Introduction: Navigating the Global Market for fabric for shoes

In the dynamic landscape of global footwear manufacturing, sourcing the right fabric for shoes presents a significant challenge for B2B buyers. With a multitude of options ranging from lightweight synthetic fibers to durable natural materials, the decision-making process can be overwhelming. This comprehensive guide aims to demystify the complex world of shoe fabrics, providing insights into various types, applications, and the critical factors that influence purchasing decisions. Whether you are looking for breathable mesh for athletic footwear or robust canvas for casual designs, understanding the nuances of fabric characteristics is essential.

Throughout this guide, we will explore essential aspects such as fiber composition, weave patterns, and surface treatments, alongside practical advice on supplier vetting and cost considerations. By equipping international buyers from Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Saudi Arabia—with actionable insights, this resource empowers you to make informed decisions that align with your business goals. From selecting sustainable options to navigating import regulations, our objective is to enhance your sourcing strategy in the competitive global market for shoe fabrics. Embrace the opportunity to innovate and elevate your footwear offerings through informed material choices that meet consumer demands and industry standards.

Table Of Contents

- Top 5 Fabric For Shoes Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric for shoes

- Understanding fabric for shoes Types and Variations

- Key Industrial Applications of fabric for shoes

- 3 Common User Pain Points for ‘fabric for shoes’ & Their Solutions

- Strategic Material Selection Guide for fabric for shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric for shoes

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for shoes’

- Comprehensive Cost and Pricing Analysis for fabric for shoes Sourcing

- Alternatives Analysis: Comparing fabric for shoes With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric for shoes

- Navigating Market Dynamics and Sourcing Trends in the fabric for shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric for shoes

- Strategic Sourcing Conclusion and Outlook for fabric for shoes

- Important Disclaimer & Terms of Use

Understanding fabric for shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotton Canvas | Durable, breathable, and can be treated for water resistance | Casual shoes, sneakers, and vulcanized footwear | Pros: Eco-friendly, customizable. Cons: Less durable than synthetics. |

| Polyester | Lightweight, strong, and resistant to shrinking and stretching | Athletic footwear, outdoor shoes | Pros: High durability, moisture-wicking. Cons: Less breathable than natural fibers. |

| Nylon | Excellent abrasion resistance and elasticity | Performance shoes, work boots | Pros: High strength-to-weight ratio, quick-drying. Cons: Can be less comfortable in hot climates. |

| Lycra | Highly elastic and stretchable, often blended with other fabrics | Sports shoes, performance footwear | Pros: Enhances fit and comfort. Cons: Limited durability when used alone. |

| Синтетическая кожа | Mimics leather appearance, often more affordable | Fashion shoes, casual footwear | Pros: Cost-effective, easy to clean. Cons: Less breathable and may not age as well as genuine leather. |

What Are the Characteristics of Cotton Canvas for Shoes?

Cotton canvas is a versatile fabric known for its durability and breathability. This natural fiber is particularly suitable for casual shoes and sneakers, especially in vulcanized construction. Buyers should consider its eco-friendliness and customization options, such as color and print treatments. However, while cotton canvas offers a classic aesthetic, it may not match the durability of synthetic alternatives, making it less ideal for high-performance applications.

How Does Polyester Benefit Athletic Footwear?

Polyester is a synthetic fabric renowned for its lightweight and moisture-wicking properties, making it a popular choice for athletic footwear. Its resilience against shrinking and stretching ensures longevity, which is crucial for B2B buyers focused on performance. While polyester provides excellent durability, it may fall short in breathability compared to natural fibers, which is an essential consideration for hot climates or high-intensity activities.

What Makes Nylon a Preferred Choice for Performance Shoes?

Nylon stands out in the footwear industry for its exceptional abrasion resistance and elasticity, making it ideal for performance shoes and work boots. This fabric’s high strength-to-weight ratio allows for durable yet lightweight designs. B2B buyers should consider nylon’s quick-drying capabilities, which are beneficial for outdoor applications. However, its potential discomfort in hot conditions may necessitate careful selection based on the target market’s climate.

Why is Lycra Used in Sports Shoes?

Lycra, known for its incredible elasticity, is often blended with other fabrics to enhance the fit and comfort of sports shoes. This stretchable material allows for greater freedom of movement, making it a favorite in performance footwear. B2B buyers should weigh Lycra’s benefits against its limited durability when used alone, as it may require reinforcement with more robust materials to ensure longevity in high-demand environments.

What Are the Advantages of Synthetic Leather for Fashion Shoes?

Synthetic leather offers an appealing alternative to traditional leather, providing a similar look at a more affordable price point. Its ease of cleaning and maintenance makes it suitable for fashion shoes and casual footwear. B2B buyers should consider the trade-offs, including reduced breathability and potential longevity issues compared to genuine leather. Understanding these factors is crucial for making informed purchasing decisions that align with market demands.

Key Industrial Applications of fabric for shoes

| Industry/Sector | Specific Application of fabric for shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Athletic Gear | Performance footwear for athletes | Enhanced durability, breathability, and performance | Consider moisture-wicking fabrics, lightweight materials, and specific certifications for performance standards. |

| Fashion and Lifestyle | Trendy casual and formal shoes | Unique designs, brand differentiation, and consumer appeal | Focus on sustainable materials, colorfastness, and innovative weaves or prints to attract fashion-conscious consumers. |

| Safety and Industrial | Safety footwear for hazardous environments | Compliance with safety standards, comfort, and longevity | Ensure fabrics meet safety regulations, are resistant to chemicals, and provide slip resistance. |

| Medical and Orthopedic | Customizable shoes for rehabilitation and comfort | Improved patient outcomes and satisfaction | Look for fabrics with antimicrobial properties, cushioning, and adaptability for various foot shapes and sizes. |

| Children’s Footwear | Durable and easy-to-clean shoes for kids | Long-lasting products that can withstand active play | Prioritize lightweight, breathable materials that are also easy to maintain and safe for children. |

How is Fabric for Shoes Used in the Sports and Athletic Gear Sector?

In the sports and athletic sector, fabric for shoes is crucial for creating performance footwear that enhances athletes’ capabilities. Materials like nylon and polyester are often employed for their lightweight and breathable properties, while specialized weaves allow for flexibility and support. International buyers should ensure that the fabrics they source meet specific performance standards and certifications, especially in regions like Africa and South America, where climate and terrain can influence material choice.

What Role Does Fabric Play in the Fashion and Lifestyle Industry?

In the fashion and lifestyle industry, fabric choices significantly influence a shoe’s aesthetic appeal and marketability. Designers utilize an array of textiles to create trendy casual and formal footwear that resonates with consumers. Sustainable options are increasingly in demand, prompting buyers to look for materials that are not only visually appealing but also environmentally friendly. This is particularly relevant in European markets, where eco-consciousness is a strong consumer driver.

Why is Fabric Essential for Safety and Industrial Footwear?

Safety and industrial footwear relies heavily on specialized fabrics to ensure worker protection in hazardous environments. These fabrics must comply with strict safety regulations, offering features such as chemical resistance and slip resistance. For B2B buyers in the Middle East and Africa, sourcing durable and reliable materials is paramount, as they must withstand extreme working conditions while maintaining comfort for the end-user.

How Can Fabric Improve Medical and Orthopedic Footwear?

In the medical and orthopedic sector, fabric for shoes plays a vital role in creating customizable footwear that enhances patient comfort and recovery. Fabrics with antimicrobial properties and cushioning are essential for preventing infections and providing support. Buyers in this field should prioritize sourcing materials that can be adapted to various foot shapes and sizes, ensuring patient satisfaction and improved outcomes.

What Are the Key Considerations for Children’s Footwear Fabrics?

Children’s footwear necessitates durable and easy-to-clean fabrics that can endure active play. Lightweight, breathable materials are essential to ensure comfort and safety for young wearers. B2B buyers should focus on sourcing fabrics that are not only robust but also safe and easy to maintain, as these attributes are crucial for parents looking for reliable footwear options for their children.

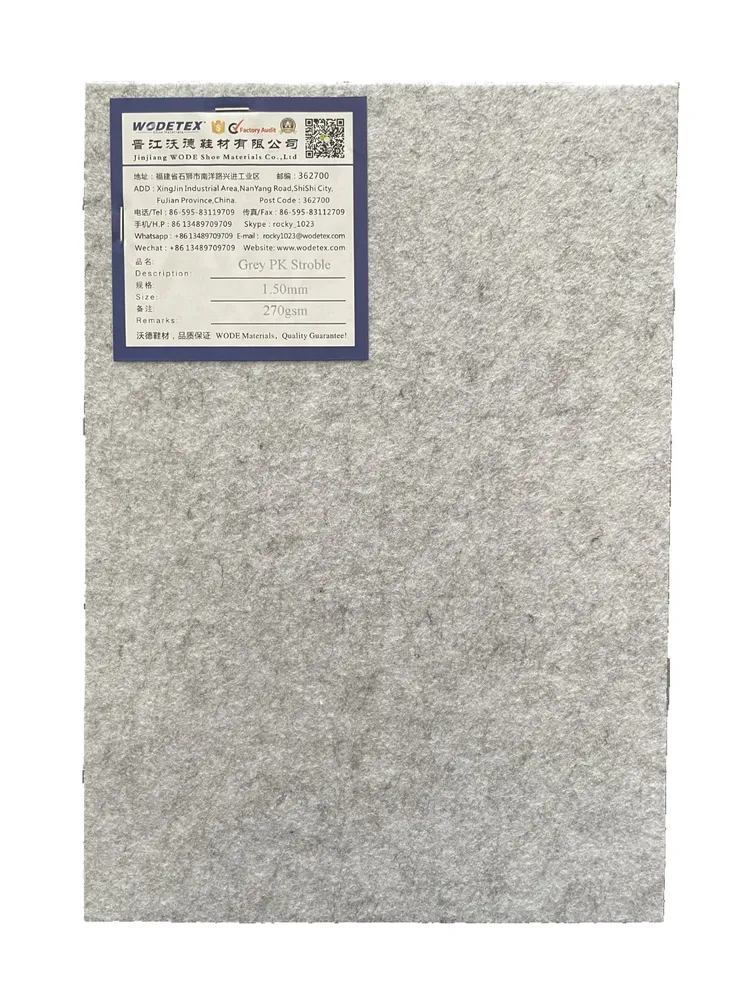

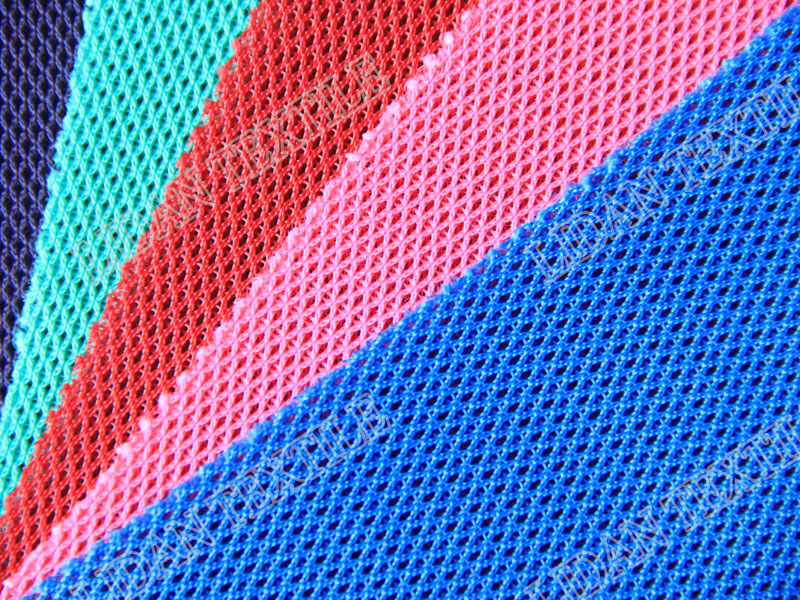

Illustrative image related to fabric for shoes

3 Common User Pain Points for ‘fabric for shoes’ & Their Solutions

Scenario 1: Sourcing Quality Fabric for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality fabrics that meet the diverse needs of their target markets. This challenge is particularly pronounced when considering the varying climatic conditions and consumer preferences across regions like Africa, South America, the Middle East, and Europe. For instance, a buyer may find that a lightweight, breathable fabric is essential for the hot climates in Africa, while a more durable, water-resistant material is preferred in Europe. This disparity can lead to significant delays in production and increased costs if the wrong materials are selected.

The Solution: To effectively source quality fabric that meets regional demands, buyers should start by conducting thorough market research to understand the specific fabric requirements of their target demographics. Collaborating with local fabric suppliers who have insights into regional preferences can also provide invaluable guidance. When specifying materials, buyers should focus on the fabric’s physical properties—such as weight, durability, and moisture-wicking capabilities—and ensure that they align with their intended use. Establishing partnerships with manufacturers that offer a wide range of textiles can also facilitate quicker adaptations to changing market demands, ultimately leading to more efficient production processes.

Scenario 2: Managing Fabric Costs and Import Duties

The Problem: Many B2B buyers face challenges related to the high costs of imported fabrics, particularly when navigating complex import duties that can significantly increase overall expenses. For example, in some regions, footwear made with over 51% textile surface area incurs a 20% duty, which can be a dealbreaker for companies trying to maintain competitive pricing. This issue is compounded by fluctuating currency rates and changing trade regulations that can impact sourcing decisions.

The Solution: To effectively manage fabric costs and navigate import duties, buyers should first familiarize themselves with the specific import regulations of their target countries. This knowledge allows them to strategically select fabrics that minimize duty costs. For example, incorporating molded textiles into the sole of the shoe can help avoid high duty rates. Additionally, buyers should consider bulk purchasing or long-term contracts with suppliers to lock in favorable pricing. Exploring local manufacturing options can also reduce reliance on imports and associated duties, while potentially improving supply chain efficiency.

Illustrative image related to fabric for shoes

Scenario 3: Ensuring Fabric Durability and Performance

The Problem: A frequent pain point for B2B buyers is ensuring that the fabrics chosen for shoe production are durable and perform well under various conditions. Fabrics that fail to meet performance standards—such as wear resistance, stretchability, and weatherproofing—can lead to product returns and damage brand reputation. Buyers may find it challenging to balance cost with the quality and durability needed for their target market, leading to confusion over which materials to select.

The Solution: To ensure fabric durability and performance, buyers should prioritize testing fabrics for their specific applications. This can involve conducting wear tests, moisture absorption tests, and UV resistance assessments to ensure that the selected materials can withstand the intended use. Engaging with suppliers who offer detailed technical specifications and performance data can provide critical insights into fabric capabilities. Additionally, establishing a feedback loop with end-users can help manufacturers fine-tune their fabric selections based on real-world performance, allowing for continuous improvement and enhanced customer satisfaction. By investing in quality and performance from the outset, buyers can create a strong product offering that stands out in competitive markets.

Strategic Material Selection Guide for fabric for shoes

When selecting materials for shoe fabrics, it is essential to consider various factors that influence performance, durability, and suitability for specific applications. Below, we analyze four common materials used in shoe fabric production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Polyester in Shoe Fabrics?

Polyester is a synthetic fiber known for its excellent durability and resistance to shrinking and stretching. It performs well under varying temperatures and has good moisture-wicking properties, making it suitable for athletic footwear. Polyester fabrics can also be treated for water resistance, enhancing their usability in different climates.

Pros & Cons: Polyester’s durability and cost-effectiveness make it a popular choice for mass production. However, it may not offer the same breathability as natural fibers, which can affect comfort in hot conditions. Additionally, polyester can be less environmentally friendly, raising concerns among eco-conscious consumers.

Illustrative image related to fabric for shoes

Impact on Application: Polyester is compatible with various finishing treatments, allowing for customization in aesthetics and functionality. However, it may not be suitable for high-end luxury shoes where natural fibers are preferred.

Considerations for International Buyers: Buyers from regions such as Africa and South America should be aware of local regulations regarding synthetic materials. Compliance with international standards like ASTM or ISO may also be necessary, especially for athletic footwear.

How Does Nylon Compare as a Fabric for Shoes?

Nylon is another synthetic option that offers exceptional strength and elasticity. It is lightweight and resistant to abrasion, making it ideal for outdoor and performance footwear. Nylon fabrics can withstand high-pressure conditions and are often used in rugged designs.

Pros & Cons: The main advantage of nylon is its resilience and versatility. However, it can be more expensive than polyester and may require complex manufacturing processes. Additionally, like polyester, nylon is derived from petrochemicals, which may deter environmentally conscious consumers.

Impact on Application: Nylon performs well in applications requiring stretch and durability, such as in sports shoes. However, it may not be the best choice for formal footwear due to its casual appearance.

Illustrative image related to fabric for shoes

Considerations for International Buyers: Buyers in Europe and the Middle East should consider the impact of nylon on product sustainability. Compliance with environmental regulations and standards is crucial, especially in markets with strict eco-labeling requirements.

What Are the Advantages of Cotton Canvas in Shoe Fabric?

Cotton canvas is a natural fiber that offers breathability and comfort. It is commonly used in casual and vulcanized shoes due to its ability to withstand heat and moisture. Cotton can also accept various finishing treatments, enhancing its aesthetic appeal.

Pros & Cons: The primary advantage of cotton canvas is its comfort and natural origin, making it attractive to eco-conscious consumers. However, it is less durable than synthetic options and may require more care to maintain its appearance. Additionally, cotton can be more expensive to source and process.

Impact on Application: Cotton canvas is ideal for casual footwear but may not perform well in high-performance scenarios where durability is critical. Its absorbent nature can also lead to moisture retention, which may not be suitable for all climates.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local cotton production and availability. Compliance with organic certifications may also be relevant for buyers targeting eco-friendly markets.

Illustrative image related to fabric for shoes

How Does Lycra Enhance Shoe Fabric Performance?

Lycra, or spandex, is a synthetic fiber known for its exceptional stretchability and recovery. It is often blended with other fabrics to enhance comfort and fit, making it popular in performance footwear.

Pros & Cons: The key advantage of Lycra is its ability to provide a snug fit without sacrificing comfort. However, its cost can be higher than traditional fibers, and it may not be suitable for all shoe types. Additionally, Lycra can degrade under prolonged exposure to sunlight and chlorine.

Impact on Application: Lycra is particularly effective in athletic and performance shoes, where flexibility and comfort are paramount. However, its limitations in durability may restrict its use in rugged outdoor footwear.

Illustrative image related to fabric for shoes

Considerations for International Buyers: Buyers should be aware of the sourcing and production standards for Lycra, especially in regions with stringent regulations regarding synthetic materials. Compliance with international standards is essential to ensure market acceptance.

Summary Table of Material Properties

| Материал | Typical Use Case for fabric for shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Athletic and casual footwear | Durable and cost-effective | Less breathable than natural fibers | Medium |

| Nylon | Outdoor and performance footwear | High strength and elasticity | More expensive and complex to manufacture | Высокий |

| Cotton Canvas | Casual and vulcanized shoes | Breathable and comfortable | Less durable and more care needed | Medium |

| Lycra | Performance and athletic shoes | Excellent stretch and fit | Degrades under sunlight and chlorine | Высокий |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for shoe fabrics, ensuring that they can make informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric for shoes

What Are the Main Stages in the Manufacturing Process of Shoe Fabrics?

The manufacturing of shoe fabrics is a meticulous process that involves several key stages, each critical to ensuring the final product meets quality standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to fabric for shoes

-

Material Preparation: This initial phase involves selecting the right fibers based on desired properties such as durability, water resistance, and stretchability. Common fibers used in shoe fabric production include polyester, nylon, cotton, and lycra. The chosen materials undergo treatment processes like dyeing and sizing. Sizing, which involves applying a liquid resin, enhances the fabric’s strength and stability, preparing it for subsequent manufacturing stages.

-

Forming: In this stage, the prepared materials are woven or knitted into fabric. The choice between weaving and knitting is influenced by the desired characteristics of the final product. Weaving typically produces sturdier fabrics suitable for shoe exteriors, while knitted fabrics offer elasticity and comfort, ideal for linings. Various weave patterns such as plain, twill, and satin can be employed to achieve specific aesthetic and functional qualities.

-

Assembly: During assembly, the fabric is cut into the required shapes and stitched together to create the shoe’s upper. This process often includes laminating the fabric with additional materials, such as PU foam, to enhance durability and ease of handling during production. The assembly must be precise to ensure comfort and performance, with attention paid to seam strength and alignment.

-

Finishing: The final stage involves applying surface treatments to enhance the fabric’s performance characteristics. Treatments may include water resistance, anti-microbial finishes, or abrasion resistance. This stage often also involves quality checks to ensure that the fabric meets all specified standards before it is sent for final inspection.

How Is Quality Assurance Implemented in Shoe Fabric Manufacturing?

Quality assurance (QA) is critical in the manufacturing of shoe fabrics, ensuring that products meet both international and industry-specific standards. Key elements of QA include established international standards such as ISO 9001, as well as industry-specific certifications like CE and API.

-

International Standards: ISO 9001 outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. Compliance with this standard is crucial for manufacturers aiming to export their products internationally. It assures B2B buyers of consistent quality and reliability.

-

Quality Control Checkpoints: Within the QA framework, several checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC focuses on monitoring production processes to identify and rectify issues in real time.

– Final Quality Control (FQC): The final inspection checks the finished products against quality benchmarks and specifications, ensuring they are ready for shipment. -

Common Testing Methods: Various testing methods are employed to assess the performance and durability of shoe fabrics. These may include:

– Abrasion Resistance Tests: To evaluate how well the fabric withstands wear and tear.

– Water Resistance Tests: To determine the fabric’s ability to repel water.

– Colorfastness Tests: To ensure that colors remain stable under various conditions, including exposure to light and washing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those sourcing from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is vital for mitigating risks associated with product quality.

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s quality control processes. Audits can verify compliance with international standards and provide insights into the manufacturing environment and practices.

-

Quality Reports: Requesting detailed quality reports can help buyers understand a supplier’s quality management practices. These reports should include data on past performance, defect rates, and adherence to specified standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services often include pre-shipment inspections that verify product quality before it leaves the factory.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers should be aware of specific nuances in quality control and certification that can affect their sourcing decisions.

-

Regional Regulations: Different regions have varying regulatory requirements regarding textile and shoe manufacturing. Buyers should familiarize themselves with these regulations to ensure compliance and avoid potential penalties or import issues.

-

Certification Validity: It’s crucial to verify the validity of certifications claimed by suppliers. Certifications should be current and recognized by relevant authorities in the buyer’s region. This verification can help prevent fraud and ensure that the materials meet quality and safety standards.

-

Cultural and Communication Considerations: When dealing with suppliers from diverse regions, understanding cultural differences in business practices and communication styles can facilitate smoother interactions. Clear communication about quality expectations and standards is essential to ensure that both parties are aligned.

Заключение

Understanding the manufacturing processes and quality assurance protocols for shoe fabrics is vital for B2B buyers. By recognizing the key stages of production, implementing robust quality assurance measures, and verifying supplier capabilities, buyers can make informed decisions that support their business objectives. This proactive approach not only enhances product quality but also fosters long-term partnerships with suppliers across different regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for shoes’

Введение

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure fabrics specifically designed for footwear. Understanding the nuances of fabric selection is essential, as it directly impacts the quality, durability, and aesthetics of the final product. This guide will help you navigate the complexities of sourcing materials that meet your specific needs.

Step 1: Define Your Technical Specifications

Start by outlining your requirements for the fabric, including weight, durability, and intended use. This clarity will guide your selection process and help ensure that the fabric performs well in the final shoe design.

– Consider factors such as breathability, water resistance, and stretchability based on the shoe type.

– Specify whether the fabric needs to be lightweight for athletic shoes or more robust for casual or formal footwear.

Illustrative image related to fabric for shoes

Step 2: Research Fabric Types

Familiarize yourself with various fabric types available for footwear. Each material has unique properties that can affect the overall performance of the shoe.

– Look for common fibers such as nylon, polyester, and cotton, noting their respective benefits like UV resistance and moisture management.

– Understand the implications of using synthetic versus natural fibers, especially in terms of comfort and environmental impact.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they can meet your quality and delivery requirements.

– Request company profiles, certifications, and case studies to gauge their experience and reliability.

– Reach out to other businesses in your region or industry for references and feedback on their experiences with specific suppliers.

Step 4: Assess Fabric Weaves and Knits

Investigate the different weaves and knits available, as these will influence the fabric’s strength and elasticity.

– Familiarize yourself with terms like plain weave, twill, and jersey knit, and consider how these will affect the shoe’s performance and style.

– Ensure the selected weave aligns with your design vision and the functional requirements of the footwear.

Step 5: Verify Compliance with Import Regulations

Understand the import regulations related to textiles in your target markets. This is crucial to avoid unexpected costs and delays.

– Research the duty rates applicable to textile shoes, as they can vary significantly by country and material composition.

– Ensure that your chosen fabric complies with any local standards or certifications required in your target market.

Step 6: Request Samples and Test Fabrics

Always request samples before making a large purchase. Testing materials firsthand is essential to ensure they meet your specifications and quality standards.

– Evaluate the samples for texture, color fastness, and durability through physical tests.

– Consider the fabric’s performance under real-world conditions to ensure it meets your expectations.

Illustrative image related to fabric for shoes

Step 7: Establish Clear Communication with Suppliers

Maintain open lines of communication with your suppliers throughout the sourcing process. Clear communication helps prevent misunderstandings and ensures that your requirements are met.

– Set expectations for timelines, quality control measures, and shipping logistics.

– Regularly update your suppliers on any changes in your needs or market conditions to foster a collaborative relationship.

By following these steps, B2B buyers can make informed decisions when sourcing fabric for shoes, ensuring that they select materials that meet both their design and functional requirements.

Comprehensive Cost and Pricing Analysis for fabric for shoes Sourcing

When considering the cost and pricing analysis for sourcing fabric for shoes, various components and influencers play a crucial role in determining the overall expenses. Understanding these factors can help international B2B buyers make informed decisions, ensuring cost-efficiency and value.

What Are the Main Cost Components in Sourcing Fabric for Shoes?

Materials: The primary cost driver in fabric sourcing is the raw materials used. Fabrics such as polyester, nylon, cotton, and specialized blends have different price points based on their quality, availability, and market demand. For example, high-performance fabrics like moisture-wicking or UV-resistant textiles may incur higher costs compared to standard cotton.

Illustrative image related to fabric for shoes

Labor: Labor costs vary significantly based on the manufacturing location. Countries with lower labor costs, such as Vietnam or Bangladesh, can offer competitive pricing. However, this should be weighed against potential quality concerns and communication challenges.

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs, which are typically passed on to buyers.

Tooling: Customization often requires specialized tooling, which can add to upfront costs. This is particularly relevant for unique fabric patterns or weaves that require specific machinery adjustments.

Illustrative image related to fabric for shoes

Quality Control (QC): Implementing quality control measures is essential for ensuring the fabric meets the required specifications. QC processes can add to labor and overhead costs, but they are crucial for maintaining product standards, especially for international buyers who may face stricter regulations.

Logistics: Shipping and handling costs can vary widely based on the origin and destination of the fabrics. Factors such as distance, shipping method, and incoterms (the international commercial terms defining the responsibilities of buyers and sellers) can significantly impact the total cost.

Margin: Suppliers will typically add a margin to their costs to ensure profitability. This margin can vary based on competition, demand, and the supplier’s business model.

How Do Price Influencers Affect Fabric Sourcing for Shoes?

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, as suppliers are willing to lower prices to secure bulk purchases. Understanding the MOQ can help buyers negotiate better pricing.

Specifications and Customization: Highly specialized fabrics with unique characteristics will generally command higher prices. Buyers should clearly define their needs to avoid unnecessary costs associated with last-minute changes.

Illustrative image related to fabric for shoes

Quality and Certifications: Fabrics that come with certifications (e.g., OEKO-TEX, GOTS) may cost more but provide assurance regarding environmental and safety standards. Buyers should weigh the benefits of these certifications against their budget constraints.

Supplier Factors: The reliability and reputation of a supplier can also influence pricing. Established suppliers may charge a premium due to their proven track record, while newer entrants may offer lower prices to attract business.

Incoterms: Understanding incoterms is vital for international transactions. They define who bears the costs and risks during shipping. Buyers should select terms that align with their logistical strategies and budget capabilities.

What Are the Key Buyer Tips for Cost-Efficiency in Fabric Sourcing?

Negotiate Strategically: Leverage volume orders and long-term partnerships to negotiate better pricing. Building strong relationships with suppliers can lead to favorable terms and conditions.

Evaluate Total Cost of Ownership: Consider not just the upfront costs but also the long-term expenses associated with fabric sourcing, including maintenance, durability, and potential waste.

Understand Pricing Nuances for International Transactions: Be aware of potential tariffs, import duties, and currency fluctuations that can affect overall costs. Countries like Saudi Arabia and those in Africa may have specific regulations that impact pricing.

Disclaimer on Indicative Prices: Prices can fluctuate based on market conditions, material availability, and other external factors. Buyers are advised to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

By comprehensively understanding the cost structure and pricing influencers, international B2B buyers can make more informed decisions in sourcing fabric for shoes, ultimately leading to enhanced profitability and market competitiveness.

Alternatives Analysis: Comparing fabric for shoes With Other Solutions

Exploring Alternatives to Fabric for Shoe Production

In the competitive landscape of footwear manufacturing, selecting the right material is crucial for product quality, performance, and cost efficiency. While fabric is a popular choice due to its versatility and aesthetic appeal, several alternative solutions exist that can meet specific needs and preferences. This analysis will compare fabric for shoes against two viable alternatives: synthetic leather and rubber.

Comparison Table

| Comparison Aspect | Fabric For Shoes | Синтетическая кожа | Rubber |

|---|---|---|---|

| Performance | Lightweight, breathable, customizable | Durable, water-resistant, easy to clean | Excellent grip, waterproof, high durability |

| Cost | Moderate cost, varies by type | Generally higher than fabric | Cost-effective for mass production |

| Ease of Implementation | Requires skilled labor for assembly | Easier to cut and sew | Can be molded, but requires special equipment |

| Maintenance | Requires special cleaning | Low maintenance, wipe clean | Very low maintenance, resistant to wear |

| Best Use Case | Casual footwear, fashion applications | Formal and casual shoes, outdoor gear | Sports shoes, work boots, heavy-duty footwear |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, or vegan leather, is a popular alternative to traditional fabric in footwear production. Its primary advantage lies in its durability; it is resistant to wear and tear, making it suitable for various applications, including outdoor footwear. Additionally, synthetic leather is easier to clean and maintain, as it can simply be wiped down. However, it is generally more expensive than fabric options, which could impact overall production costs. Furthermore, while synthetic leather mimics the look of real leather, it may lack the breathability and comfort that fabric offers, making it less suitable for casual wear.

How Does Rubber Compare as an Alternative Material?

Rubber is another alternative that stands out, especially in the production of sports shoes and work boots. Its performance is unmatched when it comes to grip and waterproofing, making it ideal for environments that require durable footwear. Rubber shoes are also incredibly low-maintenance, resisting dirt and moisture effectively. However, the implementation of rubber can be more complex, as it often requires specialized molding equipment, which may not be feasible for all manufacturers. Additionally, the weight of rubber can be a concern, particularly for casual footwear, where lightweight materials are preferred.

How Can B2B Buyers Choose the Right Footwear Material?

When selecting the appropriate material for footwear production, B2B buyers should evaluate their specific needs based on the end-use of the shoes. Considerations such as performance requirements, target market, and production costs play vital roles in the decision-making process. For instance, if durability and low maintenance are priorities, synthetic leather or rubber may be the better choice. Conversely, if breathability and customization are critical, traditional fabric might be more suitable. Ultimately, understanding the unique benefits and limitations of each alternative will empower buyers to make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for fabric for shoes

What Are the Key Technical Properties of Fabrics for Shoes?

When sourcing fabric for shoe production, understanding the essential technical properties is crucial for ensuring quality and performance. Here are some critical specifications to consider:

1. Fiber Composition

The type of fiber used in shoe fabrics significantly affects their characteristics, including durability, comfort, and moisture management. Common fibers include nylon, polyester, cotton, and lycra. Nylon and polyester are favored for their strength and water resistance, making them ideal for performance footwear. Cotton is preferred for its breathability and comfort, particularly in casual shoes.

2. Denier

Denier (D) is a unit of measurement for the thickness of the thread used in fabric. This specification is vital as it influences the weight and durability of the fabric. For example, fabrics with a denier of 420D to 600D are typical for everyday shoes, while heavier fabrics like 1000D are used for boots and bags. Understanding denier helps manufacturers select the right fabric for the intended use and wear conditions.

Illustrative image related to fabric for shoes

3. Weave Pattern

The weave pattern of the fabric determines its texture, strength, and flexibility. Common patterns include plain, twill, and satin weaves. Each weave has unique benefits; for instance, twill offers enhanced durability, while satin provides a smoother surface. Selecting the appropriate weave is essential for balancing aesthetic appeal and functional performance.

4. Surface Treatments

Surface treatments enhance the fabric’s properties, such as water resistance or abrasion resistance. Durable Water Repellent (DWR) coatings are popular for athletic footwear, providing a barrier against moisture. Understanding available treatments allows buyers to specify fabrics that meet environmental and functional requirements.

5. Backing Material

The backing material used in the fabric can significantly affect its overall performance. Common backing types include polyurethane (PU) and polyvinyl chloride (PVC). PU provides a lightweight, flexible layer, while PVC offers greater durability and waterproofing. Choosing the right backing is crucial for achieving the desired functionality and performance in shoe applications.

What Are Common Trade Terms Related to Fabric Sourcing for Shoes?

Understanding industry jargon is essential for effective communication in the fabric sourcing process. Here are some common terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the context of shoe fabrics, this could involve sourcing materials that meet specific design and performance criteria. Buyers should clearly communicate their requirements to ensure the final product aligns with their brand standards.

Illustrative image related to fabric for shoes

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of products a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cost efficiency. Understanding MOQ helps businesses plan their purchases and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This is an essential step in the procurement process, as it allows buyers to compare offers and make informed decisions. A well-prepared RFQ can streamline negotiations and lead to favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping and delivery. Familiarity with these terms helps buyers understand their obligations concerning costs and risks associated with transporting fabric materials. This knowledge is essential for managing supply chain logistics effectively.

5. Lead Time

Lead time refers to the time required from placing an order to receiving the goods. This metric is critical in supply chain management as it affects production schedules and inventory levels. Understanding lead times helps buyers plan their orders to avoid delays in the production process.

Illustrative image related to fabric for shoes

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing fabric for shoes, ensuring they meet both quality and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the fabric for shoes Sector

What Are the Key Trends Shaping the Global Fabric for Shoes Market?

The global fabric for shoes market is witnessing significant transformation driven by a confluence of technological advancements and evolving consumer preferences. One of the most notable trends is the increasing use of lightweight, durable synthetic fibers such as nylon and polyester, which offer superior performance characteristics. These materials not only enhance comfort but also contribute to the longevity of footwear products, appealing to both manufacturers and end-users alike.

Emerging technologies, such as 3D knitting and digital printing, are reshaping sourcing practices and enabling brands to offer customized solutions at scale. This shift is particularly relevant for international B2B buyers, who are increasingly seeking agility and speed in their supply chains. For regions like Africa and South America, where local manufacturing is on the rise, leveraging these technologies can significantly reduce lead times and costs.

Additionally, the market is experiencing a rising demand for versatile fabrics that can cater to various shoe types—from athletic to formal footwear. Buyers are encouraged to stay attuned to trends such as multifunctional materials that combine aesthetics with performance features, like moisture-wicking and UV resistance. As sustainability becomes a focal point in manufacturing, eco-friendly fabrics are gaining traction, prompting buyers to rethink their sourcing strategies to align with these shifts.

How Is Sustainability Influencing Sourcing Trends in the Fabric for Shoes Sector?

Sustainability has emerged as a critical factor in the fabric for shoes sector, reshaping sourcing decisions among B2B buyers. The environmental impact of fabric production, particularly in terms of water usage and chemical runoff, is under increasing scrutiny. As a result, brands are compelled to adopt ethical sourcing practices that prioritize sustainability, not just for compliance, but as a competitive advantage in a crowded marketplace.

Buyers are now actively seeking suppliers who can provide ‘green’ certifications, such as Global Organic Textile Standard (GOTS) and OEKO-TEX, which validate environmentally friendly practices. The use of recycled materials, organic cotton, and biodegradable synthetics is gaining momentum, offering buyers a way to meet consumer demand for sustainable products without compromising on quality.

Furthermore, transparency in the supply chain is becoming a non-negotiable requirement for international B2B buyers. They are increasingly focused on understanding the origins of the materials used and the conditions under which they are produced. This trend not only enhances brand reputation but also fosters consumer trust, making it imperative for suppliers to adopt ethical practices that align with these expectations.

What Is the Historical Context of the Fabric for Shoes Industry?

The fabric for shoes industry has evolved significantly over the decades, transitioning from traditional materials like leather and canvas to a diverse range of innovative textiles. Historically, the use of natural fibers dominated the market, with cotton and wool being staples due to their availability and comfort. However, the mid-20th century saw the introduction of synthetic materials, which revolutionized footwear design by offering improved durability, flexibility, and cost-effectiveness.

As global trade expanded, so did the sourcing of fabrics, leading to the development of complex supply chains that now span multiple continents. The late 20th century marked a turning point as brands began to recognize the importance of performance attributes, paving the way for advanced materials like air mesh and moisture-wicking fabrics. This evolution has been further accelerated by advancements in manufacturing technologies, enabling the production of customized fabrics that cater to specific consumer needs.

Today, the interplay of sustainability, technological innovation, and market dynamics continues to shape the fabric for shoes sector, making it essential for B2B buyers to stay informed and agile in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric for shoes

-

How do I choose the right fabric for my shoe designs?

Selecting the appropriate fabric for shoe design involves considering several factors, including fiber composition, weight (denier), weave pattern, and intended use. For performance footwear, lightweight and breathable materials like nylon or polyester are ideal. If durability is a priority, opt for cotton canvas or high-denier fabrics. Additionally, evaluate surface treatments that may enhance water resistance or flexibility. Always align your fabric choices with the specific requirements of your target market and consumer preferences. -

What types of fabrics are best suited for athletic shoes?

Athletic shoes benefit from fabrics that offer breathability, flexibility, and moisture-wicking properties. Common choices include polyester mesh for its lightweight and quick-drying capabilities, and Lycra for stretchability. Additionally, high-tech materials like air mesh or 3D knit fabrics provide enhanced ventilation and comfort. Always test fabric samples to ensure they meet performance standards and align with your brand’s quality expectations. -

What minimum order quantities (MOQs) should I expect when sourcing fabric for shoes?

MOQs can vary significantly based on the supplier and the type of fabric. Generally, for custom fabrics, MOQs may range from 500 to 1,000 meters. However, some suppliers may offer lower MOQs for standard stock fabrics. It’s advisable to communicate your requirements clearly with potential suppliers and negotiate MOQs that suit your production needs, especially if you’re a smaller manufacturer or startup. -

How can I vet suppliers when sourcing fabric for shoes?

To effectively vet suppliers, consider their industry experience, reputation, and production capabilities. Request samples to evaluate fabric quality and performance. Additionally, check for certifications such as ISO or Oeko-Tex, which indicate adherence to quality and environmental standards. Building a relationship with suppliers through clear communication and regular visits can also help establish trust and ensure reliability in your sourcing process. -

What payment terms are typically available for international fabric purchases?

Payment terms can vary widely among suppliers, but common practices include advance payment, partial payment upon order confirmation, and balance payment prior to shipment. For larger orders, suppliers may accept letters of credit or escrow services to secure transactions. It’s crucial to negotiate terms that provide both parties with confidence while considering currency risks and international banking fees. -

How do I handle logistics and shipping when importing fabric for shoes?

When importing fabric, it’s essential to coordinate logistics in advance. Engage a reliable freight forwarder to manage shipping, customs clearance, and delivery. Understand the incoterms (like FOB or CIF) that dictate responsibility for shipping costs and risk. Additionally, factor in lead times for production and shipping to ensure timely delivery to your manufacturing facility, especially when sourcing from international suppliers. -

What quality assurance measures should I implement when sourcing shoe fabrics?

Quality assurance (QA) is critical to ensure that the fabrics meet your specifications and performance standards. Implement a multi-step QA process that includes initial sample testing, in-line inspections during production, and final quality checks before shipment. Establish clear quality criteria with your suppliers and consider third-party inspection services for additional assurance, especially for large orders. -

Are there any specific import duties or regulations I should be aware of when sourcing fabric for shoes?

Import duties on textiles can vary by country, often based on the fabric’s composition and the final product classification. For example, shoes with a textile surface area exceeding 51% might incur a 20% duty rate in certain regions. Research the import regulations for both the exporting and importing countries to avoid unexpected costs. Additionally, consult with customs brokers to navigate compliance requirements effectively and minimize delays in your supply chain.

Top 5 Fabric For Shoes Manufacturers & Suppliers List

1. Etsy – Unique Shoe Fabrics

Domain: etsy.com

Registered: 2004 (21 years)

Введение: This company, Etsy – Unique Shoe Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Shoemakers Academy – Essential Textiles for Shoe Design

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Введение: Textiles for Shoe Design: Understanding fabrics is essential for shoe design. Key textiles include nylon, polyester, lycra, and cotton canvas. Important considerations are thread size (measured in denier), fiber composition (cotton, wool, nylon, polyester, polypropylene, rayon, lycra), weave patterns (plain, twill, satin, basket, doddy, ripstop), backing materials (PU and PVC), and surface treatme…

3. Shoe Print Fabric – Various Colors and Lengths

Domain: ebay.com

Registered: 1995 (30 years)

Введение: Shoe Print Fabric available in various colors including Blue, Green, Black, Multicolor, White, Pink, Red, Beige, Gray, Brown, Purple, and Yellow. Available lengths/amounts include By the Yard, 1 – 2 yards, 3 – 5 yards, 6 – 12 yards, Fat Quarters, Bundles, Jelly Rolls, Strips, Less than 1 yard, Squares, Panels, and Bolts. Suitable for various applications such as apparel, quilting, crafts, upholste…

4. Monofabrics – Expert Shoe Fabrics

Domain: monofabrics.com

Registered: 2018 (7 years)

Введение: Expert Fabrics for Shoes by Wei-Syun, a trusted shoe fabric manufacturer. Key features include: 63 products in the shoe fabric line, suitable for shoe uppers such as sneakers and hiking shoes. Fabrics offer extension, abrasion, and tearing resistance. Options include Nylon mesh (lightweight, breathable, good tear resistance), Polyester mesh (lightweight, breathable, good abrasion resistance), Synt…

5. WikiHow – Crafting Supplies

Domain: wikihow.com

Registered: 2004 (21 years)

Введение: Old shoes, Fabric, Fabric glue or Mod Podge, Craft paint brush, Fabric scissors, Tailor’s chalk

Strategic Sourcing Conclusion and Outlook for fabric for shoes

As the global footwear market continues to evolve, understanding the intricacies of fabric selection is vital for manufacturers aiming to stay competitive. Strategic sourcing of fabrics not only allows for enhanced product quality but also helps in meeting diverse consumer demands across regions. By considering factors such as fiber composition, thread size, and weave patterns, B2B buyers can make informed decisions that elevate their product offerings.

For international buyers from Africa, South America, the Middle East, and Europe, leveraging local suppliers with expertise in innovative textiles can lead to significant cost savings and improved supply chain efficiency. The growing trend towards sustainability also presents opportunities for sourcing eco-friendly materials that resonate with environmentally-conscious consumers.

Moving forward, the landscape of footwear textiles will be shaped by advancements in technology and shifting consumer preferences. Buyers are encouraged to explore new fabric innovations and collaborate with suppliers who are committed to quality and sustainability. By prioritizing strategic sourcing, businesses can not only enhance their product lines but also position themselves favorably in an increasingly competitive marketplace. Engage with your suppliers today to unlock the potential of your footwear designs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.