Introduction: Navigating the Global Market for car vinyl fabric

In today’s competitive automotive market, sourcing high-quality car vinyl fabric can pose significant challenges for international buyers. With varying standards, material specifications, and regional preferences, navigating this landscape requires a comprehensive understanding of the available options. This guide aims to demystify the complexities of car vinyl fabric, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

By delving into the characteristics and benefits of automotive vinyl, including its durability, ease of maintenance, and aesthetic versatility, this resource empowers B2B buyers from Africa, South America, the Middle East, and Europe—regions like Saudi Arabia and Brazil—to make informed purchasing decisions. Whether you’re looking to enhance vehicle interiors for luxury models or seeking cost-effective solutions for mass production, understanding the nuances of car vinyl fabric is crucial.

This guide not only provides insights into selecting the right materials but also equips buyers with strategies to effectively evaluate suppliers, ensuring that their investments meet both quality standards and budget constraints. With actionable information and expert recommendations, you’ll be better positioned to navigate the global market and secure the ideal car vinyl fabric for your specific needs.

Table Of Contents

- Top 8 Car Vinyl Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car vinyl fabric

- Understanding car vinyl fabric Types and Variations

- Key Industrial Applications of car vinyl fabric

- 3 Common User Pain Points for ‘car vinyl fabric’ & Their Solutions

- Strategic Material Selection Guide for car vinyl fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for car vinyl fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car vinyl fabric’

- Comprehensive Cost and Pricing Analysis for car vinyl fabric Sourcing

- Alternatives Analysis: Comparing car vinyl fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for car vinyl fabric

- Navigating Market Dynamics and Sourcing Trends in the car vinyl fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car vinyl fabric

- Strategic Sourcing Conclusion and Outlook for car vinyl fabric

- Important Disclaimer & Terms of Use

Understanding car vinyl fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Vinyl | Durable, abrasion-resistant, easy to clean | Automotive upholstery, RVs, marine interiors | Pros: Cost-effective, low maintenance. Cons: Less breathable than fabric. |

| PU Vinyl | Soft feel, leather-like appearance, environmentally friendly | Luxury automotive upholstery, custom interiors | Pros: Aesthetic appeal, more eco-friendly. Cons: Higher cost than PVC. |

| Marine-Grade Vinyl | UV resistant, mildew resistant, designed for wet conditions | Boats, automotive, and outdoor applications | Pros: Excellent durability in harsh environments. Cons: Limited color options. |

| Perforated Vinyl | Allows breathability, often used in high-performance seating | Sports cars, custom automotive applications | Pros: Enhanced comfort, stylish design. Cons: May require more upkeep. |

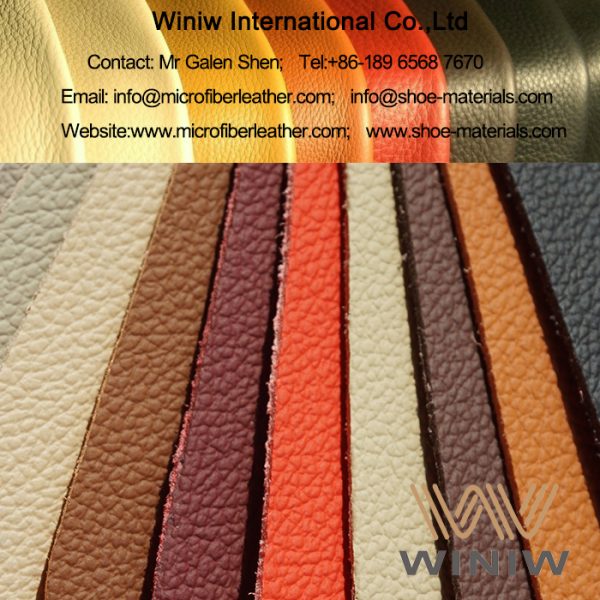

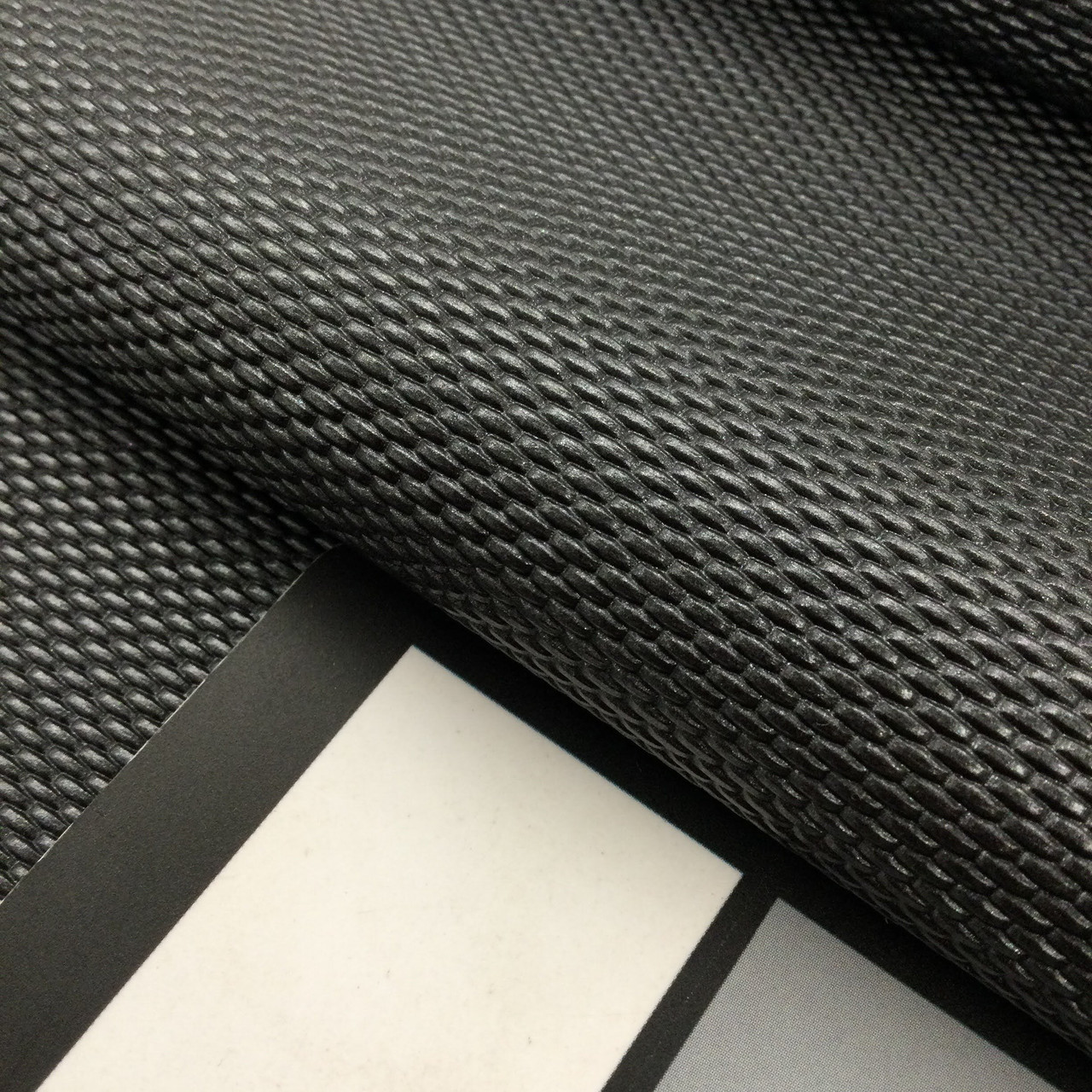

| Textured Vinyl | Varied surface textures, mimics leather or fabric | Luxury vehicles, custom upholstery projects | Pros: Aesthetically pleasing, adds depth to design. Cons: Can be more expensive. |

What Are the Key Characteristics of PVC Vinyl?

PVC (Polyvinyl Chloride) vinyl is a widely used material in automotive applications due to its exceptional durability and ease of maintenance. It is resistant to wear, spills, and UV exposure, making it suitable for daily use in vehicles. B2B buyers should consider PVC vinyl for its affordability and long-lasting performance. However, it is less breathable compared to fabric options, which could affect comfort in warmer climates.

How Does PU Vinyl Differ from Other Options?

PU (Polyurethane) vinyl offers a soft, leather-like feel that appeals to buyers looking for a premium finish. This material is often chosen for luxury automotive upholstery and custom interiors due to its aesthetic qualities and environmental friendliness. While PU vinyl tends to be more expensive than PVC, its appeal lies in its visual and tactile qualities, making it a worthy investment for high-end applications.

Why Choose Marine-Grade Vinyl for Automotive Use?

Marine-grade vinyl is specifically designed to withstand harsh environmental conditions, including UV exposure and moisture. This makes it an excellent choice for automotive applications in humid or coastal regions. B2B buyers should consider marine-grade vinyl for vehicles that experience significant exposure to the elements, as its durability can lead to lower replacement costs over time. However, color options may be limited compared to standard automotive vinyl.

What Are the Benefits of Using Perforated Vinyl?

Perforated vinyl is designed to allow air circulation, making it a popular choice for high-performance seating in sports cars and custom automotive projects. This type of vinyl enhances comfort while maintaining a stylish appearance. B2B buyers should weigh the benefits of comfort and aesthetics against the potential for increased maintenance requirements associated with this type of material.

How Can Textured Vinyl Enhance Automotive Interiors?

Textured vinyl offers varied surface finishes that can mimic the look of leather or fabric, adding depth and interest to automotive interiors. It is often used in luxury vehicles and custom upholstery projects, appealing to buyers seeking a sophisticated design. While textured vinyl can be more expensive than standard options, its aesthetic benefits can justify the investment, especially in high-end markets.

Key Industrial Applications of car vinyl fabric

| Industry/Sector | Specific Application of car vinyl fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior Upholstery | Enhances aesthetics and durability of vehicles | Quality certifications, material composition, and durability tests |

| RV and Marine Industries | Seating and Interior Finishes | Provides weather resistance and easy maintenance | UV stability, mildew resistance, and customization options |

| Custom Vehicle Fabrication | Custom Seats and Panels | Enables tailored designs for unique customer needs | Flexibility in color and texture, bulk purchasing options |

| Transportation Services | Fleet Vehicle Interiors | Improves comfort and reduces maintenance costs | Cost-effectiveness, durability under heavy use, and cleanability |

| Hospitality and Leisure | Automotive Rentals and Shuttles | Offers a polished appearance while being easy to maintain | Aesthetic appeal, stain resistance, and compliance with safety standards |

How is Car Vinyl Fabric Used in Automotive Manufacturing?

In the automotive manufacturing sector, car vinyl fabric is primarily used for interior upholstery, including seats, door panels, and dashboards. This material not only enhances the visual appeal of vehicles but also provides exceptional durability against wear and tear. For international buyers, particularly from regions like Africa and South America, sourcing high-quality vinyl that meets specific durability standards is essential. Additionally, manufacturers should ensure that the vinyl complies with local regulations regarding emissions and safety.

What Are the Benefits of Car Vinyl Fabric in RV and Marine Industries?

In the RV and marine industries, car vinyl fabric is utilized for seating and interior finishes due to its weather-resistant properties and low maintenance requirements. This material can withstand exposure to moisture and UV rays, making it ideal for environments where traditional fabrics might deteriorate quickly. Buyers from the Middle East and Europe should prioritize sourcing vinyl that offers mildew resistance and easy cleaning capabilities, ensuring long-term performance in challenging conditions.

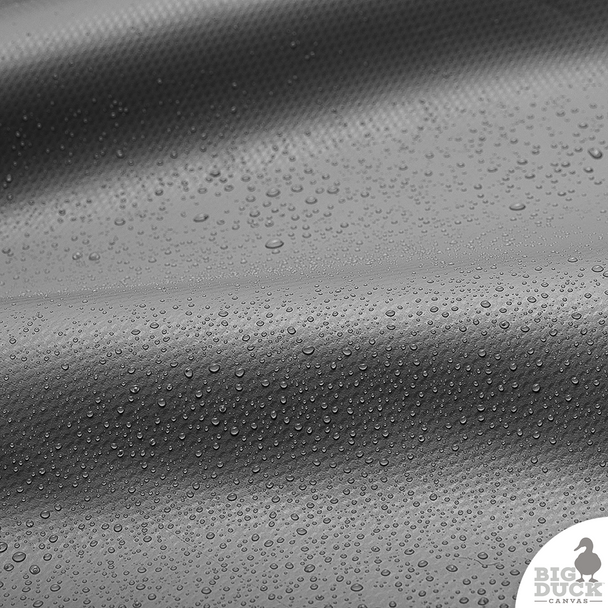

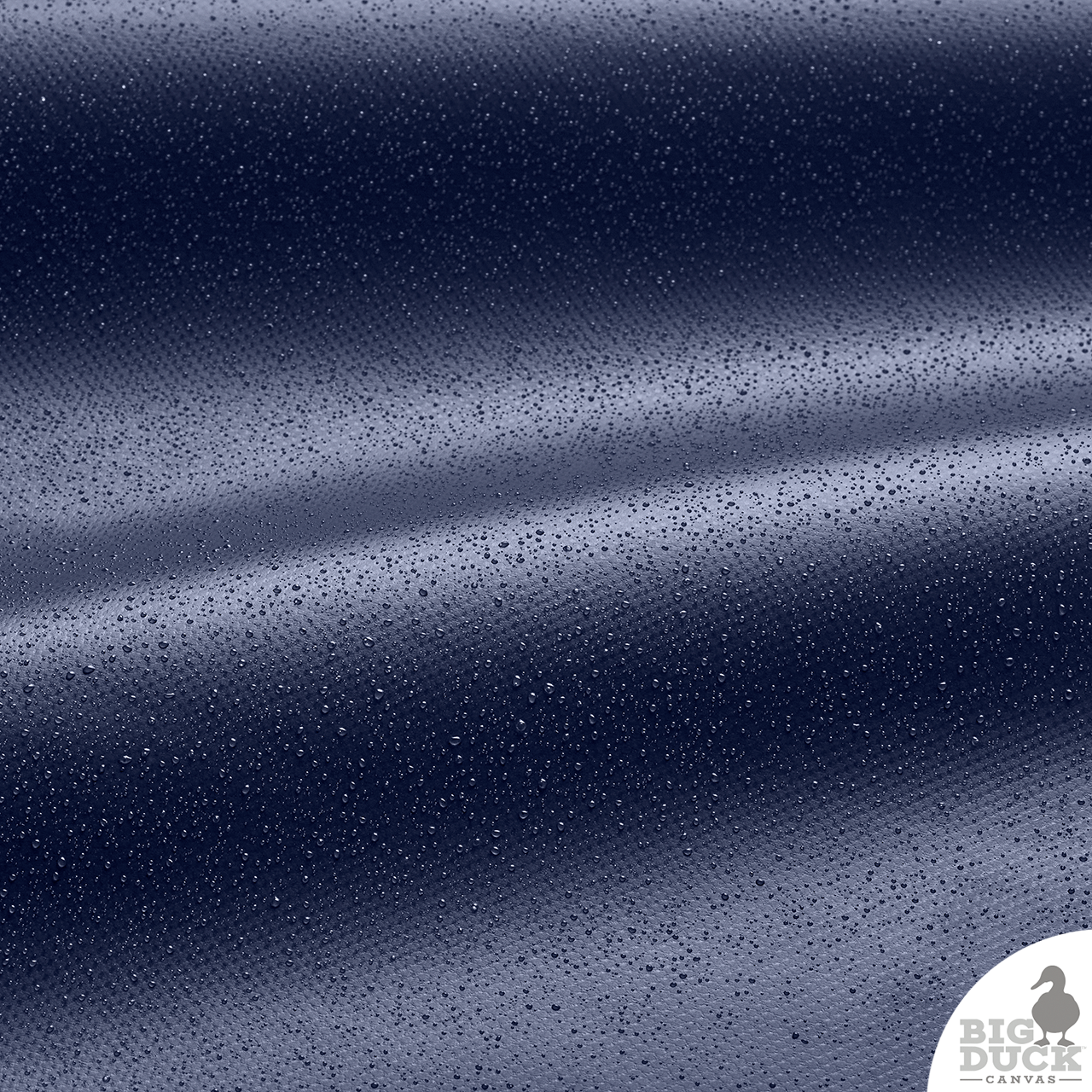

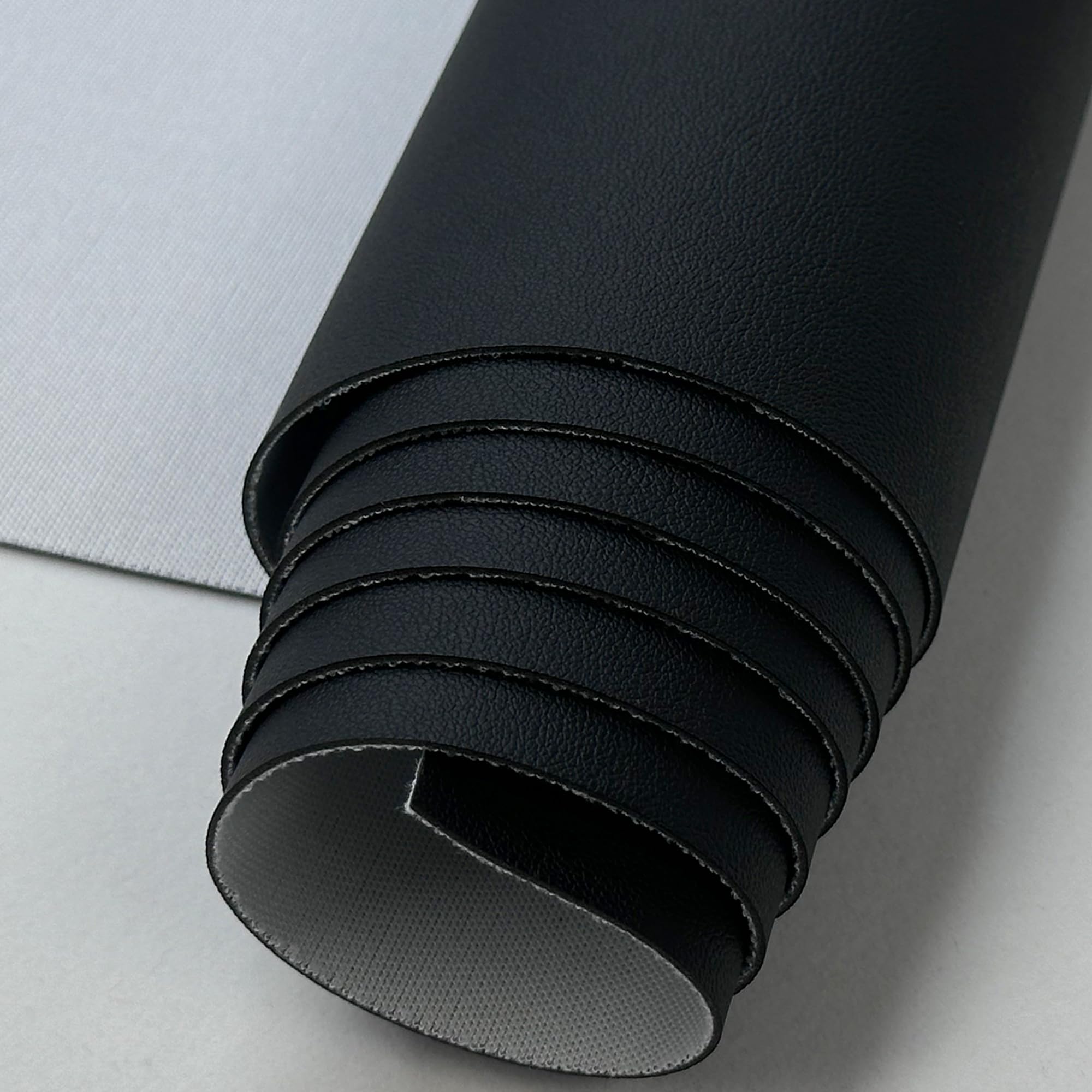

Illustrative image related to car vinyl fabric

How Does Car Vinyl Fabric Support Custom Vehicle Fabrication?

Custom vehicle fabrication heavily relies on car vinyl fabric for creating bespoke seats and interior panels that cater to unique customer specifications. This flexibility allows fabricators to offer tailored designs that enhance the vehicle’s aesthetic and functional appeal. B2B buyers in this sector should focus on sourcing vinyl that provides a wide range of colors and textures, as well as bulk purchasing options to meet varying project demands efficiently.

Why is Car Vinyl Fabric Important for Transportation Services?

Transportation services, including fleet management, benefit from car vinyl fabric by using it for vehicle interiors, which improves passenger comfort and reduces maintenance costs. The non-porous nature of vinyl makes it easy to clean, a significant advantage for companies that operate in high-usage environments. When sourcing, businesses should consider the cost-effectiveness of vinyl options and ensure that the selected materials can withstand heavy use without compromising on aesthetics or functionality.

What Role Does Car Vinyl Fabric Play in the Hospitality Sector?

In the hospitality sector, particularly for automotive rentals and shuttle services, car vinyl fabric is chosen for its polished appearance and ease of maintenance. This material allows companies to maintain a professional look while ensuring that interiors remain clean and inviting for customers. For international buyers, it is crucial to select vinyl that complies with safety standards and offers stain-resistant properties, ensuring a high-quality experience for end-users.

3 Common User Pain Points for ‘car vinyl fabric’ & Their Solutions

Scenario 1: Difficulties in Sourcing Quality Vinyl Fabric for Automotive Applications

The Problem: B2B buyers in the automotive upholstery sector often struggle to find high-quality car vinyl fabric that meets their specific needs. This can include issues with durability, resistance to wear and tear, and aesthetic appeal. For instance, a manufacturer in Brazil might source vinyl that looks good initially but fails under the heavy usage conditions typical of tropical climates, leading to rapid deterioration and unhappy customers. The lack of reliable suppliers who can provide consistent quality and performance can lead to costly reworks and damaged reputations.

The Solution: To overcome these challenges, buyers should focus on establishing relationships with reputable suppliers known for their high-quality automotive vinyl fabrics. It’s essential to inquire about the specifications of the materials, such as abrasion resistance, UV stability, and moisture resistance. Buyers should also request samples and conduct rigorous testing under actual usage conditions before committing to large orders. Engaging with suppliers who offer a variety of products, including those designed for specific climates or conditions, can ensure that the selected vinyl will perform optimally. Additionally, leveraging industry certifications and reviews can help identify trustworthy manufacturers.

Illustrative image related to car vinyl fabric

Scenario 2: Challenges with Maintenance and Cleaning of Vinyl Upholstery

The Problem: Another common pain point for B2B buyers is the maintenance and cleaning of vinyl upholstery in vehicles. Buyers may find that while vinyl is marketed as easy to clean, certain types can become stained or discolored, especially in high-use environments. For instance, a fleet operator in Saudi Arabia might discover that vinyl seats are not maintaining their appearance due to the intense sun and dust, leading to increased maintenance costs and customer complaints.

The Solution: To address these maintenance challenges, it’s crucial for buyers to select vinyl products with built-in resistance to UV rays and stains. Investing in vinyl with properties such as mildew resistance and easy-clean surfaces can significantly reduce long-term upkeep. Furthermore, buyers should implement a standardized cleaning protocol that uses appropriate cleaning agents specifically designed for vinyl, ensuring longevity and maintaining the upholstery’s aesthetic appeal. Regular training for staff on proper cleaning techniques can also enhance the durability of the vinyl, ensuring that the product remains in top condition even under challenging environmental conditions.

Scenario 3: Misalignment Between Aesthetic Expectations and Material Performance

The Problem: Many B2B buyers encounter a disconnect between the aesthetic expectations for car interiors and the performance characteristics of vinyl fabric. For example, a custom car fabricator in Europe might choose a vinyl for its luxurious appearance but later find that it doesn’t provide the durability needed for everyday use, leading to a mismatch that disappoints clients and jeopardizes future business.

The Solution: To bridge this gap, it’s important for buyers to prioritize a balance between aesthetics and functionality when selecting vinyl fabrics. Before making a decision, they should thoroughly research various options that combine attractive designs with robust performance characteristics. This includes reviewing technical data sheets and performance ratings, such as abrasion resistance and colorfastness. Collaborating with suppliers who can offer customization options can also help buyers achieve the desired look without compromising on quality. Additionally, conducting market research on current trends can guide buyers in choosing vinyl that meets both aesthetic and functional requirements, ensuring client satisfaction and repeat business.

Illustrative image related to car vinyl fabric

Strategic Material Selection Guide for car vinyl fabric

What Are the Key Materials Used in Car Vinyl Fabric?

When selecting car vinyl fabric for automotive applications, understanding the properties, advantages, and limitations of various materials is crucial for B2B buyers. Here, we analyze four common materials used in car vinyl fabric: Polyvinyl Chloride (PVC), Polyurethane (PU), Vinyl Coated Fabric, and Synthetic Leather. Each material has unique characteristics that influence its suitability for different applications.

How Does Polyvinyl Chloride (PVC) Perform in Automotive Applications?

PVC is one of the most widely used materials for automotive vinyl due to its exceptional durability and low cost. It offers excellent resistance to abrasion, moisture, and UV exposure, making it suitable for car interiors that experience high wear and tear. PVC can withstand temperatures ranging from -10°F to 140°F, ensuring performance across various climates.

Pros: PVC is cost-effective, easy to clean, and resistant to stains and spills. It also provides a wide range of colors and textures, allowing for customization.

Cons: While PVC is durable, it can become brittle over time, especially when exposed to extreme temperatures. Additionally, it may not be as environmentally friendly as other options.

Impact on Application: PVC is commonly used for car seats, door panels, and dashboards, providing a polished look with minimal maintenance.

Illustrative image related to car vinyl fabric

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential, particularly for markets in Africa and the Middle East. Buyers should also be aware of local regulations regarding PVC materials.

What Advantages Does Polyurethane (PU) Offer for Car Vinyl Fabric?

Polyurethane is a more advanced material compared to PVC, known for its flexibility and soft feel. It is often used in high-end automotive applications where aesthetics and comfort are priorities. PU has excellent abrasion resistance and is less prone to cracking than PVC, making it suitable for various climates.

Pros: PU is breathable, lightweight, and offers a luxurious appearance. It is also more environmentally friendly than PVC, making it a better choice for eco-conscious manufacturers.

Illustrative image related to car vinyl fabric

Cons: The cost of PU is generally higher than PVC, which may impact budget-sensitive projects. Additionally, while it is durable, it may not withstand extreme temperatures as well as PVC.

Impact on Application: PU is ideal for premium car interiors, including seating and trim, where comfort and appearance are paramount.

Considerations for International Buyers: Buyers in Europe may prefer PU for its eco-friendly properties, while those in regions with extreme temperatures should assess its suitability based on climate conditions.

How Does Vinyl Coated Fabric Compare in Durability and Cost?

Vinyl coated fabric consists of a textile base coated with a layer of vinyl, providing a balance between flexibility and durability. This material is particularly resistant to moisture and mildew, making it suitable for vehicles exposed to humid environments.

Pros: Vinyl coated fabric is lightweight, easy to clean, and offers good resistance to wear and tear. It is also available in various colors and patterns.

Cons: While it offers decent durability, vinyl coated fabric may not be as robust as pure PVC or PU options. Its lifespan can be shorter in high-stress applications.

Impact on Application: This material is commonly used for car interiors, particularly in climates where moisture resistance is essential.

Considerations for International Buyers: Buyers from humid regions, such as parts of South America and Africa, should prioritize moisture-resistant materials. Compliance with local standards for automotive materials is also crucial.

What Role Does Synthetic Leather Play in Car Vinyl Fabric?

Synthetic leather, often made from PU or PVC, mimics the look and feel of genuine leather while offering enhanced durability and ease of maintenance. It is increasingly popular in the automotive industry for its aesthetic appeal and performance characteristics.

Illustrative image related to car vinyl fabric

Pros: Synthetic leather is visually appealing, easy to clean, and resistant to stains and spills. It provides a luxurious feel at a lower cost than genuine leather.

Cons: While synthetic leather is durable, it may not have the same longevity as genuine leather. Additionally, it can be more expensive than traditional vinyl options.

Impact on Application: This material is often used for high-end seating and trim, enhancing the overall aesthetic of the vehicle.

Considerations for International Buyers: Buyers in Europe and the Middle East may favor synthetic leather for its luxury appeal, while those in cost-sensitive markets may need to weigh its higher price against benefits.

Illustrative image related to car vinyl fabric

Summary Table of Car Vinyl Fabric Materials

| Материал | Typical Use Case for car vinyl fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Car seats, door panels, dashboards | Cost-effective and durable | Can become brittle over time | Низкий |

| Polyurethane (PU) | Premium car interiors, seating | Luxurious feel and eco-friendly | Higher cost than PVC | Высокий |

| Vinyl Coated Fabric | Car interiors in humid climates | Lightweight and moisture-resistant | Shorter lifespan in high-stress applications | Med |

| Синтетическая кожа | High-end seating and trim | Aesthetic appeal and easy maintenance | Less durable than genuine leather | Med |

This strategic material selection guide aims to empower B2B buyers with the knowledge needed to make informed decisions when sourcing car vinyl fabric for their automotive applications. Understanding the properties, benefits, and regional considerations will help in selecting the most suitable material for specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for car vinyl fabric

What Are the Key Stages in the Manufacturing Process of Car Vinyl Fabric?

The manufacturing process of car vinyl fabric encompasses several critical stages, ensuring that the final product meets the rigorous demands of the automotive industry. Here’s a detailed look at each stage:

Material Preparation: What Raw Materials Are Used?

The primary raw material for car vinyl fabric is polyvinyl chloride (PVC). This material is favored for its durability, resistance to wear and tear, and low maintenance requirements. Before production, the PVC is blended with various additives to enhance properties such as UV resistance, flexibility, and fire retardancy. Additionally, color pigments and stabilizers are incorporated to ensure that the vinyl maintains its aesthetic appeal and structural integrity over time.

Forming: How Is the Vinyl Fabric Created?

The forming stage involves the extrusion of PVC into sheets or rolls. This is achieved through a process called calendering, where the PVC mixture is passed through a series of rollers to achieve the desired thickness and finish. Various textures, such as leather-like grains or smooth surfaces, can be produced by modifying the roller surfaces. This stage is crucial as it determines the material’s appearance, feel, and performance characteristics.

Illustrative image related to car vinyl fabric

Assembly: What Techniques Are Employed?

Once the vinyl sheets are formed, they undergo an assembly process where they are cut to specific dimensions for various automotive applications. Techniques such as ultrasonic welding or stitching are employed to join different pieces together, depending on the design requirements. This stage ensures that the vinyl is tailored to fit automotive seats, door panels, dashboards, and other interior components.

Finishing: How Is Quality Enhanced?

The finishing stage includes applying protective coatings to enhance durability and resistance to environmental factors. Coatings may include UV protectants, anti-microbial treatments, or stain-resistant finishes. These enhancements significantly improve the longevity and maintainability of the vinyl fabric, making it suitable for both commercial and personal vehicles.

What Are the Quality Control Measures in Place for Car Vinyl Fabric?

Quality control (QC) is a vital aspect of car vinyl fabric manufacturing, ensuring that the products meet international standards and customer expectations. Here are key components of the QC process:

Which International Standards Are Relevant to Car Vinyl Fabric?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems, ensuring consistent product quality. Industry-specific certifications like CE (Conformité Européenne) are also crucial, especially for markets in Europe, as they signify compliance with safety and health regulations. For buyers in regions like Africa and South America, understanding these certifications can help in assessing product quality and safety.

Illustrative image related to car vinyl fabric

What Are the Checkpoints in Quality Control?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the raw materials’ quality before production begins. Suppliers must provide certificates of analysis to confirm that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to ensure that the processes are running smoothly and that products meet quality benchmarks. This includes checking the thickness, finish, and texture of the vinyl fabric.

-

Final Quality Control (FQC): Once production is complete, the finished products undergo thorough testing. This includes abrasion resistance, UV stability, and chemical resistance tests to ensure that the vinyl will perform well in real-world conditions.

What Testing Methods Are Commonly Used for Car Vinyl Fabric?

Various testing methods are utilized to validate the performance of car vinyl fabric. These include:

-

Abrasion Testing: Using the Wyzenbeek test, manufacturers assess how well the vinyl can withstand wear over time. This is crucial for products expected to endure heavy use.

-

UV Resistance Testing: This test evaluates the vinyl’s ability to resist fading and degradation from sunlight exposure, which is particularly important for regions with high UV levels.

-

Chemical Resistance Testing: This involves exposing the vinyl to various chemicals, including oils and cleaning agents, to ensure that it does not degrade or discolor.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must have robust verification processes to ensure that their suppliers adhere to high-quality standards. Here are some effective strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their compliance with international standards and certifications.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports, including test results and compliance certificates. This information can help assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. This is particularly beneficial for international transactions where trust and transparency are paramount.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, there are several nuances to consider:

Illustrative image related to car vinyl fabric

-

Understanding Regional Standards: Different regions may have specific requirements and standards for automotive materials. Buyers should familiarize themselves with local regulations to ensure compliance.

-

Shipping and Customs Regulations: Quality certifications can affect customs clearance. Buyers must ensure that their suppliers provide all necessary documentation to facilitate smooth import processes.

-

Cultural Differences in Business Practices: Understanding the cultural context of suppliers can aid in establishing better communication and expectations regarding quality assurance processes.

Заключение

The manufacturing processes and quality assurance measures for car vinyl fabric are complex and multifaceted, focusing on durability, aesthetics, and compliance with international standards. By understanding these processes and verification methods, B2B buyers can make informed decisions, ensuring that they source high-quality materials that meet their specific needs and expectations. With the right approach, businesses can leverage the benefits of car vinyl fabric to enhance their product offerings and satisfy their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car vinyl fabric’

Введение

This guide serves as a comprehensive checklist for B2B buyers looking to source high-quality car vinyl fabric. By following these steps, you can ensure that your procurement process is efficient, informed, and aligned with your specific needs, whether you are an automotive manufacturer, upholsterer, or a custom fabricator.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the vinyl fabric you need. This includes factors such as durability, UV resistance, and chemical resistance. Establishing these specifications upfront will help you communicate effectively with suppliers and ensure you receive materials that meet your performance needs.

Illustrative image related to car vinyl fabric

- Durability: Look for fabrics with high abrasion resistance ratings, such as those tested by the Wyzenbeek method.

- Chemical Resistance: Ensure the vinyl can withstand exposure to oils and other automotive fluids.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers who specialize in automotive vinyl fabric. Check their reputation in the industry by reading reviews and seeking recommendations from peers.

- Supplier Experience: Look for suppliers with a proven track record in providing automotive materials.

- Certifications: Ensure they have relevant certifications that attest to the quality and safety of their products.

Step 3: Evaluate Product Variety and Customization Options

Assess the range of vinyl fabric options available from each supplier. A diverse product line allows you to select materials that fit your aesthetic and functional requirements.

- Color and Texture: Verify if the supplier offers a variety of colors and textures that can align with your design vision.

- Customization: Inquire about the possibility of custom designs or formulations, which can help differentiate your product in the market.

Step 4: Request Samples

Always request samples before making a bulk purchase. This allows you to evaluate the material’s quality, feel, and performance firsthand.

- Testing for Durability: Use the samples to conduct your own tests for abrasion, UV resistance, and ease of cleaning.

- Assess Aesthetics: Ensure that the color and texture meet your design standards.

Step 5: Verify Supplier Certifications

Before finalizing your supplier, confirm that they hold necessary certifications related to environmental standards, safety, and product quality.

Illustrative image related to car vinyl fabric

- Environmental Compliance: Check if the materials are free from harmful substances and comply with regulations such as REACH or RoHS.

- Quality Standards: Look for certifications such as ISO 9001, which indicates a commitment to quality management.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms. Discuss pricing, payment options, and delivery timelines.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

- Lead Times: Ensure you understand the lead times for production and shipping, especially if you have tight deadlines.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your chosen supplier to facilitate smooth interactions throughout the procurement process.

- Regular Updates: Agree on the frequency and method of updates regarding order status and any potential issues.

- Point of Contact: Designate specific contacts from both sides to streamline communication and expedite problem-solving.

By following this checklist, B2B buyers can effectively navigate the sourcing process for car vinyl fabric, ensuring they select the best products for their needs while establishing strong supplier relationships.

Illustrative image related to car vinyl fabric

Comprehensive Cost and Pricing Analysis for car vinyl fabric Sourcing

What Are the Key Cost Components for Car Vinyl Fabric Sourcing?

When considering the sourcing of car vinyl fabric, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality and type of vinyl used significantly impact the price. High-performance options with features like UV resistance, anti-microbial properties, or enhanced durability typically command higher prices. For example, specialized vinyls like those offering abrasion resistance or flame retardancy may be priced at a premium.

-

Labor: The labor cost encompasses the workforce involved in manufacturing, cutting, and finishing the vinyl fabric. Skilled labor may be necessary for custom designs or high-quality finishes, which can increase overall costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: Custom tooling, particularly for unique patterns or specifications, can add to initial costs. However, these costs may be amortized over larger orders.

-

Quality Control (QC): Ensuring the vinyl meets industry standards and buyer specifications may require rigorous QC processes, contributing to overall expenses.

-

Logistics: Shipping and handling costs vary based on location, order size, and chosen Incoterms. International shipping may incur additional duties and tariffs, affecting the total cost.

-

Margin: Suppliers typically apply a margin based on their operational costs and market conditions. This can vary widely among suppliers and is influenced by their positioning in the market.

How Do Price Influencers Affect Car Vinyl Fabric Costs?

Several factors can influence pricing when sourcing car vinyl fabric:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom orders tailored to specific requirements can increase costs. Buyers should weigh the need for customization against potential budget constraints.

-

Materials and Quality Certifications: Higher-quality materials with certifications (such as flame retardancy or environmental compliance) typically increase prices but may offer long-term benefits in durability and safety.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the chosen Incoterms is crucial, as they dictate responsibility for shipping costs, risk, and insurance. This can significantly impact the total landed cost.

What Tips Can Help Buyers Optimize Costs in Car Vinyl Fabric Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs is vital. Here are some actionable tips:

-

Negotiation: Leverage volume purchasing and long-term contracts to negotiate better pricing. Establish clear expectations and maintain open communication with suppliers to foster favorable terms.

-

Cost Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, durability, and potential replacement costs. Investing in higher-quality vinyl may yield savings in the long run.

-

Understand Pricing Nuances: Be aware of pricing variations based on regional market dynamics. For instance, certain suppliers may have competitive advantages or disadvantages depending on local demand and supply chain logistics.

-

Research and Comparison: Conduct thorough market research to identify multiple suppliers and compare their offerings. Look for reviews and references to gauge reliability and quality.

-

Plan for Fluctuations: Be prepared for price fluctuations due to raw material costs, currency changes, and geopolitical factors. Secure agreements that allow for flexibility in pricing adjustments.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and regional factors. Buyers should conduct comprehensive research and seek multiple quotes to ensure competitive pricing tailored to their specific needs.

Illustrative image related to car vinyl fabric

Alternatives Analysis: Comparing car vinyl fabric With Other Solutions

Understanding Alternative Solutions to Car Vinyl Fabric

In the automotive upholstery market, car vinyl fabric stands out for its durability and versatility. However, various alternatives exist that can cater to different needs and preferences. For international B2B buyers, understanding these options is crucial for making informed decisions that align with specific market demands and client expectations.

Comparison Table

| Comparison Aspect | Car Vinyl Fabric | Leather Upholstery | Fabric Upholstery |

|---|---|---|---|

| Performance | Highly durable, UV resistant, easy to clean | Luxurious feel, excellent comfort | Varies widely; can be less durable |

| Cost | Affordable, typically lower than leather | Generally expensive due to material costs | Moderate to low, depending on fabric type |

| Ease of Implementation | Straightforward installation and customization | Requires specialized skills for installation | Easy to install for DIY projects |

| Maintenance | Low maintenance; wipe clean with soap and water | Requires regular conditioning and care | Can stain easily; requires careful cleaning |

| Best Use Case | Ideal for high-wear environments (e.g., fleet vehicles) | Luxury vehicles and high-end customization | Family vehicles and casual applications |

Detailed Breakdown of Alternatives

Leather Upholstery

Leather upholstery is often seen as the premium choice for automotive interiors, providing a luxurious aesthetic and unparalleled comfort. Its natural properties allow for breathability, which can enhance passenger comfort. However, leather can be significantly more expensive than vinyl and requires regular maintenance to prevent cracking and fading. Additionally, installation may necessitate specialized skills, making it less accessible for some buyers. For luxury vehicle manufacturers or high-end custom shops, leather remains a top choice despite its higher cost and maintenance demands.

Fabric Upholstery

Fabric upholstery offers a more budget-friendly option compared to both vinyl and leather. It can provide comfort and aesthetic appeal, with a wide variety of colors and patterns available. However, the performance can vary greatly depending on the fabric type; some materials may not withstand heavy use, while others can be more durable. Fabric upholstery is susceptible to stains and may require more frequent cleaning, making it less ideal for environments where spills are common. It’s often favored in family vehicles or for casual applications where cost-effectiveness is a priority.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right upholstery solution involves assessing the specific needs of your target market. For B2B buyers, factors such as budget, performance requirements, and maintenance capabilities are critical. Car vinyl fabric offers a robust and cost-effective choice for high-wear environments, while leather upholstery caters to luxury markets with its premium appeal. On the other hand, fabric upholstery serves as an economical alternative for everyday applications. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make strategic decisions that resonate with their clientele’s expectations and enhance overall satisfaction.

Illustrative image related to car vinyl fabric

Essential Technical Properties and Trade Terminology for car vinyl fabric

What Are the Key Technical Properties of Car Vinyl Fabric?

When selecting car vinyl fabric, understanding its technical properties is essential for ensuring durability, aesthetic appeal, and overall performance. Here are some critical specifications to consider:

1. Material Composition

Car vinyl fabrics are primarily made from polyvinyl chloride (PVC) or polyurethane (PU). PVC is known for its durability and affordability, while PU offers a more premium, leather-like finish. For B2B buyers, knowing the material composition helps in assessing the suitability of the fabric for specific applications, such as seating, dashboards, or door panels.

2. Abrasion Resistance

This property measures how well the vinyl can withstand wear and tear from friction. It is often quantified using the Wyzenbeek test, which indicates the number of double rubs a material can endure before showing signs of wear. High abrasion resistance is crucial for automotive applications where the upholstery will face frequent use. Buyers should prioritize fabrics with high abrasion resistance to ensure longevity and reduce replacement costs.

3. UV Stability

Vinyl fabrics should have UV stabilizers to prevent fading and degradation due to sun exposure. This is particularly important in regions with high sun exposure, such as parts of Africa and South America. UV stability ensures that the color and integrity of the upholstery remain intact over time, making it a vital specification for B2B buyers concerned about aesthetic longevity.

4. Flame Retardancy

Flame retardant properties are critical for automotive applications to meet safety standards. Fabrics are tested according to various regulations, such as FMVSS 302 in the U.S. and California T.B. 117. B2B buyers must verify that the vinyl meets these standards to ensure compliance and safety in their automotive projects.

5. Water and Mildew Resistance

Vinyl upholstery should be water-resistant to prevent moisture damage and mildew growth, particularly in humid climates. Fabrics designed with these properties facilitate easy cleaning and maintenance, making them ideal for family vehicles or commercial fleets. Buyers should look for vinyl with inherent moisture barriers for added protection.

What Are Common Trade Terms in the Car Vinyl Fabric Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B market. Here are some common trade terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of car vinyl fabric, an OEM might use specific fabric types for their vehicle interiors. Understanding OEM relationships can help buyers source high-quality materials that meet their specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is a critical consideration for B2B buyers, as it affects inventory management and cost efficiency. Knowing the MOQ helps buyers plan their purchasing strategies effectively.

Illustrative image related to car vinyl fabric

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products. This is an essential step in the procurement process, allowing buyers to compare costs and terms from various suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers, as it influences shipping costs and liability.

5. Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is vital for inventory planning and project timelines, ensuring that B2B buyers can meet their production schedules without delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions regarding car vinyl fabric, ensuring they select the right materials for their automotive applications.

Navigating Market Dynamics and Sourcing Trends in the car vinyl fabric Sector

What Are the Key Trends Shaping the Global Car Vinyl Fabric Market?

The car vinyl fabric sector is experiencing dynamic shifts driven by several global factors. The ongoing push for vehicle customization, particularly in markets such as Africa, South America, the Middle East, and Europe, is a significant driver. As consumers increasingly seek personalized automotive experiences, the demand for high-quality vinyl upholstery that offers both durability and aesthetic appeal is on the rise. Additionally, technological advancements in manufacturing processes, such as improved printing techniques and the development of more resilient materials, are enhancing product offerings and expanding market accessibility.

Emerging B2B tech trends, including the integration of e-commerce platforms and digital supply chain solutions, are transforming how international buyers source vinyl fabrics. Companies are leveraging online marketplaces to streamline procurement processes, allowing for direct access to manufacturers and suppliers. This shift is particularly beneficial for buyers in regions with limited local sourcing options, enabling them to compare products and prices efficiently.

Another notable trend is the increasing focus on functionality, with vinyl fabrics being engineered for specific applications, such as UV resistance, stain protection, and easy maintenance. These features cater to the needs of diverse end-users, from automotive manufacturers to upholstery specialists. As the market evolves, international buyers must stay abreast of these trends to make informed sourcing decisions that align with their business objectives.

How Is Sustainability and Ethical Sourcing Influencing the Car Vinyl Fabric Sector?

Sustainability and ethical sourcing have become pivotal concerns within the car vinyl fabric market. As environmental regulations tighten globally and consumers demand greener products, manufacturers are increasingly focused on reducing the ecological impact of their operations. This shift is particularly relevant for B2B buyers who are keen to align their purchasing practices with sustainable principles.

Illustrative image related to car vinyl fabric

The production of car vinyl fabrics typically involves the use of polyvinyl chloride (PVC), a material that raises environmental concerns due to its lifecycle implications. However, many manufacturers are now exploring alternative materials and processes that minimize harmful emissions and waste. For instance, some companies are adopting bio-based vinyl options or implementing closed-loop systems that recycle materials during production.

Ethical supply chains are also gaining traction, with buyers prioritizing suppliers who demonstrate transparency and accountability in their sourcing practices. Certifications such as OEKO-TEX and Global Recycle Standard (GRS) are increasingly important, providing assurances that materials are produced responsibly and sustainably. By sourcing from certified suppliers, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable industry.

What Is the Historical Context of Car Vinyl Fabric Development?

The evolution of car vinyl fabric dates back to the mid-20th century when the automotive industry began to explore synthetic materials as alternatives to traditional upholstery fabrics. Initially, vinyl was introduced for its affordability and ease of maintenance, quickly becoming popular in vehicle interiors. As technological advancements progressed, manufacturers developed more sophisticated vinyl options that mimicked the look and feel of leather while providing superior durability and stain resistance.

Illustrative image related to car vinyl fabric

By the 1980s and 1990s, the introduction of advanced coatings and finishes further enhanced the performance characteristics of vinyl fabrics, leading to widespread adoption across various vehicle types. Today, the focus has shifted toward customization and sustainability, with manufacturers continuously innovating to meet the evolving demands of international B2B buyers. This historical context underscores the importance of vinyl as a versatile and resilient material in the automotive sector, setting the stage for its continued relevance in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of car vinyl fabric

-

How do I choose the right car vinyl fabric for my needs?

Selecting the right car vinyl fabric involves assessing your specific application requirements. Consider factors such as durability, resistance to UV rays, moisture, and chemicals. For high-traffic areas, opt for fabrics with high abrasion resistance ratings, like those tested with the Wyzenbeek method. Additionally, evaluate the fabric’s texture and aesthetic appeal to ensure it aligns with your design vision. Finally, check for any certifications, like flame retardancy, which may be crucial for compliance in certain markets. -

What types of car vinyl fabrics are available for B2B buyers?

B2B buyers can find a diverse range of car vinyl fabrics, including PVC, polyurethane, and marine-grade options. Each type offers unique benefits; for instance, PVC is known for its durability and ease of cleaning, while polyurethane provides a softer, leather-like finish. Additionally, you can explore specialized options like antimicrobial and mildew-resistant vinyl for enhanced performance in challenging environments. It’s essential to assess your target market’s preferences to select the most suitable materials. -

What are the minimum order quantities (MOQs) for car vinyl fabric?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 yards, depending on the material and manufacturer. Some suppliers may offer flexible MOQs for first-time buyers or smaller businesses. Always inquire about potential bulk discounts, as ordering larger quantities can lead to cost savings. It’s advisable to establish a relationship with suppliers to negotiate terms that suit your business model, especially when dealing with international shipments. -

How can I vet suppliers of car vinyl fabric for quality assurance?

To vet suppliers effectively, start by reviewing their certifications and industry standards, such as ISO or ASTM compliance. Request samples to evaluate fabric quality, including durability, colorfastness, and texture. Additionally, seek out references or case studies from other businesses in your region that have sourced from them. Conducting factory visits or audits, if feasible, can provide insight into their production processes and ethical practices. Trust is crucial in international trade, so prioritize suppliers with a proven track record. -

What payment terms should I expect when sourcing car vinyl fabric internationally?

Payment terms can vary widely based on supplier policies and your relationship with them. Common options include advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit (typically 30-50%) upfront, with the balance due before shipment. It’s essential to clarify payment terms during negotiations to avoid misunderstandings. Consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers in different countries. -

How can I ensure timely delivery of car vinyl fabric?

To ensure timely delivery, establish clear communication with your supplier regarding lead times and shipping schedules. Confirm the production timeline and any potential delays due to customs or logistics. Utilize freight forwarders experienced in international shipping to streamline the process and minimize risks. Additionally, monitor the shipment’s progress through tracking systems and maintain open lines of communication to address any issues proactively, ensuring that your supply chain remains uninterrupted. -

What customization options are available for car vinyl fabric?

Many suppliers offer customization options, including specific colors, textures, patterns, and finishes to match your design requirements. You can also request specific performance characteristics, such as enhanced UV resistance or antimicrobial properties. Discuss your needs with suppliers early in the negotiation process to determine the feasibility of custom orders and any associated costs. Be sure to ask about the minimum quantities required for custom orders, as these can differ from standard offerings. -

What are the common quality assurance practices for car vinyl fabric?

Quality assurance practices for car vinyl fabric often include rigorous testing for durability, colorfastness, and resistance to environmental factors like UV light and moisture. Suppliers may perform tests according to industry standards, such as the Wyzenbeek test for abrasion resistance. Additionally, they should have a clear return policy for defective materials. Request documentation of quality tests and inquire about their processes for maintaining consistent quality throughout production, especially when sourcing from international suppliers.

Top 8 Car Vinyl Fabric Manufacturers & Suppliers List

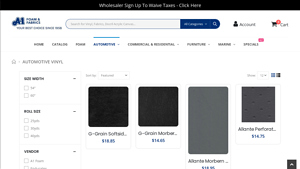

1. A1 Foam and Fabrics – G-Grain Softside Vinyl

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Введение: [{‘name’: ‘G-Grain Softside Vinyl’, ‘market_applications’: ‘Hospitality, Contract, Residential Interior, Marine Interior, Automotive, RV’, ‘characteristics’: ‘Anti Static, Sulfide Stain Resistance, Water Resistant, Formaldehyde Free, No Heavy Metals’, ‘flame_retardancy’: ‘California T.B. 117-2013FMVSS 302IMO FTP’, ‘price’: ‘$18.85’}, {‘name’: ‘G-Grain Morbern Mellohide Vinyl’, ‘market_applications…

2. Midwest Fabrics – Automotive Vinyl & Upholstery Solutions

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Введение: Automotive Vinyl Fabric, Vinyl Upholstery Fabric, Original OEM Detroit Number Fabrics, GM, Ford, Chrysler, Honda, Toyota, Mazda, Nissan OEM Fabric, Heavy Duty Flock fabric, Endurasoft Core Program, Carbon Fiber, Brushed Aluminum, Marine Vinyl, Snowmobile Vinyl, 4 way stretch vinyl, various Morbern Vinyl options, Nautolex vinyl by the roll, Boltaflex Vinyl by the roll, Upholstery Supplies including…

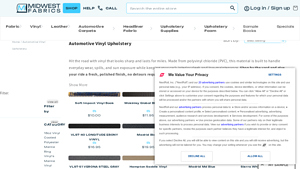

3. Sailrite – Vinyl Automotive Upholstery Fabrics

Domain: sailrite.com

Registered: 1996 (29 years)

Введение: Vinyl Automotive Upholstery Fabrics are durable, waterproof, and easy to clean. They offer a luxurious look and feel similar to real leather at a more economical price. Key features include: easy to clean, highly abrasion resistant, highly UV resistant, waterproof/water resistant, low maintenance, and a luxurious appearance. Recommended vinyl options include EverSoft, Morbern™ Carrara, Morbern™ Ba…

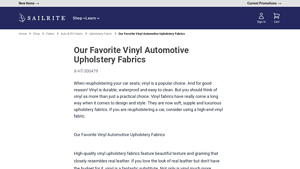

4. Fabric Warehouse – Green Automotive Vinyl

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Введение: Green Automotive Vinyl is available in various options including Seaquest Teal Blue-Green, Seagrass Green, Forest Green, Shadow Green, Sage Green, Everglade Green, and Lime Green. The vinyl is 54 inches wide and sold by the linear yard. It is suitable for both outdoor and indoor applications, being sun and salt resistant, making it ideal for marine upholstery, automotive, and commercial seating. T…

5. MiamiCorp – Automotive Vinyl Fabrics

Domain: miamicorp.com

Registered: 2001 (24 years)

Введение: This company, MiamiCorp – Automotive Vinyl Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Введение: SMS Auto Fabrics offers a wide selection of classic auto interiors, including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include various plaid fabrics for Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1956 Ford Fairlane Sunliner, 1968 Dodge Polara Convertible, and 1970…

7. Folio Fabrics – Automotive Upholstery Fabrics

Domain: foliofabrics.com

Registered: 2013 (12 years)

Введение: Explore our extensive array of automotive fabrics, offered by the yard to cater to all your vehicle upholstery needs. Options include durable and stain-resistant Crypton fabric and fade-resistant polyester. Fabrics provide superior protection against stains, spills, and UV fading, ensuring a long-lasting and vibrant appearance. Key products include: 1. Davis Cream – $44/yard 2. Lawrence Nutmeg – $…

8. Outdoor Textiles – Automotive Vinyl

Domain: outdoortextiles.com

Registered: 1998 (27 years)

Введение: Automotive Vinyl designed for vehicle interior revamp, suitable for restoring classic cars, upgrading seats, and customizing door panels and dashboards. Features high-performance vinyl that combines luxury and resilience, crafted to withstand daily wear, UV exposure, and extreme temperatures. Available in various textures, colors, and finishes including leather-look, carbon fiber, and suede-style …

Strategic Sourcing Conclusion and Outlook for car vinyl fabric

In conclusion, the strategic sourcing of car vinyl fabric presents a valuable opportunity for international B2B buyers seeking durable and cost-effective solutions for automotive upholstery. As highlighted throughout this guide, vinyl fabrics offer exceptional durability, ease of maintenance, and a variety of customization options, making them an ideal choice for diverse markets, particularly in Africa, South America, the Middle East, and Europe.

For buyers in these regions, focusing on high-quality suppliers and understanding the unique needs of local markets is crucial. The ability to source vinyl that meets specific performance criteria—such as UV resistance and mildew protection—can significantly enhance the appeal of automotive interiors, driving customer satisfaction and loyalty.

Looking ahead, the demand for innovative and sustainable materials in the automotive sector is expected to grow. By aligning sourcing strategies with these trends, businesses can not only optimize their product offerings but also position themselves as leaders in a competitive landscape. We encourage you to explore partnerships with reputable suppliers to harness the full potential of car vinyl fabrics, ensuring your offerings remain relevant and attractive in an evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to car vinyl fabric

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.