Introduction: Navigating the Global Market for what is pu leather material

Navigating the complexities of sourcing PU leather materials can be a daunting task for international B2B buyers, especially when considering factors such as quality, durability, and environmental impact. PU leather, or polyurethane leather, serves as a popular alternative to genuine leather, offering various applications across industries—from fashion to furniture. However, understanding the nuances of this synthetic material is crucial for making informed purchasing decisions.

This comprehensive guide delves into the intricacies of PU leather, covering essential topics including types, applications, cost considerations, and supplier vetting. By exploring the pros and cons of PU leather, buyers will gain insights into its manufacturing processes, potential health implications, and sustainability concerns. With a focus on practical strategies, this guide empowers B2B buyers from diverse regions—such as Africa, South America, the Middle East, and Europe—to navigate the global market effectively.

Understanding the distinct characteristics of PU leather versus genuine leather, along with recognizing the various names and grades associated with it, can significantly enhance your sourcing strategy. Ultimately, this guide aims to equip you with the knowledge needed to make confident, sustainable choices that align with your business values and market demands.

Table Of Contents

- Top 3 What Is Pu Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is pu leather material

- Understanding what is pu leather material Types and Variations

- Key Industrial Applications of what is pu leather material

- 3 Common User Pain Points for ‘what is pu leather material’ & Their Solutions

- Strategic Material Selection Guide for what is pu leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for what is pu leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is pu leather material’

- Comprehensive Cost and Pricing Analysis for what is pu leather material Sourcing

- Alternatives Analysis: Comparing what is pu leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for what is pu leather material

- Navigating Market Dynamics and Sourcing Trends in the what is pu leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is pu leather material

- Strategic Sourcing Conclusion and Outlook for what is pu leather material

- Important Disclaimer & Terms of Use

Understanding what is pu leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 100% PU Leather | Completely synthetic, vegan-friendly, available in various colors | Furniture, automotive upholstery | Pros: Cost-effective, easy to clean, water-resistant. Cons: Less durable, can crack over time, synthetic look. |

| Bicast Leather | Real leather base with a PU coating for enhanced durability | Upholstered furniture, fashion accessories | Pros: Combines real leather feel with PU durability. Cons: May still peel, less breathable than full leather. |

| Split Leather | Made from leftover leather fibers, coated with PU | Budget-friendly furniture, bags | Pros: Affordable, retains some leather characteristics. Cons: Less durable than real leather, potential for chemical exposure. |

| Vegan Leather | Derived from synthetic materials, marketed as eco-friendly | Fashion, accessories, and furnishings | Pros: Animal-friendly, diverse designs. Cons: Environmental concerns due to plastic content, less longevity. |

| Corrected Grain Leather | Real leather treated to remove imperfections, coated with PU | High-end furniture, luxury goods | Pros: Appears high-quality, retains some natural leather texture. Cons: Can be misleadingly labeled, potential durability issues. |

What Are the Characteristics of 100% PU Leather?

100% PU leather is a fully synthetic material, making it an appealing choice for businesses seeking cost-effective solutions. This type is entirely vegan, which aligns well with increasing consumer demand for cruelty-free products. It is available in a wide range of colors and styles, facilitating creative designs in furniture and automotive applications. However, its durability is often questioned, as it may crack and wear out quicker than genuine leather, necessitating regular replacement.

How Does Bicast Leather Compare to Other Types?

Bicast leather incorporates a layer of polyurethane over a base of genuine leather, providing a balance of affordability and authenticity. This hybrid material is often used in upholstered furniture and fashion accessories, appealing to buyers looking for a leather-like appearance without the full cost. While it offers better durability than 100% PU leather, it may still suffer from peeling and reduced breathability, which are critical considerations for B2B buyers in high-use environments.

Illustrative image related to what is pu leather material

What Should Buyers Know About Split Leather?

Split leather is produced from the fibrous remnants of animal hides, treated with a PU coating for added protection. This type is a budget-friendly alternative for businesses looking to offer leather-like products at a lower price point. While it retains some characteristics of genuine leather, its longevity is limited, and buyers should be aware of potential chemical exposure during manufacturing. Split leather is commonly used in lower-end furniture and bags, making it suitable for businesses targeting cost-conscious consumers.

Why Consider Vegan Leather for Your Business?

Vegan leather, often made from synthetic materials, is marketed as an eco-friendly alternative to traditional leather. This type appeals to businesses focused on sustainable practices and ethical consumerism. With a diverse range of designs, vegan leather can be used in fashion and accessories, making it versatile for various markets. However, B2B buyers should consider the environmental impact of plastic production and the material’s overall durability, as it may not withstand heavy use compared to genuine leather options.

What Are the Implications of Using Corrected Grain Leather?

Corrected grain leather is genuine leather that has undergone treatment to remove imperfections, then coated with PU for added durability. This type is often found in high-end furniture and luxury goods, appealing to businesses aiming for a premium market. While it provides a visually appealing product, buyers should be cautious of misleading labels that may imply higher quality than what the product offers. Understanding the longevity and maintenance needs of corrected grain leather is essential for B2B buyers to ensure customer satisfaction.

Illustrative image related to what is pu leather material

Key Industrial Applications of what is pu leather material

| Industry/Sector | Specific Application of what is pu leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Cost-effective, easy to clean, and versatile design | Ensure compliance with international safety standards and durability requirements. |

| Fashion and Apparel | Clothing and accessories | Affordable alternative to genuine leather, variety of colors | Look for suppliers who offer customization options and sustainable practices. |

| Automotive | Interior trims and seat covers | Lightweight, waterproof, and easy to maintain | Verify the durability under varying climate conditions and ensure compliance with automotive industry standards. |

| Footwear | Shoe production | Provides a leather-like appearance at a lower cost | Assess the breathability and comfort level for end-users, and consider sourcing from eco-friendly manufacturers. |

| Home Décor | Decorative items such as cushions and wall art | Aesthetic appeal with lower environmental impact | Source from suppliers that provide detailed product specifications and eco-certifications. |

How is PU Leather Used in Furniture Manufacturing?

In the furniture manufacturing sector, PU leather is widely used for upholstery in sofas and chairs. Its affordability and ease of maintenance make it a popular choice for businesses looking to offer stylish yet cost-effective furniture solutions. For international buyers, particularly in regions like Africa and South America, sourcing PU leather products that comply with local safety standards is essential to ensure durability and customer satisfaction.

What Role Does PU Leather Play in Fashion and Apparel?

In the fashion industry, PU leather is utilized for a variety of clothing and accessories, providing an attractive alternative to genuine leather. This material allows designers to create a wide range of colors and styles while keeping costs manageable. B2B buyers, especially from the Middle East and Europe, should prioritize suppliers who emphasize sustainable practices and offer customizable options to meet specific market demands.

How is PU Leather Beneficial for Automotive Applications?

PU leather finds significant applications in the automotive industry, particularly for interior trims and seat covers. Its lightweight nature, combined with waterproof properties, makes it a practical choice for vehicle manufacturers. Buyers in this sector must ensure that the PU leather sourced meets rigorous automotive standards, particularly regarding durability and resistance to various climate conditions, to enhance vehicle longevity.

Illustrative image related to what is pu leather material

Why is PU Leather Important in Footwear Production?

In footwear manufacturing, PU leather is favored for its ability to mimic the look of genuine leather while being more affordable. This material is particularly advantageous for producing stylish shoes that appeal to a broad consumer base. For B2B buyers, especially in emerging markets, it is crucial to assess the breathability and comfort levels of PU leather, ensuring that the final product meets consumer expectations for quality and wearability.

How is PU Leather Used in Home Décor?

PU leather is also popular in the home décor sector, where it is used for decorative items such as cushions and wall art. Its aesthetic appeal, coupled with a lower environmental impact compared to traditional materials, makes it an attractive option for consumers and businesses alike. When sourcing PU leather for home décor, buyers should seek suppliers who provide detailed specifications and eco-certifications to ensure product quality and sustainability.

3 Common User Pain Points for ‘what is pu leather material’ & Their Solutions

Scenario 1: Navigating Quality Concerns in PU Leather Sourcing

The Problem: B2B buyers often face challenges in ensuring the quality of PU leather when sourcing from various suppliers. With multiple grades and types of PU leather available, distinguishing between high-quality materials and inferior options can be daunting. This can lead to dissatisfaction among end customers, potential returns, and damage to brand reputation, especially when the PU leather products show signs of wear and tear sooner than expected.

Illustrative image related to what is pu leather material

The Solution: To effectively navigate quality concerns, B2B buyers should establish clear quality standards and specifications for PU leather products. Begin by requesting detailed product samples from suppliers that highlight different grades of PU leather. Pay close attention to the thickness, texture, and finish of the material. Conduct a comparative analysis of samples based on durability tests such as abrasion resistance and flexibility. Additionally, consider developing a checklist that includes certifications for eco-friendliness and safety standards, such as the absence of harmful VOCs. By adopting a rigorous vetting process, buyers can confidently select high-quality PU leather that meets their product requirements and enhances customer satisfaction.

Scenario 2: Managing Environmental Impact and Sustainability Concerns

The Problem: With increasing global awareness regarding sustainability, many B2B buyers face pressure from consumers and stakeholders to source environmentally friendly materials. PU leather, while often marketed as a vegan alternative, typically has a significant environmental footprint due to its petroleum-based composition and the chemicals used in its production. This can create a conflict for companies looking to position themselves as eco-conscious brands.

The Solution: B2B buyers should prioritize sourcing PU leather products from manufacturers that utilize sustainable practices. Engage with suppliers who can provide transparency about their production processes, including the use of non-toxic adhesives and lower-impact manufacturing methods. Look for certifications that indicate eco-friendliness, such as those from recognized environmental organizations. Additionally, consider exploring alternatives to traditional PU leather, such as bio-based or recycled materials that offer similar aesthetics but with a reduced environmental impact. By aligning sourcing strategies with sustainability goals, buyers can enhance their brand reputation while meeting market demands.

Scenario 3: Differentiating PU Leather from Genuine Leather for Customer Education

The Problem: B2B buyers, especially those in the retail and fashion industries, often encounter confusion among consumers regarding the differences between PU leather and genuine leather. This misunderstanding can lead to mismatched expectations, where customers expect the longevity and quality of real leather from PU products. Such discrepancies can result in returns, negative reviews, and a loss of customer loyalty.

The Solution: To effectively educate customers about the distinctions between PU leather and genuine leather, B2B buyers should implement comprehensive marketing and educational strategies. Develop informative content that clearly outlines the characteristics, benefits, and limitations of PU leather compared to genuine leather. Utilize visual aids, such as comparison charts and videos, to illustrate the differences in durability, maintenance, and appearance. Additionally, consider offering training sessions for sales staff to equip them with the knowledge needed to address customer inquiries confidently. By fostering a better understanding of PU leather, companies can set realistic expectations for customers, reduce dissatisfaction, and enhance the overall shopping experience.

Strategic Material Selection Guide for what is pu leather material

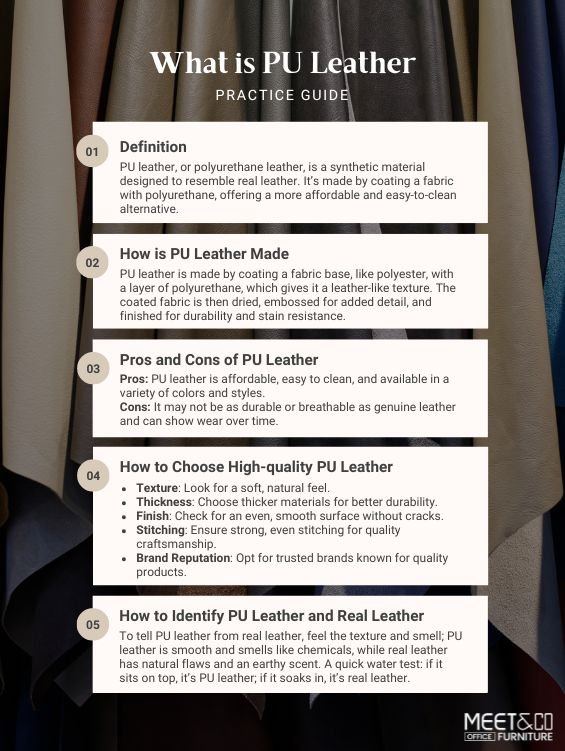

What Are the Key Properties of PU Leather?

PU leather, or polyurethane leather, is a synthetic material designed to mimic the appearance and texture of genuine leather. It is created by coating a fabric base with a layer of polyurethane, making it a popular choice for various applications, including upholstery, footwear, and fashion accessories.

Key Properties Relevant to Product Performance

-

Temperature and Pressure Rating: PU leather typically performs well in moderate temperature ranges but can degrade under extreme heat or cold. It is not suitable for high-pressure applications, as it can crack and peel when subjected to stress.

-

Corrosion Resistance: PU leather is resistant to moisture, making it easier to clean and maintain compared to genuine leather. However, it can be susceptible to chemical damage from certain solvents or cleaning agents.

-

Breathability: Unlike genuine leather, PU leather lacks breathability, which can affect comfort in applications like clothing and seating.

What Are the Pros and Cons of PU Leather for B2B Buyers?

Advantages

- Cost-Effectiveness: PU leather is significantly cheaper to produce than genuine leather, making it an attractive option for budget-conscious businesses.

- Variety of Styles: It can be manufactured in a wide range of colors and textures, allowing for customization to meet specific design needs.

- Vegan-Friendly: 100% PU leather is a vegan alternative, appealing to businesses targeting environmentally conscious consumers.

Disadvantages

- Durability Issues: PU leather generally has a shorter lifespan than genuine leather, often lasting only 1-2 years before showing signs of wear such as cracking and peeling.

- Chemical Sensitivity: Certain PU leather products may contain volatile organic compounds (VOCs) that can pose health risks and environmental concerns.

- Limited Aesthetic Aging: Unlike genuine leather, PU leather does not develop a unique patina over time, which can detract from its appeal in high-end markets.

How Does PU Leather Impact Specific Applications?

PU leather is commonly used in furniture, automotive interiors, and fashion accessories. Its ease of cleaning and maintenance makes it suitable for high-traffic environments like offices and public spaces. However, its lack of durability may limit its use in applications requiring long-lasting materials, such as high-end furniture or luxury automotive interiors.

What Should International B2B Buyers Consider When Sourcing PU Leather?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several factors are crucial:

- Compliance with Standards: Buyers should ensure that the PU leather products meet relevant international standards such as ASTM, DIN, or JIS for safety and performance.

- Environmental Regulations: Awareness of local regulations regarding VOC emissions and chemical safety is essential, especially in regions with stringent environmental laws.

- Cultural Preferences: Understanding regional preferences for materials can guide product selection. For example, markets in Europe may favor sustainable options, while emerging markets may prioritize cost-effectiveness.

Summary Table of PU Leather Materials

| Material | Typical Use Case for what is pu leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Leather | Upholstery, fashion accessories, footwear | Cost-effective and customizable | Short lifespan, prone to wear | Low |

| Bicast Leather | Budget-friendly furniture | Combines leather feel with lower cost | Less durable than genuine leather | Medium |

| Vegan Leather | Eco-conscious fashion products | Appeals to vegan and eco-friendly markets | Limited durability, synthetic feel | Medium |

| Bonded Leather | Affordable leather goods | Utilizes waste leather, eco-friendly | May contain toxic adhesives | Medium |

This strategic material selection guide provides valuable insights for B2B buyers considering PU leather, emphasizing the importance of understanding its properties, advantages, disadvantages, and regional considerations when sourcing materials.

Illustrative image related to what is pu leather material

In-depth Look: Manufacturing Processes and Quality Assurance for what is pu leather material

What Are the Main Stages in the Manufacturing Process of PU Leather?

The manufacturing process of PU leather involves several key stages, each critical to producing a high-quality synthetic material. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

1. Material Preparation: What Materials Are Used for PU Leather?

The foundation of PU leather begins with a base fabric, typically made from polyester or cotton. This base is chosen for its strength and flexibility. The fabric is then coated with a layer of polyurethane, a thermoplastic polymer that mimics the appearance and texture of genuine leather.

To enhance the quality of PU leather, additives such as color pigments, stabilizers, and plasticizers are introduced during the coating process. These materials can affect the final product’s look, feel, and durability. For B2B buyers, it’s essential to inquire about the types of materials used, as they can significantly influence the end product’s performance and sustainability.

2. Forming: How Is PU Leather Shaped and Coated?

The forming stage involves applying the polyurethane coating to the prepared fabric. This can be done using various techniques, including:

Illustrative image related to what is pu leather material

- Roll Coating: The fabric passes through rollers coated with liquid polyurethane, ensuring a uniform layer.

- Spray Coating: This technique involves spraying the polyurethane onto the fabric, allowing for detailed patterns and textures.

- Foam Coating: A foam layer of polyurethane is applied to create a thicker, more cushioned finish.

Each method has its advantages, with roll coating being the most common for producing large quantities of PU leather. B2B buyers should evaluate the coating techniques used by suppliers, as they directly affect the texture, thickness, and durability of the material.

3. Assembly: What Are the Key Steps in Assembling PU Leather Products?

Once the PU leather is formed, it is cut and sewn into the desired products, such as upholstery, bags, or footwear. This assembly process can involve several techniques:

- Cutting: Precision cutting machines are utilized to ensure that the PU leather pieces are shaped accurately.

- Sewing: High-quality stitching is essential for durability. Industrial sewing machines are typically used to handle the thickness of the material.

- Bonding: In some cases, adhesives are used to bond layers or attach the PU leather to other materials, such as foam padding.

During assembly, attention to detail is crucial to maintain the aesthetic and functional quality of the final product. B2B buyers should look for suppliers that employ skilled labor and advanced machinery to ensure high standards in assembly.

Illustrative image related to what is pu leather material

4. Finishing: How Is PU Leather Treated for Enhanced Quality?

The finishing stage involves treating the PU leather to enhance its appearance and durability. This may include:

- Surface Treatments: Coatings that provide additional protection against wear and tear, such as scratch-resistant layers.

- Texturing: Techniques that create patterns or grains on the surface to mimic real leather.

- Coloring and Dyeing: Adding color or designs through dyeing processes or printing techniques.

Finishing is vital for both aesthetics and functionality. B2B buyers should inquire about the finishing processes used and any additional treatments that can improve the longevity of the products.

What Quality Control Measures Are Applied in PU Leather Manufacturing?

Quality assurance is critical in the production of PU leather, ensuring that the final products meet international standards and buyer expectations.

International Standards: What Certifications Should You Look For?

To ensure high-quality manufacturing, B2B buyers should look for suppliers that comply with internationally recognized standards such as:

- ISO 9001: This certification ensures that the supplier adheres to a quality management system, focusing on consistent quality and customer satisfaction.

- CE Marking: Indicates compliance with health, safety, and environmental protection standards within the European Economic Area.

- API Standards: Relevant for products used in specific industrial applications, ensuring they meet the necessary safety and performance criteria.

These certifications can provide assurance of the supplier’s commitment to quality and safety.

Key QC Checkpoints: How Is Quality Monitored Throughout Production?

Quality control in PU leather manufacturing typically includes several checkpoints:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps catch defects early. This includes visual inspections and measurements at various stages of production.

- Final Quality Control (FQC): Once the products are completed, a final inspection is conducted to ensure they meet quality standards before shipping.

B2B buyers should ask suppliers about their QC processes and the frequency of inspections to gauge their commitment to maintaining high quality.

What Testing Methods Are Commonly Used in PU Leather Quality Control?

Testing methods play a vital role in verifying the quality and performance of PU leather. Common testing methods include:

- Durability Testing: Assessing the material’s resistance to wear, tearing, and cracking.

- Chemical Resistance Testing: Evaluating how the PU leather withstands exposure to various chemicals and solvents.

- Environmental Testing: Checking for VOC emissions and other environmental impacts during and after production.

B2B buyers should request detailed reports on testing outcomes to understand the material’s reliability.

Illustrative image related to what is pu leather material

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are actionable steps for buyers:

- Conduct Supplier Audits: Regular audits can help assess the supplier’s adherence to quality standards and manufacturing processes.

- Request Quality Assurance Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance with international standards.

- Engage Third-Party Inspectors: Hiring an independent inspection service can provide an unbiased assessment of the supplier’s manufacturing and quality control practices.

Are There Unique QC Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges when sourcing PU leather. Factors to consider include:

- Regulatory Compliance: Different countries have varying regulations regarding material safety, environmental impact, and labor practices. Buyers should ensure suppliers comply with local laws in their respective markets.

- Cultural and Market Expectations: Understanding regional preferences for durability, aesthetics, and sustainability can guide buyers in selecting the right suppliers.

- Logistics and Shipping: Quality control should also extend to packaging and transportation to prevent damage during transit.

By being aware of these considerations, B2B buyers can make informed decisions and establish successful partnerships with PU leather manufacturers.

Illustrative image related to what is pu leather material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is pu leather material’

Introduction

This guide serves as a comprehensive checklist for B2B buyers interested in procuring PU leather material. Understanding the nuances of this synthetic product will ensure that you make informed decisions, balancing cost, quality, and sustainability. By following this step-by-step approach, you can streamline your sourcing process and select the best suppliers for your needs.

Step 1: Define Your Technical Specifications

Establish clear specifications for the PU leather you intend to source. This includes the type of finish, thickness, color options, and intended use (e.g., upholstery, fashion accessories). Defining these parameters upfront helps you communicate effectively with suppliers and ensures that you receive materials that meet your project requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in PU leather. Utilize industry databases, trade shows, and online platforms to compile a list. Pay particular attention to suppliers with a proven track record in quality and customer service, as this can significantly impact your procurement experience.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with industry standards. Look for certifications such as ISO 9001 for quality management and OEKO-TEX for safety and environmental impact. These certifications indicate that the supplier adheres to recognized practices, ensuring the PU leather is safe and of high quality.

Step 4: Request Samples for Assessment

Always request samples of the PU leather from shortlisted suppliers. This step is crucial for evaluating the texture, durability, and overall quality of the material. Assess the samples against your specifications to ensure they meet your expectations, considering factors such as breathability, flexibility, and visual appeal.

Step 5: Inquire About Production Methods

Understanding the production methods used by your potential suppliers is vital. Inquire whether the PU leather is made using environmentally friendly processes and whether any harmful chemicals are involved. Transparency in production methods can affect not only the quality but also the sustainability of the materials you are sourcing.

Step 6: Assess Pricing and Payment Terms

Get detailed quotes from your chosen suppliers and compare them. Ensure you understand what is included in the pricing (e.g., shipping, taxes) and review payment terms. Competitive pricing is important, but also consider the overall value, including quality and service, to avoid hidden costs later.

Step 7: Establish a Communication Plan

Once you have selected a supplier, establish a clear communication plan. Outline points of contact, preferred communication channels, and response times. Consistent communication helps address any issues promptly and fosters a strong working relationship, which is essential for long-term partnerships.

Illustrative image related to what is pu leather material

By following this checklist, you will be better positioned to make informed decisions regarding the procurement of PU leather material, ensuring quality and sustainability while meeting your business needs.

Comprehensive Cost and Pricing Analysis for what is pu leather material Sourcing

What Are the Key Cost Components for Sourcing PU Leather Material?

When evaluating the costs associated with sourcing PU leather, it is essential to break down the different components that contribute to the total cost structure. Understanding these elements will empower international B2B buyers to make informed purchasing decisions and optimize their sourcing strategies.

What Are the Main Cost Components in PU Leather Production?

-

Materials: The primary cost driver in PU leather production is the raw materials, which include polyurethane resins and the base fabric (often polyester or cotton). The quality of these materials significantly influences the final product’s durability and appearance. Higher-grade materials will come with a premium price, while cheaper alternatives may compromise quality.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing; however, this can sometimes be offset by lower quality. Skilled labor is essential for ensuring that the PU leather is produced to the necessary standards, especially for higher-end applications.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and administrative expenses. Efficient production processes can help minimize overhead, but buyers should be aware of how these costs are factored into the pricing.

-

Tooling: Initial setup and tooling costs can be significant, particularly for custom designs or specifications. Buyers should consider these costs when negotiating with suppliers, as they can affect the pricing structure, especially for smaller orders.

-

Quality Control (QC): Implementing rigorous quality control processes adds to the overall cost but is crucial for ensuring that the PU leather meets industry standards. Buyers should inquire about the QC measures suppliers have in place and how they impact pricing.

-

Logistics: Shipping and handling costs must also be factored into the total cost of ownership. The distance from the manufacturer to the buyer’s location, chosen shipping methods, and any customs duties or tariffs can significantly influence the final price.

-

Margin: Suppliers will typically include a margin to ensure profitability. This margin can vary widely based on the supplier’s position in the market, brand reputation, and service level.

What Influences Pricing for PU Leather in International Markets?

Several factors can influence the pricing of PU leather, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often benefit from lower per-unit costs, allowing buyers to negotiate better pricing. Understanding the supplier’s MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Customized PU leather products may incur additional costs. Buyers should clearly communicate their specifications to avoid unexpected charges.

-

Material Quality and Certifications: The presence of certifications, such as eco-friendly or non-toxic materials, can affect pricing. Buyers should evaluate the value of these certifications against their needs and budget.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge higher prices due to their experience and quality assurance practices.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect total costs. Buyers should understand the implications of different terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), to manage costs effectively.

What Tips Can Help Buyers Negotiate Better Prices for PU Leather?

-

Negotiation Strategies: Engage suppliers in discussions about pricing based on market comparisons and your purchasing power. Building a strong relationship can also lead to better terms and discounts.

-

Cost-Efficiency Considerations: Evaluate the total cost of ownership, including durability and maintenance costs of PU leather products. Sometimes, a higher upfront cost may lead to greater savings in the long run.

-

Pricing Nuances for Different Regions: Be aware of regional market trends and economic factors that may affect pricing. For instance, currency fluctuations and local demand can influence costs, particularly for buyers in emerging markets.

In conclusion, understanding the comprehensive cost and pricing analysis for PU leather material sourcing is crucial for B2B buyers. By analyzing cost components, recognizing pricing influencers, and employing effective negotiation strategies, buyers can optimize their sourcing decisions and achieve better value in their procurement processes.

Alternatives Analysis: Comparing what is pu leather material With Other Solutions

When considering alternatives to PU leather, it’s essential to evaluate options that provide similar aesthetics and functionality while addressing some of the drawbacks associated with synthetic materials. This comparison will assist international B2B buyers in making informed decisions based on performance, cost, and environmental impact.

Illustrative image related to what is pu leather material

| Comparison Aspect | What Is PU Leather Material | Alternative 1: Genuine Leather | Alternative 2: Vegetable-Tanned Leather |

|---|---|---|---|

| Performance | Moderate durability; prone to cracking and peeling over time. | High durability; ages beautifully and develops a unique patina. | Very durable; eco-friendly and develops a rich texture over time. |

| Cost | Lower initial cost; generally more affordable than genuine leather. | Higher upfront investment; costs more due to sourcing and craftsmanship. | Moderate cost; typically more affordable than genuine leather but pricier than PU. |

| Ease of Implementation | Easy to mass-produce; widely available in various styles. | Requires skilled craftsmanship; more complex supply chain. | Needs specialized skills for production; requires sustainable sourcing practices. |

| Maintenance | Minimal maintenance; easy to clean but may wear out quickly. | Requires regular conditioning and care to maintain quality. | Low maintenance; requires occasional conditioning to preserve integrity. |

| Best Use Case | Ideal for budget-conscious consumers seeking aesthetics. | Best for high-end applications where durability and quality are paramount. | Suitable for eco-conscious brands looking for sustainable and durable options. |

How Does Genuine Leather Compare to PU Leather?

Genuine leather offers a level of durability and longevity that PU leather cannot match. While it comes with a higher price tag, its ability to develop a unique patina over time makes it a favored choice for luxury products. Genuine leather is also biodegradable, making it a more environmentally friendly option compared to PU, which is petroleum-based and non-biodegradable. However, genuine leather requires regular maintenance to preserve its quality, which can be a consideration for B2B buyers looking for low-maintenance solutions.

What Are the Benefits of Vegetable-Tanned Leather as an Alternative?

Vegetable-tanned leather stands out for its environmentally friendly production process, using natural tannins derived from plants. This type of leather is durable and develops a distinct character over time, making it an appealing option for brands that prioritize sustainability. It is less chemically treated than PU leather, reducing potential toxicity concerns. While it may require a moderate investment and some maintenance, the longevity and unique aging process can provide significant long-term value.

How Can B2B Buyers Choose the Right Solution?

When selecting between PU leather and its alternatives, B2B buyers should consider their target market, budget constraints, and sustainability goals. For brands catering to cost-sensitive consumers, PU leather might be the most practical choice. However, for those aiming to position their products as premium or eco-friendly, investing in genuine or vegetable-tanned leather could yield a higher return on investment in terms of brand perception and customer loyalty. Assessing the trade-offs between cost, durability, and environmental impact will help buyers make a decision that aligns with their business strategy and values.

Essential Technical Properties and Trade Terminology for what is pu leather material

What Are the Key Technical Properties of PU Leather?

Understanding the essential technical properties of PU leather is crucial for B2B buyers, especially when making decisions regarding sourcing, manufacturing, and product development. Here are some critical specifications:

-

Material Composition

PU leather is primarily composed of a thermoplastic polymer known as polyurethane. This synthetic material is often layered over a fabric backing to create a leather-like appearance. Understanding the composition helps buyers evaluate the product’s quality and suitability for various applications, such as furniture, footwear, and accessories. -

Durability Rating

The durability of PU leather is measured by its resistance to wear and tear, typically quantified through standardized tests (e.g., Martindale abrasion test). Buyers should look for products with a durability rating indicating a lifespan of 1 to 3 years under normal usage conditions. A higher durability rating can justify a premium price and reduce long-term replacement costs. -

Water Resistance

PU leather is inherently water-resistant, meaning it does not absorb moisture like genuine leather. This property is particularly advantageous in environments where spills are common. Buyers should assess water resistance levels, which can influence maintenance requirements and overall product longevity. -

Breathability

Unlike genuine leather, PU leather has limited breathability, which can lead to discomfort in products like clothing or upholstery. Understanding this property is vital for buyers in the fashion and furniture sectors, where comfort and user experience are key selling points. -

Tensile Strength

This property refers to the maximum amount of tensile (pulling) stress that the material can withstand before failure. Higher tensile strength indicates better performance in applications requiring durability. B2B buyers should prioritize tensile strength when sourcing materials for high-usage items to minimize returns and complaints. -

Environmental Impact

PU leather production involves chemical processes that can result in volatile organic compounds (VOCs) being released into the environment. Buyers should consider the ecological footprint and seek certifications that indicate sustainable manufacturing practices, which are increasingly important to consumers and regulatory bodies.

What Are Common Trade Terms Related to PU Leather?

Familiarity with industry jargon can streamline communication and enhance negotiation processes. Here are some essential trade terms relevant to PU leather:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For PU leather suppliers, being an OEM often means they can customize products to meet specific buyer specifications, which is crucial for differentiation in competitive markets. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to ensure they meet purchasing requirements without overcommitting capital, especially when entering new markets or launching new product lines. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Utilizing RFQs can help buyers compare offers from multiple suppliers efficiently, ensuring they secure the best deal for PU leather materials. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers involved in global trade, as they dictate shipping responsibilities, risk management, and cost allocation. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For PU leather suppliers, a shorter lead time can enhance customer satisfaction and improve inventory management for buyers, making it a critical factor in sourcing decisions. -

Certification Standards

These are guidelines that products must meet to ensure quality and safety. Certifications, such as OEKO-TEX or REACH, are particularly relevant in the PU leather industry, as they indicate compliance with environmental and health regulations, giving buyers confidence in their sourcing decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing PU leather, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the what is pu leather material Sector

What Are the Key Market Dynamics and Trends Influencing PU Leather Material?

The global PU leather market is experiencing significant growth, driven by several factors. First, the demand for affordable alternatives to genuine leather is rising, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Countries like Nigeria and Vietnam are seeing increased consumer interest in PU leather products due to their lower price points and versatility, making them an attractive option for manufacturers and retailers. Additionally, the fashion and furniture industries are increasingly incorporating PU leather in their offerings, capitalizing on its ability to mimic the aesthetics of genuine leather while providing a cost-effective solution.

Emerging technology trends, such as advanced manufacturing processes and online sourcing platforms, are reshaping how B2B buyers engage with suppliers. Digital marketplaces are making it easier for international buyers to find quality PU leather products, compare prices, and assess supplier credibility. Moreover, automation and improved quality control measures are enhancing product consistency and reducing lead times, further appealing to B2B buyers who prioritize efficiency.

Another noteworthy trend is the increasing focus on customization. As businesses look to differentiate their products, suppliers are responding by offering bespoke PU leather solutions tailored to specific customer needs. This trend not only caters to evolving consumer preferences but also creates opportunities for value-added services in the supply chain.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in PU Leather?

Sustainability is becoming a central theme in the sourcing of PU leather materials, as businesses face increasing pressure to adopt environmentally friendly practices. While PU leather is often marketed as a more sustainable alternative to genuine leather due to its lower resource consumption during production, its environmental impact should not be overlooked. PU leather is primarily made from petroleum-based materials, which are non-biodegradable and contribute to pollution throughout their lifecycle.

B2B buyers are increasingly prioritizing ethical sourcing, seeking suppliers who adhere to strict environmental standards. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can serve as indicators of a supplier’s commitment to sustainability. Buyers should also consider the entire supply chain when sourcing PU leather, ensuring that suppliers practice responsible manufacturing and labor practices. This not only mitigates potential risks but also enhances brand reputation, particularly in regions like Europe where consumers are becoming more discerning about the origins of the products they purchase.

By aligning sourcing strategies with sustainability goals, businesses can create long-term value while meeting the demands of environmentally conscious consumers. This approach not only benefits the planet but can also lead to improved customer loyalty and market competitiveness.

What Is the Historical Context of PU Leather and Its Importance in B2B Markets?

The evolution of PU leather dates back to the mid-20th century when it was first developed as a synthetic alternative to genuine leather. Initially embraced for its affordability and versatility, PU leather has since gained traction in various sectors, including fashion, furniture, and automotive industries. The material’s ability to replicate the look and feel of real leather without the ethical concerns associated with animal products has made it particularly appealing to businesses targeting younger, eco-conscious consumers.

In recent years, the production of PU leather has evolved, with innovations in technology allowing for higher-quality materials that can withstand wear and tear more effectively. As B2B buyers navigate this landscape, understanding the historical context of PU leather can provide valuable insights into its current applications and future potential. The ongoing improvements in manufacturing processes and a growing focus on sustainable practices signal a promising trajectory for PU leather in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of what is pu leather material

1. How do I identify quality PU leather when sourcing from suppliers?

When sourcing PU leather, assess the material’s thickness, texture, and smell. High-quality PU leather should feel smooth and have a consistent texture without visible imperfections. Request samples from suppliers to evaluate these characteristics firsthand. Additionally, inquire about the manufacturing process to ensure that the PU leather is produced without harmful chemicals. Certifications or compliance with international quality standards can also serve as indicators of quality.

2. What is the best application for PU leather in B2B purchases?

PU leather is ideal for a variety of applications, including furniture, automotive upholstery, and fashion accessories. Its affordability and versatility make it a popular choice for businesses looking to offer stylish products at competitive prices. It is particularly suited for items that require a leather-like appearance without the high cost associated with genuine leather. However, consider the intended use; PU leather may not be suitable for high-wear applications due to its lower durability compared to real leather.

3. What are the environmental implications of sourcing PU leather?

While PU leather is often marketed as a more sustainable option than genuine leather, it is made from synthetic materials that are non-biodegradable. The manufacturing process can involve harmful chemicals, leading to environmental pollution. When sourcing PU leather, it’s important to inquire about the supplier’s sustainability practices, such as waste management and chemical usage. Opting for suppliers who utilize eco-friendly production methods can help mitigate these environmental concerns.

4. How can I vet suppliers of PU leather for reliability and quality?

To vet suppliers, start by checking their business credentials, such as registration and compliance with international trade regulations. Request references or case studies from other clients who have sourced PU leather from them. Conduct factory visits if possible, or utilize third-party auditing services to assess production practices. Evaluate their communication responsiveness and willingness to provide product samples as part of your assessment.

5. What minimum order quantities (MOQ) should I expect when sourcing PU leather?

MOQs for PU leather can vary significantly based on the supplier and the specific product requirements. Typically, you may encounter MOQs ranging from 500 to 1,000 meters for bulk orders. It’s advisable to discuss your project needs with the supplier to negotiate favorable terms, especially if you are a small to medium-sized enterprise. Many suppliers may offer flexibility on MOQs for repeat customers or larger, long-term contracts.

6. What payment terms are common for international B2B transactions involving PU leather?

Common payment terms in international B2B transactions include a deposit upon order confirmation (usually 30-50%) and the balance before shipment. Some suppliers may also offer letters of credit or payment through escrow services for added security. Ensure that you clarify payment terms in the contract to avoid misunderstandings. Additionally, consider discussing currency exchange rates and potential fees associated with international transactions.

7. How should I manage logistics when importing PU leather?

Managing logistics involves planning for shipping methods, customs clearance, and delivery timelines. Choose a reputable freight forwarder experienced in handling PU leather shipments to navigate international regulations efficiently. Ensure that all necessary documentation, such as bills of lading and customs declarations, is in order. Additionally, factor in potential delays due to customs inspections, especially if importing into regions with stringent regulations.

Illustrative image related to what is pu leather material

8. What quality assurance (QA) measures should I implement when sourcing PU leather?

Implementing QA measures involves establishing clear specifications for the PU leather you require, including thickness, color, and durability standards. Request certifications or test reports from suppliers to ensure the material meets these standards. Consider conducting on-site inspections during production and before shipment. Additionally, plan for receiving inspections upon delivery to identify any discrepancies or defects, ensuring that the PU leather meets your quality expectations.

Top 3 What Is Pu Leather Material Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather Solutions

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: PU leather, also known as polyurethane leather, is a synthetic material made from a base layer of fabric coated with a polymer. It is often marketed as an alternative to genuine leather due to its lower cost and ease of maintenance. However, PU leather is less durable than real leather, can wear out quickly, and may not be as environmentally friendly due to the chemicals used in its production. Ad…

2. HowStuffWorks – PU Leather

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is a vegan alternative to genuine leather, made from a type of plastic. It is available in a wide variety of colors and is water resistant, making it suitable for use in kitchens and bars. There are two types of PU leather: full-synthetic (100% vegan) and semi-synthetic (contains a natural leather base). PU leather is easier to manufacture and clean compared to genuine le…

3. Carl Friedrik – PU Leather Collection

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a type of plastic. It is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl, mimicking the look and feel of animal leather. 100% PU leather is vegan-friendly as it contains no animal by-products. However, a PU coating can also be applied to split leather, which is derived from …

Strategic Sourcing Conclusion and Outlook for what is pu leather material

In the evolving landscape of materials, PU leather stands out as a versatile yet complex option for international B2B buyers. As a synthetic alternative to genuine leather, PU leather offers cost benefits and a variety of aesthetic choices, making it appealing for sectors like fashion and furniture. However, its durability concerns, potential toxicity, and environmental impact cannot be overlooked. Strategic sourcing plays a crucial role in ensuring that businesses select materials that not only meet their budgetary constraints but also align with sustainability goals and health standards.

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of PU leather is vital for making informed procurement decisions. As demand for eco-friendly and durable materials grows, consider sourcing options that prioritize transparency and ethical production practices.

Looking ahead, the market for PU leather will continue to evolve, driven by consumer preferences and regulatory changes. Embrace the opportunity to engage with suppliers who prioritize quality and sustainability, and position your business at the forefront of responsible sourcing. Your commitment to informed decision-making will not only enhance your product offerings but also contribute to a more sustainable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what is pu leather material

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.