Catalog

Material Insight: Heritage Leather Company

B2B Product Guide: Heritage Leather Applications with WINIW Faux Leather

For heritage leather companies rooted in tradition, craftsmanship, and timeless design, maintaining authenticity while embracing innovation is essential. As market demands shift toward sustainability, consistency, and ethical production, the integration of high-performance faux leather offers a strategic advantage—without compromising the premium qualities associated with classic leather goods.

Faux leather presents a compelling solution for heritage brands seeking to preserve their legacy while adapting to modern expectations. Unlike traditional leather, which can vary in texture, thickness, and sustainability footprint, faux leather delivers consistent quality, reduced environmental impact, and greater design flexibility. It enables heritage companies to uphold their standards of excellence while meeting growing consumer demand for eco-conscious, cruelty-free materials.

Key benefits of choosing faux leather for heritage applications include:

– Consistent grain and color across batches for reliable production

– Lower environmental impact through reduced water usage, no animal byproducts, and controlled manufacturing

– Enhanced durability and resistance to fading, cracking, and staining with advanced PU and microfiber technologies

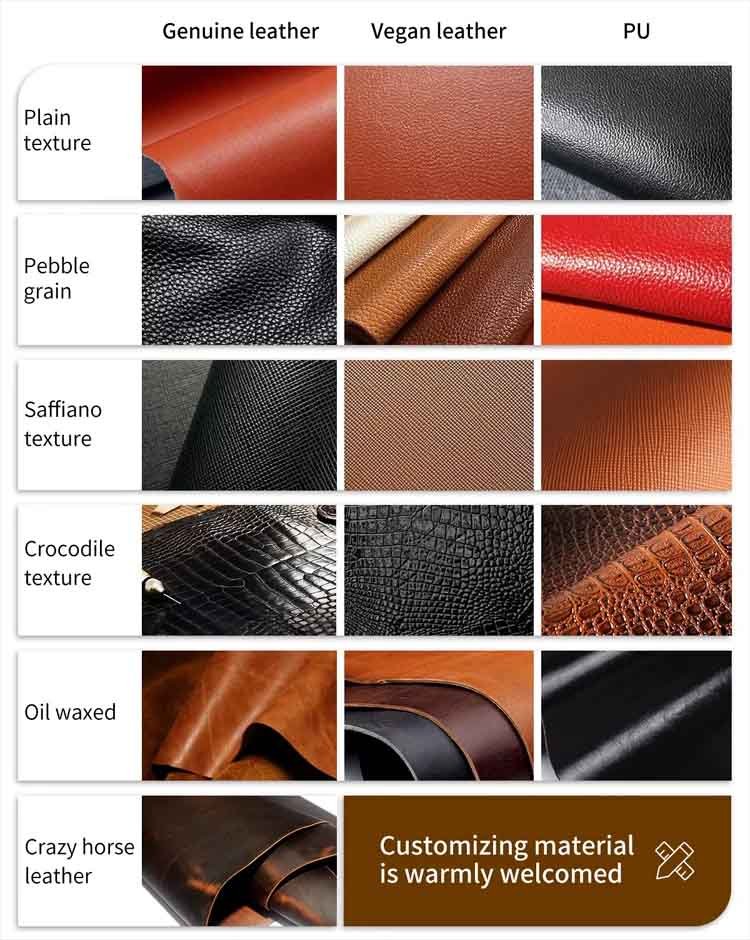

– Customization options in texture, finish, and weight to match traditional leather aesthetics

– Compliance with global regulations on animal welfare and sustainable sourcing

With over 20 years of specialized expertise, WINIW has emerged as a trusted partner for heritage and luxury brands transitioning to high-end synthetic leathers. Our R&D-driven approach combines European-inspired aesthetics with cutting-edge material science, producing premium faux leathers that mirror the look, feel, and performance of natural leather—without the ecological cost.

WINIW’s product lines are engineered for longevity, sustainability, and elegance, making them ideal for heritage applications in footwear, accessories, upholstery, and luxury goods. By combining artisanal attention to detail with scalable, eco-friendly production, WINIW empowers heritage brands to evolve responsibly—preserving their past while shaping the future of sustainable luxury.

Technical Performance & Standards

WINIW Heritage Synthetic Leather: Technical Advantages for Sustainable B2B Supply Chains

WINIW leverages decades of material science expertise to deliver high-performance synthetic leather solutions that meet rigorous industrial demands without compromising environmental responsibility. Our Heritage Series is engineered for manufacturers seeking reliable, eco-conscious materials that optimize production efficiency and product longevity. Below are the core technical advantages driving value for global partners.

Key Technical Advantages

- Cost-Effective Production Integration: Achieve up to 15% material savings through consistent roll yields (≥98.5%) and precision thickness control (±0.05mm), minimizing cutting waste. Reduced rework rates (≤0.8%) lower operational costs versus conventional PU leather.

- Engineered Durability: Withstands 50,000+ double-rub cycles (Martindale, ASTM D4966) and 120N+ tear strength (ASTM D2261), exceeding automotive/furniture industry standards. UV-stabilized formulations maintain color integrity after 1,000+ hours of xenon exposure (ISO 105-B02).

- Precision Color Customization: Access 1,200+ Pantone®-matched shades with ΔE ≤1.5 color consistency across batches. Proprietary dyeing technology ensures lightfastness (ISO 105-B02 Grade 7-8) and crocking resistance (dry/wet: ISO 105-X12 Grade 4-5).

- Guaranteed REACH Compliance: Full SVHC screening with <0.1ppm heavy metals (Cd, Pb, Hg) and zero phthalates (DEHP, BBP, DBP). Documentation includes full substance declarations (SCIP-ready) and annual third-party verification.

- ISO 9001-Certified Quality Control: End-to-end traceability from raw material sourcing to finished roll. In-line spectrophotometry and mechanical testing at 48-hour intervals ensure batch uniformity (CPK ≥1.67).

Technical Specifications Overview

All properties validated per ISO/ASTM standards; values represent WINIW Heritage Series baseline performance

| Property | WINIW Standard | Test Method | Industry Benchmark |

|---|---|---|---|

| Thickness | 0.8mm – 1.5mm | ISO 2417 | 0.7mm – 1.4mm |

| Weight | 350 – 480 g/m² | ISO 2286-2 | 320 – 450 g/m² |

| Tensile Strength | ≥35 MPa | ISO 1767 | ≥28 MPa |

| Elongation at Break | 200% – 300% | ISO 2285 | 180% – 280% |

| Martindale Abrasion | ≥50,000 cycles | ASTM D4966 | ≥30,000 cycles |

| Color Fastness (Light) | Grade 7-8 | ISO 105-B02 | Grade 6-7 |

| REACH SVHC Status | Compliant (0 listed) | EC 1907/2006 | Varies by supplier |

| Production Lead Time | 15-20 дней | – | 25-45 days |

WINIW’s Heritage Series delivers quantifiable operational advantages through scientifically optimized formulations and uncompromising quality governance. Our closed-loop water recycling system (95% reduction vs. industry average) and ISO 14001-aligned manufacturing further ensure your supply chain advances sustainability targets without sacrificing performance. Partner with WINIW for materials engineered to endure—responsibly.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Traditional Leather in Commercial Applications

In the evolving landscape of material sourcing for commercial and industrial use, businesses are increasingly evaluating the performance, sustainability, and cost-efficiency of their material choices. Two prominent options in the upholstery, automotive, fashion, and furniture sectors are heritage leather (natural animal hide) and WINIW’s advanced synthetic leather solutions. This guide provides a comparative analysis to support informed B2B procurement decisions.

Heritage leather companies traditionally offer full-grain and top-grain leathers derived from bovine hides, prized for their natural texture and historical prestige. However, these materials come with significant environmental and economic trade-offs. In contrast, modern synthetic leather—such as WINIW’s high-performance microfiber and PU-based alternatives—delivers consistent quality, enhanced durability, and a significantly lower ecological footprint.

Key advantages of synthetic leather include:

– Consistent texture and thickness across batches, reducing production waste.

– Customizable performance properties (e.g., tear resistance, UV stability, waterproofing).

– Cruelty-free and animal-free production, aligning with ESG and ethical sourcing policies.

– Lower water and energy consumption during manufacturing.

– Greater design flexibility with a wide range of colors, textures, and finishes.

Below is a comparative analysis of heritage leather and synthetic leather across critical procurement metrics:

| Metric | Heritage Leather | Synthetic Leather (WINIW) |

|---|---|---|

| Cost | High (due to raw material scarcity, labor-intensive tanning) | Moderate to low (scalable production, stable input costs) |

| Долговечность | Moderate (prone to cracking, fading, and water damage over time) | High (resistant to abrasion, UV, moisture, and microbial growth) |

| Eco-friendliness | Low (high CO₂ emissions, water pollution from tanning, land use for livestock) | High (recyclable materials, low water use, no animal farming) |

Synthetic leather outperforms heritage leather in durability and environmental sustainability while offering a cost-effective solution for high-volume and quality-sensitive industries. WINIW’s eco-conscious manufacturing process further supports compliance with international environmental standards such as REACH, RoHS, and OEKO-TEX®.

For B2B clients in automotive interiors, contract furniture, or performance apparel, transitioning to synthetic leather is a strategic move toward resilience, responsibility, and long-term value. WINIW delivers scalable, premium-grade alternatives without compromising on aesthetics or performance—empowering brands to innovate sustainably.

WINIW Factory Capabilities

WINIW Synthetic Leather: Global Manufacturing Excellence for B2B Partnerships

WINIW stands at the forefront of sustainable synthetic leather innovation, engineered specifically for discerning B2B clients in furniture, automotive, fashion, and technical textiles. Our vertically integrated manufacturing ecosystem combines scale, scientific rigor, and uncompromising quality control to deliver premium materials that meet global environmental and performance standards.

Core Factory Strengths

Our dedicated 100,000-square-meter manufacturing complex forms the backbone of reliable, high-volume production for international supply chains:

– Advanced Production Capacity: Fully automated lines with annual output exceeding 20 million meters, ensuring agile fulfillment for large-scale OEM and brand partnerships.

– Dedicated R&D Center: A 50+ member technical team specializing in material science, eco-conscious formulations (water-based PU, recycled content integration), and application-specific engineering.

– Strict Multi-Stage QC Protocol:

– Raw material screening via ISO 17025-certified in-house lab

– Real-time in-line monitoring of thickness, color consistency, and coating adhesion

– Comprehensive final testing (Martindale abrasion, lightfastness, VOC emissions per EU REACH/US CPSIA)

– Sustainable Infrastructure: LEED-certified facilities with solar energy integration, closed-loop water systems, and zero-waste-to-landfill initiatives since 2020.

Global Market Compliance & Reach

WINIW materials consistently meet stringent regulatory frameworks across key markets, enabling seamless integration into international supply chains:

| Certification Standard | Scope of Compliance | Key Market Relevance |

|---|---|---|

| OEKO-TEX® STANDARD 100 | Human-ecological safety (no harmful substances) | EU, USA, Japan retail requirements |

| ISO 14001:2015 | Environmental management systems | Mandatory for EU public tenders |

| SCS Recycled Content | Verified post-consumer/pre-consumer recycled content | Meets LEED v4.1 & EU Green Claims Directive |

| UL GREENGUARD Gold | Low chemical/VOC emissions | Required for US healthcare/education sector projects |

We maintain active export relationships with Tier-1 suppliers and brands across 40+ countries, with 65% of shipments directed to environmentally regulated markets (European Union, United States, Canada, and Japan). Our logistics network features bonded warehouses in Rotterdam and Los Angeles, reducing lead times by 18–22 days for transatlantic partners.

By partnering with WINIW, B2B clients gain access to scalable production capacity anchored in scientific innovation and verified sustainability—ensuring your end products achieve market differentiation while meeting evolving global compliance demands. All materials are backed by full lifecycle assessment (LCA) data and customizable technical support.

Contact Us for Samples

WINIW™ B2B Product Guide: Sustainable Microfiber Leather for Heritage Brands

WINIW specializes in premium synthetic leather engineered for brands that value tradition, quality, and sustainability. Our advanced microfiber leather solutions combine the timeless elegance of natural leather with the performance and environmental benefits of next-generation materials. Designed for heritage leather companies seeking to innovate responsibly, WINIW delivers durability, versatility, and eco-conscious excellence across industries—from luxury goods and furniture to automotive interiors and footwear.

Our proprietary production process uses ultra-fine fibers and high-density polyurethane to replicate the soft hand feel, breathability, and tensile strength of top-grain leather—without the environmental toll. By partnering with WINIW, heritage brands can preserve their craftsmanship legacy while embracing a more sustainable future.

Key Advantages of WINIW Microfiber Leather

- Sustainable by Design: Made with up to 30% recycled content and free from hazardous chemicals (REACH, RoHS, and OEKO-TEX® compliant).

- Consistent Quality: Uniform thickness, color fastness, and texture eliminate natural hide variations.

- High Performance: Superior abrasion resistance, tear strength, and UV stability ensure long-term durability.

- Eco-Friendly Production: Water-based processing reduces wastewater; 60% lower carbon footprint compared to bovine leather tanning.

- Customization Ready: Available in custom weights (200–800 g/m²), thicknesses (0.6–2.0 mm), finishes (matte, glossy, textured), and colors.

- Animal-Free & Cruelty-Free: Ideal for brands pursuing vegan certification and ethical sourcing standards.

Ideal Applications for Heritage Craftsmanship

- Luxury handbags, wallets, and small leather goods

- Upholstered furniture and high-end residential interiors

- Automotive and marine seating surfaces

- Footwear and accessories with artisanal detailing

- Archival and restoration projects requiring consistent material behavior

| Технические характеристики | WINIW Standard Range |

|---|---|

| Thickness | 0.6 mm – 2.0 mm |

| Weight | 200 – 800 g/m² |

| Width | 137 cm (54″) or 150 cm (59″) |

| Roll Length | 30–50 meters per roll |

| Finish Options | Nubuck, Suede, Full-Grain, Embossed |

| Certifications | REACH, RoHS, OEKO-TEX® Standard 100, ISO 14001 |

Partner with WINIW to Elevate Your Heritage Brand

We support heritage leather companies in transitioning to sustainable materials without compromising on aesthetics or performance. Our technical team collaborates closely with your designers and production units to ensure seamless integration into existing workflows.

Free samples are available upon request. Experience the look, feel, and performance of WINIW microfiber leather firsthand.

For partnership inquiries and material samples, contact:

Marketing Department – WINIW

Email: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.