Introduction: Navigating the Global Market for custom leather stamp maker

In today’s competitive landscape, sourcing the right custom leather stamp maker can be a daunting challenge for international B2B buyers. With the growing demand for personalized branding in various industries, businesses need to navigate a complex market filled with diverse suppliers and product options. This guide aims to demystify the process of acquiring custom leather stamps, providing insights into the types available, their applications, and how to effectively vet suppliers.

From brass and steel stamps to cutting dies and lettersets, understanding the nuances of each product is crucial for making informed purchasing decisions. Moreover, we delve into pricing structures and shipping considerations, which are particularly relevant for buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany.

By equipping buyers with actionable insights and a comprehensive understanding of the market, this guide empowers businesses to confidently select the right custom leather stamp makers that align with their branding needs. Whether you are a small artisan or a large-scale manufacturer, our resource will help you streamline your sourcing process, ensuring that you invest in high-quality stamps that enhance your product offerings and brand identity.

Table Of Contents

- Top 8 Custom Leather Stamp Maker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamp maker

- Understanding custom leather stamp maker Types and Variations

- Key Industrial Applications of custom leather stamp maker

- 3 Common User Pain Points for ‘custom leather stamp maker’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamp maker

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp maker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp maker’

- Comprehensive Cost and Pricing Analysis for custom leather stamp maker Sourcing

- Alternatives Analysis: Comparing custom leather stamp maker With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamp maker

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamp maker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp maker

- Strategic Sourcing Conclusion and Outlook for custom leather stamp maker

- Important Disclaimer & Terms of Use

Understanding custom leather stamp maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Leather Stamps | Made from solid brass, durable, can be customized for logos | Branding leather goods, personalized gifts | Pros: High durability, excellent detail; Cons: Higher initial cost compared to other materials. |

| Handheld Steel Stamps | Portable, versatile, can stamp various materials including leather | Small batch production, artisanal crafts | Pros: Easy to use, cost-effective for small runs; Cons: Limited in scale for larger productions. |

| Custom Leather Roll Dies | Designed for continuous stamping, can create patterns or shapes | Mass production of leather items | Pros: Efficient for high volume; Cons: Initial setup cost can be high. |

| Letterset Accessories | Includes custom font options, adaptable to various stamping machines | Custom lettering on products | Pros: Versatile and customizable; Cons: Requires additional equipment for use. |

| Branding Irons | Used for heat branding, can create deep impressions | High-end leather goods, custom branding | Pros: Creates permanent marks; Cons: Requires heat source and careful handling. |

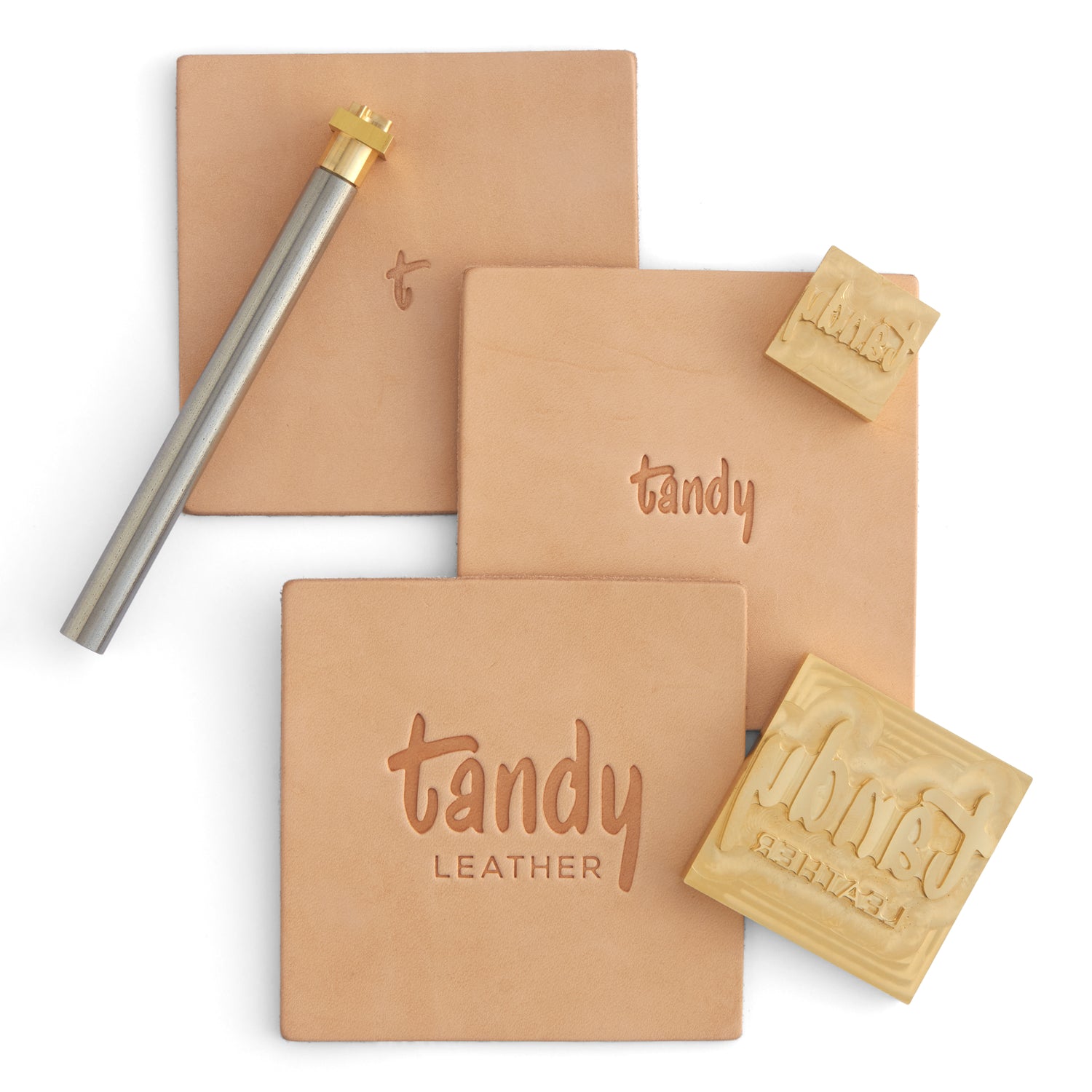

What Are Custom Brass Leather Stamps and Their B2B Applications?

Custom brass leather stamps are crafted from solid brass, making them highly durable and ideal for creating detailed impressions. These stamps are particularly suitable for businesses looking to brand leather goods, such as bags, belts, or wallets, and can also be used for personalized gifts. When purchasing, B2B buyers should consider the intricacy of their design, as more complex logos may require additional setup time and cost.

How Do Handheld Steel Stamps Serve Small Businesses?

Handheld steel stamps offer a portable and versatile solution for artisans and small businesses. They can be used on leather as well as other materials, making them a great choice for small batch production. Buyers should evaluate their production needs, as while these stamps are cost-effective for small runs, they may not be suitable for large-scale operations due to their manual nature.

What Are the Benefits of Custom Leather Roll Dies?

Custom leather roll dies are designed for continuous stamping, allowing businesses to create intricate patterns or shapes efficiently. This type of stamp is particularly advantageous for mass production in industries like fashion or upholstery. Buyers should weigh the initial setup costs against the long-term efficiency gains, as these tools can significantly reduce production time once in place.

Why Choose Letterset Accessories for Custom Lettering?

Letterset accessories provide businesses with the flexibility to create custom lettering on their products. These stamps can be adapted to various stamping machines, making them a versatile option for branding. However, buyers need to consider the additional equipment required for their use, as well as the potential learning curve associated with operating stamping machines.

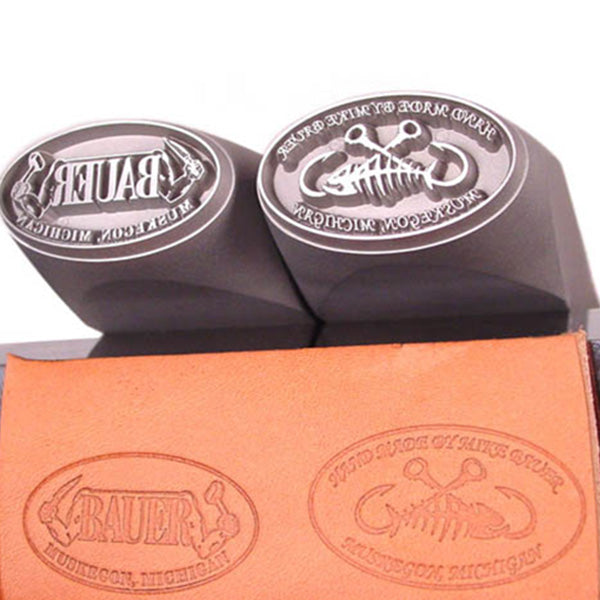

How Do Branding Irons Enhance Custom Branding?

Branding irons are used to create deep, permanent impressions on leather goods, providing a high-end finish that appeals to luxury markets. They are particularly suitable for custom branding in high-quality leather products. Buyers should consider the need for a heat source and the importance of careful handling to achieve the desired results without damaging the leather.

Key Industrial Applications of custom leather stamp maker

| Industry/Sector | Specific Application of custom leather stamp maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom branding on leather goods like bags and jackets | Enhances brand recognition and adds a professional touch to products | Quality of materials, design precision, and turnaround time |

| Leather Goods Manufacturing | Personalized stamps for wallets and belts | Facilitates mass production with unique branding options | Compatibility with existing machinery and customization options |

| Equestrian Equipment | Maker’s marks on saddles and riding gear | Establishes authenticity and builds customer loyalty | Durability of stamps under heavy use and specific design requirements |

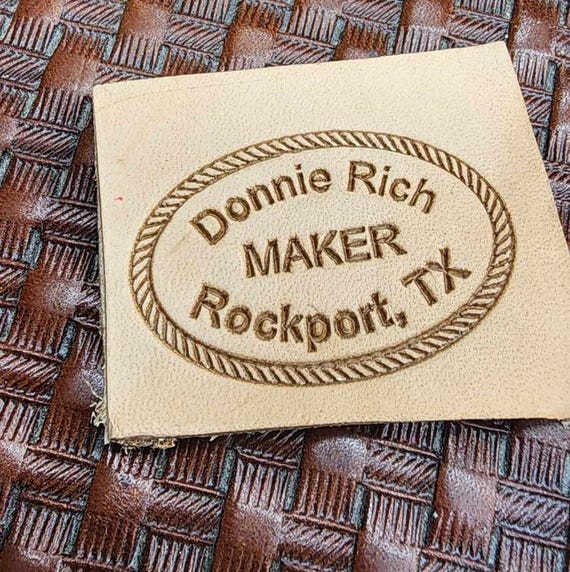

| Craftsmanship & DIY | Stamps for hobbyists and small businesses | Allows for unique creations and customization for small-scale production | Ease of use and support for beginners in the stamping process |

| Automotive & Industrial | Stamping parts or branding leather interiors | Promotes brand identity and ensures product traceability | Precision in design and ability to withstand industrial conditions |

How is Custom Leather Stamp Maker Utilized in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather stamps are used to imprint logos or brand names on leather goods such as bags, jackets, and shoes. This application not only enhances brand recognition but also adds a professional touch to products, making them more desirable to consumers. International buyers from regions like Europe and Africa should consider the quality of materials used in the stamps, as well as the design precision, to ensure that their branding stands out in a competitive market.

What Role Does Custom Leather Stamp Maker Play in Leather Goods Manufacturing?

Leather goods manufacturers often require personalized stamps to create unique branding on items like wallets and belts. This process facilitates mass production while allowing for individual brand identity, which is crucial in a saturated market. Buyers should evaluate the compatibility of custom stamps with their existing machinery and the available customization options to optimize their production efficiency.

How is Custom Leather Stamp Maker Beneficial for Equestrian Equipment?

In the equestrian sector, custom leather stamps are commonly used to mark saddles and riding gear with maker’s marks. This practice not only establishes authenticity but also fosters customer loyalty by providing a sense of ownership. Buyers in this niche must ensure that the stamps are durable enough to withstand heavy use and that they meet specific design requirements for clarity and precision.

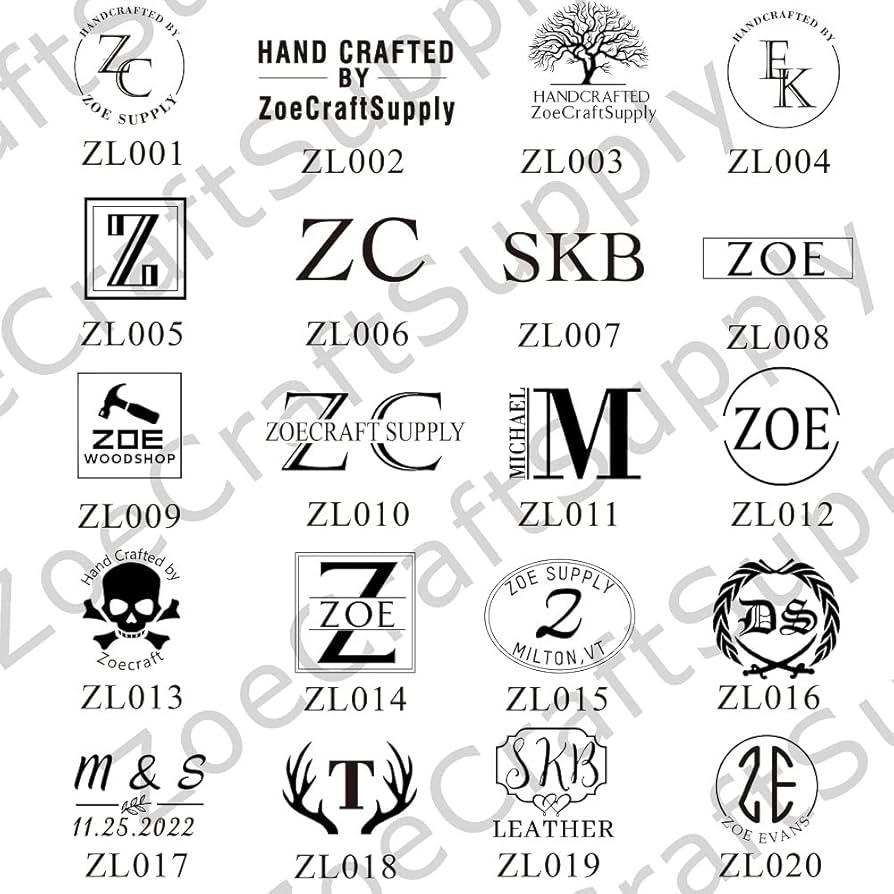

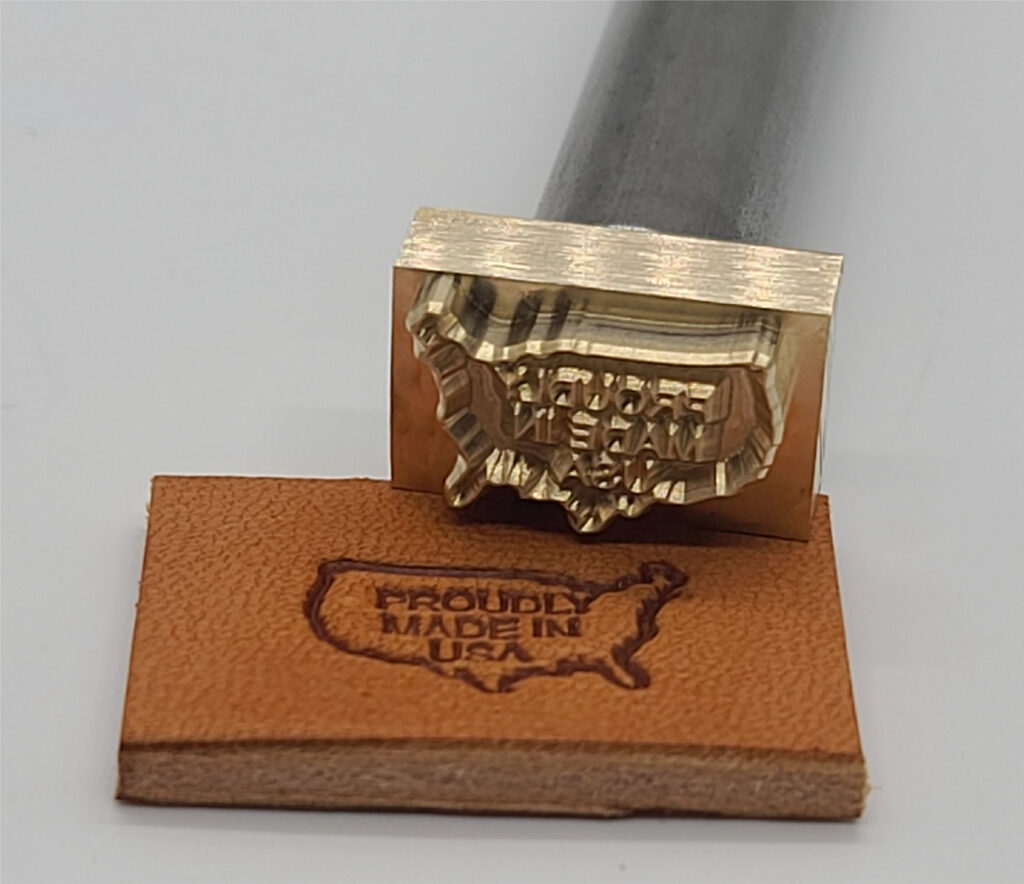

Illustrative image related to custom leather stamp maker

Why is Custom Leather Stamp Maker Important for Craftsmanship and DIY Projects?

For hobbyists and small businesses, custom leather stamps enable unique creations and personalization of products. This application is particularly valuable for those looking to differentiate themselves in the market or create bespoke items for clients. When sourcing these stamps, ease of use is essential, especially for beginners, along with support for the stamping process to ensure successful outcomes.

How Does Custom Leather Stamp Maker Enhance Branding in Automotive and Industrial Applications?

In the automotive and industrial sectors, custom leather stamps are utilized to brand leather interiors or stamp parts, promoting brand identity and ensuring product traceability. The precision of the design is critical, as it must withstand the rigors of industrial conditions. Buyers should focus on the durability of the stamps and their ability to deliver consistent results in demanding environments, which can significantly impact the overall quality of the finished product.

3 Common User Pain Points for ‘custom leather stamp maker’ & Their Solutions

Scenario 1: Long Lead Times on Custom Orders

The Problem: Many B2B buyers face frustration with long lead times when ordering custom leather stamps, which can delay production schedules and impact their ability to meet client demands. This is particularly challenging for businesses in industries such as fashion, leather goods, and manufacturing, where timing is critical. Buyers may find themselves at a standstill, unable to fulfill orders or launch new products due to the waiting period associated with custom stamp production.

Illustrative image related to custom leather stamp maker

The Solution: To mitigate lead time issues, buyers should prioritize suppliers that offer quick turnaround times. When selecting a custom leather stamp maker, inquire specifically about their production timelines and capabilities for expedited orders. Look for vendors that provide a clear timeline from order placement to delivery, ideally with options for same-day or next-day shipping on proofs and finished products. Additionally, consider establishing a partnership with a supplier that can maintain a small inventory of your most frequently used stamps. This proactive approach not only secures a faster supply but also builds a collaborative relationship that can lead to better service and pricing.

Scenario 2: Inconsistent Quality and Performance

The Problem: Another significant pain point for B2B buyers is the inconsistency in the quality of custom leather stamps. Buyers often receive products that do not meet their specifications or fail to produce the desired results during the stamping process. This inconsistency can lead to wasted materials, increased labor costs, and dissatisfaction among end customers, ultimately harming the buyer’s reputation in the market.

The Solution: To ensure quality, buyers should implement a thorough vetting process when selecting a custom leather stamp maker. This includes reviewing samples of previous work and seeking testimonials from other businesses in similar industries. Engage in direct communication with potential suppliers to discuss your specific requirements, including material specifications, design intricacies, and performance expectations. A reputable maker will often provide prototypes or proofs before final production to ensure the design meets your needs. Additionally, consider investing in quality assurance measures such as testing the stamps with various leather types before full-scale production to verify their performance and durability.

Illustrative image related to custom leather stamp maker

Scenario 3: Complexity in Customization and Design

The Problem: Buyers often struggle with the complexity involved in customizing leather stamps to match their branding or specific project requirements. The process can be overwhelming, especially for those who are not well-versed in design specifications or who lack experience in leatherwork. This can lead to miscommunications with the stamp maker, resulting in products that do not align with the buyer’s vision.

The Solution: To navigate the complexities of customization, buyers should take advantage of the consultation services offered by many custom leather stamp makers. Before placing an order, schedule a meeting or call to discuss your design ideas in detail. Provide the maker with clear examples of what you are looking for, including sketches or reference images. Many manufacturers are willing to offer design assistance or create virtual proofs to ensure that the final product aligns with your expectations. Additionally, investing time in understanding basic design principles can empower buyers to communicate their needs more effectively. Utilize online design tools or software that can help visualize the final product, making the process smoother and more collaborative.

Strategic Material Selection Guide for custom leather stamp maker

When selecting materials for custom leather stamps, it’s crucial for B2B buyers to understand the properties, advantages, and limitations of various options. This knowledge will help in making informed decisions that align with specific applications and compliance requirements.

What are the Key Properties of Brass for Custom Leather Stamps?

Brass is a popular choice for custom leather stamps due to its excellent machinability and corrosion resistance. It can withstand high temperatures, making it suitable for heat branding applications. The typical hardness of brass allows for detailed impressions, which is essential for branding logos and intricate designs on leather.

Pros: Brass is durable and offers a good balance between cost and performance. It is relatively easy to manufacture, allowing for quick turnaround times on custom orders. Additionally, brass stamps can produce clear, crisp impressions, making them ideal for high-quality branding.

Illustrative image related to custom leather stamp maker

Cons: While brass is resistant to corrosion, it can tarnish over time, which may require regular maintenance. The initial cost can be higher compared to other materials, which may deter some buyers.

Impact on Application: Brass is compatible with a wide range of leather types, particularly vegetable-tanned leather, which is favored for its ability to hold detailed impressions.

How Does Steel Compare as a Material for Leather Stamps?

Steel, particularly carbon steel, is another common material used for custom leather stamps. It is known for its strength and durability, capable of handling high pressure and temperature during the stamping process.

Pros: Steel offers exceptional longevity and resistance to wear, making it suitable for high-volume production. Its ability to maintain sharp edges ensures consistent quality in impressions over time.

Illustrative image related to custom leather stamp maker

Cons: The manufacturing process for steel stamps can be more complex and time-consuming, which may lead to longer lead times for custom orders. Additionally, steel is prone to rust if not properly maintained, necessitating protective coatings.

Impact on Application: Steel stamps work well with various leather types, including thick tooling leather, but may require more force during stamping, which could affect the quality of the impression if not handled correctly.

What are the Advantages of Aluminum in Custom Leather Stamps?

Aluminum is gaining traction in the custom leather stamp market due to its lightweight nature and good machinability. It is often used for less demanding applications where high durability is not the primary concern.

Pros: Aluminum is cost-effective and easy to manufacture, allowing for quick production of custom stamps. Its lightweight nature makes it easier to handle, reducing fatigue during extended use.

Cons: While aluminum is resistant to corrosion, it is less durable than brass or steel, which may limit its application in high-volume stamping scenarios. The impressions may not be as crisp as those made with harder materials.

Impact on Application: Aluminum is suitable for softer leathers and can be used for decorative stamping rather than heavy branding, making it ideal for artisans or small-scale producers.

What Should International Buyers Consider When Choosing Materials?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, compliance with local standards is vital. Buyers should be aware of regulations such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards) that may apply to material selection. Understanding these standards ensures that the materials used meet safety and quality benchmarks.

Additionally, preferences for specific materials may vary by region. For instance, European buyers may prioritize eco-friendly materials, while Middle Eastern buyers may focus on durability and heat resistance due to local climate conditions.

| Материал | Typical Use Case for custom leather stamp maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Ideal for detailed branding on vegetable-tanned leather | Good corrosion resistance and durability | Can tarnish over time | Medium |

| Steel | Suitable for high-volume production and heavy-duty applications | Exceptional longevity and wear resistance | Complex manufacturing process | Высокий |

| Aluminum | Best for lightweight, decorative stamping | Cost-effective and easy to handle | Less durable than brass or steel | Низкий |

| Carbon Steel | Effective for thick tooling leather applications | Maintains sharp edges for crisp impressions | Prone to rust without maintenance | Medium |

In conclusion, selecting the right material for custom leather stamps is crucial for ensuring product quality and meeting specific application needs. Understanding the properties, advantages, and limitations of each material, along with compliance considerations, will empower buyers to make informed decisions that align with their business objectives.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp maker

The manufacturing process for custom leather stamps is intricate and necessitates a blend of advanced techniques and stringent quality assurance measures. This section provides an in-depth exploration of the stages involved in manufacturing these stamps and the quality control protocols that ensure products meet international standards.

What Are the Main Stages of Manufacturing Custom Leather Stamps?

The manufacturing process for custom leather stamps typically involves four main stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in determining the quality and performance of the final product.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step involves selecting high-quality materials, primarily brass or steel, which are known for their durability and ability to create crisp, clear impressions. The selected materials are sourced from reputable suppliers who adhere to strict quality standards. After sourcing, the materials undergo a cleaning process to remove any contaminants, which can affect the stamping quality.

Illustrative image related to custom leather stamp maker

In the case of brass, the metal is often treated to enhance its resistance to corrosion. For steel, it may be heat-treated to improve hardness. Accurate measurement and cutting of the raw materials are critical, as they will determine the dimensions of the final stamp.

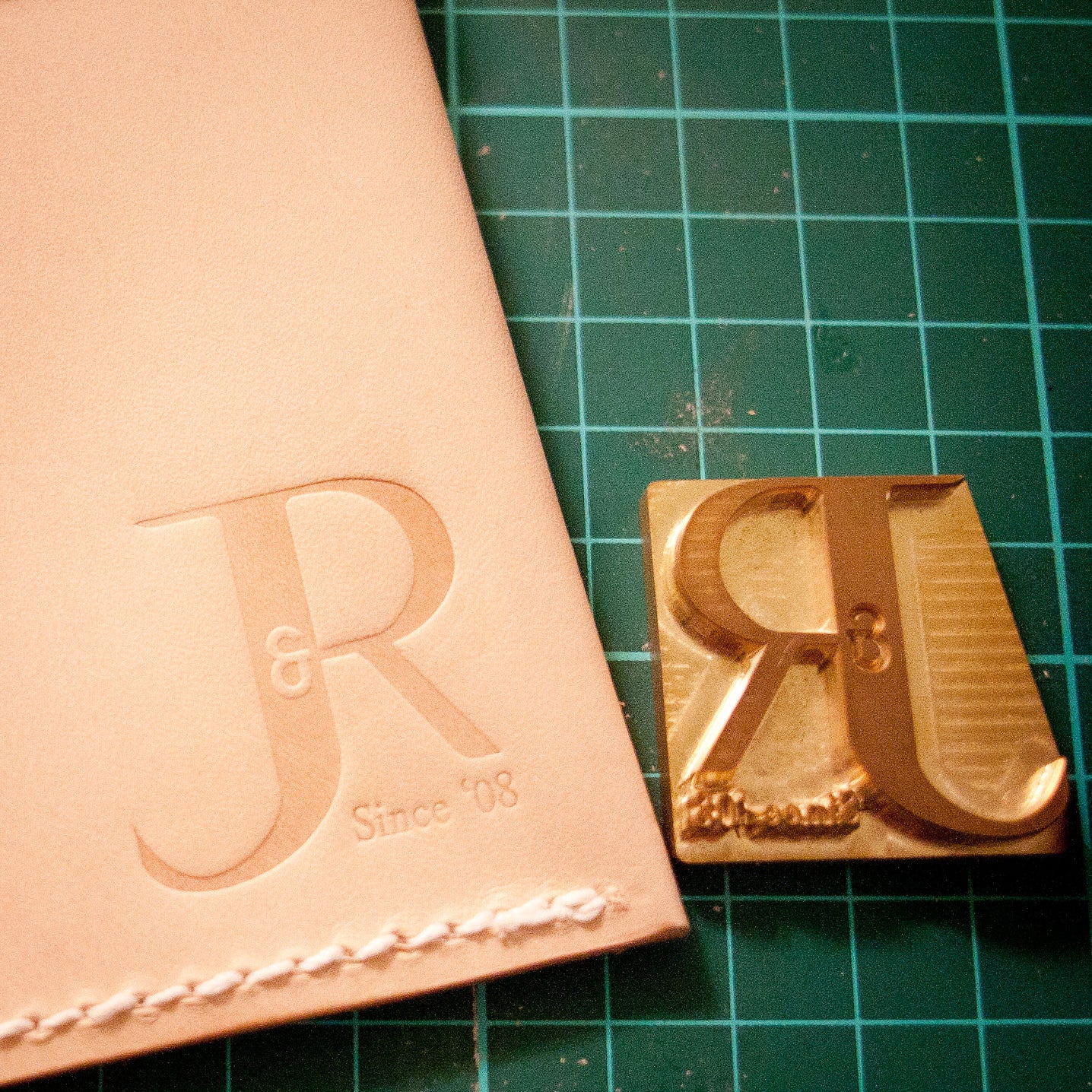

Forming: What Techniques Are Used to Shape the Stamps?

Once the materials are prepared, the forming stage begins, where the actual stamping dies are created. This process commonly utilizes CNC (Computer Numerical Control) machining, which allows for precision shaping of the stamp. CNC machines can produce complex designs with high accuracy, ensuring that every detail of the custom artwork is captured.

In addition to CNC machining, other techniques such as laser engraving may be employed for intricate designs or logos. This method is particularly beneficial for small-scale runs or highly detailed images, as it allows for rapid changes to designs without the need for new tooling.

Assembly: How Are the Components Assembled?

The assembly phase may involve combining various components, especially for more complex stamping systems that include interchangeable parts. For instance, letter sets and cutting dies might need to be assembled in a way that allows for easy changes during the stamping process.

Illustrative image related to custom leather stamp maker

Precision is crucial during assembly to ensure that all parts fit together seamlessly. Any misalignment can lead to poor-quality impressions, which can be costly for businesses relying on these stamps for branding or product marking.

Finishing: What Processes Are Involved in the Final Touches?

The finishing stage involves polishing the stamps to remove any burrs or imperfections left from the machining process. This step not only enhances the appearance of the stamps but also ensures that they operate smoothly and produce clean impressions.

Additionally, stamps may undergo a coating process to protect against corrosion and wear. This is particularly important for stamps that will be used frequently or in harsh environments.

Illustrative image related to custom leather stamp maker

What Quality Assurance Measures Are Implemented in Custom Leather Stamp Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for custom leather stamps. It ensures that every product meets the required specifications and standards, thus safeguarding the interests of B2B buyers.

What International Standards Are Relevant for Quality Control?

For manufacturers of custom leather stamps, adhering to international standards such as ISO 9001 is essential. This standard outlines the criteria for a quality management system and is based on several quality management principles, including a strong customer focus, the involvement of top management, and a process-based approach.

Additionally, industry-specific certifications like CE marking can be relevant, particularly for products sold within the European market. These certifications indicate that the products meet specific health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

The quality control process is typically divided into several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers must provide documentation proving that materials meet specified quality standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of work at various stages. This may include verifying dimensions, material properties, and ensuring that machining processes are within tolerances.

-

Final Quality Control (FQC): Once manufacturing is complete, a final inspection is conducted. This includes testing the stamps for functionality, such as ensuring they create clear impressions and assessing the finish for defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several methods to ensure quality:

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can also foster a better understanding of the supplier’s capabilities and commitment to quality.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s adherence to quality standards. These reports should include information on defect rates, customer complaints, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the products. These inspections can be particularly beneficial for large orders or when establishing new supplier relationships.

-

Certification Verification: Buyers should ensure that suppliers hold relevant certifications and can provide proof of compliance with international and industry-specific standards.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of specific nuances in quality control. Language barriers, cultural differences, and varying standards can complicate the communication of quality expectations.

Buyers should invest time in understanding the regulatory environment of the supplier’s country and how it may affect production quality. Additionally, establishing clear specifications and quality benchmarks at the outset of the relationship can mitigate misunderstandings later on.

In conclusion, the manufacturing processes and quality assurance practices for custom leather stamps are vital components that significantly influence product quality. By understanding these processes and implementing thorough verification measures, B2B buyers can ensure they partner with reliable suppliers capable of delivering high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp maker’

This guide serves as a practical checklist for B2B buyers looking to procure custom leather stamps. Custom leather stamps can enhance branding and product personalization, making it essential to choose the right supplier. Follow these steps to ensure you make an informed decision.

Illustrative image related to custom leather stamp maker

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the custom leather stamps. This includes the type of material (e.g., brass, steel), size, and design intricacies. Specific requirements will help suppliers understand your needs and provide accurate quotes.

- Consider the intended use: Are the stamps for branding, decorative purposes, or cutting dies?

- Specify design elements: Include logos, text, and any specific fonts or styles you desire.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify suppliers that specialize in custom leather stamps. This involves looking at their product offerings, manufacturing capabilities, and market reputation.

- Check online marketplaces: Websites like Alibaba or specialized leathercraft suppliers can provide a range of options.

- Read reviews and testimonials: Focus on feedback from businesses in your industry to gauge the supplier’s reliability and quality.

Step 3: Evaluate Supplier Experience and Expertise

Prioritize suppliers with a proven track record in producing custom leather stamps. A supplier with extensive experience is more likely to understand the nuances of your requirements.

- Request case studies: Ask for examples of previous work that align with your needs.

- Inquire about their design process: A supplier that offers a proofing stage shows commitment to quality and client satisfaction.

Step 4: Verify Quality Assurance Processes

Quality assurance is vital when sourcing custom leather stamps. Ensure that potential suppliers have robust quality control measures in place.

- Ask about materials used: Verify that they use high-quality materials that ensure durability and clarity of the stamps.

- Check their production methods: Suppliers should employ advanced techniques like CNC milling for precision.

Step 5: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, lead times, and any additional costs. Comparing these quotes will help you make an informed decision.

Illustrative image related to custom leather stamp maker

- Look for transparency in pricing: Ensure that all costs are itemized, including shipping and handling.

- Consider value over price: The cheapest option may not always provide the best quality or service.

Step 6: Assess Customer Support and Communication

Effective communication is crucial during the sourcing process. Evaluate how responsive and helpful suppliers are when addressing your inquiries.

- Reach out for initial questions: A supplier’s willingness to assist before the sale can indicate their commitment to customer service.

- Assess their support during the design phase: Ensure they provide guidance and support as you finalize your design.

Step 7: Finalize Terms and Place Your Order

After selecting a supplier, finalize the order details, including payment terms, delivery timelines, and any warranties or guarantees.

- Review contract terms carefully: Ensure all aspects of your agreement are documented to avoid misunderstandings.

- Confirm shipping methods: Understand how your order will be shipped and what tracking options are available.

By following these steps, you can effectively navigate the procurement process for custom leather stamps, ensuring that you choose a supplier that meets your business needs and standards.

Comprehensive Cost and Pricing Analysis for custom leather stamp maker Sourcing

What Are the Key Cost Components in Custom Leather Stamp Manufacturing?

When sourcing custom leather stamps, understanding the cost structure is crucial for B2B buyers. The primary components influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs. Custom brass and steel are commonly used due to their durability. High-quality materials ensure longevity and better impressions, which may come at a premium. Buyers should weigh the benefits of investing in superior materials against their specific application needs.

-

Labor: Skilled labor is essential for producing high-quality custom stamps. The complexity of the design and the craftsmanship involved can vary labor costs. In regions with higher labor costs, such as Europe, the price of custom stamps may be higher compared to manufacturers in lower-cost regions like parts of South America or Africa.

-

Manufacturing Overhead: This includes expenses related to the production facility, machinery maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead, making it a crucial factor in pricing.

-

Tooling: Custom tooling for specific designs can add to the initial costs. This is particularly relevant for unique or intricate designs requiring specialized equipment. Buyers should consider whether the initial tooling costs will be justified by the expected volume of orders.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets specified standards. While this may increase costs, it can prevent future losses due to defects. Investing in quality assurance can enhance buyer satisfaction and brand reputation.

-

Logistics: Shipping and handling costs can vary significantly based on the shipping method, distance, and volume. For international buyers, understanding the logistics costs, including customs duties and potential tariffs, is critical to accurately assessing the total cost.

-

Margin: Suppliers typically build a margin into their pricing to ensure profitability. This margin can vary based on the supplier’s market positioning, brand reputation, and the competitive landscape.

How Do Price Influencers Impact Custom Leather Stamp Pricing?

Various factors can influence the pricing of custom leather stamps, making it essential for buyers to understand these dynamics:

-

Volume/MOQ: Manufacturers often offer better pricing for bulk orders. Understanding minimum order quantities (MOQ) can help buyers negotiate better deals. Larger orders can reduce per-unit costs, making it beneficial for businesses with ongoing needs.

-

Specifications/Customization: The more customized the stamp, the higher the cost. Unique designs, sizes, and features will incur additional charges. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Material Quality/Certifications: Stamps made from certified materials may come at a premium. Certifications can assure buyers of material quality and compliance with industry standards, which is particularly relevant in regulated markets.

-

Supplier Factors: Supplier reputation, location, and production capabilities can significantly affect pricing. Established suppliers may charge more due to their experience and reliability. Additionally, suppliers in regions with lower production costs may offer competitive pricing.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect logistics costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for budgeting and financial planning.

What Are Effective Buyer Tips for Custom Leather Stamp Sourcing?

-

Negotiation: Engage in discussions with suppliers about pricing structures and potential discounts for larger orders. Being informed about market rates can provide leverage during negotiations.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential replacement expenses. Opting for higher-quality stamps may yield better long-term value despite higher upfront costs.

-

International Pricing Nuances: For buyers in regions like Africa and South America, currency fluctuations and import duties can impact pricing. It’s crucial to account for these factors when making purchasing decisions.

-

Research Suppliers: Investigate multiple suppliers to compare pricing, quality, and customer service. Reading reviews and testimonials can provide insights into supplier reliability and product performance.

-

Request Prototypes: Before placing a large order, consider requesting a prototype or sample stamp. This can help assess quality and suitability for your specific applications, reducing the risk of larger investments in unsatisfactory products.

By understanding these cost structures, price influencers, and effective sourcing strategies, B2B buyers can make informed decisions when procuring custom leather stamps, ensuring they receive quality products that meet their specific needs.

Alternatives Analysis: Comparing custom leather stamp maker With Other Solutions

Exploring Alternative Solutions to Custom Leather Stamp Makers

When considering options for creating leather stamps, businesses may encounter various alternative solutions that can serve similar purposes. This analysis will compare the custom leather stamp maker with two other viable methods: traditional hand stamping and laser engraving. Understanding the strengths and weaknesses of each option is essential for B2B buyers looking to make informed decisions.

Comparison Table

| Comparison Aspect | Custom Leather Stamp Maker | Traditional Hand Stamping | Laser Engraving |

|---|---|---|---|

| Performance | High precision and detail | Variable, dependent on skill | Extremely high precision |

| Cost | Moderate ($89 – $4,250) | Low to moderate (tools vary) | High initial investment |

| Ease of Implementation | Straightforward ordering process | Requires skilled labor and practice | Requires specialized machinery |

| Maintenance | Minimal, durable materials | Moderate, tools may wear out | Regular maintenance of equipment |

| Best Use Case | Custom branding and logos | Artisan crafts and small batches | High-volume production and detail |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Traditional Hand Stamping?

Traditional hand stamping involves using metal stamps struck with a hammer to imprint designs onto leather. This method is often favored by artisans for its tactile nature and creative control. However, the performance can vary significantly based on the skill of the operator. While the initial costs for tools may be low, the time required for training and practice can be a drawback. This method is best suited for small-scale projects or artisanal work where each piece requires a personal touch.

How Does Laser Engraving Compare to Custom Leather Stamp Makers?

Laser engraving technology offers exceptional precision and speed, making it ideal for high-volume production. This method uses a laser beam to etch designs into the leather, allowing for intricate detailing that might be difficult to achieve with traditional stamping. However, the initial investment in laser equipment can be substantial, and the technology requires regular maintenance. Laser engraving is best suited for businesses looking to produce large quantities of customized leather goods quickly and efficiently.

Illustrative image related to custom leather stamp maker

Conclusion: Which Solution is Right for Your Business Needs?

Choosing the right solution for leather stamping hinges on specific business needs and operational capabilities. If precision and customization are paramount, a custom leather stamp maker may offer the best balance of quality and ease of use. Traditional hand stamping is perfect for artisans and small-scale operations that prioritize craft over volume. In contrast, laser engraving is the go-to for companies needing speed and precision in high-volume production. By carefully considering the performance, cost, ease of implementation, and maintenance of each option, B2B buyers can select the solution that aligns best with their goals and resources.

Essential Technical Properties and Trade Terminology for custom leather stamp maker

What Are the Key Technical Properties for Custom Leather Stamps?

Understanding the essential technical properties of custom leather stamps is crucial for B2B buyers to make informed decisions. Here are several critical specifications to consider:

1. Material Composition

The most common materials used for custom leather stamps are brass and steel. Brass offers excellent durability and is resistant to corrosion, making it ideal for detailed stamping. Steel, particularly hardened steel, is robust and can withstand heavy use without deforming. Selecting the right material is vital for ensuring the longevity and quality of the stamps.

2. Stamp Thickness

Stamp thickness can vary significantly, with options typically ranging from 1/4 inch to 1 inch. Thicker stamps provide deeper impressions, which can be essential for designs that require high detail and durability. This property is especially important in industries where repeated use is expected, such as leather goods manufacturing.

Illustrative image related to custom leather stamp maker

3. Tolerance Levels

Tolerance refers to the allowable variation in the dimensions of the stamp. Precision in this measurement ensures that the stamp fits seamlessly into the production process, especially when used with automated machines. Tighter tolerances are often required for high-volume production, minimizing waste and ensuring consistency in branding.

4. Design Complexity

The ability to create intricate designs is a significant property of custom leather stamps. Advanced manufacturing techniques, such as CNC milling, allow for high-detail logos and custom artwork. This capability is crucial for businesses that prioritize branding and want to differentiate their products in competitive markets.

5. Application Compatibility

Custom leather stamps should be compatible with various applications, including handheld use, hydraulic presses, and branding irons. Understanding the intended use will influence the choice of stamp design and material. B2B buyers must ensure that the chosen stamps meet the specific needs of their production methods.

6. Finish Quality

The finish of the stamp, whether polished or textured, affects the impression left on the leather. A smooth finish is often preferred for logos, while a textured finish can add an artistic touch. The finish quality influences not only the aesthetic appeal but also the durability of the imprint.

What Are Common Trade Terms in the Custom Leather Stamp Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are several common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom leather stamps, an OEM may create stamps based on the specifications provided by a leather goods manufacturer, ensuring a tailored fit for their products.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to produce or sell. Understanding the MOQ is crucial for buyers as it can affect inventory levels and cash flow. For custom leather stamps, MOQs can vary based on design complexity and material type.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit pricing and terms from suppliers. When seeking custom leather stamps, submitting an RFQ allows buyers to compare options and negotiate terms effectively, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for managing shipping costs, insurance, and risk during the delivery of custom leather stamps.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the final product. For custom leather stamps, lead times can vary based on design complexity and production capacity. Knowing the lead time helps businesses plan their production schedules and manage customer expectations.

6. Customization Options

Customization options encompass the various ways in which a stamp can be tailored to meet specific needs, such as size, shape, and design. This flexibility allows businesses to create unique branding elements that resonate with their target audience, making it a vital aspect of product differentiation.

By understanding these properties and terms, B2B buyers can navigate the custom leather stamp market with confidence, ensuring they select the right products for their needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather stamp maker Sector

What Are the Current Trends Shaping the Custom Leather Stamp Maker Market?

The custom leather stamp maker sector is experiencing significant growth, driven by increasing demand for personalized products across various industries, including fashion, crafts, and leather goods manufacturing. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking unique branding solutions that reflect their identity and values. Key trends include the rise of e-commerce platforms, which facilitate easier access to suppliers and a wider variety of customization options.

Emerging technologies, such as CNC milling and laser engraving, are enhancing the precision and efficiency of stamp production. These innovations not only improve product quality but also reduce lead times, making it easier for businesses to respond to market demands quickly. Additionally, the integration of digital tools in the ordering process—like virtual proofs and real-time customization options—streamlines the customer experience, allowing buyers to visualize their designs before committing to purchase.

Furthermore, a growing emphasis on quality and craftsmanship is leading buyers to seek suppliers who offer detailed specifications and robust customer support. This trend is particularly evident in markets like Germany and Nigeria, where buyers prioritize durability and the ability to create intricate designs. As the market continues to evolve, suppliers that can combine advanced technology with exceptional service are poised to capture a larger share of the international B2B market.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Stamp Maker Industry?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the custom leather stamp maker sector. The environmental impact of leather production, including concerns about deforestation and chemical waste, has prompted many companies to seek suppliers who prioritize eco-friendly practices. This shift is particularly relevant in regions like Europe, where consumers are more environmentally conscious and regulatory frameworks are becoming stricter.

Illustrative image related to custom leather stamp maker

Buyers are now looking for suppliers that utilize vegetable-tanned leather and other sustainable materials, which have a lower environmental footprint compared to traditional tanning methods. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers seeking to establish credibility in the market.

Moreover, ethical supply chains that ensure fair labor practices and transparency are crucial for maintaining brand integrity. Buyers are increasingly inclined to partner with manufacturers that demonstrate a commitment to social responsibility, further influencing their sourcing decisions. As sustainability continues to be a central theme in global trade, suppliers who adopt green practices will not only attract more customers but also enhance their reputation in the competitive landscape.

What Historical Factors Have Influenced the Custom Leather Stamp Maker Sector?

The custom leather stamp maker sector has evolved significantly over the past few decades, shaped by technological advancements and changing consumer preferences. Traditionally, leather stamping was a labor-intensive craft, relying heavily on manual processes. However, the introduction of computer-aided design (CAD) and CNC technology has revolutionized the industry, enabling greater precision and mass customization.

Historically, leather was primarily sourced from local tanneries, with a focus on traditional craftsmanship. As global trade expanded, the supply chain became more complex, allowing for a wider variety of materials and techniques to be utilized. This evolution has facilitated the rise of international suppliers who can offer competitive pricing and faster turnaround times, catering to the diverse needs of B2B buyers worldwide.

In recent years, the resurgence of interest in artisanal and handmade products has prompted a renewed appreciation for quality and craftsmanship. As a result, suppliers who can blend traditional techniques with modern technology are increasingly sought after, ensuring their place in a market that values both heritage and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp maker

-

How do I ensure the quality of custom leather stamps before purchase?

To verify the quality of custom leather stamps, request samples or proofs from the manufacturer. Many reputable suppliers will provide a virtual proof based on your design before proceeding with production. Additionally, inquire about the materials used; high-quality stamps are typically made from solid brass or steel. Check customer reviews and testimonials for insights into the supplier’s craftsmanship and service reliability. Establishing a clear communication channel with the manufacturer is essential to address any specific quality concerns you may have. -

What factors should I consider when choosing a custom leather stamp maker?

When selecting a custom leather stamp maker, consider the following factors: their experience and expertise in the industry, the quality of materials used, customization options available, turnaround time for orders, and customer service responsiveness. Additionally, evaluate their pricing structure and whether they offer bulk order discounts. Reviewing customer testimonials and case studies can provide insights into the company’s reliability and product quality. Ensure that they can accommodate your specific needs, especially if you require unique designs or large quantities. -

What is the minimum order quantity (MOQ) for custom leather stamps?

The minimum order quantity (MOQ) for custom leather stamps can vary significantly between manufacturers. Some suppliers may offer flexibility with low MOQs, making it feasible for small businesses or startups. However, larger manufacturers often have a standard MOQ, typically ranging from 10 to 50 units. It’s essential to discuss your requirements with potential suppliers to understand their MOQ policies. If you anticipate regular orders, negotiating a lower MOQ for future transactions may also be beneficial. -

What payment terms are commonly offered by custom leather stamp makers?

Payment terms can vary by manufacturer and often depend on the order size and your relationship with the supplier. Common terms include full payment upfront, a deposit followed by the balance upon delivery, or net terms (e.g., net 30 days). Always clarify payment methods accepted, such as credit cards, bank transfers, or online payment platforms. For international transactions, consider discussing currency exchange rates and potential fees. Establishing clear payment terms upfront helps prevent misunderstandings and ensures a smooth transaction. -

How can I verify the reliability of a custom leather stamp supplier?

To verify a supplier’s reliability, conduct thorough research, including checking their business credentials, certifications, and industry reputation. Look for reviews on independent platforms and seek references from previous clients. Engaging in direct communication can also provide insight into their responsiveness and professionalism. If possible, visit their facilities or request a video tour to see their operations firsthand. Establishing a good rapport with the supplier can further indicate their commitment to quality and customer satisfaction. -

What customization options are available for leather stamps?

Customization options for leather stamps typically include design elements such as logos, text, shapes, and sizes. Many suppliers allow you to submit your artwork or collaborate with their design team to create a unique stamp that meets your specifications. You may also have choices regarding the type of material used, such as brass or steel, and whether you want handheld stamps or those compatible with machines. Discussing your specific needs with the supplier will help ensure that they can accommodate your customization requests effectively. -

What logistics considerations should I keep in mind when sourcing custom leather stamps internationally?

When sourcing custom leather stamps internationally, consider logistics factors such as shipping methods, customs duties, and import regulations. Discuss the supplier’s shipping options and estimated delivery times, as these can impact your project timelines. Ensure that you understand any additional costs associated with customs clearance, as well as the documentation required for international shipments. Building a relationship with a reliable freight forwarder can also help streamline the shipping process and mitigate potential delays. -

How do I handle quality assurance for custom leather stamps upon delivery?

Upon delivery of your custom leather stamps, conduct a thorough inspection to ensure they meet your specifications and quality standards. Check for accuracy in design, dimensions, and finish. It’s advisable to test the stamps on sample leather to assess their performance and durability. If any discrepancies are found, promptly communicate with the supplier to address the issue, as many reputable manufacturers will have a return or correction policy. Establishing a quality assurance process will help maintain high standards for your products.

Top 8 Custom Leather Stamp Maker Manufacturers & Suppliers List

1. Infinity Stamps – Leather Stamping Products

Domain: infinitystamps.com

Registered: 2001 (24 years)

Введение: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders. The company has been family-owned for over 25 years and emphasizes that all products are made in the USA.

2. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Введение: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets available. Custom stamps are CNC milled from solid brass, thickness up to 1″. Can be used with branding irons and standard presses. Custom leather cutting dies made from solid steel, compatible with mechanical, hydraulic, or clicker presses….

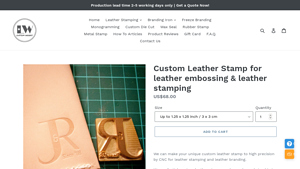

3. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Введение: Custom Leather Stamp for leather embossing & leather stamping\nRegular price: US$68.00\nSize options: Up to 1.25 x 1.25 inch (3 x 3 cm), Up to 1.5 x 1.5 inch (4 x 4 cm), Up to 2 x 2 inch (5 x 5 cm), Up to 3 x 3 inch (7.5 x 7.5 cm), Up to 4 x 4 inch (10 x 10 cm)\nProduction lead time: 2-5 working days (rush orders available)\nMaterial: Solid Brass\nStamp thickness: 8mm\nEngraving depth: 3mm\nApplic…

4. Tandy Leather – Custom Stamps

Domain: tandyleather.com

Registered: 1996 (29 years)

Введение: This company, Tandy Leather – Custom Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Введение: Custom Leather Stamps available at Steel Stamps Inc. include various categories such as Custom Jewelry Stamps, Custom Steel Stamps for Knife Makers, Blacksmiths, and Farriers, as well as Custom Locksmith Stamps and Industrial Markings. The collection features Leather Design Stamps, including Sheridan Flowers/Leaves, Leather State Stamps, and Jewelry Design Stamps. There are also Pro Series Designs…

6. Gearheart Industry – Custom Leather Stamp

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Введение: {“product_name”: “Custom Leather Stamp”, “price”: “$119.00”, “dimensions”: [“1” x “1””, “1” x “1.5””, “1.5” x “1.5””], “production_time”: [“Standard (5 Business Days)”, “RUSH (1 Business Day)”], “file_types”: [“bmp”, “gif”, “jpg”, “jpeg”, “jpe”, “jif”, “jfif”, “jfi”, “png”, “wbmp”, “xbm”, “tiff”, “ai”, “eps”, “pdf”], “max_file_size”: “524288KB”, “features”: [“Custom made per your specifications”, …

7. Buckeye Engraving – Custom Leather Stamps & Branding Irons

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Введение: Buckeye Engraving offers custom leather stamps, dies, and branding irons made in the USA. The stamps can be manufactured from aluminum, steel, or brass, with brass being the most popular choice among leather makers due to its durability and resistance to rust. The company provides options for high-detail engraving and can assist in creating original designs from artwork, signatures, or sketches. L…

8. Custom Brand – Leather Embossing Stamp

Strategic Sourcing Conclusion and Outlook for custom leather stamp maker

In the evolving landscape of custom leather stamping, strategic sourcing emerges as a pivotal factor for B2B buyers seeking high-quality, tailored solutions. By prioritizing suppliers who offer rapid turnaround times, exceptional customer service, and a commitment to quality craftsmanship, businesses can significantly enhance their operational efficiency and product offerings. The ability to customize designs—from intricate logos to unique shapes—enables brands to create distinctive products that resonate with their target markets.

Furthermore, understanding the nuances of sourcing materials, such as the type of leather and stamping tools, is essential for achieving optimal results. Buyers should consider the full range of options available—from brass stamps to cutting dies—and leverage the expertise of manufacturers to navigate the complexities of their projects.

As international buyers from regions like Africa, South America, the Middle East, and Europe pursue these opportunities, the potential for growth and innovation in the leather goods sector is immense. Engage with reliable suppliers today to explore how custom leather stamps can elevate your brand and expand your market reach. Your next successful project starts with a strategic sourcing partnership that aligns with your vision and values.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather stamp maker