Introduction: Navigating the Global Market for customize a leather jacket

In the dynamic landscape of global fashion, sourcing a customized leather jacket presents unique challenges for B2B buyers. This guide aims to illuminate the intricate process of designing and procuring bespoke leather jackets, offering insights tailored for international buyers from diverse regions, including Africa, South America, the Middle East, and Europe. As the demand for personalized apparel grows, understanding the nuances of customization—such as leather types, design options, and fit specifications—becomes essential for making informed purchasing decisions.

Throughout this comprehensive guide, we will delve into various aspects of customizing leather jackets, including the types of leather available, the different applications for these products, and the critical steps in vetting suppliers. Additionally, we will explore cost considerations and logistics to ensure that your sourcing strategy aligns with both quality and budgetary constraints. By empowering buyers with actionable insights and a clear framework for evaluating potential suppliers, this guide serves as a valuable resource for businesses looking to enhance their product offerings with high-quality, custom leather jackets. Whether you are a retailer, fashion designer, or corporate buyer, our expert recommendations will help you navigate the complexities of this global market, ensuring that your investment yields both aesthetic appeal and profitability.

Table Of Contents

- Top 6 Customize A Leather Jacket Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for customize a leather jacket

- Understanding customize a leather jacket Types and Variations

- Key Industrial Applications of customize a leather jacket

- 3 Common User Pain Points for ‘customize a leather jacket’ & Their Solutions

- Strategic Material Selection Guide for customize a leather jacket

- In-depth Look: Manufacturing Processes and Quality Assurance for customize a leather jacket

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘customize a leather jacket’

- Comprehensive Cost and Pricing Analysis for customize a leather jacket Sourcing

- Alternatives Analysis: Comparing customize a leather jacket With Other Solutions

- Essential Technical Properties and Trade Terminology for customize a leather jacket

- Navigating Market Dynamics and Sourcing Trends in the customize a leather jacket Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of customize a leather jacket

- Strategic Sourcing Conclusion and Outlook for customize a leather jacket

- Important Disclaimer & Terms of Use

Understanding customize a leather jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Biker Jackets | Classic design, reinforced stitching, often with armor | Motorcycle apparel retailers, promotional events | Pros: Durable, popular style; Cons: May not suit all markets. |

| Bomber Jackets | Shorter cut, ribbed cuffs and hem, casual style | Fashion retailers, corporate gifts | Pros: Versatile, trendy; Cons: Limited formal appeal. |

| Blazers | Tailored fit, formal appearance, often lined | Corporate uniforms, fashion boutiques | Pros: Professional look, customizable; Cons: Higher cost. |

| Printed & Embroidered Jackets | Custom logos, designs, and graphics | Branding, team uniforms, promotional items | Pros: Unique branding opportunities; Cons: Longer production times. |

| Custom Fit Jackets | Tailored to individual measurements, various styles | Fashion designers, bespoke retailers | Pros: Perfect fit for diverse body types; Cons: Requires detailed measurement process. |

What are the Characteristics of Biker Jackets in Custom Leather Apparel?

Biker jackets are characterized by their robust design, featuring reinforced stitching and often integrated protective elements like armor. They are typically made from thicker leather, providing durability and weather resistance. B2B buyers in motorcycle apparel retail find these jackets appealing due to their popularity among riders. However, while they are a staple in many markets, their niche appeal may limit broader marketability in regions where motorcycle culture is less prevalent.

How Do Bomber Jackets Stand Out in the Custom Leather Market?

Bomber jackets are distinguished by their shorter cut and ribbed cuffs, offering a casual yet stylish option. Their versatility makes them suitable for various applications, from fashion retailers to corporate gifts. B2B buyers appreciate the trendy aesthetic and adaptability of bomber jackets, which can be easily customized. However, their informal style might not meet the needs of all customer segments, particularly those seeking more formal or professional attire.

Why Choose Blazers for Custom Leather Options?

Blazers provide a tailored fit and formal appearance, making them ideal for corporate uniforms and upscale boutiques. Their structured design allows for various customizations, including fabric choices and lining options. B2B buyers looking to enhance their brand’s professional image often opt for blazers, as they convey sophistication. However, the higher cost associated with custom blazers may deter some buyers, especially in price-sensitive markets.

What are the Benefits of Printed and Embroidered Jackets?

Printed and embroidered jackets offer unique branding opportunities, allowing businesses to showcase logos, designs, or graphics prominently. This customization makes them suitable for team uniforms or promotional items. B2B buyers recognize the potential for enhanced brand visibility through these jackets. However, longer production times can be a drawback, requiring careful planning to meet promotional deadlines.

How Do Custom Fit Jackets Cater to Diverse Needs?

Custom fit jackets are tailored specifically to individual measurements, accommodating a wide range of body types and sizes. This personalization appeals to fashion designers and bespoke retailers who aim to offer a unique customer experience. Buyers appreciate the guarantee of a perfect fit, which can enhance customer satisfaction and loyalty. However, the detailed measurement process can be a barrier for some buyers, necessitating clear communication and guidance throughout the ordering process.

Key Industrial Applications of customize a leather jacket

| Industry/Sector | Specific Application of Customize a Leather Jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom leather jackets for branded collections | Enhanced brand identity and customer loyalty | Quality of leather, customization options, lead times |

| Film and Entertainment | Replica jackets for movie and TV productions | Authenticity in character portrayal | Precision in design replication, material authenticity |

| Automotive | Custom jackets for automotive brands and dealerships | Promotion of brand image and customer engagement | Durability of materials, logo placement, fit and comfort |

| Corporate Branding | Custom jackets as corporate gifts or uniforms | Strengthened corporate identity and team unity | Sizing options, embroidery quality, bulk order discounts |

| Sports and Leisure | Team jackets for sports teams and clubs | Fostering team spirit and fan loyalty | Fabric durability, customization options, color matching |

How is Customize a Leather Jacket Used in Fashion Retail?

In the fashion retail sector, customized leather jackets serve as a means to create unique branded collections that resonate with customers. Retailers can incorporate their logos, colors, and specific design elements that reflect their brand ethos. This personalization not only enhances brand identity but also fosters customer loyalty, as consumers are more likely to engage with products that feel exclusive and tailored to their tastes. For international buyers, sourcing high-quality leather and ensuring timely delivery are critical factors, especially when catering to diverse markets across Africa, South America, and Europe.

What Role Does Customize a Leather Jacket Play in Film and Entertainment?

In the film and entertainment industry, customized leather jackets are often produced as replicas of those worn by iconic characters. This authenticity is crucial for maintaining the integrity of the production and enhancing the viewer’s experience. Buyers in this sector require precise design replication, focusing on material authenticity to ensure the jackets look and feel genuine. International buyers must consider sourcing from reputable manufacturers that can deliver high-quality replicas within tight production timelines, especially for upcoming film releases.

How Can Automotive Brands Benefit from Custom Leather Jackets?

Automotive brands utilize customized leather jackets as promotional tools to enhance brand image and engage customers. These jackets often feature brand logos and design elements that align with the automotive aesthetic, creating a sense of exclusivity for customers. For automotive businesses, sourcing durable materials that withstand wear while ensuring comfort is vital. Additionally, international B2B buyers need to focus on the logistics of sourcing, ensuring that customization options meet brand standards across different markets, particularly in competitive regions like Europe and the Middle East.

Illustrative image related to customize a leather jacket

Why are Customized Leather Jackets Important for Corporate Branding?

Customized leather jackets are increasingly popular as corporate gifts or uniforms, helping to reinforce corporate identity and foster team unity. By providing employees with tailored jackets that showcase the company’s branding, businesses can enhance their visibility and promote a cohesive team spirit. Buyers in this sector should prioritize sizing options and embroidery quality to ensure a perfect fit and professional appearance. When sourcing, international buyers should also consider bulk order discounts and the ability to customize jackets according to specific regional preferences.

How Do Sports Teams Leverage Customized Leather Jackets?

Sports teams and clubs leverage customized leather jackets to build team spirit and foster fan loyalty. These jackets can feature team colors, logos, and even player names, creating a sense of belonging among fans and players alike. For B2B buyers in this sector, the focus should be on the durability of the materials used, as well as the customization options available to match team branding. Additionally, color matching with existing team merchandise is crucial, particularly for international markets where team colors may need to align with local cultural preferences.

3 Common User Pain Points for ‘customize a leather jacket’ & Their Solutions

Scenario 1: Navigating Sizing and Fit Challenges in Custom Leather Jackets

The Problem: A common issue B2B buyers face when ordering customized leather jackets is ensuring the correct sizing and fit for a diverse clientele. Given the varied body shapes and sizes, especially in international markets, a standard size chart may not suffice. Buyers often worry that the end product won’t meet the expectations of their customers, leading to dissatisfaction and potential returns, which can adversely affect their bottom line.

The Solution: To address sizing challenges, B2B buyers should prioritize a supplier that offers a comprehensive measurement guide and consultation services. Suppliers should provide detailed instructions on how to take accurate body measurements, including specific guidance for plus-size and custom-sized jackets. Implementing a systematic approach to gathering size data—such as using a digital fitting tool or providing a video tutorial—can enhance accuracy. Additionally, some manufacturers offer a fitting sample before mass production, allowing buyers to confirm sizes and make necessary adjustments. This proactive approach ensures that the final product aligns with the expectations of their customers, significantly reducing the likelihood of returns.

Scenario 2: Overcoming Design and Customization Limitations

The Problem: B2B buyers often encounter limitations regarding the design and customization options available for leather jackets. This can be particularly frustrating for fashion retailers or brands looking to create unique pieces that reflect their identity or cater to specific market trends. A lack of flexibility in design elements—such as color, fabric type, or embellishments—can hinder their ability to differentiate their offerings in a competitive landscape.

The Solution: To effectively manage design limitations, buyers should partner with manufacturers that emphasize a high degree of customization. Look for suppliers who allow for a wide range of design elements, including fabric choices, colors, linings, and hardware options. A collaborative design process can also be beneficial; engaging in consultations with design experts from the supplier can help refine ideas into feasible products. Additionally, leveraging digital design tools that allow for visual mock-ups can enhance communication between the buyer and supplier, ensuring the final product meets creative expectations. This strategic partnership can lead to innovative designs that stand out in the market.

Scenario 3: Ensuring Quality and Consistency in Production

The Problem: Quality assurance is a significant concern for B2B buyers sourcing customized leather jackets. Variability in leather quality, stitching, and overall craftsmanship can result in inconsistencies that damage a brand’s reputation. Buyers may struggle to find a reliable supplier who consistently delivers high-quality products that meet their standards, especially when sourcing from international markets with varying manufacturing practices.

The Solution: To mitigate quality risks, buyers should conduct thorough due diligence when selecting suppliers. This includes requesting samples of previous work to assess craftsmanship and material quality. Establishing clear quality standards and expectations in a contract can also protect against inconsistencies. Regular communication with the supplier during the production process is crucial; implementing quality control checkpoints can ensure that the products adhere to the agreed specifications. Furthermore, sourcing from manufacturers with established reputations and certifications can provide additional assurance of product quality, allowing buyers to confidently present their leather jackets to the market.

Strategic Material Selection Guide for customize a leather jacket

What Are the Key Properties of Different Leather Types for Custom Jackets?

When customizing a leather jacket, the choice of material is critical to the jacket’s overall performance, aesthetics, and longevity. Below, we analyze four common leather types used in custom jackets, focusing on their key properties, pros and cons, and considerations for international B2B buyers.

Illustrative image related to customize a leather jacket

How Does Lambskin Perform in Custom Leather Jackets?

Lambskin leather is known for its softness and luxurious feel. It has a relatively low temperature resistance, making it suitable for milder climates. This material is lightweight and has a smooth texture, which enhances the jacket’s appearance. However, lambskin is less durable than other leather types and can be prone to scratches and wear over time.

Pros:

– Soft and supple, providing comfort.

– Excellent for fashion-forward designs due to its aesthetic appeal.

Cons:

– Less durable compared to cowhide or buffalo hide.

– Higher maintenance requirements to keep it looking pristine.

Illustrative image related to customize a leather jacket

For international buyers, especially in regions like Europe and the Middle East, lambskin jackets may align with high fashion trends, but buyers should consider the local climate and potential wear-and-tear in harsher environments.

What Are the Advantages of Cowhide Leather for Custom Jackets?

Cowhide leather is one of the most popular choices for custom jackets due to its durability and resistance to wear and tear. It can withstand higher temperatures and is less susceptible to scratches, making it ideal for rugged use. Cowhide also offers a good balance between cost and performance.

Pros:

– Highly durable and long-lasting.

– Resistant to abrasions and tears.

Cons:

– Heavier than lambskin, which may not appeal to all customers.

– Stiffer initial feel that may require a break-in period.

International buyers from Africa and South America may find cowhide jackets particularly appealing due to their durability in varied climates and the jacket’s ability to withstand everyday wear and tear.

How Does Sheepskin Compare in Terms of Suitability for Custom Jackets?

Sheepskin leather is lighter than cowhide and offers a unique combination of warmth and breathability. It is often used in jackets designed for colder climates due to its insulating properties. However, sheepskin is generally less durable than cowhide and may not be suitable for heavy-duty applications.

Illustrative image related to customize a leather jacket

Pros:

– Excellent insulation for colder weather.

– Soft and lightweight, providing comfort.

Cons:

– Less durable than cowhide or buffalo hide.

– More susceptible to damage from moisture.

For B2B buyers in colder regions of Europe or the Middle East, sheepskin jackets can be marketed as premium products, appealing to consumers looking for warmth and comfort.

What Makes Buffalo Hide a Unique Option for Custom Jackets?

Buffalo hide is known for its exceptional toughness and durability. It can withstand extreme conditions and is resistant to abrasions, making it suitable for outdoor and heavy-duty applications. Buffalo hide also has a distinct texture that appeals to many consumers.

Pros:

– Extremely durable and resistant to wear.

– Unique texture that enhances aesthetic appeal.

Cons:

– Heavier and less flexible than other leathers.

– Higher cost due to the quality and sourcing.

International buyers, particularly those in rugged environments, may find buffalo hide jackets appealing for their longevity and ability to withstand harsh conditions, making them a worthwhile investment.

Summary of Material Selection for Custom Leather Jackets

| Material | Typical Use Case for customize a leather jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lambskin | Fashion jackets for mild climates | Soft and luxurious feel | Less durable, higher maintenance | Medium |

| Cowhide | Everyday wear jackets | Highly durable and long-lasting | Heavier, stiffer initial feel | Medium |

| Sheepskin | Cold-weather jackets | Excellent insulation | Less durable, moisture-sensitive | Medium |

| Buffalo Hide | Heavy-duty and outdoor jackets | Extremely tough and abrasion-resistant | Heavier, higher cost | High |

This strategic material selection guide provides insights for B2B buyers to make informed decisions when customizing leather jackets, ensuring that the chosen materials align with both market demands and regional preferences.

Illustrative image related to customize a leather jacket

In-depth Look: Manufacturing Processes and Quality Assurance for customize a leather jacket

What Are the Main Stages in the Manufacturing Process of Custom Leather Jackets?

The manufacturing of custom leather jackets involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages is essential for B2B buyers who seek quality and reliability from their suppliers.

Material Preparation: How Is Leather Selected and Prepared?

The first step in the manufacturing process is material preparation. Quality leather is sourced from reputable tanneries known for their craftsmanship. Common types of leather used include lambskin, sheepskin, goatskin, buffalo-hide, and cow-hide. Each type has unique characteristics, such as softness, durability, and thickness, which influence the jacket’s final look and feel.

Once the leather is selected, it undergoes conditioning to enhance its pliability and resistance to wear. This involves processes such as tanning and dyeing, where natural or synthetic substances are used to preserve the leather and give it the desired color. B2B buyers should inquire about the sourcing and treatment methods, as these can significantly affect the quality and longevity of the product.

Illustrative image related to customize a leather jacket

How Are Custom Designs Transformed into Physical Products?

After the leather is prepared, the next stage involves forming the jacket. This process includes cutting the leather into specified patterns based on the custom designs provided by clients. Advanced technologies, such as laser cutting and computer-aided design (CAD), may be employed to ensure precision and consistency.

Once the pieces are cut, they are assembled. This involves sewing the leather sections together, attaching linings, zippers, and other hardware. Skilled artisans often perform this task, as the quality of stitching is critical for both durability and appearance. B2B buyers should ensure that suppliers have skilled labor and appropriate equipment to handle intricate designs.

What Finishing Techniques Are Used to Enhance Custom Leather Jackets?

The final stage of the manufacturing process is finishing, which adds the last touches to the jacket. This may include polishing, applying protective coatings, and adding embellishments such as embroidery or printed graphics. The finishing process not only enhances the jacket’s aesthetic appeal but also contributes to its durability and resistance to environmental factors.

Custom options allow buyers to specify details such as lining colors, hardware finishes, and additional features like quilted insulation. These personalization choices can significantly differentiate products in the competitive leather market.

What Quality Control Measures Are Essential for Custom Leather Jackets?

Quality assurance is a crucial aspect of the manufacturing process, ensuring that every jacket meets international standards and customer expectations. B2B buyers should be aware of the quality control measures implemented by their suppliers.

Which International Standards Should B2B Buyers Look for in Leather Jacket Manufacturing?

Manufacturers typically adhere to international quality standards, such as ISO 9001, which focuses on consistent quality management systems. Compliance with these standards indicates that the manufacturer has established processes to ensure product quality and customer satisfaction. Additionally, industry-specific certifications, such as CE (Conformité Européenne) for products sold in Europe, may also be relevant.

B2B buyers should request documentation that verifies compliance with these standards. This may include quality management system certifications and product safety assessments.

What Are the Key Checkpoints in Quality Control During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to identify and rectify issues before the final product is completed. Common checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials, including leather and hardware, are inspected for quality upon arrival. This ensures that only materials meeting specifications are used in production.

-

In-Process Quality Control (IPQC): During the assembly phase, ongoing inspections are conducted to monitor stitching, alignment, and overall workmanship. This step helps catch defects early, minimizing waste and rework.

-

Final Quality Control (FQC): Before shipment, finished jackets undergo a comprehensive inspection. This includes checking for defects, ensuring that custom specifications are met, and verifying that products are packaged correctly.

B2B buyers should verify that suppliers have a robust quality control process in place, as this will directly impact the reliability of their products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to high-quality standards, B2B buyers can take several proactive steps:

Illustrative image related to customize a leather jacket

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insight into the production processes, quality control measures, and overall operational standards. This firsthand observation can help buyers assess supplier capabilities.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their inspection processes, defect rates, and corrective actions taken. Analyzing these reports can give buyers confidence in the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These services can conduct inspections at various stages of production and provide a comprehensive evaluation.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider several nuances when it comes to quality control:

-

Cultural Differences: Understanding regional manufacturing practices and quality expectations can help buyers communicate effectively with suppliers. What is considered acceptable in one market may not be in another.

-

Regulatory Compliance: Different countries may have varying regulations regarding leather products, including environmental standards and labor laws. Buyers should ensure that their suppliers comply with the relevant regulations in their target markets.

-

Logistics and Supply Chain Risks: Shipping and logistics can introduce additional risks to product quality. Buyers should discuss how suppliers manage these risks, including how they handle transportation and storage of finished goods.

By taking these factors into account, B2B buyers can establish strong partnerships with suppliers that prioritize quality and reliability in custom leather jacket manufacturing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘customize a leather jacket’

Introduction

This guide aims to equip international B2B buyers with a practical checklist for sourcing customized leather jackets. Given the diverse market landscape across regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of customization, supplier selection, and quality assurance is essential. By following this step-by-step approach, buyers can ensure they procure leather jackets that meet their specifications and market demands effectively.

Step 1: Identify Your Market Needs

Understanding your target audience is paramount. Research the preferences and requirements of customers in your specific market regions, including style, fit, and price points. This insight will guide your customization options and help you select suppliers who can cater to these needs.

Step 2: Define Your Technical Specifications

Clearly outline the specifications for your customized leather jackets. Consider factors such as leather type (lambskin, cowhide, etc.), design features, and any branding elements like logos or embroidery. Having a detailed specification helps suppliers provide accurate quotes and minimizes the risk of miscommunication.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, production capabilities, and references from other buyers in similar industries. Ensure they have experience in customizing leather products and can meet your quality and delivery expectations.

- Look for certifications: Verify if suppliers hold relevant certifications that indicate compliance with industry standards, such as ISO quality management or ethical sourcing practices.

Step 4: Assess Quality Control Processes

Quality assurance is critical when dealing with leather products. Inquire about the supplier’s quality control measures at various stages of production. Ensure they have a clear process for inspecting materials, craftsmanship, and final products.

- Request samples: Always ask for samples of the leather and finished jackets to evaluate the quality firsthand before placing bulk orders.

Step 5: Discuss Customization Options

Engage with suppliers to discuss the available customization options. This includes the choice of leather, colors, hardware, and any additional features like lining or insulation. A collaborative approach during this phase can lead to innovative designs that resonate with your market.

- Utilize design consultations: Many suppliers offer consultations to help refine your design ideas, ensuring the final product aligns with your vision.

Step 6: Negotiate Terms and Pricing

Once you have narrowed down potential suppliers, initiate discussions on pricing, minimum order quantities, and payment terms. Ensure that all aspects, including shipping costs and timelines, are clearly defined in the agreement to avoid surprises later.

- Consider long-term partnerships: Building a relationship with your supplier can lead to better pricing and priority service in the future.

Step 7: Plan for Logistics and Distribution

Finally, establish a logistics plan for the delivery of your customized jackets. Discuss shipping options with your supplier and consider the implications of customs regulations in your target markets. Efficient logistics will ensure timely product availability and enhance customer satisfaction.

- Factor in lead times: Understand the production timeline and factor this into your overall inventory management strategy to meet market demands effectively.

By following these steps, B2B buyers can navigate the complexities of sourcing customized leather jackets, ensuring a successful procurement process that aligns with their business objectives.

Comprehensive Cost and Pricing Analysis for customize a leather jacket Sourcing

What Are the Key Cost Components in Custom Leather Jacket Sourcing?

When sourcing customized leather jackets, several cost components come into play, each influencing the final pricing. Understanding these components can help B2B buyers make informed purchasing decisions.

Illustrative image related to customize a leather jacket

-

Materials: The type and quality of leather significantly affect the overall cost. Options include lambskin, goatskin, cowhide, and buffalo hide, each varying in price due to availability and processing techniques. Additionally, the choice of linings, zippers, and hardware can add to the material costs. For instance, opting for high-quality YKK zippers instead of standard options can increase durability but also price.

-

Labor: Labor costs encompass the wages paid to skilled artisans who craft the jackets. Customization requires more intricate skills, which typically leads to higher labor costs. Tailoring jackets to specific measurements, especially for plus sizes or unique designs, necessitates additional labor hours.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment used in the production process. Manufacturers with advanced technologies or eco-friendly processes might have higher overheads, which can be reflected in the pricing.

-

Tooling: Customization often requires specialized tools and machinery, particularly for unique designs or prints. This tooling cost is amortized over the production volume, impacting the per-unit price.

-

Quality Control (QC): Ensuring that each jacket meets specific quality standards incurs additional costs. Comprehensive QC processes are crucial, especially for international shipments where discrepancies can lead to costly returns or adjustments.

-

Logistics: Shipping costs can vary significantly based on location, shipping method, and the chosen Incoterms. International buyers should consider the impact of customs duties and taxes, which can also affect overall pricing.

-

Margin: Lastly, the manufacturer’s profit margin will be built into the final price. Higher customization levels may justify larger margins due to the additional expertise and resources involved.

How Do Price Influencers Impact Custom Leather Jacket Costs?

Several factors influence the pricing of customized leather jackets, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often come with bulk pricing discounts, making it essential for businesses to evaluate their purchasing strategies based on volume needs.

-

Specifications and Customization: The more specific and intricate the design, the higher the cost. Customized elements such as embroidery, unique fittings, and special finishes can increase the price.

-

Materials and Quality Certifications: Sourcing premium materials that come with certifications (e.g., eco-friendly, fair trade) can lead to higher costs but may also enhance the product’s marketability.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may offer better quality and reliability but at a premium price.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) can impact total costs. Buyers should clarify responsibilities for shipping, insurance, and tariffs to avoid unexpected expenses.

What Tips Can Buyers Use for Cost-Efficiency in Custom Leather Jacket Sourcing?

-

Negotiation: Engage in discussions with suppliers to negotiate better pricing, especially when placing large orders. Building long-term relationships can also yield favorable terms.

-

Total Cost of Ownership (TCO): Assess the long-term costs, including maintenance and durability, to ensure that the initial investment aligns with product longevity.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, trade tariffs, and local regulations that may affect pricing. Buyers from Africa, South America, the Middle East, and Europe should research the specific market conditions and supplier landscapes to make informed decisions.

-

Sampling: Before committing to large orders, request samples to evaluate quality. This step can prevent costly mistakes associated with poor quality or incorrect specifications.

-

Consider Local Suppliers: For buyers in Africa and South America, exploring local manufacturers can reduce shipping costs and lead times, contributing to overall cost efficiency.

Disclaimer

Prices for customized leather jackets can vary widely based on the factors discussed. The figures mentioned are indicative and should be confirmed with suppliers during the sourcing process. Always conduct thorough due diligence to ensure the best value for your investment.

Alternatives Analysis: Comparing customize a leather jacket With Other Solutions

Exploring Alternatives to Custom Leather Jackets

When considering the procurement of custom leather jackets, B2B buyers should evaluate various alternatives that can meet similar needs for style, branding, and functionality. This analysis will compare the customization of leather jackets against two alternative solutions: ready-to-wear leather jackets and synthetic leather options. Each alternative presents unique advantages and challenges that can significantly impact decision-making.

| Comparison Aspect | Customize A Leather Jacket | Ready-to-Wear Leather Jackets | Synthetic Leather Jackets |

|---|---|---|---|

| Performance | High durability; tailored fit | Moderate durability; standard fit | Varies; often less durable than genuine leather |

| Cost | Higher upfront investment; typically $290-$484 | More affordable; usually $150-$300 | Generally lower cost; $50-$150 |

| Ease of Implementation | Requires design consultation and custom measurements | Quick to purchase; minimal setup required | Simple to source; available in bulk |

| Maintenance | Requires special care due to genuine leather | Easier to maintain; may be treated for longevity | Typically easy to clean and maintain |

| Best Use Case | Unique branding, fashion statements, personalized gifts | General fashion, retail sales, promotional events | Budget-conscious fashion, eco-friendly initiatives |

What Are the Pros and Cons of Ready-to-Wear Leather Jackets?

Ready-to-wear leather jackets offer a practical solution for businesses seeking a quick and cost-effective option. These jackets are available in various styles and sizes, allowing for immediate availability without the need for extensive consultation or measurement. However, the trade-off is a lack of personalization; businesses may find it challenging to align these products with specific brand identities or unique customer preferences. Additionally, while they are generally more affordable, the quality can vary significantly depending on the manufacturer and materials used.

How Do Synthetic Leather Jackets Compare?

Synthetic leather jackets present an appealing alternative for businesses focused on sustainability or budget constraints. Often made from polyurethane or other materials, these jackets can mimic the look of leather while being more affordable. They are also easier to clean and maintain, making them suitable for high-volume retail environments. However, they may lack the durability and luxurious feel of genuine leather, which could affect customer satisfaction and brand perception in markets that value authenticity.

Conclusion: How Should B2B Buyers Choose the Right Leather Jacket Solution?

Selecting the right solution for leather jackets hinges on the specific needs and objectives of your business. Customizing a leather jacket allows for unparalleled personalization and brand representation, making it ideal for businesses that prioritize unique offerings. However, if cost and immediacy are of higher concern, ready-to-wear or synthetic leather options may provide sufficient functionality and appeal. B2B buyers should consider factors such as target market, budget, and desired brand image when making their decision to ensure they choose the most suitable option for their needs.

Essential Technical Properties and Trade Terminology for customize a leather jacket

What Are the Key Technical Properties for Customizing a Leather Jacket?

When considering the customization of leather jackets, understanding the technical properties involved is essential for B2B buyers to make informed decisions. Here are some critical specifications to keep in mind:

-

Material Grade

The grade of leather significantly impacts the jacket’s quality, durability, and appearance. Common grades include full-grain, top-grain, and corrected-grain leather. Full-grain leather, derived from the top layer of the hide, is the most robust and develops a beautiful patina over time. Understanding material grades is crucial for buyers as it affects not only the product’s longevity but also its marketability. -

Leather Type

Different types of leather, such as lambskin, sheepskin, goatskin, and cowhide, offer unique textures and characteristics. For example, lambskin is known for its softness and luxurious feel, while cowhide provides durability and toughness. Buyers should consider the intended use and target market when selecting leather types, as these factors influence consumer preferences and pricing strategies. -

Tolerance

Tolerance refers to the acceptable variation in dimensions and specifications during the manufacturing process. In leather jacket customization, maintaining tight tolerances is vital to ensure that the final product fits well and meets customer expectations. For B2B buyers, understanding tolerances helps in assessing the quality control measures of suppliers and manufacturers. -

Lining Material

The choice of lining can affect comfort, insulation, and aesthetic appeal. Common options include polyester, silk, and cotton, each offering distinct benefits. For instance, quilted polyester linings provide additional warmth for colder climates, while silk linings enhance luxury. Buyers should prioritize lining materials that align with their brand identity and customer needs. -

Zipper and Hardware Quality

The quality of zippers and hardware can significantly affect both functionality and style. YKK zippers are renowned for their reliability, while custom hardware can serve as a fashion statement. B2B buyers should evaluate hardware options to ensure they meet quality standards and align with the overall design of the jacket.

What Are Common Trade Terms in the Custom Leather Jacket Industry?

Understanding trade terminology is vital for B2B buyers to navigate the customization process effectively. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are later branded and sold by another company. In the leather jacket industry, OEMs can provide customized designs based on a buyer’s specifications, allowing for a unique product offering. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For custom leather jackets, MOQs can vary based on the manufacturer and the complexity of the design. Understanding MOQ is crucial for buyers to assess the feasibility of their customization projects and manage inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the context of custom leather jackets, an RFQ can help buyers compare prices, specifications, and delivery times, facilitating better purchasing decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. They specify who is responsible for shipping, insurance, and tariffs during the transport of goods. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth transactions. -

Customization Options

This term encompasses the various choices available to buyers when designing a leather jacket, including style, color, leather type, and embellishments. Understanding customization options allows buyers to create products that cater to specific market demands and customer preferences.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and ensure successful collaborations with leather manufacturers.

Navigating Market Dynamics and Sourcing Trends in the customize a leather jacket Sector

What Are the Global Drivers and Key Trends Influencing the Customize a Leather Jacket Market?

The global market for customized leather jackets is witnessing dynamic growth, driven by several key factors. Increasing consumer demand for personalized products is at the forefront, as buyers seek unique apparel that reflects their individual style. This trend is particularly pronounced among younger demographics across regions such as Africa, South America, the Middle East, and Europe, where fashion-forward consumers are willing to invest in bespoke items. Additionally, technological advancements in manufacturing processes, such as 3D printing and digital design software, are enabling businesses to offer more intricate customization options, enhancing the overall consumer experience.

Illustrative image related to customize a leather jacket

Another significant trend is the rise of e-commerce platforms, which facilitate direct interactions between manufacturers and consumers, streamlining the buying process. This is especially relevant in emerging markets like Vietnam and Brazil, where online shopping is rapidly gaining traction. B2B buyers are increasingly leveraging data analytics and customer feedback to refine their offerings and meet market demands more effectively. Moreover, the global leather market is evolving with the introduction of sustainable practices, making it essential for buyers to stay updated on sourcing trends that align with consumer expectations for eco-friendly products.

How Important Is Sustainability and Ethical Sourcing in the Customize a Leather Jacket Sector?

Sustainability and ethical sourcing have become critical considerations in the customized leather jacket market. The environmental impact of leather production is significant, often involving resource-intensive processes that can contribute to pollution and deforestation. As a response, many manufacturers are adopting sustainable practices, such as using vegetable-tanned leather and sourcing from certified tanneries that prioritize eco-friendly methods.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Consumers are increasingly scrutinizing the origins of their products, favoring brands that demonstrate transparency and commitment to ethical labor practices. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) provide assurance that products meet environmental and social responsibility standards. By prioritizing suppliers who adhere to these certifications, businesses can not only enhance their brand reputation but also tap into a growing market segment that values sustainability.

How Has the Customize a Leather Jacket Market Evolved Over Time?

The customize a leather jacket sector has evolved significantly over the past few decades. Initially, leather jackets were predominantly mass-produced, catering to broad market segments. However, the rise of individualism and the demand for personalized products have shifted the focus towards customization. Today, advancements in technology allow consumers to engage in the design process, selecting materials, colors, and styles that resonate with their personal identity.

Moreover, the global pandemic has accelerated the digital transformation of the industry, with online consultations and virtual fitting sessions becoming commonplace. This evolution reflects a broader shift in consumer behavior, where convenience and personalization are paramount. As the market continues to adapt to these changing preferences, B2B buyers must remain agile, leveraging these trends to meet the demands of a diverse and discerning customer base.

Frequently Asked Questions (FAQs) for B2B Buyers of customize a leather jacket

-

How do I ensure the quality of custom leather jackets when sourcing from international suppliers?

To ensure quality, start by vetting suppliers through reviews, certifications, and past client testimonials. Request samples to evaluate the leather quality, stitching, and overall craftsmanship. Establish clear quality assurance protocols, including specific standards for materials and production processes. Collaborating with suppliers who have a transparent production process and are willing to share their quality control measures can further ensure that you receive products that meet your specifications. -

What is the best way to communicate my custom design specifications to a supplier?

Effective communication is crucial for achieving your desired outcome. Provide detailed design specifications using sketches, images, or digital mock-ups. Consider creating a design brief that outlines materials, colors, styles, and any logos or embroidery. Schedule a consultation with the supplier to discuss these details and ensure that they understand your vision. Clear and open dialogue will help mitigate misunderstandings and lead to a more satisfactory final product. -

What are the typical minimum order quantities (MOQs) for custom leather jackets?

Minimum order quantities can vary significantly based on the supplier and the complexity of the design. Generally, MOQs for custom leather jackets range from 50 to 100 units per order. It’s essential to clarify MOQs during your initial discussions with suppliers, as lower MOQs may be available for certain styles or during promotional periods. Some suppliers may offer flexibility for first-time buyers or ongoing partnerships, so don’t hesitate to negotiate. -

What payment terms should I expect when ordering custom leather jackets?

Payment terms for custom leather jacket orders typically include a deposit upfront, often ranging from 30% to 50% of the total order value. The remaining balance is usually due upon completion or before shipping. It’s advisable to discuss payment methods such as wire transfers, PayPal, or letters of credit, which can offer added security for international transactions. Always request a proforma invoice detailing the terms before proceeding with the payment. -

How can I manage shipping and logistics for international orders of custom leather jackets?

To manage shipping efficiently, first, discuss shipping options with your supplier, including costs and delivery times. Choose a reliable logistics partner that specializes in international shipping to navigate customs and tariffs effectively. It’s beneficial to understand the import regulations of your country, as they can affect delivery times and costs. Additionally, consider using Incoterms (International Commercial Terms) to clarify responsibilities for shipping and insurance between you and the supplier. -

What should I include in my quality assurance (QA) process for custom leather jackets?

Your quality assurance process should encompass several key elements: establish clear specifications for materials and craftsmanship, implement routine inspections during production, and conduct a final quality check before shipping. Consider incorporating third-party inspections if sourcing from overseas to ensure compliance with your standards. Documenting the QA process not only helps in maintaining quality but also builds trust with your suppliers and clients. -

How can I customize leather jackets to appeal to diverse markets in Africa, South America, and Europe?

To effectively customize jackets for diverse markets, research regional fashion trends, cultural preferences, and climate considerations. Offer a variety of styles, colors, and sizes that cater to local tastes. Collaborate with local designers or influencers to gain insights into popular styles and preferences. Additionally, consider incorporating unique elements such as local motifs or sustainable materials to resonate with specific consumer values in each market. -

What are the common challenges faced when sourcing custom leather jackets internationally, and how can I overcome them?

Common challenges include language barriers, differing quality standards, and logistical complexities. To overcome these, establish clear communication channels and consider hiring a local agent or translator if necessary. Develop strong relationships with your suppliers by maintaining regular contact and addressing concerns promptly. Additionally, create a comprehensive contract that outlines expectations, timelines, and quality standards to protect your interests throughout the sourcing process.

Top 6 Customize A Leather Jacket Manufacturers & Suppliers List

1. The Jacket Maker – Custom Leather Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom Leather Jackets & Coats from The Jacket Maker. Options for customization include embroidery, logos, and color selection. Available styles include bomber jackets, biker jackets, suede jackets, varsity jackets, fur & shearling jackets, leather blazers, aviator jackets, hooded leather jackets, and leather vests. Customization options extend to various types of jackets, coats, bags, shoes, and …

2. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Custom Leather Jackets – Design Your Own Leather Jacket

Regular Price: $484.00

Sale Price: $367.00

Free Shipping on All Jackets

30 Days for Returns/Alterations

Available Sizes: XSmall, Small, Medium, Large, Xlarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $431.00

Customization Options: Select from a variety of fabrics and leathers, custom embroidery, sublimation printing, logos, …

3. Custom Leather Jackets – Personalized Designs and Recoloring Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is planning to customize two secondhand leather jackets. The first jacket will be painted as a gift, focusing on small designs and emblems. The second jacket is intended to be recolored dark red, but the user is advised that recoloring a black jacket is difficult and may require a lighter colored or slightly worn jacket. Recommended materials for detailing include saddle soap and Fiebings…

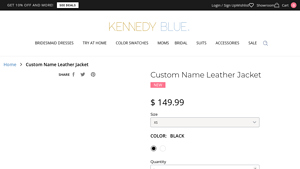

4. Kennedy Blue – Custom Name Leather Jacket

Domain: kennedyblue.com

Registered: 2011 (14 years)

Introduction: Custom Name Leather Jacket

– Price: $149.99

– Sizes Available: XS, S, M, L, XL, 2XL, 3XL, 4XL, 5XL, 6XL

– Colors Available: Black, White

– Material: High quality vegan leather

– Customization: Last name, date on collar, words on inner panel

– Features: Pockets

– Estimated Delivery: 4-6 weeks in the continental US

– Return Policy: No returns or exchanges on personalized items.

5. The Cast – Custom Leather Jackets & Vests

Domain: thecast.com

Registered: 1999 (26 years)

Introduction: Custom Leather Jackets & Vests made in NYC by The Cast. Premium quality and craftsmanship. Customization options include style selection (Bowery, Essex, Bronx, Rivington, Downtown, The ’68, Johnnie), leather type (Cowhide, CalfSkin, Horsehide, Hair on Hide Animal Print), lining options (Solid Prints, Polka Dot, Animal Print), and hardware choices (Nickel, Antique Nickel, Matte Black, Brass, Antiqu…

6. Independence Brothers – Custom Leather Jackets

Domain: independencebrothers.com

Registered: 2016 (9 years)

Introduction: Custom leather jackets crafted from premium, ethically sourced materials. Features a complete leather jacket design customization tool, allowing for personalized fit and style. Jackets are made from high-quality, semi-aniline leather that develops a patina over time. Tailored to exact measurements for a perfect fit. Family-owned business offering direct-to-consumer prices, cutting out the middlema…

Strategic Sourcing Conclusion and Outlook for customize a leather jacket

In the realm of custom leather jackets, strategic sourcing plays a pivotal role in ensuring quality, cost-effectiveness, and timely delivery. By carefully selecting suppliers who offer a diverse range of materials, styles, and customization options, international B2B buyers can meet the unique demands of their markets in Africa, South America, the Middle East, and Europe. The ability to collaborate with manufacturers that prioritize craftsmanship, sustainable practices, and innovative design will not only enhance product offerings but also strengthen brand reputation.

Moreover, embracing advanced technology in the customization process, such as 3D modeling and digital consultations, can streamline operations and improve customer satisfaction. As buyers increasingly seek personalized products, leveraging these tools will position businesses to capitalize on growing market trends.

Looking ahead, the opportunity to create bespoke leather jackets that reflect cultural nuances and individual styles is immense. By fostering strong partnerships with reliable suppliers and embracing a customer-centric approach, B2B buyers can not only enhance their product lines but also drive significant business growth. Now is the time to take action—engage with leading manufacturers and elevate your offerings to meet the evolving expectations of the global marketplace.

Illustrative image related to customize a leather jacket

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.