Catalog

Material Insight: Faux Leather Upholstery Fabric

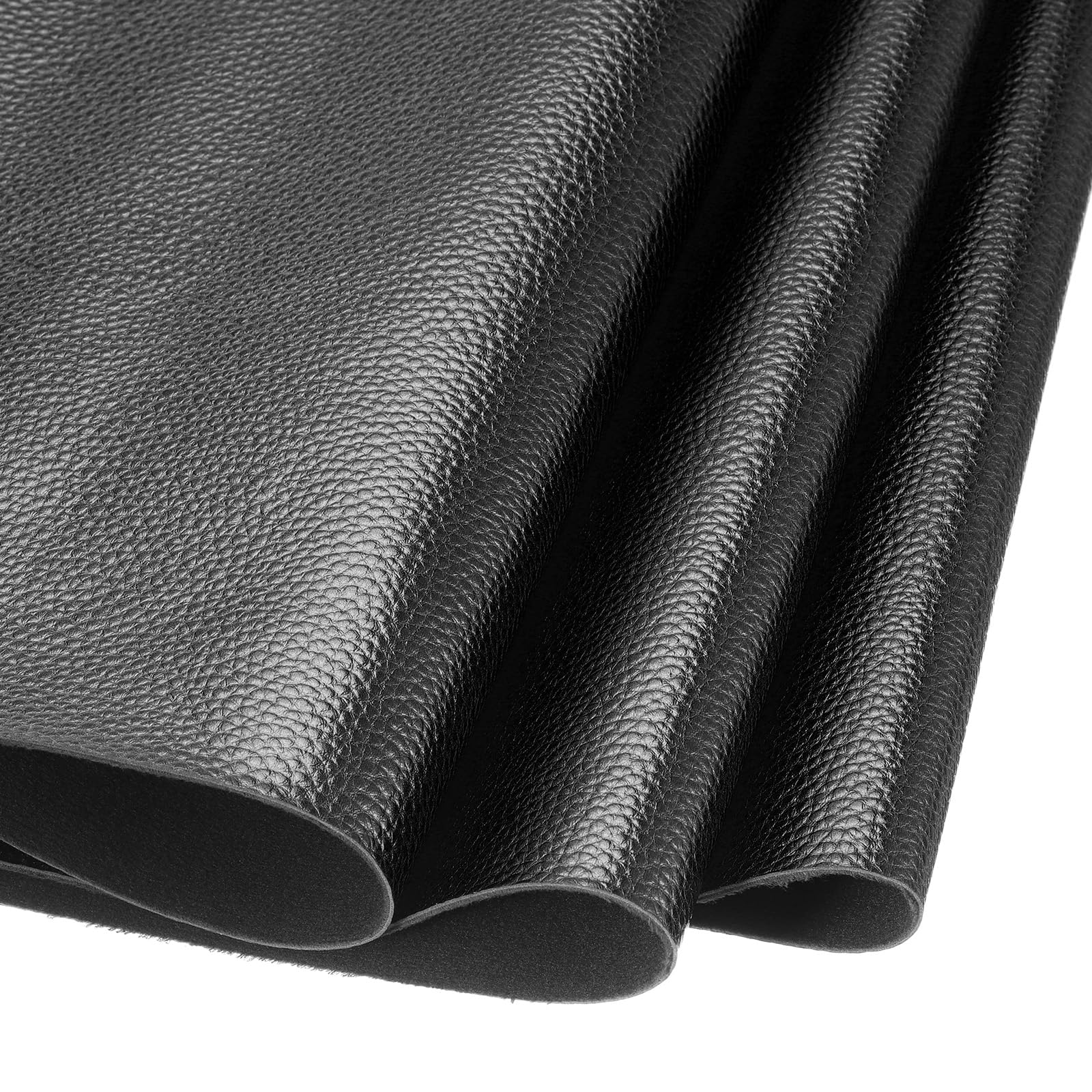

Faux leather upholstery fabric has become a preferred material in modern interior design and furniture manufacturing due to its combination of aesthetic appeal, durability, and sustainability. As a high-performance alternative to genuine leather, faux leather offers consistent texture, enhanced workability, and greater control over color and finish, making it ideal for commercial and residential furniture applications. Designed to withstand heavy use while maintaining visual elegance, it is widely used in seating, paneling, and decorative elements across hospitality, office, healthcare, and residential sectors.

Upholstery leather—particularly high-quality faux leather—is the best choice for this application because it balances resilience with comfort. It resists abrasion, fading, and staining, ensuring long-term performance in high-traffic environments. Unlike natural leather, faux upholstery leather can be engineered for specific functional needs, such as improved breathability, fire resistance, or antimicrobial properties. Additionally, it supports eco-conscious manufacturing with reduced environmental impact, offering a cruelty-free and resource-efficient solution without compromising on luxury or functionality.

WINIW is a leading innovator in synthetic leather solutions, with over 20 years of experience in research, development, and production. Specializing in microfiber and PU-based faux leather, WINIW delivers premium upholstery fabrics that meet stringent international standards for quality, durability, and sustainability. Our materials are engineered for superior texture, tear strength, and color fastness, tailored to the demands of global furniture brands, designers, and manufacturers. With a strong commitment to eco-friendly practices, WINIW utilizes low-VOC formulations and recyclable components, supporting a circular economy in the interiors industry.

Technical Performance & Standards

WINIW Faux Leather Upholstery Fabric: Technical Product Guide for Commercial Applications

WINIW’s engineered faux leather upholstery fabric delivers premium performance for demanding commercial environments, combining rigorous safety standards with sustainable manufacturing. Designed specifically for B2B clients in contract furniture, hospitality, and public transport, our solution eliminates compromises between eco-conscious material selection and uncompromising technical functionality. Below are key technical advantages validated through independent testing and global compliance frameworks.

Core Technical Advantages

- Fire Retardant Performance (UK/US Standards): Exceeds BS 5852:2015 (Source 0 & 1) and CAL TB 117-2013 without topical chemical treatments. Inherently flame-resistant polymer matrix achieves M1 (France) and Class 1 (ASTM E84) ratings, ensuring safety in high-occupancy spaces without compromising material integrity or longevity.

- Easy Clean & Stain Resistance: Features a non-porous, cross-linked surface layer repelling oils, alcohols, and common solvents. Passes ISO 105-X12 colorfastness testing (Grade 4-5). Routine maintenance requires only pH-neutral cleaners; withstands repeated sanitization with 70% isopropyl alcohol without degradation.

- Soft Touch & Durability: Utilizes a multi-layer nano-coating process to achieve a supple, leather-like drape (Shore A hardness: 75–80) while maintaining exceptional abrasion resistance (50,000+ double rubs, Martindale ISO 12947). Retains tactile comfort after 10,000+ cycles of flex testing (ISO 7814).

- REACH SVHC Compliance: Fully compliant with EU REACH Annex XVII, containing zero detectable levels of restricted substances (e.g., phthalates, AZO dyes, heavy metals). Certificate of Conformity available upon request, supporting clients’ chemical safety due diligence.

- ISO 9001-Certified Quality Control: End-to-end manufacturing under ISO 9001:2015 certified processes ensures batch-to-batch consistency in thickness, color, and physical properties. Includes real-time spectrophotometric color matching (ΔE < 0.5 tolerance).

Technical Specifications Overview

Validated per ISO, ASTM, and EN test methods

| Specification Category | WINIW Standard | Test Method Reference |

|---|---|---|

| Base Material | Recycled PET backing + PU topcoat | ISO 1888 |

| Thickness | 0.8–1.2 mm (customizable) | ISO 2427 |

| Fire Resistance (US) | CAL TB 117-2013 Pass | CA TB 117 |

| Fire Resistance (UK/EU) | BS 5852:2015 Source 0 & 1 Pass | BS 5852 |

| Abrasion Resistance | >50,000 double rubs (no failure) | ISO 12947-2 |

| Colorfastness to Rubbing | Grade 4–5 (wet/dry) | ISO 105-X12 |

| REACH Compliance | SVHC-free (<0.1% detection limit) | EC 1907/2006 Annex XVII |

| Tensile Strength | ≥60 N/5cm (warp & weft) | ISO 13934-1 |

| Seam Slippage | ≤2.0 mm displacement | ISO 13936-1 |

| pH Value | 5.0–7.0 (skin-safe) | ISO 3071 |

WINIW’s faux leather upholstery fabric is engineered for commercial resilience without environmental trade-offs. By integrating fire safety at the molecular level, eliminating hazardous chemistries, and adhering to global quality management systems, we provide B2B partners with a future-proof material that meets stringent regulatory landscapes while supporting ESG commitments. Request our full technical dossier and sample swatch kit to validate performance for your specific application.

WINIW: Precision Engineered Sustainable Performance

Why Choose Synthetic over Real Leather

B2B Product Guide: Faux Leather Upholstery Fabric vs. Real Leather

In commercial and residential furniture manufacturing, selecting the right upholstery material is critical for balancing performance, cost, and sustainability. Two of the most widely used materials—faux leather upholstery fabric and real leather—offer distinct advantages and trade-offs. This guide provides a clear comparison to help B2B buyers make informed decisions aligned with their production goals, brand values, and end-user expectations.

Overview of Materials

-

Faux Leather Upholstery Fabric

Also known as synthetic or PU leather, faux leather is an engineered material designed to replicate the look and feel of genuine leather. Made from polyurethane (PU) or polyvinyl chloride (PVC) coatings on a fabric backing, it offers a cruelty-free, consistent, and increasingly eco-conscious alternative. Modern innovations, such as those from WINIW, focus on high-performance PU leather with enhanced breathability, abrasion resistance, and reduced environmental impact. -

Real Leather

Sourced from animal hides (primarily bovine), real leather is a natural material prized for its durability, unique grain patterns, and premium aesthetic. It ages gracefully over time and is often associated with luxury. However, its production involves resource-intensive tanning processes and raises ethical and environmental concerns.

Key Differences: Performance & Application

- Aesthetic Consistency:

- Faux leather provides uniform texture and color, ideal for large-scale production where consistency is essential.

-

Real leather features natural variations, which may be desirable for high-end, artisanal products but can complicate batch uniformity.

-

Maintenance & Cleanability:

- Faux leather is generally easier to clean and resistant to staining and fading, especially in high-traffic environments.

-

Real leather requires conditioning and is more susceptible to cracking and water damage if not properly maintained.

-

Customization & Design Flexibility:

- Faux leather can be produced in a wide range of colors, textures, and finishes (e.g., matte, glossy, embossed), offering greater design versatility.

- Real leather is limited to natural grain and dye options, though it can be treated for specific effects.

Comparative Analysis: Cost, Durability, and Eco-Friendliness

| Factor | Faux Leather Upholstery Fabric | Real Leather |

|---|---|---|

| Cost | Lower initial cost; economical for large orders | Higher cost due to raw material scarcity and processing |

| Долговечность | High resistance to abrasion and fading; performs well in commercial settings | Excellent long-term durability but prone to cracking and wear if untreated |

| Eco-Friendliness | Modern PU-based options (e.g., WINIW EcoLeather) are recyclable, low-VOC, and animal-free; reduced water and energy use in production | High environmental footprint due to land use, methane emissions, and chemical tanning; not biodegradable when chrome-tanned |

Sustainability Considerations

- Faux leather, particularly water-based PU leather, supports circular economy goals with lower carbon emissions and no animal sourcing. WINIW’s advanced production techniques minimize solvent use and prioritize renewable inputs.

- Real leather utilizes a byproduct of the meat industry, but its tanning processes (especially chrome tanning) contribute significantly to water pollution and greenhouse gas emissions.

Заключение

For B2B manufacturers focused on scalability, cost-efficiency, and sustainability, high-quality faux leather upholstery fabric presents a compelling alternative to real leather. With performance metrics rivaling natural leather and a significantly lower environmental impact, modern synthetic leathers are increasingly the material of choice for eco-conscious brands and commercial projects. Real leather remains relevant in luxury markets but comes with higher costs and sustainability challenges that may not align with evolving regulatory and consumer demands.

WINIW Factory Capabilities

WINIW Synthetic Leather: Advanced Manufacturing Capabilities for Global B2B Partners

WINIW operates one of the industry’s most advanced synthetic leather manufacturing ecosystems, engineered to deliver consistent quality, innovation, and scalability for global B2B clients. Our integrated facility and processes ensure compliance with stringent international standards while prioritizing environmental responsibility.

Core Manufacturing Strengths

- 100,000 sqm Integrated Production Hub: A fully automated, vertically integrated campus enabling end-to-end control from raw material processing to finished goods. This scale supports high-volume orders (500,000+ meters monthly) with rapid turnaround and flexible customization.

- Dedicated R&D Team (60+ Specialists): In-house engineers and material scientists drive innovation in performance, sustainability, and aesthetics. Annual R&D investment exceeds 5% of revenue, resulting in 15+ patented technologies (e.g., water-based PU systems, recycled PET substrates).

- Triple-Stage Quality Assurance: Rigorous QC protocols at every phase:

- Raw material screening (REACH/OEKO-TEX® certified inputs)

- In-process testing (colorfastness, abrasion, peel strength)

- Final product validation (3rd-party lab reports for ISO 9001 compliance)

- Global Export Compliance: Direct supply to 30+ countries with full adherence to EU REACH, U.S. CPSIA, and California Proposition 65. Dedicated logistics teams manage customs documentation and LCL/FCL shipments to Europe and North America within 25–35 days.

Sustainability Integration in Production

WINIW’s eco-engineering is embedded in our manufacturing DNA:

– Resource Efficiency: Closed-loop water systems reduce consumption by 40% vs. industry average; solar energy powers 30% of operations.

– Low-Impact Materials: 85% of product lines use recycled content (rPET, bio-based polyols) and waterborne PU resins (VOC < 50g/L).

– Certified Circularity: OEKO-TEX® STANDARD 100, GRS, and ISO 14001 certified processes ensure traceability and end-of-life recyclability.

Global Performance Validation

WINIW materials consistently exceed international benchmarks for durability and safety:

| Test Parameter | WINIW Standard | Industry Average | Key Markets Verified |

|---|---|---|---|

| Martindale Abrasion | 50,000+ cycles | 25,000 cycles | EU Automotive, US Furniture |

| Colorfastness (Xenon) | Grade 5 (ISO 105-B02) | Grade 4 | Luxury Fashion (EU) |

| Heavy Metals (ppm) | < 5 | < 100 | U.S. Consumer Goods |

| Tensile Strength | 250 N/5cm | 180 N/5cm | Global Performance Apparel |

Our manufacturing excellence—backed by 20+ years of export experience—ensures WINIW is the strategic partner for brands demanding uncompromised quality, ethical production, and scalable innovation in synthetic leather solutions. Partner with us to transform material specifications into market-ready success.

Contact Us for Samples

WINIW Faux Leather Upholstery Fabric – B2B Product Guide

WINIW specializes in high-performance, eco-conscious synthetic leather solutions designed for commercial and industrial upholstery applications. Our faux leather upholstery fabrics combine durability, aesthetic versatility, and sustainable manufacturing practices to meet the evolving demands of furniture, automotive, hospitality, and contract interior markets.

Engineered with advanced microfiber technology, WINIW upholstery leathers offer a premium alternative to genuine leather—without the environmental impact. Each product is developed to deliver consistent quality, long-term resilience, and design flexibility for large-scale projects.

Key Features of WINIW Faux Leather Upholstery Fabric

- Superior Durability: High abrasion resistance (Martindale >50,000 cycles) ensures long-lasting performance in high-traffic environments.

- Eco-Friendly Composition: PVC-free and REACH-compliant; made with water-based polyurethane for reduced environmental impact.

- Soft Touch & Realistic Texture: Premium microfiber base mimics the hand feel and grain variation of natural leather.

- Color & Finish Versatility: Available in over 200 standard colors and customizable finishes (matte, glossy, embossed, anti-fingerprint).

- Easy Maintenance: Stain-resistant and wipeable with mild detergent—ideal for healthcare, transportation, and public spaces.

- Fire & Safety Certified: Meets international standards including BS 5852, CAL 117, and IMO FTPC for fire retardancy.

- Consistent Roll-to-Roll Quality: Uniform thickness (0.6–1.2 mm) and width (54” / 137 cm) for seamless fabrication.

Technical Specifications

| Property | Технические характеристики |

|---|---|

| Base Material | Ultra-fine microfiber (100% polyester) |

| Coating | Water-based polyurethane (PU) |

| Thickness Tolerance | ±0.05 mm |

| Width | 54 inches (137 cm) |

| Weight | 380–420 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Light Fastness | ≥ Grade 4 (ISO 105-B02) |

| Cold Crack Resistance | Down to -20°C |

| Environmental Compliance | REACH, RoHS,不含偶氮染料 (AZO-free) |

Приложения

- Office & conference room furniture

- Hotel, restaurant, and lobby seating

- Public transportation (buses, trains, aircraft)

- Healthcare facility furnishings

- Residential and multi-family housing projects

- Automotive interior trims (non-OEM)

Why Partner with WINIW?

- Scalable production capacity: Up to 3 million meters per month.

- Global logistics network with FOB and CIF options.

- OEM/ODM support: Custom colors, textures, and performance additives available.

- Quality assurance: Each batch tested in-house and certified with full traceability.

- Sustainable innovation: Carbon footprint reduction programs and recyclable packaging.

Request Free Samples Today

Evaluate WINIW’s faux leather upholstery fabric for your next project at no cost. Our sample program includes up to 30cm x 30cm swatches in standard or custom options, with technical data sheets provided.

Contact our B2B marketing team to begin:

MKT88@MicrofiberLeather.com

WINIW – Engineered Elegance. Sustainably Crafted for Industry.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.