplier Unlike rubber boots that trap moisture, WINIW’s design allows vapor to escape, keeping feet dry in damp conditions such as food processing plants or outdoor construction sites. The waterproof barrier is integrated into the PU coating (not a separate film), avoiding delamination and maintaining long-term performance.

3. Dimensional Stability Under Harsh Temperature Fluctuations

This variant maintains its shape and size across a temperature range of -20℃ to 80℃—critical for environments with extreme heat or cold, such as refrigerated warehouses or engine rooms. Unlike genuine leather, which contracts in cold or stretches in heat, WINIW’s oil-resistant microfiber leather undergoes less than 1% dimensional change after 72 hours of exposure to extreme temperatures. This stability ensures safety shoes fit consistently and retain their protective structure, preventing gaps that could compromise worker safety.

Flame-Retardant Premium Microfiber Leather for High-Temperature Settings

1. UL94 V-0 Flame Retardancy for Fire Safety Compliance

Tailored for welding,冶金 (metallurgy), and fire-rescue applications, this premium variant meets UL94 V-0 and ASTM F2413-18 flame-retardant standards. It self-extinguishes within 10 seconds of removing the ignition source, produces no dripping molten material, and releases minimal smoke—reducing the risk of secondary burns. WINIW’s use of halogen-free flame retardants ensures compliance with global environmental regulations while delivering superior fire protection compared to flame-treated genuine leather (which often loses retardancy after wear).

2. High Heat Resistance to Withstand Elevated Temperatures

The microfiber base is reinforced with heat-resistant fibers that tolerate short-term contact with temperatures up to 200℃ and continuous exposure to 120℃—far exceeding the 80℃ limit of standard synthetic leathers. This resistance prevents the material from melting, shrinking, or igniting when exposed to sparks, hot metal shavings, or radiant heat. For welders or foundry workers, this means an extra layer of defense against foot burns from accidental contact with high-temperature surfaces.

3. Durable Flame-Retardant Performance Through Washing Cycles

Unlike many flame-retardant materials that lose effectiveness after cleaning, WINIW’s flame-retardant microfiber leather retains its V-0 rating even after 10 industrial washing cycles. The flame-retardant additives are chemically bonded to the microfibers and PU coating, rather than applied as a surface treatment—ensuring long-term protection for safety shoes that require regular cleaning (e.g., food-processing or chemical-rescue footwear). Microfiber Pu Leather Factory This durability reduces replacement costs and ensures consistent safety compliance over the shoe’s lifespan.

WINIW’s High-Performance Microfiber Leather for Safety Shoes is more than a material—it’s a solution engineered to address the unique challenges of modern workplaces. Backed by ISO 9001 quality management and customizable options (thickness, color, performance additives), it empowers safety shoe brands to create products that protect workers, last longer, and enhance comfort. With a focus on innovation and safety, WINIW continues to set industry standards for microfiber materials, ensuring every pair of safety shoes made with its leather delivers on the promise of protection.