Introduction: Navigating the Global Market for custom leather patches for jackets

In the ever-evolving landscape of fashion and apparel, sourcing custom leather patches for jackets poses a unique challenge for international B2B buyers. As businesses strive to differentiate their offerings and enhance brand identity, the demand for high-quality, personalized leather patches is surging. This guide serves as a comprehensive resource, addressing crucial aspects such as types of patches, applications, supplier vetting processes, and cost considerations. By delving into these topics, we aim to equip buyers, particularly from Africa, South America, the Middle East, and Europe—regions with diverse market dynamics and consumer preferences—with the knowledge needed to make informed purchasing decisions.

Navigating the global market for custom leather patches can be daunting, with myriad options and suppliers to choose from. This guide streamlines the process by providing actionable insights and expert recommendations, ensuring that you can identify the best suppliers that align with your specific needs. Whether you are looking to embellish jackets for a fashion line, create promotional items, or enhance merchandise for events, understanding the nuances of custom leather patches will empower you to elevate your brand’s appeal and connect with your target audience more effectively. As you explore the sections ahead, you will gain clarity on how to leverage custom leather patches as a vital component of your branding strategy, driving growth and customer loyalty in competitive markets.

Table Of Contents

- Top 6 Custom Leather Patches For Jackets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather patches for jackets

- Understanding custom leather patches for jackets Types and Variations

- Key Industrial Applications of custom leather patches for jackets

- 3 Common User Pain Points for ‘custom leather patches for jackets’ & Their Solutions

- Strategic Material Selection Guide for custom leather patches for jackets

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather patches for jackets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather patches for jackets’

- Comprehensive Cost and Pricing Analysis for custom leather patches for jackets Sourcing

- Alternatives Analysis: Comparing custom leather patches for jackets With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather patches for jackets

- Navigating Market Dynamics and Sourcing Trends in the custom leather patches for jackets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather patches for jackets

- Strategic Sourcing Conclusion and Outlook for custom leather patches for jackets

- Important Disclaimer & Terms of Use

Understanding custom leather patches for jackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laser Engraved Patches | High detail, permanent engraving, multiple finishes available | Branding, promotional items | Pros: Durable, precise, customizable. Cons: Higher initial cost. |

| Iron-On Patches | Easy application, heat-activated backing, suitable for various fabrics | Casual wear, team uniforms | Pros: Quick to apply, no sewing required. Cons: May not withstand washing. |

| Sew-On Patches | Traditional application, highly durable, can be customized in shape and size | Fashion, motorcycle jackets | Pros: Long-lasting, versatile. Cons: Requires sewing skills. |

| Embroidered Patches | Textured finish, colorful threads, can include intricate designs | Fashion brands, sports teams | Pros: Eye-catching, high-quality appearance. Cons: Can be more expensive. |

| Custom Shapes & Sizes | Tailored designs, various dimensions, unique branding options | Niche markets, promotional events | Pros: Unique branding, adaptable to any design. Cons: May require minimum order quantities. |

What Are Laser Engraved Patches and Their B2B Benefits?

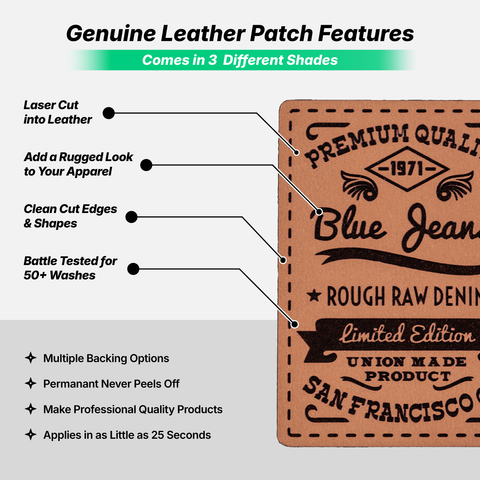

Laser engraved patches are characterized by their high detail and durability, making them an excellent choice for businesses seeking to create a lasting impression. The engraving process allows for intricate designs and logos, which can enhance brand visibility on jackets and other apparel. B2B buyers should consider the initial investment, as these patches can be more costly than simpler options, but their longevity and quality often justify the expense.

How Do Iron-On Patches Work for B2B Applications?

Iron-on patches offer a convenient and efficient way to customize jackets, especially for casual wear and team uniforms. Their heat-activated backing allows for quick application without the need for sewing, making them ideal for businesses needing rapid turnaround times. However, B2B buyers should be aware that while these patches are easy to apply, they may not hold up well under frequent washing, which could limit their lifespan in certain applications.

Illustrative image related to custom leather patches for jackets

Why Choose Sew-On Patches for Durability?

Sew-on patches are the traditional method for applying patches to jackets and are known for their durability and versatility. This type can be customized in various shapes and sizes, catering to different branding needs. For B2B buyers, the main consideration should be the need for sewing skills or equipment, as this option requires a more hands-on approach compared to iron-on alternatives. The long-lasting nature of sew-on patches makes them a worthwhile investment for businesses looking to enhance their brand presence.

What Advantages Do Embroidered Patches Offer?

Embroidered patches are popular for their textured finish and vibrant colors, making them visually appealing for brands in fashion and sports. Their intricate designs can elevate the aesthetic of jackets, appealing to a wide range of customers. While they can be more expensive than other types of patches, their quality often leads to a higher perceived value. B2B buyers should evaluate the cost versus the potential for increased brand recognition and customer loyalty.

How Do Custom Shapes and Sizes Enhance Branding?

Custom-shaped patches allow businesses to break away from standard designs, providing unique branding opportunities tailored to specific needs. This flexibility is particularly beneficial for niche markets or promotional events where standout designs can attract attention. However, B2B buyers should be mindful of potential minimum order quantities and the associated costs, as custom patches may require larger orders to be economically viable.

Key Industrial Applications of custom leather patches for jackets

| Industry/Sector | Specific Application of Custom Leather Patches for Jackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Branding and Customization of Jackets | Enhances brand visibility and customer loyalty | Quality of leather, customization options, lead times |

| Automotive & Motorsports | Team and Club Identity for Racing Jackets | Fosters team spirit and a professional appearance | Durability under harsh conditions, design flexibility |

| Outdoor & Adventure | Functional Patches for Outdoor Gear | Adds utility, such as repair or identification | Weather resistance, attachment methods, size variations |

| Hospitality & Events | Custom Souvenirs for Events and Promotions | Creates memorable experiences and brand recognition | Design options, bulk ordering, turnaround times |

| Military & Tactical | Identification and Morale Patches for Uniforms | Enhances unit cohesion and professional appearance | Compliance with regulations, durability, custom designs |

How are Custom Leather Patches for Jackets Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, custom leather patches are primarily used for branding and personalization of jackets. Brands utilize these patches to display logos or unique designs, enhancing brand visibility and fostering customer loyalty. Buyers in this industry, particularly from regions like Africa and South America, must consider factors such as the quality of leather, customization options, and lead times to ensure timely delivery and product excellence.

Illustrative image related to custom leather patches for jackets

What Role Do Custom Leather Patches Play in the Automotive & Motorsports Sector?

In the automotive and motorsports industry, custom leather patches are frequently used on racing jackets to signify team identity and affiliation. These patches not only enhance the professional appearance of team members but also foster a sense of unity and pride. For international buyers, especially in the Middle East and Europe, sourcing durable patches that withstand the rigors of racing conditions is essential, along with the ability to customize designs to reflect team branding effectively.

How Do Custom Leather Patches Enhance Outdoor & Adventure Gear?

Custom leather patches are increasingly applied to outdoor jackets and gear to provide functionality, such as repair patches or identification markers. They enhance the utility of the apparel while also adding a rugged aesthetic. Buyers in this sector should prioritize sourcing weather-resistant materials and consider various attachment methods to ensure longevity and performance in diverse outdoor conditions, particularly in regions with extreme climates.

In What Ways Are Custom Leather Patches Used for Hospitality & Events?

In the hospitality industry, custom leather patches serve as unique souvenirs for events or promotional activities. They enhance the guest experience by providing memorable takeaways that promote brand recognition. Businesses looking to source these patches should focus on design options that resonate with their target audience, as well as bulk ordering capabilities to ensure they meet demand during peak seasons or events.

How Are Custom Leather Patches Utilized in Military & Tactical Applications?

In military and tactical settings, custom leather patches are vital for identification and morale within units. These patches contribute to a professional appearance while reinforcing unit cohesion. Buyers from military sectors must ensure that the patches comply with specific regulations and standards, while also focusing on durability and the ability to customize designs that reflect unit identity and values.

3 Common User Pain Points for ‘custom leather patches for jackets’ & Their Solutions

Scenario 1: Sourcing High-Quality Custom Leather Patches

The Problem: Many B2B buyers encounter difficulties when trying to source high-quality custom leather patches that meet their specific design requirements. Whether it’s for a new fashion line or promotional merchandise, the challenge often lies in finding a supplier that can deliver not only the desired aesthetics but also durability and craftsmanship. Inconsistent quality, delays in delivery, and lack of transparency in sourcing can lead to dissatisfaction and lost business opportunities.

The Solution: To overcome this issue, buyers should conduct thorough research on potential suppliers. Start by examining their portfolio for past projects that align with your vision. Look for reviews or testimonials from previous clients to gauge their reliability and product quality. It’s also advisable to request samples before placing a bulk order; this allows you to assess the texture, color, and stitching quality firsthand. Establish a clear line of communication with the supplier to ensure that your design specifications are fully understood and can be met within your timeline. Additionally, consider suppliers who offer guarantees or warranties on their products to further secure your investment.

Scenario 2: Ensuring Proper Application Methods for Longevity

The Problem: Another common pain point for B2B buyers is the application of custom leather patches. Many buyers may not be aware of the best methods for attaching patches to jackets, leading to potential damage or patch failure. Incorrect application can result in peeling, fraying, or even damage to the leather itself, which can tarnish the brand’s reputation and lead to costly returns.

The Solution: To ensure a successful application, it’s crucial to educate your team on the various methods available for attaching leather patches. For instance, sewing is often the most reliable method as it provides strong durability. If opting for iron-on patches, verify the heat tolerance of the leather to avoid melting or warping. Utilize quality heat presses with precise temperature and pressure settings, as indicated by the patch manufacturer. Offering training sessions or instructional materials for staff on proper application techniques can significantly reduce errors. Additionally, consider packaging your patches with clear application instructions to assist customers in applying them correctly, which can enhance their overall experience with your product.

Scenario 3: Navigating Design and Customization Challenges

The Problem: B2B buyers frequently struggle with the design and customization aspects of their leather patches. Whether it’s translating a logo into a patch or ensuring that the colors used in the patch align with brand guidelines, the design process can become convoluted and time-consuming. Miscommunication during this phase can lead to results that do not meet expectations, wasting time and resources.

Illustrative image related to custom leather patches for jackets

The Solution: To streamline the design process, invest in a collaborative approach with your supplier. Start with a detailed design brief that outlines your vision, including color palettes, dimensions, and any specific features you want. Utilize design software or templates provided by the supplier to create mock-ups that visually represent your ideas. Regular check-ins and feedback loops during the design phase can help catch any discrepancies early on. Additionally, suppliers who offer digital proofs before final production can ensure that the design meets your expectations and adheres to brand standards. This proactive approach not only enhances satisfaction but also minimizes the risk of costly revisions down the line.

Strategic Material Selection Guide for custom leather patches for jackets

When selecting materials for custom leather patches for jackets, B2B buyers must consider various factors that affect performance, durability, and overall suitability. This guide analyzes four common materials used in the production of leather patches, providing insights into their properties, advantages, disadvantages, and considerations for international buyers.

What Are the Key Properties of Genuine Leather for Custom Patches?

Genuine leather is a popular choice for custom patches due to its natural aesthetic and durability. It typically has a temperature resistance of up to 200°F, making it suitable for applications that may involve exposure to heat. Additionally, genuine leather is resistant to corrosion and wear, maintaining its appearance over time.

Pros: Genuine leather offers a premium look and feel, making it ideal for high-end jackets. It is highly durable and can withstand environmental stresses, making it suitable for outdoor apparel.

Cons: The cost of genuine leather is relatively high compared to synthetic alternatives. Additionally, it requires specific care to maintain its quality, which may not be suitable for all end-users.

Illustrative image related to custom leather patches for jackets

Impact on Application: Genuine leather patches can be sewn or heat-applied, but care must be taken to avoid damage from excessive heat. This material is compatible with various fabrics, but its care requirements may limit its use on items that require frequent washing.

How Do Synthetic Leather Options Compare for Custom Patches?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is an alternative to genuine leather that offers a similar aesthetic at a lower cost. It typically has a temperature rating of around 140°F, making it less heat-resistant than genuine leather.

Pros: Synthetic leather is more affordable and easier to clean, making it a practical choice for mass production. It is also available in a wide range of colors and finishes, allowing for greater customization.

Illustrative image related to custom leather patches for jackets

Cons: While synthetic leather is durable, it may not provide the same level of longevity as genuine leather. It is also less breathable, which can affect comfort when used on jackets.

Impact on Application: Synthetic leather patches can be heat-applied or sewn, but they may not adhere well to all fabric types, particularly those that are textured or have an oil finish. Buyers should consider the specific media compatibility when selecting this material.

What Are the Benefits of Suede for Custom Leather Patches?

Suede, a type of leather with a napped finish, offers a unique texture that can enhance the visual appeal of custom patches. It is generally more temperature-sensitive, with a resistance of around 130°F.

Pros: Suede provides a soft, luxurious feel and is visually appealing, making it suitable for fashion-forward applications. It can be easily cut and shaped, allowing for intricate designs.

Cons: Suede is less durable than other leather types and can be prone to staining and water damage. Its care requirements are also more stringent, which may deter some buyers.

Illustrative image related to custom leather patches for jackets

Impact on Application: Suede patches are best suited for jackets that are not frequently washed. They can be sewn or heat-applied, but buyers should be cautious about the application method to avoid damaging the material.

How Does Faux Leather Stand Up in the Market for Custom Patches?

Faux leather, made from synthetic materials designed to mimic the look and feel of real leather, is increasingly popular among eco-conscious consumers. Its temperature resistance is similar to that of synthetic leather, typically around 140°F.

Pros: Faux leather is often more affordable than genuine leather and is available in a variety of colors and textures. It is also easier to maintain, making it a practical option for high-volume production.

Cons: The durability of faux leather can be lower than that of genuine leather, and it may not age as gracefully. Additionally, it may lack the premium feel that some consumers desire.

Impact on Application: Faux leather patches can be easily applied to various fabrics, but buyers should consider the overall quality and finish to ensure compatibility with their products.

Summary Table of Material Selection for Custom Leather Patches

| Material | Typical Use Case for custom leather patches for jackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end jackets, outdoor apparel | Premium look and durability | High cost, requires special care | High |

| Synthetic Leather | Mass-produced jackets, budget-friendly options | Affordable, wide customization | Less durable, less breathable | Medium |

| Suede | Fashion jackets, luxury apparel | Soft texture, visually appealing | Prone to staining, less durable | Medium |

| Faux Leather | Eco-friendly options, budget-conscious products | Easy maintenance, affordable | Lower durability, less premium feel | Low |

This strategic material selection guide equips B2B buyers with the necessary insights to make informed decisions when sourcing custom leather patches for jackets, ensuring that they meet both market demands and compliance standards across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather patches for jackets

What Are the Key Stages in the Manufacturing Process of Custom Leather Patches for Jackets?

The manufacturing process for custom leather patches involves several stages that ensure quality and durability. Understanding these stages is crucial for B2B buyers, especially when sourcing from different regions like Africa, South America, the Middle East, and Europe.

Material Preparation: What Should Buyers Know?

The first step in creating custom leather patches is the selection and preparation of materials. High-quality leather is sourced based on the desired texture, color, and durability. Buyers should inquire about the type of leather used, such as full-grain or top-grain, as these will affect the patch’s longevity and appearance. The leather is then cut into the required shapes and sizes, often using precision cutting tools like laser cutters or dies.

Illustrative image related to custom leather patches for jackets

Buyers should look for suppliers who utilize eco-friendly tanning processes and sustainable sourcing practices, as these factors can significantly influence the final product’s quality and environmental footprint.

Forming: How Are Custom Designs Created?

After material preparation, the forming stage involves customizing the patches according to specific designs. This may include laser engraving, embossing, or printing logos and artwork directly onto the leather. Advanced technology, such as CNC machines, can produce intricate designs with high precision, ensuring that the final product aligns with the buyer’s expectations.

For B2B buyers, it’s essential to verify the technology employed by manufacturers. Suppliers should be able to provide samples of previous work to demonstrate their capability in handling complex designs.

Assembly: What Techniques Ensure Quality?

During the assembly phase, patches may undergo various techniques to enhance their functionality and aesthetics. Common methods include sewing, heat bonding, or using adhesive backings. Each technique has its advantages; for instance, sewn patches tend to be more durable, while heat-bonded patches offer a cleaner finish.

Buyers should assess the assembly techniques used by potential suppliers, as this can affect the patch’s performance, especially in high-wear applications like jackets. It is advisable to ask for details on stitching methods, thread types, and adhesive quality to ensure the patches will withstand regular use.

Finishing: What Steps Are Taken for a Professional Look?

The finishing stage is crucial for achieving a polished and professional appearance. This includes processes like edge sealing, dyeing, and applying protective coatings. Edge sealing prevents fraying, while dyes enhance the leather’s color and aesthetic appeal. Protective coatings can offer additional resistance to water and stains, making the patches more suitable for various environments.

B2B buyers should inquire about the finishing processes used, as these can directly impact the product’s lifespan and appearance. Requesting product samples for evaluation can help in making informed decisions.

How Is Quality Assurance Implemented in Custom Leather Patch Production?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that products meet specific standards before reaching the market. For international B2B buyers, understanding the QA protocols in place is essential for mitigating risks associated with sourcing.

Illustrative image related to custom leather patches for jackets

What International Standards Should Buyers Be Aware Of?

Many manufacturers adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a manufacturer has established processes to ensure product consistency and quality. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) may be relevant, depending on the intended use of the leather patches.

Buyers should request documentation of compliance with these standards and inquire about the manufacturer’s history of successful audits. This information can help establish trust and reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for defects before production begins. This ensures that only high-quality leather is used in manufacturing.

-

In-Process Quality Control (IPQC): Throughout the production process, manufacturers should conduct regular checks to ensure that each stage is performed correctly. This includes monitoring cutting accuracy, engraving precision, and assembly integrity.

-

Final Quality Control (FQC): Once the patches are completed, a final inspection is conducted to ensure that they meet the specified requirements. This may include checking dimensions, design accuracy, and overall appearance.

Buyers should ask potential suppliers about their QC processes and how they handle defects or deviations from standards.

Illustrative image related to custom leather patches for jackets

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is crucial for ensuring that the products meet expectations. Here are several approaches that buyers can take:

-

Conducting Audits: Buyers can perform audits of potential suppliers to assess their manufacturing and QC processes. This can be done in person or through third-party audit services.

-

Requesting Reports: Suppliers should be willing to provide quality control reports, including results from IQC, IPQC, and FQC. These documents can provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and the final products.

What Nuances Should International B2B Buyers Consider?

When sourcing custom leather patches from international suppliers, B2B buyers should consider regional nuances that may affect quality and compliance. For example, regulations regarding leather sourcing, environmental standards, and labor practices can vary significantly between regions like Africa, South America, the Middle East, and Europe.

Buyers should familiarize themselves with these regulations and ensure that their suppliers comply. This may involve additional documentation or certifications, particularly when importing goods across borders.

In conclusion, understanding the manufacturing processes and quality assurance protocols for custom leather patches is vital for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and robust QC measures, buyers can ensure they partner with reliable manufacturers that deliver high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather patches for jackets’

To successfully procure custom leather patches for jackets, it is essential to follow a systematic approach that ensures quality, compliance, and alignment with your brand’s needs. This guide serves as a comprehensive checklist for B2B buyers looking to navigate the sourcing process effectively.

Illustrative image related to custom leather patches for jackets

Step 1: Define Your Technical Specifications

Clearly outlining your requirements is the first step in the sourcing process. Consider factors such as the size, shape, color, and design of the patches, along with the type of leather you prefer (genuine, suede, etc.). Specificity here helps suppliers understand your needs and reduces the risk of miscommunication later.

- Design Complexity: Determine if you need simple logos or intricate designs, as this will affect production techniques and costs.

- Attachment Methods: Decide whether you want iron-on, sew-on, or adhesive patches based on the intended use and material of the jackets.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for companies with a proven track record in producing custom leather patches. Online reviews, case studies, and testimonials from previous clients can provide insights into their capabilities and service quality.

- Industry Experience: Prioritize suppliers who specialize in leather products and have experience with your specific market.

- Geographic Considerations: Consider suppliers located in regions with established leather industries, as they may offer better quality and pricing.

Step 3: Evaluate Supplier Certifications

Ensuring that your chosen supplier meets industry standards is vital for quality assurance. Look for certifications that indicate adherence to quality management systems, environmental standards, and ethical practices.

Illustrative image related to custom leather patches for jackets

- ISO Certifications: Check for ISO 9001 for quality management and ISO 14001 for environmental management.

- Fair Trade Practices: Ensure suppliers adhere to fair labor practices, especially if sourcing from developing regions.

Step 4: Request Samples

Before placing a bulk order, always request samples of the patches. This allows you to assess the quality of materials, craftsmanship, and how well the designs match your specifications.

- Material Quality: Inspect the leather for texture, durability, and finish.

- Design Accuracy: Verify that the colors and designs align with your expectations.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted potential suppliers, engage in negotiations to secure the best pricing and terms. Understand the minimum order quantities, lead times, and payment terms that each supplier offers.

- Bulk Discounts: Inquire about discounts for larger orders which can significantly reduce costs.

- Payment Flexibility: Discuss payment terms, including deposits and net payment options, to ensure they align with your cash flow needs.

Step 6: Confirm Production and Delivery Timelines

Establish clear timelines for production and delivery to avoid delays that could impact your operations. Confirm these timelines in writing to ensure accountability.

- Production Capacity: Assess the supplier’s capacity to meet your deadlines, especially during peak seasons.

- Shipping Logistics: Factor in international shipping times and customs clearance, particularly if sourcing from overseas.

Step 7: Review and Finalize the Contract

Before finalizing your order, ensure that all terms are documented in a contract. This should include specifications, pricing, delivery timelines, and any warranties or guarantees.

Illustrative image related to custom leather patches for jackets

- Legal Considerations: Consult with legal counsel if necessary to ensure that the contract protects your interests.

- Amendment Clauses: Include clauses for potential changes in order specifications or delivery due to unforeseen circumstances.

By following these steps, B2B buyers can effectively navigate the sourcing process for custom leather patches for jackets, ensuring high quality and satisfaction with their final product.

Comprehensive Cost and Pricing Analysis for custom leather patches for jackets Sourcing

What Are the Key Cost Components in Custom Leather Patches for Jackets?

When sourcing custom leather patches for jackets, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of leather significantly affects the price. Genuine leather typically costs more than synthetic alternatives. Additional materials, such as threads for stitching or adhesives for iron-on patches, should also be considered.

-

Labor: Labor costs encompass the wages of artisans who cut, sew, and finish the patches. Skilled labor, particularly for intricate designs or high-quality finishing, can increase overall costs.

-

Manufacturing Overhead: This includes the costs of utilities, equipment maintenance, and facility expenses. Overhead can vary by region and the scale of the manufacturing operation.

-

Tooling: Custom tooling is often required for unique designs. These upfront costs can be significant but are amortized over larger production runs.

-

Quality Control (QC): Implementing a robust QC process ensures that the patches meet specifications. This may involve additional inspections and testing, which contribute to overall costs.

-

Logistics: Shipping costs can be a significant factor, especially for international orders. Factors such as distance, weight, and choice of shipping method will influence logistics expenses.

-

Margin: Suppliers will typically add a markup to cover their costs and profit. Understanding the margin expectations of suppliers can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of Custom Leather Patches?

Several factors influence the pricing of custom leather patches, making it essential for buyers to be informed:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing discounts. Understanding the supplier’s MOQ can help in planning purchases effectively.

-

Specifications and Customization: Highly customized designs with intricate details may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Patches made from premium leather or certified sustainable sources will generally be more expensive. Buyers should assess whether the added cost aligns with their brand values.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record may charge more but offer better quality assurance and service.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) can affect the total landed cost. Buyers should clarify these terms to understand their responsibilities regarding shipping and customs duties.

What Are the Best Buyer Tips for Negotiating Prices on Custom Leather Patches?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

-

Conduct Market Research: Understanding the market rates for similar products can provide leverage during negotiations. This information can help establish a baseline for what constitutes a fair price.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with the patches, including durability, maintenance, and potential for repairs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Frequent communication and transparency can foster trust and cooperation.

-

Be Prepared to Walk Away: If a supplier’s terms do not meet your budget or quality requirements, be ready to explore alternative options. This willingness can often lead to improved offers.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import tariffs, and local regulations that may impact the final cost. Working with suppliers familiar with international trade can mitigate risks.

Disclaimer on Pricing

Prices for custom leather patches can vary widely based on the aforementioned factors. Buyers are encouraged to request detailed quotes from multiple suppliers to ensure competitive pricing. Factors such as market conditions, material availability, and production capacity can also influence prices, necessitating regular reassessment of sourcing strategies.

Alternatives Analysis: Comparing custom leather patches for jackets With Other Solutions

Exploring Alternatives to Custom Leather Patches for Jackets

In the competitive landscape of apparel branding and customization, businesses often seek alternatives to custom leather patches for jackets. While leather patches offer a unique aesthetic and durable branding solution, other methods may provide similar benefits with varying features, costs, and applications. This section explores how custom leather patches compare to alternative solutions such as embroidered patches and heat transfer vinyl.

| Comparison Aspect | Custom Leather Patches for Jackets | Embroidered Patches | Heat Transfer Vinyl |

|---|---|---|---|

| Performance | Highly durable, withstands wear and tear; provides a premium look. | Good durability; can fray over time but offers vibrant colors. | Good for short-term use; less durable against heavy washing. |

| Cost | Generally higher due to material and craftsmanship. | Moderate cost; varies with complexity and size. | Typically lower cost, especially for bulk orders. |

| Ease of Implementation | Requires sewing or heat application; some skill needed. | Easy to apply using heat or sewing; suitable for various fabrics. | Simple application process but requires specific equipment. |

| Maintenance | Low maintenance; can be wiped clean but not machine washable. | Moderate maintenance; can be washed but may fade or fray. | Very low maintenance; can withstand washing but design may degrade. |

| Best Use Case | Ideal for high-end fashion, motorcycle gear, and rugged apparel. | Best for casual wear, team uniforms, and promotional items. | Suitable for fast fashion, events, or temporary branding needs. |

What Are the Advantages and Disadvantages of Embroidered Patches?

Embroidered patches are a popular alternative that provides a vibrant and textured finish. They are typically made by stitching designs onto fabric, allowing for intricate detailing and a range of colors. One of the significant advantages of embroidered patches is their versatility; they can be easily applied to various fabrics using heat or sewing methods. However, while they offer a decent level of durability, embroidered patches may fray over time, especially with frequent washing. This makes them less suitable for items that require heavy-duty wear, such as outdoor jackets or gear.

Illustrative image related to custom leather patches for jackets

How Does Heat Transfer Vinyl Compare?

Heat transfer vinyl (HTV) is another effective alternative, often used for quick, cost-effective branding solutions. This method involves cutting designs from colored vinyl sheets and applying them to fabric with heat. The primary advantage of HTV is its affordability and the ease of application; it requires minimal skill and can be used on a variety of garments. However, HTV is generally less durable than leather patches and may not hold up as well under rigorous washing conditions. This makes it more suitable for short-term applications, such as promotional events or seasonal fashion lines.

Making the Right Choice: How to Select the Best Customization Solution?

When selecting the best solution for jacket customization, B2B buyers should consider their specific needs and target market. Custom leather patches are ideal for brands aiming for a high-end, durable product that conveys a sense of quality and prestige. In contrast, embroidered patches are suitable for businesses that prioritize vibrant designs and ease of application, while heat transfer vinyl is perfect for those seeking cost-effective, quick solutions for temporary branding.

Ultimately, understanding the unique advantages and limitations of each option will empower businesses to make informed decisions that align with their branding strategy and customer expectations.

Illustrative image related to custom leather patches for jackets

Essential Technical Properties and Trade Terminology for custom leather patches for jackets

What Are the Key Technical Properties of Custom Leather Patches for Jackets?

When sourcing custom leather patches for jackets, understanding the essential technical properties can significantly influence purchasing decisions. Here are critical specifications that B2B buyers should consider:

1. Material Grade

The material grade of leather patches is paramount. Genuine leather is typically classified by its quality and durability, which directly affects the patch’s longevity and appearance. High-grade leather, such as full-grain or top-grain, offers superior resistance to wear and tear, making it ideal for jackets that experience regular use. B2B buyers should prioritize high-quality materials to ensure customer satisfaction and brand reputation.

2. Thickness

The thickness of leather patches is another vital specification. It often ranges from 0.8mm to 1.5mm, with thicker patches providing increased durability and a more robust appearance. A thicker patch is less likely to fray or peel, making it suitable for heavy-duty applications. Buyers should evaluate the intended use of the jacket to determine the appropriate thickness for the patches.

3. Finish Type

Leather patches can come in various finishes, including matte, glossy, or distressed. The finish impacts not only the aesthetic appeal but also the patch’s resistance to environmental factors. For instance, a matte finish may be preferred for a vintage look, while a glossy finish can enhance vibrancy and protect against moisture. Understanding the finish type helps buyers align product offerings with market trends and consumer preferences.

4. Attachment Method

The method of attaching the leather patch to the jacket is critical for durability and ease of application. Common methods include sewing, heat transfer, and iron-on. Each method has its advantages; for example, sewn patches are often more durable, while iron-on patches offer convenience. Buyers should assess their production capabilities and customer preferences when selecting the appropriate attachment method.

Illustrative image related to custom leather patches for jackets

5. Customization Options

Customization capabilities, including laser engraving and embroidery, are essential for adding brand identity to patches. The ability to personalize patches not only enhances brand visibility but also meets specific client needs. Buyers should inquire about the range of customization options available, including design complexity and color choices, to ensure they can offer tailored solutions to their customers.

What Are Common Trade Terms in the Custom Leather Patch Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are common trade terms relevant to custom leather patches:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of leather patches, an OEM may create custom patches for a brand that sells apparel. Understanding OEM relationships can aid buyers in establishing reliable supply chains.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For custom leather patches, MOQs can vary based on the manufacturer and the complexity of the design. Buyers should consider MOQs when budgeting and planning inventory to avoid excess costs or stock shortages.

Illustrative image related to custom leather patches for jackets

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing and terms for a specific quantity of goods. For custom patches, an RFQ can help buyers compare costs, lead times, and customization options from multiple suppliers, ensuring informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in cross-border purchases of leather patches. Key Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate shipping costs, risk transfer, and delivery responsibilities.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the custom leather patch market, lead times can significantly vary based on order complexity and production capacity. Buyers should communicate their timeline expectations clearly to suppliers to ensure timely delivery of patches for promotional events or product launches.

By understanding these essential properties and trade terms, B2B buyers can navigate the custom leather patch market more effectively, ensuring they make informed decisions that align with their business objectives.

Illustrative image related to custom leather patches for jackets

Navigating Market Dynamics and Sourcing Trends in the custom leather patches for jackets Sector

What Are the Key Market Trends Influencing Custom Leather Patches for Jackets?

The global market for custom leather patches for jackets is experiencing dynamic growth, driven by several factors. The rising demand for personalized fashion and the increasing popularity of branded apparel are significant drivers. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly keen on sourcing unique patches to enhance brand identity and customer engagement. The trend towards customization is further fueled by advancements in digital printing and laser engraving technologies, allowing for intricate designs and faster turnaround times.

Additionally, the marketplace is witnessing a shift towards online sourcing platforms, which offer extensive catalogs and user-friendly design tools. This trend is particularly beneficial for international buyers who can access diverse suppliers without geographical constraints. Sustainable sourcing is becoming increasingly important, with buyers seeking suppliers who prioritize eco-friendly materials and ethical production practices. The integration of e-commerce solutions with supply chain management systems is also streamlining purchasing processes, making it easier for businesses to manage their inventory and order fulfillment.

How Is Sustainability Shaping the Sourcing of Custom Leather Patches for Jackets?

Sustainability is a pivotal concern for modern B2B buyers, especially in the fashion and apparel industry. The environmental impact of leather production has prompted many businesses to seek sustainable alternatives, including vegetable-tanned leather and synthetic options that mimic the appearance and feel of genuine leather. International buyers, particularly from Europe and North America, are increasingly prioritizing suppliers with transparent supply chains that adhere to ethical labor practices and environmental regulations.

Certifications such as Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming essential for brands aiming to enhance their sustainability credentials. These certifications assure buyers that the products are sourced from environmentally responsible manufacturers. Furthermore, the focus on reducing waste has led to innovations in upcycling leather scraps into patches, promoting a circular economy. By prioritizing sustainability in their sourcing strategies, businesses not only align with consumer expectations but also mitigate risks associated with supply chain disruptions and regulatory compliance.

What Is the Historical Context of Custom Leather Patches for Jackets?

The use of leather patches can be traced back to traditional craftsmanship, where artisans would create unique identifiers for clothing, especially in workwear and military uniforms. Over the years, these patches evolved into a fashion statement, particularly within subcultures such as motorcycle and punk communities. The resurgence of interest in vintage and personalized fashion has further propelled the demand for custom leather patches in contemporary apparel.

Illustrative image related to custom leather patches for jackets

As global fashion trends shift towards individuality and self-expression, the custom leather patch industry has adapted by embracing advanced manufacturing techniques and digital customization tools. This evolution has allowed businesses to cater to a diverse clientele, from small startups to large brands, all seeking to differentiate themselves in a competitive marketplace. The historical roots of leather patches continue to influence their modern applications, making them a staple in the realm of personalized fashion.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather patches for jackets

-

How do I choose the right custom leather patch supplier for my business?

Choosing the right supplier involves thorough research and consideration of several factors. Look for suppliers with a proven track record in producing high-quality leather patches and positive reviews from previous clients. Request samples to assess the material quality and craftsmanship. Additionally, ensure they can meet your design specifications and production timelines. Consider their ability to handle international shipping and customs regulations, especially if you are sourcing from regions like Africa or South America. Engaging in direct communication can also help gauge their responsiveness and customer service standards. -

What is the minimum order quantity (MOQ) for custom leather patches?

The MOQ for custom leather patches can vary significantly depending on the supplier. Generally, you can expect MOQs to range from as low as 12 to upwards of 100 pieces. It’s essential to clarify this with your supplier before placing an order, as some may offer flexibility based on your specific needs or future orders. If you are a smaller business or just starting, look for suppliers that offer lower MOQs to minimize your initial investment while still allowing you to test the market. -

What customization options are available for leather patches?

Customization options for leather patches are extensive. You can choose from various sizes, shapes, colors, and finishes to suit your brand identity. Many suppliers offer embroidery, laser engraving, or debossing for logos and designs. Be sure to inquire about the types of leather used, as this can affect the patch’s look and durability. Additionally, confirm the methods of attachment, such as sew-on, iron-on, or adhesive backing, to ensure they meet your product requirements. -

What payment terms should I expect when sourcing leather patches internationally?

Payment terms can vary by supplier, but common arrangements include upfront payments, deposits, and net payment terms (e.g., net 30, net 60). Ensure you discuss and agree on payment methods that work for both parties, such as wire transfers, letters of credit, or online payment platforms. Be aware of potential currency conversion fees if you are dealing with suppliers in different countries. Establishing clear payment terms early can help avoid misunderstandings and ensure a smoother transaction process. -

How can I ensure the quality of custom leather patches I receive?

To ensure quality, start by requesting samples before placing a bulk order. This allows you to evaluate the leather’s texture, durability, and overall craftsmanship. Establish quality assurance (QA) protocols with your supplier, such as detailed product specifications and inspection processes. You might also consider third-party inspections, especially for larger orders, to verify that the patches meet your standards before shipment. Open communication regarding your quality expectations will help align your needs with the supplier’s capabilities. -

What are the shipping and logistics considerations for importing leather patches?

When importing leather patches, consider shipping methods, costs, and delivery times. Different options include air freight for faster delivery or sea freight for cost-effectiveness on larger shipments. Understand the customs regulations in your country, as some regions may have specific import restrictions or duties on leather goods. Collaborating with a logistics partner who specializes in international shipping can simplify the process and ensure compliance with all regulations, minimizing delays and additional costs. -

What are common uses for custom leather patches in B2B applications?

Custom leather patches are versatile and can be used across various B2B applications. They are often employed in branding for apparel, such as jackets, vests, and hats, providing a rugged yet professional appearance. Additionally, they can serve as promotional items for events or corporate giveaways. Businesses in the fashion, outdoor, and motorcycle industries frequently utilize leather patches to enhance their products’ aesthetic appeal and brand recognition. Understanding your target market can help you decide on the best applications for your patches. -

How do I handle design approval and revisions with my leather patch supplier?

Effective communication is crucial when managing design approvals and revisions. After submitting your design, request a digital proof or mock-up from the supplier to ensure it meets your expectations. Be clear about your feedback and any required changes, and establish a timeline for revisions to keep the project on track. Some suppliers may charge for multiple revisions, so clarify their policy upfront. Document all approvals and changes to maintain a clear record, which can help prevent misunderstandings and ensure you receive the final product you envisioned.

Top 6 Custom Leather Patches For Jackets Manufacturers & Suppliers List

1. Lazer Designs – Custom Leather Patches

Domain: lazerdesigns.com

Registered: 2002 (23 years)

Introduction: This company, Lazer Designs – Custom Leather Patches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Stahls – Custom Leather Patches

Domain: stahls.com

Registered: 1996 (29 years)

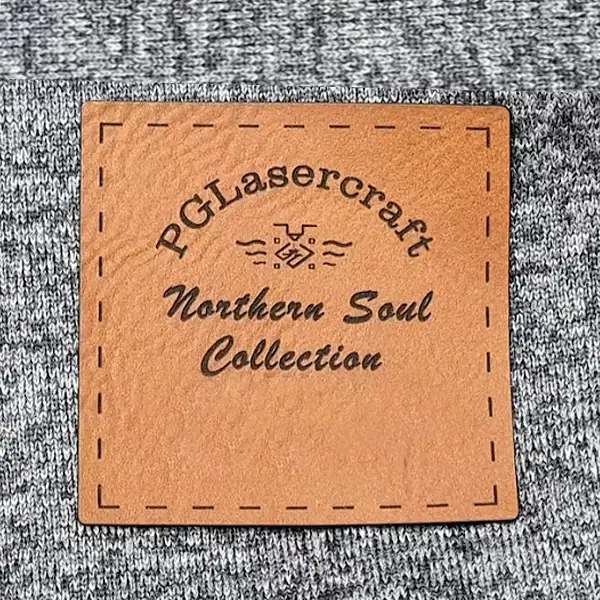

Introduction: Custom Leather Patches for Apparel

– Material: Genuine leather

– Colors Available: Taupe, Caramel, Natural

– Minimum Order: 12 pieces

– Ideal Applications: Hats, bags, heavy apparel (like outerwear not regularly laundered), and hard goods

– Application Methods: Can be heat applied or stickered to any hard good

– Customization: Logos laser etched into patches, with options for fine detailed designs…

3. Custom Woven Labels – Leather Patches

Domain: customwovenlabels.com

Registered: 2004 (21 years)

Introduction: Custom leather patches for hats, jeans, and other apparel types. Made from high-quality genuine leather available in various colors. Options for embossing (raised) or debossing (pressed) designs. Ability to add a print color to specific areas. Sew-on leather patches can include iron-on or peel & stick backing for easy application. Digital proof provided within 1 business day for approval. Free sam…

4. Digit Punch – Custom Leather Patches

Domain: digitpunch.com

Registered: 2014 (11 years)

Introduction: Custom leather patches available in original and faux leather. Types of patches include hot cut border, merrow border, and laser cut. Backing options include iron on, velcro, plain sew on, and peel and stick. Features include high-quality craftsmanship, durability, and a classic appearance. Customization options for jackets, hats, and logos. Free quote, free artwork and design, free setup, and fre…

5. Dutch Label Shop – Custom Jacket Patches

Domain: dutchlabelshop.com

Registered: 2014 (11 years)

Introduction: Custom Jacket Patches from Dutch Label Shop offer a way to personalize jackets with unique designs. Key features include:

– Ships from New Jersey with no import tariffs.

– Fast delivery within 10 to 14 days.

– Low minimum order quantities starting from 5 patches.

– Money-back guarantee if not satisfied.

– Various materials available: woven, embroidered, printed, PVC, TPU, and leather, each with di…

6. Ultra Patches – Custom Leather Patches

Domain: ultrapatches.com

Registered: 2017 (8 years)

Introduction: Custom Leather Patches – Available in real, suede, or faux leather. Options for embossing, printing, or embroidery. Types of leather: genuine cow skin, synthetic, faux suede. Design options include embossed, embossed burn, embossed printed, cut to shape borders, screen printing, single/double stitch lines, embroidery on patch, stitching channel, zig zag stitch line, and X stitch lines. Backing opt…

Strategic Sourcing Conclusion and Outlook for custom leather patches for jackets

As the demand for custom leather patches continues to rise across diverse markets, strategic sourcing emerges as a crucial factor in enhancing product quality, reducing costs, and ensuring timely delivery. Buyers should focus on establishing relationships with reputable suppliers who offer a range of customization options, such as laser engraving and various attachment methods, to meet their specific needs. The ability to create unique designs not only adds value to products but also strengthens brand identity, making it essential for businesses looking to differentiate themselves in competitive markets.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should leverage the growing trend of personalized apparel. Investing in high-quality custom leather patches can significantly enhance customer satisfaction and loyalty. As businesses increasingly prioritize sustainability and ethical sourcing, selecting suppliers that adhere to these principles will also resonate well with conscious consumers.

Looking ahead, the market for custom leather patches is poised for growth. Now is the time for businesses to capitalize on this trend by forging strong partnerships with suppliers and embracing innovative designs. By doing so, they can position themselves at the forefront of this burgeoning industry, ready to meet the evolving demands of their customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather patches for jackets